Page 1

INSTALL ATION AND

MAINTENANCE

OF

WA SL3 M

TK SL3 M

TA SL3 M

WASHING MACHINE 2-15

TUMBLE DRYER 16-34

INDEX 36

Page 2

CONTENTS – WASHING MACHINE

SAFETY 3

Transit screws

General

Child lock on Start/Stop button

Door

Overfill cut-out

Packaging

Transport/Winter storage

Scrapping

PARTS OF THE WASHING MACHINE 4

TECHNICAL INFORMATION 4–5

Technical data

Programme cycles

MECHANICAL INSTALLATION 6–8

Transit screws

Positioning the washing machine

Adjusting the feet

Connecting to water supply

Water intake – mixed or cold water

Connecting to drain

CHANGING SETTINGS 10–11

Language

Locking the programme

Wash temperature, C or F

Changing preset wash temperature

Child lock

MAINTENANCE 12–13

Emptying/cleaning trap and drain pump

Inspection holes under drum paddles

Cleaning the detergent drawer

Cleaning the outside of the machine

In areas with hard water

TROUBLESHOOTING 14–15

Door will not open

Machine will not start

Error messages

The display is lighting when a program

me is selected, but no characters or

digits are shown

Wrong language displayed

ELECTRICAL INSTALLATION 9

Electrical installation

Connecting to coin mechanism

WASHING MACHINE CONTENTS

2

Page 3

SAFETY

GENERAL

• Read and keep this manual!

• Any electrical work or plumbing must be car-

ried out by qualified tradesmen.

• Remove the transit screws before you use the

machine, see Mechanical installation.

CHILD LOCK ON BUTTON

To prevent accidental button pushes on the

button you can activate the child lock

function. The

button then must be held

in for three seconds to activate the machine.

DOOR

The door is opened electrically, so it cannot be

opened until the machine is connected to the

electrical supply! The door can however be ope-

ned in an emergency, see Troubleshooting.

OVERFILL CUT-OUT

If the water level in the machine rises above

normal the overfill cut-out shuts off the water

intake and starts pumping out the water. The

programme resumes when the water level has

dropped.

TRANSPORT/WINTER STORAGE

If you intend to transport the machine or store

it over winter in unheated premises, empty the

trap and the drain pump, see the chapter on

Maintenance.

Any questions? Call service.

SCRAPPING

At the end of its life the machine must be disa-

bled before being scrapped.

Contact your local recycling centre to find

out where to dispose of it or recycle it.

The machine has been built and marked to

facilitate recycling.

PACKAGING

Recycle the packaging according to recommen-

dations in your area.

SAFETY WASHING MACHINE

3

Page 4

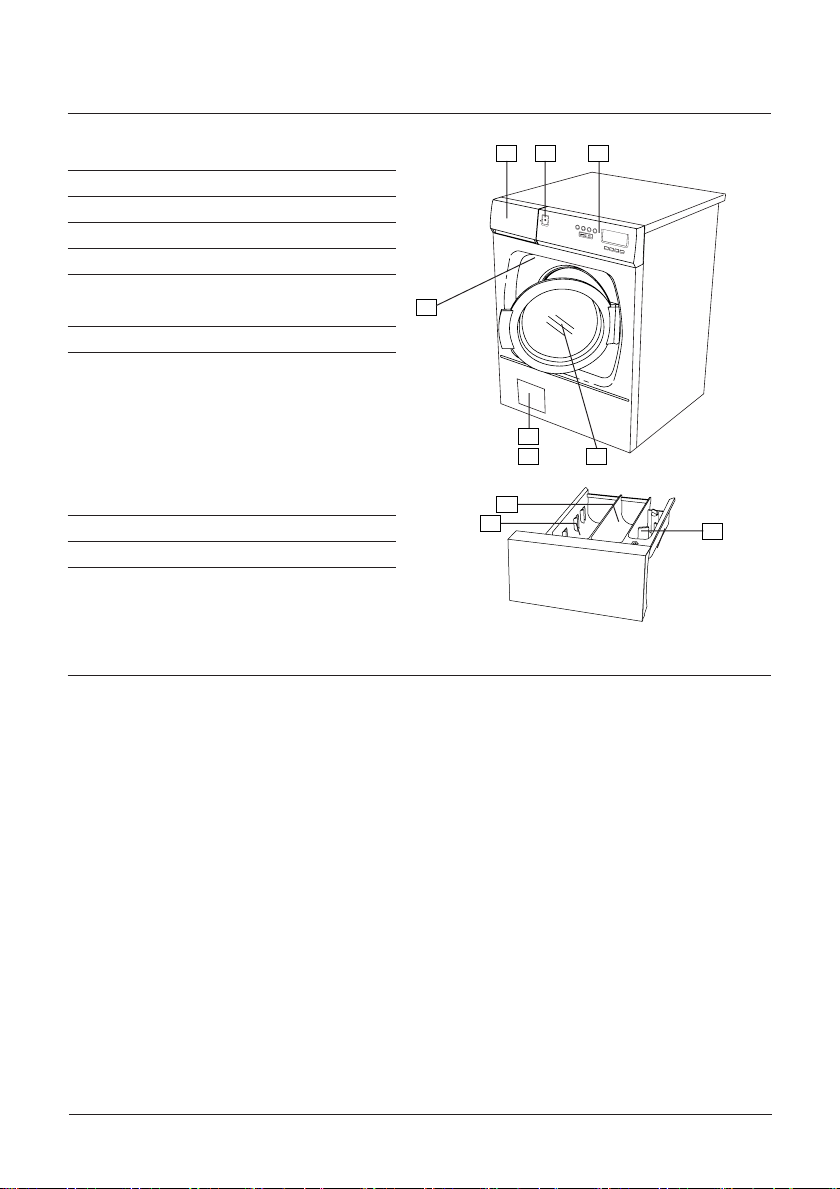

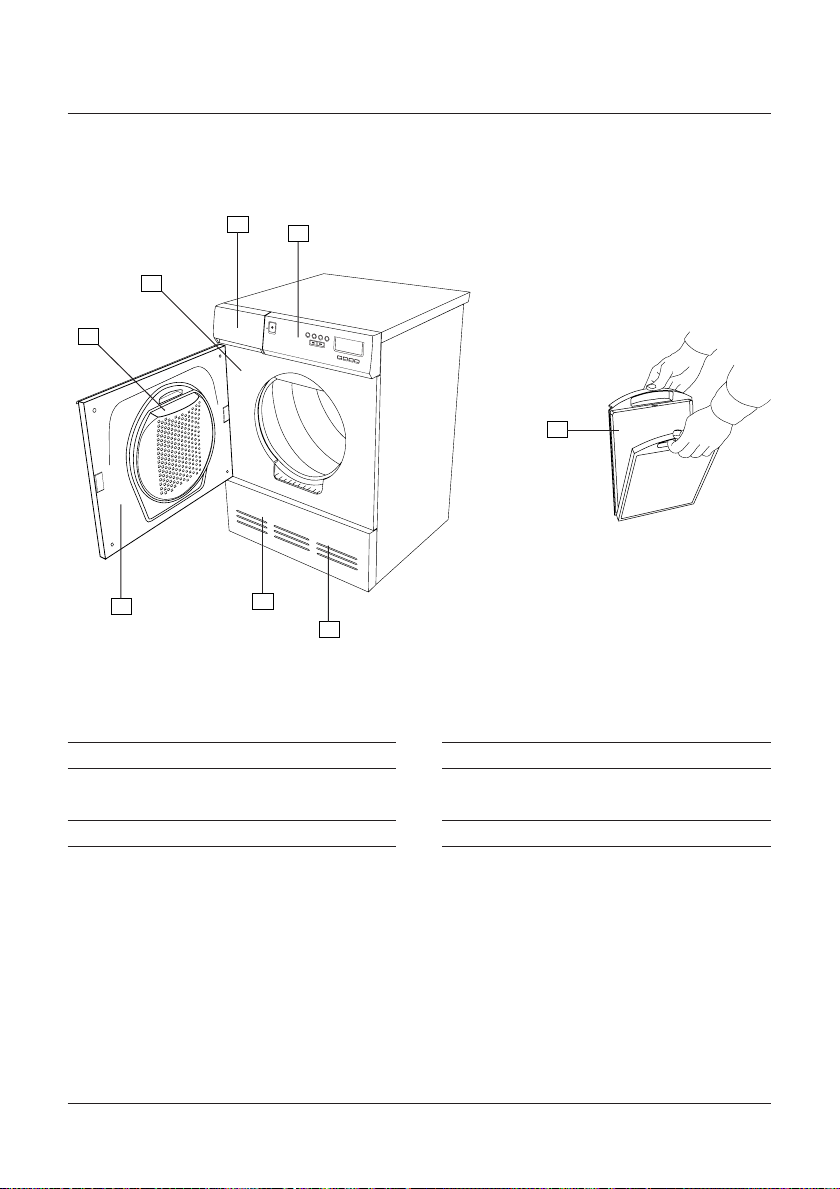

PARTS OF THE WASHING MACHINE

1

7

6

5

8

2

4

3

1. DETERGENT DRAWER

2. POWER SWITCH

3. PROGRAMME PANEL

4. RATING PLATE

5. DOOR-DRAIN PUMP/EMERGENCY OPEN

6. DRAIN PUMP/EMERGENCY OPEN (BEHIND

FLAP)

7. DOOR

1. DETERGENT COMPARTMENT – PRE-WASH

2. DETERGENT COMPARTMENT – MAIN WASH

3. FABRIC CONDITIONER COMPARTMENT

4

1 2 3

5

6

1

2

7

TECHNICAL INFORMATION

TECHNICAL DATA

Height, Width, Depth: 850 mm, 595 mm, 585 mm.

