Page 1

820 41 72 58

USER

USER

s MANU

s MANU

AL -

AL -

NO

NO

TICE DUTILIS

TICE DUTILIS

AATION -

TION -

MANU

MANU

AL DEL USU

AL DEL USU

ARIO

ARIO

TCW 1990

ICE LINING REFRIGERATOR FREEZER

GB

REFRIGERATEUR / CONGELATEUR

A PAROI REFRIGERANTE - ILR

FRIGORIFICO/CONGELADOR

REVESTIDO DE HIELO

F

E

Page 2

USER MANUAL

2

ICE LINING REFRIGERATOR FREEZER

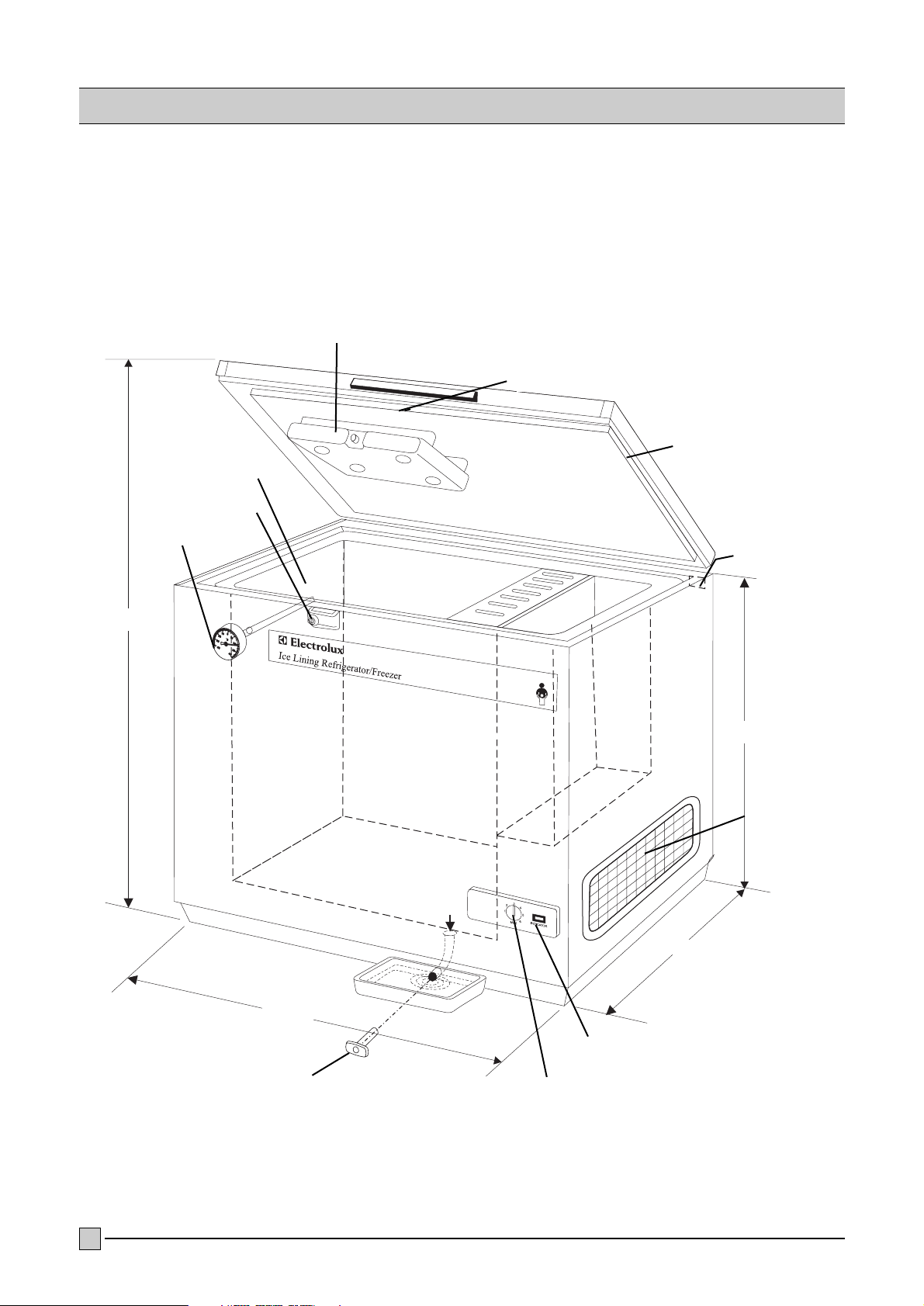

Handle

Lid ice accu

Rubber gasket

Data label

Thermometer

850

1050

630

1465

Compressor

compartment

Pilot lamp ON

Thermostat for

refrigerator function

Drain plug

Locking device

Interior wall

Page 3

1. GENERAL INFORMATION......................................................page 4

2. INSTALLATION .....................................................................page 5-9

3. PREPARATIONS....................................................................page 10-11

4. USE THE APPLIANCE ...........................................................page 12

5. DEFROSTING & CLEANING ..................................................page 13-14

6. PERIODIC OBSERVATIONS/CHECKS/ACTIONS .....................page 15

7. TROUBLE SHOOTING ...........................................................page 16-17

(A) ILR not working

(B) Compressor is working,

but cabinet temperature is higher than normal

(C) Cabinet temperature is lower than normal

(D) Abnormal noise in the ILR

8. SHUTTING DOWN ................................................................page 18

9. STORAGE OF VACCINES IN THE ILR .....................................page 18

INDEX

3

Page 4

THE ILR

One of the most important links in the cold-chain is Ice

Lining Refrigerator (ILR). This is a unit which operates

on the principle of vapour compression system,

similar to any conventional compressor type

refrigerator operating on 1 15 or 230 volts, A.C. mains

supply. However, the ILR has top opening door to

prevent loss of cold air during door opening.

ICE LINING

The Icelined Refrigerator and Freezer has a icebank

