Page 1

QUICK START

USER GUIDE

8335

PowerPad

®

IMPORTANT WARRANTY NOTE:

By registering online within 30 days from the date of

purchase, your warranty will be extended to 3 years

Page 2

Statement of Compliance

Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments

certifies that this instrument has been calibrated

using standards and instruments traceable to

international standards.

We guarantee that at the time of shipping your

instrument has met its published specifications.

An NIST traceable certificate may be

requested at the time of purchase, or obtained

by returning the instrument to our repair and

calibration facility, for a nominal charge.

The recommended calibration interval for this

instrument is 12 months and begins on the date of

receipt by the customer. For recalibration, please

use our calibration services. Refer to our repair

and calibration section at www.aemc.com.

Serial #: ________________________________

Catalog #: ______________________________

Model #: 8335

Please fill in the appropriate date as indicated:

Date Received: _________________________________

Date Calibration Due:

_______________________

Chauvin Arnoux®, Inc.

d.b.a AEMC® Instruments

www.aemc.com

Page 3

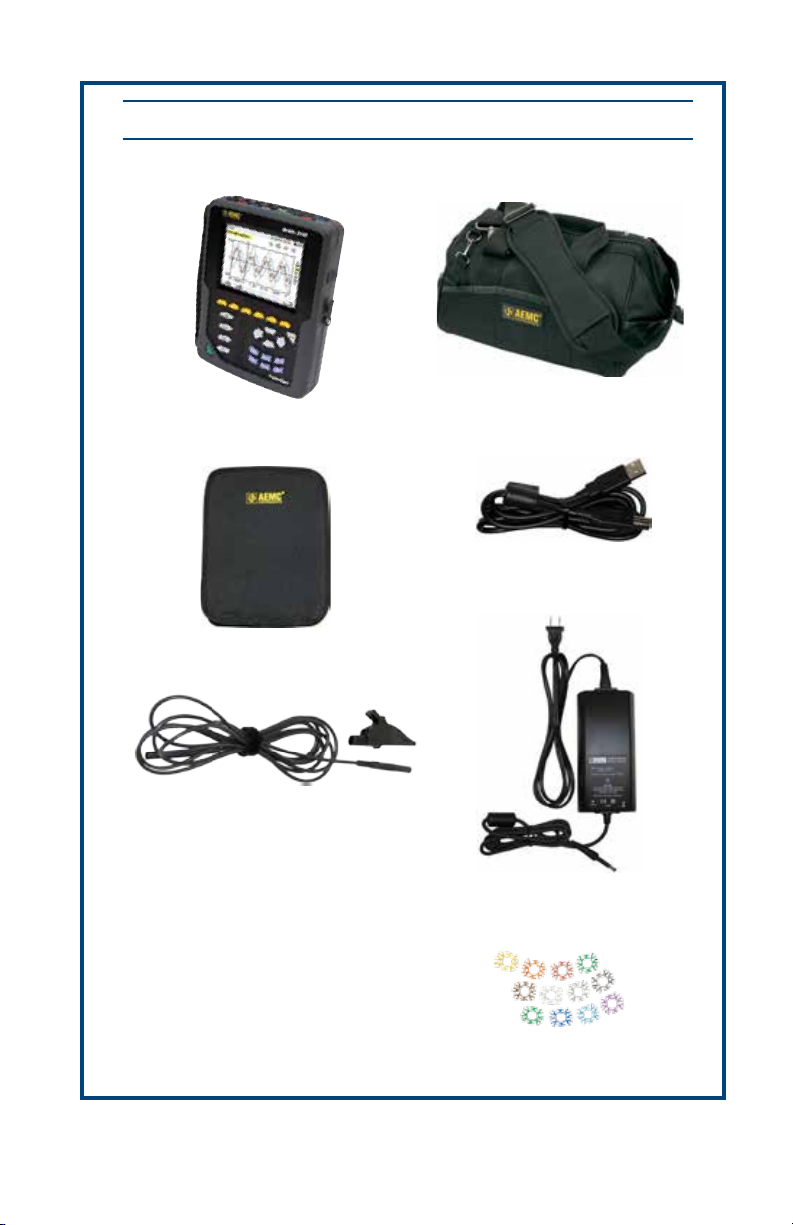

Shipping Contents:

(1) PowerPad® Model 8335

Cat. #2136.20

(1) Soft Carrying Pouch

Cat. #2140.15

PRODUCT PACKAGING

(1) Large Classic Tool Bag

Cat. #2133.73

(1) 5 ft USB Cable

Cat. #2140.46

(5) Black Test Leads and Alligator Clips

Also Included:

4 GB USB Stick (DataView/User Manual)

NiMh Battery - installed

Kits will also include (order dependent):

(4) MN93-BK current probes

(4) MN193-BK current probes

(4) SR193-BK current probes

(4) AmpFlex® 193-24-BK (24") current sensors

(4) AmpFlex® 193-36-BK (36") current sensors

(4) MR193-BK current probes

(4) MiniFlex® MA193-10-BK current sensors

(3) AmpFlex® 193-24-BK and (1) MN193-BK

Cat. #2140.43

(1) Power Adapter 110/240V w/ Power Cord

Cat. #5000.19

(12) ID Markers

Cat. #2140.45

USB STICK: DataView® software and complete user manual for the Model 8335

can be located on the USB stick supplied with the instrument.

