Page 1

Compact Reader ARE i2 - HF

Installation Guide

for Systems with a

USB interface

Page 2

1 INTRODUCTION ............................................................................................................ 5

2 SYSTEM OVERVIEW .................................................................................................... 5

3 INSTALLATION ............................................................................................................. 5

3.1 Mounting of the housing ............................................................................................................................ 5

3.2 Grounding of the reader ............................................................................................................................ 6

3.2.1 Connecting of the plug ........................................................................................................................ 6

3.3 Connecting of the power supply cable ........................................................................................................ 7

3.3.1 Using the pc connection cable ID 1002237 ......................................................................................... 7

3.3.2 Using a self assembled connecting cable .............................................................................................. 8

3.3.2.1 Assembling of the cable pipe ........................................................................................................ 8

3.3.2.2 Mounting of the cable ................................................................................................................. 9

3.3.2.3 Pin assignment of the SAB connectors ....................................................................................... 10

3.4 Mounting of the external antenna / of the AMP 4 / AMP 8 ...................................................................... 11

4 VISUAL SIGNAL LAMPS ............................................................................................ 12

5 AEG ID INSTRUCTION SET ........................................................................................ 13

5.1 General ................................................................................................................................................... 13

5.1.1 Entering instuctions ......................................................................................................................... 13

5.1.2 Output format .................................................................................................................................. 14

5.1.2.1 Instruction specific output ......................................................................................................... 14

5.1.2.2 Output after changing a parameter ............................................................................................ 14

5.1.2.3 Output at parameter query ......................................................................................................... 14

5.1.3 Blank instuction ............................................................................................................................... 14

5.1.4 Incorrect instruction / error codes ..................................................................................................... 15

5.1.5 Upper and lower case ....................................................................................................................... 16

5.1.6 Linefeed ........................................................................................................................................... 16

5.2 Instructions for the hardware settings...................................................................................................... 17

5.2.1 BD – baudrate .................................................................................................................................. 17

5.2.2 RE – read EEPROM ........................................................................................................................ 17

5.2.3 RF – radio frequency ........................................................................................................................ 17

5.2.4 RST – reset ...................................................................................................................................... 18

5.2.5 WE – write EEPROM ...................................................................................................................... 19

5.2.6 VER – version .................................................................................................................................. 19

5.3 Instructions for reading settings .............................................................................................................. 20

5.3.1 CE – convert error code .................................................................................................................... 20

5.3.2 CID – suppression of ID Codes .......................................................................................................... 20

--------------------------------------------------------------------------------2/48--------------------------------------------------------------------------------

Page 3

5.3.3 CN – suppression of No Reads .......................................................................................................... 21

5.3.4 INIT – initialization ......................................................................................................................... 22

5.3.5 MC – mirror code ............................................................................................................................. 22

5.3.6 TOR – maximum reading time .......................................................................................................... 22

5.3.7 SI – set iso standard ......................................................................................................................... 23

5.3.8 VSAVE – variables save ................................................................................................................... 23

5.3.9 VS – variables show ......................................................................................................................... 23

5.4 General reading instructions .................................................................................................................... 25

5.4.1 GA – get active ................................................................................................................................. 25

5.4.2 GT – get tag ..................................................................................................................................... 25

5.4.3 HD – halt detected code .................................................................................................................... 26

5.4.4 MD – mode of operation ................................................................................................................... 26

5.4.5 RD – read page ................................................................................................................................ 26

5.4.6 RDM – read page manual ................................................................................................................. 27

5.4.7 WD – write page .............................................................................................................................. 28

5.4.8 WDM – write page manual ............................................................................................................... 29

5.5 Mifare instructions .................................................................................................................................. 31

5.5.1 AC – anticollision ............................................................................................................................. 31

5.5.2 AC2 – anticollision ........................................................................................................................... 31

5.5.3 KM – key mode ................................................................................................................................ 31

5.5.4 KT – key type ................................................................................................................................... 31

5.5.5 LOG – transponder log in .................................................................................................................. 32

5.5.6 PBU – purse backup ......................................................................................................................... 32

5.5.7 PDC – purse decrement .................................................................................................................... 33

5.5.8 PIC – purse increment ...................................................................................................................... 34

5.5.9 PIV – purse init value ....................................................................................................................... 35

5.5.10 PRV – purse read value .................................................................................................................... 35

5.5.11 RQ – request .................................................................................................................................... 36

5.5.12 SE – select ....................................................................................................................................... 36

5.5.13 SE2 – select level 2 .......................................................................................................................... 36

5.5.14 WK – write key ................................................................................................................................ 37

5.6 ISO 15693 instructions............................................................................................................................ 38

5.6.1 AFI – application family identifier .................................................................................................... 38

5.6.2 BS – block size ................................................................................................................................. 38

5.6.3 GMS – get multiple block security .................................................................................................... 38

5.6.4 GS – get system information ............................................................................................................. 39

5.6.5 LA – lock AFI .................................................................................................................................. 39

5.6.6 LD – lock data ................................................................................................................................. 39

5.6.7 LDS – lock DSFID ........................................................................................................................... 40

5.6.8 RTR – reset to ready ........................................................................................................................ 40

5.6.9 WA – write AFI ............................................................................................................................... 40

5.6.10 WDS – write DSFID ......................................................................................................................... 40

6 OPERATING MODES OF THE READER ...................................................................... 42

6.1 MD 2 - Triggered by an Software Command ............................................................................................ 42

6.2 MD 0 - Continuous Reading ..................................................................................................................... 43

7 STARTUP AND TESTING THE READER .................................................................... 44

--------------------------------------------------------------------------------3/48--------------------------------------------------------------------------------

Page 4

8 INSTRUCTIONS .......................................................................................................... 45

9 FCC INFORMATION .................................................................................................... 46

10 HOTLINE .................................................................................................................. 47

11 REVISIONS .............................................................................................................. 48

--------------------------------------------------------------------------------4/48--------------------------------------------------------------------------------

Page 5

1 Introduction

This document will describe the components of the Compact Reader System ARE i2 / RS 232 and the

procedure how to do the first set up of the reader.

The main features of the reader are listed below:

• integrated USB Interface with tunable baudrate

• the allowed supply voltage is 9 to 30V DC

• low power consumption of reader < 1.2 Watt

• high reliability for reading and writing within an industrial environment

• compact housing of the reader with multiple ways for mounting

• the cabling concept of the reader is optimised to service demands

• the protection class of the housing is IP65

• there is a set of external antennas available to meet special application demands (X-tended version)

2 System overview

The ARE i2 HF is only available with external antenna.

3 Installation

To get the specified reading performance it is necessary to do the installation carefully step by step as it

is described in the following Chapters. All the work must be done by well educated people.

3.1 Mounting of the housing

The reader can be mounted to any other mechanic construction. The distance between reader and transponder has to tuned

--------------------------------------------------------------------------------5/48--------------------------------------------------------------------------------

Page 6

It is recommended to protect the housing against heavy mechanical interactions and drippy fluids.

Attention!

The side of the housing showing the antenna symbol must not be brought next to a metal surface. This

could lead to a significant change of the properties of the antenna circuit, which in turn reduces the

reading range considerably.

With the help of the plastic bars, the reader can mounted or screwed on to the most fastening elements

without open the housing of the device.

3.2 Grounding of the reader

To get reliable reading results, the reader must be grounded. The connector is placed at the side of the

housing (6.35 mm flat contact).

To avoid EMV-problems, the cable to ground ought to be very short with low impedance.

Attention!

The topology of the ground wires must be done in the right way (according state of art).