Weight: 73 kg.

Drum capacity: 50 l.

Max wash load: 6.0 kg.

Spin speed: 1200 rpm.

Power rating and element power: See rating plate.

Water pressure: 0.1–1 MPa, 1–10 kp/cm2, 10–100 N/cm2.

Composition of drum and fluid container: Stainless steel.

Composition of casing: Powder-painted and hot-dip galvanized sheet steel

or stainless steel.

Installation: Static on four adjustable, rubber-covered feet.

Water supply: 1.5 m PEX hose.

Drain: 1.7 m polypropylene hose (pump) or 0.4 mm EPDM

This machine is approved for all UK applications as suitable for Category 5.

Product is listed in the WRAS regulations advisory scheme directory and is suitable for direct

connection to mains drinking water.

No special plumbing arangements e.g. break tanks are required.

WASHING MACHINE PARTS OF THE WASHING MACHINE/ TECHNICAL INFORMATION

4

rubber hose (valve).

3

Page 5

EURO

PROGRAMMES

Main wash

Pre wash

Max .load

P1 Heavy wash 90°C

P2 Normal wash 60°C

P3 Light wash 60°C

P4 Normal wash 40°C

P5 Synthetic wash 40°C

P6 Super quick wash 40°C

P7 Wool/hand wash 30°C (1)

P8 Spin

(1) High water level and gentle motor action.

MEDICAL

PROGRAMMES

Main wash

Pre wash

Max .load

P1 Heavy wash 90°C (2)

P2 Heavy wash 80°C (2)

P3 Normal wash 60°C

P4 Normal wash 40°C

P5 Synthetic wash 40°C

P6 Super Quick wash 40°C

P7 Wool/hand wash 30°C (1)

P8 Rinse

(1) High water level and gentle motor action. (2) Cannot be interrupted.

Rinse

Rinse

Spin

Spin

Rinse

Rinse

Spin

Spin

Rinse

Rinse

Spin

80

110

54

40

25

20

25

4

Spin

90

86

54

40

25

20

25

11

Length (appr. min)

Length (appr. min)

TECHNICAL INFORMATION WASHING MACHINE

5

Page 6

MECHANICAL INSTALLATION

2

1

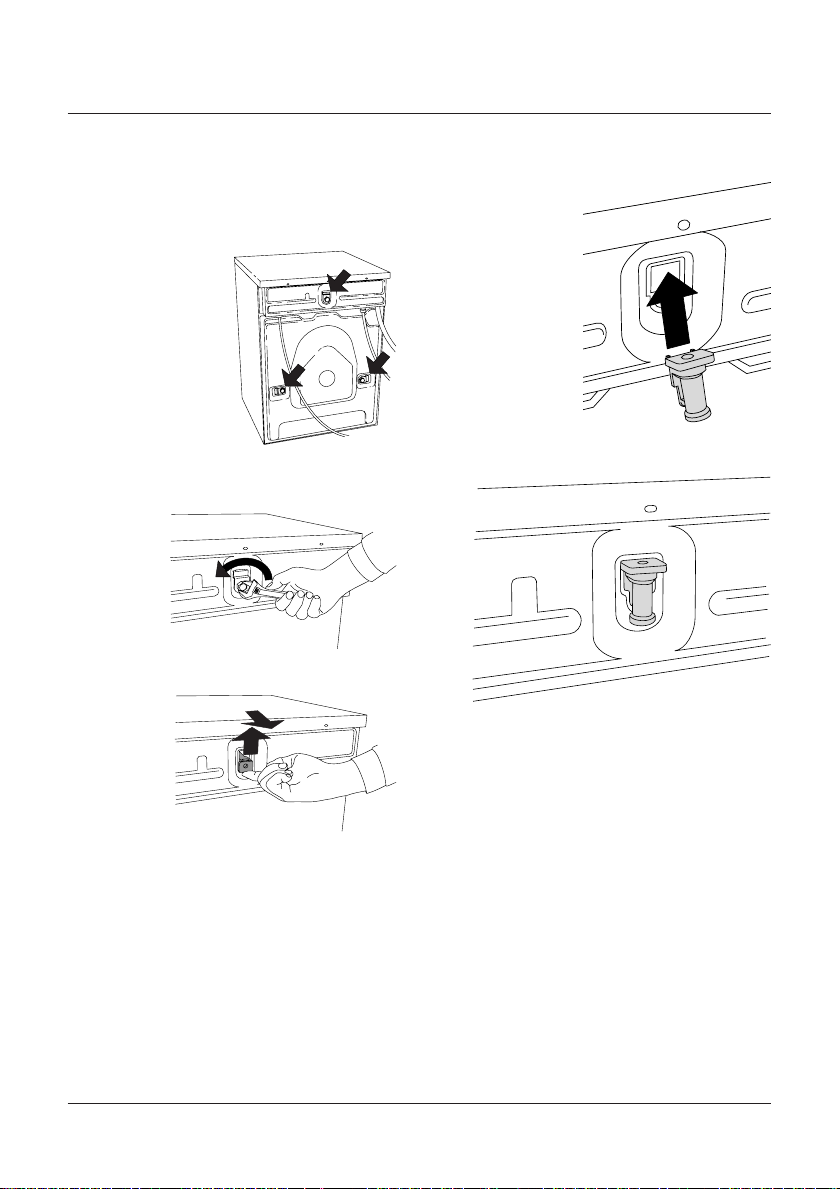

TRANSIT SCREWS

Before the machine can be used the three trans-

it screws must be removed as described below.

Each transit screw has a washer and a rubber

spacer. The rubber

spacers are used to

protect the screw ho-

les after the screws

have been removed.

1. First unscrew the screw and remove the was-

her.

2. Then pull out the rubber spacer.

3. Finally, refit the rubber spacers to cover the

transit holes.

WASHING MACHINE MECHANICAL INSTALLATION

6

Page 7

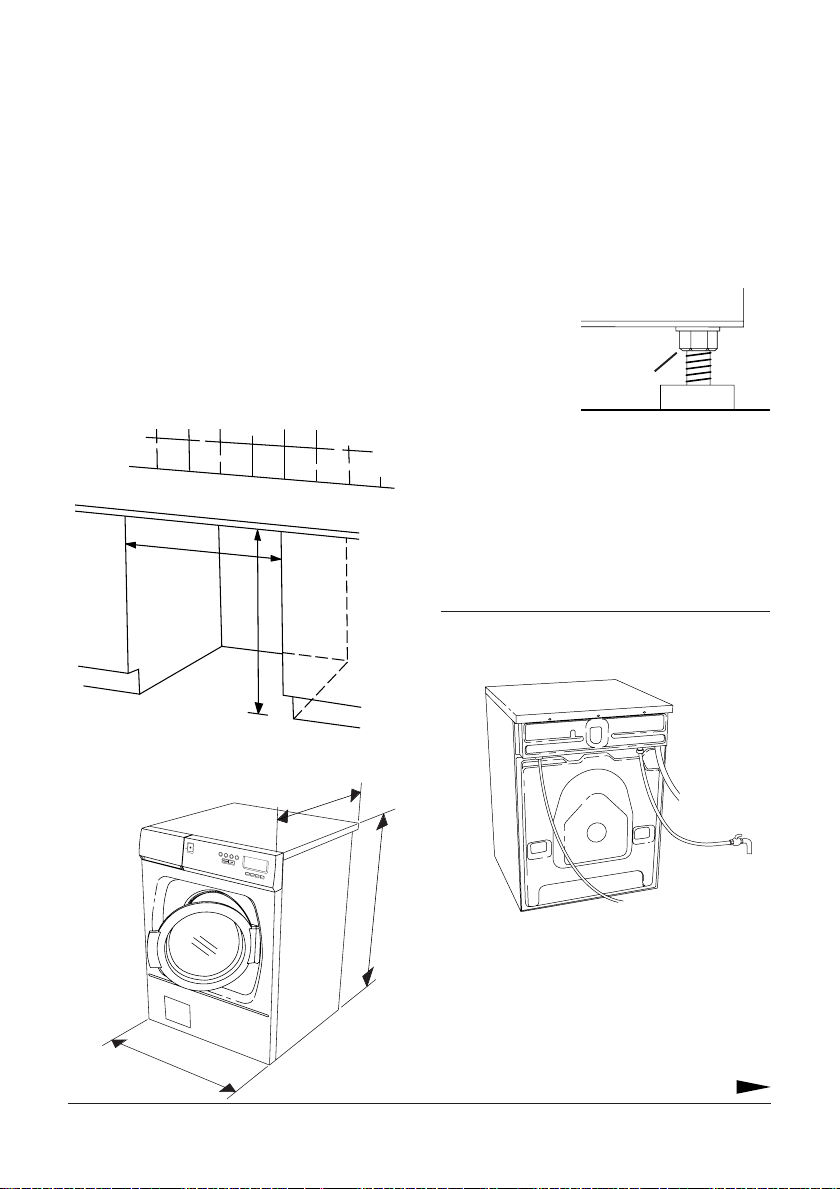

POSITIONING THE WASHING MACHINE

The washing machine can be built-in or free-

standing. It should be positioned so that there

is an electrical socket within easy reach.

