Page 1

DATA LOGGER

MODELS DL-1080/1081

USER MANUAL

V1.5x

INTRODUCTION ................................................................................................................................................................. 4

CONNECTIONS AND INSTALLATION ............................................................................................................................... 5

MECHANICAL INSTALLATION ..................................................................................................................................... 5

ATTACHING AND DETACHING THE FRONT COVER .......................................................................................... 8

ATTACHING AND DETACHING THE DISPLAY ..................................................................................................... 9

ELECTRICAL CONNECTIONS ..................................................................................................................................... 9

SAFETY SUMMARY ..................................................................................................................................................... 9

RECOMMENDATIONS FOR INSTALLATION ....................................................................................................... 10

POWER SUPPLY .................................................................................................................................................. 11

DIGITAL I/O ........................................................................................................................................................... 11

RELAYS ................................................................................................................................................................. 11

RS485 .................................................................................................................................................................... 11

AUXILIARY POWER SUPPLY FOR POWERING TRANSMITTERS .................................................................... 12

ANALOG INPUTS .................................................................................................................................................. 13

CONNECTIVITY RESOURCES .................................................................................................................................. 14

FLAGS (LEDS) .................................................................................................................................................................. 15

INSTALLING THE USB DRIVER ...................................................................................................................................... 16

WINDOWS 7 ............................................................................................................................................................... 16

DEFINITION AND SELECTION OF SERIAL PORT (COM) - WINDOWS ......................................................................... 19

CONFIGURATION AND DATA DOWNLOAD SOFTWARE .............................................................................................. 20

CONFIGURATION ...................................................................................................................................................... 21

GENERAL CONFIGURATIONS ............................................................................................................................ 23

RS485 INTERFACE CONFIGURATION ................................................................................................................ 24

ETHERNET INTERFACE CONFIGURATION ....................................................................................................... 25

ETHERNET INTERFACE CONFIGURATION - TCP/IP ................................................................................... 26

ETHERNET INTERFACE CONFIGURATION – FTP ....................................................................................... 27

ETHERNET INTERFACE CONFIGURATION - SMTP ..................................................................................... 28

ETHERNET INTERFACE CONFIGURATION - E-MAIL RECEIVERS ............................................................. 28

ETHERNET INTERFACE CONFIGURATION - SNMP .................................................................................... 29

ETHERNET INTERFACE CONFIGURATION – HTTP .................................................................................... 30

ETHERNET INTERFACE CONFIGURATION – MODBUS TCP ...................................................................... 31

ANALOG CHANNELS CONFIGURATION............................................................................................................. 32

ANALOG CHANNELS CONFIGURATION – CUSTOM CALIBRATION ........................................................... 34

DIGITAL CHANNELS CONFIGURATION.............................................................................................................. 35

REMOTE CHANNELS CONFIGURATION ............................................................................................................ 37

VIRTUAL CHANNELS CONFIGURATION ............................................................................................................ 40

ALARMS CONFIGURATION ................................................................................................................................. 41

LOG CONFIGURATION ........................................................................................................................................ 45

DIAGNOSTICS ............................................................................................................................................................ 47

DOWNLOAD ............................................................................................................................................................... 50

DOWNLOAD DATA ............................................................................................................................................... 51

DOWNLOAD MANAGER ....................................................................................................................................... 54

USING THE STEP-BY-STEP (WIZARD) ......................................................................................................... 54

NON STEP-BY-STEP ...................................................................................................................................... 62

PREFERENCES .......................................................................................................................................................... 66

PASSWORD PROTECTION .................................................................................................................................. 66

COMMAND-LINE OPERATION .................................................................................................................................. 67

BATCH FILE .......................................................................................................................................................... 67

ACTION TYPE ................................................................................................................................................. 67

CONNECTION MODE ..................................................................................................................................... 67

ACTION PARAMETERS .................................................................................................................................. 68

Page 2

AEMC INSTRUMENTS DATA LOGGERS

EXPORT PARAMETERS ................................................................................................................................. 68

DATA LOGGER OPERATION .......................................................................................................................................... 69

ANALOG INPUTS ....................................................................................................................................................... 69

DIGITAL INPUTS/OUTPUTS ...................................................................................................................................... 70

COUNTING ............................................................................................................................................................ 70

OUTPUT RELAYS ....................................................................................................................................................... 71

RS485 INTERFACE .................................................................................................................................................... 71

AUXILIARY RS485 ...................................................................................................................................................... 71

REMOTE CHANNELS ................................................................................................................................................. 71

VIRTUAL CHANNELS ................................................................................................................................................. 72

USB INTERFACE ........................................................................................................................................................ 73

USB DEVICE ......................................................................................................................................................... 73

USB HOST ............................................................................................................................................................. 74

ETHERNET INTERFACE ............................................................................................................................................ 74

MODBUS-TCP ....................................................................................................................................................... 74

SENDING E-MAILS - SMTP .................................................................................................................................. 75

WEB PAGES - HTTP ............................................................................................................................................. 75

UNCHANGEABLE PAGES .............................................................................................................................. 75

CUSTOM PAGES ............................................................................................................................................ 77

MARKERS ............................................................................................................................................................. 77

FILE TRANSFER - FTP ......................................................................................................................................... 79

NETWORK MANAGEMENT - SNMP .................................................................................................................... 79

DATA LOGGING AND DOWNLOAD ........................................................................................................................... 81

ALARMS ...................................................................................................................................................................... 83

DATA COMMUNICATION ................................................................................................................................................. 85

DISPLAY (HUMAN-MACHINE INTERFACE) .................................................................................................................... 86

“FAVORITES” SCREEN .............................................................................................................................................. 88

“CHART” SCREEN ...................................................................................................................................................... 88

“CHANNEL LIST” SCREEN ......................................................................................................................................... 88

“ALARMS” SCREEN ................................................................................................................................................... 88

“STATUS” SCREEN .................................................................................................................................................... 89

“CONFIGURATION” SCREEN .................................................................................................................................... 90

EQUIPMENT SOFTWARE/FIRMWARE UPDATE ............................................................................................................ 91

CLOCK BATTERY REPLACEMENT................................................................................................................................. 92

SPECIFICATIONS ............................................................................................................................................................ 94

REPAIR AND CALIBRATION ...................................................................................................................................... 96

TECHNICAL AND SALES ASSISTANCE.................................................................................................................... 96

LIMITED WARRANTY ................................................................................................................................................. 97

WARRANTY REPAIRS ............................................................................................................................................... 97

AEMC® INSTRUMENTS – 99-MAN 100386 v5 2

Page 3

AEMC INSTRUMENTS DATA LOGGERS

AEMC® INSTRUMENTS – 99-MAN 100386 v5 3

Page 4

AEMC INSTRUMENTS DATA LOGGERS

INTRODUCTION

The Data Logger Models DL-1080/1081, hereafter, will be referred to in this document as Data Logger.

The Data Logger is a high-resolution and high-speed data acquisition and logging equipment for analog and digital

signals. The result of an advanced technological development, the product is distinguished in diverse aspects, such as

high-performance, high-connectivity and ease of configuration and operation. This technology is presented as the ideal

solution for applications that require flexibility and functionality for diverse communication networks.

Its main features include:

• Analog inputs: 8

• Digital inputs/outputs: 8

• Relay outputs: 2

• 2 MB internal memory

• SD Card interface (up to 16 GB – not available in some models)

• RS485 interface

o Main: Modbus RTU master and slave

o Auxiliary (DB9 connector – not available in some models): Modbus RTU slave

• Ethernet services (not available in some models):

o DHCP

o HTTP (web page)

o FTP (client and server)

o SMTP (e-mails sending)

o SNMP

o Modbus TCP

• USB:

o Host

o Device

• DISPLAY (HMI - human-machine interface [DISPLAY] – optional)

There are four input channel types in the Data Logger: analog, digital, remote and virtual. Analog and digital channels

are those acquired directly by Data Logger through their respective inputs. The remote channels are those acquired

through Modbus RTU protocol, operating as master on its RS485 interface. Virtual channels are a special type of input

channel where mathematical operations can be carried out, allowing the calculation of complex formulas from the

measured information.

The analog input channels are configurable for reading voltage, current, thermocouples, Pt100 and Pt1000 signals.

These inputs count on the precision of a 24 bit A/D converter with high acquisition speed, which can reach 1000 samples

per second. The digital channels can be configured individually as inputs or outputs.

The Ethernet interface allows data download and data access of the inputs and outputs, through services that can be

individually enabled and configured. Through a web browser (HTTP), one can visualize the data of the enabled channel,

diagnostics and general information of the Data Logger. FTP client can be used for logging data downloads. Data

Logger can identify up to 32 distinct alarm conditions, allowing the triggering of outputs, sending e-mails or SNMP traps

whenever an alarm condition is detected. All the information relative to the variables, status and diagnostics of the Data

Logger are available in Modbus registers that can be accessed through the Modbus TCP interface or the Modbus RTU

interface available either through USB interface (device) or RS485 (when operating as slave).

The USB Interface device is used for connection to a computer for configuration, monitoring or download. Whereas the

USB interface host is used for connection of a USB flash drive, for data downloading from the logging memory.

The data logging memory can be transferred by any of the interfaces to the configuration software, which allows the

exportation for the most diverse data formats.

When the indication of the measured data from the process is necessary, an exclusive color graphical DISPLAY

(Human-Machine Interface) can be attached or installed remotely (optional).

NOTE: The DISPLAY is also referred to as HMI in the software provided with the data logger.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 4

Page 5

AEMC INSTRUMENTS DATA LOGGERS

, located below

wiring and

CONNECTIONS AND INSTALLATION

When unpacking, remove the insulating film of the Data Logger battery

the chassis according to Fig. 01, before carrying through the electrical

configuration.

Fig. 01 – Insulating film of the battery

MECHANICAL INSTALLATION

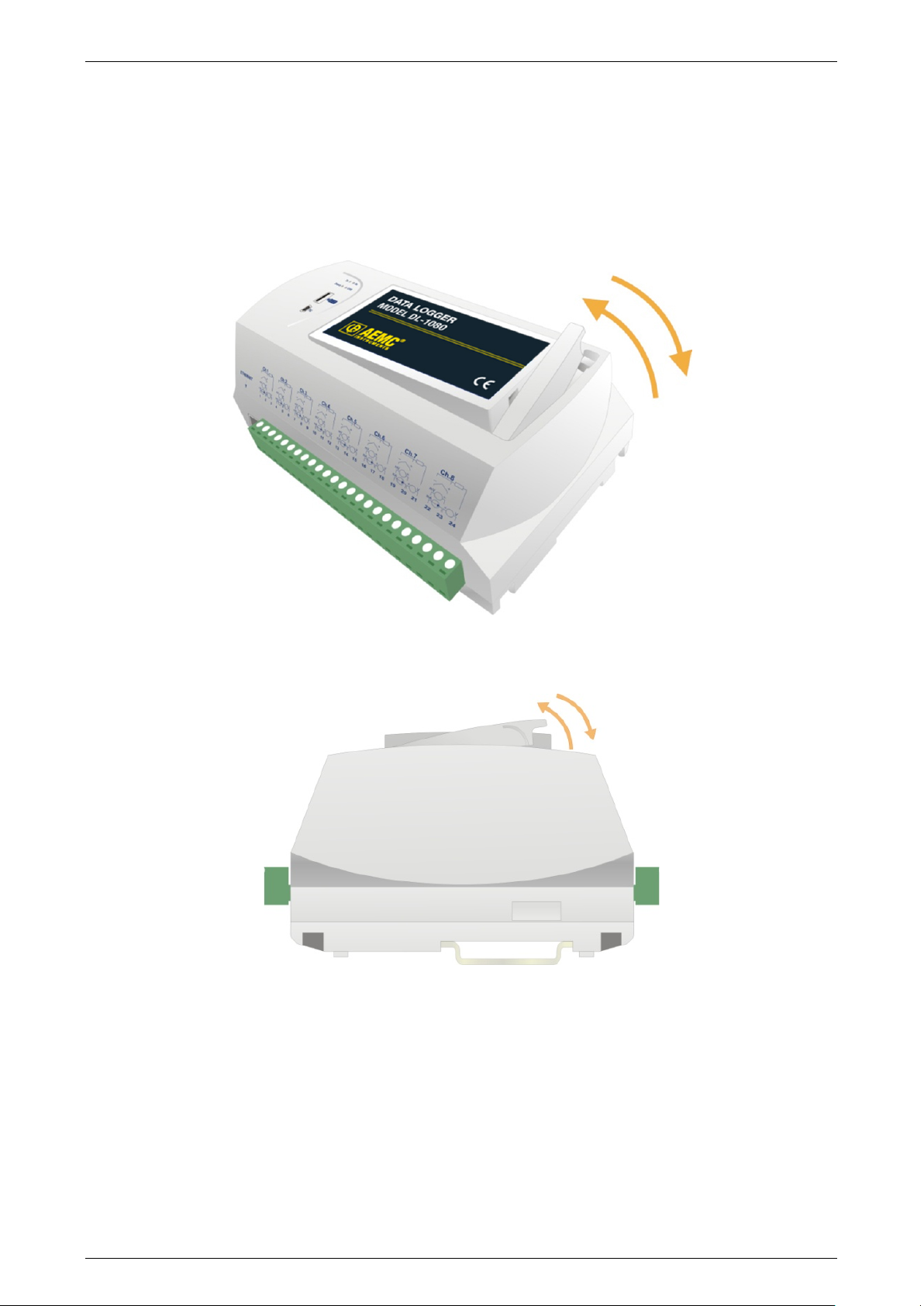

Data Logger chassis can be installed on a 35 mm DIN rail.

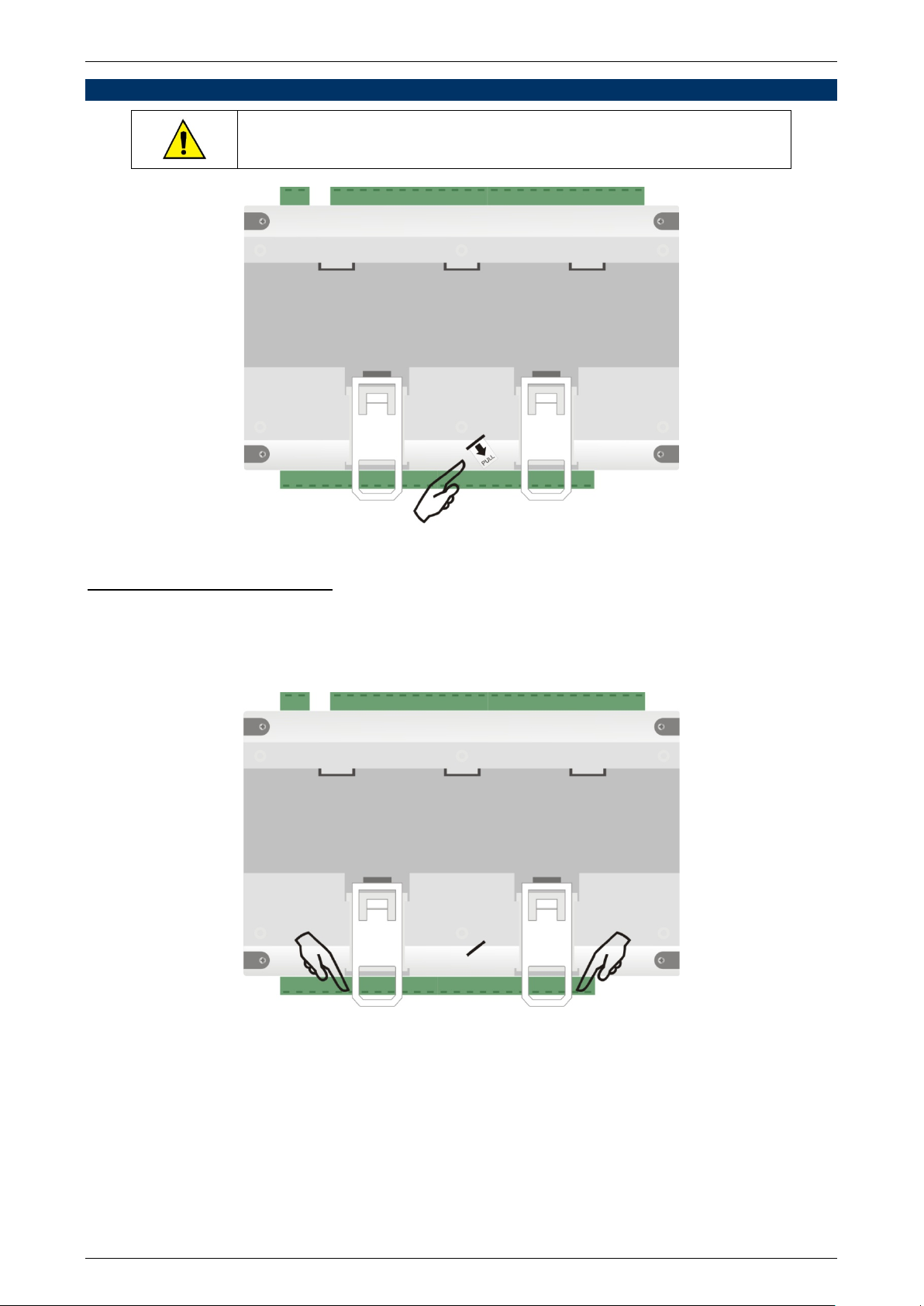

For the installation on the rail, you must pull out the two clamps located right below the connections of the channels,

taking care not to remove them, as per Fig. 02.

Note: If necessary, the connector may be removed for installation of DIN rail.