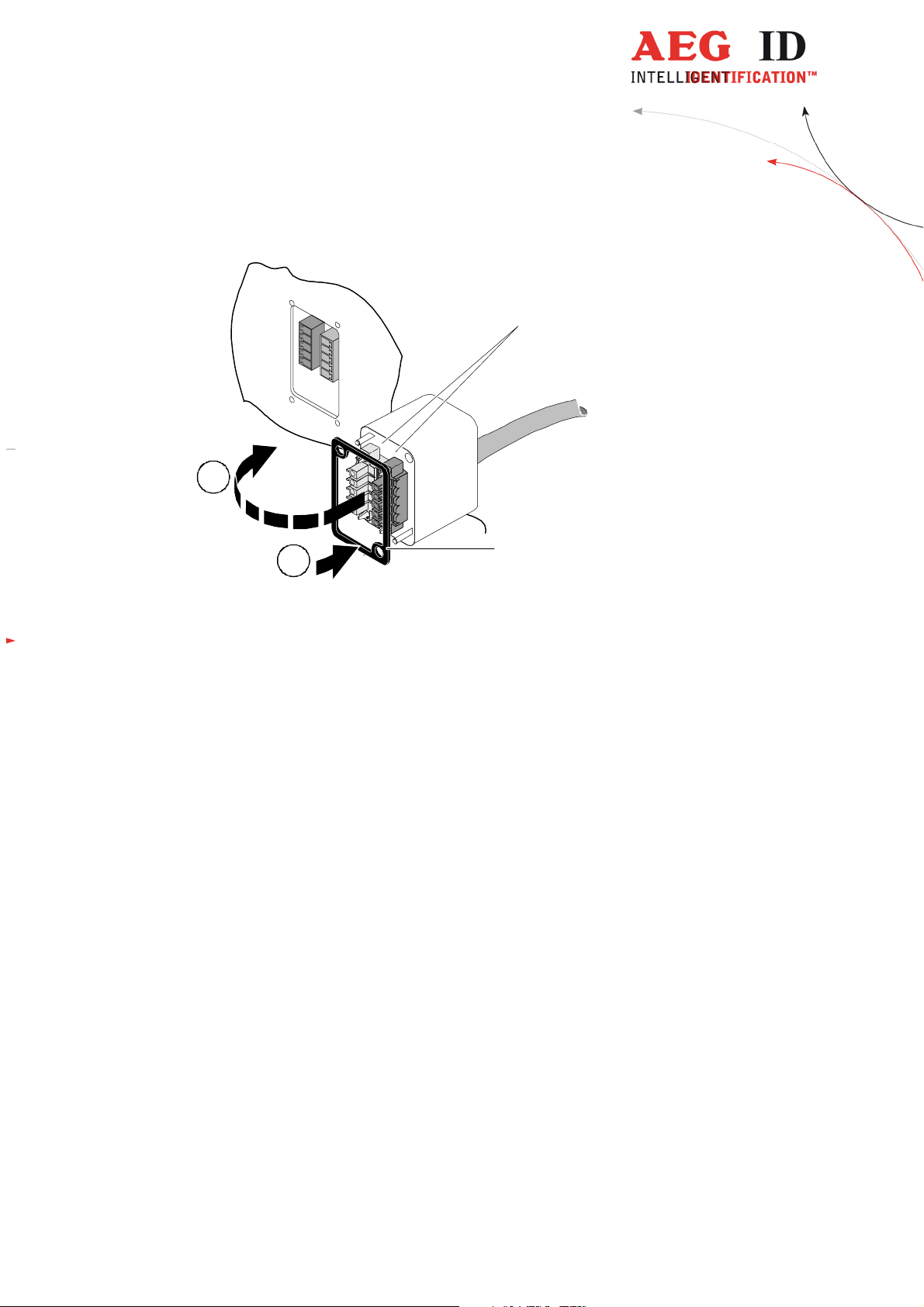

3.2.1 Connecting of the plug

Attention!

Be sure that the grounding of the reader is well done and the power supply is not connected(chapter 3.2).

Otherwise the electronic may be destroyed by electrostatic discharge (ESD).

--------------------------------------------------------------------------------6/48--------------------------------------------------------------------------------

Page 7

1

B

A

Figure 1: Connecting of the plug

Put on the sealing 2 to the SAB Cab (A).

Plug in the SAB Cab to the connector at the bottom of the reader device (B).

There is only one way to plug in the SAB Cab to the connector rim of the reader.

Fasten the SAB Cab with the help of the screws.

To meet the protection class of IP 65, it’s necessary to apply a turning moment of 0.5 Nm to the screws.

2

3.3 Connecting of the power supply cable

The reader has to be supplied with 9..30V DC. The maximum output power of the power supply has to be

1.2 Watt. Be sure that you use the right polarity.

3.3.1 Using the pc connection cable ID 1002237

Power supply: brown = + 9 .. 30 Volt

white = ground

--------------------------------------------------------------------------------7/48--------------------------------------------------------------------------------

Page 8

3.3.2 Using a self assembled connecting cable

Using the following SAB cabs you can assemble your own connecting cable.

ID 70211 SAB cab with 1 PG9 cable pipe

ID 70215 SAB cab with 2 pre-assembled cable pipes

ID 70219 SAB cab without any cable pipe

ID 1002237 pc connection cable for ARE i2- USB

ID 1002373 pc connection cable for ARE i2- USB with power supply 12V

You can use any shielded five-pole cable. The allowed diameter of the cable must be in the range from

∅3,5 to ∅8mm. For this case, IP 65 is reached.

Attention!

The minimum voltage at the readers input mustn’t be lower then 9V.

The maximum length of the serial USB cable is 5m.

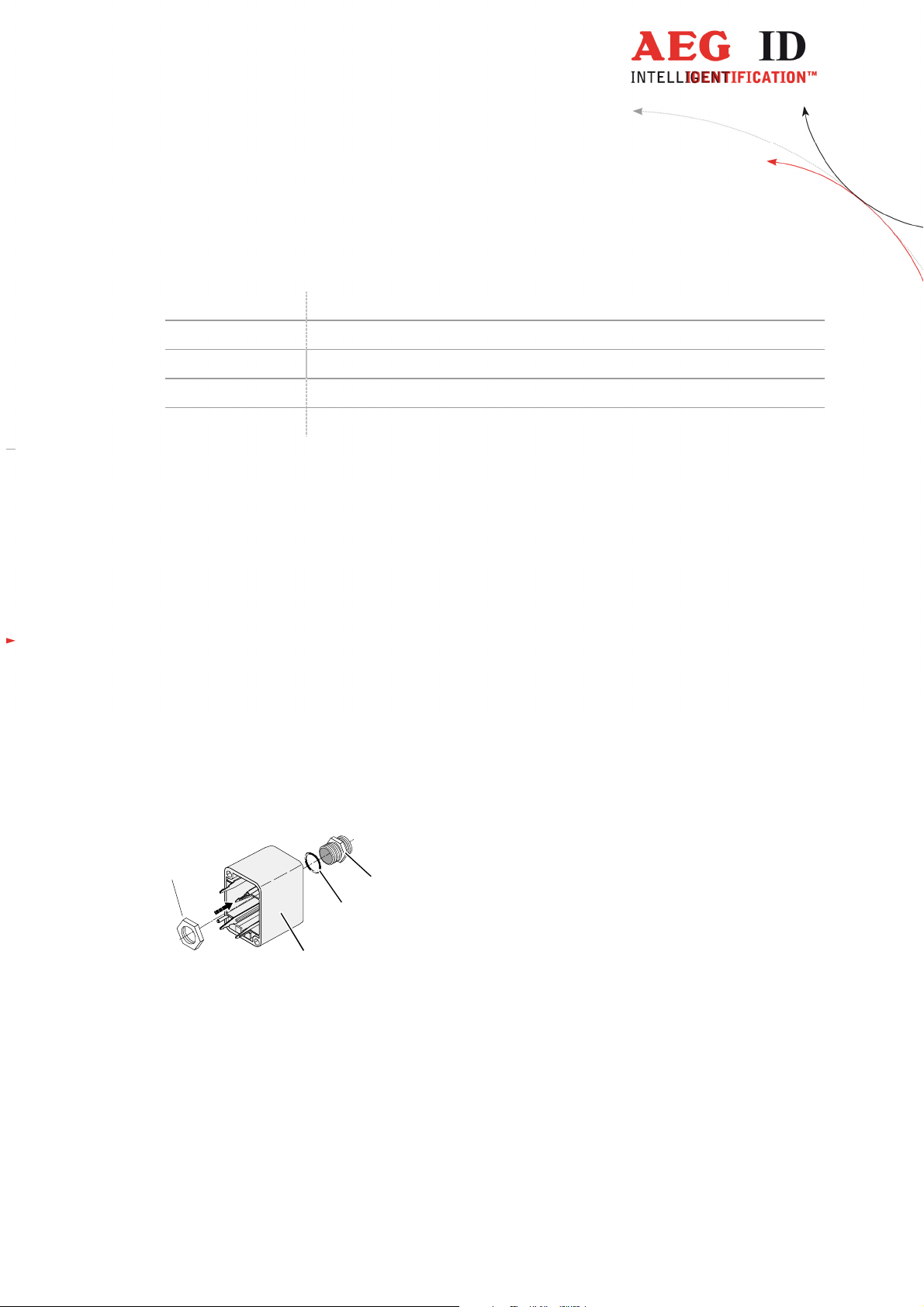

3.3.2.1 Assembling of the cable pipe

• Breakthrough the prepared areas at the surface of the SAB Cabs. There are two prepared areas seen

at the SAB Cab: central and at one side of the cab.