A. Built-in

The washing machine can be built in under a

worktop with a working height of 850–900 mm.

Leave a 5 mm gap around the machine. This

also applies between the rear edge of the top

the machine and the wall behind.

min 600 mm

min 850 mm

B. Free-standing

The washing machine can be placed alongside

or underneath the tumble dryer.

585 mm

The machine can be anchored to the floor, see

enclosed bag containing instructions and parts.

ADJUSTING THE FEET

Adjust the feet so that the machine is level and

steady on the floor.

Tighten the lock-

ing nuts.

Locking nut

CONNECTING TO WATER SUPPLY

The machine should be connected to the water

supply by someone who has the necessary skill.

The machine is connected using the supplied

inlet hose.

NOTE!

It is important that you use the inlet hose that

is supplied, not an old hose.

1

2

3

4

5

6

7

8

m

50 m

8

The water pressure must be 0.1–1 MPa

(about 1–10 kp/cm

2

; 10–100 N/cm2).

The water supply pipe must be fitted with a

shut-off valve.

595 mm

If the supply pipe has just been installed we

recommend that it is flushed out thoroughly

MECHANICAL INSTALLATION WASHING MACHINE

7

Page 8

first to remove any dirt. Otherwise this could

clog the intake filter in the machine and block

the water supply.

WATER INTAKE – MIXED OR COLD WATER

On delivery the machine is set to use mixed hot

and cold water. The machine can be reset to use

only cold water or hot water.

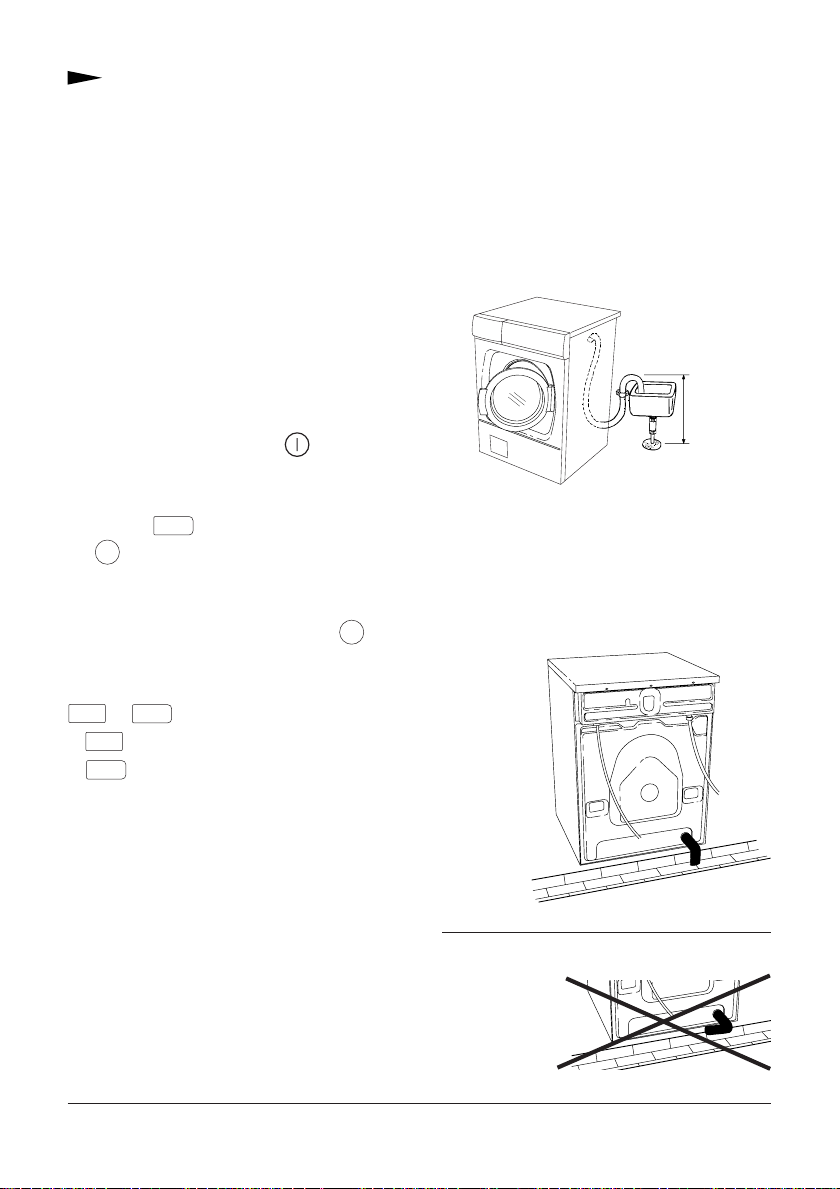

CONNECTING TO THE DRAIN

Machine with drain pump

The machine is supplied with a drain hose al-

ready fitted and this should be connected to a

laundry sink, or the like, at a height of 600–900

mm above the floor.

To change the water intake setting, do as

follows:

Switch off the power switch, , then switch

it on again so that the machine is in start-up

mode.

Press the

button five times, then press

8

the 4 button five times. You have to comple-

te these ten button presses within fifteen se-

conds.

Within three seconds of pressing the 4 but-

ton for the fifth time you must then select the

type of water intake you want by pressing the

or

6

6

8

buttons.

8

to use cold water only (C).

to use mixed hot and cold water (E).

A letter C near the bottom right of the dis-

play shows that cold water is being used and

the letter E indicates mixed hot and cold.

600-900 mm

The lower height (600 mm) is always prefera-

ble. Make sure the drain hose is not kinked.

Machine with drain valve

An outlet hose is supplied with the machine.

This must be connected to the outlet on the

machine and

empty into a

floor drain

or gutter

drain.

NOTE!

The end of the outlet hose must be lower than

the lowest

point of the

outlet valve.

WASHING MACHINE MECHANICAL INSTALLATION

8

Page 9

ELECTRICAL INSTALLATION

ELECTRICAL INSTALLATION

The washing machine must be connected using

a permanently installed cable through an isola-

ting switch by a qualified electrician.

Power supply

The machine is supplied, depending on market,

for one of the following supplies (see rating

plate):

A. 3-phase, 400V, 50 Hz supply, 10 A.

B. Single-phase, 230 V, 50 Hz supply, 13/16 A.

C. Single-phase, 230 V, 50 Hz supply, 10 A.

If an earth leakage circuit breaker is fitted it

must be of type A.

Reconfiguration

The machine can be reconfigured. The machi-

ne should be reconfigured as shown in the wi-

ring diagram underneath the top panel of the

machine.

NOTE!

Electrical connection /reconfiguring must be car-

ried out by a qualified electrician.

CONNECTING TO A COIN MECHANISM

Connection to a coin mechanism must be car-

ried out by a qualified electrician.

A special connecting cable is required to con-

nect the machine to a coin mechanism. This

can be ordered as a spare part, art. no. 92 090

95.

Recommendations for choice of coin mechanism

The connecting cable (92 090 95) supplies the

coin mechanism with power (230 V). The coin

mechanism must be able to short-circuit two

signal leads for a period of time (around 0–10

minutes). This is so that the user has time to

load the laundry, select the programme and start

the programme after inserting the coins.

ELECTRICAL INSTALLATION WASHING MACHINE

9

Page 10

CHANGING SETTINGS

LANGUAGE

You can change the language of the displayed

text.

The languages you can choose from are Dansk,

Deutsch, English, Espanol, Français, Italiano,

Nederlands, Norsk, Portugués, Suomi and

Svenska.

To change language do as follows:

Switch off the power switch, , then switch it

on again so that the machine is in start-up mode.

Press the

button five times, then press

8

the 1 button five times. You have to comple-

te these ten button presses within fifteen se-

conds.

Within three seconds of pressing the 1 but-

ton for the fifth time you should then select the

language you want by pressing the 6 or

7

buttons.

LOCKING A PROGRAMME

If for some reason you want to limit the number

of programmes that can be used you can lock

one or more programmes.