Fig. 02 - DIN rail installation

AEMC® INSTRUMENTS – 99-MAN 100386 v5 5

Page 6

AEMC INSTRUMENTS DATA LOGGERS

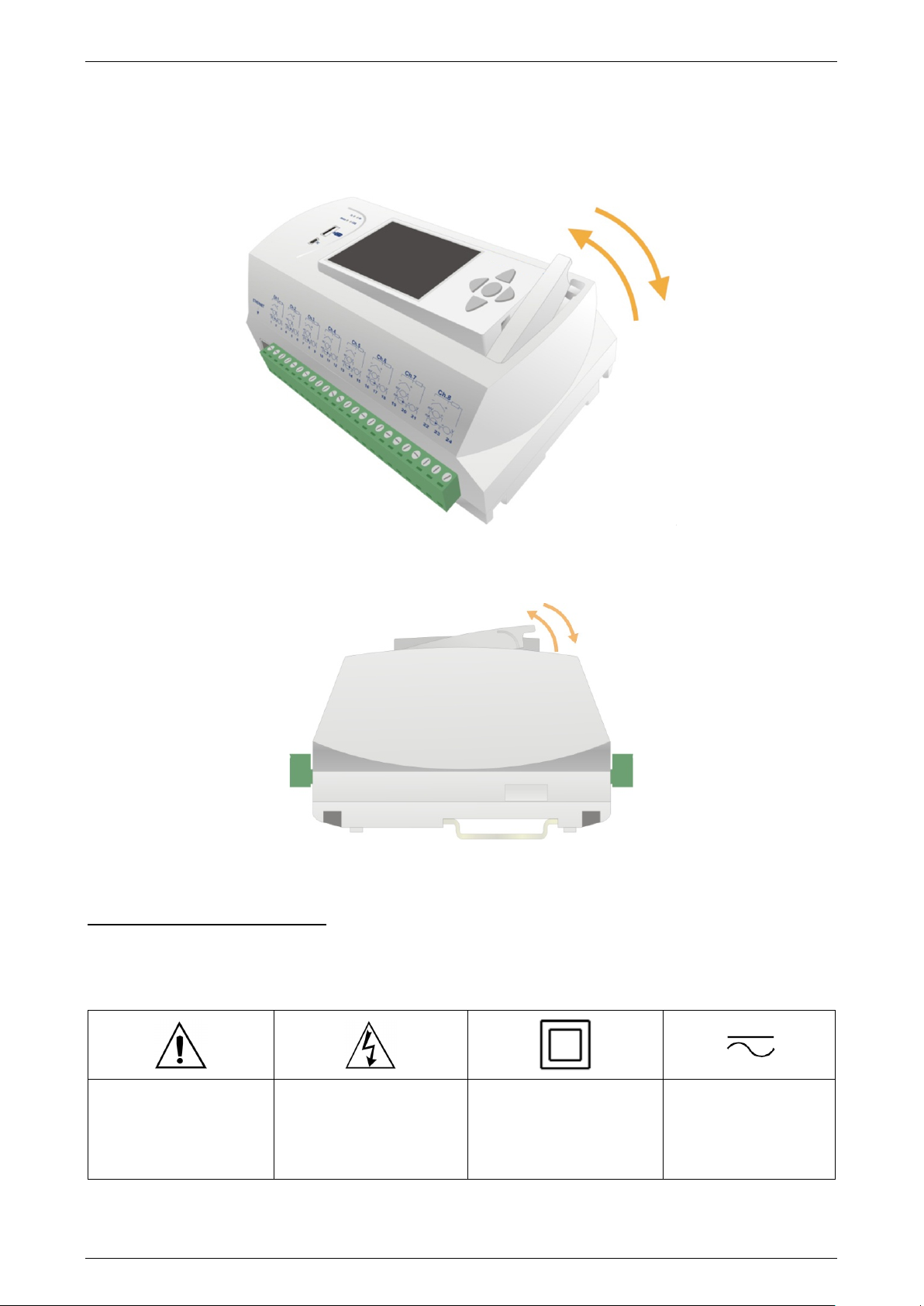

Afterwards, attach the Data Logger to the rail according to Fig. 03.

Fig. 03 - DIN rail installation

Finally, push the two clasps up until you hear a double-click to complete the installation, as shown in Fig. 04.

Fig. 04 - DIN rail installation

AEMC® INSTRUMENTS – 99-MAN 100386 v5 6

Page 7

AEMC INSTRUMENTS DATA LOGGERS

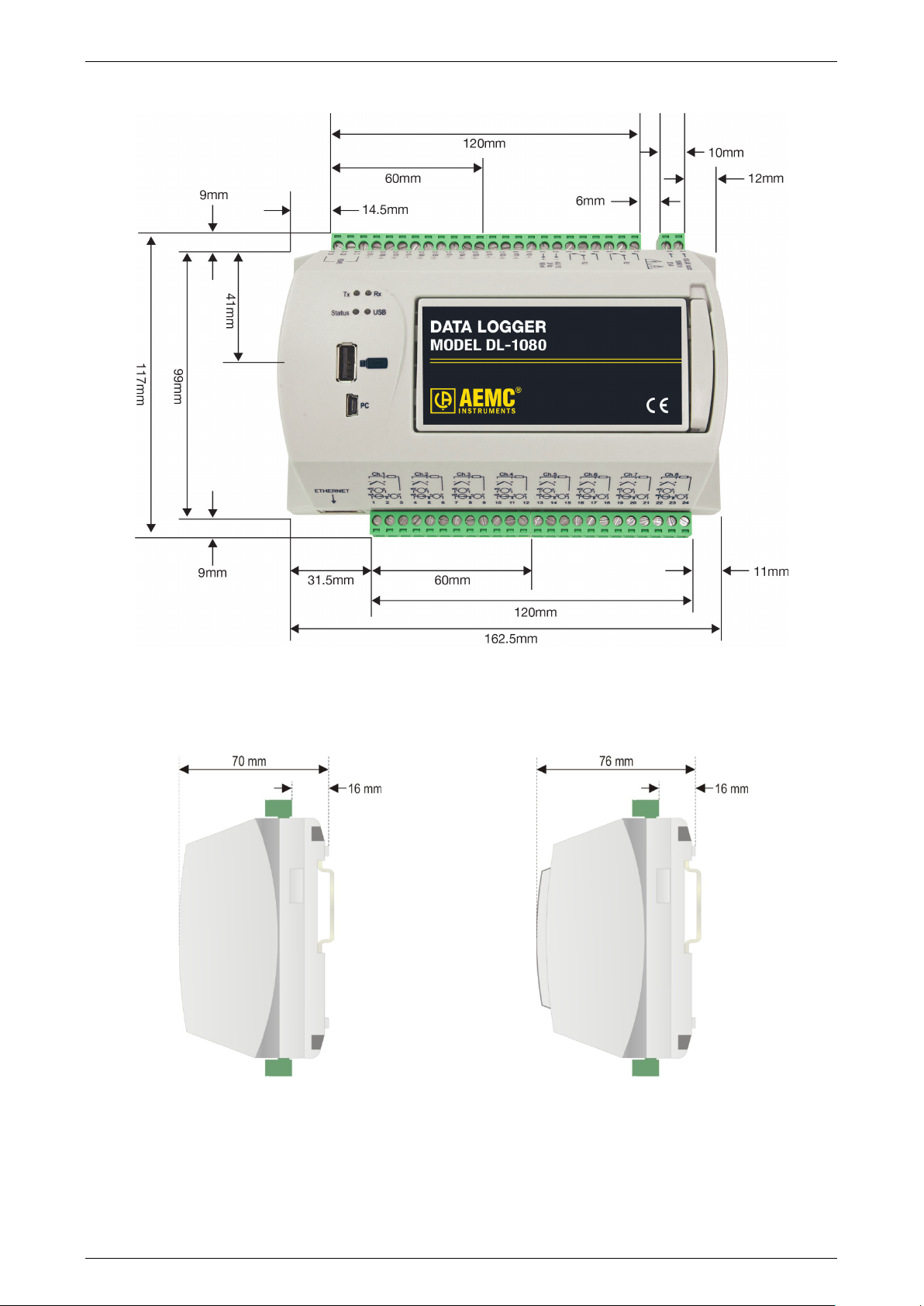

Dimensions:

Fig. 05 – Dimensions without DISPLAY module

Fig. 06 – Dimensions of the side without DISPLAY module Fig. 07 – Dimensions of the side with DISPLAY module

AEMC® INSTRUMENTS – 99-MAN 100386 v5 7

Page 8

AEMC INSTRUMENTS DATA LOGGERS

ATTACHING AND DETACHING THE FRONT COVER

NOTE: The DISPLAY is also referred to as HMI in the software provided with the data logger.

When detaching the front cover, pull the lever at the right side of the Data Logger up to the end.

When attaching it, insert the cover (left side first) and press its right side gently. After that, press the lever back into the

chassis.

Fig. 08 – Attaching and detaching Data Logger front cover

Fig. 09 – Attaching and detaching Data Logger front cover (side view)

AEMC® INSTRUMENTS – 99-MAN 100386 v5 8

Page 9

AEMC INSTRUMENTS DATA LOGGERS

ATTACHING AND DETACHING THE DISPLAY

NOTE: The DISPLAY is also referred to as HMI in the software provided with the data logger.

When detaching the DISPLAY, pull up the lever at the right side of the Data Logger up to the end.

When attaching it, insert the DISPLAY (left side first) and press its right side until DB9 connectors are firmly connected.

After that, press the lever down into the chassis.

Fig. 10 – Attaching and detaching the Data Logger DISPLAY

Fig. 11 – Attaching and detaching the Data Logger DISPLAY (side view)

ELECTRICAL CONNECTIONS

SAFETY SUMMARY

The symbols below are used on the equipment and throughout this document to draw the user’s attention to important

operational and safety information.

CAUTION or WARNING:

Read complete instructions

prior to installation and

operation of the unit.

CAUTION or WARNING:

Electrical Shock Hazard

DOUBLE INSULATION

The Data Logger power supply

is double insulated, represented

by the above symbol printed on

the equipment’s connection

label.

POWER INPUT

The Data Logger may be

powered from either AC or

DC power source.

All safety related instructions that appear in the manual must be observed to ensure personal safety and to prevent

damage to either the instrument or the system. If the instrument is used in a manner not specified by the manufacturer,

the protection provided by the equipment may be impaired.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 9

Page 10

AEMC INSTRUMENTS DATA LOGGERS

Supply Voltage

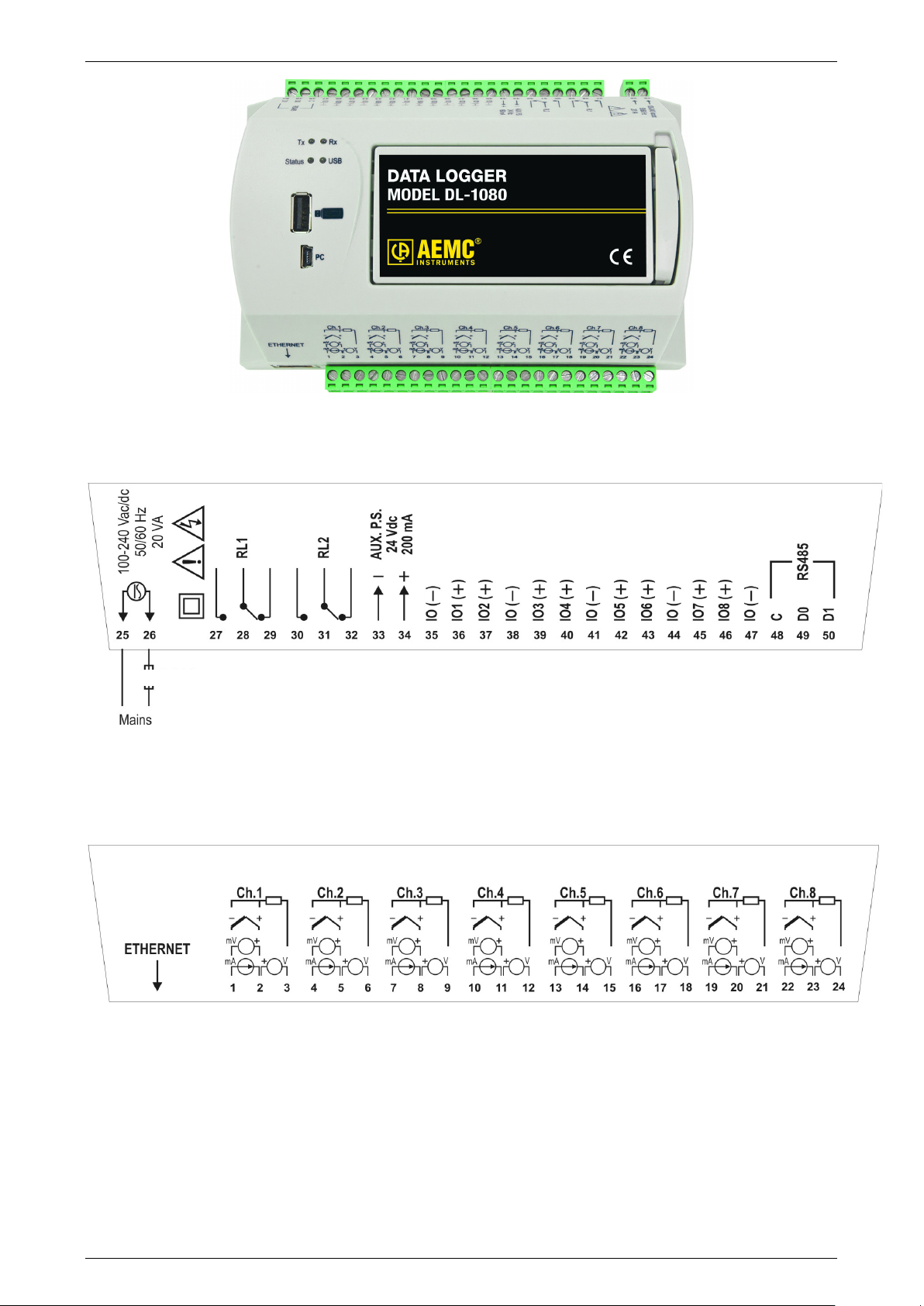

Fig. 12 - Data Logger front panel

The Data Logger has two rows of terminals. Among them are the following items: Ethernet, input connections, power

supply, output relays, auxiliary power supply output, digital inputs and serial communication. This information is identified

according to Fig. 13 and Fig. 14:

Fig. 13 - Upper side connections

NOTES: 1) An external protection device consisting of a 0.5A slow blow fuse (UL Listed) must be wired near to the

2) A switch or circuit-breaker placed near to the

Fig. 14 - Lower side connections

Data Logger shall be used as the disconnecting device.

Data Logger.

RECOMMENDATIONS FOR INSTALLATION

• Input signal leads must be installed in grounded conduits and away from power or contactor wires.

• Instruments must be powered only by an exclusive power supply.

• Installing RC filters (47Ω and 100nF, serial) is strongly recommended at contactor coils or any other inductors.

• System failure should always be taken into account when designing a control panel to avoid irreversible damage to

equipment or injury to people. The RL1 and RL2 output relays, used as alarms, do not warrant total protection.

• Wiring section: minimum gauge 0.14 mm².

AEMC® INSTRUMENTS – 99-MAN 100386 v5 10

Page 11

AEMC INSTRUMENTS DATA LOGGERS

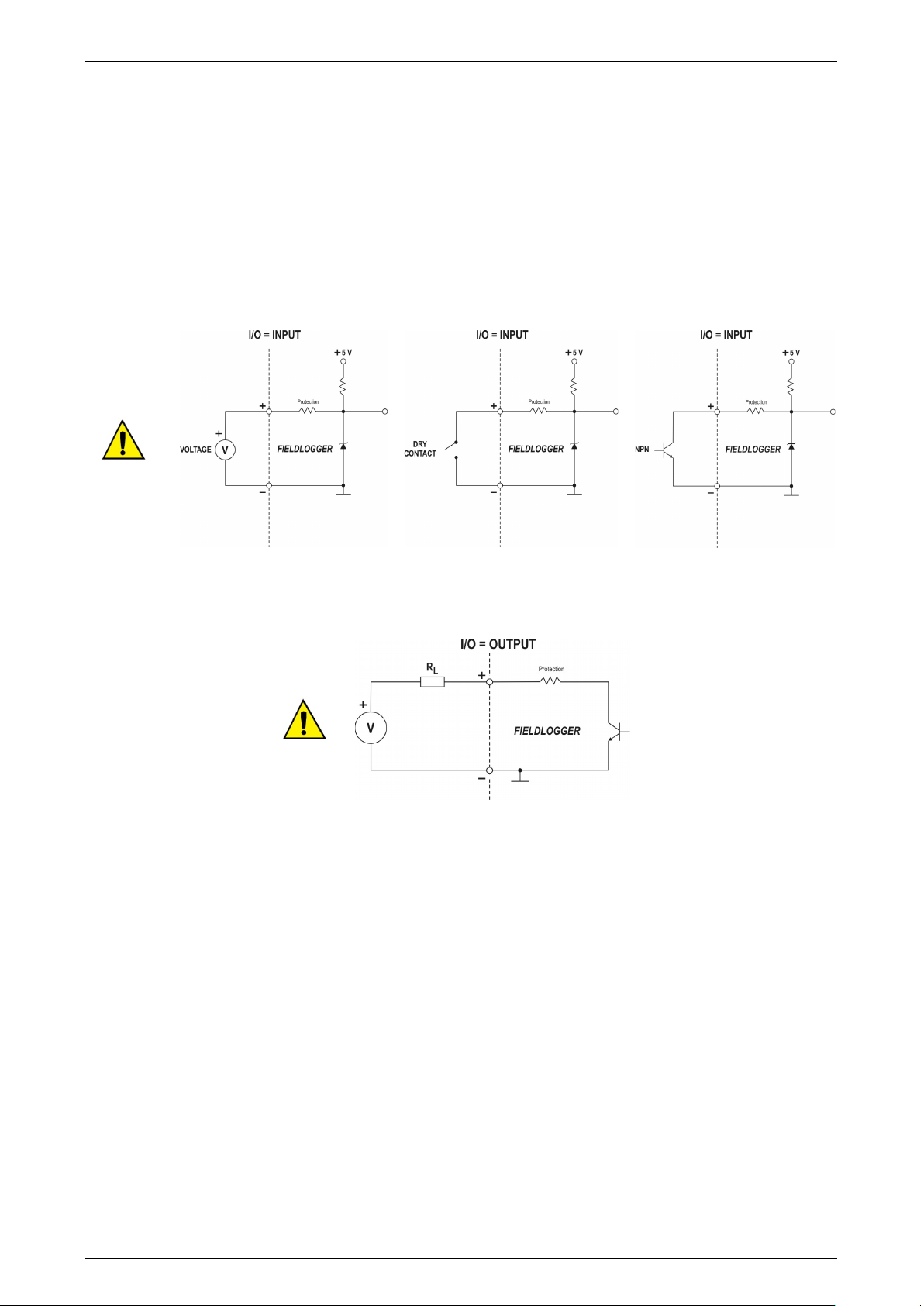

Fig. 15 - Voltage connection

Fig. 16 - Dry-contact connection

Fig. 17 - NPN Connection

POWER SUPPLY

The terminals 25 and 26 are used to supply power to the Data Logger.