inside the cabinet. The ice bank consists of frozen

icepacks during its operation. During periods of

power failure and load procedures, the ice bank acts

as cold storage to protect the vaccines. The ice bank

keep the temperature is not above +8°C for 30 hours.

HOLD OVER TIME

In case of power failure this unit is capable to hold the

temperature (if all the ice-packs are installed) inside

the Refrigeration compartment between 2 and 8°C

under following conditions.

Ambient temperature: Minimum hold over:

32°C 30 hours

43°C 20 hours

POWER SUPPLY

The ILR is fitted with heavy duty compressor which

requires low starting current and can also operate

within a range of voltage variations.

E.g. if the normal operating voltage is 230 volts, 50

Hz., A.C., it can work even when the supply voltage

occasionally go as low as 150 volts or as high as

280 volts.

THERMOMETER

To enable to measure the temperature inside the

cabinet without opening the lid, a thermometer is

provided with its dial on the front side. This makes

monitoring of the vaccine temperature easy.

LOCKING SYSTEM

The ILR is equipped with a lock, operated with a

key.

POWER-SUPPLY ARRANGEMENT

For smooth functioning of the ILR it is advisable to

connect the same to a 15 Amps power plug socket

outlet, wired from the mains with PVC insulated

cables of minimum 2.5 mm section of Aluminium

(see also page 5 under `Installation'). The larger

size of the plug and socket decreases the contact

resistance which in turn reduces voltage drop and

provides an easy path for the current.

Safety of the personnel and the equipments can not

be guaranteed unless the earth wire (green/yellow)

of the cord is really earthed. It is advisable to have

the earth connections to the socket checked by a

competent electrician.

VOLTAGE STABILIZER

Though the ILR is capable of operating within a

wide range of voltage variations, for extra safety one

separate Automatic Voltage Stabilizer should be

used with it.

