Page 1

Model PL36PC40EC

ENGLISH.....................................2

FRANÇAIS................................10

Page 2

READ AND SAVE THESE INSTRUCTIONS

!

INTENDED FOR DOMESTIC COOKING ONLY

!

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the address or

telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and lock service panel to prevent power from being switched on

accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag,

to the service panel.

3. Installation work and electrical wiring must be done by a qualified person(s) in accordance with all applicable codes and standards,

including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning equipment to prevent

backdrafting. Follow the heating equipment manufacturer’s guidelines and safety standards such as those published by the National

Fire Protection Association (NFPA), and the American Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE),

and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any separate solid-state speed control device.

8. To reduce the risk of fire, use only metal ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high settings. Boilovers cause smoking and greasy spillovers that may ignite. Heat oils

slowly on low or medium settings.

B. Always turn hood ON when cooking at high heat or when flambeing food (i.e. Crepes Suzette, Cherries Jubilee, Peppercorn Beef

Flambe’).

C. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or filter.

D. Use proper pan size. Always use cookware appropriate for the size of the surface element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS.

If the flames do not go out immediately, EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

!

CAUTION

1. To reduce risk of fire and to properly exhaust air, be sure to duct air outside. Do not vent exhaust air into spaces within walls or

ceilings or into attics, crawl spaces, or garages.

2. Take care when using cleaning agents or detergents.

3. Avoid using food products that produce flames under the Range Hood.

4. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

5. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall spray, construction dust, etc. off power unit.

6. Your hood motor has a thermal overload which will automatically shut off the motor if it becomes overheated. The motor will restart

when it cools down. If the motor continues to shut off and restart, have the hood serviced.

7. For best capture of cooking impurities, the bottom of the hood should be a minimum of 24" and a maximum of 30" above the cooking

surface. See “Install Mounting Bracket” section for mounting restrictions.

8. Two installers are recommended because of the large size and weight of this hood.

9. Use with approved cord-connection kit only.

10. Please read specification label on product for further information and requirements.

- 2 -

Page 3

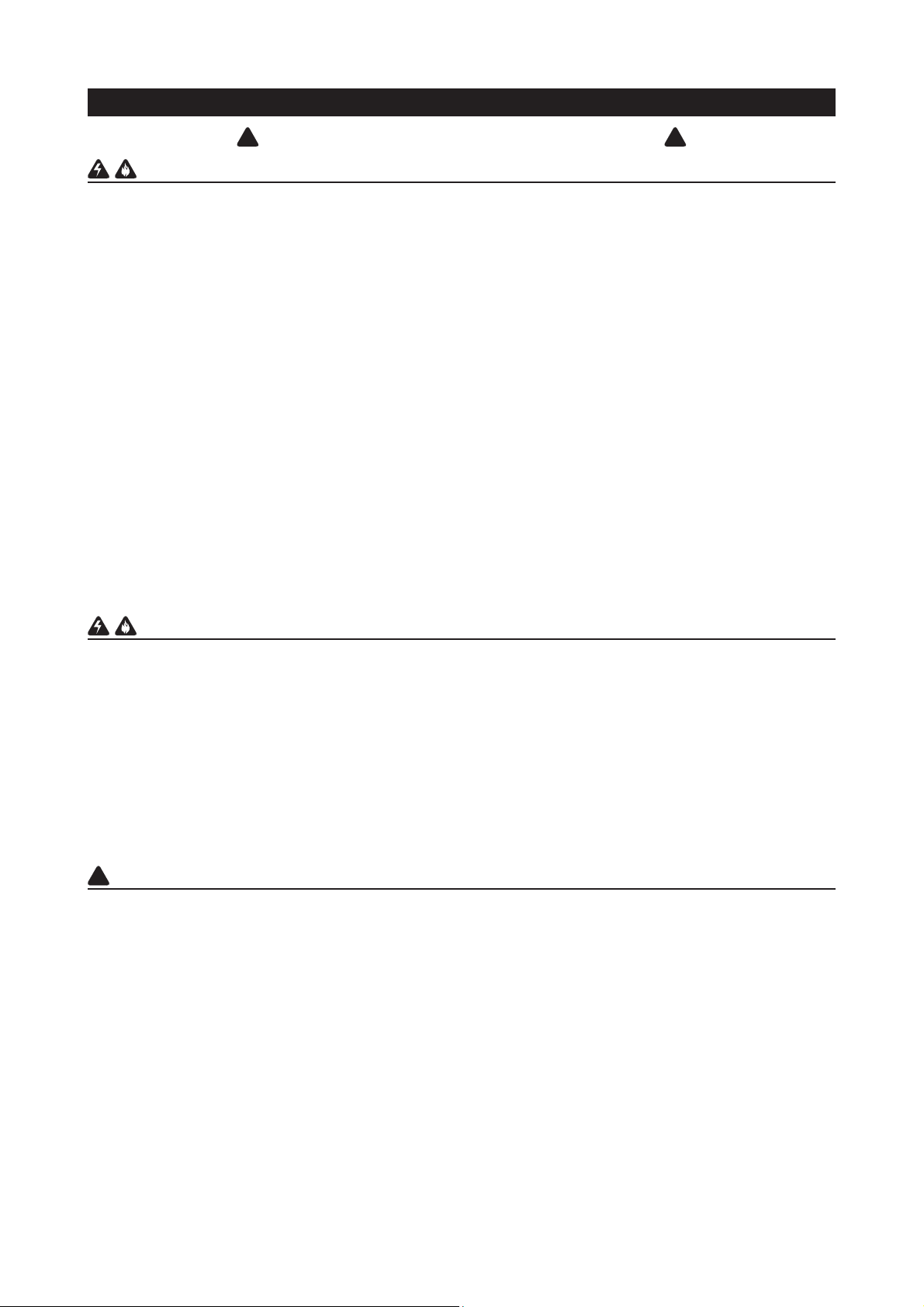

OPERATION

Controls

The hood is operated using the (5) push-buttons located at eye-level, on the front

edge of the hood.

The light switch turns the halogen lights on and off. Push the light switch once to

turn the lights ON - push a second time to turn the lights ON to a brighter level push a third time to turn the lights OFF.

The blower on-off / speed 1 switch turns the blower on to its lowest running speed.

To turn OFF the blower, push in and hold this blower switch for approximately 2

seconds.

The blower speed 2 switch turns the blower on to medium-low running speed.

Pressing this switch a second time sets a timer which keeps the blower operating

at this speed for 10 minutes. The LED will blink during this time and the blower will

shut off automatically.

The blower speed 3 and blower speed 4 switches operate the same as blower

speed 2 switch except: Blower speed 3 is medium-high and blower speed 4 is

high.

After every 30 hours of operation, the LED above the “blower speed 1 switch” will

be illuminated (RED) and blink for 30 seconds after turning off the blower. This is

a reminder to clean the grease filters. Once the grease filters are cleaned and

installed, press in and hold the “light switch” button for approximately 2 seconds

during the blink of the LED.

FIG. 1

HALOGEN BULBS

This range hood requires 4 halogen bulbs (Type JC, 12Volt, 20Watt Max, G-4

Base).

WARNING: Always switch off the electrical supply before carrying out any

operation on the appliance.

To change bulbs:

1. Open the cover by prying from the proper slots.

2. Remove the bulb by pulling sideways. (DO NOT ROTATE).

!

CAUTION: Bulb may be hot.

3. Replace with Type JC, 12Volt, 20 Watt Max, G-4 Base halogen bulb. Do not

touch replacement bulb with bare hands!

!

CAUTION: Use of bulbs greater than 20 watts will cause the fuse to open.

FUSE REPLACEMENT

IF LIGHTS FAIL TO OPERATE, DISCONNECT POWER AT THE SERVICE ENTRANCE. CHECK THE FUSE AND REPLACE IF NECESSARY.

