Page 1

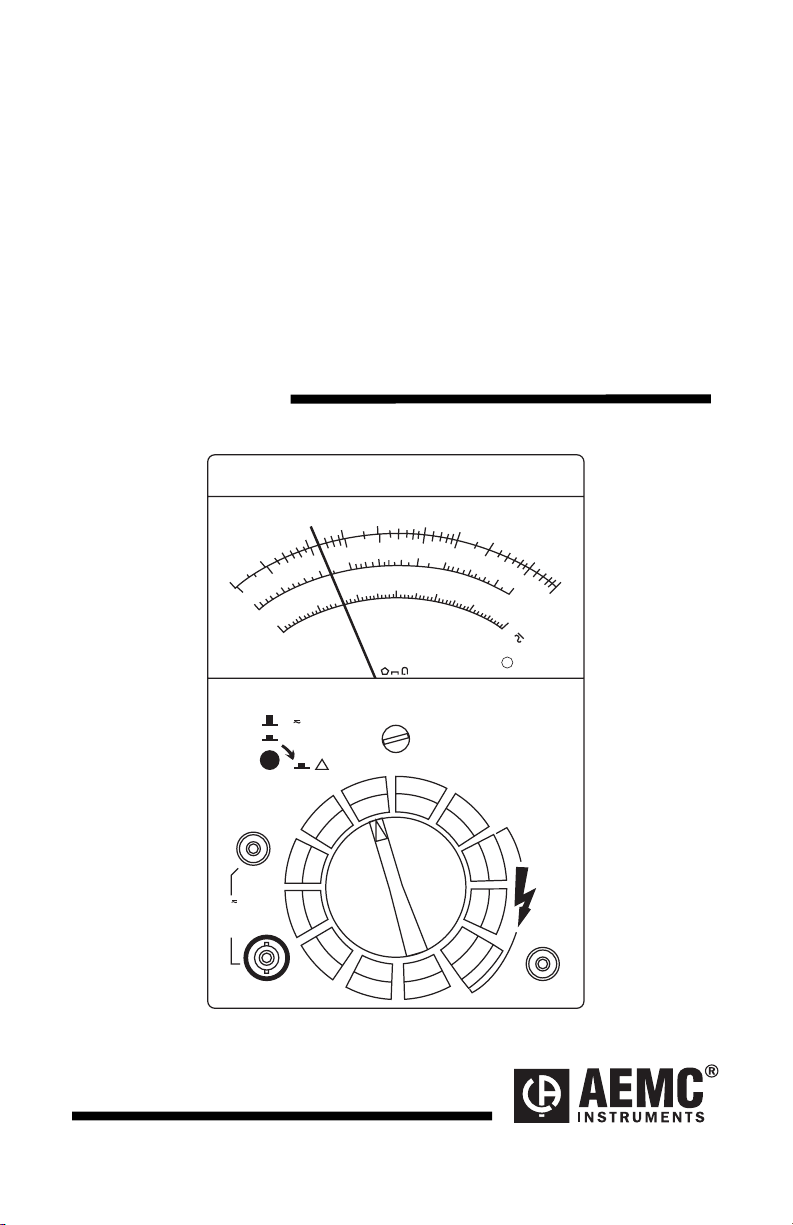

90HJRKPPHWHU

0RGHO1

(6'&RQGXFWLYLW\7HVW.LW

0RGHO1

USER MANUAL

0

2

5

0

1

5

2

1

0

5

0

0

1

0

0

1

0

2

0

0

2

0

0

1

0

1

0

0

2

0

2

5

0

0

3

4

0

0

1

0

.

0

5

5

0

5

0

0

0

0

1

.

0

2

0

0

0

.

1

G

Ω

M

Ω

kΩ

x 1

6

0

Ω

0

V

OFF

ON

TURN TO

LOCK

V

GΩ

MΩ

kΩ

+ EARTH

5

Bat.

MEGOHMMETER

V

!

0

5

2

V

G

0

5

2

Ω

M

V

0

Ω

0

1

G

V

Ω

0

M

0

1

G

5

Ω

0

V

M

5

0

5

V

M

Ω

Ω

V

1

MODEL 1000N

0

0

V

5

Ω

0

0

G

V

Ω

1

0

M

Ω

G

Ω

V

Ω

A

k

m

m

1

V

Ω

0

0

0

2

1

A

m

0

0

V

1

0

0

0

x

a

Ω

- GUARD- LINE

Page 2

/LPLWHG:DUUDQW\

The Megohmmeter Models 1000N and 1100N are warranted to the

owner for a period of 1 year from the date of original purchase against

defects in manufacture. This limited warranty is given by AEMC

Instruments, not by the distributor from whom it was purchased. This

warranty is void if the unit has been tampered with, abused or if the

defect is related to service not performed by AEMC

®

What AEMC

Instruments Will Do:

If a malfunction occ urs within the 1

®

Instruments.

year period, you may return the instrument to us for repair or

replacement free of charge, provided we have your REGISTRATION

CARD on file. AEMC

®

Instruments will, at its opt ion, repair or repl ace the

faulty material.

Note: If a registration card is not on file, we will require a dated

proof of purchase as well as your REGISTRATION CARD

accompanied by the defective material.

REGISTER ON LINE AT:

www.aemc.com

®

What You Must Do:

or by fax from AEMC

First request a return authori zation form by phone

®

Instruments, then return the instrum ent along with

the signed authorization repair form. Return material, postage pre-paid

to:

Chauvin Arnoux

d.b.a. AEMC

®

, Inc.

®

Instruments

Service Department

15 Faraday Drive

Dover, NH 03820 USA

Tel: (800) 945-2362 (X360)

(603) 749-6434 (X360)

Fax: (603) 742-2346

Caution:

To protect against in-transit loss, we recommend you insure

your returned material.

For full warranty coverage, please r ead the Warranty Ca rd which is

affixed to the Warrant y Regist ratio n Card . Pleas e keep t he W arrant y

Card with your records.

- 1 -

Page 3

Table of Contents

Warning ........................................................................................... 4

International Electrical Symbols ...................................................... 4

Megohmmeter Model 1000N

Receiving Your Shipment ......................................................... 5

Packaging ................................................................................. 5

Accessories and Replacement Parts........................................ 5

Description ................................................................................ 6

Specifications............................................................................ 7

Control and Connector Identification......................................... 9

Battery Replacement .............................................................. 10

AC Supply Module .................................................................. 10

......................................................... 5

Operation

Understanding Insulation Testing

...................................................................................... 11

The Analog Scale.................................................................... 11

Preliminary Check................................................................... 12

How to use the Push-to-Measure Button................................ 12

Utilizing the Guard Terminal ................................................... 13

Voltage Measurements (Safety Check).................................. 14

Audible Signal......................................................................... 15

Precautions When Making DC Insulation Tests ..................... 15

Insulation Measurement - Connections .................................. 16

Insulation Resistance Measurements on Motors.................... 19

............................................. 21

Types of Tests......................................................................... 22

Spot Reading Test............................................................ 22

Ratio Testing .................................................................... 22

Dielectric Absorption Test................................................. 23

Step Voltage Test............................................................. 24

Effects of Temperature ........................................................... 25

Interpreting the Results........................................................... 26

- 2 -

Page 4

ESD Conductivity Test Kit Megohmmeter Model 1100N

Receiving Your Shipment ...................................................... 27

Packaging .............................................................................. 27

Accessories and Replacement Parts...................................... 27

Description ............................................................................. 28

Specifications ......................................................................... 29

Battery Replacement ............................................................. 31

AC Supply Module ................................................................. 31

Resistance Testing of Conductive Flooring ........................... 32

Measurement Results ............................................................ 34

Maintenance................................................................................... 35

Cleaning................................................................................... 35

Repair and Calibration .................................................................. 36

Technical Assistance .................................................................... 36

......... 27

- 3 -

Page 5

Megohmmeter Model 1000N/1100N

:DUQLQJ

These safety warnings are provided to ensure the safety of

personnel and proper operation of the instrument.

