Page 1

Teppan Yaki Grill plate

OPERATING AND

INSTALLATION INSTRUCTIONS

374 404 303/03.04

Model TY 58 CN/Vi and TY 38 CN/Vi

CH

Page 2

Dear customer,

Please read these operating instructions carefully.

Pay particular attention to the section „Safety information" on the first few pages. Please keep these operating instructions in a safe place for future reference.

Pass them on to any new owner of the appliance.

1

1. These numbers indicate step-by-step how to use

2. ...

3. ...

3

2

The warning triangle and/or signal words

(Warning!, Caution!, Danger!) emphasise

instructions important for your safety or proper

functioning of the appliance. Please observe

these without fail.

the appliance.

This symbol is followed by supplementary

information for the operation and practical use

of the appliance.

This symbol indicates tips and advice for the

economic and environmentally-friendly application of the appliance.

• Our WORKS CUSTOMER SERVICE is available

close at hand at all times in case of technical problems (addresses and telephone numbers can be

found in the section „Customer service offices").

Please also note the section „Service“.

Printed on environmentally-friendly paper.

Ecological thinking also means acting ecologically

2

Page 3

CONTENTS

OPERATING

INSTRUCTIONS . . . . . . . . 4

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Description of appliance . . . . . . . . . . . . . . . . . . . 5