No characters or digits are shown on the dis-

play when a locked programme is selected.

To lock or unlock a programme, do as follows:

Switch off the power switch, , then switch it

on again so that the machine is in start-up mode.

Press the

the

7

-button five times, then press

8

-button five times. You have to com-

plete these ten button presses within fifteen se-

conds.

Within three seconds of pressing the

7

button for the fifth time you should hold in the

programme button for the programme you want

to lock for 5-10 seconds until the information

in the display starts flashing.

Then you can lock the programme by relea-

sing the programme button and pressing the

-button once.

Do the same to unlock the programme.

WASH TEMPERATURE - CENTIGRADE OR FAHRENHEIT

You can change the way the temperature is dis-

played from centigrade (C) to Fahrenheit (F).

To change the temperature display, do as follows:

Switch off the power switch, , then switch it

on again so that the machine is in start-up mode.

Press the

button five times, then press

8

the 2 button five times. You have to comple-

te these ten button presses within fifteen se-

conds.

Within three seconds of pressing the

button for the fifth time you should then press

the 6 or 7 buttons to select centigrade

(C) or Fahrenheit (F).

CHANGING PRESET WASH TEMPERATURE

You can change the preset wash temperatures

for each of the programmes. The temperatures

you can choose from are:

Heavy wash - C, 30, 35, …, 85, 90ºC.

Normal wash - C, 30, 35, …, 85, 90ºC.

Light wash - C, 30, 35, …, 85, 90ºC.

Synthetic wash - C, 30, 35, …, 85, 90ºC.

Super quick wash - C, 30, 35, …, 85, 90ºC.

Wool/hand wash - C, 30, 35, 40ºC.

2

WASHING MACHINE CHANGING SETTINGS

10

Page 11

If you choose C, the wash temperature will

be the same as the intake water temperature.

To change the wash temperature, do as follows:

Switch off the power switch, , then switch it

on again so that the machine is in start-up mode.

Press the

button five times, then press

8

the 6 button five times. You have to com-

plete these ten button presses within fifteen se-

conds.

Press the programme button, 1 -

, to

8

select the programme you want to change the

wash temperature for.

Then use buttons

(increase time) to choose the wash tem-

7

(reduce time) and

6

perature. As you scroll through to the chosen

temperature it appears at the bottom of the

display alongside the

symbol.

When your chosen wash temperature appears

press the

button again to confirm your

8

choice.

Within three seconds of pressing the

but-

3

ton for the last time you must then press the

or 7 button to choose whether you

6

want the child lock on or off.

Press

to activate the child lock.

7

Press 6 to disable the child lock.

CHILD LOCK ON BUTTON

To prevent accidental button pushes on the

button you can activate the child lock

function. The

button then must be held

in for three seconds to activate the machine.

To switch the child lock on or off, do as follows:

Switch off the power switch, , then switch it

on again so that the machine is in start-up mode.

Press the

button five times, then press

8

the 3 button five times. You have to comple-

te these ten button presses within fifteen se-

conds.

CHANGING SETTINGS WASHING MACHINE

11

Page 12

2

1

MAINTENANCE

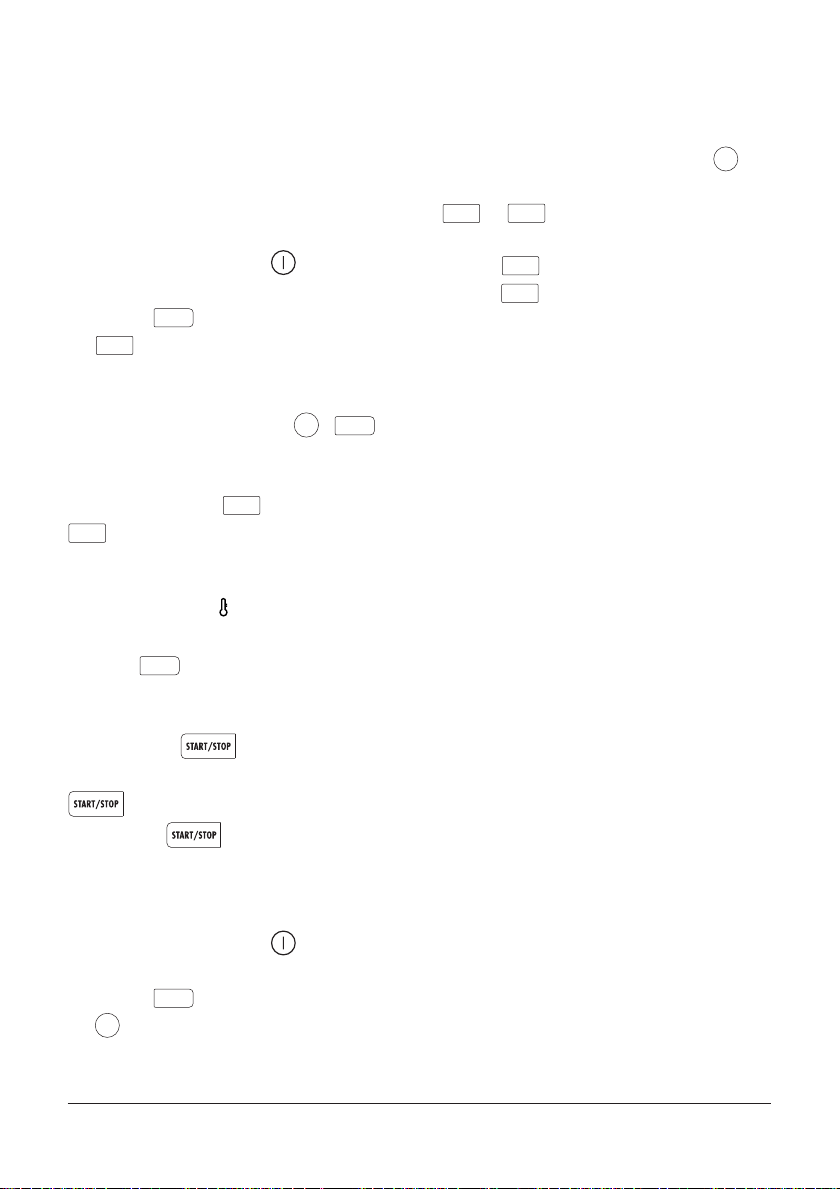

EMPTYING/CLEANING TRAP AND DRAIN PUMP

(only machines with drain pump)

The washing machine has a trap that is desig-

ned to catch coins, hair clips, etc. To clean the

trap and the drain pump, do as follows:

1. Make sure the machine is empty of water and

that the power switch is off.

2. Open the flap that conceals the drain pump

at the bottom

left of the mach-

ine. Use a screw-

driver as shown.

3. Pull the hose off the spigot inside the flap

and drain the water

into a suitable con-

tainer.

4. Open the pump by turning the cap anti-

clockwise. Remove

the cap and trap.

5. Remove any objects and waste from the pump

housing. Check

that the pump im-

peller at the back

rotates freely.

6. Screw the cap and trap back into place, re-

connect the drain

hose and close the

flap.

INSPECTION HOLES UNDER DRUM PADDLES

If you think that an item such as a nail, paper-

clip, hair clip or the like has fallen through the

wash drum you should inspect the outer drum

through the inspection holes in the paddles.

Items such as this can rust and produce stains

on clothes. Nails and other sharp items could

tear clothes.

Do as follows

1. Use a screwdriver or similar tool.

2. Insert the screwdriver

through the hole in

the middle of the

paddle and lever

the handle of the

screwdriver gently

to the left.

3. Grasp the rear edge of

the paddle cover

with your other

hand and pull it

towards you as

shown.

4. Lift off the paddle cover.

5. Examine the space between the inner and

outer drum as you turn the inner drum. Rem-

ove any items you see.

6. Engage the paddle cover in its locating holes

with the F marking nearest you. Make sure that

all the clips engage in their holes in the drum.

WASHING MACHINE MAINTENANCE

12

Page 13

Push the paddle cover away from you until it is

in its original position.

CLEANING THE DETERGENT DRAWER

Pull the drawer out as far as it will go.

Then lift it upwards and outwards as shown.

Wash and wipe clean the detergent compart-

ments.

NOTE!

Do not put the detergent drawer in a dishwash-

er!

CLEANING THE OUTSIDE OF THE MACHINE

Clean the outside and the programme panel

using mild detergent. Do not use abrasives or

solvents as they may damage the machine. Do

not spray the machine with water.

IN AREAS WITH HARD WATER

If the machine is installed in an area with hard

water a greyish white deposit may appear on

the wash drum. To remove this, empty a 20

gram packet of citric acid into the wash drum

and run a Normal wash programme at 85ºC.

You will find citric acid on the spice shelf at

your supermarket.

MAINTENANCE MAINTENANCE INTERVAL

Trap and drain pump 12 times a year or each 25 cycle

Inspection holes under drum paddles Twice a year

or each 150 cycle

Cleaning detergent drawer 12 times a year or each 25 cycle

Cleaning outside of machine As necessary or when cleaning

laundry room.