1. GENERAL INFORMATION

4

Page 5

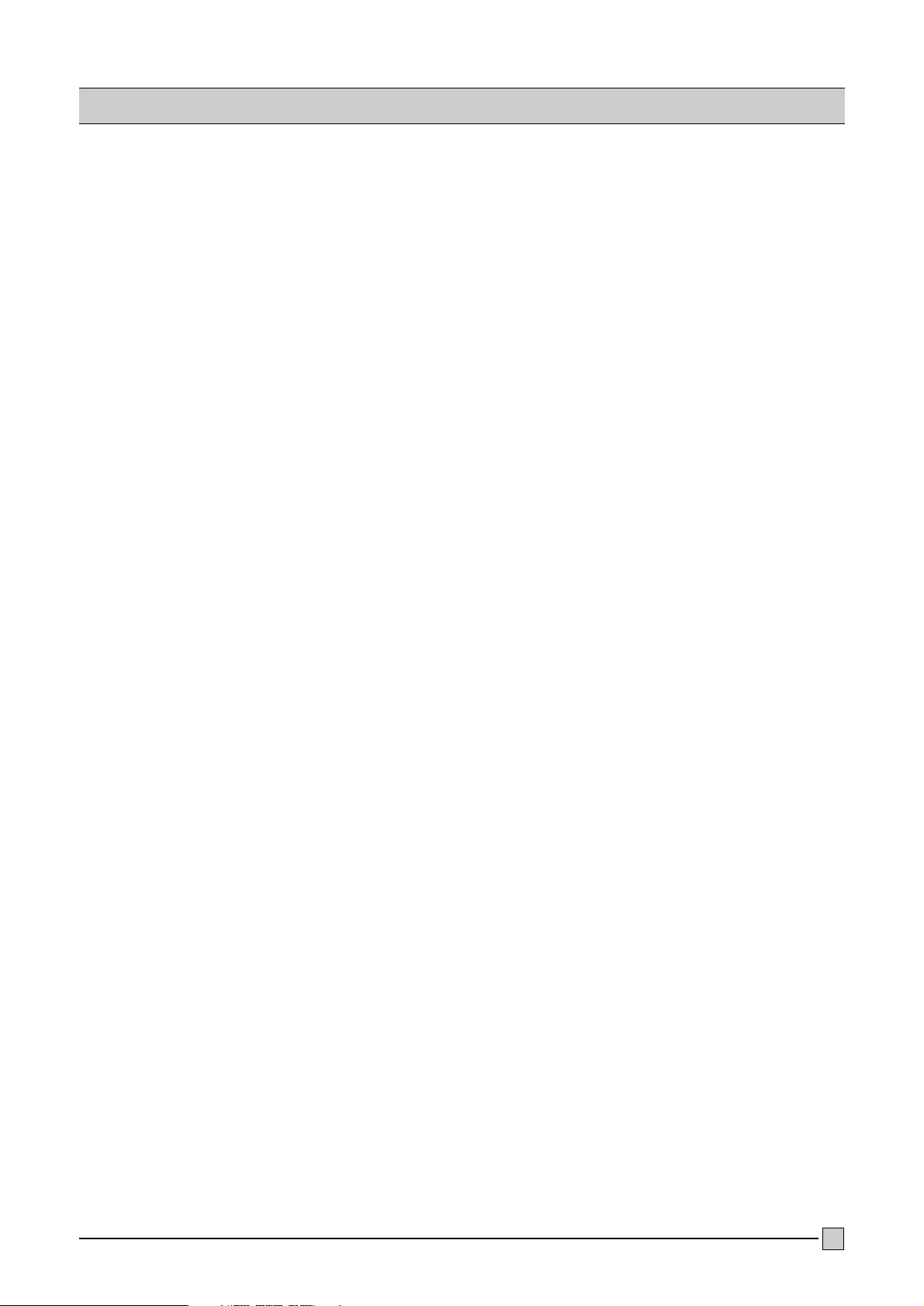

Check the manufacturer's plate, at the back of the ILR

and make sure that the ILR has correct voltage for

local supply, i.e. 1 15 or 230 volts (fig. 1).

CAUTION

Connecting the equipment to wrong supply

voltage may damage it.

If you have received equipments of wrong voltage

ratings, notify concerned authorities and keep the

equipments repacked.

The ILR is to be installed in a well ventilated room,

avoiding direct sunshine or any other source of heat.

Power supply socket (15 amps socket with switch,

fuse and mains indicator lamp is advisable) should be

available nearest to the place of installation of the ILR.

1.

Unscrew and remove the screws holding the side

cover of the compressor compartment on the right

hand side of the ILR and remove carefully the side

cover (fig. 2)

2. INSTALLATION

5

Fig. 2.

Fig. 1.