Page 4

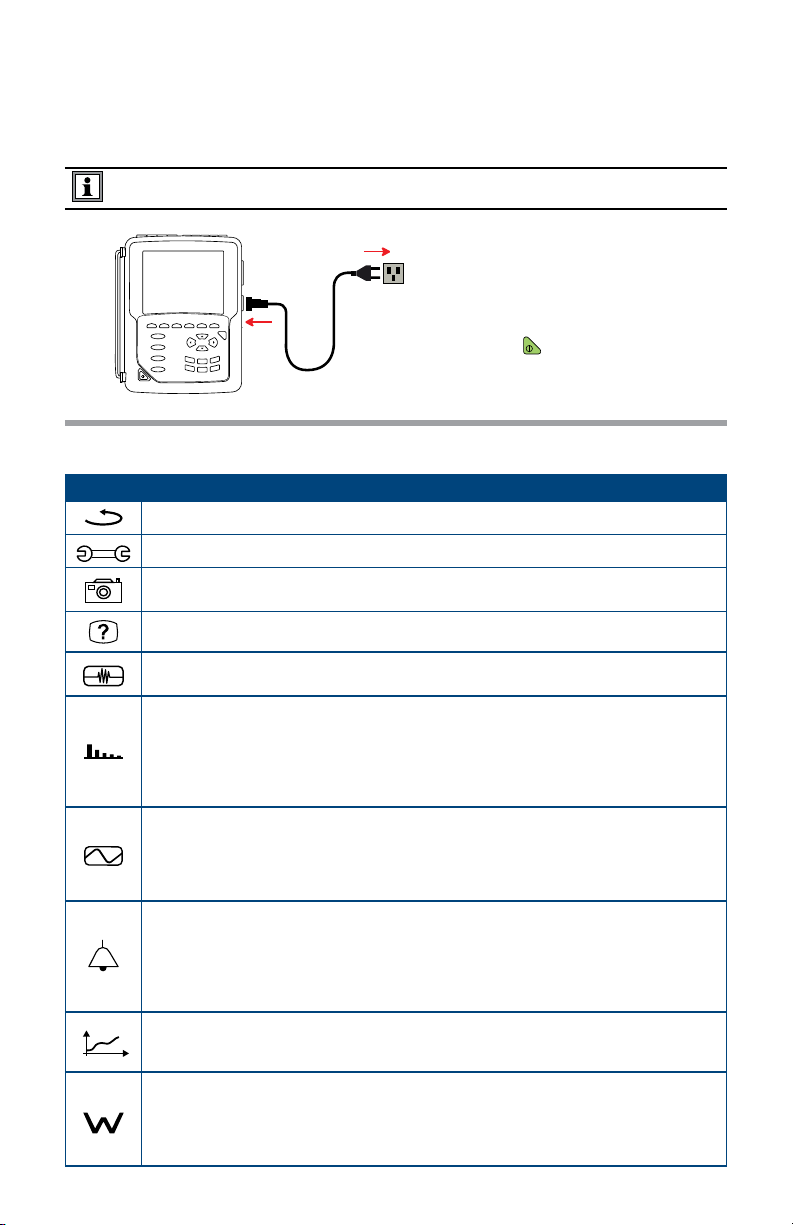

Charging the Battery

Fully charge the battery before the first use.

The batteries automatically begin recharging when the instrument is connected to AC power.

Only use the supplied AC power adapter to recharge the batteries.

NOTE: A full recharge of a completely discharged battery takes 5 hours approx.

120V ± 10%, 60Hz

230V ± 10%, 50Hz

Button Functions

BUTTON DESCRIPTION

Return to the choice of measurement view.

Configure the PowerPad® (SET-UP).

Take a snapshot of the current screen or access screens already stored in the memory.

Record associated waveform and power measurement data.

Get help on the current display functions, in the language chosen by the user.