WARNING: HIGH VOLTAGE PRESENT

•

Do not attempt to perform any tests with these instruments

until you have read the instruction manual.

•

Safety is the responsibility of the operator!

•

Tests are to be carried out only on non-energized circuits!

Check for live circuits before making resistance

measurements (safety check).

•

The Megohmmeters Models 1000N and 1100N are sources

of high voltage, as is the sample connected to them. All

persons performing or assisting in the tests must em ploy all

safety precautions to prevent electrical shock to themselves

and to others.

•

AEMC

•

When testing capaci tance sam ples , m ak e sure that they h ave

•

Megohmmeters should never be used in an explosive

•

Use the leads supplied with the megohmmeters. If they are

®

considers the use of rubber gloves to be an excellent

safety practice even if the equipment is pro per l y oper ate d and

correctly grounded.

been properly discharged and that they are safe to touch.

Dielectric insulation samples should be short-circuited for at

least five times the amount of time they were energized.

environment.

defective or worn, replace before testing.

,QWHUQDWLRQDO(OHFWULFDO6\PEROV

This symbol signif ies that the instrument is protected b y double

or reinforced insulation. Use only specified replacement parts

when servicing the instrum ent.

This symbol signifies CAUTION! and requests that the user refer

to the user manual before using the instrument.

Risk of electric shock. The voltage at the parts marked with this

symbol may be dangerous.

- 4 -

Page 6

Megohmmeter Model 1000N/1100N

0(*2+00(7(502'(/1

5HFHLYLQJ<RXU6KLSPHQW

Upon receiving your shipment, make sure that the contents are

consistent with the packing list. Notify your distributor of any missing

items. If the equipm ent appears to be damaged, f ile a c laim immediatel y

with the carrier and notify your distributor at once, giving a detailed

description of any damage.

3DFNDJLQJ

The Megohmmeter Model 1000N (Cat. #185.100) is ship ped with eight

1.5V “AA” batteries, two color- coded safety leads with insulated all igator

clips, a separate shielded lead, a separate insulated alligator clip, test

probe, one spare fuse, carrying case and instruction manual.

$FFHVVRULHVDQG5HSODFHPHQW3DUWV

AC power supply module with line cord and plug for

switch-selectable 110/220V

AC

at 47 to 400Hz.....................

Cat. #100.142

Protective rubber case with handle ......................................

Rugged plastic carrying case, 19 x 14 x 7" ..........................

Fuse, set of five, 0.1A slow-blow for AC supply module ......

Fuse, set of one, 0.3A, for Model 1000 ................................

One test probe and one insulated alligator clip....................

Replacement leads for Models 1000N/1100N/5000N..........

7-pin shielded lead, 10 ft, for Models 1000N/5000N/5100...

Replacement Leads for Model 1000

Coaxial shielded lead ...........................................................

Set of leads: one coaxial shielded lead, pair of

safety leads, alligator clip, and test probe ............................

- 5 -

Cat. #2980.02

Cat. #2118.07

Cat. #100.438

Cat. #100.429

Cat. #100.404

Cat. #1017.23

Cat. #2950.10

Cat. #100.439

Cat. #100.482

Page 7

Megohmmeter Model 1000N/1100N

'HVFULSWLRQ

The AEMC® Model 1000N (Cat. #185.100) is a portable, multi-range,

high-sensitivity megohmmeter capable of measuring a wide range of

insulation resistanc es from 1 kilohm to 1000 gi gohms. The Model 10 00N

has five test voltages of 50, 100, 250, 50 0 and 1000V. E ach test vo ltage

setting has two resistance ranges: 1 to 1000MΩ and 1 to 1000GΩ.

In addition, the Mode l 1000N has a unique lo w insulat ion test ra nge of 1

to 1000kΩ with a constant current of 1mA (maximum voltage of

DC

1200V

voltmeter (safety check) with a range of 0 to 600V is standard.

The Model 1000N may be powered by either AC or DC. DC power is

supplied by eight 1. 5V alkaline “AA” batteri es. As an option, an AC line

supply module and c ord for 110/220V

in the battery compartment.

An audible signal consisting of approximately ten beeps per minute is

present when the megohmm eter is ON, and serves as a time base for

tests of long duration. A green LED, when ON, indicates that the

batteries are good when the PUSH-T O-T EST button is depress ed. It also

serves as a warning li ght when the instrument is in us e, indicating that

the selected test voltage is present at the terminals.

), which is useful for testing old or flooded installations. A

AC

at 47 to 400Hz can be i nserted

- 6 -

Page 8

Megohmmeter Model 1000N/1100N

6SHFLILFDWLRQV

INSULATION TESTS

DC Test Voltages:

50, 100, 250, 500, 1000V

Megohm Ranges:

For each test voltage two direct reading ranges:

1 to 1000M

1 to 1000G

Ω

Ω

Short Circuit Current:

Accuracy:

Charging Time:

1000 MΩ range: 0.3 seconds/µF

1000 GΩ range: 4 seconds/µF

Discharging Time:

Automatic discharge when test button is released; 0.1 seconds/µF

Scale:

Two large overlapping scales: 4.7" (119 mm) for each range

Test Voltage Generation:

Solid state circuitry generating rated test voltage across the full range

5% of reading typical

15% of reading between 100 and 1000GΩ on the 50V range

5mA (max)

RESISTANCE TESTS

Test Current:

Kilohm Range:

Maximum Test Voltage:

Accuracy:

Constant 1mA DC

1 to 1000kΩ (1MΩ)

1200V

5% of reading typical

DC

CONTINUITY TESTS

Resistance Range:

0.1 to 100Ω; 3Ω mid-scale

Accuracy:

Audible Tone:

Fuse:

6% of reading

Continuous for continuity resistances under 200

High interrupting capacity (0.315A)

Ω

- 7 -

Page 9

Megohmmeter Model 1000N/1100N

VOLTAGE TESTS (SAFETY CHECK)

Voltage Range:

Accuracy:

3% of full scale

0 to 600V

AC/DC

GENERAL SP E CIFICATIONS

Audible Test Signal:

Ten beeps per minute (constant tone for continuity resistance under

200Ω)

Power Supply:

Eight 1.5V “AA” alkaline batteries (NEDA 15A). Typical battery life: 350

one-minute tests; power consumed only when test button is depressed;

built-in battery check by green LED.