• The o-ring (3) has to be assembled proberly to the cable pipe (4) to ensure the protection class IP

65.

2

1

Figure 2: Assembling of the cable pipe

4

3

• Bring the nut (2) of the cable pipe inside of the SAB Cab (1).

• To fasten the nut please use the right tool (17mm).

--------------------------------------------------------------------------------8/48--------------------------------------------------------------------------------

Page 9

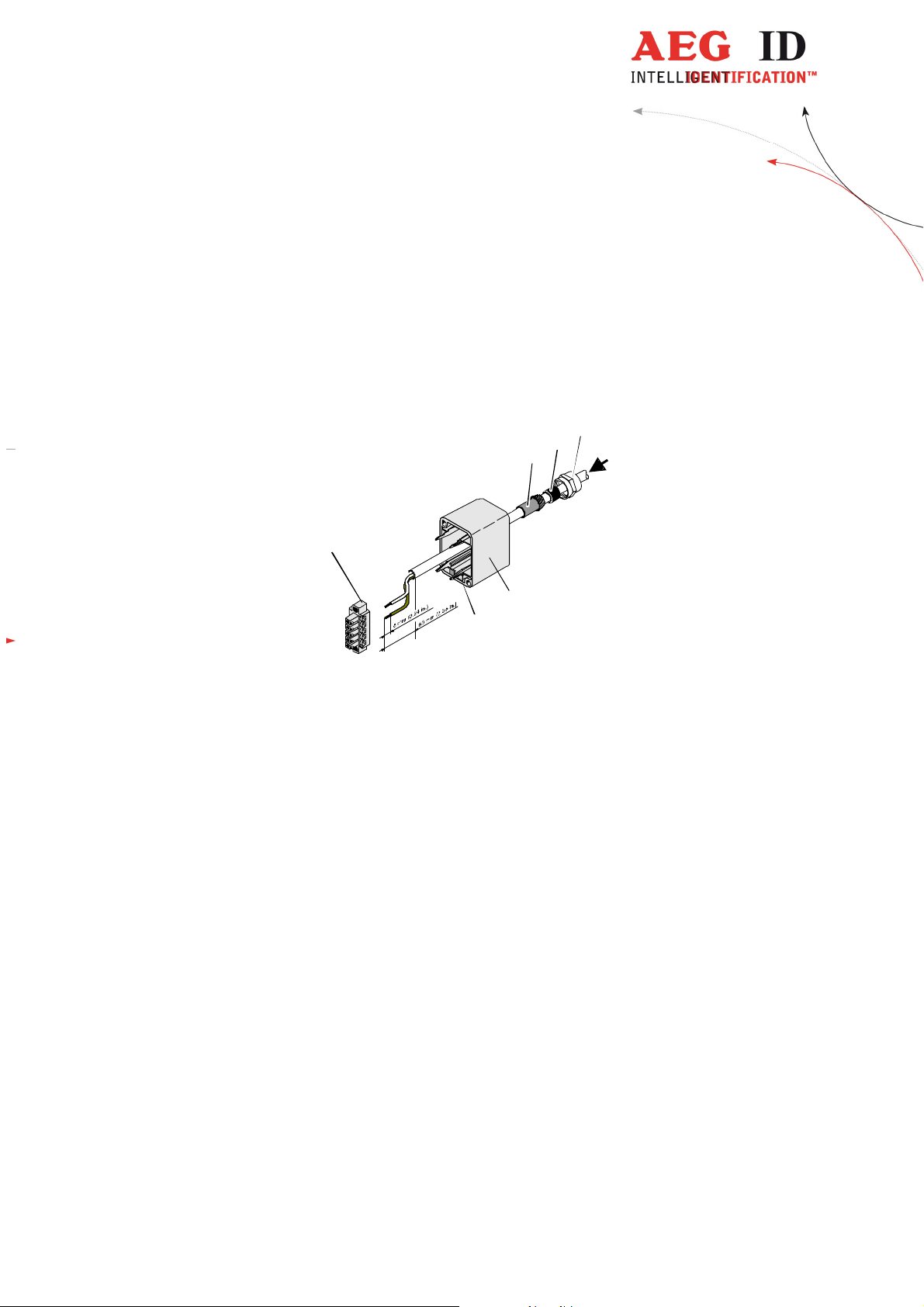

3.3.2.2 Mounting of the cable

The cable must be mounted in following steps:

• Remove all inner parts from the cable pipe at the SAB Cab (1) ( nut (5), cable fastener (3), pipe(4))

(see Figure 3)

• Put all the removed parts (nut (5), cable fastener (3), pipe (4),) and the cable pipe of the SAB Cab

as well (1 to 4) to the cable.

3

5

4

Cable

6

1

7

Figure 3: Mounting for the cable

• Remove the outer isolation of the cable at a length of 6cm .

• Remove the isolation of the wires at a length of 6mm and stick a covering hull to the litz wire.

• Put the cable to the cable pipe. The length of the cable coming out the SAB Cab must long enough to

do all further installation steps in an easy way.

• Stick the pipe (4) into the cable fastener (3).

• Stick the cable fastener (3) into the cable pipe.

• Connect the cables into the right places of the MINI-COMBICON-Connectors (6).

• The pin assignment is shown in the figure below.

• Put the MINI-COMBICON-Connectors into the SAB cab. Look after the color coding.

--------------------------------------------------------------------------------9/48--------------------------------------------------------------------------------