DIGITAL I/O

There are eight I/O ports that can be individually configured as inputs or outputs. There is a terminal for the positive

signal of each I/O, and a common negative terminal for all of them (there is no isolation between the channels).

• Inputs:

When configured as inputs, they may be connected to voltage outputs (please check the acceptable levels in the

Specifications section), dry-contact outputs and NPN outputs. Care must be taken when connecting multiple outputs

because there is no isolation between the Data Logger inputs.

• Outputs:

When configured as outputs, they can activate limited power loads (please check the Specifications section).

Fig. 18 - Connection of a load RL to a digital output

RELAYS

The Data Logger has 2 relays that can be used in the activation of electrical loads (please check the Specifications

section). For each relay, there is a common terminal, NC (normally closed) terminal and a NO (normally open) terminal.

When deactivated, the relay common is in contact with the NC terminal. When activated, the common is in contact with

the NO terminal.

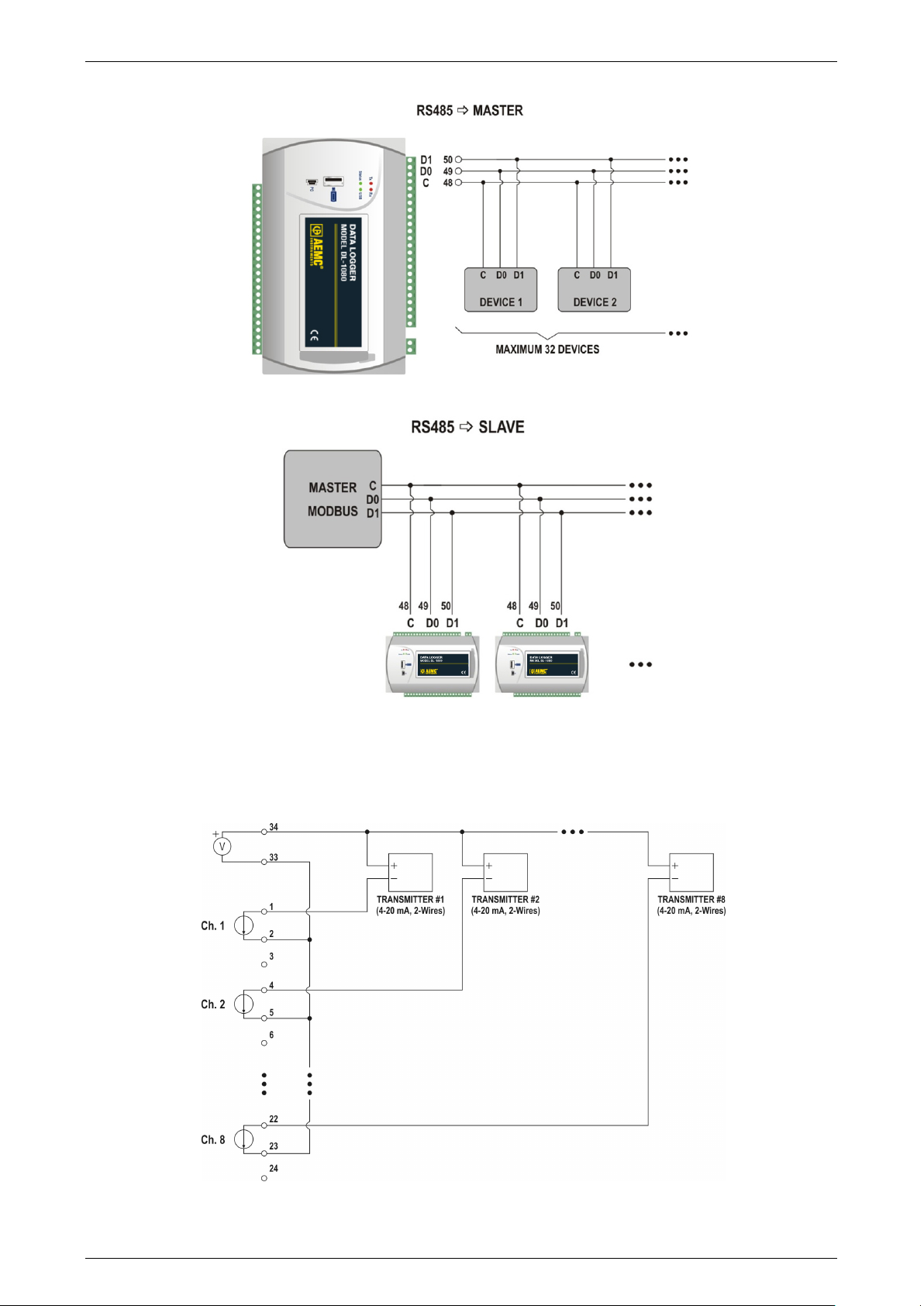

RS485

The RS485 Interface of the Data Logger has terminals for the 3-wire communication, including the common. The

connection in a Modbus network will depend if the device is configured to operate as a master or a slave.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 11

Page 12

AEMC INSTRUMENTS DATA LOGGERS

• Master

• Slave

Fig. 19 – Master and Slave

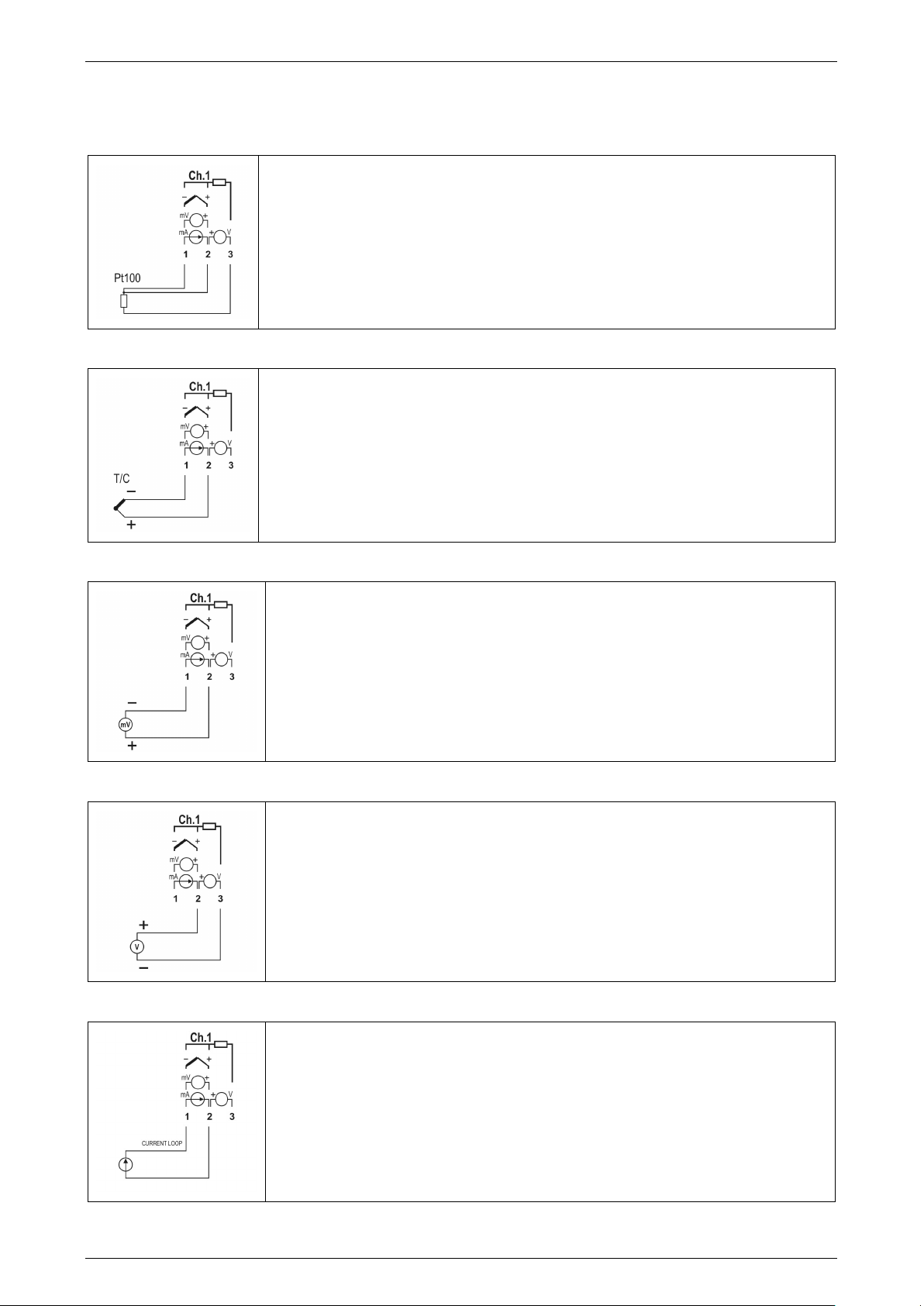

AUXILIARY POWER SUPPLY FOR POWERING TRANSMITTERS

For non 24V transmitters, there is a built in 24V

DC power supply available in the Data Logger. This auxiliary power

supply is electrically isolated from the other Data Logger terminals.

Below is the correct way to use the auxiliary power supply for powering 4-20mA transmitters (2-wire).

Fig. 20 – Auxiliary power supply powering 4-20mA (2-wire) transmitters

AEMC® INSTRUMENTS – 99-MAN 100386 v5 12

Page 13

AEMC INSTRUMENTS DATA LOGGERS

The RTD connection for the channels is made to the terminals in accordance with the

the cancellation of the error caused by the lead resistance. All

Cables used for connecting thermocouples must have the same thermoelectric

correct polarity can cause

The voltage connection for the channels is made to the terminals in accordance with the

The milliamp connection for the channels is made to the terminals in accordance with the

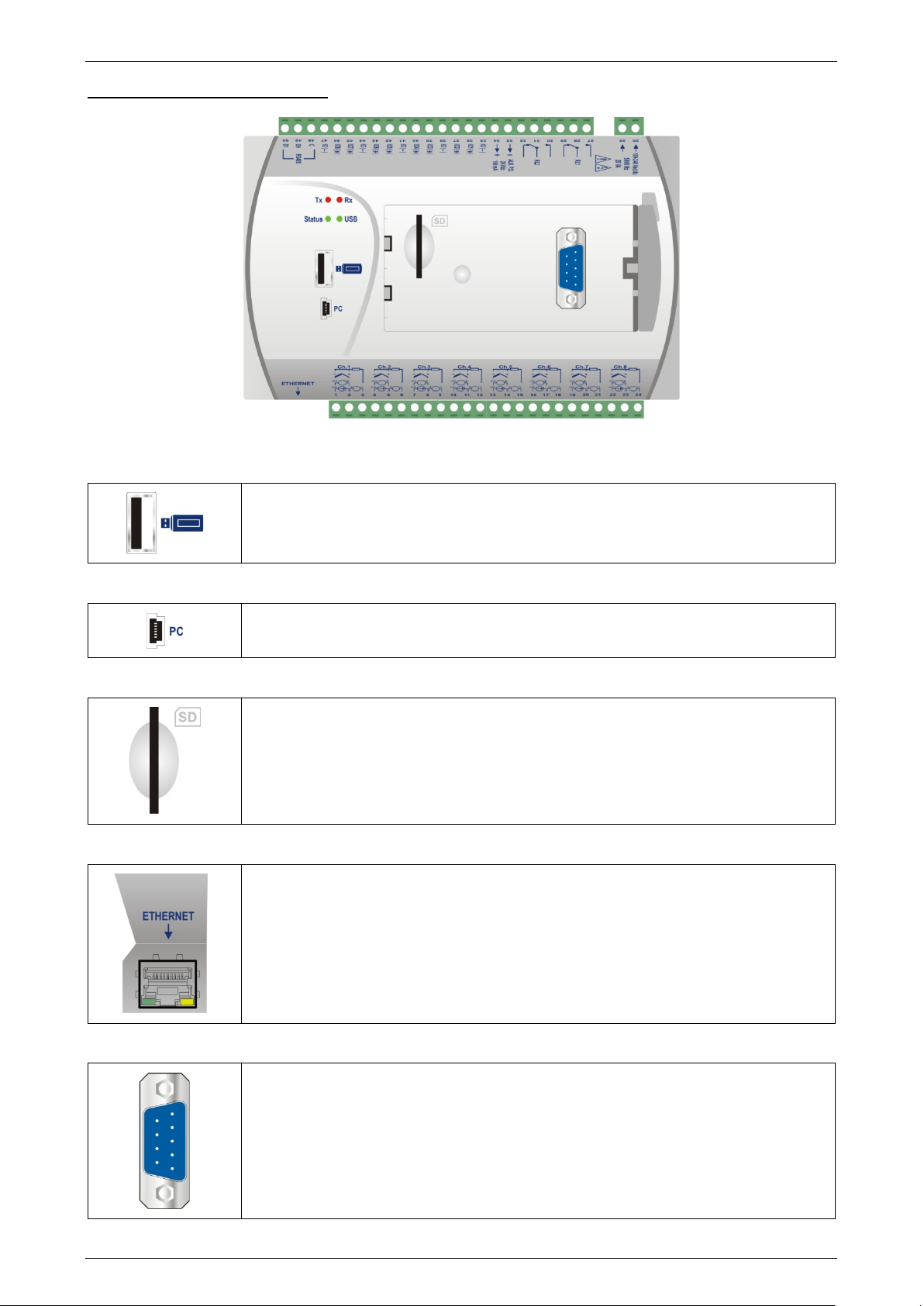

ANALOG INPUTS

Pt100/Pt1000 connection

figure at the left. The 3-wire connection from the Pt100 sensing element to the Data

Logger input guarantees

three wires must have the same gauge and length.

For the two-wire Pt100, interconnect terminals 1 and 2.

Thermocouple connection

The Thermocouple connection for the channels is made to the terminals in accordance

with the figure at the left. Please observe the correct connection polarity.

characteristics as the thermocouple used (compensation cable or extension cable), and

also must be connected with the correct polarity.

The non-use of compensation cables or the use with the in

significant measurement errors.