Option:

110/220V selectable, 47 to 400Hz AC supply module

AC

Dielectric Test:

4000V

Fuse Protection:

0.3A high interrupting capacity fuse between line and guard terminals

Meter Movement:

Dimensions:

Weight:

2.2 lbs (1 kg)

Rugged taut band suspension

7.7 x 5.2 x 3.75" (196 x 132 x 95mm)

Temperature Range:

, 50/60Hz, 1 minute

23° to 122°F (-5° to +50°C)

Case:

High impact gray polycarbonate

Terminals:

Color-coded safety terminals; guard terminal eliminates surface leakage

errors

- 8 -

Page 10

Megohmmeter Model 1000N/1100N

&RQWURO&RQQHFWRU,GHQWLILFDWLRQ

0

2

5

0

1

5

2

1

0

0

1

OFF

ON

TURN TO

LOCK

8

7

+ EARTH

V

GΩ

MΩ

kΩ

6

1

0

2

0

5

0

0

1

0

V

!

V

0

5

2

Ω

M

V

0

Ω

0

1

G

V

Ω

0

0

M

1

G

5

Ω

0

V

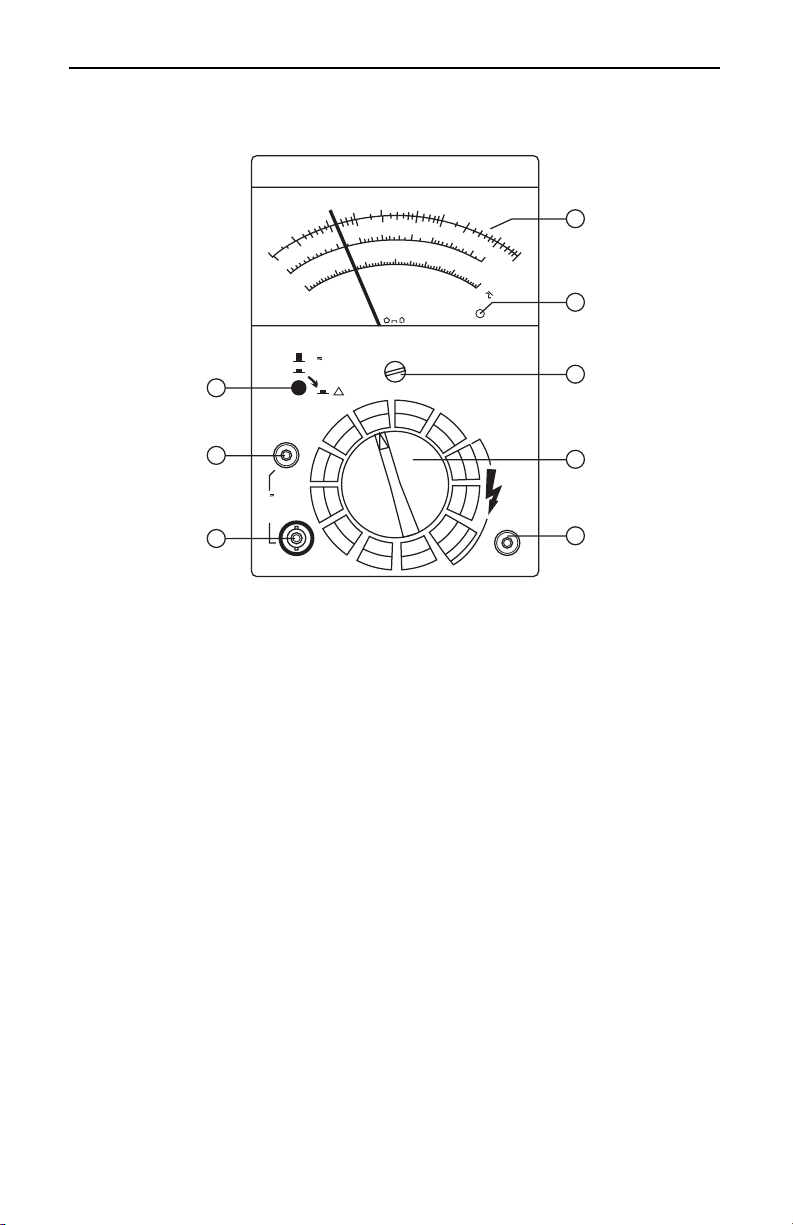

1. Analog Measurement Scale

2. Battery Power Indicator:

Green lamp ON indicates batteries are good when PUSH-TO-TEST

button is depressed. Audible “beep” is also emitted approximately

every 6 seconds.

3. Mechanical Zero Adjust

4. Selection Switch

5. GUARD terminal (blue):

Used to minimize the effect of leakage current.

Also used for the 10Ω range.

6. LINE terminal (black):

Connects to the equipment to be tested.

7. EARTH terminal (green):

Connects to ground for insulation testing.

8. PUSH-TO-TEST button

Lock “ON” by turning button a quarter turn to the right.

OFF Position: Voltmeter position

ON Position: Test position with voltage present at outputs

0

5

2

0

0

0

3

0

0

2

5

MEGOHMMETER

5

0

0

V

V

0

5

2

M

Ω

Ω

G

M

Ω

Ω

5

0

m

V

0

1

1

0

0

2

0

0

1

0

.

5

0

.

2

0

.

4

0

1

0

5

0

0

6

0

V

MODEL 1000N

5

0

0

V

G

Ω

1

0

M

0

0

Ω

V

1

G

0

Ω

0

0

V

Ω

A

k

x

a

m

m

1

V

0

0

2

1

A

Bat.