Hard water (greyish white deposit in drum) Twice a year

Maintenance chart for washing machine.

MAINTENANCE WASHING MACHINE

or each 150 cycle

13

Page 14

TROUBLESHOOTING

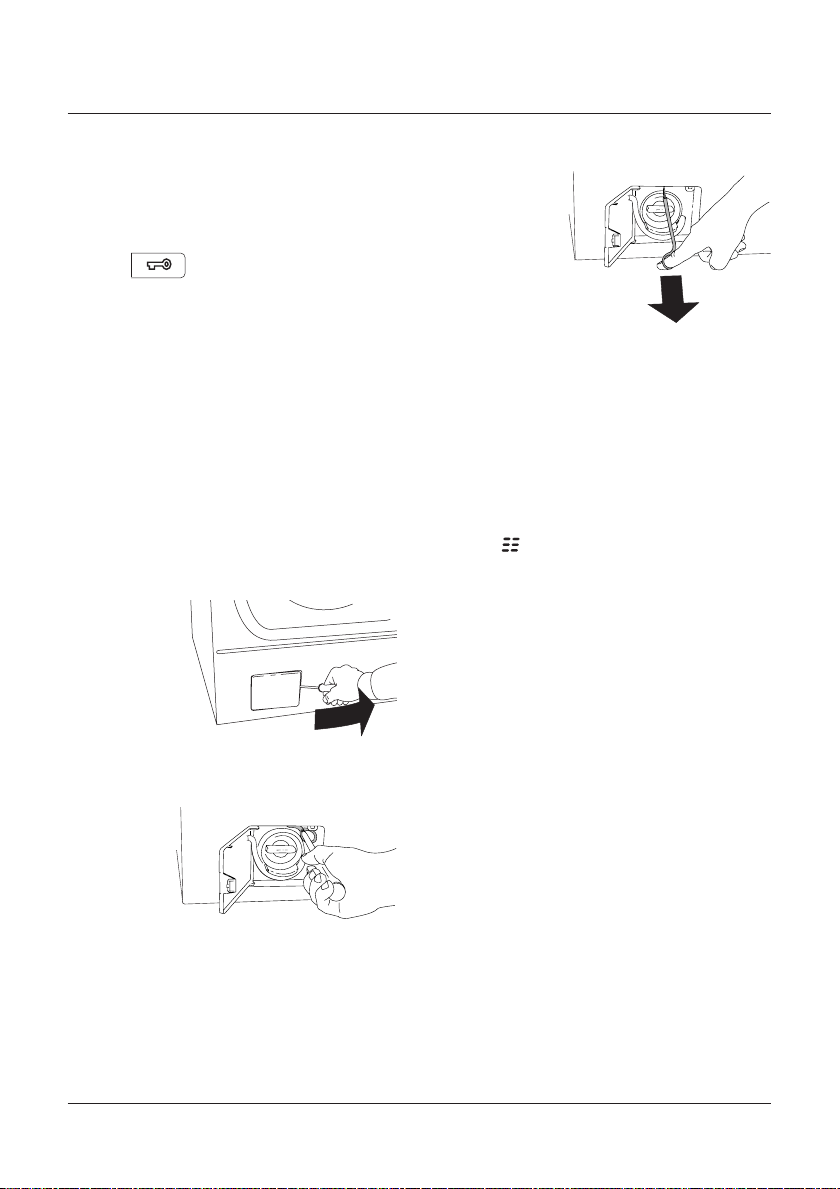

DOOR WILL NOT OPEN

1. Check that the power switch is on.

2. Has there been a power cut? Check the fuses

in the fuse box. The door cannot be opened

with the

3. If everything else fails the door can be ope-

ned in an emergency as follows:

• Make sure the power switch is off.

• Machines with a drain pump: First check that

there is no water left in the machine. If there is,

empty the machine as described under the

heading Checking trap and drain pump, in the

chapter on Maintenance.

• Open the flap at the bottom left. Use a screw-

driver as shown.

button if there is no power.

• Pull the handle to open the door.

• Press the handle back into its recess and secu-

re it with the screw. Close the flap.

If you have problems opening the door nor-

mally again, call service.

MACHINE DOES NOT START

1. Is the door shut properly? Push it firmly. A

flashing symbol appears in the display if the

machine is started with the door open.

2. Check if the child lock is activated. To start

the tumble dryer when the child lock is acti-

vated, hold in the start button for 3 seconds.

See Changing settings.

3. Is there power to the machine. Check the

fuse box.

• Unscrew the screw that holds the red plastic

handle.

WASHING MACHINE TROUBLESHOOTING

14

ERROR MESSAGES

The character display shows whether a fault has

occurred during the programme. To cancel an

error message after the fault has been corrected

as described below, switch off the machine or

change the programme.

You can check and fix some faults yourself:

Problem emptying. Machine not emptying pro-

perly. Check:

– that nothing has got stuck in the drain hose

outlet.

Page 15

– that the drain pump is not blocked by a fo-

reign object. Clean the pump, see chapter on

Maintenance.

– that the drain hose is not kinked.

After doing this, run programme P8. If there is

still a problem, call service.

Machine not filling. Fault in water supply, check:

- is the tap on the water pipe open?

- is the filter in the machine’s water intake bloc-

ked? Turn off the tap. Unscrew the hose and

check.

is flashing in the bottom right corner of the

display. The programme has tried to start but

the door is open. Close the door and start again.

THE DISPLAY IS LIGHTING WHEN A PROGRAMME

IS SELECTED, BUT NO CHARACTERS OR DIGITS

ARE SHOWN

No characters or digits are shown on the dis-

play when a locked programme is selected.

To unlock a programme, see Changing set-

tings.

WRONG LANGUAGE DISPLAYED

If the display language has changed for some

reason you can go back to the original langua-

ge.

The languages you can choose between are

Dansk, Deutsch, English, Espanol, Français,

Italiano, Nederlands, Norsk, Portugués, Suomi

and Svenska.

0000 is flashing at the top right of the display.

The machine has not spun.

1. The machine has a built-in imbalance sensor

that reduces the speed or prevents spinning if

the load is poorly distributed. Switch off the

power switch,

, then switch it on again.

Open the door and redistribute the load.

2. After doing this, run programme P8.

To change language do as follows:

Switch off the power switch, , then switch it

on again so that the machine is in start-up mode.

Press the

button five times, then press

8

the 1 button five times. You have to comple-

te these ten button presses within fifteen se-

conds.

Within three seconds of pressing the 1 but-

ton for the fifth time you should then select the

If there is some other fault, call service and say

which error message appears in the display.

TROUBLESHOOTING WASHING MACHINE

language you want by pressing the

buttons.

or

7

6

15

Page 16

CONTENTS - TUMBLE DRYER

SAFETY 17

General

Using the dryer first time

Child lock on Start/Stop buttons

Thermal cut-out

Float

Door

Packaging

Scrapping

PARTS OF THE TUMBLE DRYER 18

TECHNICAL INFORMATION 19

Technical data

Programme cycles

MECHANICAL INSTALLATION 20–25

Positioning the tumble dryer

Adjusting the feet

Condensed water

Venting

Reversing the door

CHANGING SETTINGS 28

Language

Locking the programme

Child lock

MAINTENANCE 30–32

Cleaning the outside of the machine

Cleaning the fan

Cleaning the condenser

Cleaning the lint filter

In areas with hard water

Emptying the condensation water tank

TROUBLESHOOTING 33–34

Machine will not start

Thermal cut-out

Drying takes too long

Error messages

The display is lighting when a program

me is selected, but no characters or

digits are shown

Wrong language displayed

ELECTRICAL INSTALLATION 26

Electrical installation

Connecting to coin mechanism

TUMBLE DRYER CONTENTS

16

Page 17

SAFETY

GENERAL

• Read and keep this manual!

• Any electrical work must be carried out by a

qualified electrician.

USING THE DRYER FOR THE FIRST TIME

When you start the dryer for the first time, or if

it has not been used for a long time, you may

hear a faint clunking noise. This is entirely nor-

mal and will disappear after a few cycles.

CHILD LOCK ON BUTTON

To prevent accidental button pushes on the

button you can activate the child lock

function. The

button then must be

held in for three seconds to activate the mach-

ine.

THERMAL CUT-OUT

The tumble dryer is protected by a thermal cut-

out. This switches off the machine if it gets too

hot.

DOOR

The tumble dryer has a magnetic lock, which

makes it easy to open the door from the outside

or inside. The door is fitted with a switch that

automatically switches off the tumble dryer

when the door is opened. The tumble dryer

does not start automatically when the door is

closed (for example if a child pulls the door

closed from the inside).

PACKAGING

Recycle the packaging according to recommen-

dations in your area.

SCRAPPING

At the end of its life the machine must be disa-

bled before being scrapped.

Contact your local recycling centre to find

out where to dispose of it or recycle it.

The machine has been built and marked to

facilitate recycling.