Key features of your appliance . . . . . . . . . . . . . . . . 5

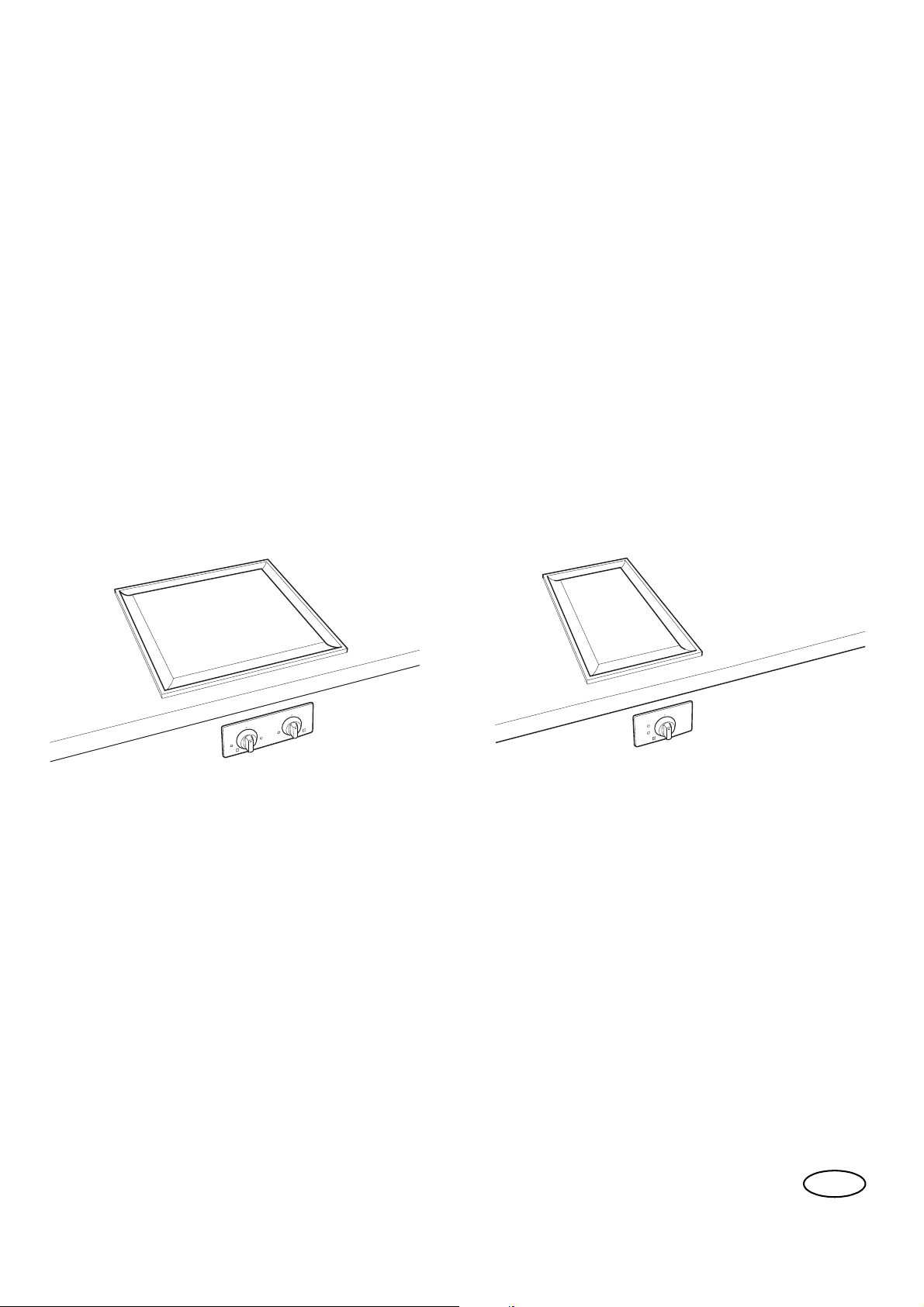

TY 58 unit construction . . . . . . . . . . . . . . . . . . . . . 6

TY 38 unit construction . . . . . . . . . . . . . . . . . . . . . 6

Special accessories . . . . . . . . . . . . . . . . . . . . . . . . 7

Before using for the first time . . . . . . . . . . . . . . . 8

Initial cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Using the grill plate . . . . . . . . . . . . . . . . . . . . . . . 9

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Switching on and off . . . . . . . . . . . . . . . . . . . . . . . . 9

Application, tables, tips . . . . . . . . . . . . . . . . . . . 10

Fat temperatures . . . . . . . . . . . . . . . . . . . . . . . . . 10

Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . 12

Final cleaning of grill plate . . . . . . . . . . . . . 12

Cleaning the grill plate between

two courses . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning control panel . . . . . . . . . . . . . . . . 12

Cleaning turning spoon TY WS and

cooking cover TY GG24 . . . . . . . . . . . . . . . 12

Cleaning cutting board cover TY SB38

and TY SB58 . . . . . . . . . . . . . . . . . . . . . . . 12

INSTALLATION

INSTRUCTIONS . . . . . . . 14

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TY 58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TY 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Regulations, standards, guidelines . . . . . . . . . . . 14

Safety instructions for the installer . . . . . . . . . . . 15

Electrical connection . . . . . . . . . . . . . . . . . . . . . . 15

Rating plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Versions with two thermostats . . . . . . . . . 15

Versions with one thermostat . . . . . . . . . . 15

Fitting/installation in working surface:

surface mounting (coated, lined, Inox or stone) . 16

Fitting/installation: flush mounting in stone

working surfaces . . . . . . . . . . . . . . . . . . . . . . . . . 18

SERVICE/CUSTOMER

SUPPORT. . . . . . . . . . . . 13

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Customer service . . . . . . . . . . . . . . . . . . . . . . . . 13

Service centres . . . . . . . . . . . . . . . . . . . . . 13

Spare-parts sales . . . . . . . . . . . . . . . . . . . . 13

Cooking advice / sales . . . . . . . . . . . . . . . . 13

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3

Page 4

OPERATING INSTRUCTIONS

1 Safety

The safety of this appliance complies with accepted

technical standards and the Appliance Safety Law.

As manufacturers, however, we also believe it is our

responsibility to familiarise you with the following

safety instructions.

Electrical safety

• The installation and connection of the new appliance must only be carried out by qualified personnel.

• Repairs to the appliance must only be carried out

by approved service engineers. Repairs carried

out by unqualified persons may cause injury or

serious malfunction. If your appliance needs

repairing, please contact your local customer centre or your dealer.

3

• Flush-mounted appliances may only be operated

• If your appliance malfunctions or if fractures,

Please follow these instructions, otherwise

the warranty is void in the event of damage.

following installation in suitable installation cabinets and working surfaces which conform with the

relevant standards. This ensures sufficient protection against contact for electrical units as required

by the safety provisions.

cracks or splits appear:

– switch off all heating zones,

– disconnect or remove the fuse for the grill

plate.

Child safety

The heating zones become hot when you cook and

grill. Therefore, always keep young children away

from the appliance. This also applies after switching

off until the temperature of the grill plate has cooled

sufficiently.

Note: A child cooker protector can be fitted to protect

small children. Information can be obtained from the

Bfu (advisory office for accident prevention), Berne,

tel. 031/390 22 22.

• Take care when plugging electric appliances into

mains sockets near the unit. Connecting leads

must not come into contact with the hot grill plate.

• Overheated fat and oil catch fire quickly. If food is

flambéed, the cooking process should be supervised.

• Switch off the grill plate every time after use.

Special information for the grill

plate

Do not place any objects which can be magnetised

on the grill plate while in operation.

3

Noises may occur during operation by

expansion of the grill plate. These are not

faults in the unit and the function is not

impaired in any way.

Safety when cleaning

• The unit must be switched off and cooled below

90 °C before cleaning.

• For safety reasons it is not permitted to clean the

unit with a steam jet or high-pressure cleaner.

How to avoid damage to the

appliance

• Do not use cast iron pans or pans with a rough,

burred or damaged base. Scratching may occur if

the pans are slid across the surface.

• Keep all items and materials that can melt away

from the grill plate, e.g. plastics, aluminium foil or

oven foils. If something of this nature should melt

onto the grill plate, it must be removed immediately with a metal spatula.

Safety during use

• This appliance may only be used for normal cooking, frying and grilling of food in the home.

• Do not use the grill to heat the room.