5

0

0

kΩ x 10

Ω

1

1

0

0

0

GΩ

MΩ

2

3

4

5

Ω

- GUARD- LINE

- 9 -

Page 11

Megohmmeter Model 1000N/1100N

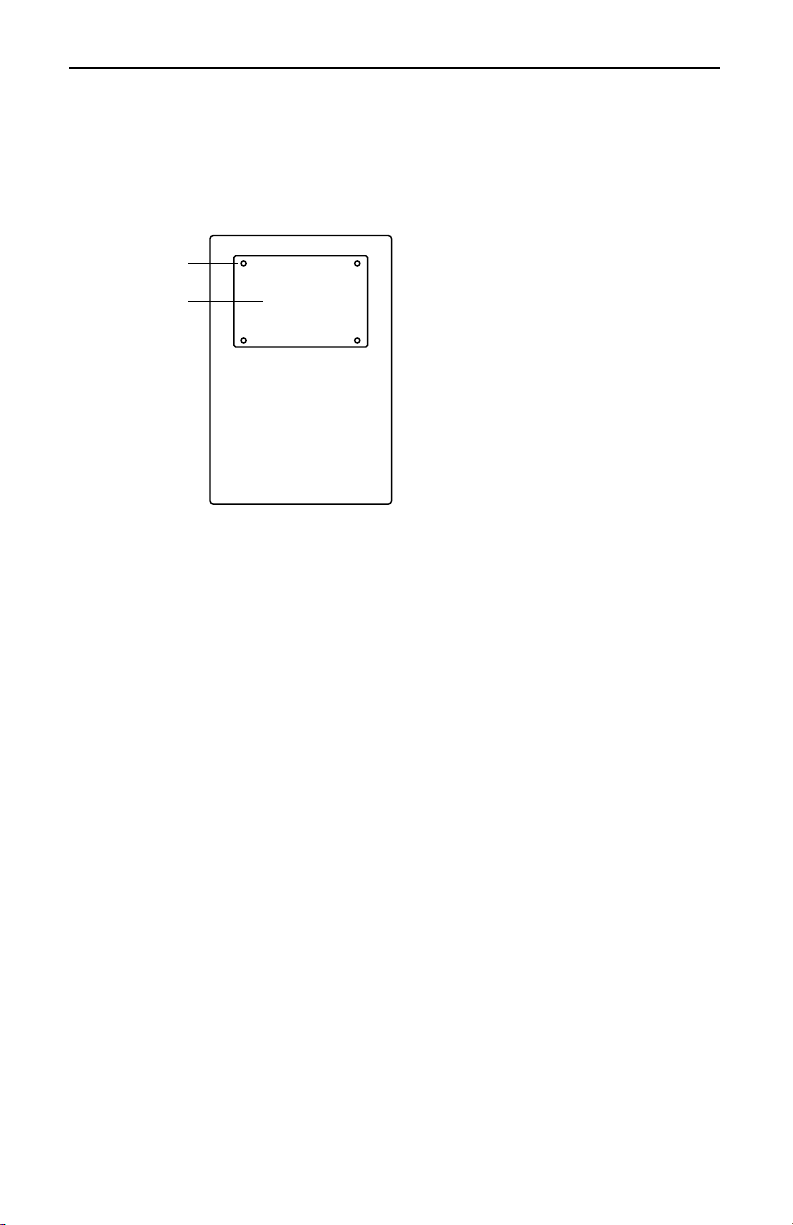

%DWWHU\5HSODFHPHQW

The Model 1000N is powered by eight 1.5V “AA” batteries. To replace

the batteries, disconnect the instrument from any circuits, verify the

PUSH-TO-TEST button is in the OFF position and proceed as follows.

Access panel

screws

Access panel

•

Unscrew the four standard

screws on the four corners of

the battery pack and remove

the battery pack.

•

Replace the batteries, observing

the proper polarities.

•

Replace the battery case, taking

care not to pinch the

connecting wire, and tighten

the four screws.

$&6XSSO\0RGXOH

The optional AC supply module (Cat. #100 .142) provides power to the

Model 1000N at 110 or 220V

designed to plug into the back portion of the instrument, directly

replacing the batteries. The module is protected by a 0.1A slow-blow

fuse.

Note:

Cat. #100.142 is supplied with 110V US plug.

•

Unscrew the four screws on the corners of the back panel battery

pack.

•

Disconnect and remove the battery pack.

•

Connect the AC supply module to the power supply connector.

•

Place the AC supply module into the back of the instrument and

tighten the four corn er screws, making sure not to p inch the wires of

the power supply connector.

•

With the tip of a screwdriver, select the proper voltage with the

110/220 supply switch on the back panel of the AC supply module

•

Plug AC supply cord into the appropriate voltage receptacle.

AC

. The AC power supply module is

- 10 -

Page 12

Megohmmeter Model 1000N/1100N

23(5$7,21

7KH$QDORJ6FDOH

Before taking any measurements, verify that the pointer is zeroed

correctly (AC scale "0"). If it is not , adjust w ith th e mechanical zero

adjust screw.

The analog scale serves two functions. First, it indicates the actual

resistance of the insulating material under test (black scales). The top

scale is used for measur ement on the MΩ and GΩ ranges. The bottom

half (MΩ) covers the range of 1MΩ to 1000MΩ, reading from left to r ight

The upper portion of th e s c ale (GΩ) covers the rang e of 1GΩ to 1000G

and reads left to right.

The center scale is used for the low insulation test range of 1kΩ to

1000kΩ, reading from right to left.

The bottom arc is an AC/DC voltmeter which is divided into 10-volt

increments. The voltm eter function is operable any tim e the PUSH-TOTEST button is out. The voltmeter detects th e pres ence of volt age on the

equipment to be test ed.

the insulation test.)

The voltmeter function also indicates if, after completing insulation

testing, the samp le un der tes t has s tore d a dangerous c a pac it i ve c harge.

The instrument disc harges th is capac itance intern ally an d the need le wil l

drop accordingly. Disconnect the meter when the sample is discharged.

(If voltage is detected, do not proceed with

Ω

Warning:

Electrical equipm ent an d cab les m a y have suff icient cap acit ance t o s tore

a dangerous charge from the instrument test current. For proper

discharge to occur the PUSH-TO-TEST button must be in the OFF

position with the sample connected between the EARTH and LINE

terminals.

On prolonged tests, the PUSH-TO-TEST button may be locked in the ON

position; care should be tak en in this m ode th at no d am age is do ne if the

instrument is left unattended.

- 11 -

Page 13

Megohmmeter Model 1000N/1100N

3UHOLPLQDU\&KHFN

When the PUSH-TO-TEST button is in the OFF position, the pointer

should be on zero of the vo ltmeter scale, and on t h ree of th e GΩ scale. If

it is not, use the mechanical zero adjust on the front of the instrument.

•

Detach the leads from the instrument.

•

Press the PUSH-TO-TEST button into the ON position. The pointer

should deflect com pletely to the f ar right of the sc ale. The green neon

“Bat.” lamp should light up.

Note:

Ensure that the “Bat.” light (green) does not go out at any point

during the testing. If the light does not illuminate, stop the test and

change the batteries before continuing.

Verify that NO VOLTAGE is present on the circuit to be tested.

+RZWR8VHWKH386+727(67%XWWRQ

OFF:

PUSH-TO-TEST button is in the raised position. This is for

measurement of AC or DC voltages (safety check).

Note:

Do not depress the PUSH-TO-TEST button if voltage is present.

ON:

PUSH-TO-TEST button is d epres s ed and he ld down for the duration

of the test. This is for insulation resistance tests.

LOCK-IN:

90° to lock into position. This is for insulation resistance tests of long

duration such as the Time Resistance or Absorption Test.

PUSH-TO-TEST button is depressed and turned clockwise

- 12 -

Page 14

Megohmmeter Model 1000N/1100N

Utilizing the Guard Terminal

Guard terminals are useful when measuring high resistance values and

for stabilizing readings.

When testing the insulation at the end of a cable, it is necessary to

eliminate the error from surface leakage which occurs, particularly at

high resistance values. The guard terminal provides a third terminal

within the path of the surface leakage “E”. Connect the instrument as

shown in Figure 3.

ABCD

The guard terminal

is useful when

measureing very

high resistance

values.