Voltage (mV) connection

Voltage (V) connection

Current (mA) connection

The millivolt connection for the channels is made to the terminals in accordance with the

figure at the left. Please observe the correct polarity of the connection.

figure at the left. Please observe the correct polarity of the connection.

figure at the left. Please observe the correct polarity of the connection.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 13

Page 14

AEMC INSTRUMENTS DATA LOGGERS

Interface used for SD card expansion. The data from the logger memory can be transferred

by any of the interfaces to the configuration software, which allows exportation for a wide

Interface used for Ethernet 10/100 communication. It is recommended to use a category 5 (or

tion to the Ethernet network; the yellow LED (on the right

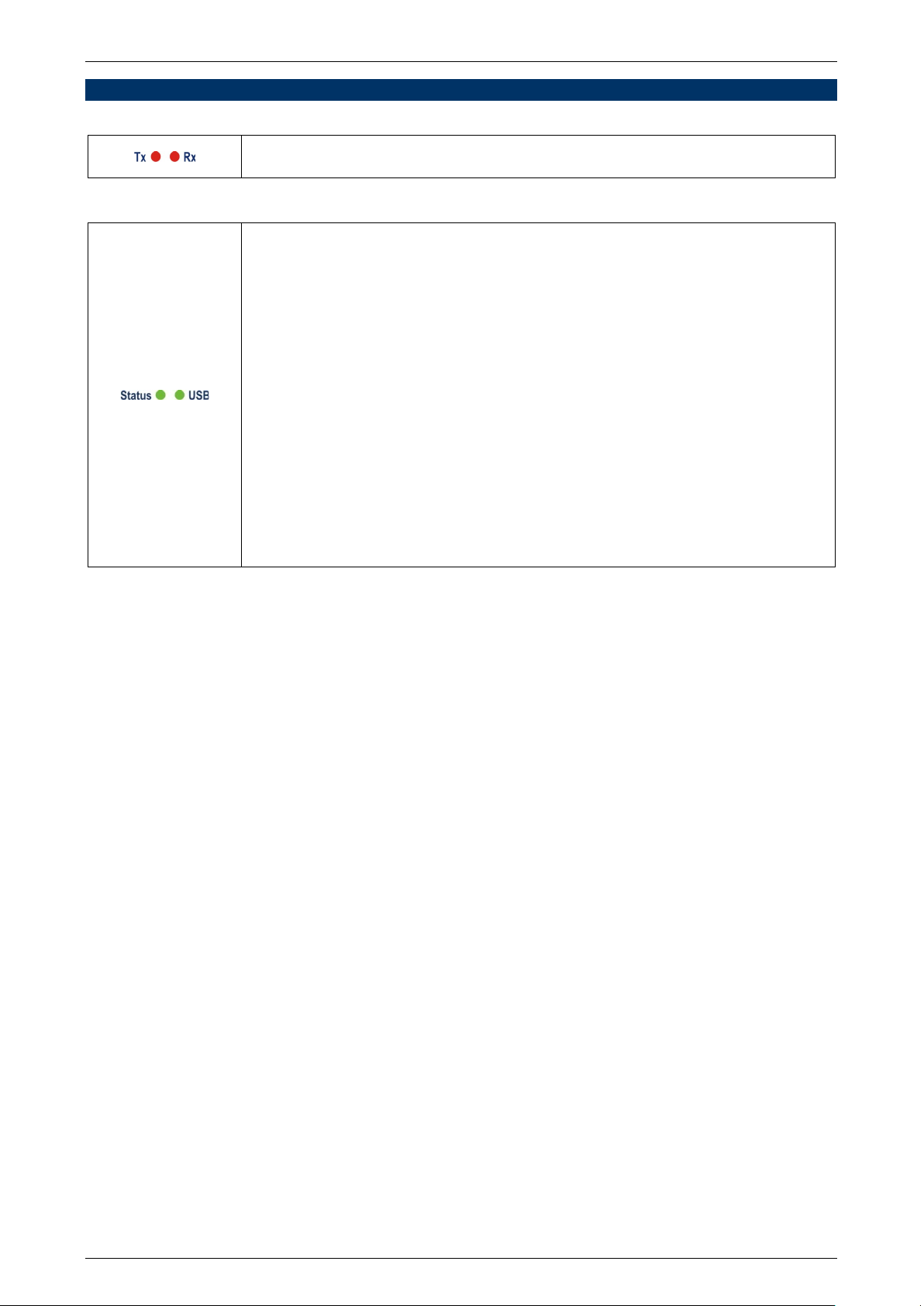

CONNECTIVITY RESOURCES

Fig. 21 - Data Logger connectivity resources

USB Connection

PC Connection

SD card connection

Ethernet

Interface used for a USB drive connection, for downloading data from the logger memory.

Interface used for connection to a computer for configuration, monitoring or data download.

varity of data formats.

higher) cable in a RJ45 connector.

The Ethernet connector on the Data Logger has two indicating LEDS: the green LED (on the

left side) lights indicating the connec

side) flashes indicating that there is data traffic in the interface.

DB9 connection for DISPLAY (Optional)

Connection for installation of the DISPLAY (Human–Machine Interface) on the Data Logger

used for indicating measured signals and configuration. With firmware version 1.20 and

higher, it can be used as a generic RS485/Modbus RTU (slave) port.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 14

Page 15

AEMC INSTRUMENTS DATA LOGGERS

us interface,

When connecting the equipment, both LEDs initially flash two times and then turn off until all

remains ON in normal condition. When it is logging, flashes 2 times at 3

they are wrong, probably the clock battery has run down and needs to be replaced. If it is OK,

try rebooting the machine by turning off its power supply and restarting it after 10 seconds. If

flag remains ON only while a cable is connected to a USB device or while the USB

ive: flash drive with insufficient writing space,

inability to write to the flash drive (write protected) or flash drive not compatible

(sector different from 512 bytes, for example), the USB LED flashes while the error

the flash drive has been removed). Check the "USB

At the end of the download, if everything is correct, the USB flag remains ON until the

FLAGS (LEDS)

Tx/Rx flags

Status / USB flags

These LEDs signal transmission and reception of data by the RS485/Modb

regardless if it is configured to operate in master or slave mode.

the initialization has been completed.

The Status flag

second intervals. In error conditions, this LED will be flashing 3 times at 8 second intervals.

In the error cases, please check if the Data Logger clock has the correct date and time. If

the LED continues to indicate an error, there may be something wrong with your Data

Logger requiring service.

The USB

flash drive is plugged into the USB host interface. The following exceptions are:

• Download errors via USB flash dr

condition remains (typically, until

Interface" section in the "Data Logger Operation" chapter for more details.

•

flash drive has been removed from the equipment.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 15

Page 16

AEMC INSTRUMENTS DATA LOGGERS

INSTALLING THE USB DRIVER

When installing the configuration software, the USB driver is automatically installed. If you need to install the driver

without depending on the software, this can be done by following the procedure described below.

The following installation steps may vary from PC to PC, even for the same operating system version. The steps and

screens that follow below are only for guidance purposes.

NOTE: The Data Logger may be referred to as the FieldLogger in some instances.

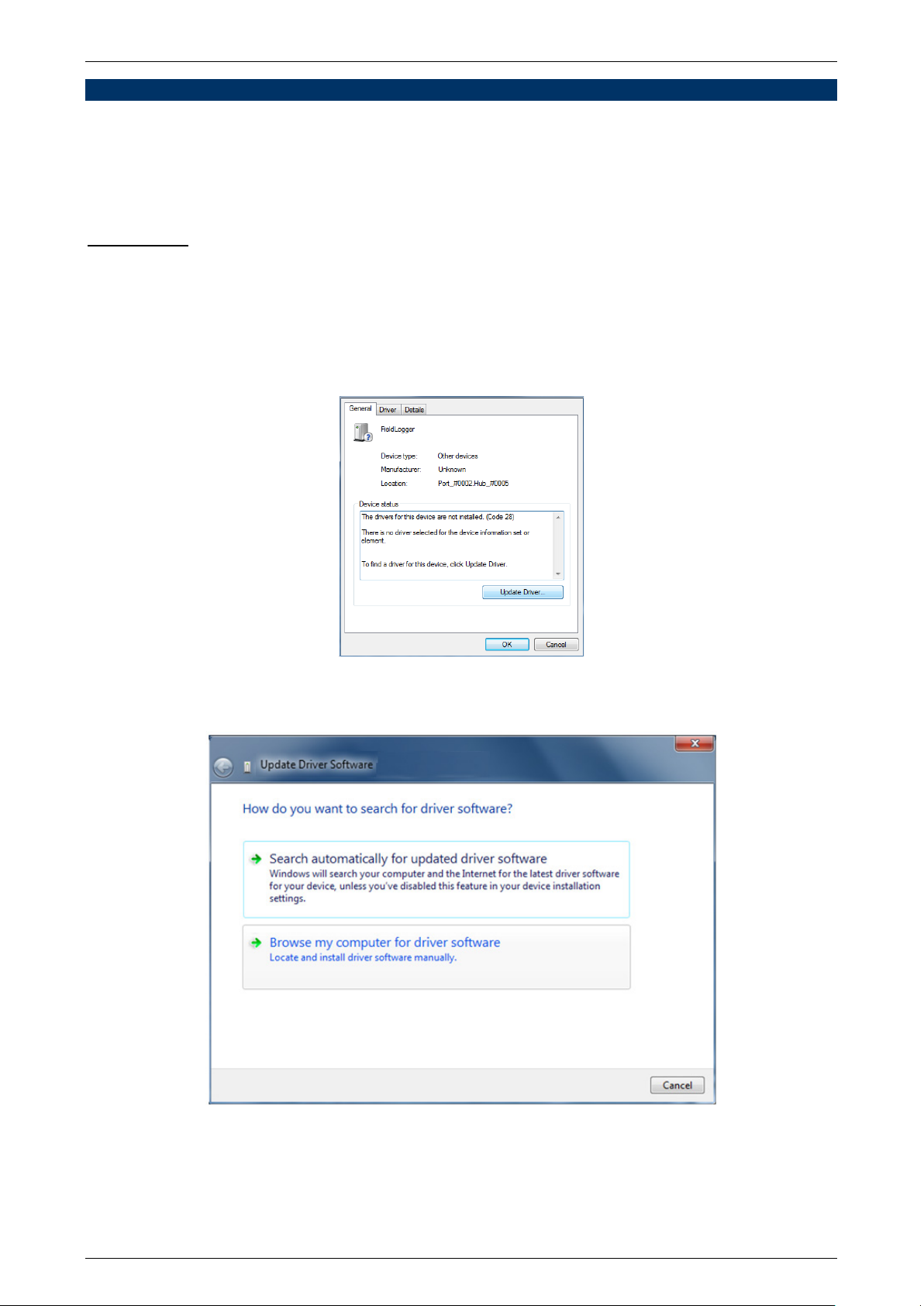

WINDOWS 7

1. Connect the Data Logger to a USB port on your computer. Windows will try to install a driver automatically and will

not succeed, because the necessary driver is not in its standard library.

2. Click on "Start>Control Panel". Click on "System", then on the "Device Manager".

3. Locate the Data Logger (the icon with an exclamation mark next to it) and double-click on it.

4. Click on "Update Driver...".

5. Ask to "Browse my computer for driver software".

6. Enter the path for the folder where the drivers are located (the product CD or folder where you saved them when

downloaded from the site).

AEMC® INSTRUMENTS – 99-MAN 100386 v5 16

Page 17

AEMC INSTRUMENTS DATA LOGGERS

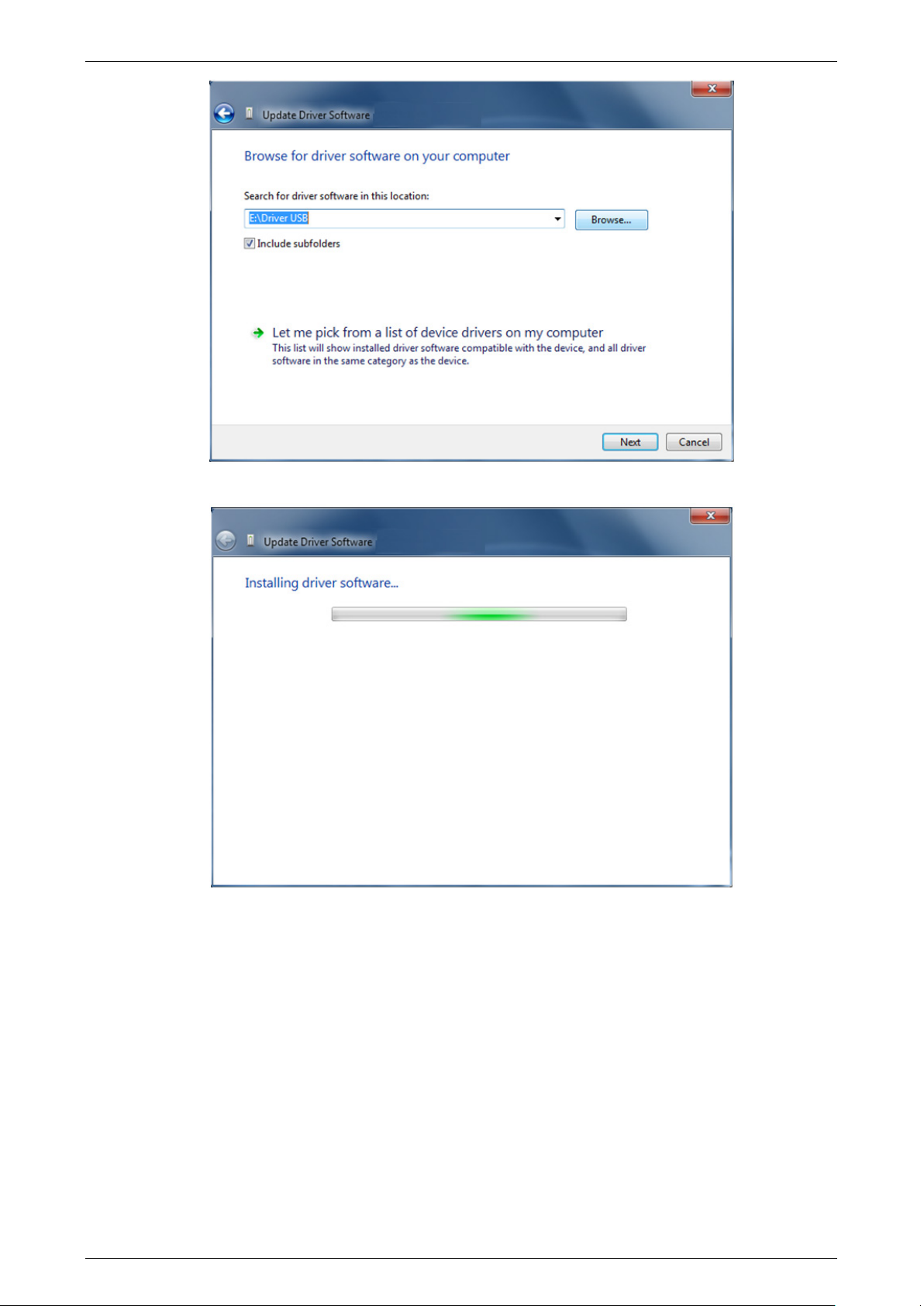

7. Wait for the installation to begin.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 17

Page 18

AEMC INSTRUMENTS DATA LOGGERS

9. Windows will indicate that it cannot verify the editor of this driver. Confirm the installation anyway.

10. A message indicating successful installation will then display.

11. Returning to the Device Manager screen will allow you to check which virtual serial port is allocated to the Data

Logger.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 18

Page 19

AEMC INSTRUMENTS DATA LOGGERS

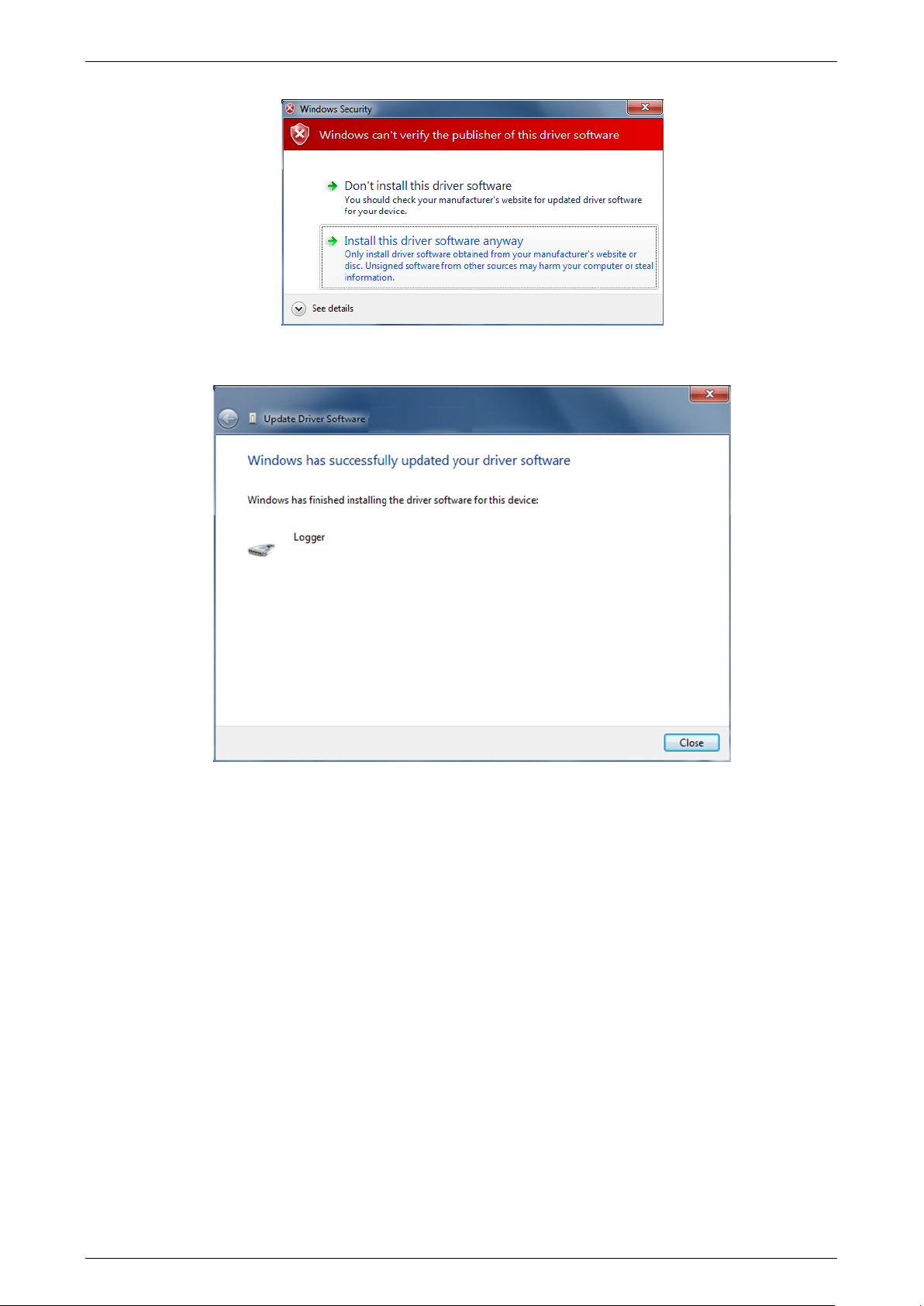

DEFINITION AND SELECTION OF SERIAL PORT (COM) - WINDOWS

The serial port associated to the Data Logger is automatically defined by the operating system right after connecting the

Data Logger. The user can easily identify or change the COM port associated with Data Logger:

NOTE: The Data Logger may be referred to as the FieldLogger in some instances.

