Page 1

Understanding Power &

AC

Power Quality Measurements

is the actual transformer voltage. This

system is frequently used for power

loads in commercial and industrial

buildings. In such cases, service to the

premises is made at 208V, three-phase.

Feeders carry the power to panel

boards supplying branch circuits for

motor loads. Lighting loads are usually

handled by a separate single-phase

service. The 480V distribution

is often used in industrial buildings

with substantial motor loads.

ACB

A

The threatened limitations of

conventional electrical power sources

have focused a great deal of attention

on power, its application, monitoring

and correction. Power economics

now play a critical role in industry as

never before. With the high cost of

power generation, transmission, and

distribution, it is of paramount concern to

effectively monitor and control the

use of energy.

The electric utility’s primary goal is

to meet the power demand of its

customers at all times and under

all conditions. But as the electrical

demand grows in size and complexity,

modifications and additions to existing

electric power networks have become

increasingly expensive. The measuring

and monitoring of electric power have

become even more critical because of

down time associated with equipment

breakdown and material failures.

For economic reasons, electric power

is generated by utility companies at

relatively high voltages (4160, 6900,

13,800 volts are typical). These

high voltages are then reduced at

the consumption site by step-down

transformers to lower values which may

be safely and more easily used

in commercial, industrial and residential

applications.

Personnel and property safety are

the most important factors in the

operation of electrical system operation.

Reliability is the first consideration

in providing safety. The reliability of

any electrical system depends upon

knowledge, preventive maintenance

and subsequently the test equipment

used to monitor that system.

Typical Voltage Configurations

Single-Phase Systems

Single-phase residential loads are

almost universally supplied through

120/240V, 3-wire, single-phase services.

Large appliances such as ranges,

water heaters, and clothes dryers

are supplied at 240V. Lighting, small

appliances, and outlet receptacles

are supplied at 120V. In this system the

two “hot” or current carrying conductors

are 180° out-of-phase

with respect to the neutral.

A

0

B

LINE (HOT)

NEUTRAL

LINE (HOT)

Figure 1. 1Ø System

Three-Phase, 3-Wire Systems

In this type of system, commonly known

as the “DELTA” configuration, the

voltage between each pair of line wires

t

B

C

Figure 2. 3Ø, 3-wire system

Three-Phase, 4-Wire Systems

Known as the “WYE” type connection,

this is the system most commonly used

in commercial and industrial buildings.

In office or other commercial buildings,

the 480V three-phase,

4-wire feeders are carried to each floor,

where 480V three-phase is tapped to

a power panel or motors. General area

fluorescent lighting that uses 277V

ballasts is connected between each leg

and neutral; 208Y/ 120 three-phase,

4-wire circuits are derived from stepdown transformers for local lighting and

receptacle outlets.

Typical voltage:

phase-to-phase = 208/480V

phase-to-neutral = 120/277V

B

A

Neutral

B

C

Figure 3. 3Ø, 4-Wire System

Understanding Power & Power Quality Instruments (pdf) 05/09

Technical Assistance (800) 343-1391 www.aemc.com 1 of 8

Page 2

Balanced vs. Unbalanced Loads

A balanced load is an AC power

system using more than two wires,

where the current flow is equal in each

of the current carrying conductors.

Many systems today represent an

unbalanced condition due to uneven

loading on a particular phase. This

often occurs when electrical expansion

is affected with little regard to even

distribution of loads between phases or

several nonlinear loads on the

same system.

RMS vs. Average Sensing

The term RMS (root-mean-square)

is used in relation to alternating

current waveforms and simply means

“equivalent” or “effective,” referring

to the amount of work done by the

equivalent value of direct current (DC).

The term RMS is necessary to describe

the value of alternating current, which

is constantly changing in amplitude

and polarity at regular intervals. RMS

measurements provide a more accurate

representation of actual current or

voltage values. This is very important

for nonlinear (distorted) waveforms.

Until recently, most loads were “linear”;

that is, the load impedance remained

essentially constant regardless of

the applied voltage. With expanding

markets of computers, uninterruptible

power supplies, and variable speed

motor drives, resulting nonlinear

waveforms are drastically different.