Page 10

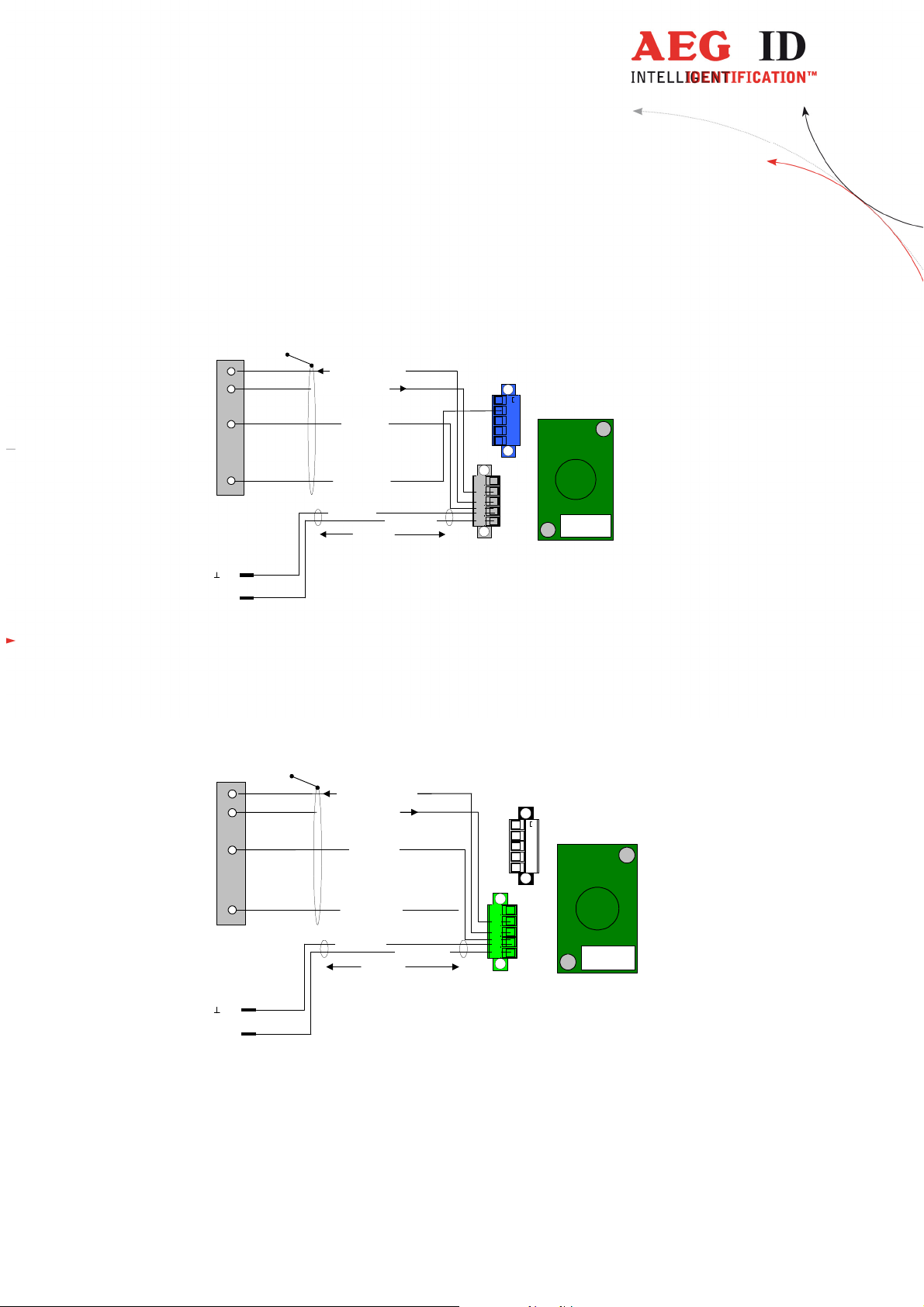

3.3.2.3 Pin assignment of the SAB connectors

USB Connector

Type: USB A

D+ - green

D- - white

GND -

black

VBus - red

GND - white

V+DC - brown

3 m

Power

V+

DC

Figure 4: Pin assignment of the SAB connectors

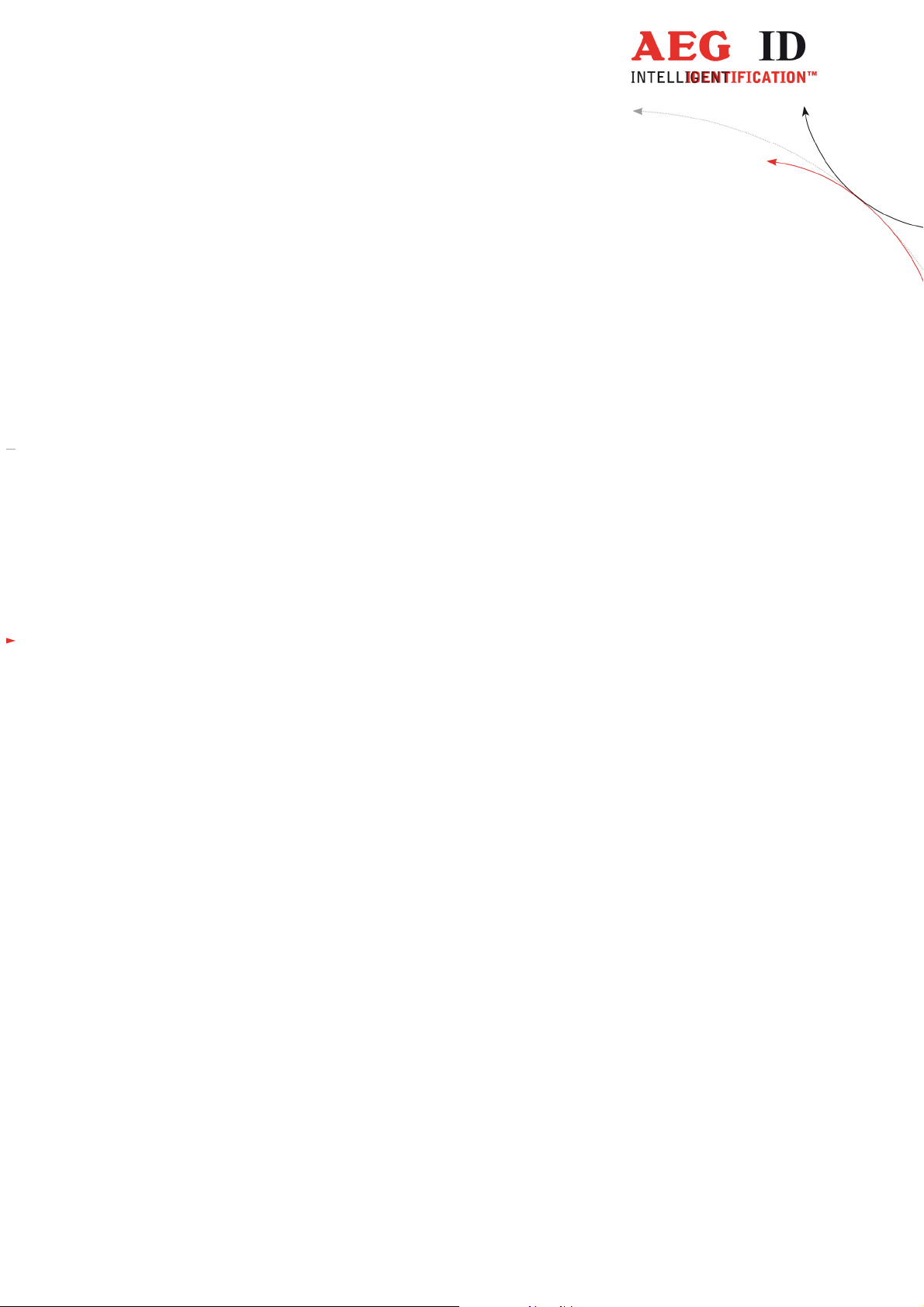

USB Connector

Typ: USB A

D+ - green

D- - white

GND - black

blue

+U

S

-U

S

L

U

L

G

F

J

H

K

grey

+U

S1

-U

S1

+U

S2

-U

S2

black

ID

1002237

VBus - red

GND - white

V+DC - brown

3 m

Power

V+

DC

B

A

D

C

E

green

ID

1002237

Figure 5: Pin assignment of the SAB connectors

--------------------------------------------------------------------------------10/48--------------------------------------------------------------------------------

Page 11

3.4 Mounting of the external antenna / of the AMP 4 / AMP 8

If you have an i2 with external antenna the connector is on the topside of the reading device. You just

have to plug the antenna into the connector and bold it on. Alternative you can connect an AMP 4 / AMP

8 with this connector, too.

You may not connect or deconnect an antenna or AMP 4 / AMP 8 while the reader is running. It can

cause, that the reader hangs up.

--------------------------------------------------------------------------------11/48--------------------------------------------------------------------------------

Page 12

4 Visual signal lamps

To show the operational state or results there are 5 LED at the side of the housing.

BFH

ID

L1: twinkles, if the processor works.

ARE i2

L1

L2

L3

L4

L5

L2: twinkles one time after successful instruction

L3: twinkles one time after bad instruction

L4: lit, if the reader receives data’s at the serial data port (Rx)

L5: lit, if the reader sends data’s at the serial data port (Tx)

Figure 6: Visual signal lamps

--------------------------------------------------------------------------------12/48--------------------------------------------------------------------------------

Page 13

5 AEG ID instruction set

5.1 General

The command set described below defines the transfer of data on the serial interface.

The commands consist of a command code and optionally of a parameter value. Commands are terminated by the control character <CR> (0Dh). The control character serves as command line terminator.

Command codes and parameters,including all letters and numerical values, are principally transmitted as a sequence of ASCII characters (the value 255 (decimal) consequently as 32H, 35H, 35H; the

command RST as 52H, 53H, 54H).

All numbers (e.g. sectors, blocks) are in the hexadecimal format (see chapter 9).

With the command CS you can change to the alternative instruction set. If the reader is set to alternative instruction set, you can change back to the AEG ID instruction set via the command AEG (see

chapter 5.3.3).

5.1.1 Entering instuctions

The protocol format is as follows

Command <SP> parameter <CR>

The space character <SP> separates commands from parameters and the <CR> character acts as

command line terminator.