Control Panel / System / Hardware / Device Manager / COM & LPT Ports

Select the device "USB Serial Port" corresponding to the Data Logger and click on "Properties". Select "Port Settings"

and click on "Advanced". In the "COM Port Number", select the serial port to be associated with Data Logger. Some

serial ports can be checked while In Use. Just select one of these ports if you know that it is not being used by another

peripheral device on your computer.

In some cases, the serial ports can be checked as in use even when the associated device is no longer installed on your

computer. In this case it is safe to associate this port to Data Logger. The following figure presents the view of the

device manager containing a Data Logger, and property screens where you can reset the associated COM port.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 19

Page 20

AEMC INSTRUMENTS DATA LOGGERS

CONFIGURATION AND DATA DOWNLOAD SOFTWARE

The configuration software (Configurator) allows you to configure Data Logger, download and export recorded data and

read input channels and status information. This chapter is intended to show and explain software usage. The use of the

Data Logger with all its features will be detailed in the chapter "Data Logger Operation”.

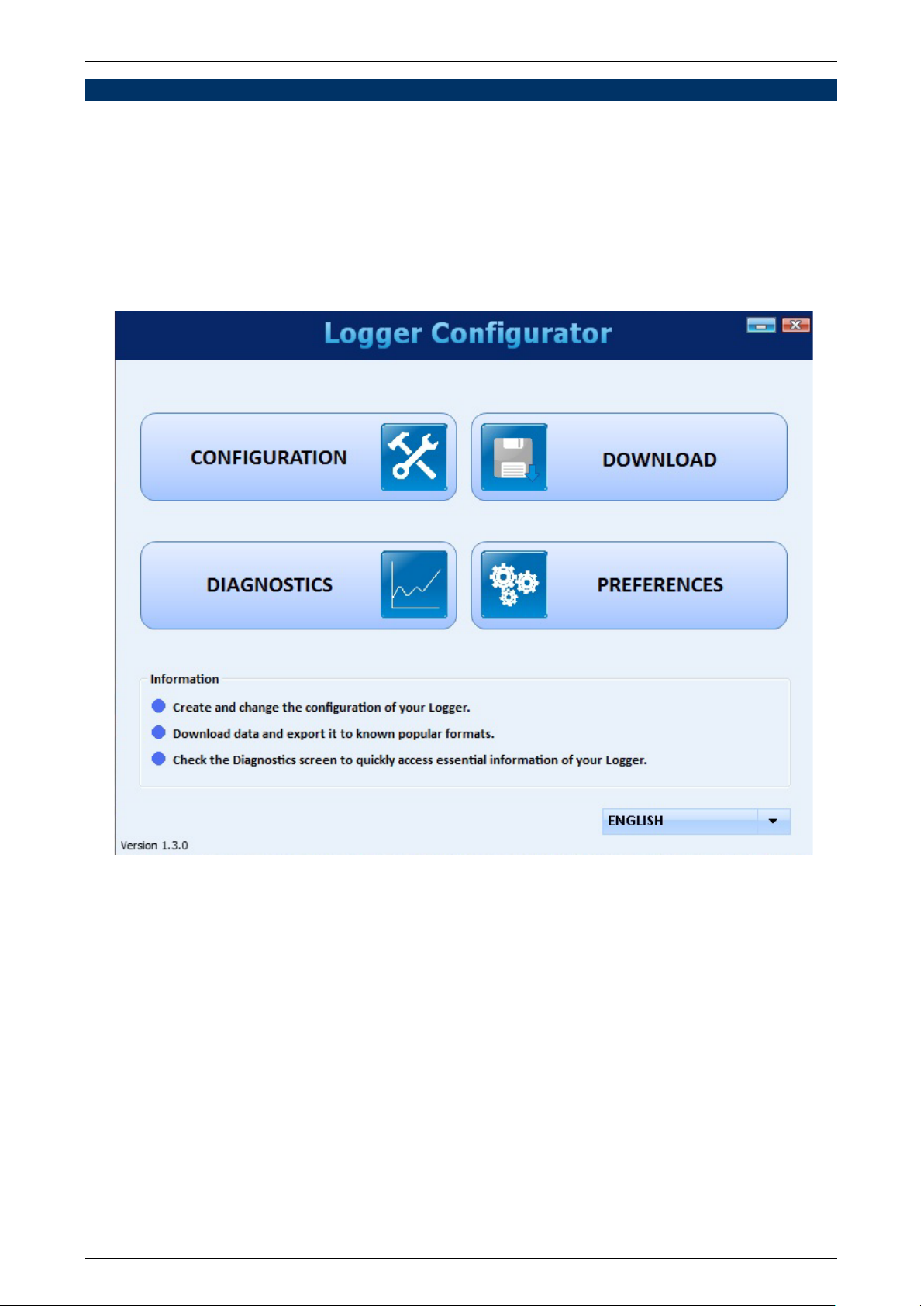

On the main screen, choose the function that you want to run from the four available:

• Configuration: Allows you to change the Data Logger configuration.

• Diagnostics: Allows you to read the values of the enabled channels, the status of configured alarms and general

information and device status.

• Download: Allows you to download data from the Data Logger memory, view and export them in various

formats.

• Preferences: It allows modifying some of the software options.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 20

Page 21

AEMC INSTRUMENTS DATA LOGGERS

CONFIGURATION

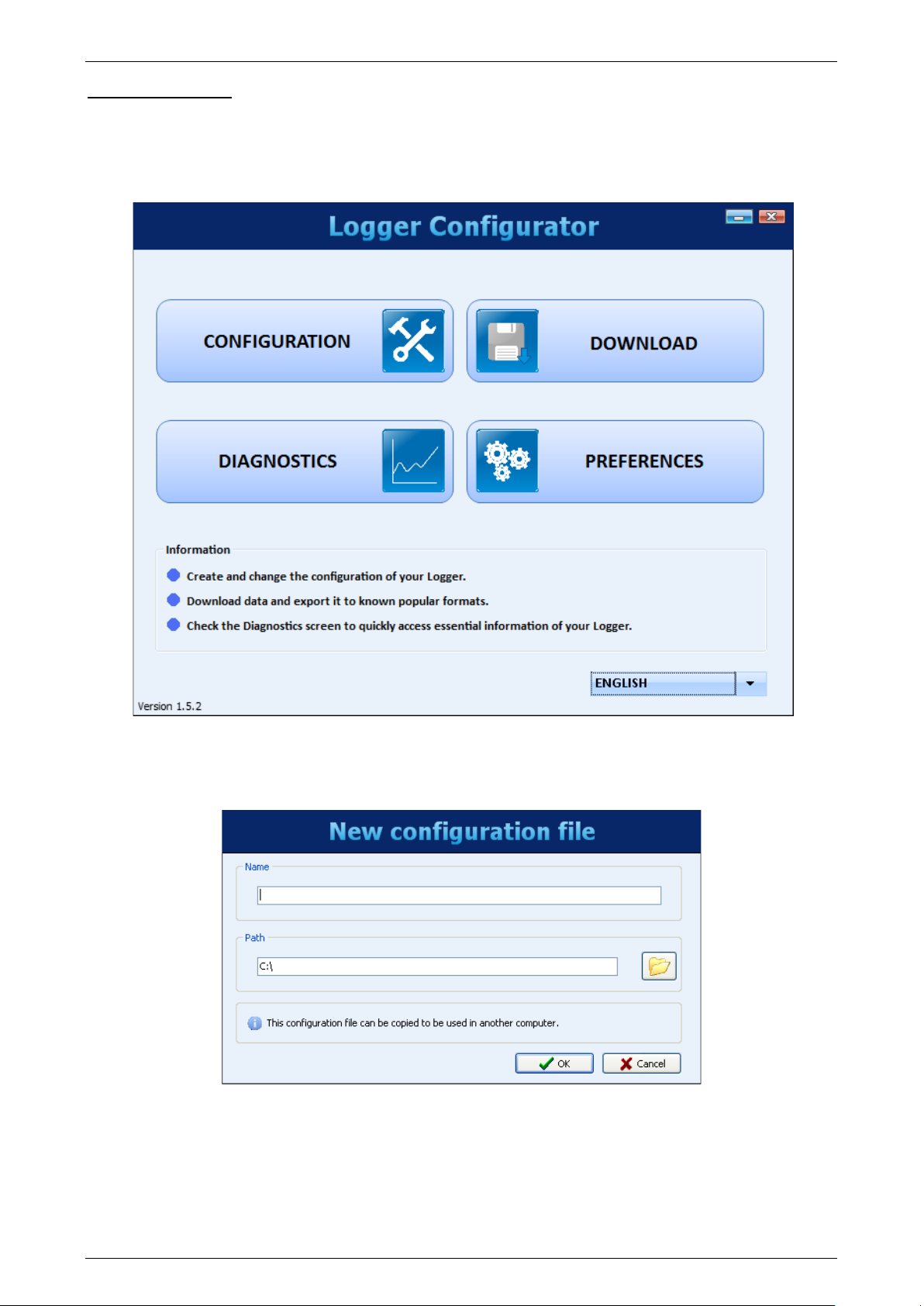

On the configuration screen, you can select one of the following options:

• Read Configuration: Reads the current configuration of a Data Logger.

• New Configuration: Creates a configuration from the scratch.

• Open Configuration: Loads a previously configuration saved to a file on your PC.

When choosing to create a new configuration, you must specify a file where this configuration will be saved.

For software version 1.40 and higher, you must select which Data Logger you are about to configure (power – normal or

24V – does not matter on this case):

• Complete model, with Ethernet, USB, expansible memory using an SD Card and a second RS485 interface

ready to accept an optional HMI.

• Model with USB but no Ethernet, non-expansible memory (internal flash only – no SD Card) and only one

RS485 interface.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 21

Page 22

AEMC INSTRUMENTS DATA LOGGERS

Once the configuration has been loaded into the software (originated from a device, a file, or simply created from scratch,

according to the selected option), then you can make the desired configuration changes. There is a sequence of screens

with various parameters arranged by functionality to accomplish this.

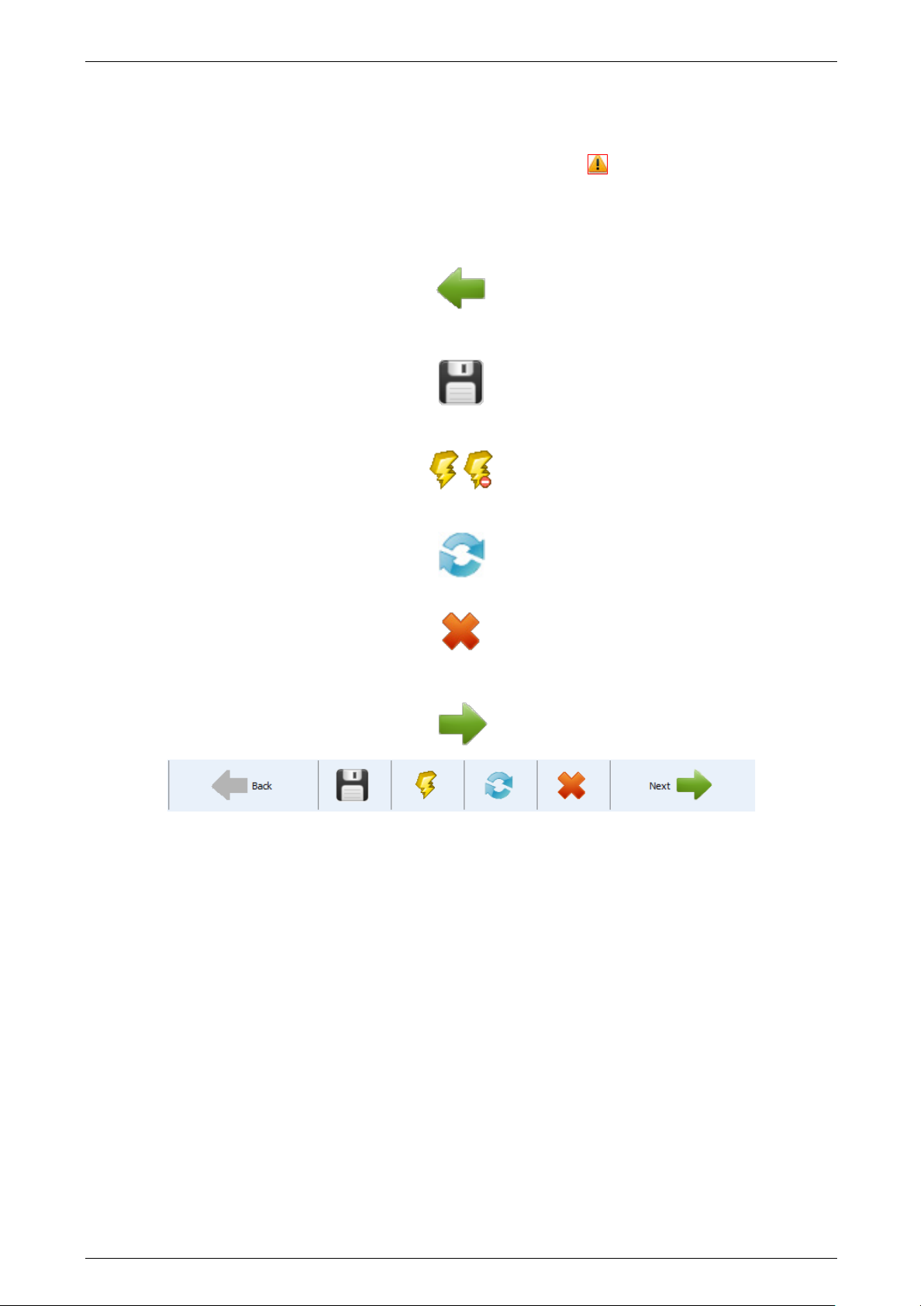

Each time you try to move onto the next screen (via the "Next" button), the configured parameters are checked. If there

are problems with any parameter, an error window is displayed and the symbol " ” shows up next to the field that may

not be consistent with other previous settings.

The icon bar at the bottom of the window has icons for the following functions:

• Back: Returns to the previous configuration screen.

• Save: Saves the current configuration to a file. If a file has not yet been associated with this configuration, it

opens a dialog screen for the user to choose the name and location of the file.

• Connection: Allows connection to a Data Logger (opens a window for the interface selection) when it is

disconnected and the disconnection when it is connected.

• Load Screen Initial Configuration: Undo the changes made by the user and returns to the initial configuration

of the current screen.

• Cancel: Closes the current configuration.

• Next: Performs the settings check of the current configuration screen and, if everything is OK, goes to the next

screen.

Icon toolbar

AEMC® INSTRUMENTS – 99-MAN 100386 v5 22

Page 23

AEMC INSTRUMENTS DATA LOGGERS

GENERAL CONFIGURATIONS

The first screen shows some general parameters for configuration for the Data Logger:

• Tag (name) to be given to the equipment (maximum of 16 characters).

• When using the DISPLAY with the Data Logger, you need to indicate the level of access that the operator will

have:

o No DISPLAY access: Prevents the use of the DISPLAY, because no parameter can be viewed by it in

the Data Logger.

o Parameters reading: The DISPLAY can be used only to view the channels and status of the Data

Logger, no configuration changes are allowed.

o DISPLAY configuration and overall reading: Full configuration of the DISPLAY is allowed, as well

as viewing the channels and status of the Data Logger.

o Overall configuration and reading: The DISPLAY can be used to configure parameters (its own and

some for the Data Logger), in addition to viewing the channels and status of the Data Logger.

• Enabling data download by using a USB flash drive: it enables or disables the data download using a USB flash

drive. When enabled, it also indicates the priority in case of a USB flash drive without enough space to

download all requested data: more recent data or older data. In addition, you can configure the number of days

(from the day of download, if the priority is the latest, or from the oldest data, if the priority is the oldest) that you

want to download. Because of the fact that we do not make a copy of all data from the equipment’s memory

(which, in the case of SD cards, can be a lot of data), this can accelerate download time significantly.