FLOAT (only applies to condenser dryer)

A float switches off the machine if there is a

blockage in the condensed water hose.

CAUTION!

During the programme, the back of the tumble

dryer will get very hot. Leave the machine to

cool completely before touching the back.

SAFETY TUMBLE DRYER

17

Page 18

PARTS OF THE TUMBLE DRYER

3

2

1

5

6

1. LINT FILTER HOLDER

2. RATING PLATE

3. CONDENSATION WATER TANK –

CONDENSER TUMBLE DRYERS ONLY

4. PANEL

4

1

2

3

4

5

6

7

8

8

7

5. DOOR

6. FAN (BEHIND FRONT PANEL)

7. CONDENSER – ONLY CONDENSER TUMBLE

DRYERS (BEHIND FRONT PANEL)

8. LINT FILTER

TUMBLE DRYER PARTS OF THE TUMBLE DRYER

18

Page 19

TECHNICAL INFORMATION

TECHNICAL DATA

Height: 850 mm.

Width: 595 mm.

Depth: 585 mm.

Weight: 39 kg (vented) / 47 kg (condenser).

Drum capacity: 111 l.

Drying capacity: 6.0 kg.

Speed: 52 rpm.

Power rating: See rating plate.

Composition of drum: Stainless steel.

Composition of casing: Powder-painted and hot-dip galvanized sheet

steel or stainless steel.

Installation: Stacked, free-standing or built-in.

Drain (condenser tumble dryer): 2.0 m EPDM rubber hose.

Vent hose (venting tumble dryer): 3.0 m PVC.

PROGRAMME CYCLES

Cooling

(appr.

min)

20

20

20

20

20

20

P1 Extra dry

P2 Dry

P3 Normal dry

P4 Iron dry

P5 Extra dry

P6 Dry

Normal

Normal

Normal

Normal

Low

Low

Temperature

Drying

P7 Normal dry

P8 Iron dry

The length of the drying depends on the moisture of the items being dried. The time for drying shown in the table

above indicates the relative time for each programme.

TECHNICAL INFORMATION TUMBLE DRYER

Low

Low

20

20

19

Page 20

MECHANICAL INSTALLATION

POSITIONING THE TUMBLE DRYER

The tumble dryer can be installed free-stan-

ding, built-in or stacked on top of a washing

machine. Remember that the dryer generates

heat and should not therefore be placed in a

room that is too small. If the room is very small,

drying will take longer due to the limited volu-

me of air.

TIP!

To improve the air supply, leave open the door

of the room in which the dryer is placed.

WARNING!

Electrical installation must be carried out by a

qualified electrician.

A. Free-standing

The tumble dryer can be placed next to the

washing machine. The dimensions of the tum-

ble dryer are:

585 mm

1

2

3

4

5

6

7

8

B. Built-in

The tumble dryer can be built in under a work-

top with a minimum height of 850 mm. The

gap must be at least 600 mm wide.

min 600

min 850

103

120

135

140

C. Stacked

The tumble dryer can be stacked on top of an

Electrolux Wascator WE 50 washing machine.

Use the stacking kit that is supplied with the

machine:

2 plastic holders. Plastic bag inside the drum.

m

2 metal tip guards. Attached to the lower back

of the machine.

850 m

120

140

595 mm

An optional pull-out top can be purchased

from your dealer: Art no. 80 619 07-0 (white)

and 80 619 07-33 (black).

TUMBLE DRYER MECHANICAL INSTALLATION

20

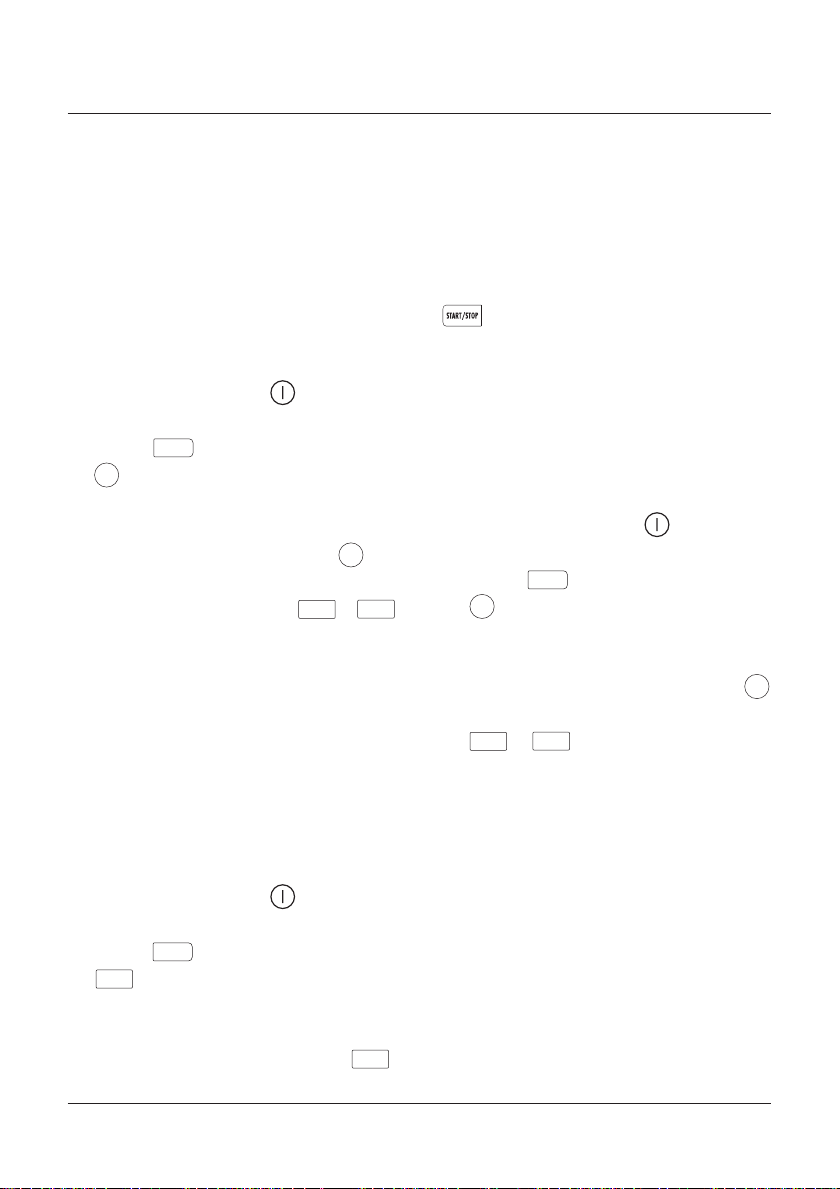

Page 21

Fit the stacking kit as follows:

1. Unscrew the two arrowed screws at the rear of the

washing machine.

2. Fit the metal brackets as shown, using the screws.

3. The plas-

tic cups that will hold the front feet of the tumble

dryer must be attached to the top of the washing

machine. This is important since the feet of the

tumble dryer must be located in the plastic cups to

ensure that the dryer is correctly positioned.

Break tab A off the cup that goes on the right side

and break tab B off the cup that goes on the left

side. Then peel the

backing paper off the

self-adhesive base of

the cups.

A

B

4. Position the plastic cups so that the arrowed lugs

are flush with the front

and side of the top, then

press down onto the top.

Now break off the re-

maining tabs.

5. Open the knock-out holes on the back of the

tumble dryer (where present)

with the aid of a hammer and

screwdriver. They must not

be fully removed, just ope-

ned!

6 Slide the tumble dryer

under the metal brackets,

keeping the front edge rai-

sed 1–2 cm.

7. Lower the front feet of the

dryer into the plastic cups and

adjust the feet so that the dry-

er is level.

ADJUSTING THE FEET

Screw the feet in or out until the dryer is

steady and level

on the floor or

washing machi-

ne. Then tighten

the locking nuts.

Locking nut

MECHANICAL INSTALLATION TUMBLE DRYER

21

Page 22

CONDENSED WATER

(only applies to condenser tumble dryer)

The machine is supplied with a 2.0 metre-long

drain hose. Use this to remove the condensed

water.

max 1000 mm

NOTE!

It is important that you use the new rubber

hose that is supplied, not an old hose.

VENTING

(only applies to venting tumble dryer)

The exhaust air from the tumble dryer must be

led to a ventilation duct or a wall outlet using

the accompanying vent hose.

Connect the vent hose as follows:

1. Slide the vent hose over the end of the adap-

ter and secure with the plastic strap.

2. Remove the plastic cover from the hole if you

intend to connect the hose to a hole other than

the one that is already open.

3. Insert the end of the adapter in the hole.

4. Fit the cover to the open hole.

Connecting to vent duct

The vent hose must follow the shortest, straigh-

test path possible from the tumble dryer to the

vent duct. Cut the vent hose to length if it is

too long. If necessary the vent hose can be ex-

tended to a maximum length of 8 metres (inter-

nal diameter 102 mm). If a longer hose is requi-

red it must have a larger internal diameter in

order to maintain the fan capacity of the dryer.