For commands without parameter values (e.g. GT ) the <SP> character and parameter values are

omitted. The command line is as short as this:

Command <CR>

--------------------------------------------------------------------------------13/48--------------------------------------------------------------------------------

Page 14

5.1.2 Output format

Generally, every input terminated by <CR> is acknowledged by the reader. The following response

protocols are different:

5.1.2.1 Instruction specific output

After entering a valid command without a parameter value, the system answers by sending the parameter value and <CR>. Example:

Command: GT <CR>

Output: Transponder number or No Read <CR>

5.1.2.2 Output after changing a parameter

After entering a valid command together with a parameter value, the system answers by sending the

parameter value and <CR>. Example:

Command: MD <SP> 2 <CR>

Output: 2 <CR>

After entering an invalid parameter value, the system answers with the corresponding error code. Error

message:

Command: MD <SP> 4 <CR>

Output: NAK <SP> #02 <CR>

5.1.2.3 Output at parameter query

Parameter settings can be queried by sending the command without adding a parameter value. Example:

Command: MD <CR>

Output: 2 <CR>

5.1.3 Blank instuction

If a single <CR> is input, the reader answers with a single <CR>. Example:

--------------------------------------------------------------------------------14/48--------------------------------------------------------------------------------

Page 15

Command: <CR>

Output: <CR>

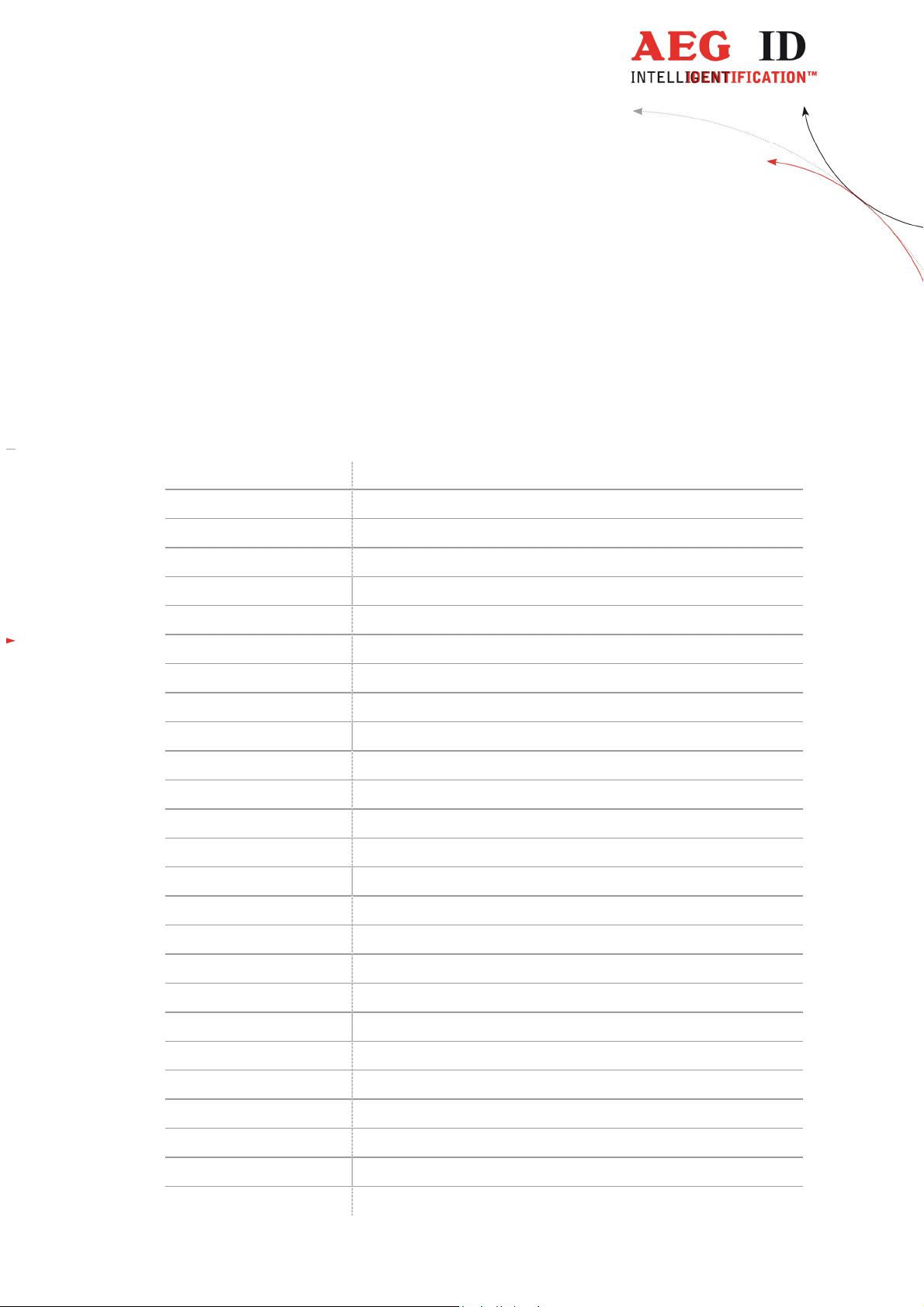

5.1.4 Incorrect instruction / error codes

If a command is not entered correctly, the reader sends one of the following error codes:

ERROR CODE MEANING

NAK #00 <CR> unknown command

NAK #02 <CR> wrong parameter

NAK #03 <CR> EEPROM error

NAK #04 <CR> wrong transponder type/command not available

NAK #05 <CR> buffer overflow

NAK #06 <CR> not logged in

NAK #08 <CR> wrong password

NAK #10 <CR> antenna failure

NAK #11 <CR> anticollision error level 1

NAK #12 <CR> anticollision error level 2

NAK #13 <CR> select error level 1

NAK #14 <CR> select error level 2

NAK #15 <CR> transceiver IC error

NAK #16 <CR> not acknowlegde

NAK #17 <CR> no valid value block

NAK #18 <CR> EEPROM full

NAK #19 <CR> code already saved in EEPROM

NAK #20 <CR> Decoder communication error

NAK #21 <CR> wrong standard

NAK #22 <CR> wrong transpondercode length

NAK #23 <CR> transpondercode length and transponder don’t match

NAK #24 <CR> data is not multiple of the block size

NAK #25 <CR> data length shorter than block size

NAK #26 <CR> no communication to AMP

NAK #40 <CR> ISO 15693 error 01h: command not supported

--------------------------------------------------------------------------------15/48--------------------------------------------------------------------------------

Page 16

NAK #41 <CR> ISO 15693 error 02h: command not recognized

NAK #42 <CR> ISO 15693 error 03h: option not supported

NAK #43 <CR> ISO 15693 error 0Fh: unknown error (default)

NAK #44 <CR> ISO 15693 error 10h: block does not exist

NAK #45 <CR> ISO 15693 error 11h: block already locked

NAK #46 <CR> ISO 15693 error 12h: block cannot be changed (locked)

NAK #47 <CR> ISO 15693 error 13h: not successfully programmed

NAK #48 <CR> ISO 15693 error 14h: not successfully locked

NAK #49 <CR> ISO 15693 error A0h-DFh: custom error codes

NAK #50 <CR> all other ISO 15693 errors: RFU

XXXXXXXX <CR> no read

ACK no error/acknowledge

5.1.5 Upper and lower case

The instruction set isn’t case-sensitiv.

5.1.6 Linefeed

The reader does never send a linefeed. If you use a terminal program it can add the linefeed. You have to

choose the option “displace CR with CR LF”.

--------------------------------------------------------------------------------16/48--------------------------------------------------------------------------------

Page 17

5.2 Instructions for the hardware settings

5.2.1 BD – baudrate

The command BD enables the change of the baud rate. The settings are directly effective.

Input format: BD <SP> parameter <CR>

Output (example): 2 <CR>

Parameter:

PARAMETER FUNCTION

0 4800 baud

1 9600 baud

2 19200 baud

3 38400 baud

4 57600 baud

5 115200 baud

5.2.2 RE – read EEPROM

You can read out the internal EEPROM with the RE command.

Input format: RE <SP> parameter <CR>

Output (example): FF <CR>

Parameter:

PARAMETER FUNCTION

0000h..079Fh address

5.2.3 RF – radio frequency

With the command RF you can switch the antenna field on and off.

Input format: RF <SP> parameter <CR>

--------------------------------------------------------------------------------17/48--------------------------------------------------------------------------------

Page 18

Output (example): 1 <CR>

Parameter:

PARAMETER FUNCTION

0 off

1 on

5.2.4 RST – reset

With the command RST the reader does a warmstart and loads the saved settings from the internal

EEPROM. The antenna field is off after the reset.

Input format: RST <CR>

Output (example): ACK <CR>

--------------------------------------------------------------------------------18/48--------------------------------------------------------------------------------

Page 19

5.2.5 WE – write EEPROM

Using the command WE you can write one byte to the internal EEPROM.