1. Remove the grease filters.

FIG. 2

FUSE BOX

2. Open the fuse box. Fig. 3.

3. Unscrew the cap from the fuse holder and remove the fuse.

4. Replace the fuse with the same size and amperage (5 x 20mm, 4 amp, 125 volt).

!

CAUTION: Use of a fuse greater than 4 amps may damage the

transformer.

5. Reinstall the fuse holder cap.

6. Reconnect power at the service entrance.

- 3 -

FUSE

FIG. 3

Page 4

MAINTENANCE

Proper maintenance of the Range Hood will assure proper performance of the unit.

Grease Filters

The grease filters should be cleaned frequently. Use a warm detergent solution. Grease filters are dishwasher safe.

See “INSTALL FILTERS” section for removal and installation instructions.

Non-Ducted Recirculation Filter

The non-ducted recirculation filter should be changed every 6 months.

See “INSTALL FILTERS” section for removal and installation instructions.

Hood Cleaning

Stainless steel is one of the easiest materials to keep clean. Occasional care will help preserve its fine appearance.

Cleaning tips:

● Hot water with soap or detergent is all that is usually needed.

● Follow all cleaning by rinsing with clear water. Wipe dry with a clean, soft cloth to avoid water marks.

● For discolorations or deposits that persist, use a non-scratching household cleanser or stainless steel polishing

powder with a little water and a soft cloth.

● For stubborn cases, use a plastic scouring pad or soft bristle brush together with cleanser and water. Rub lightly in

direction of polishing lines or "grain" of the stainless finish. Avoid using too much pressure which may mar the surface.

● DO NOT allow deposits to remain for long periods of time.

● DO NOT use ordinary steel wool or steel brushes. Small bits of steel may adhere to the surface causing rust.

● DO NOT allow salt solutions, disinfectants, bleaches, or cleaning compounds to remain in contact with stainless steel

for extended periods. Many of these compounds contain chemicals which may be harmful. Rinse with water after

exposure and wipe dry with a clean cloth.

Painted surfaces should be cleaned with warm water and mild detergent only.

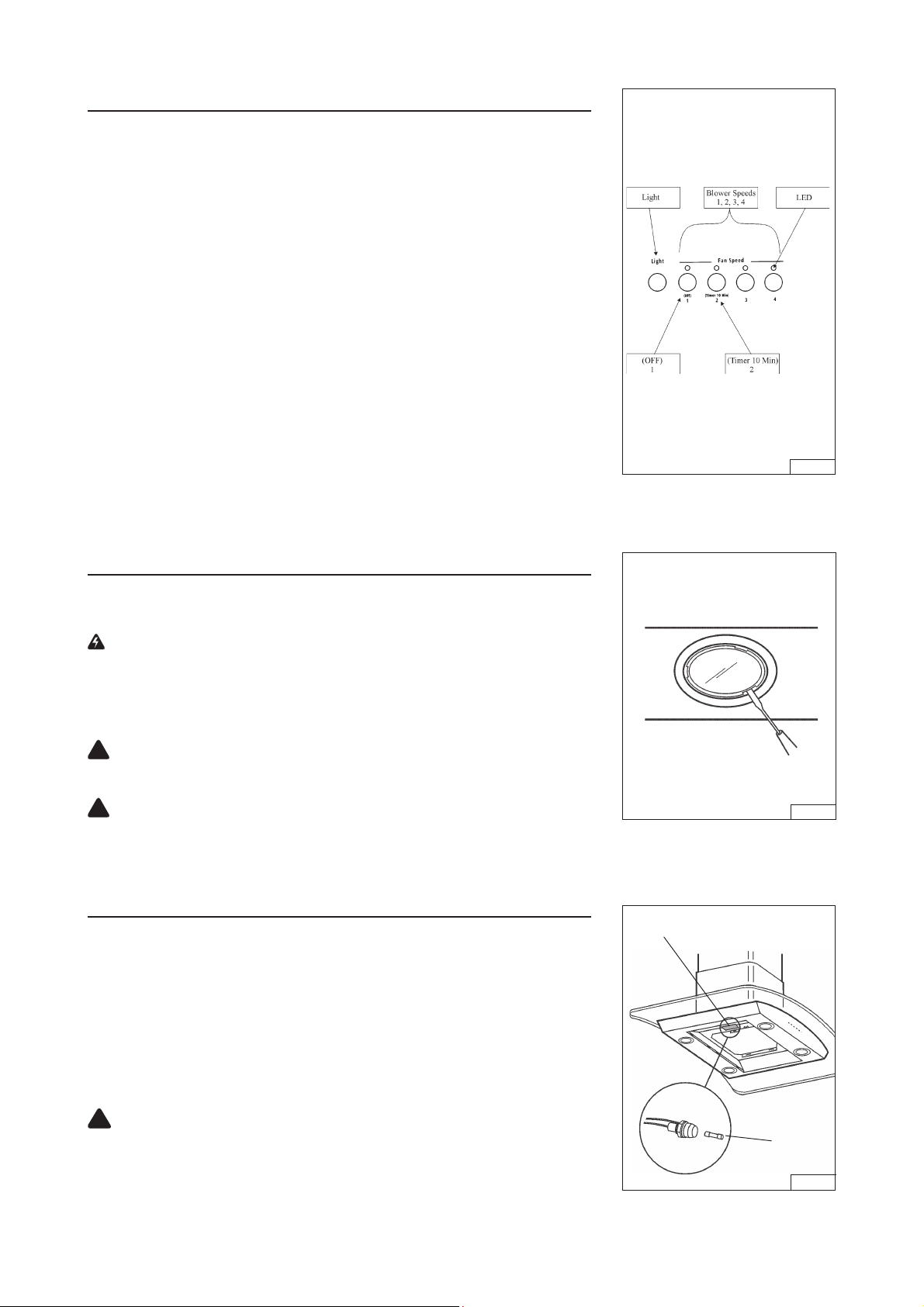

PREPARE THE HOOD

Unpack hood and check contents.

You should receive:

1 - Hood

1 - Decorative Flue Assembly

1 - Support Frame

1 - Parts Bag containing:

1 - Support Frame Bracket

1 - Discharge Collar

4 - Mounting Screws (6 x 70)

14 - Mounting Screws (3,9 x 9,5mm Pan Head)

2 - Mounting Screws (2.9 x 9.5mm Pan Head)

4 - Washers D.6.4mm

6 - Serrated Washers

1 - Wiring Box Cover

1 - Wire Clamp

1 - Installation Instructions

1 - Warranty Card

DISCHARGE

COLLAR

SUPPORT FRAME

BRACKET

WIRE

CLAMP

WIRING BOX

COVER

4 WASHERS

D.6.4mm

4 MOUNTING

SCREWS (6 x

70mm)

6 SERRATED

WASHERS

DECORATIVE

FLUE

SUPPORT

FRAME

14 MOUNTING

SCREWS (3.9 x

9.5mm Pan Head)

- 4 -

2 MOUNTING

SCREWS (2.9 x

9.5mm Pan Head)

FIG. 4

Page 5

INSTALL THE DUCTWORK

(DUCTED HOODS ONLY)

!

CAUTION: To reduce the risk of fire, use only metal ductwork.

1. Decide where the ductwork will run between the hood and the outside.

2. A straight, short duct run will allow the hood to perform most efficiently.

3. Long duct runs, elbows, and transitions will reduce the performance of the

hood. Use as few of them as possible. Larger ducting may be required for best

performance with longer duct runs.

4. Install a roof or wall cap. Connect round metal ductwork to cap and work back

towards hood location. Use duct tape to seal the joints between ductwork sections.