Measuring nonsinusoidal voltage and

current waveforms requires a True

RMS meter. Conventional meters

usually measure the average value of

amplitudes of a waveform. Some meters

are calibrated to read the equivalent

RMS value (.707 x peak); this type

calibration is a true representation only

when the waveform is a pure sine wave

(i.e., no distortion). When distortion

occurs, the relationship between

average readings and True RMS values

changes drastically. Only a meter which

measures True RMS values gives

accurate readings for a nonsinusoidal

waveform. RMS measuring circuits

sample the input signal at a high

rate of speed. The meter’s internal

circuitry digitizes and squares each

sample, adds it to the previous samples

squared, and takes the square root of

the total. This is the True RMS value.

V

÷

Ø

I

Figure 4. Nonlinear current waveform

Demand

The amount of electrical energy

consumed over time is known as

demand. Demand is the average load

placed on the utility to provide power

(kilowatts) to a customer over a utilityspecified time interval (typically 15 or

30 minutes). If demand requirements

are irregular, the utility must have

more capability available than would

be required if the customer load

requirements remained constant. To

provide for this time-varying demand,

the utility must invest in the proper size

equipment to provide for these power

peaks. Brief high peaks such

as those present when large equipment

initially comes on line are not critical

in the overall equation because the

duration is short with respect to the

demand averaging interval.

Consumption

Watts and vars are instantaneous

measurements representing what is

happening in a circuit at any given

moment. Since these parameters

vary so greatly within any period, it is

necessary to integrate (sum) electrical

usage over time.

The fundamental unit for measuring

usage is the watt hour (Wh), or more

typically the kilowatt hour (kWh). This

value represents usage of 1000W for

one hour. Typical costs in the United

States for one kilowatt hour range

from 8 to 15 cents.

Power Factor

Power factor is the ratio of ACTUAL

POWER used in a circuit to the

APPARENT POWER delivered by a

utility. Actual power is expressed in

watts (W) or kilowatts (kW); apparent

power in voltamperes (VA) or

kilovoltamperes (kVA). Apparent power

is calculated simply by multiplying the

current by the voltage.

Power Factor = Actual Power = kW

Apparent Power kVA

Certain loads (e.g., inductive type

motors) create a phase shift or delay

between the current and voltage

waveforms. An inductive type load

causes the current to lag the voltage by

some angle, known as the phase angle.

On purely resistive loads, there is

no phase difference between the

two waveforms; therefore the power

factor on such a load will be 0 degrees,

or unity.

The following examples of a soldering

iron and a single-phase motor illustrate

how power factor is consumed in

different types of loads. In a soldering

iron, the apparent power supplied by

the utility is directly converted into heat,

or actual power. In this case, the actual

power is equal to the apparent power,

so that the power factor

is equal to “1” or 100% (unity).

KVA

ø

Kw

V

√

Figure 5. Power factor on nondistorted

sine wave.

Kvar (inductive)

Ø

I

In the case of a single-phase motor,

the actual power is the sum of several

components:

a. the work performed by the system;

that is, lifting with a crane, moving air

with a fan, or moving material, as with

a conveyer.

b. heat developed by the power lost in

the motor winding resistance

c. heat developed in the iron through

eddy currents and hysteresis losses

d. frictional losses in the moor bearings

e. air friction losses in turning the motor

rotor, more commonly known as

windage losses.

We now observe that with a singlephase motor, the apparent power

obtained is greater than the actual

power. This difference is the power

factor.

Understanding Power & Power Quality Instruments (pdf) 05/09

Technical Assistance (800) 343-1391 www.aemc.com 2 of 8

Page 3

Power factor reflects the difference

which exists between loads. The

soldering iron is a purely resistive load

which absorbs the current, which is

then absorbed directly into heat.

The current is called actual current

because it directly contributes to the

production of actual power.

On the other hand, the single-phase

electric motor represents a partially

inductive load consisting of actual

current which will be converted into

actual power, and magnetizing current

which generates the magnetic field

required to operate the electric motor.

This magnetizing current, called the

reactive current, corresponds to an

exchange of energy between the

generator and the motor, but it is not

converted into actual power.

Reactive Compensation Power

Reactive compensation power refers

to the capacitive values required to

correct low power factor to as close

to unity (1.0) as possible. Most

industrial loads are inductive, so the

load current lags the line voltage by

some degree. In order to bring the

value closer to unity, something must

be added to the load to draw a leading

current. This is done by connecting a

capacitor in parallel with the load. Since

a capacitor will not dissipate any real

power, the charge for real power will be

the same.

AEMC recommends consulting a power

factor correction capacitor manufacturer

prior to any installation to reduce

the possible effects of harmonics,

resonance, etc.