4

Page 5

2 Disposal

Disposal of packaging material

• All parts of the packaging can be fully recycled;

foil and expanded polyurethane parts are appropriately identified. Please dispose of packaging

material and, if appropriate, your old appliance

properly.

• Please follow the national and regional regulations

and material identification (material separation,

refuse collection, waste disposal sites).

Information on disposal

• The appliance must not be disposed of with

• Information about collection dates or public refuse

• Warning! Before disposing of old appliances make

Description of appliance

Key features of your appliance

• The highly conducting grill plate is 10 mm thick. It

consists of twin-layer stainless steel and therefore

has a good thermal capacity. This prevents a rapid

decrease in temperature, e.g. when preparing

meat from the refrigerator.

• The channeld edge fulfils three important functions:

– It reduces the temperature at the installation

surfaces so much that the grill plate can be fitted in various kitchen working surfaces.

– The curvature of the channel absorbs the

expansion of the heated grill plate to keep it

flat.

– Minor food remnants and liquids can easily be

fed to the channel and removed.

• The thermostat with readable temperature setting

• The food is prepared (heated) directly on the grill

• The heating time, e.g. to 180 °C, is approx.

household rubbish.

disposal sites can be obtained from your local

refuse department or council.

them inoperable. Remove power cable.

ensures a constant temperature. This prevents

overheating of the food and permits low-fat cooking with retention of nutritional value.

plate with or without fat. It is also possible, however, to cook with pots.

6–7 minutes.

The cooling time, e.g. from 180 °C to 100 °C, is

approx. 45 minutes, or to 60 °C approx.

60 minutes.

5

Page 6

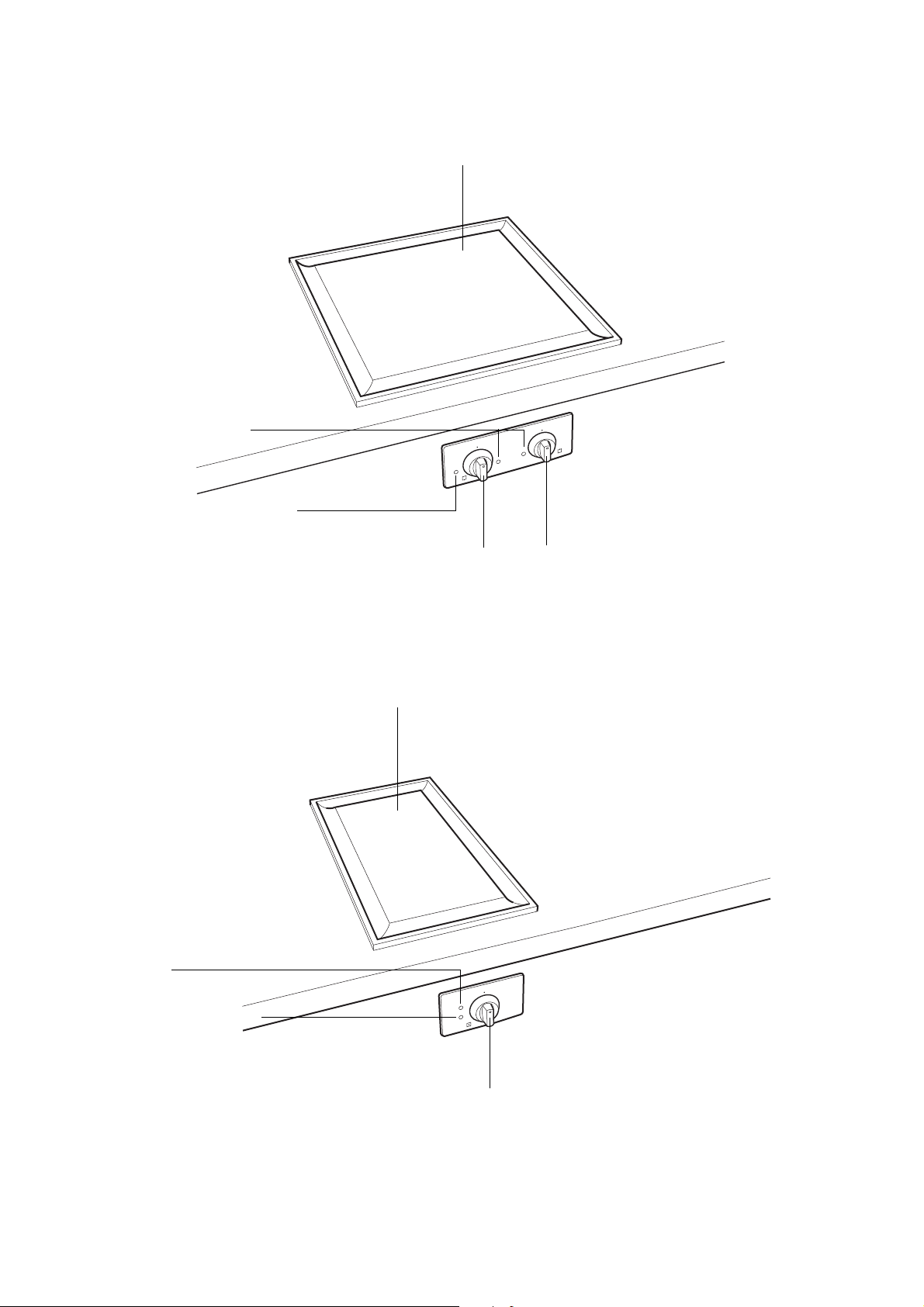

TY 58 unit construction

Temperature

indication lamps (yellow)