Conductor

to

Line (-)

Terminal

Insulation

to

Guard

Terminal

Exposed

Surface

Shield

to

Earth (+)

Terminal

Figure 3

If there is no shield at “B”, use a copper wire wound several times around

the exposed surface “B”. (Note: If a shield is not available and you do not

make up a shield around

“B” and connect to the

guard terminal (-), the

measurement will be

No Connection to

Guard Terminal

B

i

1

erroneous and lead to

confusion as to the

cable’s condition.)

If the guard terminal is

Ry

Rz

not connected at “B”, the

instrument measures the

current “I” flowing through

the insulation and a

surface leakage current

1

“i

”. See Figure 4.

Figure 4

To EARTH

Terminal

AC

Rx

i

To LINE

Terminal

- 13 -

Page 15

Megohmmeter Model 1000N/1100N

When the guard term inal is connected at “B”, the instrument meas ures

the current “I” and not the surface leakage current “i

included in the m easurement. See Figure 5. This type of m easurement

will give the true value of

the resistance “Rx”,

providing the “Ry” and

1

”, which is not

To Guard

Terminal

i

B

1

“Rz” are not too low.

Ry

Rz

To EARTH

Terminal

AC

Rx

i

To LINE

Terminal

Figure 5

9ROWDJH0HDVXUHPHQWV6DIHW\&KHFN

Insulation resistance tests are to be car ried o ut on n on-en ergize d circ uits

only. Voltage measurements are made as a safety precaution. If any

voltage is present do not proceed with insulati on resistance t esting. This

instrument can measure both AC or DC voltages. For voltage

measurements, proceed as follows:

•

The PUSH-TO-TEST button should be in the OFF position.

•

Connec t the instrum ent with the vo ltage lea ds connect ed bet ween the

Line (-) and Earth (+) terminals on the unit.

•

Read the voltage directl y on the volta ge sc al e.

- LINE

+ EARTH

MEGOHMMETER

Figure 6

- 14 -

Page 16

Megohmmeter Model 1000N/1100N

$XGLEOH6LJQDO

When the PUSH-TO- TEST button is in the ON or LO CK-IN position, an

audible signal wil l result. This s ignal consists of approxim ately one beep

every six seconds (ten beeps per minute). The signal c an be used as a

time base for monitoring the duration of the test. On the MΩ and G

ranges, the signal indicates that the instrument is i n operation and that

the selected DC test voltage may be present on the terminals of the

instrument.

3UHFDXWLRQVZKHQ0DNLQJ'&,QVXODWLRQ7HVWV

•

The equipment should b e taken off the line suff iciently in advance to

permit it to cool to ambient temperature.

•

When you are testing windings, they should be clean and dry; let

solvents and cleaners evaporate. Should foreign matter or wet

surfaces be present, erroneous readings may result. (A clean, dry

sample’s resistanc e ma y rise for 5 to 15 m inutes , where as a wet, dir ty

one will stabilize quick l y).

•

Make sure that the equipment tested is properly discharged and

grounded before testing.

•

When testing individual windings, connect all other windings (not

under test) together and ground to motor frame.

•

When testing phases, be sure they are open to test each individually.

•

Af ter applying a tes t voltage , allo w sufficient d ischarge time. As a rule,

discharge twice as long as tested.

Note:

The instrument voltmeter will indicate the discharge volt age at the

terminals.

Ω

- 15 -

Page 17

Megohmmeter Model 1000N/1100N

,QVXODWLRQ0HDVXUHPHQW&RQQHFWLRQV

Conductor under test

Figure 7 shows the connections to measure the

insulation of one conductor

to the other conductors.

The cable should be

disconnected at both ends

to avoid leakage through

switchboards and panels.

GUARD

+ EARTH- LINE

MEGOHMMETER

Figure 7

Figures 8 and 9 sho w the connection f or testing ins ulation f rom a supply

conductor to a ground (motor frame). The connection to the guard

terminal is used to eliminate the effects of surface leakage across

exposed insulation at one end of the cable . Refer to the sec tion “ Utilizing

the Guard Terminal.” T he cable should b e disconnected at both ends to

avoid leakage through switchboards and panels.

Conductor under test

GUARD

+ EARTH- LINE

MEGOHMMETER

Figure 8

- 16 -

Page 18

Conductor under test

Megohmmeter Model 1000N/1100N

GUARD

+ EARTH- LINE

MEGOHMMETER

Figure 9

Figure 10 shows the connections to a transformer. Make sure that the

switches and/or circu it breakers on both sides are o pen. Check the high

voltage winding to ground, low voltage to ground, and the resistance

between them with no winding grounded.

Winding under test

Transformer

grounding lug

GUARD

+ EARTH- LINE

MEGOHMMETER

Figure 10

- 17 -

Page 19

Megohmmeter Model 1000N/1100N

Figure 11 shows the conn ections f or meas uring the insulation of a thre ephase line to ground by connecting the jumpers between phases. This

gives a reading of all conductors at once. If a load such as a motor,

heater, etc., is attached to the other end of the line, it will read the l oad

resistance to ground at the same time. By removing the jumpers,

readings can be made between the individual conductors and ground.

A

Jumper

B

Jumper

C

GUARD

+ EARTH- LINE

MEGOHMMETER

Figure 11

- 18 -

Page 20

Megohmmeter Model 1000N/1100N

,QVXODWLRQ5HVLVWDQFH0HDVXUHPHQWVRQ0RWRUV

Figure 12 shows reading the

resistance to ground of a threephase motor winding. Since the

three-phase motors are internally

connected, it is only necessary to

connect one lead to the motor lead

and the other lead to the motor

frame as shown.

GUARD

+ EARTH- LINE

MEGOHMMETER

Figure 13 shows the

windings of a three-phase

motor separated. Sometimes this can be done at

the lead terminals while

other times the end bells

must be removed to get at

the lead wires of the coils.

By connecting the m egohmmeter as shown, the phase

insulation resistance value

can now be determined.

Read between phases “A”

and “B”, then “B” and “C”,

then “C” and “A”.

A

Figure 12

C

B

GUARD

+ EARTH- LINE

MEGOHMMETER

Figure 13

- 19 -

Page 21

Megohmmeter Model 1000N/1100N

Figure 14 shows connections for testing insulation from a supply

conductor in a switchbox to ground (m otor frame). An identical t est may

be carried out from the motor starter.

Connect to one leg on

the motor side of the switch

Starter in

Grounded

motor frame

GUARD

+ EARTH- LINE

MEGOHMMETER

Figure 14

- 20 -

Page 22

Megohmmeter Model 1000N/1100N

8QGHUVWDQGLQJ,QVXODWLRQ7HVWLQJ

Insulation is the m aterial betwe en two points of different potent ial which,

through high resistivity, prevents the flow of current between those

points. Insulation f ailure is one of the most comm on problems associated

with electrical equipm ent breakdown.

A megohmmeter is an insulation resist ance tester whic h is essentia lly a

high resistance ohmmeter (MΩ or greater) providin g a high DC potential

(up to 5000V). This high potent ial causes lo w amounts of c urrent to flow

through and over the insulation which is under test.