Electrical Harmonics

Until fairly recently, power quality

referred to the ability of the electric

utilities to supply electric power

without interruption. Today, the phrase

encompasses any deviation from a

perfect sinusoidal waveform. Power

quality now relates to short-term

transients as well as continuous state

distortions. Power system harmonics

are a continuous state problem with

dangerous results. harmonics can be

present in current, voltage, or both. It is

estimated that as many as 60% of all

electrical devices operate with nonlinear current draw.

Utility companies invest millions of

dollars each year to ensure that voltage

supplied to their customers is as close

as possible to a sinusoidal waveform.

If the power user connects loads to the

system which are resistive, such as

incandescent light bulb, the resulting

current waveform will also be sinusoidal.

However, if the loads are nonlinear,

which is typically the case, the current

is drawn in short pulses and the current

waveform will be distorted. Total current

that is then drawn by the nonlinear load

would be the fundamental as well as all

the harmonics.

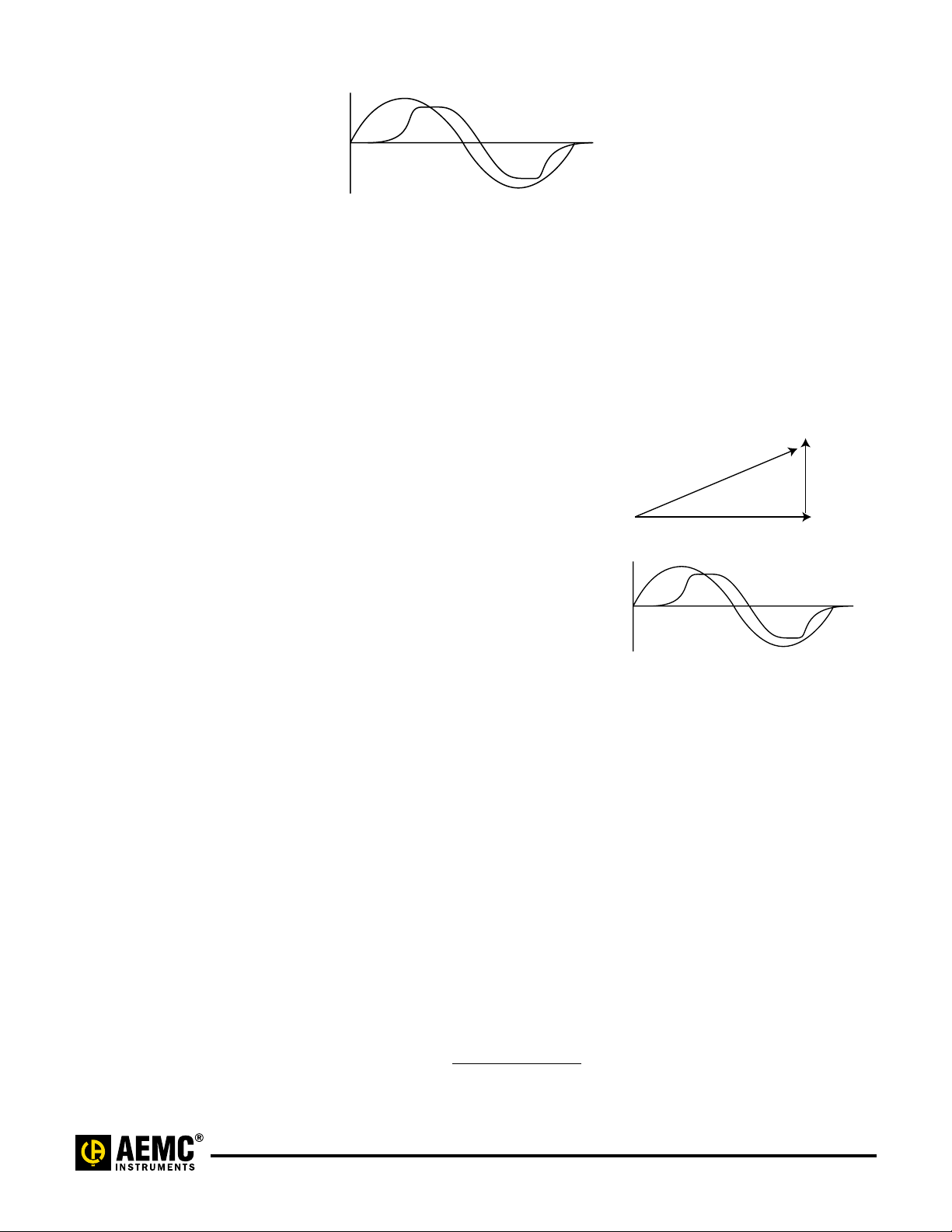

Fundamental

3rd Harmonic

Resultant Distorted Waveform

Figure 6. Composite waveform

Harmonic distortion can cause serious

problems for the users of electric

power, from inadvertent tripping

of circuit breakers to dangerous

overheating of transformers and neutral

conductors, as well as heating in motors

and capacitor failure. Harmonics

can cause problems that are easy to

recognize but tough to diagnose.