Transients or Inrush Current:

• Sets and views transient and inrush current waveforms associated with rapid changes in input

Harmonics Mode:

• Displays the harmonics in percent and value ratios for voltage, current and power for each

harmonic through the 50th

• Determines harmonic current produced by non-linear loads

• Analyzes the problems caused by harmonics according to their order

(heating of neutrals, conductors, motors, etc)

Waveforms Mode:

• Displays voltage and current waveforms or vector representation

• Identifies signal distortion signatures

• Displays of amplitude and phase unbalance for voltage and current

• Checks connections for correct phase order

Alarm Events:

• Provides a list of the alarms recorded according to the thresholds programmed during

configuration

• Logs interruption with half-cycle resolution

• Determines energy consumption exceedances

• Stores value, duration, date, time and set point for up to 4096 events

Trend Mode:

• Lists all recording trends and views them on the display

(Urms, Vrms, Arms, etc)

Power / Energy:

• Displays power levels and the associated parameters (power factor, displacement and tangent)

• Energy monitoring

• Four quadrant measurement to discern produced/consumed active energies and inductive/capacitive reactive energies

To recharge the battery:

• Connect the supplied power

cord to the instrument and AC

power.

• The

button lights and will

go out when the power cord is

disconnected.

Page 5

Control Features

1

2

6

7

8

3

4

?

5

1. Over molded protective housing

2. LCD Display

3. Six function buttons (yellow)

4. Four function buttons (see chart, left)

5. ON/OFF button

6. Four current inputs and five voltage

inputs

Connection Terminals

1

®

PowerPad

7. USB port

8. Input for external power supply

and battery charging

9. Confirm/Enter button

10. Navigation buttons

11. Six mode buttons (see chart, left)

2

9

10

11

3

1. Four (4) current inputs on the top of

the instrument to enable the use of

current sensors (MN, SR, AmpFlex®,

MiniFlex®, and MR probes).

2. Five (5) voltage inputs.

3. Insertion locations for the current and

voltage color-coded ID markers

Page 6

Instrument Configuration

NOTE: The instrument configurations can also be modified through the DataView® software.

NOTE: The instrument must be configured the first time it is used. The configuration is

saved in memory when the instrument is turned OFF.

Press the

button to configure the unit. The following sub-menus appear:

• Set the display language by pressing the yellow button corresponding to the screen

language icons.

• The parameter that is ready to be configured will be highlighted in yellow. To move to a

different parameter, use the ▲ and ▼ buttons.

• Press the Enter

button to select a parameter.

• Use the ◄ and ► buttons to change a value or setting.

• When finished, return to the Configuration menu by pressing the

button.

PARAMETER FUNCTION

Date / Time

Display

Calculation Methods

Electrical Connection

Sensors & Ratios

Transient Mode

Trend (Recording) Mode

Alarm Mode

Erase Memory

About

Sets the date and time format

Adjusts the contrast and brightness of the display;

Defines the color of the voltage and current curves

Determines if harmonics are used or not used in calculations of reactive quantities

(power and energy)

• With harmonics: Harmonics are taken into account when calculating reactive

parameters.

• Without harmonics: Only the fundamental part is used for the calculation of

reactive parameters

Determines the type of connection to the network

• Single-Phase

• Split-Phase

• 3-Phase 4-Wire

• 3-Phase 5-Wire

Defines the type of current probe to connect

• MN93: 200A

• MN193: 100A or 5A (with variable ratio)

• SR193: 1000A

• SL261: 10A and 100A range

• AmpFlex

• MiniFlex

• MR193: 1000A

• 5A three-phase adapter (3-channel only)

Configures the voltage and current thresholds

Selects the parameters to record (up to 4 configurations)

Defines the parameters of an alarm

Deletes configurations, alarm settings, snapshots and recordings

Displays the serial number, software and hardware version

®

Sensors: 3000A (measures up to 6500Arms)

®

Sensors: 1000A

AC/1200ADC

Page 7

Getting Started

NOTE: Make sure the PowerPad® is fully charged before use.

Connecting:

• Start the instrument by pressing the

• Configure the instrument to obtain the required results and type of network.

• Connect the current leads and sensors to the PowerPad®.

• Connect the ground and/or neutral lead to the network ground and/or neutral (when

distributed), as well as the corresponding current sensor.

• Connect the L1 phase lead to the network L1 phase, as well as the corresponding

current sensor.

• Repeat the procedure for phases L2, L3 and N.

Disconnecting:

• Proceed in the reverse order to connecting, always finishing by disconnecting the

ground and/or neutral (when distributed).

• Disconnect the leads and press the

• Recharge the battery, if necessary.

button.

button to turn the instrument off.

Installation of the Leads and Current Sensors

Twelve sets of color-coded rings and inserts are supplied with the PowerPad®. Use these ID

markers to identify the leads and input terminals.

• Detach the appropriate inserts from the color-coded marker and place them in the holes

provided under the terminals (larger inserts for current terminals, smaller inserts for voltage terminals).