Page 6

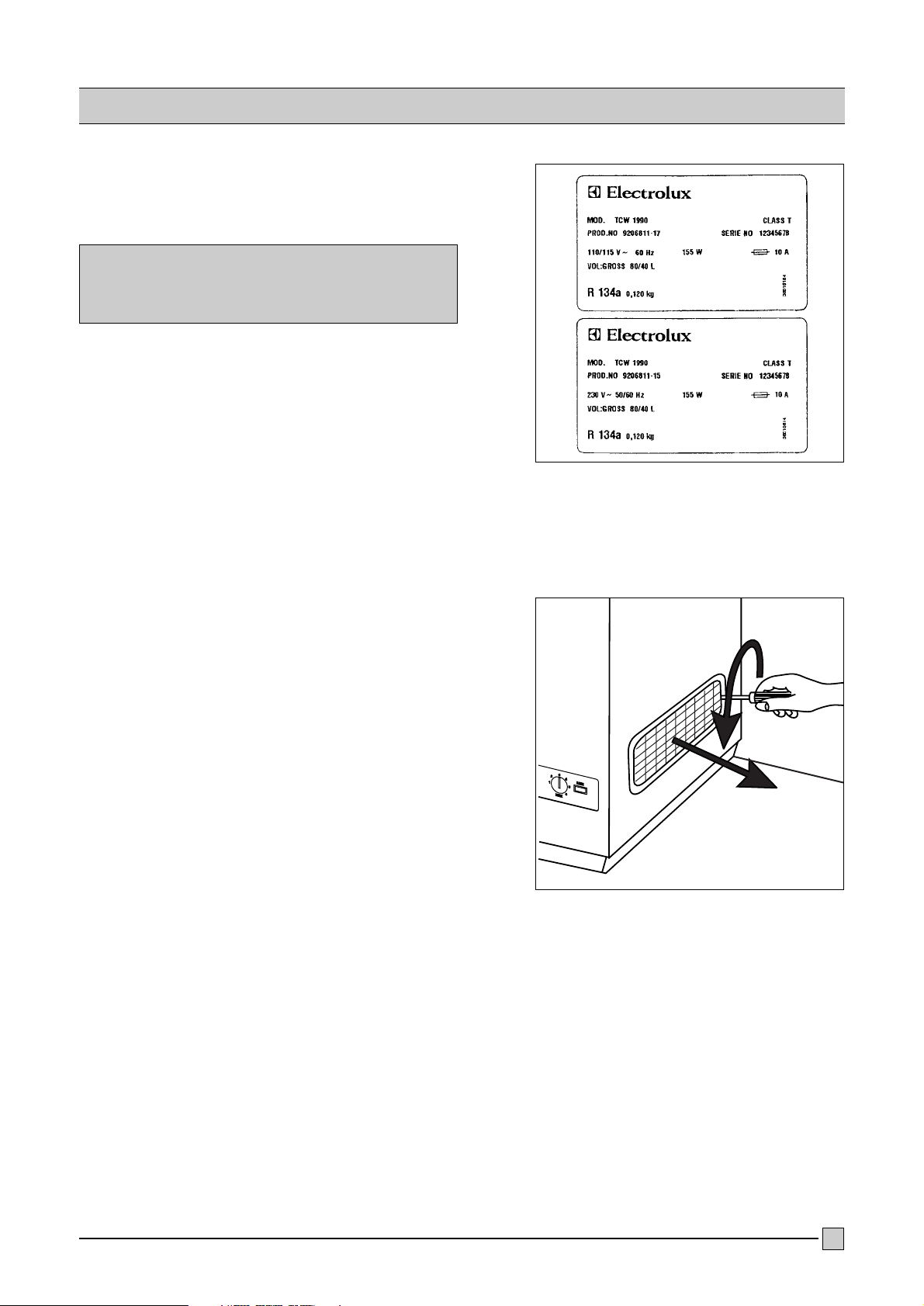

3.

EXAMINE the compressor compartment (fig. 3;

Check carefully for any damage, dislocation or

looseness etc. of the components, specially at

locations A, B. C, and D as below and rectify if

necessary.

LOCATION A (fig. 4)

Check that all 4 mounting brackets of the compressor

are in place and secured.

2. INSTALLATION

6

Fig. 4.

Fig. 3.