Many factors can cause insu lation to fail: m echanical dam age, moisture,

heat, foreign debris, corrosion, etc. As time passes, these factors

combine to perm it excessive current to flo w through insulation at points

where it would norm ally be bloc ked by the insu lation resistance. Usua lly,

the resistance on degrading insulation will drop gradually, providing

plenty of warning. Other times it will drop suddenly, as when it is

immersed. With periodic r esistance tests and good rec ord keeping, it is

possible to get an acc urate picture of the insulat ion condition. Insulation

resistance testing is intende d to in dica te n ot onl y if equipment is bad, but

also whether it is becoming bad.

Resistance of many types of insulation can vary greatly with

temperature. The resistance data obtained should be corrected to the

standard temperature for the class of equipment under test.

Please note that although we present information on test procedures,

values and recomm ended freque ncy of testing , the manuf acturer of your

particular piece of equipment is the definitive source for testing

parameters and procedures. While we refer to commonly applied ru les

and practices, every test will not be practical to each piece of electrical

equipment in your facility.

- 21 -

Page 23

Megohmmeter Model 1000N/1100N

1

7\SHVRI7HVWV

SPOT READING TEST

Method

For this test, the m egohmmeter is connect ed acros s the insulati on of the

windings of the m ac hine bei ng t es ted . A tes t vol tag e is a pp li ed f or a fixed

period of time, usually 60 seconds, and a reading is taken. The spot

reading test should only be carried out when the wind ing temperature is

above the dewpoi nt

so that the reading may be corrected to a base temperature of 20°C

(68°F).

Test Duration

To obtain comparable results, tests must be of the same duration.

Usually the reading is taken after 60 seconds.

Interpreting the Results

Proper interpretation of spot reading tests requires access to r ecords of

results from previous spot re ading tests . For concl usive resu lts, only use

results from tests performed at the same test voltage for the same

amount of time under similar temperature and humidity conditions. These

readings are used to p lot a c urv e of the his t ory of insulation resist anc e. A

curve showing a downward trend usually indicates a loss of insulation

resistance due to unfavorable conditions such as humidity, dust

accumulation, etc. A very sharp drop indicates an insulation failure.

1

. The operator shou ld note the winding temperature

RATIO TESTING

In time resistance reading (die lect ric absor pt ion r ati o), r ead in gs are taken

at 30 seconds and 60 seconds to obtain the dielectric absorption ratio.

Insulation resistance @ 60s

Insulation resistance @ 30s

This test is useful for increas ing the accurac y of spot testing. I n general,

a ratio of 1.25 to 2 or bett er shou ld be required. (B el o w 1 .1 is dangero us;

1.1 to 1.25 is quest ionable; 1.25 to 1.4 is fair; and 1. 4 to 2 and above is

good.) A ratio below this indicates that repair is probably needed.

Dewpoint temperature is the temperature at which the moisture vapor in the air condenses as a liquid.

= Dielectric Absorption Ratio (DAR)

- 22 -

Page 24

Megohmmeter Model 1000N/1100N

2

Remember that a DC insulation tes t m ay be used for acceptanc e testi ng,

but is more commonly used to check the gradual deterioration of

equipment over its lifetime. Consult your equipment manufacturer for

specific test or test voltage if not known.

Insulation resistance decreases with moisture, tem perature and age, and

should be recorded over time at a given temperature and corrected.

DIELECTRIC ABSORPTION TEST

Method

This test is based on the comparison of absorption characteristics of

good insulation vs. the absorpt ion characteristics of humid or other wise

contaminated insulatio n. During the test, a test voltage is ap plied for an

extended period, usual ly 10 m inutes . T he operator takes a rea ding ever y

10 seconds for the first m inute, and then every minute up to 10 minutes .

A curve is drawn showing the insulation resistance value versus time.

Test Duration

10 minutes

Interpreting the Results

If the results were plotted on a graph, the slope of the curve would

indicate the conditi on of the insulation under test. A good insu lation will

show a continual increase in resistance for typically 10 to 15 minutes.

Contaminated, moist, or cracked insulation will produce a relatively flat

curve.

A ratio known as the

polarization index

can be obtained by dividing the

value from the 10-minute reading by the value from the one-minute

reading. This polarization index is indicative of the slope of the curve.

A low polarization index usually indicates excessive moisture and

contamination. On larg e motors or gener ators, values as h igh as 10 are

commonly expected.

Polarization index =

10-minute reading

1-minute reading

The IEEE Std 43-1974

2

lists the following minimum values for the

polarization index for AC and DC rotating machines:

Class A: 1.5 Class B: 2.0 Class C: 2.0

IEEE Std. 43-1974, -

Recommended Practice for Testing Insulation Resistance of Rotating Machinery

- 23 -

Page 25

Megohmmeter Model 1000N/1100N

STEP VOLTAGE TEST

Method

In this test, the operat or applies two or m ore test volt ages in steps . The

recommended ratio f or the test voltage s teps is 1 to 5. A t eac h step , test

voltage should be applied for the same length of time, usually 60

seconds. The applic ation of i ncreased voltage creates electr ical s tresses

on internal insulat ion c rack s . This c an revea l aging and physical dam age

even in relatively dry and clean insulation which would not have been

apparent at lower voltages.

Test Duration

A series of “steps,” each step lasting 60 seconds.

Interpreting the Results

Compare the readings taken at diff erent voltage levels, looking for an y

excessive reduction in ins ulation resistance va lues at the higher voltage

levels. Insulation that is thoroughly dry, clean, and without physical

damage should provide roughly the same resistance values despite

changes in test voltage levels . If r es is tance values decrease substantiall y

when tested at higher voltag e levels, t his should s erve as a warning that

insulation quality may be deteriorating due to dirt, moisture, cracking,

aging, etc.

- 24 -

Page 26

Megohmmeter Model 1000N/1100N

7KH(IIHFWVRI7HPSHUDWXUH

Insulation resistance measurements are changed by variations in

temperature of the insulation material. T ypically, when the temperature

goes up, the insulation resistance will go down. Inversely, when the

temperature drops the insulat ion r es istanc e wi ll inc reas e in va lu e.

The best way to obtain consistent measurement results is to test the

insulation at a standard temperature, typically 68°F (20°C). If the

temperature of the material you ar e testing is eith er higher or lo wer than

68°F (20°C), refer to t he temperature correctio n chart (see table). As a

general rule the insulation resistance value may be corrected by:

•

Halving the resistance meas urement value for every 10°C above t he

base temperature of 68°F (20°C), or

•

Doubling the resistance value for every 10°C below 68°F (20°C)

°C °F

0320.25

5410.36

10 50 0.50

15 59 0.75

20 68 1.00

25 77 1.40

30 86 1.98

35 95 2.80

40 104 3.95

45 113 5.60

50 122 7.85

55 131 11.20

60 140 15.85

65 149 22.40

70 158 31.75

75 167 44.70

80 176 63.50

Multiplication

Factor

- 25 -

Page 27

Megohmmeter Model 1000N/1100N

,QWHUSUHWLQJWKH5HVXOWV

Insulation resistance values are a function of the type of insulating

material. The actual value you read may vary greatly and is not as

important as the trends of the values over time. This is why the

resistance measurem ent must be tak en in a greater context. Some other

factors to consider are:

Previous Testing Results

These are very important, since they will indicate the decline in the

insulation resistance over time. All new equipm ent should be tested and

documented to serve as a benchmark for future testing.