Operating indication lamp (red)

Grill plate with two heating zones

(front half and rear half)

Thermostat for front

heating zone (with symbol)

TY 38 unit construction

Operating indication

lamp (red)

Temperature

indication lamp (yellow)

Thermostat for rear

heating zone (with symbol)

Grill plate with one heating zone

Thermostat

6

Page 7

Special accessories

Turning spoon TY WS (spatula)

The ergonomic turning spoon serves as a multipurpose

tool for turning food or removing cooked remnants.

Stainless steel cooking cover TY GG24 (255 x 140)

The cooking cover is specially suitable for steaming

vegetables, for keeping cooked food warm or heating it

up, e.g. rice, noodles.

If roasting is performed under the cover, everything is

kept nice and fresh. Annoying evaporation or splashing

is largely avoided.

Cutting board cover TY SB38

of Swiss beechwood for TY 38 (W 400/D 605)

1

3

Warning! The cutting board may only be

placed over the grill surface when this has

cooled below 30 °C.

Wood is a natural product and therefore warping and cracking can occur, in addition to differences in colour.

Cutting board cover TY SB58

of Swiss beechwood for TY 58 (W 600/D 605)

1

3

Warning! The cutting board may only be

placed over the grill surface when this has

cooled below 30 °C.

Wood is a natural product and therefore warping and cracking can occur, in addition to differences in colour.

7

Page 8

Before using for the first time

Initial cleaning

Wipe over the control panel with a damp synthetic

fibre cloth.

1

Wipe over the grill plate when cold with a damp cloth

or for example with 3M Scotch-Brite Handpads type

no. 350 and with 3M Pad holder type no. 961 (handle)

(available from IBZ Industrie AG, tel. 01/711 10 90) in

the grinding direction, if required for example use

Sipuro glass ceramic cleaner. Finish cleaning thoroughly with a damp cloth.

Warning: Do not use any caustic, abrasive

cleaning agent, which could damage the surface.

8

Page 9

Using the grill plate

The food is prepared (heated) directly on the grill plate

with or without fat. It is also possible, however, to cook

with pots.

When using pots on the grill plate, however, the cooking time is considerably longer than on glass-ceramic,

gas rings or cast iron plates.

Garnishings accompanying the menu, e.g. sauces,

rice, etc. can be cooked or kept warm very well in the

pan directly on the grill plate.

It is not recommended to cook large amounts on the

grill plate, e.g. spaghetti.

3

Thermostat

The required temperature of the grill plate can be set

fully variably within the range 50 °C and 250 °C.

3

Do not hesitate to turn over or remove the food

with the spoon while cooking on the grill plate.

Working marks on the grill plate are normal

and do not result in impairment of function.

The heating time, e.g. to 180 °C, is approx.

6–7 minutes.

Switching on and off

1. Turn the thermostat clockwise to the required tem-

perature.

– The red operating indication lamp lights.

– The yellow temperature indication lamp lights

while the unit is heating up.

2. When the temperature indication lamp extinguishes,

the temperature set is reached.

– The temperature is kept constant by the thermo-

stat.

– The temperature indication lamp lights again dur-

ing further heating.

3. To switch off turn back to the off position.

3

If more rapid cooling of the grill plate is desired

after switching off, this can be performed by

placing a pot on it with a large base and containing 2–3 litres cold water.

100

150

50

200

250

9

Page 10

Application, tables, tips

Fat temperatures

If fats and oils are used the correct temperature is of

vital importance. Heating should not be too great for

health reasons, since this could produce substances

injurious to health, e.g. acryl amine.

With the correct temperature setting the valuable constituents of the oils and fats are largely retained.

Fats/oils

Butter 130 °C 150 °C

Pork fat 170 °C 200 °C

Beef fat 180 °C 210 °C

Olive oil 180 °C 200 °C

Sunflower oil 200 °C 220 °C

Peanut oil 200 °C 235 °C

Coconut fat 220 °C 240 °C

Fat temperature

(max. temperature)

The fat temperature is the maximum temperature

which can be reached before the fat or oil begins to

smoke.

If the smoke point is exceeded, the fats and oils

burn, are modified and become useless; the smoke

point should not be exceeded.

Smoke point

Tables

Cooking material Temperature

(°C)

Fish and crustaceans 170–180 Preheat grill plate

Salmon cutlets 170 8 mins., turn after 4 mins.