Page 7

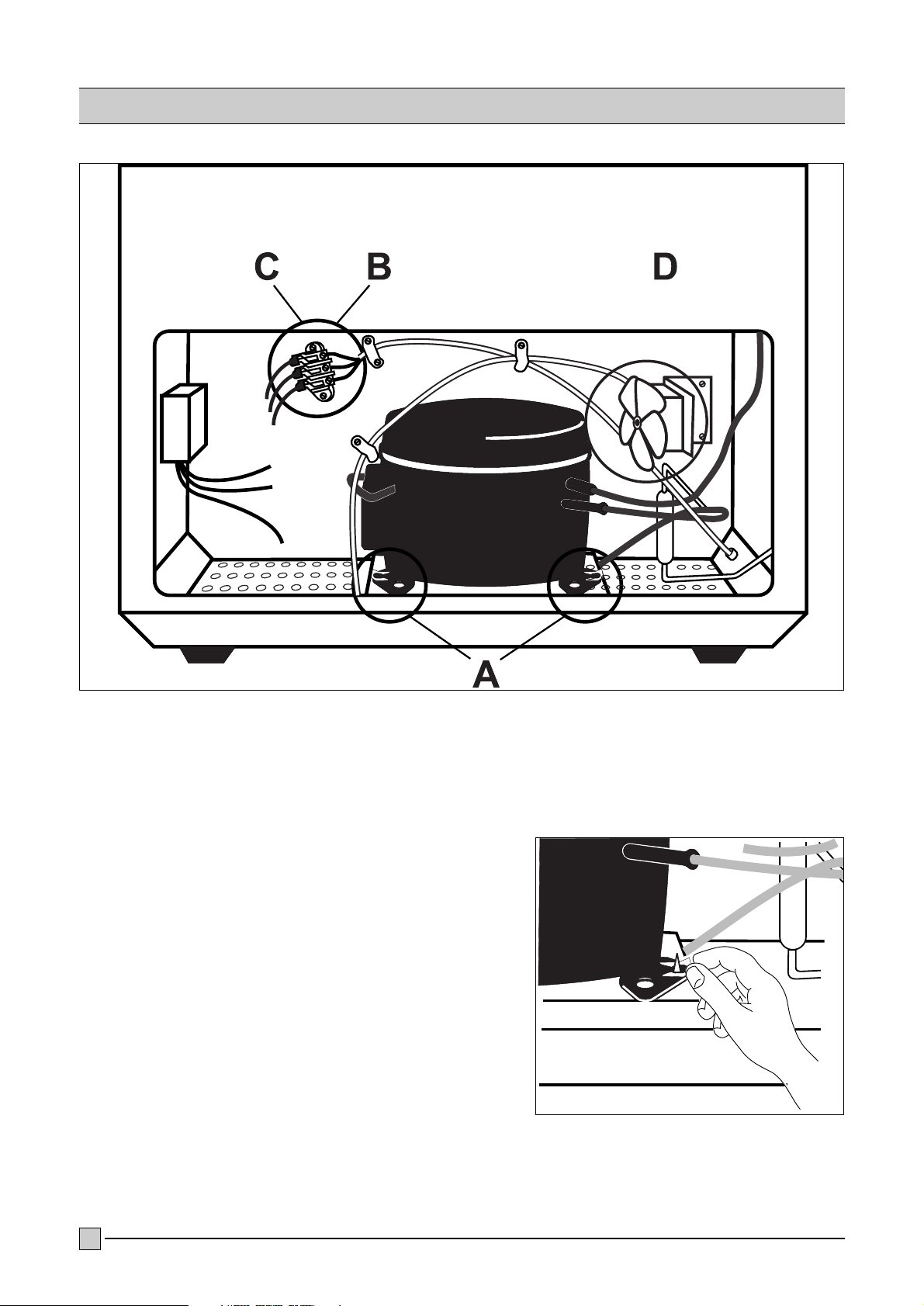

LOCATION B (fig. 5)

Check that the incoming electrical connections of the

power supply cord to the terminal strip are tight.

LOCATION C (fig. 6)

Check that the outgoing electrical connections from

the terminal strip are tight.

LOCATION D (fig. 7)

Check that the mounting brackets of the fan are tight

and also that the fan blades are free to rotate.

2. INSTALLATION

7

Fig. 5.

Fig. 6.

Fig. 7.

Page 8

8

4.

Refit side cover of the compressor compartment into

position refixing the screws holding the side cover (fig. 8)

5.

INSTALL firmly the ILR on a level

floor, preferably on wooden

blocks or on a wooden platform to

protect it from damp and dirt.

(fig. 5)

Leave sufficient space on all sides

of the ILR, keep it away from the

walls for good circulation of air

around it, see below:

Back and left side should be

minimum 3 cm away from the

walls (fig. 9a)

Hinges can be pushed against the

wall

Right side should be minimum

10 cm away from the wall (fig. 9b)

6.

The ILR has 4 supporting legs. If

the ILR is not in a level and stable

position, adjust this by adding

wooden blocks or similar under

the legs.

2. INSTALLATION

Fig. 8.

Fig. 9.

Fig. 9a

Fig. 9b

Page 9

9

7.