Input format: WE <SP> parameter 1 <SP> parameter 2 <CR>

Output (example): FF <CR>

Parameter:

PARAMETER 1 FUNCTION

0005h..079Fh address

PARAMETER 2 FUNCTION

00h..FFh data

5.2.6 VER – version

With the command VER the reader sends the actual firmware version.

Input format: VER <CR>

Output (example): AEG ID V1.22 <CR>

--------------------------------------------------------------------------------19/48--------------------------------------------------------------------------------

Page 20

5.3 Instructions for reading settings

5.3.1 CE – convert error code

With CE=1 the reader sends no error codes, except the no read error, during the md0 mode or the

commands Get Tag. The leds are not influenced by this command. This command has only effect in

the ISO 14443A standard.

This command is not available in profibus communication and can not be saved with the VSAVE

command.

Input format: CE <SP> parameter <CR>

Output (example): 0 <CR>

Parameter:

PARAMETER FUNCTION

0 No suppression

1 Suppression of error codes

5.3.2 CID – suppression of ID Codes

In the MD0 mode with CID=1 only the first of in succession identical transponder numbers is output

on the serial interface. The possibly following identical transponder numbers are suppressed, as long

as no new valid transponder number is received, processed and output. The get tag command is not

influenced by this command. NoReads do not influence the data filtering.

This command is not available in profibus communication and can not be saved with the VSAVE

command.

Input format: CID <SP> parameter <CR>

Output (example): 0 <CR>

Parameter:

PARAMETER FUNCTION

0 No suppression

1 Suppression of equal transponder numbers

--------------------------------------------------------------------------------20/48--------------------------------------------------------------------------------

Page 21

Example: A, B, C are different transponder codes, N is NoRead error code:

Sequence of reading cycles Output sequence

after filtering with

CN=0 und CID=1

N, N, ......,N, A, A, A, ....A, N,N,

.........

N. N, N, A, A, A, N, A, A, B, A,

C, C, C, .......

N, N, ......,N, A, N,

N, .......

N. N, N, A, N, B,

A, C, .....

The settings are directly effective.

Note: The internal reference number is deleted in the following conditions:

• after a cold start

• after a warm start (command line RST <CR>)

• after entering the command line CID <SP> 1 <CR>

This causes that the next transponder code is output definitely.

Output sequence

after filtering with

CN=1 und CID=1

A

A, B, A, C

Note: The filter function CID picks up the results of the complete reading cycles, while the parameter

NID proceeds from the results of single readings! The filter function CID has effect on the serial interface only.

5.3.3 CN – suppression of No Reads

Through the setting CN=1 the NoRead results after a get tag command or in MD0 mode are suppressed on the serial interface.

This command is not available in profibus communication and can not be saved with the VSAVE

command.

Input format: CN <SP> parameter <CR>

Output (example): 0 <CR>

Parameter:

--------------------------------------------------------------------------------21/48--------------------------------------------------------------------------------

Page 22

PARAMETER FUNCTION

0 No suppression

1 Suppression of equal transponder numbers

5.3.4 INIT – initialization

With the command INIT all paramters of this command set are set to the default values. After that

you can save the settings with the command VSAVE.

Input format: INIT <CR>

Output (example): ACK <CR>

5.3.5 MC – mirror code

With this command you can change the output order of the bytes from a transpondercode.

Input format: MC <CR>

Output (example): 0 <CR>

5.3.6 TOR – maximum reading time

Timeout time for the reader. TOR is used in operation mode 2 as maximum gating time for a reading

process. The length of the maximum gating time results from the equation gating_time = TOR * TB.

The time constant TB (time base) has always the default value 100ms.

Input format: TOR <SP> parameter <CR>

Output (example): 05 <CR>

Parameter:

PARAMETER FUNCTION

00h limits the reading process duration of exactly one reading cycle

01h..FFh limits the reading process duration to maximum 1..256 times

TB

--------------------------------------------------------------------------------22/48--------------------------------------------------------------------------------

Page 23

5.3.7 SI – set iso standard

With this command you can switch the iso standard of the reader.

Input format: SI <SP> parameter <CR>

Output (example): 0 <CR>

Parameter:

PARAMETER FUNCTION

0 ISO 14443A

1 ISO 15693

5.3.8 VSAVE – variables save

With the command VSAVE the following parameters are saved to the internal EEPROM:

AFI2, KM1, KT1, MD, SI, TOR

Input format: VSAVE <CR>

Output (example): ACK <CR>

1

just available in the ISO 14443A standard

2

just available in the ISO 15693 standard

5.3.9 VS – variables show

With the command VS the reader shows the settings of the following parameters:

AFI2, KM1, KT1, MD, SI, TOR

Input format: VS <CR>

Output (example): ACT <SP> 14 <CR>

AM <SP> 0 <SP>

…

--------------------------------------------------------------------------------23/48--------------------------------------------------------------------------------

Page 24

Note: The function VS shows just the settings that are used in the actual ISO standard.

1

just available in the ISO 14443A standard

2

just available in the ISO 15693 standard

--------------------------------------------------------------------------------24/48--------------------------------------------------------------------------------

Page 25

5.4 General reading instructions

5.4.1 GA – get active

The command GA causes one reading cycle. There are different cycles for different transpondertypes.

This command is only available in the ISO 14443A standard.

Mifare standard 1K/4K: request (REQA)

anticollision

select

Mifare Ultralight/Desfire request (REQA)

anticollision level 1

select 1

anticollision level 2

select 2

The reader answers the UID of an active (non halt) transponder. The length of the UID can be between 4 and 7 bytes.

Input format: GA <CR>

Output (example): 625E562A <CR>

5.4.2 GT – get tag

With the command GT you select a transponder. The command GT causes one reading cycle. There

are different cycles for different transpondertypes.

Mifare standard 1K/4K: request (WUPA)

anticollision

select

Mifare Ultralight/Desfire: request (WUPA)

anticollision level 1

select 1

--------------------------------------------------------------------------------25/48--------------------------------------------------------------------------------

Page 26

anticollision level 2

select 2

ISO 15693: inventory

The reader answers the UID of a transponder. The length of the UID can be between 4 and 8 bytes.

Input format: GT <CR>

Output (example): 625E562A <CR>

5.4.3 HD – halt detected code

The command HD mutes the last selected transponder.

Input format: HD <CR>

Output (example): ACK <CR>

5.4.4 MD – mode of operation

There a two modes of operation available. It is possible, that the reader reads constantly or triggered by

an instruction.

Input format: MD <SP> parameter <CR>

Output (example): 2 <CR>

Parameter:

PARAMETER FUNCTION

0 constant reading mode

2 single reading mode

5.4.5 RD – read page

With the command RD you can read out a page of the transponder. The command executes internally the

commands get tag, if using mifare 1K/4K log in (with the key attuned to KM) and the reading command.

Input format mifare 1K/4K: RD <SP> parameter 1 <SP> parameter 2 <CR>

Input format ultralight: RD <SP> parameter 2 <CR>

--------------------------------------------------------------------------------26/48--------------------------------------------------------------------------------

Page 27

Input format ISO 15693 one block: RD <SP> parameter 2 <CR>

Input format ISO 15693 multiple blocks: RD <SP> parameter 2 <SP> parameter 3 <CR>

Output: parameter 4 <CR>

Parameters:

PARAMETER 1 FUNCTION

1 or 2 characters sector

PARAMETER 2 FUNCTION

1 or 2 characters block/start block

PARAMETER 3 FUNCTION

1 or 2 characters end block

PARAMETER 4 FUNCTION

32 characters data (mifare 1K/4K)

8 characters data (ultralight)

up to 64 charac-

data (ISO 15693)

ters

5.4.6 RDM – read page manual

With the command RDM you can read out a page of the transponder. The reading command is executed

single. You have to do a get tag first. If you are using a mifare standard 1K/4K you have to log in, too.

Input format mifare 1K/4K: RD <SP> parameter 1 <SP> parameter 2 <CR>

Input format ultralight: RD <SP> parameter 2 <CR>

Input format ISO 15693: RD <SP> parameter 2 <CR>

Input format ISO 15693 multiple blocks: RD <SP> parameter 2 <SP> parameter 3 <CR>

Output: parameter 4 <CR>

--------------------------------------------------------------------------------27/48--------------------------------------------------------------------------------

Page 28

Parameters:

PARAMETER 1 FUNCTION

1 or 2 characters sector

PARAMETER 2 FUNCTION

1 or 2 characters block/start block

PARAMETER 3 FUNCTION

1 or 2 characters end block

PARAMETER 4 FUNCTION

32 characters data (mifare 1K/4K)

8 characters data (ultralight)

up to 64 charac-

data (ISO 15693)

ters

5.4.7 WD – write page

With the command WD you write one page to the transponder. The command executes internally the

commands get tag, log in (with the key attuned to KM) and the writing command.