Any bends should be as gentle as possible. If

Connecting to tumble dryer

The tumble dryer can be vented in three ways:

Examples of

installations

from the rear, from the right

side or from the left side.

One of the holes is open

when the dryer is delivered.

The other two

are fitted

with covers.

The tumble dryer is supplied

1

2

3

it is necessary to make 90º bends there must be

no more than four of them. More bends reduce

the fan capacity of the dryer.

with an adapter (1), a plastic collar (2) and a

vent hose (3).

TUMBLE DRYER MECHANICAL INSTALLATION

22

Page 23

Installation in warm climates

When installing in temperatures above 25°C

(77°F) with a high level of humidity, do not

route the air exhaust hose upwards.

The hose must always run downwards or stay

level with the tumble dryer.

Condensation problems

If the hose is long and the room is cold, con-

densation will form inside the hose. This is una-

voidable.

If the air exhaust hose is slack, water may

build up at the low points, blocking he air flow.

To avoid water build-up in the hose or that

water runs back into the machine, drill a hole

(Ø3 mm) at the lowest point in the hose and

put a water collector underneath.

If there is only one vent duct from the room

then a vent spacer must be fitted, article num-

ber 92 059 01.

Vent spacer

REVERSING THE DOOR

The dryer is supplied with the door hinged on

the left side. You can reverse the door so that

the hinge is on the right side

Do as follows:

1. Remove the lower front panel and unscrew

the three screws that hold the door hinge brack-

et.

Accessories

If the vent hose is ta-

ken to a wall outlet you

can prevent cold air

getting in by fitting a

ventilation grille, artic

le number 9205900.

The ventilation grille

Ventilation grille

Door hinge

bracket

can be installed inside or outside.

MECHANICAL INSTALLATION TUMBLE DRYER

23

Page 24

2. Pull the bottom edge of the door outwards

while twisting the hinge bracket in the direc-

tion shown by

the arrows.

3. Move the hinge pin to the other side of the

bracket. When the door is hung

on the right side the hinge brack-

et must be turned upside down.

Hinge pin

4. Then transfer the hinge pin in

the underside of the top panel to the right side.

6. Unscrew the two screws from the edges of

the door about five millimetres so that you can

remove the door magnet and plate from the

inside of the door.

7. Lift out the door magnet (1) and plate (2).

1

2

8. Refit the door magnet where the plate was.

5. Now transfer the plastic plugs in the top and

bottom of the door to the right side of the door.

Use a screwdriver to prise them out.

TUMBLE DRYER MECHANICAL INSTALLATION

24

9. Refit the plate where the magnet was.

Page 25

1

3

2

10. Screw in the screws to secure the door mag-

net and plate.

11. Unscrew the arrowed

screw. If the dryer is a con-

denser model you must also

open the cover over the con-

denser.

12. Now fit the door to the right side of the

machine.

13. Fit the hinge bracket, tightening the screws

in the order shown.

14. Refit the screw you unscrewed in step 11.

15. Refit the lower front panel.

1

2

2

2

2

1

2

MECHANICAL INSTALLATION TUMBLE DRYER

25

Page 26

ELECTRICAL INSTALLATION

ELECTRICAL INSTALLATION

The washing machine must be connected using

a permanently installed cable through an isola-

ting switch by a qualified electrician.

Configuration on delivery

The machine is configured for a single-phase,

400V supply, has a heating output of 3000 W

and is fitted with a 10 A fuse. If an earth leaka-

ge circuit breaker is fitted it must be of type A.

It is possible to reconfigure the dryer for a sing-

le-phase supply, see below.

Reconfiguring

The machine can be reconfigured for single-

phase, 10 or 16 A. Reconfiguring for single-

phase requires a 3-core cable with a plug. The

machine should be reconfigured as shown in

the wiring diagram underneath the top of the

machine.

Single-phase, 230 V, 50 Hz, heating output

1950 W, fuse 10 A.

Single-phase, 230 V, 50 Hz, heating output

2500 W, fuse 16 A.

NOTE!

Electrical connection /reconfiguring must be

carried out by a qualified electrician.

Connecting the tumble dryer and washing

machine together

Wiring the two machines together as described

below must be carried out by a qualified elec-

trician.

To ensure a uniform load on the phases when

installing the tumble dryer together with an

washing machine for single-phase operation the

phases should be connected as follows:

Tumble dryer:

Terminal marked L1 to phase 1.

Terminal marked L2 to phase 2.

Terminal marked L3 to phase 3.

Washing machine:

Terminal marked L1 to phase 1.

Terminal marked L2 to phase 2.

Terminal marked L3 to phase 3.

CONNECTING TO A COIN MECHANISM

Connection to a coin mechanism must be car-

ried out by a qualified electrician.

The coin mechanism must be connected bet-

ween the tumble dryer’s power lead and the

wall socket.

TUMBLE DRYER ELECTRICAL INSTALLATION

26

Page 27

DELIBERATELY WHITE PAGE

ELECTRICAL INSTALLATION TUMBLE DRYER

27

Page 28

CHANGING SETTINGS

LANGUAGE

You can change the language of the displayed

text.

The languages you can choose from are Dansk,

Deutsch, English, Espanol, Français, Italiano,

Nederlands, Norsk, Portugués, Suomi and

Svenska.

To change language do as follows:

Switch off the power switch, , then switch it

on again so that the machine is in start-up mode.

Press the

the

button five times. You have to comple-

1

button five times, then press

8

te these ten button presses within fifteen se-

conds.

Within three seconds of pressing the

but-

1

ton for the fifth time you should then select the

language you want by pressing the

or

7

6

buttons.

LOCKING A PROGRAMME

If for some reason you want to limit the number

of programmes that can be used you can lock

one or more programmes.

No characters or digits are shown on the dis-

play when a locked programme is selected.

To lock or unlock a programme, do as follows:

Switch off the power switch, , then switch it

on again so that the machine is in start-up mode.

Press the

the

7

-button five times, then press

8

-button five times. You have to com-

plete these ten button presses within fifteen se-

conds.

Within three seconds of pressing the

7

button for the fifth time you should hold in the

programme button for the programme you want

to lock for 5-10 seconds until the information

in the display starts flashing.

Then you can lock the programme by relea-

sing the programme button and pressing the

-button once.

Do the same to unlock the programme.

CHILD LOCK ON BUTTON

To prevent accidental button pushes on the

button you can activate the child lock

function. The

button then must be

held in for three seconds to activate the mach-

ine.

To switch the child lock on or off, do as follows:

Switch off the power switch, , then switch it

on again so that the machine is in start-up mode.

Press the

the

button five times. You have to comple-

3

button five times, then press

8

te these ten button presses within fifteen se-

conds.

Within three seconds of pressing the

ton for the last time you must then press the

or 7 button to choose whether you

6

want the child lock on or off.

Press

Press

to activate the child lock.

7

to disable the child lock.

6

-

but-

3

TUMBLE DRYER CHANGING SETTINGS

28

Page 29

DELIBERATELY WHITE PAGE

29

Page 30

MAINTENANCE

1

4

3

5

2

CLEANING THE OUTSIDE OF THE MACHINE

Clean the outside and the programme panel

using mild detergent. Do not use abrasives or

solvents as they may damage the machine. Do

not spray the machine with water.

NOTE!

Do not let dust collect around the machine.

Keep the area around the dryer clean and cool.

Heat and moisture prolong the drying time.

CLEANING THE FAN

Once a year check whether the fan needs clea-

ning.

1. Switch off the power switch.

2. Remove the lower front panel.

3. Remove the safety screw (1). Prise out the

four clips in the

order shown and

remove the fan

cover.

4. Hold the fan and unscrew the nut.

5. Take out the fan and clean it with water and

a brush.

6. Refit the fan and tighten the nut.

7. Refit the fan cover, making sure the clips

hold the cover

in place. Don’t

forget to fit the

safety screw.

8. Refit the front panel.

2

2

1

30

TUMBLE DRYER MAINTENANCE

2

2

Page 31

CLEANING THE CONDENSER

The condenser should be cleaned at least six

times a year, or more often if the user has pets.

1. Switch off the power switch.

2. Remove the front panel.

3. Open the cover over the condenser by tur-

ning the two

levers anti-

clockwise.

4. Take out the condenser and wash the fins

using a hand shower. Do not poke anything

into the gaps bet-

ween the fins as

this could dama-

ge the conden-

ser. Do not use

any sharp metal

objects when cle-

aning.

NOTE!

Do not try to clean the condenser in a dis-

hwasher.

5. Refit the condenser. Make sure you put it in

the right way

up. The top

of the con-

P

P

U

P

U

N

E

B

O

denser is mar-

ked “upp”, “up”

and “oben”.

6. Refit the front panel.

2

2

2

2

1

MAINTENANCE TUMBLE DRYER

31

Page 32

IN AREAS WITH HARD WATER

1

2

If the machine is installed in an area that has

hard water this can produce a limescale deposit

on the lint filter.