ROOF CAP

DECORA-

TIVE

FLUE

24” TO 30” ABOVE

COOKING SURFACE

ROUND

DUCT

ROUND

ELBOW

HOOD

6” ADAPTER

EAVE

VENT

FIG. 5

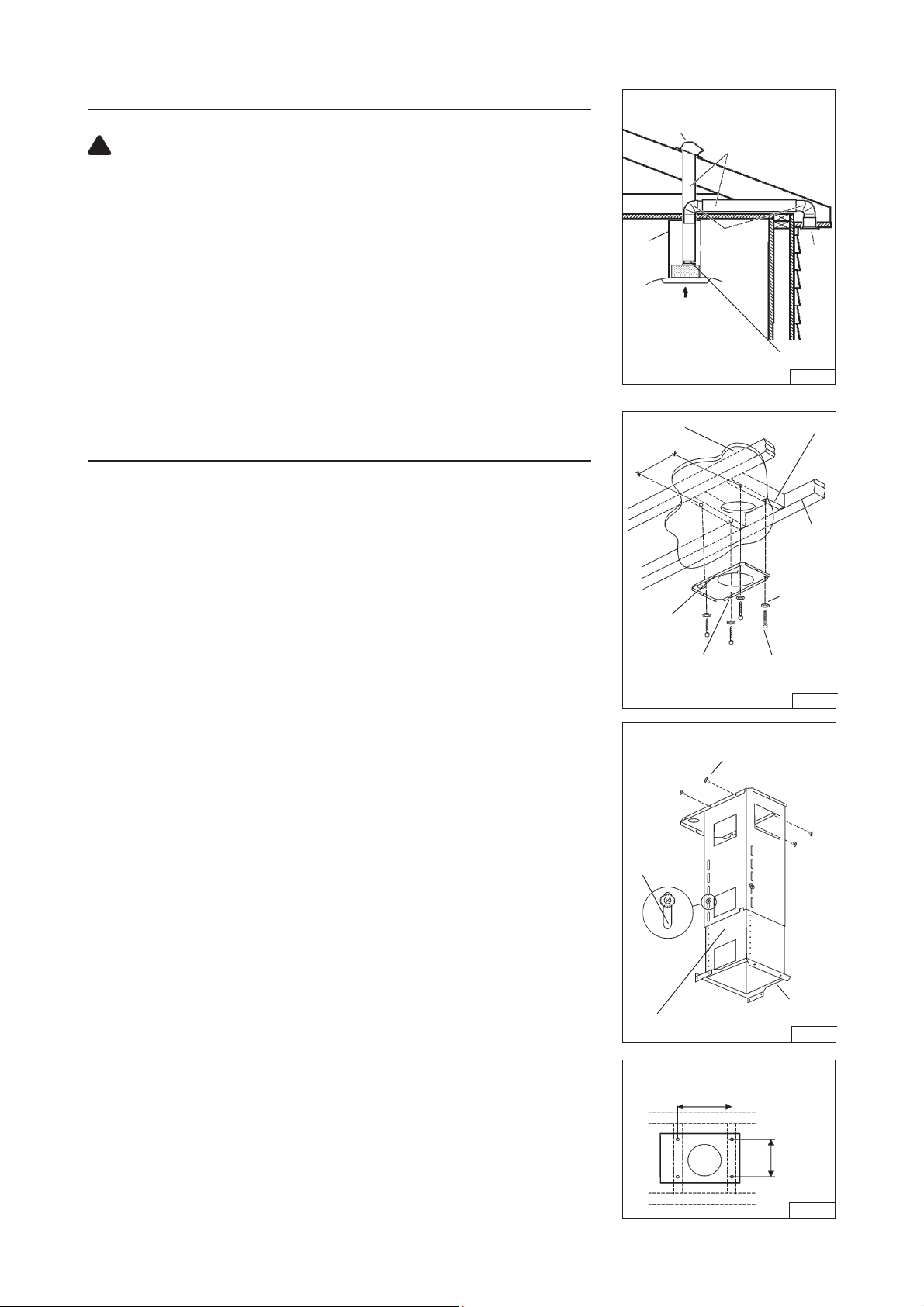

INSTALL SUPPORT SYSTEM

1. At hood location, install 2 X 4 cross framing between ceiling joists using

dimensions shown.

2. Finish the ceiling surface. Be sure to mark the location of the ceiling joists and

cross framing.

3. Secure the support frame bracket to joists and cross framing with four screws

provided (6x70mm) and four washers (D. 6.4mm). Make sure screws are driven

into center of joists and framing for maximum strength. Be careful, because the

position of the bracket determines the final position of the apparatus: the side with

the slot B corresponds to the side opposite the controls. Fig. 6.

4. Fix the support frame to the support frame bracket with (4) 3.9x9.5mm mounting

screws. Fig. 7.

5. Adjust the overall height of the support frame. Loosen and re-tighten the 4 screws

in the height adjustment slots as necessary.

DRYWALL

81/16”

FRONT

SLOT B

MOUNTING SCREWS

HEIGHT

ADJUSTMENT

SLOTS

CROSS FRAMING

CEILING

JOISTS

WASHERS

(Ø6.4mm)

MOUNTING SCREWS

(6x70mm)

FIG. 6

(3.9x9.5mm)

- 5 -

SUPPORT

FRONT

TOP VIEW OF SUPPORT FRAME

81/16”

FRAME

15

5

FIG. 7

/16”

FIG. 8

Page 6

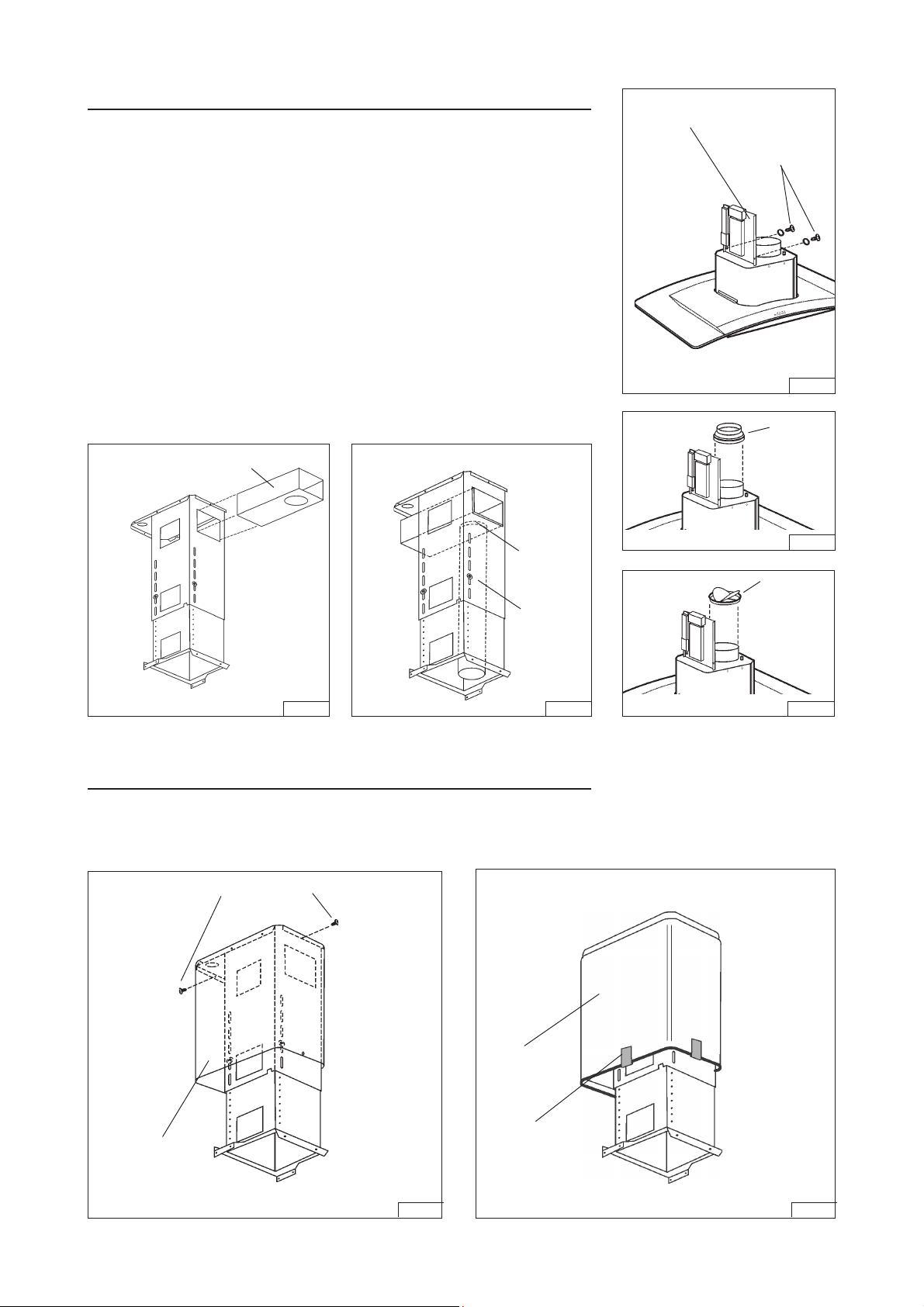

PREPARE THE HOOD

(DUCTED AND NON-DUCTED HOODS)

Fix the electrical mounting plate with (2) 3.9x9.5mm screws and (2) serrated washers.