Connect the leads of the power supply cord to a

suitable 3-pin plug as shown below (fig. 10)

Lead of cord Pin of plug

Green/yellow Earth

Blue Neutral

Brown Phase

CAUTION:

DO NOT CONNECT THE ILR TO POVER SUPPLY

NOW

2. INSTALLATION

Fig. 10.

Page 10

10

1.

Open the lid of the appliance. Unscrew the the lid

ballast container. (fig. 11)

2.

Unscrew the cap of the lid ice accu and fil it with clean

water.

3.

Unscrew the 3 frame screws and remove the plastic

Refrigerator innerliner. (fig. 12)

4.

Remove all 36 ice-packs from the ice bank and the 5

ice-packs in the refrigeration compartment.

5.

Plug in the appliance for test. The green lamp

indicates that the unit is under power. (fig. 13)

6.

Check in the compressor compartment that the

compressor starts and the fan on the left side is running.

7.

Check that the blower in the bottom of the dividing wall

is running. Check by pushing with your fingers to the

flap thermostat, if a free moving to open and close the

cold air channel is granted.

3. PREPARATIONS

Fig. 11.

Fig. 12.

Fig. 13.

Page 11

11

8.

Fill the ice-packs to the marked level and screw on

the cap. To remove the cap, you press on the cap

from the top and simultaneously you turn the cap

anticlockwise. With your finger nail or a small

screw driver you push of the plastic protection.

(fig. 14)

9.

Put the 5 (filled with water) small ice-packs in the

bottom of the refrigeration compartment. (fig. 15)

10.

Fill all the 36 ice-packs with water, tight the cap

carefully and stack them in the greater freezing

compartment.

It is important that they are stacked exactly as

shown on the sketch in order to obtain air

circulation through the ice-packs and in order to

avoid damages caused by expansion during

freezing. (fig. 16)

11.

After correct installation of all the ice-packs insert

the plastic innerliner and fix it with his 3 screws.

12.

Refit the filled ballast container on the lid.

13.

Check that the drainage plug is always at his

position.

3. PREPARATIONS

Fig. 15.

Fig. 16.

Fig. 14.

Page 12

12

1.

Close the lid and plug in the appliance. The green

indicator light on the front control panel shows you

that the unit is switched on. (fig. 17)

2.

Turn the thermostat button to the position 1"

(20°C ambient) or at 2" (32°C ambient) and

leave the unit for minimum 48 hours. After this

time, check if the ice-packs in the ice bank are

completely frozen.

If you find after 48 hours that the temperature on

the front thermometer is warmer then the desired

range from 2 to 8°C you can adjust the thermostat

button to position 3" or 4".

If you find after 48 hours that the temperature on

the font thermometer is colder then the desired

range from 2 to 8°C you must check if the water

in the ballast container is frozen. If this is the case

you have to check the flap thermostat.

3.

When the temperature on the front thermometer

is observed to be steady for several hours within

the range from +2° to +8°C only then the

vaccines to be preserved should be transferred to

the ILR. (fig. 18)

4.

After storing the vaccines keep the lid properly

closed and locked.

5.

The inner temperature of the cabinet can fluctuate

due to several reasons:

to high ambient temperature,

to many openings of the lid,

to many vaccines at on time,

inner arrangement of the vaccines,

air circulation around the unit,

inner blower is not running.

4. USE THE APPLIANCE

Fig. 17.

Fig. 18.

Page 13

13

DEFROSTING & CLEANING

The moisture in the air, which enters the ILR due to lid

opening (and also may be due to defective lid-gasket

or door alignment) is attracted by the cold surfaces

inside the ILR. So, formation of frost and ice occurs

on the walls around the tubes inside the lining

compartment. When the frost layer is 1 /4" to 1 /2"

(6-12 mm) thick, it is time for `defrosting' the ILR.

MOST IMPORTANT:

Before defrosting the ILR, the vaccines preserved in it

will have to be removed and stored temporarily in

other working ILR or Refrigerator.

If a second ILR or Refrigerator is not available, the

vaccines will have to be preserved in Cold-Box or

Vaccine carrier, properly lining the same with frozen

ice packs, such that the vaccine temperature remains

within the recommended storage temperature during

the defrosting of the ILR.

DEFROSTING & CLEANING

PROCEDURE

1.

When the frost formation around the evaporator is 6 to

10 mm thick, it is time for Defrosting".

2.