Careful Visual Inspection

By taking a very close l ook at the equipment you are testing it may be

possible to see crack s, exc essive m ois ture, burn m ark s, etc ., which m a y,

over time, cause catastrophic equipment failure.

Manufacturers’ Recommendations for Specific Equipment

The definitive sour ce for information o n a specific piece of equipment is

its manufacturer. Most manufacturers will provide basic information

about the insulation resistance which may be encountered during testing.

Comparisons with Similar Equipment

Similar equipment should provide similar insulation resistance values.

This would also remain true when testing cables. For three-phase

systems, it would be v ery useful to compare r es isti ve values bet wee n th e

phases.

By performing insulation resis tance tests regularl y and recordin g the test

results, it may be possible to predict failure by detecting a downward

trend in the resistance. Careful notations should be made as to

time/date, temperature, applications, etc.

The information co ntained in this manual is intended only as a g uide to

acceptable procedure; it is not inte nded to be used as a tes t spec ific ation

for specific electrical equipment.

- 26 -

Page 28

Megohmmeter Model 1000N/1100N

(6'&21'8&7,9,7<7(67.,70(*2+00(7(5

0RGHO1

5HFHLYLQJ<RXU6KLSPHQW

Upon receiving your shipment, check that the contents agree with the

packing slip. Notify your distributor at once of any shortages. If the

equipment appears to be damaged, file a claim immediately with your

carrier, and notify your distributor at o nce, gi ving a det ailed des cript ion of

the damages. Save t he damaged pac king container to s ubstantiate your

claims.

3DFNDJLQJ

ESD Conductivity Tes t Kit Megohmmeter Model 1 100N (Cat. #2110.03)

is shipped with the AEMC

weights, 25-foot shielded lead, two safety leads, an alligator clip, test

probe, batteries, carrying case and ins tr uct ion manual.

®

Model 1000N megohmmeter, two floor

$FFHVVRULHV5HSODFHPHQWVIRU0RGHO1

1000V Megohmmeter...........................................................

Cat. #2110.02

Fuse, set of one, 0.3A ..........................................................

Floor weights, set of two.......................................................

Carrying case........................................................................

Set of 3 leads for 1100N.......................................................

7-Pin shielded lead, 25-ft, for 1100N/5100...........................

AC power supply module with line cord and plug for

AC

switch-selectable 110/220V

Fuse, set of five, 0.1A slow-blow for AC supply module ......

Replacement Leads for Model 1100

Set of leads: 25-ft shielded lead, two safety leads,

alligator clip and test probe...................................................

at 47 to 400Hz.....................

- 27 -

Cat. #100.429

Cat. #2118.05

Cat. #2118.07

Cat. #2118.42

Cat. #2118.26

Cat. #100.142

Cat. #100.438

Cat. #2118.06

Page 29

Megohmmeter Model 1000N/1100N

'HVFULSWLRQ

ESD Conductivity Test Kit Megohmmeter Model 1100N Kit (Cat.

#2110.03) is designed specifically for floor resistance testing in areas

where electrostatic discharge is a problem, such as computer rooms,

electronic assembly rooms, hospitals, etc. The kit includes a 1000V

megohmmeter which features excellent resolution in the critical 10

9

Ω

ranges, and fine r esolution up to 1 0

10

12

Ω

; 25-foot shielded lead; and

two floor weights - NFPA probes for consistent and repeatable contact

with the surface under test. The Model 1100N is useful for testing

effectiveness of conductive carpets, mats, tables, chairs, etc.

The Model 1000N is es pecially su ited for this t ype of measur ement, due

to high accuracy and resolution in the megohm and gigohm ranges.

Conductivity testers are im portant in any operation wher e the presence

of electrostatic discharge charges poses a danger to personnel or the

operation of electronic equipment.

There are several standards in the industry which may be referenced

when performing ESD testing of conductive flooring or tiles.

Standard 99

Reduction in Electrostatic Hazar d

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

Standard F 150-72

Electrical Resistance of Conductive Resilient Flooring

American Society for Testing and Materials

1916 Race St.

Philadelphia, PA 19103

Standard #4 EOS/ESD

Standard for Protection of Electrostatic Discharge Susceptible Items

EOS/ESD Association inc.

201 Mill St.

Rome, NY 13440

Additional standar ds and specific recomm endations for your application

may be obtained from equipment and flooring manufacturers.

7

to

- 28 -

Page 30

Megohmmeter Model 1000N/1100N

6SHFLILFDWLRQV

INSULATION TESTS

DC Test Voltages:

50, 100, 250, 500, 1000V

Megohm Ranges:

For each test voltage two direct reading ranges:

1 to 1000MΩ (10

1 to 1000GΩ (10

6

to 10

9

to 10

9

Ω

)

12

Ω

)

Short Circuit Current:

Accuracy:

5% of reading typical

5mA (max)

Charging Time:

MΩ range: 0.3 seconds/µF

GΩ range: 4 seconds/µF

Discharging Time:

Automatic discharge when test button is released; 0.1 seconds/µF

Scale:

Two large overlapping scales: 4.7" (119mm) for each range

Test Voltage Generation:

Solid state circuitry generating rated test voltage across the full range

RESISTANCE TESTS

Test Current:

Kilohm Range:

Maximum Test Voltage:

Accuracy:

Constant 1mA DC

1 to 1000kΩ (1MΩ)

1200V

5% of reading typical

DC

CONTINUITY TESTS

Resistance Range:

0.1 to 100Ω; 3Ω mid-scale

Accuracy:

6% of reading

Audible Tone:

Continuous for continuity resistances under 200

Fuse:

High interrupting capacity (0.315A)

- 29 -

Ω

Page 31

Megohmmeter Model 1000N/1100N

VOLTAGE TESTS (SAFETY CHECK)

Voltage Range:

Accuracy:

3% of full scale

0 to 600V

AC/DC

GENERAL SP E CIFICATIONS

Audible Test Signal:

Ten beeps per minute

(constant tone for continuity resistance under 200Ω)

Power Supply:

Eight 1.5V “AA” alkaline batteries (NEDA 15A). Typical battery life: 350

one-minute tests; power consumed only when test button is depressed;

built-in battery check by green LED

Option:

110/220V selectable, 47 to 400Hz AC supply module

AC

Dielectric Test:

4000V

Fuse Protection:

0.3A high interrupting capacity fuse between line and guard terminals

Meter Mov e ment :

Dimensions:

Weight:

7.7 x 5.2 x 3.75" (196 x 132 x 95mm)

2.2 lbs (1 kg)

Temperature Range:

, 50/60 Hz, 1 minute

Rugged taut band suspension

23° to 122°F (-5° to +50°C)

Case:

High impact gray polycarbonate

Terminals:

Color-coded safety terminals; guard terminal eliminates surface leakage

errors

- 30 -

Page 32

Megohmmeter Model 1000N/1100N

%DWWHU\5HSODFHPHQW

The Model 1100N is powered by eight 1.5V “AA” batteries. To replace

the batteries, disconnect the instrument from any circuits, verify the

PUSH-TO-TEST button is in the OFF position and proceed as follows:

•

Unscrew the four standard screws on the f our corners of the battery

pack and remove the battery pack.