Giant prawns (without shell) 170 6 mins., turn after 3 mins.

Shark steaks, 2.5 cm thick 180 10 mins., turn after 5 mins.

Sole (in butter) 180 8 mins., turn after 4 mins., light side first

Fillets of plaice 180 6 mins., turn after 3 mins.

Veal 170-190 Preheat grill plate

Veal cutlet 180 10 mins., turn after 5 mins.

Veal medallions, 4 cm thick 180 10 mins., turn after 5 mins.

Veal steaks, 3–4 cm thick 180 6 mins., turn after 3 mins.

Escalope of veal, plain 180 5 mins., turn after 2½ mins.

Chopped veal 180 6 mins., turn after 3 mins.

Time/tips

(the strips of meat should not touch)

10

Page 11

Cooking material Temperature

(°C)

Beef 200–220 Preheat grill plate

Time/tips

Beef steak very rare

rare

medium

well done

Hamburger 200 6–8 mins., turn after 3–4 mins.

Châteaubriand 200

Pork 180–220 Preheat grill plate

Pork medallions 180 8 mins., turn after 4 mins. (according to thickness)

Neck steak 200 8 mins., turn after 4 mins.

Escalope 200 6 mins., turn after 3 mins.

Spare ribs 180 8–10 mins., turn several times

Pork kebab 200 6–8 mins., grill well from all sides

Lamb 180–200 Preheat grill plate

Lamb chop 180 10 mins., turn after 5 mins.

Lamb fillet 180 10 mins., turn after 5 mins.

220

220

220

220

100

2 mins., turn after 1 min.

4 mins., turn after 2 mins.

6 mins., turn after 3 mins.

8 mins., turn after 4 mins.

without fat the times are increased by around 20 %

Roast meat in oil fully on all sides

(only turn when the meat detaches)

10 Min. finish cooking on one side

(it is important to grill the fillets all round)

Lamb steak 200 6–8 mins., turn after 3–4 mins.

Poultry 160–180 Preheat grill plate

Chicken breast fillet 180 8–10 mins., turn after 4–5 mins.

Turkey breast strips 170 6 mins., turn several times

Bratwurst (pork sausage) 200 Preheat grill plate

11

Page 12

Cleaning and care

Final cleaning of grill plate

1

1

1. Switch off unit and allow to cool to approx. 100 °C.

3

2. Place ice cubes on the grill plate and simultane-

3

3. Allow grill plate to cool to approx. 100 °C. Clean

4. Remove spots which could originate from egg

Danger: Danger of injury from burns when

cleaning the hot grill plate!

Danger: Always clean the grill plate in the

grinding direction (not with circular motions)!

Never use abrasive powders or aggressive

cleaning agents!

If the grill plate has already cooled before

cleaning, heat to approx. 100 °C and switch

off again.

ously detach dirt with the turning spoon and push

into the channel until all the major remnants have

been removed. Remove these from the channel

(e.g. with kitchen paper). Danger: Hot!

Cold water can also be used instead of ice

cubes.

thoroughly with 3M Scotch-Brite Handpads type

no. 350 and with 3M Pad holder type no. 961

(handle) (available from IBZ Industrie AG, tel. 01/

711 10 90) and a little cold water in the grinding

direction.

white or acids in foods when cold with a little

lemon juice and clean Scotch-Brite Handpad. Finish cleaning thoroughly with a damp cloth.

Cleaning the grill plate between two courses

Similar to point 2–3 „Final cleaning of grill plate".

Cleaning control panel

Wipe over the control panel with a damp synthetic

fibre cloth.

1

Caution: Do not use a caustic, abrasive

cleaning agent, which could damage the surface.

Cleaning turning spoon TY WS and cooking cover TY GG24

The turning spoon and cooking cover can be cleaned

in the dishwasher.

Cleaning cutting board cover TY SB38 and TY SB58

Clean with a damp cloth and a little hand washing

agent.

1

If rinsing is performed under running water,

always clean on all sides to ensure that the

board warps less.

12

Page 13

SERVICE/CUSTOMER SUPPORT

Service

Our extensive service and support is available to all

our customers.

Before you call on the customer service

Make sure that no operating errors have occurred.

If you call on the customer service

Make a note of the following data given on the rating

plate on page 15 of the operating instructions:

– Model Code

TY ..... ....

– PNC 949 480 . . . . .

Customer service

Service centres

5506 Mägenwil/Zürich

Industriestr. 10

9000 St. Gallen

Vonwilstrasse 15

Please always specify these data:

– When requesting customer service

– When ordering spare-parts or accessories

– With technical inquiries

Make an exact note of your observations to simplify

the work and preparations of our service engineer.

Dial the service number (see "Customer service").

Your call will be directed automatically to the nearest

service centre.