Input format mifare 1K/4K: WD <SP> parameter 1 <SP> parameter 2 <SP> parameter 3

<CR>

Input format ultralight: WD <SP> parameter 2 <SP> parameter 3 <CR>

Input format ISO 15693: WD <SP> parameter 2 <SP> parameter 3 <CR>

Output (example): ACK <CR>

Parameters:

PARAMETER 1 FUNCTION

1 or 2 characters sector

--------------------------------------------------------------------------------28/48--------------------------------------------------------------------------------

Page 29

PARAMETER 2 FUNCTION

1 or 2 character block

PARAMETER 3 FUNCTION

32 characters mifare 1K/4K

8 characters ultralight

up to 32 charac-

ISO 15693

ters

Note: The ISO 15693 regulates just the maximum length of one block. With the write instruction you

can write multiple blocks at once. The datalenght has to be at least the block size or a multiple of the

block size.

5.4.8 WDM – write page manual

With the command WDM you write one page to the transponder. The writing command is executed

alone. You have to select the transponder first. If you are using a mifare standard 1K/4K you have to log

in, too.

Input format mifare 1K/4K: WD <SP> parameter 1 <SP> parameter 2 <SP> parameter 3

<CR>

Input format ultralight: WD <SP> parameter 2 <SP> parameter 3 <CR>

Output (example): ACK <CR>

Parameters:

PARAMETER 1 FUNCTION

1 or 2 characters sector

PARAMETER 2 FUNCTION

1 or 2 characters block

--------------------------------------------------------------------------------29/48--------------------------------------------------------------------------------

Page 30

PARAMETER 3 FUNCTION

32 characters mifare 1K/4K

8 characters ultralight

up to 32 charac-

ISO 15693

ters

Note: The ISO 15693 regulates just the maximum length of one block. With the write instruction you

can write multiple blocks at once. The datalenght has to be at least the block size or a multiple of the

block size.

--------------------------------------------------------------------------------30/48--------------------------------------------------------------------------------

Page 31

5.5 Mifare instructions

5.5.1 AC – anticollision

The command AC answers with the UID of the transponder, that will be selected with the next select

command. For ultralight and DESFire transponders it is the anticollision level 1 command.

Input format: AC <CR>

Output (example): 595B1B80 <CR>

5.5.2 AC2 – anticollision

With the command AC2 the reader executes the anticollision level 2 command.

Input format: AC2 <CR>

Output (example): 595B1B80 <CR>

5.5.3 KM – key mode

With the command KM you switch the key that is used by the commands RD and WD. It is possible to

use the default key or one of the keys saved with the command WK.

Input format: KM <SP> parameter <CR>

Output (example): parameter <CR>

PARAMETER FUNCTION

0 use default key

(FFFFFFFFFFFF)

1..8 use saved key 1 to 8

5.5.4 KT – key type

With this command you switch if the key that is used with the commands RD and WD is type A or B.

Input format: KT <SP> parameter <CR>

Output (example): parameter <CR>

--------------------------------------------------------------------------------31/48--------------------------------------------------------------------------------

Page 32

PARAMETER FUNCTION

A key type A

B key type B

5.5.5 LOG – transponder log in

The command LOG is only valid with mifare standard 1K/4K transponders. The log in is necessary to

read or write a page:

Input format: LOG <SP> parameter 1 <SP> parameter 2 <SP> parameter 3 <CR>

Input (example): LOG <SP> A <SP> 1 <SP> FFFFFFFFFFFF <CR>

Output (example): ACK <CR>

Parameters:

PARAMETER 1 FUNCTION

A or B type of the key

PARAMETER 2 FUNCTION

1 or 2 characters sector

PARAMETER 3 FUNCTION

12 characters key

5.5.6 PBU – purse backup

With this command it is possible to copy a purse value to an other block of the same sector. This command is only valid with mifare standard 1K/4K. You have to log in first.

Input format: PBU <SP> parameter 1 <SP> parameter 2 <SP> parameter 3 <CR>

Output: parameter 4 <SP> parameter 5 <CR>

Parameters:

PARAMETER 1 FUNCTION

1 or 2 characters sector

--------------------------------------------------------------------------------32/48--------------------------------------------------------------------------------

Page 33

PARAMETER 2 FUNCTION

1 character source block

PARAMETER 3 FUNCTION

1 character target block

PARAMETER 4 FUNCTION

8 characters new purse value

PARAMETER 5 FUNCTION

2 character optional address

5.5.7 PDC – purse decrement

With this command you can decrement a value. This command is only valid with mifare standard 1K/4K.

You have to log in first.

Input format: PDC <SP> parameter 1 <SP> parameter 2 <SP> parameter 3 <CR>

Output: parameter 4 <SP> parameter 5 <CR>

Parameters:

PARAMETER 1 FUNCTION

1 or 2 characters sector

PARAMETER 2 FUNCTION

1 character block

PARAMETER 3 FUNCTION

8 characters value change

--------------------------------------------------------------------------------33/48--------------------------------------------------------------------------------

Page 34

PARAMETER 4 FUNCTION

8 characters new purse value

PARAMETER 5 FUNCTION

2 character optional address

5.5.8 PIC – purse increment

With this command you can increment a value. This command is only valid with mifare standard 1K/4K.

You have to log in first.

Input format: PDC <SP> parameter 1 <SP> parameter 2 <SP> parameter 3 <CR>

Output: parameter 4 <SP> parameter 5 <CR>

Parameters:

PARAMETER 1 FUNCTION

1 or 2 characters sector

PARAMETER 2 FUNCTION

1 character block

PARAMETER 3 FUNCTION

8 characters value change

PARAMETER 4 FUNCTION

8 characters new purse value

PARAMETER 5 FUNCTION

2 character optional address

--------------------------------------------------------------------------------34/48--------------------------------------------------------------------------------

Page 35

5.5.9 PIV – purse init value

With this command you can initialize a value. This command is only valid with mifare standard 1K/4K.

You have to log in first.

Input format: PIV <SP> parameter 1 <SP> parameter 2 <SP> parameter 3 <SP> param-

eter 4 <CR>

Output: parameter 3 <SP> parameter 4 <CR>

Parameters:

PARAMETER 1 FUNCTION

1 or 2 characters sector

PARAMETER 2 FUNCTION

1 character block

PARAMETER 3 FUNCTION

8 characters value

PARAMETER 4 FUNCTION

2 characters optional address

5.5.10 PRV – purse read value

With this command you can read out a value. This command is only valid with mifare standard 1K/4K.

You have to log in first.

Input format: PRV <SP> parameter 1 <SP> parameter 2 <CR>

Output: parameter 3 <SP> parameter 4 <CR>

Parameters:

PARAMETER 1 FUNCTION

1 or 2 characters sector

--------------------------------------------------------------------------------35/48--------------------------------------------------------------------------------

Page 36

PARAMETER 2 FUNCTION

1 character block

PARAMETER 3 FUNCTION

8 characters value

PARAMETER 4 FUNCTION

2 characters optional address

5.5.11 RQ – request

The RQ command answers the type of the detected transponder.

Input format: RQ <SP> parameter <CR>

Output (example): ACK <CR>

Parameters:

PARAMETER FUNCTION

0 non halt transponders

1 all transponders

5.5.12 SE – select

The command SE selects that transponder that answered at the anticollision. For ultralight and DESFire

transponders it is select level 1 command.

Input format: SE <CR>

Output (example): ACK <CR>

5.5.13 SE2 – select level 2

The command SE2 selects that transponder that answered at the anticollision level 2. For ultralight and

DESFire transponders it is select level 2 command.

Input format: SE2 <CR>

--------------------------------------------------------------------------------36/48--------------------------------------------------------------------------------

Page 37

Output (example): ACK <CR>

5.5.14 WK – write key

With the command WK you save a key to the EEPROM. You can save 8 different keys. It is not possible

to read out the saved keys.