General Configurations

AEMC® INSTRUMENTS – 99-MAN 100386 v5 23

Page 24

AEMC INSTRUMENTS DATA LOGGERS

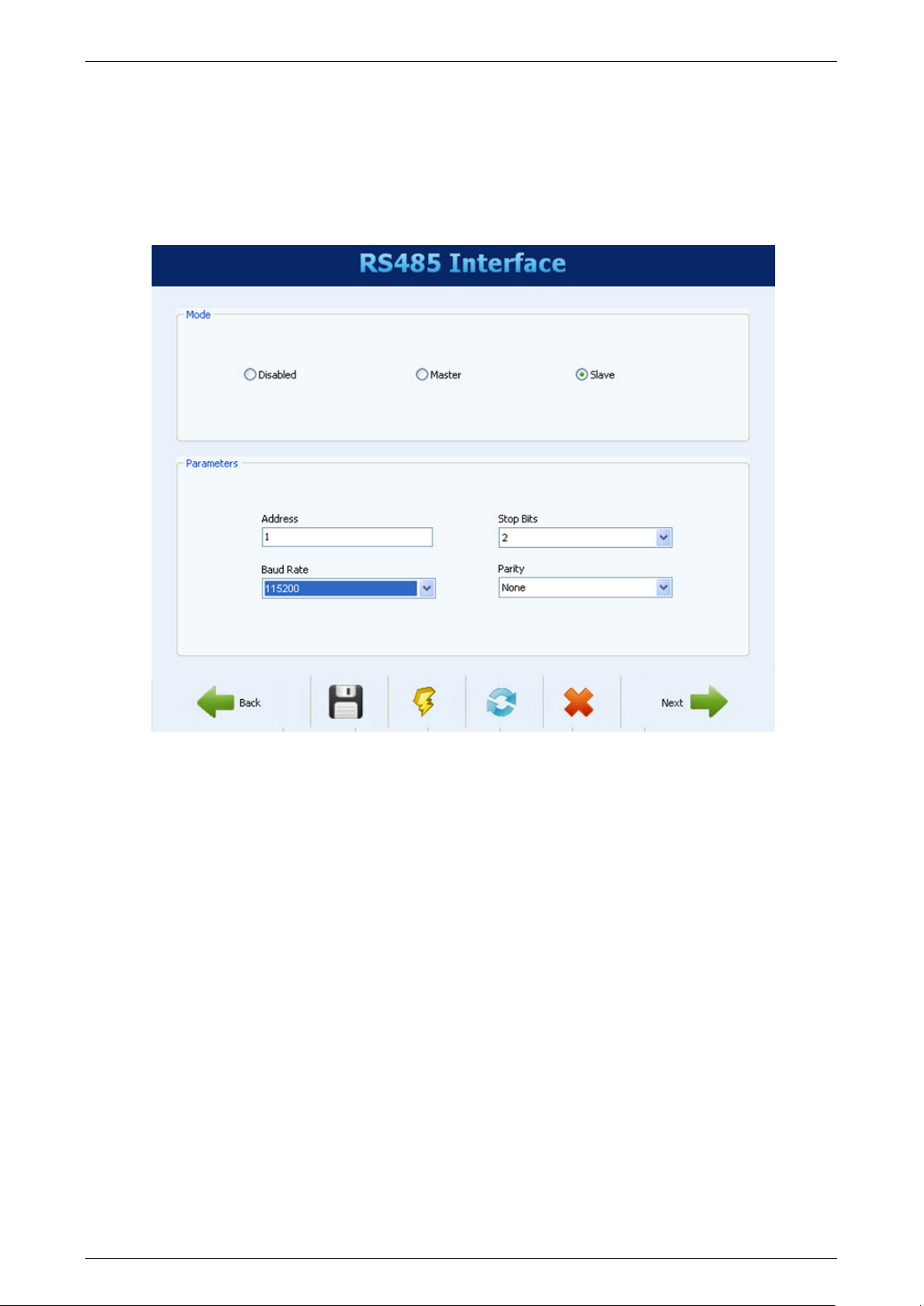

RS485 INTERFACE CONFIGURATION

Next configuration screen is the RS485 Interface screen. On this screen, you can choose the type of behavior for this

interface: whether it will be a Modbus RTU slave, a Modbus RTU master or not be used at all. It is recommended to

disable the interface if it is not used.

When it is used as a slave, you must configure your Modbus address, the baud rate, parity and number of stop bits.

When it is used as a master, it is not necessary to configure the Modbus address (only valid for the slaves). In this case,

the configuration of Modbus network, where it indicates which registers are read from what slaves, will be carried through

later, on the Remote Channels screen.

Interface RS485

AEMC® INSTRUMENTS – 99-MAN 100386 v5 24

Page 25

AEMC INSTRUMENTS DATA LOGGERS

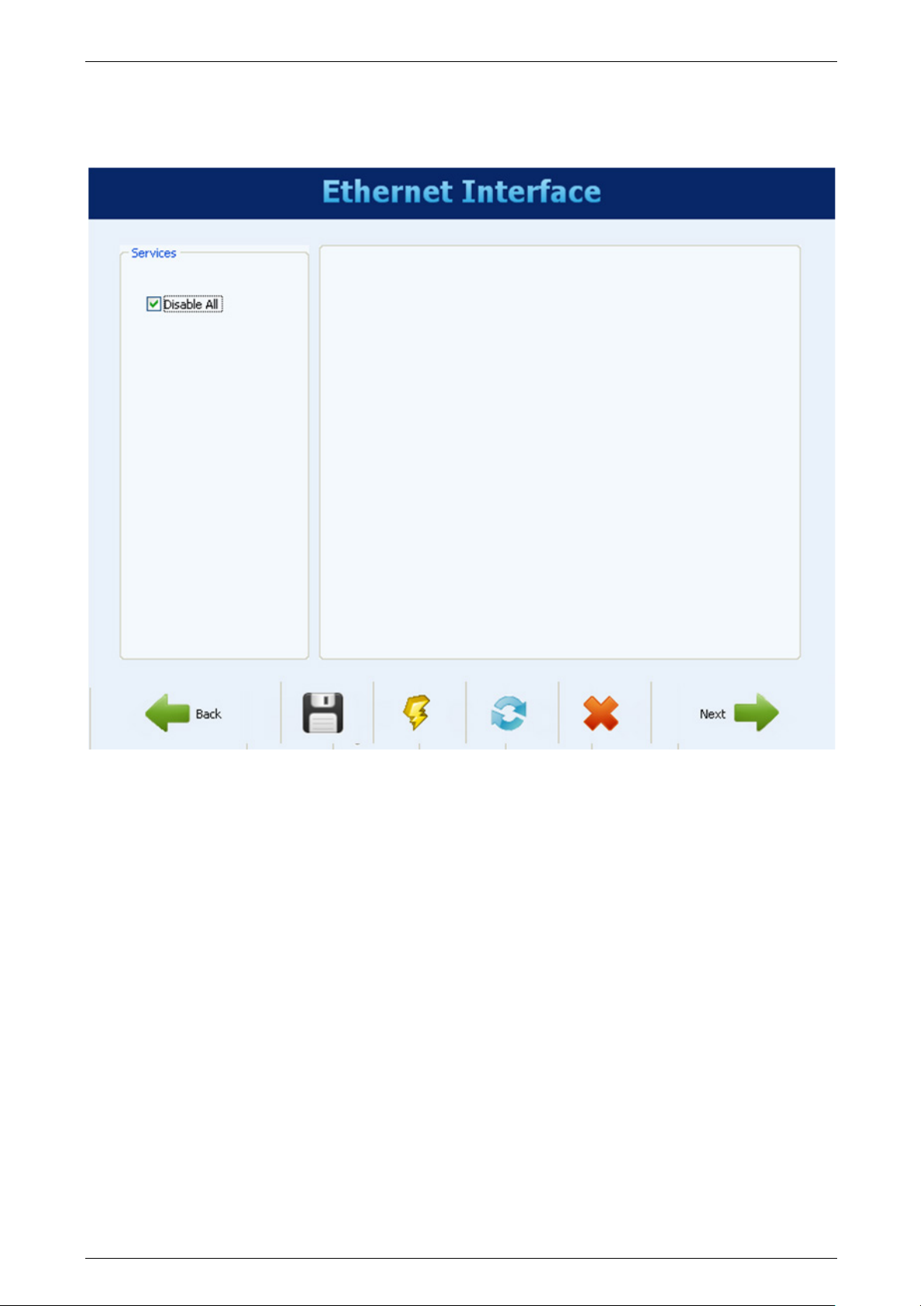

ETHERNET INTERFACE CONFIGURATION

The Ethernet interface configuration should be carried through the screen below. If it is to be used, it is recommended to

disable it, as shown here.

Disabled Ethernet Interface

AEMC® INSTRUMENTS – 99-MAN 100386 v5 25

Page 26

AEMC INSTRUMENTS DATA LOGGERS

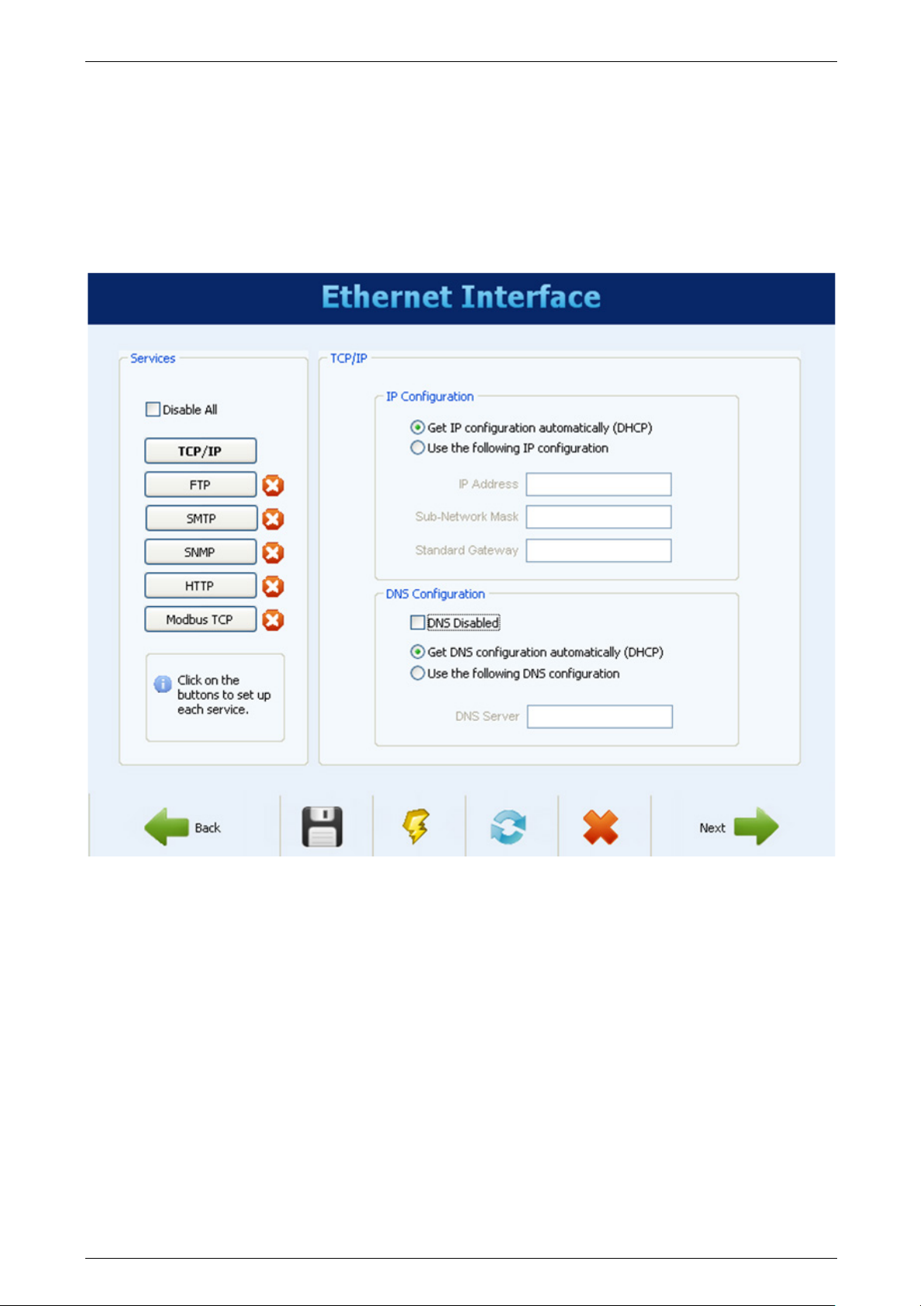

ETHERNET INTERFACE CONFIGURATION - TCP/IP

Once the interface is enabled, the buttons on the left allow you to enable and configure each of the services offered by

this interface. The icon on the right of each button shows whether the related service is enabled or not.

The first configuration to be made is the selection of fixed IP or DHCP and, in the case of fixed IP, to choose the

parameters relating to it, such as Data Logger IP, the subnet mask and default gateway.

You must choose whether or not to use DNS, which can be used to connect to the e-mail server or FTP server (when the

Data Logger is the FTP client for the daily download of data through this service). If so, you must configure the DNS

server's IP address or, if the DHCP option has been selected, you can choose to search for the DNS server’s IP from the

DHCP server.

Ethernet Interface - TCP/IP Configuration

AEMC® INSTRUMENTS – 99-MAN 100386 v5 26

Page 27

AEMC INSTRUMENTS DATA LOGGERS

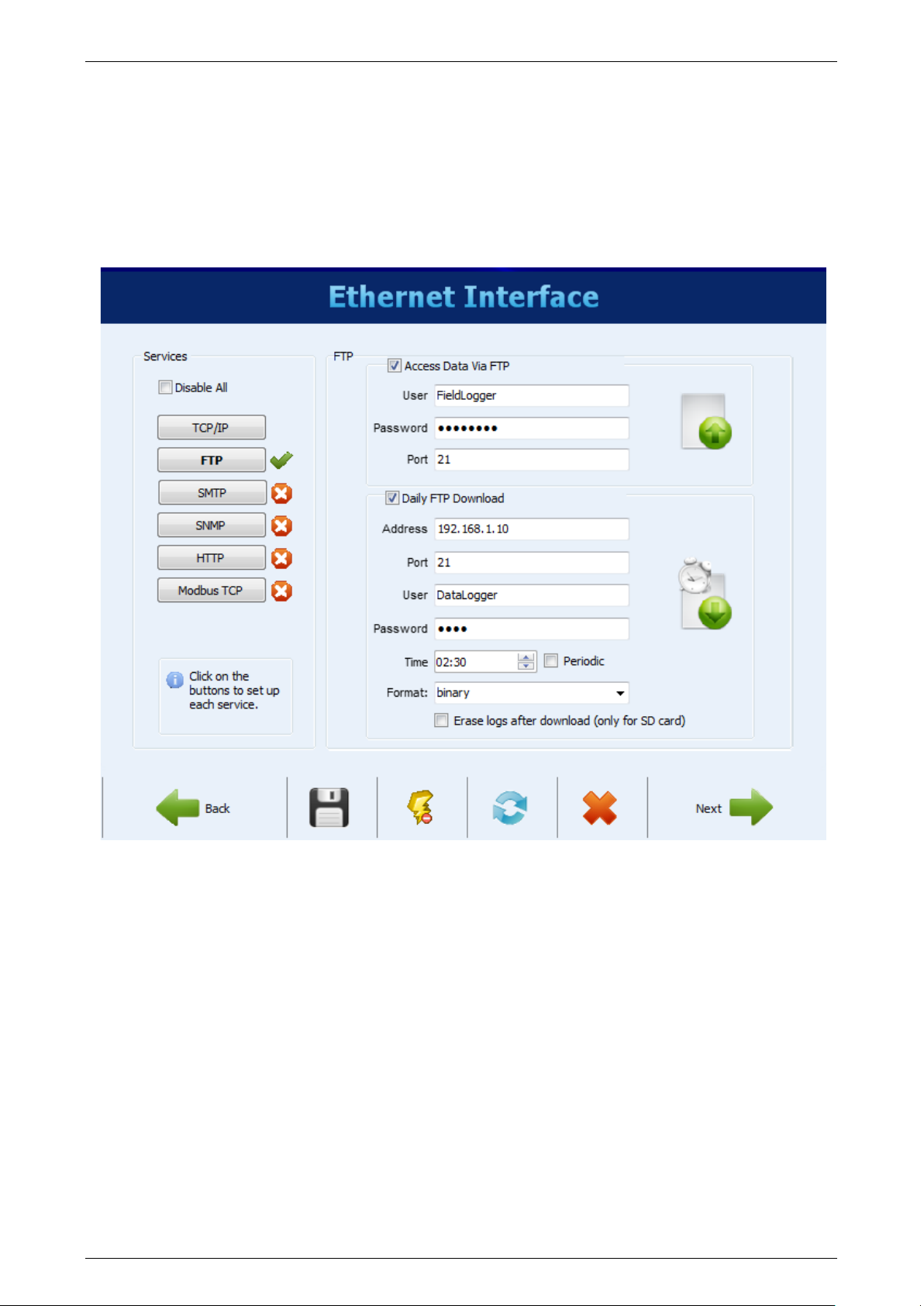

ETHERNET INTERFACE CONFIGURATION – FTP

The FTP button allows you to configure the options related to the FTP services. There are two types of FTP related

functionality to choose from in the Data Logger: client and server.

As a server, the Data Logger allows for an external client to connect to it in order to download logged data, both from the

SD card as well as from internal memory. You must configure the connection and access data, for user name (maximum

of 10 characters), password (maximum of 10 characters) and connection port.

As a client, once a day at a set time, it will connect to a FTP server to send the data from its memory (internal or SD

card). You must configure the following access parameters so the Data Logger will be able to access the server: user

(maximum of 50 characters) and password (maximum of 10 characters), in addition to the IP address or server name (in

case you enabled the DNS – name being up to 50 characters) and the server’s port.