Prepare the temporary storage and transfer the

vaccines to another refrigerator or cold box.

3.

Unplug the unit and open the lid for minimum 24 hours

so that all the ice around the evaporator and the ice

bank can melt.

4.

Open the drainage plug at the bottom, inside the

cabinet.

Keep a suitable container under the drain hose to

collect the defrost water. (fig. 19)

5. DEFROSTING & CLEANING

Fig. 19.

Page 14

14

5. DEFROSTING & CLEANING

5.

Unscrew the plastic innerliner and remove them.

6.

Remove all the ice-packs and store them in a transport

box, so that they not defrost at all.

7.

Use a scrapper the remove the ice formation around

the surfaces, never use a hairdryer to melt the ice

formation.

8.

Before you insert the ice-packs again you must be

sure that all the inner parts are absolutely dry.

9.

Check that the blower and the flap thermostat are

working correctly.

10.

If everything is 100% dry, you can insert the plastic

innerliner. Don´t forget to refit the drainage plug.

Page 15

15

DAILY

1.

Take temperature readings from the thermometers

and note down the temperature and the time of

reading.

Keep the temperature records systematically. It is

suggested that minimum 2 readings should be taken

(in the morning and afternoon) preferably at the same

hours of each day.

If the temperature is observed to be below or above

the required range, adjust the thermostat by steps,

allow the ILR to run for about one hour under

observation. If required, adjust the thermostat further

until the required temperature range is obtained.

To make the inside colder, the thermostat knob is to

be turned clockwise to a higher setting.

To make the inside warmer, the thermostat knob is to

be turned anti-clockwise to a lower setting.

2.

Check if the inner blower is running (by feeling the air

flow with your hand).

WEEKLY

1.

Check if ice formation has started around the

evaporator and the ice bank. Prepare for defrosting.

2.

Check if the gasket if not broken and if it seals tight

against the frame.

3.

Check if the ballast container in the lid is not frozen.

MONTHLY

1.

Clean the compressor compartment:

a) Put off the switch, if any, and take out the plug

from the wall socket.

b) Take out the side-cover of the compressor

compartment (see page 5, actions 1 ). Clean the

interior of the compressor compartment with a

soft brush.

c) Check the mounting brackets of compressor and

the bolts of the fan, if they are tight. If not, rectify.

d) Fit back the side cover (see page 8, actions 4)

2.

Clean the lid seal.

3.

If possible, put a standard mercury thermometer

inside the cabinet and compare the readings with

those of the dial thermometers and see if they are

correct.

Dial thermometers with incorrect readings may have

to be re-adjusted or replaced, as incorrect readings

may lead to wrong storage temperature and loss of

the potency of the vaccines preserved.

6. PERIODIC OBSERVATIONS/CHECKS/ACTIONS

Page 16

16

IMPORTANT:

When an ILR is found to be not working at all or not

working properly, see that the vaccine temperature is

within the recommended limits.

Do not open the lid unless very essential.

Observe temperature from time to time and if you feel

that temperature may exceed the higher limit before

the ILR is repaired - transfer the vaccines to other

working ILR/refrigerator or cold-box.

If required use smaller pieces of commercial ice in

polythene bags in the cold-box - in absence of frozen

ice packs.

For any abnormal sound, smoke, smell etc. in the ILR

disconnect the plug from the wall socket and notify

refrigerator technician.

A) THE ILR IS NOT WORKING

1. Observe the `green' mains-on indicator light on

right on the front panel.

a) IF NOT GLOWING

I) Check if wall socket switch is OFF.

II) Check if the voltage stabilizer, if any, is working

or not.

III)Check if power supply is available at the wall

socket. This can be tested by connecting an

electric lamp or other appliances to the socket.

The lamp should glow or the appliances should

work, if supply is available at the socket.

If not available:

There may be some defect in the power supply circuit

(viz: blow-off fuse, loose connections, faulty switch or

socket, single phasing etc.) which should be rectified

through competent Electrical Maintenance

Technicians.

If power is available at the socket:

IV Check that the plug is inserted properly into the

socket.

V Check the plug for loose connection or

dislocation of power supply cable connections -

rectify if required.

VI)Remove the plug from socket. Check the

incoming and outgoing cable connections on the

terminal strip in the compressor compartment

(see page 6 & 7, actions 3B and 3C)

VII) Even after actions as above, the `yellow' lamp

is not glowing - Notify Refrigerator Technician.

b) IF GLOWING

I) Observe if the compressor cooling fan is

working. If the fan is working but the

compressor is not running - Notify Refrigerator

Technicians.