Fig. 9.

(NON-DUCTED HOODS ONLY)

Purchase a Non-ducted recirculation KIT from your dealer (Model

DFKTPC40EC).

1. Insert the non-ducted recirculation plenum through the support frame openings.

Fig. 10.

2. Through the support frame openings fit the duct connector to the plenum locking

it with a turning movement. Fig. 11.

3. Fix a 5” duct to the duct connector of the non-ducted recirculation plenum.

Fig.11.

4. Mount the 6”/5” adapter above hood. Fig. 12.

(DUCTED HOODS ONLY)

Mount the discharge collar above the hood. Fig. 13.

NON-DUCTED

RECIRCULATION

PLENUM

ELECTRICAL MOUNTING

PLATE

MOUNTING

SCREWS

(3.9x9.5mm)

FIG. 9

6”/5”

ADAPTER

DUCT

CONNECTOR

5” DUCT

FIG.10

FIG.11

CONNECT DECORATIVE FLUE

1. Secure the upper flue to the upper support frame with the mounting screws

(2.9x9.5mm). Fig. 14.

2. Insert the lower flue moving it completely towards the top and fix it temporarily

with a tape. Fig. 15.

MOUNTING SCREWS

(2.9x9.5mm)

FIG.12

DISCHARGE

COLLAR

FIG.13

UPPER

FLUE

LOWER

FLUE

TAPE

FIG.14 FIG.15

- 6 -

Page 7

INSTALL THE HOOD

Fix the hood to the support frame with (6) 3.9x9.5mm mounting screws and (2)

serrated washers.

CONNECT DUCTWORK

(DUCTED HOODS ONLY)

1. Use 6" round metal duct to connect the discharge collar on the hood to the

ductwork above.

2. Use duct tape to make all joints secure and air tight.

3. Remove the tape from the lower flue and set it in place on the hood.

MOUNTING SCREWS

(3.9x9.5mm)

SERRATED

WASHERS

FIG.16

TAPE

INSTALL FILTERS

(DUCTED AND NON-DUCTED HOODS)

1. To remove the GREASE filter, push in on the metal latch tab and tilt filter

downward to remove.

2. To install the GREASE filter, align rear filter tabs with slots in the hood. Depress

the metal latch tab, push filter into position and release. Make sure filter is

securely engaged after installation.

NOTE: Prior to use, remove protective film from the filter frame.

(NON-DUCTED HOODS ONLY)

1. To remove the CHARCOAL filter, push in on the front filter latch. Pull the filter

down to disengage the rear filter tabs.

2. To install the CHARCOAL filter, align the rear filter tabs with slots in the hood.

Push the filter up into place until the front latch snaps securely into the slot.

Make sure the filter is securely engaged after assembly.

3. Install GREASE filter after charcoal filter is installed.

6” ROUND METAL

DUCT

TABS

GREASE

FILTERS

FIG.17

FIG.18

- 7 -

LATCH

NON-DUCTED

RECIRCULATION

FILTER

FIG.19

Page 8

WIRING

Note: Electrical wiring must be done by a qualified person(s) in accordance with all applicable codes and standards.

This range hood must be properly grounded. Turn off electrical power at service entrance before wiring.

1. Remove the (2) screws of the upper flue and move the upper flue towards the bottom.

2. Feed 6” of power cable through the top opening of the support frame bracket (installed on ceiling) and into the wiring

box. For the Non-Ducted Hoods, do not use the upper hole of the wiring box.

Secure cable to the wiring box using an appropriate connector.

3. Feed the range hoods power cable through the lower hole of the wiring box (use a wire clamp located in the Hardware

Package.

4. Make electrical connections. Wire white-to-white, black-to-black and green-to-green.

5. Push all wiring inside the wiring box. Install the wiring box cover with (2) 3.9x9.5mm screws and (2) serrated washers

making sure wires are not pinched.

6. Tuck excess power cable inside the flue.

7. Reinstall the upper flue.

LINE IN 120 VOLTS - 60 HZ

WIRING BOX

COVER

BLK-BLK

WHT-WHT

GRN-GRN

WIRE CLAMP

FIG. 20

- 8 -

Page 9

Major Appliance Warranty Information

Your appliance is covered by a one year limited warranty. For one year from your original date of

purchase, Electrolux will pay all costs for repairing or replacing any parts of this appliance that prove to

be defective in materials or workmanship when such appliance is installed, used and maintained in

accordance with the provided instructions.

Exclusions This warranty does not cover the following:

1. Products with original serial numbers that have been removed, altered or cannot be readily

determined.

2. Product that has been transferred from its original owner to another party or removed outside the USA

or Canada.

3. Rust on the interior or exterior of the unit.

4. Products purchased "as-is" are not covered by this warranty.

5. Food loss due to any refrigerator or freezer failures.

6. Products used in a commercial setting.

7. Service calls which do not involve malfunction or defects in materials or workmanship, or for

appliances not in ordinary household use or used other than in accordance with the provided

instructions.

8. Service calls to correct the installation of your appliance or to instruct you how to use your appliance.

9. Expenses for making the appliance accessible for servicing, such as removal of trim, cupboards,

shelves, etc.,which are not a part of the appliance when it is shipped from the factory.

10. Service calls to repair or replace appliance light bulbs, air filters, water filters, other consumables, or

knobs, handles, or other cosmetic parts.

11. Surcharges including, but not limited to, any after hour, weekend, or holiday service calls, tolls, ferry

trip charges, or mileage expense for service calls to remote areas, including the state of Alaska.

12. Damages to the finish of appliance or home incurred during installation, including but not limited to

floors, cabinets, walls, etc.

13. Damages caused by: services performed by unauthorized service companies; use of parts other than

genuine Electrolux parts or parts obtained from persons other than authorized service companies; or

external causes such as abuse, misuse, inadequate power supply, accidents, fires, or acts of God.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF REMEDIES

CUSTOMER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE

PRODUCT REPAIR OR REPLACEMENT AS PROVIDED HEREIN. CLAIMS BASED ON IMPLIED

WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW, BUT NOT

LESS THAN ONE YEAR. ELECTROLUX SHALL NOT BE LIABLE FOR CONSEQUENTIAL OR

INCIDENTAL DAMAGES SUCH AS PROPERTY DAMAGE AND INCIDENTAL EXPENSES RESULTING

FROM ANY BREACH OF THIS WRITTEN LIMITED WARRANTY OR ANY IMPLIED WARRANTY. SOME

STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES, SO

THESE LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO YOU. THIS WRITTEN WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS. YOU MAY ALSO HAVE OTHER RIGHTS THAT VARY FROM STATE TO

STATE.