• Clip the rings of the same color to the ends of the lead you will be connecting to the

terminal.

Page 8

Installing DataView

DO NOT CONNECT THE INSTRUMENT TO THE PC BEFORE INSTALLING THE

SOFTWARE AND DRIVERS.

1. Insert the USB stick into an available USB port (wait for driver to be installed).

2. If Autorun is enabled, an AutoPlay window should appear. If Autorun is disabled, it will be

necessary to open Windows Explorer, then locate and open the USB stick drive labeled

“DataView” to view the files on the drive.

3. In the AutoPlay window, select “Open folder to view files”.

4. Double-click on Setup.exe from the opened folder view to launch the Dataview® setup

program.

NOTE: For more information on using DataView®, refer to the Model 8335 user manual that is

supplied on the USB stick.

®

Updating Software & Firmware

To provide our customers the best possible service in terms of performance and technical upgrades,

AEMC® offers free software and firmware updates on our website.

• Visit us at: www.aemc.com

• Click on the Tech Info tab and choose the desired software or firmware download.

DataView® can also be updated by selecting “Update” from the Help menu within the software.

WARNING: Updating the firmware will erase all stored data in the instrument. It is

recommended to download all stored data before performing any firmware updates.

Page 9

Repair and Calibration

To ensure that your instrument meets factory specifications, we recommend that it

be scheduled back to our factory Service Center at one-year intervals for recalibration, or as required by other standards or internal procedures.

For instrument repair and calibration:

You must contact our Service Center for a Customer Service Authorization Number

(CSA#). This will ensure that when your instrument arrives, it will be tracked and

processed promptly. Please write the CSA# on the outside of the shipping container.

If the instrument is returned for calibration, we need to know if you want a standard

calibration, or a calibration traceable to N.I.S.T. (Includes calibration certificate plus

recorded calibration data).

Ship To: Chauvin Arnoux

15 Faraday Drive

Dover, NH 03820 USA

Phone: (800) 945-2362 (Ext. 360)

(603) 749-6434 (Ext. 360)

Fax: (603) 742-2346 or (603) 749-6309

E-mail: repair@aemc.com

(Or contact your authorized distributor)

Costs for repair, standard calibration, and calibration traceable to N.I.S.T. are

available.

NOTE: You must obtain a CSA# before returning any instrument.

®

, Inc. d.b.a. AEMC® Instruments

Technical and Sales Assistance

If you are experiencing any technical problems, or require any assistance with the

proper operation or application of your instrument, please call, mail, fax or e-mail

our technical support team:

Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments

200 Foxborough Boulevard

Foxborough, MA 02035 USA

Phone: (800) 343-1391

(508) 698-2115

Fax: (508) 698-2118

E-mail: techsupport@aemc.com

www.aemc.com

NOTE: Do not ship Instruments to our Foxborough, MA address.

Page 10

Limited Warranty

The Model 8335 is warranted to the owner for a period of one year from the date

of original purchase against defects in manufacture. This limited warranty is given

by AEMC® Instruments, not by the distributor from whom it was purchased. This

warranty is void if the unit has been tampered with, abused or if the defect is related

to service not performed by AEMC® Instruments.

Full warranty coverage and registration is available on our website:

www.aemc.com/warranty.html.

IMPORTANT WARRANTY NOTE:

By registering online within 30 days from the date of

purchase, your warranty will be extended to 3 years

Please print the online Warranty Coverage Information for your records.

What AEMC® Instruments will do:

If a malfunction occurs within the one-year period, you may return the instrument

to us for repair, provided we have your warranty registration information on file or

a proof of purchase. AEMC® Instruments will, at its option, repair or replace the

faulty material.

Warranty Repairs

What you must do to return an Instrument for Warranty Repair:

First, request a Customer Service Authorization Number (CSA#) by phone or by fax

from our Service Department (see address below), then return the instrument along

with the signed CSA Form. Please write the CSA# on the outside of the shipping

container. Return the instrument, postage or shipment pre-paid to:

Ship To: Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments

15 Faraday Drive

Dover, NH 03820 USA

Phone: (800) 945-2362 (Ext. 360)

(603) 749-6434 (Ext. 360)

Fax: (603) 742-2346 or (603) 749-6309

E-mail: repair@aemc.com

Caution: To protect yourself against in-transit loss, we recommend you insure your

returned material.

You must obtain a CSA# before returning any instrument.

Page 11

NOTES:

Page 12

10/13

99-MAN 100392 v2

Chauvin Arnoux

®

, Inc. d.b.a. AEMC® Instruments

15 Faraday Drive • Dover, NH 03820 USA • Phone: (603) 749-6434 • Fax: (603) 742-2346

www.aemc.com

Loading...

Loading...