It is becoming increasingly important

to understand the fundamentals of

harmonics, and to be able to recognize

and monitor the presence of damaging

harmonics. Harmonics within an

electrical system vary greatly within

different parts of the same distribution

system and are not limited simply to

the supply of the harmonic producing

device. Harmonics can interact within

the system through direct system

connections or even through capacitive

or inductive coupling.

A harmonic may be defined as an

integer multiple of a fundamental

frequency. Harmonics are designated

by the harmonic number. For our

discussion, we will focus on the 60Hz

power frequency. The second harmonic

would be two times the fundamental or

120Hz. The third would be three times

the fundamental or 180Hz, and so on.

Nonlinear equipment generates

harmonic frequencies. The nonlinear

nature of a device draws current

waveforms that do not follow the

voltage waveform. Electronic

equipment is a good example. While

this broad category encompasses many

different types of equipment, most of

these devices have one characteristic

in common. They rely on an internal DC

power source for their operation.

Loads which produce harmonic

currents include:

•Electroniclightingballasts

•Adjustablespeeddrives

•Electricarcfurnaces

•Personalcomputers

•Electricweldingequipment

•Solidstaterectifiers

•Industrialprocesscontrols

•UPSsystems

•Saturatedtransformers

•Solidstateelevatorcontrols

•Medicalequipment

This is by no means an exhaustive

list of equipment which generates

harmonics. Any electronic-based

equipment should be suspected of

producing harmonics.

Due to the ever increasing use

of electronics, the percentage of

equipment which generates harmonic

current has increased significantly.

The harmonic problem manifests itself

with proliferation of equipment using

diode capacitor input power supplies.

This type of equipment draws current

in a short pulse only during the peak

of the sine wave. The result of this

action, aside from improved efficiency,

is that high frequency harmonics are

superimposed onto the fundamental

60Hz frequency.

The harmonics are produced by the

diode-capacitor input section which

rectifies the AC signal into DC. The

circuit draws current from the line

only during the peaks of the voltage

waveform, thereby charging a capacitor

to the peak of line voltage.

Understanding Power & Power Quality Instruments (pdf) 05/09

Technical Assistance (800) 343-1391 www.aemc.com 3 of 8

Page 4

The equipment DC requirements

are fed from this capacitor and as a

result the current waveform becomes

distorted.

Voltage

Current

Figure 7 Nonlinear current draw

Harmonics in the electric power

system combine with the fundamental

frequency to create distortion. The

level of distortion is directly related to

the frequencies and amplitudes of the

harmonic current. The contribution of

all harmonic frequency currents to the

fundamental current is known as “Total

Harmonic Distortion” or THD. This THD

value is expressed as a percentage of

the fundamental current. THD values of

over 10% are reason for concern.

THD is calculated as the square root of

the sum of the squares of all the

harmonics divided by the fundamental

signal (50 or 60Hz). This calculation

arrives at the value of distortion as a

percentage of the fundamental.

Mathematically, %THD is the ratio

of the sum of the root-mean square

(RMS) of the harmonic content to the

root-mean square (RMS) value of the

fundamental 50 or 60Hz signal, and

expressed as a percentage.

TOTAL HARMONIC DISTORTION

Sum of squares of amplitudes of all harmonics

%THD =

Square of amplitude of fundamental

[

%THD (current) =

%THD (voltage) = [(V2)2 + (V3)2 + (V4)2 + (V5)2 .../(V1)

(I2)2 + (I3)2 + (I4)2 + (I5)2 .../(I

DISTORTION FACTOR

Sum of squares of amplitudes of all harmonics

%DF =

Square of Total RMS

[

%DF (current) =

%DF (voltage) = [(V2)2 + (V3)2 + (V4)2 + (V5)2 .../(V1)

(I2)2 + (I3)2 + (I4)2 + (I5)2 .../(I

Another useful parameter is the

Distortion Factor, or %DF. Distortion

Factor is the Total Harmonic Distortion

referenced to the total RMS signal.