If You Need

Service

This warranty only applies in the USA and Canada. In the USA, your appliance is warranted by Electrolux Major Appliances

North America, a division of Electrolux Home Products, Inc. In Canada, your appliance is warranted by Electrolux Canada

Corp. Electrolux authorizes no person to change or add to any obligations under this warranty. Obligations for service and

parts under this warranty must be performed by Electrolux or an authorized service company. Product features or

specifications as described or illustrated are subject to change without notice.

USA

1.800.944.9044

Electrolux Major Appliances

North America

P.O. Box 212378

Augusta, GA 30907

Keep your receipt, delivery slip, or some other appropriate payment record to establish the warranty period

should service be required. If service is performed, it is in your best interest to obtain and keep all receipts.

Service under this warranty must be obtained by contacting Electrolux at the addresses or phone numbers

below.

Canada

1.800.668.4606

Electrolux Canada Corp.

5855 Terry Fox Way

Mississauga, Ontario, Canada

L5V 3E4

- 9 -

Page 10

LISEZ ET CONSERVEZ CES INSTRUCTIONS

!

SEULEMENT POUR UTILISATION DOMESTIQUE

!

AVERTISSEMENTS

POUR REDUIRE LES RISQUES D’INCENDIE, DE DECHARGES ELECTRIQUES OU DE DOMMAGES AUX PERSONNES,

OBSERVEZ LES INSTRUCTIONS SUIVANTES:

1. N’utilisez cet appareil que comme cela est indiqué par le constructeur. Si vous avez des problèmes, contactez le fabriquant à l’adresse

ou au numéro de téléphone indiqués dans la garantie.

2. Avant de pourvoir à l’entretien ou au nettoyage de votre appareil, éteignez-le au tableau des commandes ou bloquez le tableau des

commandes afin d’éviter de le mettre en marche accidentellement. Si vous ne pouvez pas bloquer le système permettant d’éteindre

votre appareil, appliquez un avertissement extérieur d’une façon sure, comme par exemple un panneau, sur le tableau des commandes.

3. L’assemblage et la connexion électrique doivent être faits par des personnes qualifiées en respectant les normes et règlement s en

vigueur, y compris les normes et règlements concernant les possibilités d’incendie.

4. Il est indispensable qu’il y ait suffisamment d’air pour que la combustion et l’évacuation des gaz à travers le tuyau du brûleur du

combustible ait lieu sans retour de flamme. Suivez les indications données par le fabricant du brûleur ainsi que les normes de sécurité

comme celles qui sont publiées par l’Association Nationale pour la Protection contre les Incendies National Fire Protection Association

(NFPA) et la American Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), et les autorités locales en matière

de normes.

5. Quand vous coupez ou percez des trous dans le mur ou le plafond, n’abîmez pas les fils électriques ou autres.

6. Le ventilateur canalisé doit toujours évacuer l’air vers l’extérieur.

7. N’utilisez pas cet appareil avec un appareil contrôlant la vitesse à état solide.

8. Afin de diminuer tout risque d’incendie n’utilisez que des conduits en métal.

9. Votre appareil doit être relié à la terre.

ATTENTION - POUR REDUIRE LES RISQUES D’INCENDIE DES MATIERES GRASSES QUI SONT EN TRAIN DE CUIRE:

A. Ne laissez jamais ni vos éléments chauffants, ni vos casseroles ou poêles sur le feu sans les contrôler si vous réglez l’apport de

chaleur sur une position élevée. Si vos casseroles ou poêles débordent cela provoque de la vapeur et des éclaboussures de graisse

qui peuvent prendre feu. Chauffez les huiles lentement à feu bas ou moyen.

B. Faites toujours fonctionner votre hotte quand vous cuisez à des températures élevées ou quand vous cuisinez des plats flambés.

(par ex. crêpes Suzette, Cerises “Jubilé”, Steack au poivre flambé).

C. Nettoyez régulièrement les ailes de vos ventilateurs. Ne permettez pas que la graisse s’accumule sur le ventilateur ou sur le filtre.

D. Utilisez des casseroles de taille appropriée. Utilisez toujours des ustensiles de cuisson dont la taille est appropriée à la surface de

votre élément de cuisson.

AVERTISSEMENTS

POUR REDUIRE LES RISQUES DE DOMMAGES AUX PERSONNES AU CAS OÙ VOTRE CUISINIERE PRENDRAIT FEU, OBSERVEZ

LES INSTRUCTIONS SUIVANTES:*

1. ETEINDRE LES FLAMMES à l’aide d’un couvercle le plus hermétique possible, une plaque à gâteaux, ou un plateau en métal, puis

éteindre le brûleur. ATTENTION à NE PAS VOUS BRÛLER. Si les flammes ne s’éteignent pas immédiatement, SORTEZ ET

APPELEZ LES POMPIERS.

2. NE PRENEZ JAMAIS EN MAIN UNE POÊLE OU UNE CASSEROLE QUI A PRIS FEU - Vous pourriez vous brûler.

3. N’UTILISEZ PAS D’EAU, ni torchons ou serviettes mouillés - vous provoqueriez une violente explosion de vapeur.

4. Utilisez un extincteur SEULEMENT si:

A. Vous savez que vous avez un extincteur Classe ABC, et vous en connaissez déjà le mode d’emploi.

B. Ce n’est pas un très gros incendie et qu’il se limite à l’endroi où il a explosé.

C. Vous êtes en train d’avertir les pompiers.

D. Vous avez la possibilité d’essayer d’éteindre l’incendie en ayant le dos tourné vers une issue.

* D’après les “Suggestions concernant la Sécurité contre les incendies des cuisines” publiées par NFPA.

!

ATTENTION

1. Pour réduire tout risque d’incendie et pour évacuer correctement l’air, assurez-vous de prévoir un conduit de ventilation extérieur.

Ne videz pas l’air dans les espaces limités par des murs ou des plafonds, les combles, les passages étroits ou les garages.

2. Faites très attention quand vous utilisez des produits de nettoyage ou des détergents.

3. Évitez d’utiliser des aliments pouvant s’enflammer sous la Range Hood.

4. N’utilisez cet appareil que pour une ventilation générale. Ne l’utilisez pas pour évacuer des matières ou des vapeurs dangereuses

ou qui peuvent exploser.

5. Pour éviter de causer des dommages au moteur et de rendre les rotors bruyants et/ou non équilibrés, évitez que les sprays pour

murs secs, la poussière de construction entrent en contact avec la partie électrique.

6. Le moteur de votre hotte a un thermostat qui éteindra automatiquement le moteur s’il est surchauffé. Le moteur se remettra en

marche lorsqu’il se sera refroidi. Si le moteur continue à s’éteindre et à se remettre en marche, faites vérifier votre hotte.

7. Pour mieux capturer les impuretés de cuisine, le bas de votre hotte devrait être à une distance minimum de 24” et à une distance

maximum de 30” au-dessus du plan de cuisson. Voir la section “ Installation etrier d’assemblage “ pour les restrictions de montage.

8. Vu que cette hotte est grande et lourde, il est recommandé de confier l’installation de cette hotte à deux personnes.

9. Utiliser uniquement avec un kit de connexion pour alimentation homologué.

10. Nous vous recommandons de lire l’étiquette indiquant les caractéristiques de votre hotte pour de plus amples informations et

exigences.

- 10 -

Page 11

FONCTIONNEMENT

Commandes

Votre hotte fonctionne grâce aux (5) boutons sur lesquels vous devez appuyer et

qui se trouvent à la hauteur de vos yeux, sur le devant de votre hotte.

Le bouton de la lumière allume et éteint les lampes halogènes. En pressant 1 fois

la touche, la lumière s’allume au 1

ème

niveau s’allume (éclairage plus intense); en pressant encore une fois la

du 2

touche, la lumière s’éteint.

Le bouton ON/OFF vitesse 1 du ventilateur fait fonctionner le ventilateur à la

vitesse la plus basse. Vous éteignez le ventilateur appuyant sur le bouton pendant

2 secondes environ.