Please be at home when the service engineers

arrives because he depends on your information

Cooking advice / sales

8048 Zürich

Badenerstrasse 587

Tel. 01 405 81 11

Warranty

4127 Birsfelden

Hauptstrasse 52

8604 Volketswil

Hözliwiesenstrasse 12

6032 Emmen

Buholzstrasse 1

7000 Chur

Comercialstrasse 19

3063 Ittingen/Bern

Ey 5

1028 Préverenges

Le Trési 6

6916 Grancia

Zona Industriale

Spare-parts sales

5506 Mägenwil

Industriestrasse 10

Tel. 0848 848 023

We grant a 2 year warranty on every product from the

date of sale or delivery to the final consumer. (The

warranty certificate, invoice or sales document serves

as evidence of entitlement.)

The warranty benefit includes the costs of materials,

labour and travel time.

The warranty lapses in the event of failure to comply

with the instructions for use and operation, incorrect

installation, and also in the event of damage by external influences, acts of god, intervention by third parties and use of non-original parts.

13

Page 14

INSTALLATION INSTRUCTIONS

Warning! Installation and connection of the

1

new appliance must only be performed by a

certified expert.

Please pay attention to these instructions,

since otherwise the warranty becomes

invalid if any damage occurs.

Technical data

TY 58

Power consumption

• Grill heater front 1500 W

• Grill heater rear 1500 W

Heater voltage 230 V ~ 50 Hz

Total consumption 3,0 kW

Power supply 400 V 2N

TY 38

Power consumption 2200 W

Heater voltage 230 V ~ 50 Hz

Total consumption 2,2 kW

Power supply 230 V

Regulations, standards, guidelines

This appliance satisfies the following standards:

• EN 60 335-1 and EN 60 335-2-6

governing the safety of electrical appliances for

household use and

• EN 60 350

governing basic protection requirements for electro-magnetic compatibility (EMC).

• EN 55014-2

• EN 55014-1999-10

• EN 61000-3-2

• EN 61000-3-3

governing basic protection requirements for electro-magnetic compatibility (EMC).

;

This appliance complies with the following

EU directives

•

93/68/EWG CE designation directive

• 73/23/EWG dated 19.02.1973

(low voltage directive)

• 89/336/EWG dated 03./05.1989 (EMC

directive including modification directive

92/31/EWG)

14

Page 15

Safety instructions for the

Electrical connection

installer

• This appliance corresponds to the type EN 60

335-2-6 with respect to protection against fire.

Only units of this kind may be fitted one-sided to

adjoining high-level cabinets or walls.

• When fitted in combustible material, the NIN 2000,

section 4.2.2 and the fire-protection regulations of

the association of local fire insurance companies

must be observed without fail.

• Limit to room width 550 mm, height 127 mm from

lower side of grill plate, depth 560 mm from rear

with a working surface depth of 600 mm. Combustible walls and ceilings must be provided with a

flame-retardant lining above the grill plate in conformity with the official fire regulations for the relevant area.

• Protection against contact must be ensured by the

installation.

Rating plates

• Electrical connection must be made by a certified

installer.

• The mains connection to the built-in switchbox

must be made with the existing connecting cable

and corresponding to the connection diagram. An

isolating device with at least 3 mm contact opening to disconnect the appliance from the mains

supply at all poles simultaneously should be provided in the permanent home installation conforming with NIN 2000.

• Warning! While being serviced the appliance

must be disconnected from the power supply. The

rating plate is fitted on the underside of the built-in

switchbox.

• Before putting into operation detach any protective

foil from the grill plate.

• After connecting to the power supply all grill plates

should be switched on briefly (approx. 2 minutes)

in succession at the 100 °C position to check their

readiness for operation.

Versions with two thermostats Versions with one thermostat

Model Code

TY 58 CN/Vi

PNC 949 480 191

00

Model Code

TY 38 CN/Vi

PNC 949 480 190

00

15

Page 16

Fitting/installation in working surface: surface mounting (coated, lined, Inox or stone)

When fitting in combustible material the NIN 2000,

section 4.2.2 and the fire protection regulations, in

addition to the directives of the association of cantonal fire insurance companies, must be observed

without fail.

1. The lateral spacing of the working surface cut-out

from a high-level cabinet and the rear wall must be

at least 50 mm.

2. Cut out working surface according to specified

cut-out dimensions. The tolerances must be

observed. Seal the cut-out area of the working

surface against moisture with suitable varnish.

3. Holes for the built-in switchbox in the front of the

cabinet with template as illustrated.

Panel thickness min. 16 mm, max. 22 mm.

4. Guide the built-in switchbox with the bundle of

connecting conductors from above through the

working surfaces cut-out and from the rear to the

front of the cabinet.

Warning: There are capillary tubes in the bunch

of conductors between the built-in switchbox and

the grill plate. Do not bend sharply or separate or

the appliance will be destroyed!