Input: WK <SP> parameter 1 <SP> parameter 2 <CR>

Output (example): ACK <CR>

Parameters:

PARAMETER 1 FUNCTION

1..8 key number

PARAMETER 2 FUNCTION

12 characters 6 byte key

--------------------------------------------------------------------------------37/48--------------------------------------------------------------------------------

Page 38

5.6 ISO 15693 instructions

5.6.1 AFI – application family identifier

With this command you can change the application family identifier of the reader. The reader reads only

transponders, with the same application family identifier as the reader. If the application family identifier is set to 00h the reader reads each transponder.

Input format: AFI <SP> parameter <CR>

Output (example): 00 <CR>

Parameter:

PARAMETER FUNCTION

00 every transponder is read

01h..FFh just transponders with the

same application identifier are

read

5.6.2 BS – block size

With the command BS you can choose the block size of the used transponder. If the ISO 15693 transponders support the “get system information” command, the parameter BS is not used. Only if there is

no information of the block size of the transponder available, the parameter regulates the reading process. The block size is defined in the ISO 15693, e.g. parameter 00H means the blocksize is 1 byte.

Input format: BS <SP> parameter <CR>

Output (example): 00 <CR>

PARAMETER FUNCTION

00h..1Fh 1 byte..32bytes

5.6.3 GMS – get multiple block security

This commands shows if one/multiple blocks of a transponder are locked or not. You have to do a get tag

first.

--------------------------------------------------------------------------------38/48--------------------------------------------------------------------------------

Page 39

Input format one block: GMS <SP> parameter 1 <CR>

Input format multiple blocks: GMS <SP> parameter 1 <SP> parameter 2 <CR>

Output (example): parameter 3 <CR>

Parameter:

PARAMETER 1 FUNCTION

1 or 2 characters block/start block number

PARAMETER 2 FUNCTION

1 or 2 characters end block number

PARAMETER 3 FUNCTION

00h block is not locked

01h block is locked

5.6.4 GS – get system information

This command sends the get system information to the transponder. The answer format is described in

the ISO 15693 chapter 9.3.12. You have to do a get tag first.

Input format: GS <CR>

Output (example): 0F7FAA9006000104E000201B0301 <CR>

5.6.5 LA – lock AFI

This command locks the AFI of a transponder. You have to do a get tag first.

Input format: LA <CR>

Output (example): ACK <CR>

5.6.6 LD – lock data

This command locks the data of a block. You have to do a get tag first.

Input format: LD <SP> parameter <CR>

--------------------------------------------------------------------------------39/48--------------------------------------------------------------------------------

Page 40

Output (example): ACK <CR>

Parameter:

PARAMETER FUNCTION

0h..FFh block number

5.6.7 LDS – lock DSFID

This command locks the DSFID of a transponder. You have to do a get tag first.

Input format: LDS <CR>

Output (example): ACK <CR>

5.6.8 RTR – reset to ready

With this command the transponder enteres the ready state. A muted transponder answers again after

this command.

Input format: RTR <CR>

Output (example): ACK <CR>

5.6.9 WA – write AFI

With this command the reader writes the AFI into the transponder. You have to do a get tag first.

Input format: WA <SP> parameter <CR>

Output (example): ACK <CR>

Parameter:

PARAMETER FUNCTION

00h..FFh AFI

5.6.10 WDS – write DSFID

With this command the reader writes the DSFID into the transponder. You have to do a get tag first.

Input format: WDS <SP> parameter <CR>

Output (example): ACK <CR>

--------------------------------------------------------------------------------40/48--------------------------------------------------------------------------------

Page 41

Parameter:

PARAMETER FUNCTION

00h..FFh DSFID

--------------------------------------------------------------------------------41/48--------------------------------------------------------------------------------

Page 42

6 Operating Modes of the Reader

There are two operational modes defined:

• MD 0 - continuous mode

• MD 2 - the reading process is triggered by the serial interface

In the next capters can you find a detailed functional description.

The default mode is MD 0.

6.1 MD 2 - Triggered by an Software Command

The master sends the command to read a transponder code. The reader answers with the code or an error

code.

If you use “read- and writable”-transponders you just get the transponder code using the command “Get

Tag” (GT).

You can execute specific commands “Read” (RD) and “Write” (WD) just in mode MD2. (capter 8)

In operating mode 2, the exciter is always turned off. Triggered by the software command (GT; RD ;

WD), the exciter is activated. After successful reading or writing of a transponder number the exciter is

turned off automatically.

exciter

processor

interface

Figure 7: Software triggered reading operation

If the first reading cycle yields no result (NoRead), the on-time of the exciter is limited by the parameter TOR (time out reader): Reading cycles are continuously started until either a transponder is read

successfully or the time span corresponding to the value of the parameter TOR has expired. The reader will not interrupt the last running readout cycle. If no transponder number has been read, a

NoRead is output.

GT

reading cycle

ID

--------------------------------------------------------------------------------42/48--------------------------------------------------------------------------------

Page 43

TOR

exciter

processor

interface

reading cycle reading cycle reading cycle

GT

reading process

NoRead

Figure 8: Software triggered reading operation with TOR>0

Please note: The TOR parameter is only active, if the GT-Command is applied. Within the time span

defined by the value of TOR no NoRead will be output on the interface!

6.2 MD 0 - Continuous Reading

When operating continuously the exciter is switched on permanently. The reading cycles are initiated

periodically.

After an accomplished reading cycle the reading information is evaluated. After that data (either transponder number or NoRead code) is output to the serial interface

exciter

processor

interface

reading cycle

reading cycle reading cycle

ID ID ID

Figure 9: continuous operation

--------------------------------------------------------------------------------43/48--------------------------------------------------------------------------------

Page 44

7 Startup and testing the reader

• Connect the reader via cable with the serial interface (COM) from your notebook or pc.

• Connect the reader with your power supply (9..30V DC). Look after the polarity!

• Switch the power supply on. The yellow LED OP of the reader starts to blink.

• Start your terminal programme. You have to set the following settings: 8 data bits, 1 start bit

und 1 stop bit, no parity check (often called 8N1), baud rate 19200 baud, no flow control(e.g.

XOFF/XON).

• Send the command „VER <CR>“ to the reader. The reader answers with the actual firmware

version (e.g. AEG ID V1.23).

• Send the command “MD <SP> 0 <CR>” to the reader. The reader sends No Read messages

(e.g. „FFFFFFFFFF“ or „XXXXXXXXXX“), while there is no transponder in the antenna field

available. The red LED L3 is active. If there is a transponder in the antenna field available the

reader sends its transponder code. The green LED L2 starts to glow.

--------------------------------------------------------------------------------44/48--------------------------------------------------------------------------------

Page 45

8 Instructions

To avoid any reduction of the reading distance of the reader, the antenna must not be brought next to a

metal surface. This could lead to a significant change of the properties of the antenna circuit, which in

turn reduces the reading range considerably!

To get reliable readings, the distance between antenna and transponder must be within the specified

reading volume.

The reading characteristic in front of the antenna is not isotropic. It depends also strongly on the orientation between antenna and transponder. To get the maximum reading distance, the orientation between

reader and transponder must be well suited. The best orientation depends on the type of antenna inside of

the housing ( ferrite – type or plane coil type) and the applied transponder.

To get a reliable readings or writings, the time of transponder while crossing the sensitive area of the

antenna must be coordinated to the data transfer characteristics of transponder

In general the time depends on the speed of the transponder, the size of the transponder and the way the

transponder is mounted on the vehicle and must be verified by field tests.

Environmental electromagnetic noise may also reduce the read and write range consid-erably.

Arrangement to eliminate such troubles must be done specific to the application by the help of engineers

of the manufacturer.

--------------------------------------------------------------------------------45/48--------------------------------------------------------------------------------

Page 46

9 FCC Information

Federal Communications Commissions (FCC) Statement

15.21

You are cautioned that changes or modifications not expressly approved by the part responsible for compliance could void the user’s authority to operate the equipment.

15.105(b)

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connect-

ed.

- Consult the dealer or an experienced radio/TV technician for help.

--------------------------------------------------------------------------------46/48--------------------------------------------------------------------------------

Page 47

10 Hotline

If there are questions or suggestions please call the hotline:

Sales und Marketing: +49 (0)731-140088-0

Fax: +49 (0)731-140088-9000

e-mail: sales@aegid.de

http://

www.aegid.de

--------------------------------------------------------------------------------47/48--------------------------------------------------------------------------------

Page 48

11 Revisions

19.05.16 Revision 00: Initial edition (FW)

22.06.16 Revision 01: FCC information correction

--------------------------------------------------------------------------------48/48--------------------------------------------------------------------------------

Loading...

Loading...