Le bouton deuxième vitesse fait fonctionner le ventilateur à une vitesse

moyennement basse. En appuyant une deuxième fois sur ce bouton vous faites

fonctionner un timer qui fera fonctionner le ventilateur à cette vitesse pendant 10

minutes. Le voyant lumineux clignotera pendant tout ce temps et le ventilateur

s’arrêtera automatiquement.

Les boutons du ventilateur 3ème et 4ème vitesse font fonctionner ce dernier

comme le bouton deuxième vitesse avec la différence que le bouton 3ème vitesse

est une vitesse moyennement élevée et le bouton 4ème vitesse est une vitesse

élevée.

Au bout d'environ 30 heures de fonctionnement, le LED rouge du “Bouton -vitesse

1” se mette à clognoter; cela indique que les filtres anti-graisse doivent être

nettoyées. Après avoir remonté les filtres anti-graisse propres, appuyez sur le

bouton de la lumière pendant 2 secondes environ, au même temps les voyants

lumineux clignotons

er

niveau; en pressant 2 fois la touche, la lumière

AMPOULES HALOGENES

FIG. 1

Ce modèle de hotte veut 4 ampoules halogènes (Type JC, 12Volt, 20Watt Max, G4 Base).

ATTENTION: Avant de procéder à quelconque opération, débranchez

l’appareil.

Pour changer les ampoules:

1. Ouvrez le couvercle en faisant levier grâce aux fissures prévues à cet effet.

2. Enlevez l’ampoule en tirant des deux côtés. (NE PAS FAIRE TOURNER).

!

ATTENTION : L’ampoule peut être chaude.

3. Remplacer par une ampoule ayant les mêmes caractéristiques (JC, 12Volt,

20Watt Max, G-4 Base). Ne touchez pas l’ampoule de remplacement à main

nue!

!

ATTENTION : L’utilisation d’ampoules supérieures à 20 watts ouvrira le

fusible.

REMPLACEMENT FUSIBLE

SI LA LUMIÈRE NE FONCTIONNE PAS, DÉCONNECTEZ LA PUISSANCE À

L’ENTRÉE DU BRANCHEMENT. VÉRIFIEZ LE FUSIBLE ET REMPLACEZ-LE

SI NÉCESSAIRE.

1. Enlever les filtres à graisse.

2. Ouvrir la boîte du fusible. Fig. 3.

FIG. 2

BOÎTE DU FUSIBLE

3. Dévissez le capot du support du fusible et retirez le fusible.

4. Remplacez le fusible par un fusible de même taille et de même intensité (5 x 20

mm, 4 amp, 125 volts).

!

ATTENTION : L’utilisation d’un fusible supérieur à 4 amps peut endommager

le transformeur.

5. Réinstallez le capot du support du fusible.

6. Reconnectez l’alimentation à l’entrée du branchement.

- 11 -

FUSIBLE

FIG. 3

Page 12

ENTRETIEN

Un bon entretien de votre hotte garantira une excellente performance.

Filtres à graisse

Les filtres à graisse devront être fréquemment nettoyés. Utilisez une solution à base de détergent tiède. Les filtres à graisse

peuvent aller au lave-vaisselle.

Voir la section “ INSTALLATION DES FILTRES “ pour les instructions d’installation et de retrait.

Filtres à charbon (Configurations non carénées)

Le filtre à charbon devra être changé tous les 6 mois.

Voir la section “ INSTALLATION DES FILTRES “ pour les instructions d’installation et de retrait.

Nettoyage de votre hotte

L’acier inoxydable est une des matières les plus faciles à nettoyer. Un entretien de temps en temps permettra de le

conserver en parfait état. Conseils pour le nettoyage:

● Eau chaude et savon ou détergent est tout ce qui est normalement nécessaire.

● Après chaque nettoyage, rincez bien à l’eau claire. Essuyez avec un chiffon propre et doux afin d’éviter les taches

d’eau.

● Si des décolorations ou des dépôts persistent, utilisez un nettoyant domestique non abrasif ou de la poudre pour

l’acier inoxydable et un peu d’eau et un chiffon doux.

● Dans les cas difficiles, utilisez une éponge en plastique ou une brosse douce avec du nettoyant et de l’eau. Frottez

légèrement en suivant la direction du polissage ou du “grain” de l’acier inoxydable. Evitez de frotter trop fort afin de ne

pas abîmer la surface.

● NE LAISSEZ PAS les taches trop longtemps.

● N’UTILISEZ PAS de laines d’acier ordinaires ou des brosses en acier. Des débris d’acier pourraient adhérer à la

surface et causer de la rouille.

● NE PERMETTEZ PAS que des solutions salées, des désinfectants, des blanchissants ou des produits nettoyants

restent en contact avec l’acier pendant longtemps. Beaucoup de ces produits contiennent des produits chimiques qui

pourraient causer des dommages. Rincez à l’eau immédiatement s’ils entrent en contact et essuyez avec un chiffon

humide.

Les surfaces peintes doivent être nettoyées avec de l’eau tiède additionnée d’un détergent doux seulement.

PREPAREZ LA HOTTE

Enlever la hotte dans l’emballage et controller le

contenu.

Vous devez recevoir :

1 - Hotte

1 - Conduit décoratif

1 - Structure de support

1 - Sachet avec:

1 - Etrier de la structure de support

1 - Collier d’évacuation

4 - Vis d’assemblage (6 x 70)

14 - Vis d’assemblage (3,9 x 9,5mm Tête ronde)

2 - Vis d’assemblage (2.9 x 9.5mm Tête ronde)

4 - Rondelles D.6.4mm

6 - rondelles déntées

1 - Couvercle boîte de connexion électrique

1 - Serre cable

1 - Instructions pour l’installation

1 - Garantie

COLLIER

D’EVACUATION

SERRE

CABLE

4 RONDELLES

D.6.4mm

ETRIER DE LA

STRUCTURE DE

SUPPORT

COUVERCLE DE LA

BOÎTE DE CONNEXION

ELECTRIQUE

CONDUIT

DECORATIF

STRUCTURE

DE SUPPORT

6 RONDELLES

DENTEES

- 12 -

14 VIS

D’ASSEMBLAGE

(3.9 x 9.5mm Tête

ronde)

4 VIS

D’ASSEMBLAGE

(6 x 70mm)

2 VIS

D’ASSEMBLAGE

(2.9 x 9.5mm

Tête ronde)

FIG. 4

Page 13

INSTALLATION DU SYSTEME D’EVACUATION

(HOTTES CARÉNÉES)

!

ATTENTION: Pour réduire les risques d’incendie, n’utilisez que des tuyaux

en métal.

1. Décidez où le tuyau rond doit être installé, entre votre hotte et l’extérieur.

2. Un tuyau droit et court permettra à votre hotte de fonctionner d’une façon plus

efficace.

3. Un tuyau long avec des coudes et des transitions réduira le bon fonctionnement

de votre hotte. En utiliser le moins possible. Pour de longues utilisations, il faut

un tuyau d’évacuation d’air ayant un diamètre plus large.

4. Installez un couvercle sur le toit ou au mur. Reliez un tuyau en métal rond au

couvercle et faites-le aller jusqu’à l’emplacement de votre hotte. Rendez les

jonctions du tuyau hermétiques au moyen d’un ruban pour tuyaux.

COUVERCLE DU

TOIT

CONDUIT

DÉCORATIF

DE 24”(61cm) À 30”

(76cm) AU-DESSUS

DU PLAN DE CUISSON

TUYAU ROND

COUDE

ROND

HOTTE

6” (15cm)

ADAPTATEUR

FIG. 5

TROU

D’ÉVA-

CUATION

INSTALLATION DU SYSTEME DE SUPPORT

1. Installez, à l’emplacement de votre hotte, un cadre croisé de 2 x 4 entre les

solives du plafond en suivant les dimensions qui vous sont indiquées.

2. Perfectionnez la surface du plafond. Assurez-vous de bien marquer l’empla-

cement des solives et du cadre croisé au plafond.