5a.Assembly with CN-front panel (CN)

Guide the signal lamps from the rear through the

12 mm dia. holes in the front of the cabinet (the

12 mm dia. holes can be enlarged to 15 mm to

simplify assembly). Take the switch spindle(s) of

the built-in switchbox from the rear through the

13 mm dia. hole(s) and insert the signal lamps in

the signal lamp lenses mounted on the CN front

panel from the rear.

– TY58: insert signal lamp with red wires in the

left-hand red lens.

– TY38: insert signal lamp with red wires in

upper red lens.

Screw CN-front panel with screws to front of cabinet under switch knobs. Attach switch knobes and

then secure built-in switchbox in front of cabinet

from rear

5b.Assembly without CN-front panel (Vi)

Insert the signal lamp lenses supplied from the

front in the 12 mm dia. holes of the front of the

cabinet.

– TY58: left-hand red lens.

– TY38: upper red lens.

Insert the signal lamps from the rear through the

front of the cabinet in the signal lamp lenses.

– TY58: insert signal lamp with red wires in the

left-hand red lens.

– TY38: insert signal lamp with red wires in

upper red lens.

Take the switch spindle(s) of the built-in switchbox

from the rear through the 13 mm dia. hole(s),

attach white or black switch knobs as required and

then secure the built-in switchbox from the rear to

the front of the cabinet.

6. For tiled working surfaces the joints must be completely filled with jointing material in the supporting

zone for the grill plate.

7. The enclosed sealing tape must be attached to

the underside of the grill plate.

8. Clean the working surface thoroughly in the seal

supporting zone.

9. Place grill plate in cut-out from above, centre and

press down firmly. It requires no additional fixing

owing to its own heavy weight.

Please do not apply any additional silicone sealing

compound, since in the event of removal of the

grill plate both the seal and the working surface

could be damaged.

Warning: If not fitted correctly it would be difficult

to remove for servicing and the grill plate and

working surface could be damaged.

Warning: A recess base which can be dismantled

must be fitted as contact protection under the grill

plate/built-in switchbox.

Removing the grill plate

1. Remove power supply from built-in switchbox/grill

plate

.

2. Place a clean spatula as protection on the working

surface. Then carefully run a firmer chisel under

the edge of the grill plate and raise.

3. For a new fitting it must be ensured that the old

seal is removed completely cleanly and a new

seal fitted (available from spare-parts sales).

Removing the built-in switchbox (for servicing)

1. Remove power supply from built-in switchbox and

dismantle the recess base.

2. Pull off switch knobs (if present remove CN front

panel forwards). Withdraw signal lamps from the

lenses from the rear, release fixing screws of builtin switchbox on the front of the cabinet from the

rear, draw the switchbox forwards carefully

through the opening in the recess base. Re-fitting

is performed according to the fitting/installation

text.

Warning: There are capillary tubes in the bunch

of conductors between the built-in switchbox and

the grill plate. Do not bend sharply or separate or

the appliance will be destroyed.

16

Page 17

Surface mounting TY 38 CN/Vi

Grill plate with built-in switchbox

Width of fume exhaust hood 550 mm min.

==

R2

380

488

358

55

490 1

+

–

1,8 m

230 V (10 A)

Connection to socket provided by client

510

55

360

R5

55

1,8 m

130

195

16-22

ø12

ø12

45

600

min. 25

75

ø13

25

12,5

12,5

min. 75

min.75

x

3

70

x

160

Surface mounting TY 58 CN/Vi

Grill plate with built-in switchbox

Width of fume exhaust hood 550 mm min.

R2

580

488

55

L

1

b

L

N

l

a

2

c

b

k

r

o

w

n

b

e

l

u

/

E

P

490 1

+

–

400 V 2 N

Connection to socket provided by client

2 m

558

510

55

560

R5

55

1,8 m

130

315

16-22

ø12 ø12 ø12

ø13 ø13

8080 45 45

600

min. 25

85 85

85

x

10

min. 75

280

min. 75

10

x

3

70

17

Page 18

Fitting/installation: flush mounting in stone working surfaces

When fitting in combustible material the NIN 2000,

section 4.2.2 and the fire protection regulations, in

addition to the directives of the association of cantonal fire insurance companies, must be observed

without fail.

1. The lateral spacing of the working surface cut-out

from a high-level cabinet and the rear wall must be

at least 50 mm.

2. Cut out working surface according to specified

cut-out dimensions. The tolerances must be

observed.

3. Holes for the built-in switchbox in the front of the

cabinet with template as illustrated.

Panel thickness min. 16 mm, max. 22 mm.

4. Guide the built-in switchbox with the bundle of

connecting conductors from above through the

working surfaces cut-out and from the rear to the

front of the cabinet.

Warning: There are capillary tubes in the bunch

of conductors between the built-in switchbox and

the grill plate. Do not bend sharply or separate or

the appliance will be destroyed!