Ethernet Interface - FTP Configuration

AEMC® INSTRUMENTS – 99-MAN 100386 v5 27

Page 28

AEMC INSTRUMENTS DATA LOGGERS

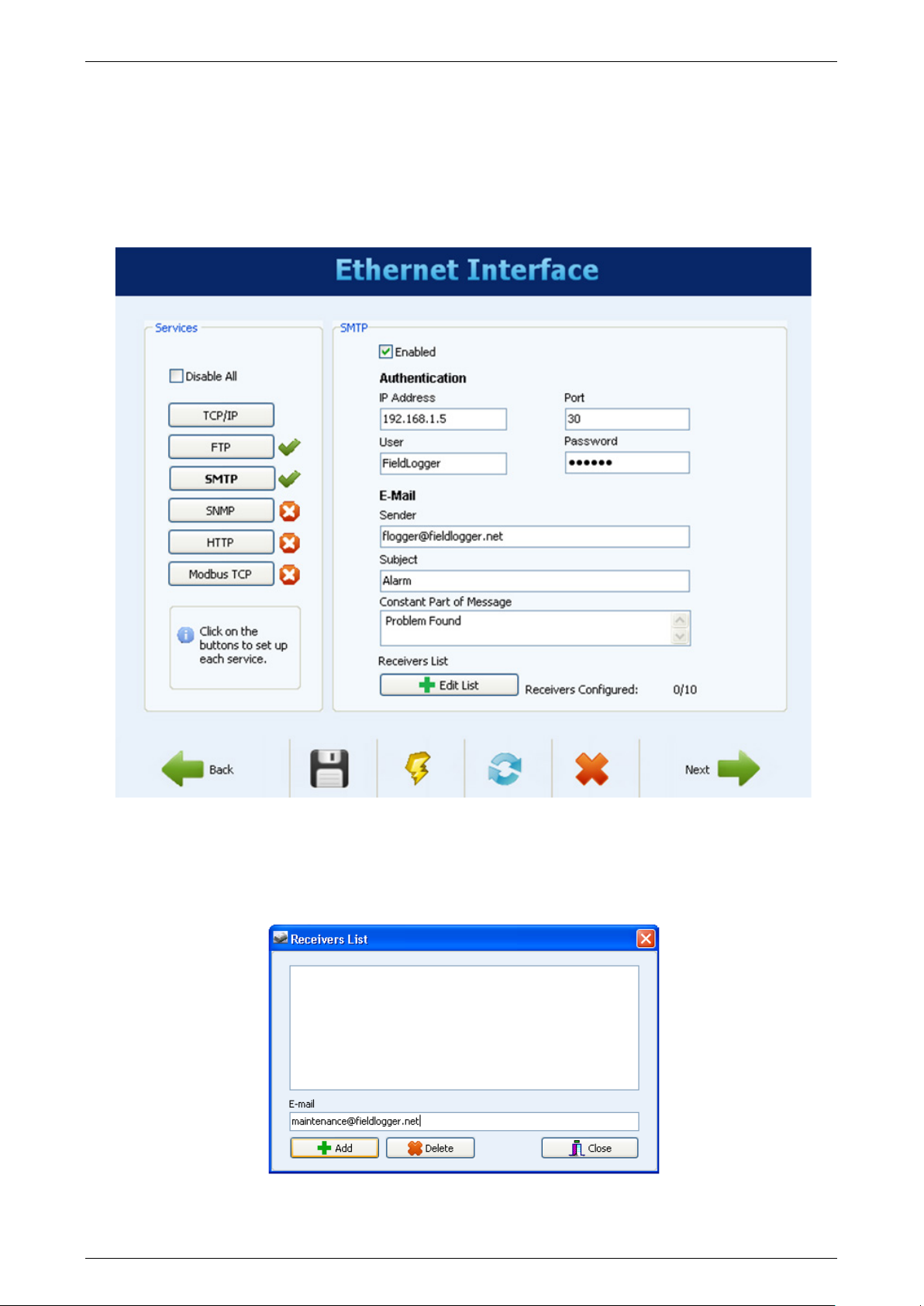

ETHERNET INTERFACE CONFIGURATION - SMTP

The SMTP button allows access to the parameters related to sending e-mails. The Data Logger allows e-mails to be

sent to multiple receivers when alarms or events are active. On this screen, the parameters related to the access to the

e-mail server must be configured, such as its IP address or server name (in case you enabled the DNS – name being up

to 50 characters), in addition to the user (maximum of 50 characters) and password (maximum of 12 characters).

Finally, you must configure the e-mail parameters to be sent in case of an alarm event. This e-mail has a subject

(maximum of 32 characters) and has a part of the message body that is user defined (up to 64 characters) and it is the

same for all alarms or events. The e-mail of the sender (maximum of 50 characters) and the e-mails of the receivers

(maximum of 50 characters for each one) must also be configured.

Ethernet Interface - SMTP Configuration

ETHERNET INTERFACE CONFIGURATION - E-MAIL RECEIVERS

To insert e-mail receivers, click on the "Edit List" button. A new window will open, allowing for the inclusion and removal

of e-mails from the receivers list. All potential receivers of alarm or event e-mails must be included in this window. The

choice of which alarms or events will be sent to which receivers will be made later, on the alarms configuration screen.

Ethernet Interface - Configuration of E-mail Receivers

AEMC® INSTRUMENTS – 99-MAN 100386 v5 28

Page 29

AEMC INSTRUMENTS DATA LOGGERS

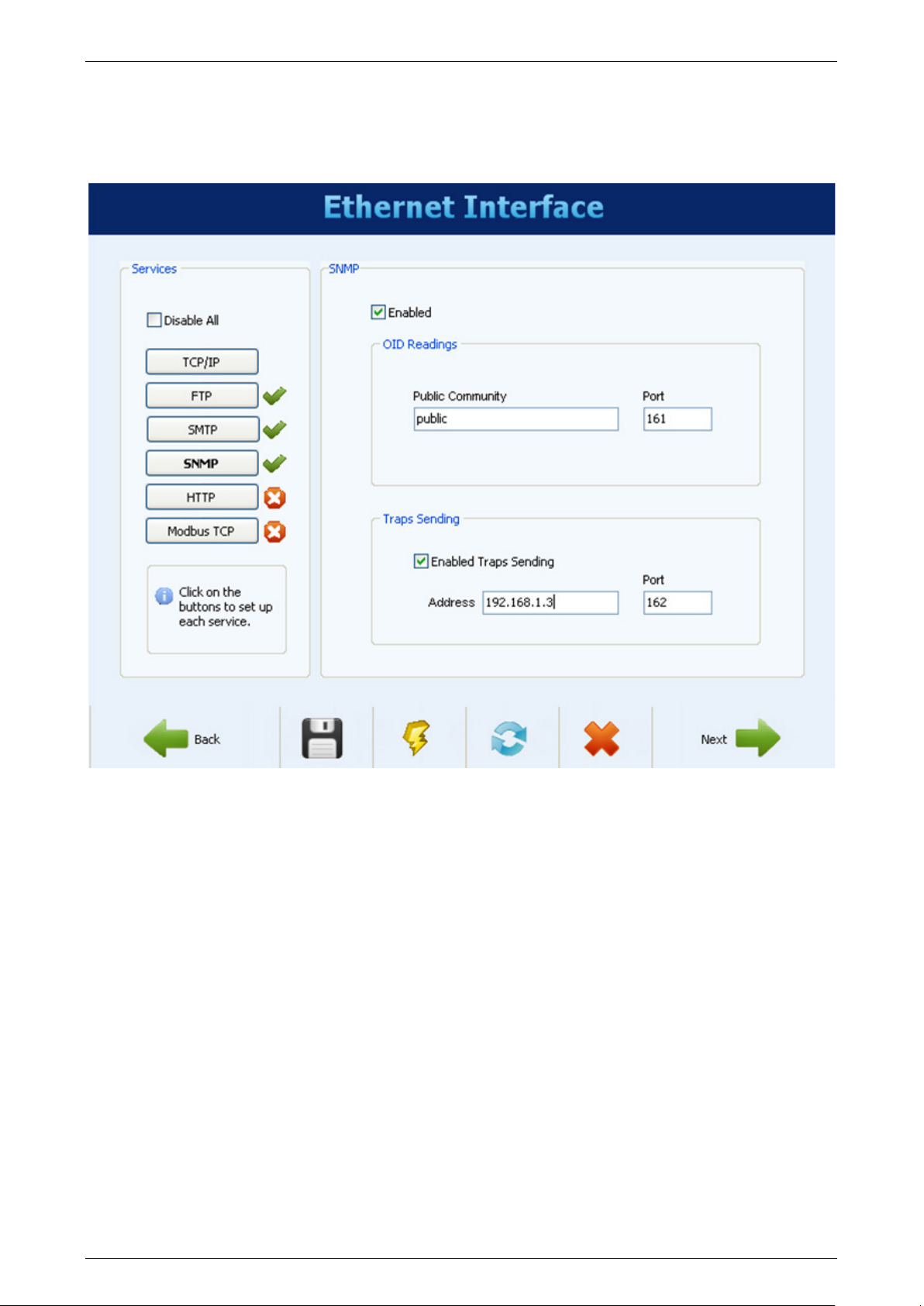

ETHERNET INTERFACE CONFIGURATION - SNMP

The SNMP protocol can be enabled and configured by clicking on the SNMP button. SNMP in the Data Logger is read-

only. Thus, you should set up the public access (maximum of 16 characters) and connection port.

For using traps, you must enable them separately. You should also set up the IP address and destination port for the

traps.

Ethernet Interface – SNMP Configuration

AEMC® INSTRUMENTS – 99-MAN 100386 v5 29

Page 30

AEMC INSTRUMENTS DATA LOGGERS

ETHERNET INTERFACE CONFIGURATION – HTTP

The HTTP button enables the Data Logger to serve a web page with some of its data. This page has an auto-refresh

parameter, indicating to the browser software that the page should be reloaded with updated data from periodically. For

this, the configuration needed is the connection port and the time in seconds between page updates.

Ethernet Interface – HTTP Configuration

AEMC® INSTRUMENTS – 99-MAN 100386 v5 30

Page 31

AEMC INSTRUMENTS DATA LOGGERS

network is

ETHERNET INTERFACE CONFIGURATION – MODBUS TCP

Finally, the Modbus TCP button allows you to enable the Modbus TCP communication protocol, used to read and write

data to the Data Logger. Additionally the Configuration software itself uses this protocol to communicate with the Data

Logger in order to read and write configuration parameters, view diagnostic data and download recorded data, when

Ethernet interface has been selected. The Data Logger should be accessed by the “255” identification (ID). Any other ID

used in a Data Logger Modbus-TCP access will be understood as being targeted to a RS485 slave in the RS485

network, reached through the gateway function. In this case, if this functionality is enabled, the data packet will be

forwarded to the RS485 bus.

When the RS485 interface is configured as a Modbus master and Modbus TCP protocol is enabled, the gateway

functions can be enabled, which allows the user to send Modbus commands using the Ethernet interface (Modbus TCP)

to the slaves connected to the Modbus RTU network through Data Logger.

Data Logger operation as a gateway between a Modbus TCP network and a Modbus RTU

only available from firmware version 1.10 or later.

Ethernet Interface - Modbus TCP Configuration

AEMC® INSTRUMENTS – 99-MAN 100386 v5 31

Page 32

AEMC INSTRUMENTS DATA LOGGERS

ANALOG CHANNELS CONFIGURATION

On the next screen, you must configure the analog channels that will be used. Each channel is individually configured, so

you should first select which channel to be configured in the list on the left.

After the channel has been selected, you must configure its parameters on the right. For each channel, you must

configure a tag (name with a maximum of 16 characters) and an input type. Depending on the selected input type, the

indication limits must also be configured. For temperature sensors, you must choose whether the indication will be in

Celsius or Fahrenheit, for the others, you can type a string for the unit (maximum of 10 characters).

There is also the option to enter an error value to be displayed when an error is detected on the input signal, such as an

open 4-20mAloop or a Pt100 with a broken cable. It is also the possible to configure a digital filter for the input channel

(the higher the value, the more filtering applied to the channel, making the response more immune to noises on the input

signal, but also slower to respond to variations - maximum filter value is 20).

There is also an option to use Custom Calibration. This feature allows up to 10 pairs of points to be inserted in a

“correction table” (per analog input) in the device, creating segments for adjustments to the indicated value. Further

details can be found in the "Data Logger Operation” chapter.

The number of decimal places to be displayed must also be configured. This parameter refers to the following cases:

• Reading the value of the channel via Modbus 16 bits registers (INT16 with signal). Further details can be found in

"Data Logger – Modbus”.

• Reading the value of the channel via DISPLAY.

• Reading the value of the channel through the HTML page generated by Data Logger itself (HTTP service on the

Ethernet interface).

• Reading the value of the channel through the OID reading of SNMP protocol (SNMP service of Ethernet

interface).

• Reading the alarm value related to the channel when receiving e-mails from the Data Logger (SMTP service on

the Ethernet interface).

Analog Channels - Configuration of a temperature channel

AEMC® INSTRUMENTS – 99-MAN 100386 v5 32

Page 33

AEMC INSTRUMENTS DATA LOGGERS

Analog Channels – Configuration of a linear channel

AEMC® INSTRUMENTS – 99-MAN 100386 v5 33

Page 34

AEMC INSTRUMENTS DATA LOGGERS

ANALOG CHANNELS CONFIGURATION – CUSTOM CALIBRATION

Using the "Custom Calibration" button, you can enter up to 10 custom calibration points for each analog channel as

described below:

1. Disable the custom calibration of the channel to be adjusted, deleting all points configured for it, and apply this

setting.

2. In the points to be adjusted, apply the standard value and write down the value indicated by the equipment.

3. Afterwards, insert the pairs of Custom Calibration points (source value and indicted value) and apply the

configuration.

Analog Channels - Custom Calibration

Analog Channels - Custom Calibration

AEMC® INSTRUMENTS – 99-MAN 100386 v5 34

Page 35

AEMC INSTRUMENTS DATA LOGGERS

DIGITAL CHANNELS CONFIGURATION

After configuring the analog channels, next configure the digital channels and relays. Just as it is in the analog channels,

on the list on the left, you can select which channel is to be configured.

Each channel can be configured as an input or an output. As an input, you can enable it or not. If it is disabled, it will not

appear as an option in the logs, alarms, in the virtual channels or even on the DISPLAY. Once the input has been

enabled, you must provide a unique tag (name - maximum of 16 characters) for this channel. You should also provide a

value to be displayed when in "0" level (low voltage level or contact closed at the input) and another value to be indicated

when in "1" level (high voltage level or contact open at the input). These values will be shown in the channel reading.

Optionally configure a unit (maximum 10 characters) for the input.

Digital channels - Configuring an input

It is possible to perform counting on the digital inputs from firmware version 1.10 or later. No special configuration is

needed; just configure digital channels as inputs. The counting values can be accessed by Modbus registers (check the

section on “Data Logger – Modbus”) and can also be copied to a virtual channel, where it can be logged or used by the

alarms, for example. When applying a new configuration in the digital channels, the all previously collected counting

values are reset to zero.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 35

Page 36

AEMC INSTRUMENTS DATA LOGGERS

When configured as an output, you should indicate whether this output may be triggered by Data Logger alarms &

events or if it will be controlled by external Modbus commands, coming from a PLC or SCADA software, for example.

Digital channels – Configuring an output

The two Data Logger relays are also configured on this screen and their configuration is similar to that of other digital

outputs. You must indicate whether they are triggered by internal alarms or external Modbus commands.

Digital Channels - Configuring a relay

AEMC® INSTRUMENTS – 99-MAN 100386 v5 36

Page 37

AEMC INSTRUMENTS DATA LOGGERS

REMOTE CHANNELS CONFIGURATION

The configuration of remote channels is only available when the RS485 interface has been configured as a Modbus

master. In the case of the RS485 interface having been configured as a slave or disabled, the remote channels screen

will display a message indicating the inability of its configuration.

Remote Channels Disabled

AEMC® INSTRUMENTS – 99-MAN 100386 v5 37

Page 38

AEMC INSTRUMENTS DATA LOGGERS

If the RS485 interface was configured as Modbus master, the following screen will be displayed. You should set up a tag

(name - maximum of 16 characters), unique for each channel, and optionally a unit (maximum of 10 characters) for the

reading value.

In addition, for each channel, you should set up which network slave is to be read, what Modbus command should be

used and what is the initial register to be read from the slave. In the current version, the number of registers is always

"1", which means that you cannot do block reading.

An error value must also be configured. This value is shown on the channel when there is a problem, for example, a

communication error with the slave.

After channel configuration, you must click on the “Add” button in order to enter the channel in the list to the left. If you

want to remove a channel from the list, you must select it from the list and click on "Remove".

Remote Channels - Setting up a channel

AEMC® INSTRUMENTS – 99-MAN 100386 v5 38

Page 39

AEMC INSTRUMENTS DATA LOGGERS

At the bottom of the screen there are the general parameters for the Modbus Master configuration. The reading interval,

given in tenths of seconds (maximum 18,000, equivalent to 30 minutes) is the time that you want the Data Logger to

perform a new scan of all configured remote channels. The number of trials (valid range: 1 to 10) is how many attempts

are made in sequence for the reading of each channel (if the communication fails in all attempts it will display the error

value set up for the channel).

The maximum response time it will wait for the slave’s response (valid range: 2 to 10,000 ms) indicates how long it will

wait after sending the command from the master. If the answer does not come within this time, it will be considered a

communication error and a retry (if configured) will be carried through. The time between commands (valid range: 1000

to 5000 ms) indicates how much time Data Logger will wait between receiving the slave’s response and sending the

next command.

Remote Channels - Inserting a channel in the list

AEMC® INSTRUMENTS – 99-MAN 100386 v5 39

Page 40

AEMC INSTRUMENTS DATA LOGGERS

VIRTUAL CHANNELS CONFIGURATION

The following screen allows configuration of the virtual channels. Each virtual channel is the result of a mathematical or

logical operation and must be configured by selecting a unique tag (name - maximum of 16 characters) for this channel.

You should then select the first channel that will serve as the operand (depending on the selected operation, it will be the

only one). When you select "Constant Value", you will be able to assign a numeric value to the virtual channel (this value

can be used as an operand in other virtual channels). Next, you must choose the operation to be performed and which

channel is to be used as the second operand in the operation (when previously chosen "Constant Value", place the

numeric value of the channel).