3. Fixez l’etrier de la structure de support aux solives et au cadre croisé au moyen

des quatre vis (6x70mm) et quatre rondelles (D-6.4mm) qui vous sont fournies.

Assurez-vous que les vis soient bien centrées dans les solives et dans le cadre

croisé de sorte que le tout soit bien solide. Faites attention car le positionnement

de l’étrier détermine la position finale de l’appareil: le côté avec la fente B

correspond au côté opposé aux commandes. Fig. 6.

4. Fixez la structure de support à l’etrier au moyens des (4) vis d’assemblage

3.9x9.5mm. Fig. 7.

5. Réglez la hauteur totale de la structure de support. Désserrez et resserrez les

4 vis dans les fissures permettant de régler la hauteur selon ce qui est

nécessaire.

SURFACE DU

PLAFOND

81/16”

(205mm)

DEVANT

FENTE B

FISSURE POUR

RÉGLAGE EN

HAUTEUR

CADRE CROISÉ

SOLIVES DU

RONDELLES

D’ASSEMBLAGE

(6x70mm)

VIS D’ASSEMBLAGE

(3.9x9.5mm)

PLAFOND

(Ø6.4mm)

VIS

FIG. 6

- 13 -

STRUCTURE

DEVANT

VUE DE HAUT DE LA STRUCTURE

DE SUPPORT

1

/16”

8

(205mm)

DE SUPPORT

15

5

(151mm)

FIG. 7

/16”

FIG. 8

Page 14

PREPAREZ LA HOTTE

(HOTTES CARÉNÉES ET NON-CARENEES)

Fixez la plaque de l’installation electriqe au moyens des (2) vis d’assemblage

3.9x9.5mm et (2) rondelles déntées. Fig. 9.

(HOTTES NON-CARENEES)

Procurez-vous un KIT version recyclant l’air (Modele DFKTPC40EC) chez votre

fournisseur.

1. Enfiler le déflecteur d’air dans la structure de support. Fig. 10.

2. Par les ouvertures de la structure de support, montez la bride sur le déflecteur en

le bloquant avec un mouvement rotatoire. Fig. 11.

3. Fixer un tuyau de 5” (125mm) à la bride du déflecteur. Fig. 11.

4. Mounter l’adaptateur de 6”/5” sur la hotte. Fig. 12.

PLAQUE INSTALLATION

ELECTRIQUE

VIS D’ASSEMBLAGE

(3.9x9.5mm)

(HOTTES CARENEES)

Montez le collier d’évacuation sur la hotte. Fig. 13.

DEFLECTEUR

BRIDE

TUYAU

DE 5”

FIG.10 FIG.11

ASSEMBLAGE DU CONDUIT DECORATIF

1. Fixez le conduit supérieur à la structure de support du haut avec les vis

d’assemblage (2.9x9.5mm). Fig. 14.

2. Installer le conduit inférieur pour qu’il touche le plafond et le fixer provisoirement

à l’aide du ruban. Fig. 15.

FIG. 9

ADAPTATEUR

6”/5”

FIG.12

COLLIER

D’EVACUATION

FIG.13

CONDUIT

SUPERIEUR

VIS D’ASSEMBLAGE

(2.9x9.5mm)

CONDUIT

INFERIEUR

RUBAN

FIG.14 FIG.15

- 14 -

Page 15

INSTALLATION DE LA HOTTE

Fixez la hotte à la structure de support au moyen des (6) vis d’assemblage 3.9x9.5mm

et de (2) rondelles déntées.

CONNEXION DU SYSTEME D’EVACUATION

(CONFIGURATIONS CARÉNÉES)

1. Reliez le collier d’évacuation qui se trouve sur votre hotte au système d’évacuation

qui se trouve au-dessus au moyen d’un tuyau rond en métal de 6” (15cm).

2. Utilisez du ruban pour tuyauterie afin de rendre toutes les jonctions sures et étan-

ches.

3. Enlever le ruban provisoire sur le conduit inférieur et poser le conduit sur la

hotte.

VIS D’ASSEMBLAGE

(3.9x9.5mm)

RONDELLES

DENTEES

FIG.16

RUBAN

INSTALLATION DES FILTRES

(CONFIGURATIONS CARÉNÉES ET NON CARÉNÉES)

1. Pour retirer le filtre à GRAISSE, attrapez la languette du taquet et abaissez-la afin

de dégager le filtre de la hotte.

2. Pour remettre le filtre à GRAISSE en place, alignez les languettes arrière du filtre

avec les fentes de la hotte. Abaissez la languette vers le bas, poussez le filtre pour

le remettre à sa place, puis relâchez. Vérifiez que le filtre est bien placé.

REMARQUE : Avant utilisation, retirez le film de protection du cadre du filtre.

(CONFIGURATIONS NON CARÉNÉES)

1. Pour retirer le filtre à CHARBON, appuyez sur le taquet frontal du filtre.

Abaissez le filtre pour dégager ses languettes arrière.

2. Pour remettre le filtre à CHARBON en place, alignez les languettes arrière du

filtre avec les fentes de la hotte. Poussez le filtre pour le remettre en place jusqu’à

ce que le taquet frontal s’emboîte complètement dans la fente. Vérifiez que le

filtre est bien placé.

3. Mettez le filtre à GRAISSE en place après avoir installé le filtre à charbon.

TUYAU ROND EN METAL

DE 6” (15CM)

FILTRES

ANTI-GRAISSE

LANGUETTES

FIG.17

FIG.18

- 15 -

LOQUET DE

BLOCAGE

FILTRE A

CHARBON

FIG.19

Page 16

INSTALLATION ELECTRIQUE

Remarque : le câblage électrique doit être effectué par une personne qualifiée, et conformément aux codes et normes

en vigueur. La hotte doit être correctement reliée à la terre. Mettez l’alimentation électrique hors tension avant de

procéder au câblage.

1. Retirez les (2) vis du conduit superieur etpositionné-le en bas.

2. Faites glisser un câble d’alimentation de 6" jusqu’à l’ouverture supérieure de l’etrier de la structure de support (installée au

plafond) et dans la boîte de connexion electrique. Pour les hottes non-carénées, ne pas utilizer le trou supérieur de la boîte

de connexion electrique.

Fixez le câble à la boîte de connexion electrique au moyen d’un connecteur appropriée.

3. Faites glisser le câble d’alimentation de la hotte dans le trou inférieur de la boîte de connexion electrique (utiliser le serrecable qui se trouve dans le sachet accessoires).

4. Réalisez les connexions électriques. Reliez les deux câbles blancs, les deux câbles noirs et les deux câbles verts.

5. Insérez tous les câbles dans la boîte de connexion electrique. Installer le couvercle de la boîte de connexion electrique au

moyen de (2) vis 3.9x9.5mm et de (2) rondelles déntées en vérifiant qu’aucun câble ne dépasse et n’est coincé dans le

couvercle.

6. Regroupez les câbles d’alimentation dans le conduit.

7. Installer le conduit superieur.

LIGNE À 120 VOLTS - 60 HZ

COUVERCLE DE LA BOÎTE DE

CONNEXION ELECTRIQUE

NOIR-NOIR

BLANC-BLANC

VERT-VERT

SERRE CABLE

FIG. 20

- 16 -

Page 17

Informations sur la garantie des gros électroménagers

Votre appareil est couvert par une garantie limitée d’un an. Pendant un an à partir de la date d’achat

originale, Electrolux assumera les coûts des réparations ou du remplacement des pièces de cet appareil

qui présente un défaut de fabrication ou de matériau, si cet appareil est installé, utilisé et entretenu selon

les instructions fournies avec celui-ci.

Exclusions Cette garantie ne couvre pas ce qui suit :

1. Les produits dont le numéro de série original a été enlevé, modifié ou qui n’est pas facilement

déterminable.

2. Les produits qui ont été transférés de leur propriétaire inital à une autre partie ou qui ne sont plus aux

États-Unis ou au Canada.