II) If the fan, too, is not working, check the

thermostat setting, if it is wrongly turned

completely anti-clockwise. If so, turn it

clockwise to a higher setting and observe if

the fan and the compressor are working now.

If working - Allow the ILR to run and adjust

thermostat to obtain recommended temperature.

If not working - Notify Refrigerator Technician.

B) COMPRESSOR IS WORKING, BUT

CABINET TEMPERATURE IS HIGHER

THAN NORMAL

NOTE:

The cabinet temperature may go little higher than

normal, but should come down after some time

when:

New vaccines are stored

The lid is opened frequently or kept open for

longer duration

Unfrozen ice packs are put in for freezing.

1.

Check if recommended space is left on back and

sides of the ILR for air circulation (see page 8,

action 6.

2.

Check if there is too much frost formation in the

liner chamber on the inside walls. If so, defrost (see

page 13 for Defrosting and Cleaning)

3.

Check if the compressor is cut `off' by the

thermostat before required temperature is attained.

If so, adjust thermostat setting.

7. TROUBLE SHOOTING

Page 17

17

4.

If the compressor is observed to be running

continuously but no cooling is attained - this may be

due to leakage of refrigerant gas from the system or

defect in the unit, - Notify Refrigerator Technician.

5.

Check if the compressor tries to start but trips-off early

by the over-load protector. This may be either due to

too low supply voltage or defect in the compressor or

starting relay - put `off' the ILR till return of normal

voltage and try to run once again. If the defect

prevails, - Notify Refrigerator Technician.

C) CABINET TEMPERATURE IS

LOWER THAN NORMAL

Turn the thermostat knob, anti-clockwise, to a lower

setting and observe if the compressor is cut `off' by the

thermostat. If the same does not cut `off' even at the

lowest (1) setting, the thermostat may be defective and

may have to be replaced - Notify Refrigerator Technician.

NOTE:

In such cases, till the repair is done, the vaccines

should be preserved as follows

a) Take out the floors and the layer of ice packs

b) Put one layer of fresh (non-frozen) ice packs o n

the bottom and replace the floors

c) Keep some not-frozen ice packs on and around the

vaccines also

d) Run the ILR under surveillance and put it `off' when

lowest recommended temperature is attained. Put

the ILR `on' again when the highest recommended

temperature is reached and keep it running until the

lowest recommended temperature is attained

again. Repeat as above till the ILR is repaired.

D) ABNORMAL NOISE IN THE ILR

In case of any abnormal noise coming out from the

ILR, try to locate the source of the noise. Generally

it may come from the compressor compartment. In

such cases,

1. Take out the plug of the ILR from socket and

open the side cover of the compressor

compartment (see page 5, actions 1 )

2. Examine if the mounting brackets of the

compressor are in place and secure, and if the

mounting bolts for the fan are tight. If required

replace broken or lost brackets and tighten loose

bolts (see page 6 & 7, fig. 4 & 7)

3. Check if any pipe or component has come out of

its position and also touching others. If so, rectify

carefully.

4. Check if the ILR is level and firm on its base. If

not, rectify.

5. Even after actions as above if it is observed that

the noise is still present or it is coming from the

inside of the compressor - Notify Refrigerator

Technician.

7. TROUBLE SHOOTING

Page 18

18

IF THE ILR IS TO BE SHUT DOWN FOR

TRANSPORTATION ETC.

Disconnect the power-supply plug from socket

Allow the ice in the liner tuber (if any) to melt and

pour out the water completely and put back the

plugs on the tubes

Defrost and clean the interior

Leave the lid open till the ILR is absolutely dry ·

Roll the power supply cord into a coil and bind

and place it carefully to avoid damage

8. SHUTTING DOWN

FOR STORING VACCINES

1.

Keep the packets containing the vaccines in neat

rows,

2.

Different vaccines should be kept separately to

facilitate easy identification.

3.

Keep about 2 cm space between rows for circulation

of air.

4.

Store DPT & TT vaccines, not touching the inside walls

or bottom of the ILR. It is better to keep them in the

baskets.

5.

Keep a separate thermometer among the vaccines to

ascertain the actual vaccine temperatur

9. STORAGE OF VACCINES IN THE ILR

Page 19

19

Loading...

Loading...