When you clean the lint filter check if there

is any limescale deposit. If there is, wash out

the lint filter by hand.

1. Grasp the filter handle

and pull it towards you.

2. Slide the filter out of the

filter holder.

3. Open the filter

and rub off any

lint with your

hand. Rinse out the

filter to remove any

limescale deposit.

4. Fold the filter and put it back in the filter

holder.

CLEANING THE LINT FILTER HOLDER

Dust and dirt can gather in the bottom of the

lint filter holder. Take out the lint filter and use

a vacuum cleaner to clean the filter holder.

EMPTYING THE CONDENSATION WATER TANK

(only applies to condenser tumble dryer, when

drain hose isn’t used)

Empty the condensation water tank after each

tumble drying.

Pull out the condensation

water tank, empty the

water and put the tank

back.

If the tank becomes

too full the program will be interrupted. Empty

the tank and press the

-button and the

program will continue from where it was inter-

rupted.

MAINTENANCE MAINTENANCE INTERVAL

Clean the outside of the machine As necessary or when cleaning

the laundry room.

Clean the fan At least once a year or each 300 cycle

Clean the condenser Approx. 6 times a year or each 50 cycle

Clean the lint filter and lint filter holder After each tumble drying

Maintenance chart for tumble dryer.

TUMBLE DRYER MAINTENANCE

32

Page 33

TROUBLESHOOTING

MACHINE WILL NOT START

Check

• that the door is closed properly.

• if the child lock is activated. To start the tum-

ble dryer when the child lock is activated, hold

in the start button for 3 seconds. See Changing

settings.

• that the power switch is pressed in.

• that the plug (if fitted) is plugged in.

• that the fuse in the fuse box has not blown.

Try switching two fuses with the same rating.

• that the thermal cut-out has not tripped, see

below.

OVERHEATING PROTECTION

The dryer is designed with an overheat protec-

tion switch that will automatically turn the

machine off if the temperature gets too high.

The machine will not start until it has cooled

down sufficiently.

If the unit shuts down because of overheating,

check that the lint filter exhaust hose, vent duct,

and the condenser unit are free of lint. These

components need to be cleaned on a regular

basis. Additionally, the lint filter may need to

be cleaned with warm, soapy water and a soft

brush a few times a year to ensure the filter

screen is not blocked. Using dryer sheets (not

recommended) can also cause this problem.

Should the machine turn itself off because of

overheating, it will not be possible to restart

the unit until it has cooled down sufficiently.

This could possibly take up to thirty minutes.

To restart the unit once it has cooled down,

press the ”Start” button.

NOTE:

If your dryer overheats frequently, it may not be

vented properly or the room in which it is loca-

ted may not have sufficient air circulation. Con-

tact your installer to have these issues checked

out.

DRYING TAKES TOO LONG

Check that the lint filter and condenser are not

clogged, see the Maintenance chapter. The dry-

ing time may also be long if a condenser dryer is

placed in too small a room or if the air in the

room is too warm. Make sure the dryer has

access to more cool air, for example by opening

doors and/or windows.

ERROR MESSAGES

The character display shows whether a fault has

occurred during the programme. To cancel an

error message after the fault has been corrected

as described below, switch off the machine or

change the programme.

You can check and fix some faults yourself:

Over flow. Indicating that the condensation

water tank is full or that the lower water maga-

zine is full, due to the pump or hoses being

clogged or malfunctioning. Empty the tank and

check to ensure there are no kinks or blockage

in the hose. If this does not help, call service.

TROUBLESHOOTING TUMBLE DRYER

33

Page 34

Maximum programme duration. After the

machine has run for the maximum time (3

hours) it automatically stops. Check and repla-

ce any blown fuses in the fuse box. To cancel

the error message, switch off the machine or

open the door. If this does not work, call servi-

ce.

Sensor fault. Faulty moisture sensor. This error

message may also appear if you run the machine

with dry clothes or no clothes at all. Open the

door and the error message should disappear. If

not, call service.

If there is some other fault, call service and say

which error message appears in the display.

THE DISPLAY IS LIGHTING WHEN A PROGRAMME

IS SELECTED, BUT NO CHARACTERS OR DIGITS

ARE SHOWN

No characters or digits are shown on the dis-

play when a locked programme is selected.

To unlock a programme, see Changing set-

tings.

To change language do as follows:

Switch off the power switch, , then switch it

on again so that the machine is in start-up mode.

Press the

the

button five times. You have to comple-

1

button five times, then press

8

te these ten button presses within fifteen se-

conds.

Within three seconds of pressing the

but-

1

ton for the fifth time you should then select the

language you want by pressing the

or

7

6

buttons.

WRONG LANGUAGE DISPLAYED

If the display language has changed for some

reason you can go back to the original langua-

ge.

The languages you can choose between are

Dansk, Deutsch, English, Espanol, Français,

Italiano, Nederlands, Norsk, Portugués, Suomi

and Svenska.

TUMBLE DRYER TROUBLESHOOTING

34

Page 35

SERVICE

SERVICESTELLEN POINTS DE SERVICE SERVIZIO DOPO VENDITA

Zürich/Mägenwil

5506 Mägenwil

Industriestr. 10

9000 St. Gallen

Vonwilstrasse 15

4127 Birsfelden

Hauptstrasse 52

8604 Volketswil

Hözliwiesenstrasse 12

6032 Emmen

Buholzstrasse 1

7000 Chur

Comercialstrasse 19

3063 Ittingen/Bern

Ey 5

ERSATZTEILVERKAUF POINT DE VENTE DE RECHANGE VENDITA PEZZI DI RICAMBIO

1028 Préverenges

Le Trési 6

1950 Sion

Rue de la Piscine

6916 Grancia

Zona Industriale E

5506 Mägenwil

Industriestrasse 10

Tel. 0848 848 023

KOCHBERATUNG / VERKAUF DEMONSTRATION / VENTE CONSULENTE (CUCINA) / VENDITA

8048 Zürich

Badenerstrasse 587

Tel. 01 405 81 11

GARANTIE GARANTIE GARANZIA

Wir gewähren auf allen

Produkten, die in der

Schweiz gekauft und in

Betrieb sind, eine einjährige Vollgarantie, gerechnet ab Lieferdatum

an den Endver-braucher. Massgebend für den

Garantieanspruch ist die

Faktura oder ein entsprechen-der Verkaufsbeleg

5506 Mägenwil

Industriestrasse 10

Tel. 0848 848 023

8048 Zürich

Badenerstrasse 587

Tel. 01 405 81 11

L’utilisateur final de

tout produit acheté et

utilisé en Suisse, bénéficie d’une garantie

complète d’une année à

partir de la date de livraison. La facture ou le

justificatif d’achat correspondant fait foi en la

matière.

5506 Mägenwil

Industriestrasse 10

Tel. 0848 848 023

8048 Zürich

Badenerstrasse 587

Tel. 01 405 81 11

Per questo prodotto

concediamo una garanzia di 12 mesi a partire

della data di vendita. La

garanzia è valida dietro

presentazione della fattura o dello scontrino

d’acquisto.

35

Page 36

INDEX

WASHING MACHINE

Adjustable feet 7

Centigrade or Fahrenheit 1 0

Changing preset wash

temperature 1 1

Child lock 3

Cleaning 1 3

Coin mechanism 9

Connecting to drain 8

Connecting to water 7,8

Detergent drawer 4,13

Door 3,4,14

Drain pump 12,14

Drum paddles 1 2

Emergency open 1 4

Error messages 1 4

TUMBLE DRYER

Adjustable feet 21

Child lock 17,28

Cleaning 3 0

Coin mechanism 2 6

Condensed water 2 2

Condenser 18,31

Connecting washing machine and tumble dryer

together 2 6

Door 17,18

Page

Page

Hard water 13

Page

Hardness of water 13

Imbalance sensor 1 5

Inspection holes 1 2

Installation, electrical 9

Installation, mechanical 6

Language 10,15

Locking programme 1 0

Maintenance 1 2

Overfill cut-out 3

Packaging 3

Parts of washing machine 4

Positioning 7

Programme cycles 5

Page

Installation, electrical 26

Installation, mechanical 20

Language 28,34

Locking the programme 2 8

Maintenance 3 0

Packaging 1 7

Parts of the dryer 1 8

Positioning 2 0

Programme cycles 1 9

Rating plate 4

Page

Safety precautions 3

Scrapping 3

Technical data 5

Transport 3

Transit screws 6

Tra p 1 2

Troubleshooting 14

Winter storage 3

Page

Safety precautions 17

Scrapping 17

Stacking the dryer 20

Technical data 1 9

Thermal cut-out 17,33

Troubleshooting 33

Ventilation 2 2

Error messages 3 3

Float 1 7

Fan 18,30,32

Art. No. 80 806 73. Rev. 01. The right to make changes is reserved.

Printed on environment friendly paper.

36

Reconfiguring 2 6

Reversing door 23

Loading...

Loading...