The THD is expressed as a percentage

and may not be greater than the

fundamental. The %DF never exceeds

100%. We provide this term because of

the market need and the requirement

of this value under the international

standard IEC-555. Mathematically,

it is the ratio of the sum of the rootmeansquare (RMS) of the harmonic

content to the root-mean square (RMS)

value of the total signal, and expressed

as a percentage.

Please note that our %DF is not the

same value as the Distortion Factor

as expressed the IEEE standard

519-1992 (in which Distortion Factor

is the same as THD).

Figure 8. Computer current waveform

Wherever there are large numbers of

nonlinear loads, there are sure to be

harmonics in the distribution system.

Harmonic-producing equipment is found

in varied locations from administrative

offices to manufacturing facilities.

In the factory

environment,

electronic power

x 100

converters such

as variable speed

drives, SCR

drives, etc., are the

largest contributors

RMS

2

)

]

x 100

to harmonic

2

]

x 100

distortion. It is not

uncommon to have

THD levels as

high as 25% within

some industrial

settings.

x 100

Most single-phase

office equipment

draws nonlinear

current. While

RMS

2

)

]

x 100

fluorescent lighting

with electronic

ballasts and

2

]

x 100

many types of

office equipment

contribute to creating harmonics,

personal computer power supplies are

the largest contributor within the office

environment. Although THD levels will

be lower than in an industrial setting,

the susceptibility of office equipment to

variations in power quality is extremely

high.

In the industrial environment, there can

be many three-phase, nonlinear loads

drawing high levels of load current. The

most prevalent harmonic frequencies

are the odd integer multiples of the

60Hz frequency. The third harmonic

(180Hz) is always the most prevalent

and troublesome.

Large commercial buildings have many

different sizes and types of loads.

In most installations the power is

distributed with 208/ 120V transformers

in a Delta-Wye configuration. When

multiple loads are

supplied, each

generates triple

harmonic currents on

the neutral conductor

which are sent onto the

transformer secondary

Current Draw

and reflected into the

delta primary. These

currents circulate

within the delta primary

causing overheating and shortened

service life.

Harmonics can cause a variety of

problems to any user of electric power.

For large users, the problems can

be intense. For electronic equipment

that relies on the zero crossing of the

sinusoidal waveform, such as clock

timing devices, heavy harmonic content

can cause a zero crossing point offset.

480V/208V

Transformer

C1

Primary

C2

C3

Figure 9. Delta primary, circulating current

Secondary

A

B

C

Neutral

Odd number harmonics (third, fifth

and seventh) cause the greatest

concern in the electrical distribution

system. Because the harmonic

waveform usually swings equally in

both the positive and negative direction,

the even number harmonics are

mitigated.

Understanding Power & Power Quality Instruments (pdf) 05/09

Technical Assistance (800) 343-1391 www.aemc.com 4 of 8

Page 5

Heating effect causes the greatest

problem in electric equipment. Many

times, electrical distribution equipment

has overheated and failed even when

operating well below the suggested

rating requirements. Temperature

increase is directly related to the

increase in RMS current.

To Source of Power

Main Service

Entrance Switch

Fused

Disconnect

Switch for

Capacitors

To Load

Figure 10. Power factor capacitors at resonant frequency.

voltage drops between neutral and

ground which are well above normal.

Readings above four volts indicate high

neutral current.

False tripping of circuit breakers is also

a problem encountered with the higher

frequencies that harmonics produce.

Capacitors

susceptible equipment (e.g., electronic

equipment, variable speed motors,

etc.). Remember that most distribution

systems are designed specifically to

carry 60Hz.

Most nonlinear harmonic problems

can be detected at the electrical panel.

Excessive current flow on the neutral

can be detected with a True RMS

current meter, but may be indicated

by a resonant buzzing sound or by

discolored connections on the neutral

buss.

Because harmonic frequencies

are always higher than the 60Hz

fundamental frequency, “skin effect” also

becomes a factor. Skin effect is

a phenomenon where the higher

frequency causes the electrons to

flow toward the outer sides of the

conductor, effectively reducing the

cross-sectional diameter of the

conductor and thereby reducing the

ampacity rating of the cable. This effect

increases as the frequency and the

amplitude increase. As a result, higher

harmonic frequencies cause a greater

degree of heating in conductors.