•

Replace the batteries, observing the proper polarities.

•

Replace the battery case, taking care n ot t o p inch the connect ing wire,

and tighten the four screws.

Access panel

screws

Access panel

$&6XSSO\0RGXOH

The optional AC supply module (Cat. #100 .142) provides power to the

AC

Model 1100N at 110 or 220V

designed to plug into the back portion of the instrument, directly

replacing the batteries. The module is protected by a 0.1A slow blow

Note:

fuse.

•

Unscrew the four screws on the corners of the back panel battery

pack.

•

Disconnect and remove the battery pack.

•

Connect the AC supply module to the power supply connector.

•

Place the AC supply module into the back of the instrument and

tighten the four corn er screws, making sure not to p inch the wires of

the power supply connector.

•

With the tip of a screwdriver, select the proper voltage with the

110/220 supply switch on the back panel of the AC supply module

•

Plug AC supply cord into the appropriate voltage receptacle.

Cat. #100.142 is supplied with 110V US plug.

. The AC power supply module is

- 31 -

Page 33

Megohmmeter Model 1000N/1100N

5HVLVWDQFH7HVWLQJRI&RQGXFWLYH)ORRULQJ

Background

There are numerous standar ds currently being de veloped for m easuring

conductive flooring resistance under 100V and 500V. Actual resistance

values vary from specification to specification, but 10

typical values. The follo wing simplified procedure is a n ex tr a pol ation from

the ASTM standard F 150-72. You ma y also refer to other so urces, such

as the NFPA or EOS/ESD for alternate procedures.

General Notes

The floor sample should consist of a section covering 48 x 48 inches

(1.22 x 1.22 meters) in area.

When the sample is to be tested after installation, the test area

dimensions should not exceed a section of floor 20 x 20 feet (6 x 6

meters).

Conditioning

Whenever possible, condit ion the test area at least twenty-four ho urs at

73.4°F ±1.8°F (23°C ±1°C) and 50% ±5% RH and test under the sam e

conditions.

4

to 10

10

Ω

are

Test Procedure

1.

For uninstalled panels:

General Notes #1 on a nonconductive surfac e and lightly wipe with a

lint-free cloth to rem ove any foreign material prior to the placing of

the weights. Place the weights 2" (50.8 mm ) in from an edge of the

sample and 36" (914.4 mm) apart. Apply 500 volts and take a

reading five seconds after application of the voltage.

2.

For installed panels:

least 36" (914.4 mm) from any ground connections or grounded

object resting on the floor sample described in General Notes #2.

Apply 500 volts and take a reading five seconds after application of

the voltage.

3. Unless otherwise spec ified, make five measurem ents on each floor

section with the weights at different loc ations for each m easurement

and record the value of two significant figures (see Figure 16).

Place the dry specimen as described in

Place the weights 36" (914.4 mm) apart and at

- 32 -

Page 34

Megohmmeter Model 1000N/1100N

4. Repeat the above procedure with the megohmmeter connected

between one weight and a k nown electrical groun d (see Figure 17).

In the case of an unins talled floor sample as in step #1, the ground

should be part of the s ample panel. In the cas e of an insta lled floor

sample as in step #2 , the ground should be a water pipe or known

electrical ground. Interchange the leads at the megohmmeter for

each measurement and report the average value obtained as the

value for that measurement.

5. When finished, turn off the megohmmeter and return it to the case.

Note:

If the resistance changes with time during a measurement, the

value observed after about 5 seconds shall be considered to be the

measured value.

Table Top

Electrodes

36 "

GUARD

+ EARTH- LINE

MEGOHMMETER

Figure 16

- 33 -

Page 35

Megohmmeter Model 1000N/1100N

Table Top

Groundable Points

Electrode

GUARD

+ EARTH- LINE

MEGOHMMETER

Figure 17

0HDVXUHPHQW5HVXOWV

Specific measur ement results for eac h in di vi du al app lic at io n of the Model

1100N are difficult to determine. The definitive information on which

voltage level to apply, as well as whic h meas urem ent values will indicat e

a proper resistivity, should be determined by the manufacturer of the

conductive flooring or tiles.

The following va lues (based on EOS/ESD, S4.1-199 0) may serve as a

minimum resistivity level which has been proven to provide an

appropriate level of protection in the manufacturing environment.

Resistance from test electrode to a groundable point (Figure 17):

Measured value: ≤ 10,000 megohms (10 gigohm s )

Resistance from electrode to electrode (Figure 16):

Measured value: ≥ 1 megohm

- 34 -

Page 36

Megohmmeter Model 1000N/1100N

0DLQWHQDQFH

Warning:

•

For maintenance use only original factory replacement parts.

•

To avoid electrical shock, do not attempt to perform any servicing

unless you are qualified to do so.

•

Do not perform any service while the Megohmmeter Model

1000N/1100N is on any circuit.

•

To avoid electrical shock and/or damage to the instrument, do not let

water or other foreign agents into the electronic module.

Cleaning:

The megohmmeter may be gently cleaned with a soft cloth, soap and

water. Dry immediately after cleaning. Avoid water penetration into the

electronic module.

Make sure the megohmmeter and all leads are dry before further use.

- 35 -

Page 37

Megohmmeter Model 1000N/1100N

5HSDLUDQG&DOLEUDWLRQ

To guarantee that your instrument complies with the factory

specifications, we recommend that the megohmmeter be submitted to

our factory service center at one-year intervals for recalibration, or as

required by other standards.

For instrument repair and calibration:

Call (800) 945-2362 (X360) • (603) 749-6434 • Fax: (603) 742-2346

®

Chauvin Arnoux

d.b.a. AEMC

15 Faraday Drive

Dover, NH 03820 USA

(Or contact your authorized distributor.)

Costs for repair, standard calibration, and calibration traceable to N.I.S.T.

are available.

Note: All customers must call for a CSA# before returning any

instrument.

, Inc.

®

Instruments

7HFKQLFDODQG6DOHV$VVLVWDQFH

If you are experiencing any technica l pro bl ems, or require any as s istanc e

with the proper use or application of this instrument, please call our

technical hotline:

Chauvin Arnoux

d.b.a. AEMC

Phone: (800) 343-1391

(508) 698-2115

Fax: (508) 698-2118

www.aemc.com

®

, Inc.

®

Instruments

- 36 -

Page 38

Chauvin Arnoux®, Inc. d.b.a AEMC® Instruments

99-MAN 100020 v7 01/02

15 Faraday Drive • Dover, NH 03820, USA

www.aemc.com

Loading...

Loading...