Finally, choose a unit (optional - maximum of 10 characters) for the channel, plus an error value and the number of

decimal places desired in the indication of the same one. When clicking on "Add", the newly configured channel is added

to the list of virtual channels.

When a virtual channel is configured, all enabled input channels are available for use as operands, including virtual

channels already placed in the list. This enables you to generate relatively complex expressions, using the result of an

operation as an operand in another one. For more details, please refer to the section on "Virtual Channels" under the

chapter "Data Logger Operation”.

Clicking on any virtual channel in the list, its parameters are loaded at the top fields. To delete a channel, you must select

it from the list and click on "Remove". To delete all the virtual channels, you must click on "Remove All".

Virtual Channels

AEMC® INSTRUMENTS – 99-MAN 100386 v5 40

Page 41

AEMC INSTRUMENTS DATA LOGGERS

Whenever a digital channel is used for an alarm, hysteresis shall not be used (must be

ALARMS CONFIGURATION

After setting up all channels, you can configure alarms to indicate error or exception conditions. You must choose which

channel must be used for the alarm, what the alarm condition is, and what the set point (trigger value for the alarm) is.

For example, you can select an analog temperature channel to alarm when the temperature exceeds a critical threshold,

or a digital input channel to alarm when your state is different from the expected value.

A hysteresis can be configured to prevent a marginal condition, such as an input that hovers around the set point value,

which would generate multiple alarm events. In some cases, like when the alarm channel is a digital input, the hysteresis

does not make much sense and should be maintained at “0”.

configured with “0”)!

Each alarm can have one or more associated actions. You should then choose what actions should be performed on the

occurrence of an alarm or event (different actions are organized by tabs). The available actions are: activation of relays,

activation of digital outputs (if they are configured to be triggered by an alarm), sending of e-mails to one or more

receivers (selected from among the ones configured on the Ethernet interface configuration page), sending a SNMP trap

and the start and/or stop of the recording. Finally, when everything is set up, include the alarm in the list by clicking on

the “Add” button.

When clicking on an alarm from the list on the left, its parameters are loaded into the fields on the right. To delete a

channel from the list, you must select it from the list and click on "Remove". To modify parameters of an alarm, you must

select it from the list, make the desired changes and click on "Modify". The button "Delete all" deletes all alarms in the

list.

Alarms Configuration - Relays selection

AEMC® INSTRUMENTS – 99-MAN 100386 v5 41

Page 42

AEMC INSTRUMENTS DATA LOGGERS

Alarms Configuration - Digital outputs selection

Alarms Configuration - Logs control configuration

AEMC® INSTRUMENTS – 99-MAN 100386 v5 42

Page 43

AEMC INSTRUMENTS DATA LOGGERS

Alarms Configuration - E-mail receivers selection

Alarms Configuration - Enabling SNMP traps

AEMC® INSTRUMENTS – 99-MAN 100386 v5 43

Page 44

AEMC INSTRUMENTS DATA LOGGERS

Alarms Configuration – Selection the internal variables

Alarms Configuration - Alarm added to the list

AEMC® INSTRUMENTS – 99-MAN 100386 v5 44

Page 45

AEMC INSTRUMENTS DATA LOGGERS

LOG CONFIGURATION

The last page of the configuration is about logging. If data logging is not desired, you should disable it.

Log configuration should begin initially by choosing the start mode and stop mode for the logging process. If, on the

previous screen, the start and/or stop of the loggings were assigned to one or two alarms or events, this option is

disabled and cannot be changed on the Logs screen.

If you want to use the start and/or stop of the loggings through Modbus commands, you must enable these options. In

addition, you must select where the logging data must be stored in the memory; in the internal flash (512k logs) or in the

SD card inserted by the user.

Finally, you must select which channels you want to log and what is the desired storage rate. The channels can be

selected for logging moving them from the left side column (available channels) to the right side column (channels to be

logged). A maximum of 100 channels can be logged, but keep in mind that the more channels to be logged, the slower

the storage rate that can be used.

The storage rate is given as a logging interval and it is common to all channels. For example, a rate of 1 second means

that all channels selected will be stored once per second. Although the equipment allows for a rate of up to 1000 per

second, you must bear in mind the following side effects:

• It is not good to have a storage rate faster than the scan rate of the analog channels or the scan rate of the

remote channels. In this case, the logs would have repeated data.

• The more data that is in memory, the slower the download process will be and more data will be processed in

preview and export.

Logs Configuration – Logging configuration

AEMC® INSTRUMENTS – 99-MAN 100386 v5 45

Page 46

AEMC INSTRUMENTS DATA LOGGERS

After completing the configuration, you can send it to the data logger by clicking on the "Send" button. If the configuration

was previously read from the data logger and the interface was not disconnected, the same interface used for reading

will be used for writing otherwise you must choose which interface to use for sending the configuration.

At the end of the transmission, a message will appear indicating the success (or failure) of the operation. You can save

the configuration to a file to be retrieved in the future if desired.

If you just want to save it to a file instead of sending the configuration to the Data Logger, you must choose the file name

and click on the “Save” button.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 46

Page 47

AEMC INSTRUMENTS DATA LOGGERS

DIAGNOSTICS

When you select Diagnostics, the login screen will appear. You must indicate what interface will be used for reading the

diagnostics parameters: RS485 (RS485 interface of the Data Logger should be selected as "slave"), USB or Ethernet

(the Ethernet interface of the data logger must be enabled, as well as Modbus TCP protocol).

Reading parameters is then performed and the General parameters window is opened. This window shows the data

logger’s tag, serial number, firmware version and model. It also shows the time of its clock compared to the computer's

clock. In this window you can also see the configuration parameters for the RS485 interface. For the Ethernet interface,

the current status (connected or disconnected) is indicated, as well as the IP and MAC addresses. On the right side of

the window, there is an indication of the connection status of the DISPLAY and the USB flash drive, in addition to the

capacity and free space of the internal flash memory and the SD card (when connected). Finally, there is an indication of

the current state of the recording and, when the start or stop of these through Modbus commands is enabled. There are

buttons in order to perform the respective actions of starting and stopping the recording.

Diagnostics - General Status

AEMC® INSTRUMENTS – 99-MAN 100386 v5 47

Page 48

AEMC INSTRUMENTS DATA LOGGERS

On the Chart tab, you can select up to 6 channels to be viewed in a chart. At the bottom, you can select the channel to

be displayed and its associated color on the chart. When all desired channels are selected, click on the "Start" button.

The channel values will be read approximately every 2 seconds and will be plotted on the chart. If any channel is in error,

the channel selection will be shown in red.

Diagnostics - Monitoring channels

AEMC® INSTRUMENTS – 99-MAN 100386 v5 48

Page 49

AEMC INSTRUMENTS DATA LOGGERS

On the Alarms tab, you can check the real-time status of all configured alarms or events. At the top, there is an indication

of how many alarms are enabled and how many are in a state of alarm. In the list below, the settings for each alarm are

shown. If the alarm is active, its configuration is shown in red.

Diagnostics - Monitoring Alarms

AEMC® INSTRUMENTS – 99-MAN 100386 v5 49

Page 50

AEMC INSTRUMENTS DATA LOGGERS

DOWNLOAD

By selecting Download, you can download data from the Data Logger, search data previously downloaded from a folder

or view or export logged data.

The user can create a folder on their computer (or their network) where a recording database will be created. This

database may have data from one or more Data Loggers and will be the destination of all data downloaded from the

Data Logger. From this database, the views and data export will look for the channel data.

The Download Manager screen has the following options:

• Download Data

• Download Manager

These options will be viewed in detail in the following sections.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 50

Page 51

AEMC INSTRUMENTS DATA LOGGERS

DOWNLOAD DATA

When selecting this option, the first thing to do is choose the data source where the software should read data from.

The available options are:

• Download data from a Logger (requires a connection with the logger).

• Download data from a USB flash drive (in cases when the flash drive was used to retrieve data from Data

Logger). The flash drive must be plugged in the computer.

• Download data from a SD card. The card must have been used in the Data Logger as the recording memory

target. The SD card is recommended when large logging recording takes place because it is the fastest way of

moving data to the computer.

• Download data from a Windows folder. This folder/directory can be located in your local computer or on your

network. This option should be used to process data previously downloaded via FTP.

When selecting downloading data directly from Data Logger, a window will pop up asking for the connection mode to the

logger. One of these interfaces can be selected to download data: Ethernet (Modbus TCP) interface, USB (device)

interface or RS485 (Modbus RTU) interface.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 51

Page 52

AEMC INSTRUMENTS DATA LOGGERS

After completing the connection, the next screen will show data logger information.

This screen is very useful, as it helps to assure you are accessing the right logger when downloading via

Ethernet/Modbus TCP or RS485/Modbus RTU if there are multiple Data Loggers in the network. Next, the Data Logger

memory location, where logged data is stored (internal flash or SD card), must be chosen.

If you select to download data from the SD card, the next screen will ask the desired time period for the recorded data.

You can download all data (in case of SD cards, the amount of data can be very large and take a long time to download)

or data just from a certain period of time.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 52

Page 53

AEMC INSTRUMENTS DATA LOGGERS

Next, you must confirm the data base folder (folder where all data should be stored in your computer or in the network)

and choose whether downloaded data should be deleted from Data Logger memory or should be kept.

The next step is to transfer the data from Data Logger to data base folder. Click the right green arrow button in order to

proceed, downloading will start and a progress bar will be displayed indicating the download progress. Once

downloaded, a new screen will be opened for data review/export as described in the “Download Manager” section.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 53

Page 54

AEMC INSTRUMENTS DATA LOGGERS

DOWNLOAD MANAGER

The Download Manager allows you to choose the format for viewing the data and to choose the data to be viewed.

Using the step-by-step “wizard” format makes it easy and intuitive to complete the download and viewing process.

USING THE STEP-BY-STEP (WIZARD)

First, choose the way data will be processed. The available ways include viewing in table format, viewing in chart format,

exporting data to a file and creation of a report with the desired data.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 54

Page 55

AEMC INSTRUMENTS DATA LOGGERS

Next, choose the database folder, where data will be saved.

Next, you must select which Data Logger’s data will be viewed. Selection is done by the logger’s serial number.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 55

Page 56

AEMC INSTRUMENTS DATA LOGGERS

Next, the desired time period must be selected.

Lastly, choose which channels must be viewed or exported, as well as the number of decimal places for the

channels.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 56

Page 57

AEMC INSTRUMENTS DATA LOGGERS

Table Format View

The table view shows data in a table sorted by time, with oldest data first. At the top of the dialog box, there are

several navigation buttons that allow the user to move forward or back one screen, or go to the beginning or end of

data. In order to view data in this format, no more than 16 channels can be viewed.

Viewing logged data in table format

AEMC® INSTRUMENTS – 99-MAN 100386 v5 57

Page 58

AEMC INSTRUMENTS DATA LOGGERS

Chart Format View

The chart view shows data in a chart format. Moving the mouse over the chart shows the instantaneous values of

each viewed channel at the bottom of the screen. No more than 16 channels can be viewed at one time.

Viewing logged data in chart format

The button on the upper left corner of the screen allows the chart to be printed.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 58

Page 59

AEMC INSTRUMENTS DATA LOGGERS

Data Export

To export selected data, click on the “Export” button. A window will appear where you must select the destination

folder, the file name and the file extension to be exported.

When selecting the “Other Formats” option, a second screen will show up, where it will be possible to choose some

parameters related to the chosen format: RTF, HTML, XML, PDF, CSV, SQL, XLSX or DOCX.

For exporting in “SuperView” or “FieldChart” format, there is a top limit of 16 channels. For exporting in “PDF” or

“RTF” format, there is a top limit of 8 channels

When a successful export is completed, the following window will open.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 59

Page 60

AEMC INSTRUMENTS DATA LOGGERS

Report Generation

The file name and destination folder must be entered. Additionally, fields that will be used in the report must be filled

in, including report and author names, company name and report title. An image can also be selected to be

presented in the report, such as company logo.

Clicking the “OK” button will bring up a progress bar shown at the bottom of the screen and, when ready, the chart

from the desired period will display. A comment field is available to add text to be included with the final report.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 60

Page 61

AEMC INSTRUMENTS DATA LOGGERS

10/15/2012

At this point, clicking on the “OK” button will generate and display the report. This report can be printed or saved to a

file for later access.

03:10

AEMC

AEMC® INSTRUMENTS – 99-MAN 100386 v5 61

Page 62

AEMC INSTRUMENTS DATA LOGGERS

NON STEP-BY-STEP

In the previous versions of the configuration software, this was the only available procedure and it was kept for

compatibility reasons.

The proper procedure is to select the source folder of the logged data (logging database). In the "available downloads"

field will be displayed all devices that have downloaded data available.

You must choose, through the respective serial number, the equipment that has data of interest at this time. After that,

you must define the time period of interest and click on "Show available channels".

AEMC® INSTRUMENTS – 99-MAN 100386 v5 62

Page 63

AEMC INSTRUMENTS DATA LOGGERS

Then, select which channels, among those available, are of interest.

Finally, the chosen channels can be viewed in several ways.

Viewing logged data in table format

AEMC® INSTRUMENTS – 99-MAN 100386 v5 63

Page 64

AEMC INSTRUMENTS DATA LOGGERS

Viewing logged data in chart format

There is a button on the upper left corner that allows users to print the chart.

To export the selected data, you must click on the “Export” button. After a prior processing, a window will appear where

you must select the destination folder, the file name and the file extension to be exported.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 64

Page 65

AEMC INSTRUMENTS DATA LOGGERS

Since configuration software version 1.50, the exporting process was improved, providing more control over the fields

and formats of the exportation. The basic window with the format choice became different:

Whenever choosing the “Other formats” options, a second window pops up, allowing the choice of the type of the file and

many other options.

Upon completion of the export process, a window is displayed showing its success.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 65

Page 66

AEMC INSTRUMENTS DATA LOGGERS

PREFERENCES

Using the Preferences screen, you can change the way the software application is started, adapting it to the procedure

that is desired. The configurable options are:

• Do Nothing: Normal behavior of the software. You will see the initial application screen where you may select what

tasks to perform.

• Read Configuration: The application will automatically open the connection screen and then execute reading the

parameters configured in the data logger connected.

• Open Last Configuration: The application will read the last used configuration file and show it in the configuration

screen, without connecting to the logger. If there is no last file, the software will indicate the error and display the

initial screen.

• Download Logging Data: Will open the screen where you can choose what type of download will be performed.

• Open Diagnostics Screen: It will open the connection screen, and read from the connected logger.

On this screen you can also change the language that the software will adopt as default.

PASSWORD PROTECTION

It is possible to protect the access to the equipment by using passwords. You can register a password for configuration

and another one for data download. First one protects the equipment from undesired changes in its configuration and the

second one does not allow data to be downloaded by unauthorized people. In order to remove the need of a password to

access the equipment, simply leave the new passwords fields blank.

This property is available since firmware version 1.40. Data Logger leaves factory with no passwords set.

AEMC® INSTRUMENTS – 99-MAN 100386 v5 66

Page 67

AEMC INSTRUMENTS DATA LOGGERS

COMMAND-LINE OPERATION

The Data Logger Configurator has the ability to be called with “command-line” parameters, which means it can be used

to download and export data by other applications.

It is advisable to create a batch file (.bat) to help organize the desired parameters. Once this batch file is done, it can be

called (executed) from any other software in order to run the desired tasks, which include:

• Download data from the device.

• Get data from a folder where data has already been downloaded to.

• Export downloaded data to a file.

• Export data from the Data Logger data base to a file.

• Create a report with logged data.

Some parameters are sent in the command-line, others are read by the INI files of the Configurator. So, it is important

that you perform the desired action with the Configurator at least once before trying to do it by the command-line. It

assures you that the method you are about to use works properly, and it saves the needed parameters in the INI file as

well, so they can be used later.

Parameter order is important! Do not try to use them in any order but the one shown here.

Parameter examples are shown inside quotation marks (“). Do not use quotation marks in the real file.

BATCH FILE

The batch file is exactly the same of those ancient DOS batch files. Its name must have no more than 8 characters, a dot

(.) and 3 more for its extension (“bat”).

In the file, we separate the parameters in four parts:

1. PART1 – Action type

2. PART2 – Connection mode

3. PART3 – Action parameters

4. PART4 – Export parameters

All parameters are separated by semicolons.

ACTION TYPE

The following actions are allowed:

• “1” to download and export data.

• “2” to export data from the data base.

• “3” to download data without exporting it.

CONNECTION MODE

The connection mode can be:

• “1” to connect by Ethernet/Modbus TCP. In this case, it will read the port and reconnection time from the

Configurator “INI” file, which means that it should have been done before in the Configurator “normal” operation.

This option requires the IP address as an additional parameter. For software version 1.30 and higher, a port

number must be also included and a time out in milliseconds. Example: “1;10.51.10.78;502;3000;”

• “2” to connect by the USB cable. This option requires the COM port as an additional parameter. Example: “2;3;”

• “3” to connect by the RS485/Modbus RTU interface. In this case, it will read the baud rate, parity, stop bits and

timeout from the Configurator “INI” file, which means that it should have been done before in the Configurator

“normal” operation. This option requires the COM port and the Modbus address as additional parameters.

Example: “3;2;7;”

• “4” getting data from a folder. This option should be used when data was already downloaded from the Data

Logger through a USB flash drive, FTP or when reading directly from the device SD card (plugged in your