On balanced three-phase systems

with no harmonic content, the line

currents are 120 degrees out-of-phase,

canceling each other and resulting in

very little neutral current. However,

when there is distortion in any one

of the phase currents, the harmonic

currents increase and the cancellation

effect is lessened. The result is typically

a neutral current that is significantly

higher than planned.The triple

harmonics (odd multiples of three) are

additive in the neutral and can quickly

cause dangerous overheating.

In theory, the maximum current that

the neutral will carry is 1.73 times the

phase current. If not sized correctly,

overheating will result. Higher than

normal neutral current will cause

Peak sensing circuit breakers often will

trip even though the amperage value

has not been exceeded. Harmonic

current peak values can be many times

higher than sinusoidal waveforms.

Power factor correction capacitor failure

in many cases can be directly attributed

to harmonic content. Capacitors appear

as extremely low impedance values

and are more susceptible to harmonics.

Inductive reactance varies directly

with frequency (XL = 2pfl). Parallel

resonance between the capacitor

bank and the source impedance can

cause system resonance resulting

in higher than normal currents and

voltages. High harmonic currents have

been known to overheat correction

capacitors, causing premature failure

and sometimes resulting in explosion.

Most harmonic problems result when

the resonant frequency is close to

the fifth or seventh harmonic. These

happen to be the largest harmonic

amplitudenumbersthatadjustable

speed drives create. When this

situation arises, capacitor banks should

be resized to shift the resonant point to

another frequency.

Detection and Measurement

In harmonic analysis, field

measurements are performed to

identify frequency and magnitude

of harmonic currents generated by

Figure 11. Measuring at the service entrance

panel.

Beginning at the service entrance

panel, measure and record the True

RMS current in each phase, as well

as the neutral of the distribution

transformer secondary. Compare

this measured neutral current to the

anticipated current due to phase

imbalance. If the phase currents are

equal, the vector sum of the neutral

currents will add to zero. If there are

excessive amounts of triple harmonics

in the neutral, neutral current may

exceed phase current. Consult the

®

for the maximum ampacity for

NEC

each of the tested conductors.

Measure each feeder for harmonic

content. A high degree at this location

can often be heard as a buzzing sound.

A voltage THD reading is also useful at

this location.

IEEE standard 519-1992 specifies both

maximum distortion levels and recommended correction levels. A harmonic

distortion limit of 5% is the point where

harmonics begin to have

a detrimental effect on electrical

distribution systems.

Harmonic current measurements define

the harmonic generating characteristics

Understanding Power & Power Quality Instruments (pdf) 05/09

Technical Assistance (800) 343-1391 www.aemc.com 5 of 8

Page 6

of the load, so measurements should

be taken at the load when possible.

Voltage measurements define the

system response and are usually taken

at the individual busses.

Effects on the System

To compound the problems that

harmonic currents present to the

system, nonlinear harmonic load also

have an Ohm’s law relationship with

the source impedance of the system to

produce voltage harmonics. Consider

a heavily loaded transformer that is

affected by one branch circuit feeding a

non-linear load. The creation of voltage

harmonics can then be passed down to

all the remaining circuits being fed by

that transformer.

Voltage harmonics may cause havoc

within the electrical system. Motors are

typically considered to be linear loads;

however, when the source voltage

supply is rich in harmonics, the motor

will draw harmonic current. The typical

result is a higher than normal operating

temperature and shortened service life.

Different frequency harmonic currents

can cause additional rotating fields in

the motor. Depending on the frequency,

the motor will rotate in the opposite

direction (counter-torque). The fifth

harmonic, which is very prevalent, is a

negative sequence harmonic causing

the motor to have a backward rotation,

shortening the service life.

Noise can be picked up in

communication equipment and

telephone systems when harmonics

at audio or radio frequencies are

inductively or capacitively coupled into

communication or data lines.

When induction-disc watt-hour meters

are monitoring nonlinear loads,

depending on the content of the

harmonics, the disk may run slower or

faster, resulting in erroneous readings.

Transformer Derating

Most generators and transformers

base their operating characteristics on

undisturbed 60Hz waveforms. When

the waveforms are rich in harmonics,

shortened service or complete failure

often follows.

The derating K factor can be applied

specifically to transformers to ensure

that dangerous heating will not result

due to the transformer supplying load

currents rich in harmonic content.

The K factor is determined by

measuring the True RMS current

of each harmonic, multiplied by the

harmonic order and squared. The

total sum of this is then multiplied by

the harmonic order and squared. The

total sum of this is then multiplied by

the eddy current losses. Transformer

parasitic heating due to harmonic

currents is frequency dependent, i.e.,

higher frequency harmonic currents

cause a higher degree of transformer

heating and failure.