5a.Assembly with CN-front panel (CN)

Guide the signal lamps from the rear through the

12 mm dia. holes in the front of the cabinet (the

12 mm dia. holes can be enlarged to 15 mm to

simplify assembly). Take the switch spindle(s) of

the built-in switchbox from the rear through the

13 mm dia. hole(s) and insert the signal lamps in

the signal lamp lenses mounted on the CN front

panel from the rear.

– TY58: insert signal lamp with red wires in the

left-hand red lens.

– TY38: insert signal lamp with red wires in

upper red lens.

Screw CN-front panel with screws to front of cabinet under switch knobs. Attach switch knobes and

then secure built-in switchbox in front of cabinet

from rear

5b.Assembly without CN-front panel (Vi)

Insert the signal lamp lenses supplied from the

front in the 12 mm dia. holes of the front of the

cabinet.

– TY58: left-hand red lens.

– TY38: upper red lens.

Insert the signal lamps from the rear through the

front of the cabinet in the signal lamp lenses.

– TY58: insert signal lamp with red wires in the

left-hand red lens.

– TY38: insert signal lamp with red wires in

upper red lens.

Take the switch spindle(s) of the built-in switchbox

from the rear through the 13 mm dia. hole(s),

attach white or black switch knobs as required and

then secure the built-in switchbox from the rear to

the front of the cabinet.

6. Clean the working surface thoroughly in the cutout and in the rebate.

7. The enclosed rubber tape (3x10x2400 mm) must

be attached to the cut-out supporting surface (to

soften blows and prevent silicone joint sealing

compound running under the grill plate under all

circumstances when pointing).

Warning: If not fitted correctly, removal would be

made more difficult for servicing. The grill plate

and working surface could be damaged in this

way.

8. Place grill plate carefully in cut-out and align so

that the joint is the same size on all sides, The grill

plate is not fastened!

Warning: A recess base which can be dismantled

must be fitted as contact protection under the grill

plate/built-in switchbox.

9. Clean grill plate and working surface in area of

joint (e.g. with isopropyl alcohol S-150 and flufffree cloth) and fill the joint with a heat-resistant (at

least 160 °C) silicone joint sealing compound (e.g.

Pactan 6076 anthracite).

Note: Since the grill plate and working surface cutout are subject to a certain dimensional tolerance,

the width of the joint can vary (min. 2 mm).

Removing the grill plate

1. Remove power supply from built-in switchbox/grill

plate

.

2. Cut open the silicone joint sealing compound provided by the client with a suitable knife along the

edge of the grill plate to the full depth of the joint.

Raise the grill plate carefully from below to the

lower construction shell with a screwdriver.

3. For a new fitting it must be ensured that the old silicone compound and the rubber tape are cleanly

removed completely and a new rubber tape fitted

for softening blows (available from spare-parts

sales, 3x10x2400 mm).

according to the fitting/installation text

Removing the built-in switchbox (for servicing)

1. Remove power supply from built-in switchbox and

dismantle the recess base.

2.

Pull off switch knobs (if present remove CN front

panel forwards). Withdraw signal lamps from the

lenses from the rear, release fixing screws of builtin switchbox on the front of the cabinet from the

rear, draw the switchbox forwards carefully through

the opening in the recess base. Re-fitting is performed according to the fitting/installation text.

Warning:

conductors between the built-in switchbox and the

grill plate. Do not bend sharply or separate or the

appliance will be destroyed!

There are capillary tubes in the bunch of

Re-fitting is performed

.

18

Page 19

Flush mounting TY 38 CN/Vi

Grill plate with built-in switchbox

Width of fume exhaust hood 550 mm min.

R5

min. 7

380

488

490

R5

R2

510

360

60

13

600

==

ø12

ø13

ø12

45

12,5

12,5

25

min. 75

R5

358

386

360

1,8 m

min. 25

516

490 1

+

–

=

130

195

75

min.75

x

3

=

70

1,8 m

230 V (10 A)

16-22

x

Connection to socket provided by client

Flush mounting TY 58 CN/Vi

Grill plate with built-in switchbox

Width of fume exhaust hood 550 mm min.

R2

580

488

L

1

b

L

2

b

r

o

w

N

b

e

l

u

/

E

P

=

l

a

c

k

n

516

400 V 2 N

Connection to socket provided by client

510

558

586

490 1

2 m

160

R5

min. 7

490

R5

560

13

85 85

60

600

ø12 ø12 ø12

ø13 ø13

8080 45 45

min. 75

10

560

1,8 m

+

–

min. 25

85

x

10

=

130

315

3

min. 75

70

16-22

x

280

19

Page 20

ELECTROLUX HOME PRODUCTS OPERATIONS EUROPE

The Electrolux Group. The world’s No.1 choice.

The Electrolux Group is the world´s largest producer of powered appliances for kitchen, cleaning and outdoor use. More than 55 million Electrolux

Group products (such as refrigerators, cookers, washing machines, vacuum cleaners, chain saws and lawn mowers) are sold each year to a value of

approx. USD 14 billion in more than 150 countries around the world.

Loading...

Loading...