3. La rouille à l’intérieur ou à l’extérieur de l’appareil.

4. Les produits vendus « tels quels » ne sont pas couverts par cette garantie.

5. Les aliments perdus en raison de pannes du réfrigérateur ou du congélateur.

6. Les produits utilisés dans les établissements commerciaux.

7. Les appels de service qui ne concernent pas un malfonctionnement, un défaut de fabrication ou un

vice de matériau ou pour les appareils qui ne font pas l’objet d’un usage domestique ou qui ne sont

pas utilisés conformément aux instructions fournies.

8. Les appels de service pour vérifier l’installation de votre appareil ou pour obtenir des instructions sur

la façon d’utiliser votre appareil.

9. Les frais qui rendent l’appareil accessible pour une réparation, par exemple enlever des garnitures,

les armoires, les étagères, etc. qui ne faisaient pas partie de l’appareil lorsqu’il a quitté l’usine.

10. Les appels de service au sujet de la réparation ou du remplacement des ampoules, des filtres à air,

des filtres à eau, d’autre matériel ou des boutons, poignées ou autres pièces esthétiques.

11. Les frais supplémentaires, y compris, sans s’y limiter, les appels de service après les heures

normales de bureau, le week-end ou les jours fériés, les droits et péages, les frais de convoyage ou

les frais de déplacement pour les appels de service dans des endroits isolés, notamment l’État de

l’Alaska.

12. Les dommages causés au fini de l’appareil ou à la maison pendant l’installation, y compris, sans s’y

limiter, aux planchers, aux armoires, aux murs, etc.

13. Les dommages causés par : des réparations faites par des techniciens non autorisés; l’utilisation de

pièces autres que les pièces Electrolux d’origine qui n’ont pas été obtenues par l’entremise d’un

réparateur autorisé; ou les causes étrangères comme l’abus, l’alimentation électrique inadéquate ou

les cas de force majeure.

AVIS DE NON-RESPONSABILITÉ SUR LES GARANTIES IMPLICITES; LIMITATIONS DES RECOURS

L’UNIQUE RECOURS DU CLIENT EN VERTU DE CETTE GARANTIE LIMITÉE EST LA RÉPARATION OU

LE REMPLACEMENT DU PRODUIT COMME DÉCRIT PRÉCÉDEMMENT. LES DEMANDES BASÉES

SUR DES GARANTIES IMPLICITES, Y COMPRIS LES GARANTIES IMPLICITES DE QUALITÉ

MARCHANDE ET D’ADAPTATION À UN USAGE PARTICULIER SONT LIMITÉES À AU MOINS UN AN OU

À LA PÉRIODE LA PLUS COURTE PERMISE PAR LA LOI. ELECTROLUX NE SERA PAS TENUE

RESPONSABLE DES DOMMAGES DIRECTS OU INDIRECTS NI DES DOMMAGES MATÉRIELS ET DES

DÉPENSES IMPRÉVUES RÉSULTANT D’UNE VIOLATION DE CETTE GARANTIE ÉCRITE OU DE

TOUTE AUTRE GARANTIE IMPLICITE. CERTAINS ÉTATS ET CERTAINES PROVINCES NE

PERMETTENT PAS DE RESTRICTION OU D’EXEMPTION SUR LES DOMMAGES DIRECTS OU

INDIRECTS OU DE RESTRICTION SUR LES GARANTIES IMPLICITES. DANS CE CAS, CES

RESTRICTIONS OU EXEMPTIONS POURRAIENT NE PAS ÊTRE APPLICABLES. CETTE GARANTIE

ÉCRITE VOUS PROCURE DES DROITS LÉGAUX SPÉCIFIQUES. IL SE PEUT QUE VOUS AYEZ

D’AUTRES DROITS QUI VARIENT SELON L’ÉTAT OU LA PROVINCE.

Si vous avez

besoin d’une

réparation

Cette garantie n’est valide qu’aux États-Unis et au Canada. Aux États-Unis, votre appareil est garanti par Electrolux Major

Appliances North America, une division de Electrolux Home Products, Inc. Au Canada, votre appareil est garanti par

Electrolux Canada Corp. Personne n’est autorisé à modifier ou à ajouter aux obligations contenues dans cette garantie. Les

obligations de cette garantie concernant la réparation et les pièces doivent être remplies par Electrolux ou par une

compagnie de réparation autorisée. Les caractéristiques et spécifications décrites ou illustrées peuvent être modifiées sans

préavis.

Conservez votre reçu, votre bon de livraison ou une autre preuve valide de paiement pour établir la

période de la garantie dans le cas où vous devriez faire appel aux services d’un technicien autorisé. Si

une réparation doit être effectuée, veuillez obtenir et conserver tous les reçus. Le service auquel vous avez

recours en vertu de cette garantie doit être obtenu en communiquant avec Electrolux à l’adresse ou aux

numéros de téléphone indiqués ci-dessous.

ÉTATS-UNIS

1.800.944.9044

Electrolux Major Appliances

North America

Case postale 212378

Augusta, GA 30907, ÉTATS-UNIS

- 17 -

Canada

1.800.668.4606

Electrolux Canada Corp.

5855 Terry Fox Way

Mississauga, Ontario, Canada

L5V 3E4

Page 18

SERVICE PARTS - LISTE PIECES DE RECHANGE

MODEL PL36PC40EC

KEY No.

DESCRIPTION (ENGLISH )

N.

DESCRIPTION (FRANCAIS)

9 Grease Filter

14 Motor Capacitor

16 Electrical Box Support

19 Transformer Protection

26 Bulb

38 Board Box

38 Control Cover + Board

39 Board Box Cover

45 Blower

48 Motor

49 Blower Wheel

53 Rubber Washer

62 Blower Mounting Cover

63 Support Frame Bracket

64 Filter Support

76 Glass

86 Discharge Collar

92 Controls Support

110 Glass Plastic Gasket

110 Flue Plastic Gasket

113 Logo

115 Wiring Box

116 Wiring Box Cover

118 Decorative Flue Bottom

119 Decorative Flue Top

124 Bottom Support Frame

125 Top Support Frame

144 Wire Clamp

165 Electrical Box Capacitor

166 Board

208 Transformer

223 Switch Button

230 Switch Board Box Cover

234 Switch Board Box

274 Fuse Box

329 Electrical Box Support Plate

332 Cover

407 Blower Support Bracket

472 Glass Bracket

474 Halogen Lamp

477 Transformer Protection Cover

998 Hardware Package

AQI Controls Assembly (Includes Keys Nos.234,

38, 223, 230)

9 Filtre à graisse

14 Condensateur

16 Support boîte electrique

19 Protection transformateur

26 Ampoule

38 Boîte circuit imprimé electrique

38 Coiuvercle commandes + circuit imprimé

39 Couvercle boîte circuit imprimé electrique

45 Convoyer

48 Moteur

49 Turbine

53 Pare chocs

62 Couvercle convoyeur

63 Etrier de la structure de support

64 Support filtre

76 Vitre

86 Bride de raccordement

92 Support commandes

110 Garniture plastique du conduit

110 Garniture plastique vitre

113 Plaquette logo

115 Boîte de connexion electrique

116 Couvercle boîte de connexion electrique

118 Conduit décoratif inférieur

119 Conduit décoratif supérieur

124 Structure de support inferieure

125 Structure de support superieure

144 Serre cable

165 Boîte installation electrique

166 Circuit imprimé electrique

208 Transformateur

223 Bouton

230 Couvercle commandes

234 Boîte commandes

274 Boîte fusible

329 Plaque support boîte electrique

332 Couvercle

407 Etrier support convoyer

472 Etrier vitre

474 Lampe halogène

477 Couvercle protection transformateur

998 Accessoires de fixation

AQI Ensemble Commandes (Comprenant N. 234,

38, 223, 230)

- 18 -

Page 19

SERVICE PARTS - LISTE PIECES DE RECHANGE

MODEL PL36PC40EC

- 19 -

Page 20

04307536

Loading...

Loading...