The K factor is basically an index of the

transformer’s ability to handle nonlinear

load current without abnormal heating.

Some distribution transformers are

now being designed with magnetic

cores and windings to accommodate

harmonic content. A K-rated transformer

is specifically designed to handle

nonlinear loads. The higher the K factor

value, the better the transformer’s

ability to handle nonlinear loads.

IEEE C57.110-1986 is a prescribed

procedure used to derate the

transformer loading based on the

specific harmonic content. Each

specific electrical application is unique

in type and amount of harmonic

interaction.

IEEE C57.1200-1987 has proposed a

limit of 5% for transformer harmonic

current factor.

An alternate method for derating

transformers is available for buildings

which supply single phase, 120V

receptacles. This method is established

by The Computer & Business

Equipment Manufacturers Association

(CBEMA).

CBEMA Derating Factor =

Crest Factor

1.414

Meter Readings

Harmonic problems can be analyzed

more easily when the proper test

equipment is used.

The term “True RMS”, or Root-MeanSquare, relates to the equivalent DC

heating value of the current or voltage

waveform. If a pure sine wave and a

distorted sine wave were both applied

to a resistive load, the point where they

both create the same heating value

is the point where they both have the

same RMS value.

True RMS capability is required to

accurately measure systems where

harmonic current is present. Average

responding instruments will yield

erroneous measurement results from

25 to 40% below the actual value when

harmonic distortion is present.

Many instruments on the market

measure average or Peak values of a

waveform and internally multiply by

1.11 or .707 respectively to indicate

RMS values. These devices work well

when measuring a pure sine wave.

Instruments with True RMS converters

sample the waveform at many different

points and provide accurate readings

on distorted waveforms. Microprocessor

based circuits sample, digitize and

square each sample, add it to the

previous sample squared, and take the

square root of the total. This process

yields a True RMS value regardless of

the amount of distortion.

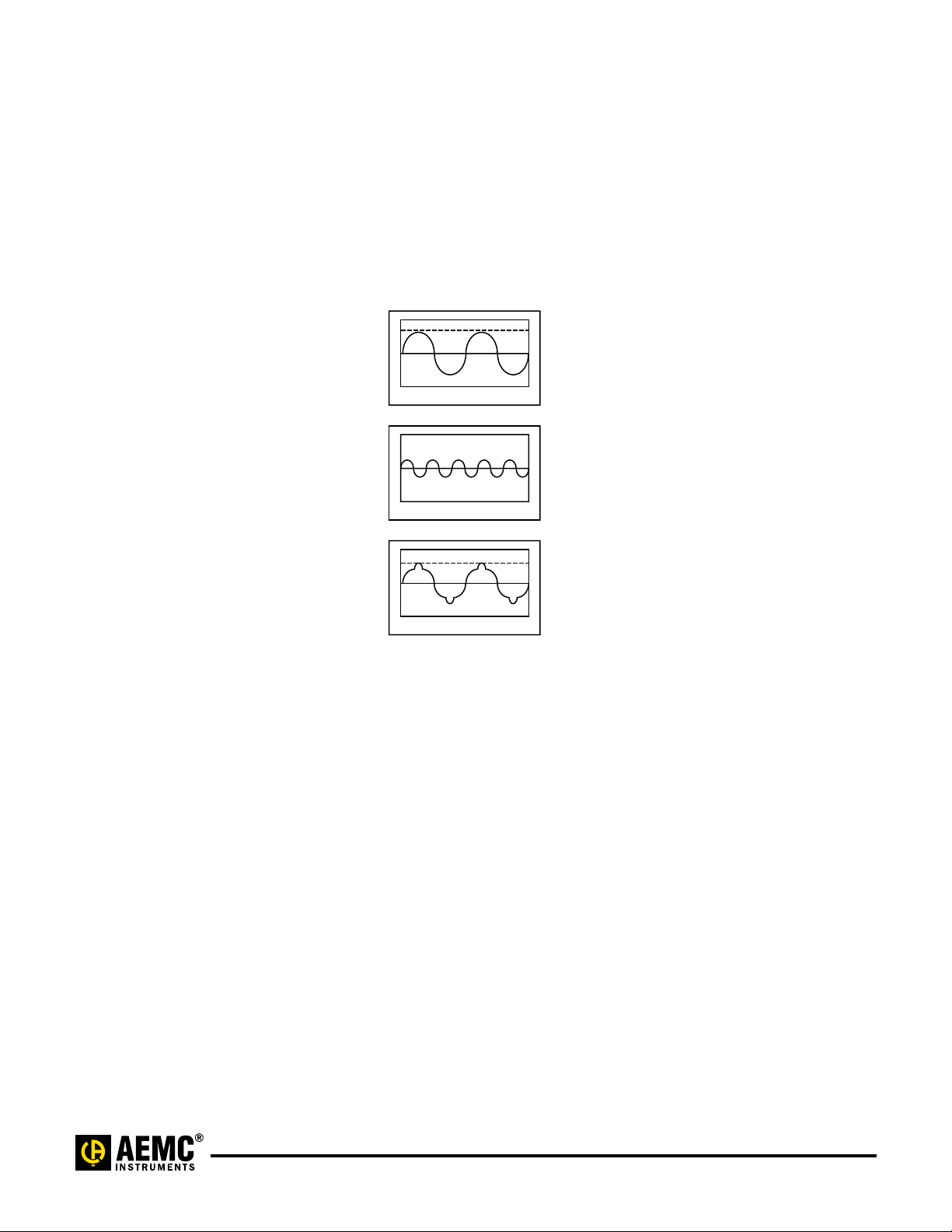

Crest Factor

Crest factor is the ratio of the Peak

value of a sinusoidal waveform to its

RMS value.

Crest Factor (CF) =

RMS value

Peak value

Crest factor indicates the level of

peaking which an instrument can

handle without measurement errors.

For a perfect sine wave the crest factor

would be 1.414. This relates to the

Peak amplitude that an instrument

can measure accurately. Typical crest

factor ratings are from 2.0 to 6.0. The

higher the factor, the more capable the

instrument of measuring a complex

waveform correctly. When harmonics

are present crest factors may be less

than (CF of a square wave = 1) or

greater than 1.414.

Understanding Power & Power Quality Instruments (pdf) 05/09

Technical Assistance (800) 343-1391 www.aemc.com 6 of 8

Page 7

Peak value

RMS value

Average value

Figure 12. RMS — Avg — Peak

Relationship in sine wave

Limiting the Effects of Harmonics

Derating certain types of electrical

equipment is the easiest way to limit

the effects that increased heating has

on the equipment. A 25% derating

for transformers and generators is

commonly employed in industry.

Phase

A

B

C

Figure 13. Single tuned shunt filter.

Reactor

Capacitor

Bank

Filtering is currently the most common

method used to limit the effects that

harmonics present to the rest of the

system. Filters typically consist of tuned

series L — C circuits. Filter impedance

is negligible with respect to the rest

of the system, limiting its interaction

effects for harmonic control. Filters are

sized to withstand the RMS current

as well as the value of current for the

harmonics.

In the future, systems may be available

which will offset the harmonics by

applying signals that are equal in

amplitude but opposite in phase,

thereby canceling or severely limiting

harmonic effects.

©

2002 Chauvin Arnoux® Inc.

d.b.a. AEMC

®

Instruments

Understanding Power & Power Quality Instruments (pdf) 05/09

Technical Assistance (800) 343-1391 www.aemc.com 7 of 8

Page 8

Contact Us

United States & Canada:

Chauvin Arnoux

d.b.a. AEMC

200 Foxborough Blvd.

Foxborough, MA 02035 USA

(508)698-2115•Fax(508)698-2118

www.aemc.com

Customer Support — for placing an order, obtaining price & delivery:

customerservice@aemc.com

Sales Department — for general sales information:

sales@aemc.com

Repair and Calibration Service — for information on repair & calibration, obtaining a user manual:

repair@aemc.com

Technical and Product Application Support — for technical and application support:

techinfo@aemc.com

Webmaster — for information regarding www.aemc.com:

webmaster@aemc.com

®

, Inc.

®

Instruments

South America, Central America, Mexico, Caribbean, Australia & New Zealand:

Chauvin Arnoux

d.b.a. AEMC

®

, Inc.

®

Instruments

15 Faraday Drive

Dover, NH 03820 USA

(978)526-7667•Fax(978)526-7605

export@aemc.com

www.aemc.com

All other countries:

Chauvin Arnoux SCA

190, rue Championnet

75876 Paris Cedex 18, France

33144854528•Fax33146277389

info@chauvin-arnoux.com

www.chauvin-arnoux.com

Understanding Power & Power Quality Instruments (pdf) 05/09

Technical Assistance (800) 343-1391 www.aemc.com 8 of 8

Loading...

Loading...