Page 1

Patent No.: US D450, 829 S

READ AND SAVE THESE INSTRUCTIONS

PROFESSIONAL SERIES MODELS

PL30WC4IEC

PL36WC4IEC

GALLERY SERIES MODELS

GL30WC4IES

GL36WC4IES

GL30WC4IEB

GL36WC4IEB

!!

FOR DOMESTIC COOKING ONLY

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you

have questions, contact the manufacturer at the address or telephone

number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and

lock the service disconnecting means to prevent power from being

switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a

tag, to the service panel.

3. Installation work and electrical wiring must be done by a qualified

person(s) in accordance with all applicable codes and standards, including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases

through the flue (chimney) of fuel burning equipment to prevent

backdrafting. Follow the heating equipment manufacturer’s guideline

and safety standards such as those published by the National Fire Protection Association (NFPA), and the American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code

authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical

wiring and other hidden utilities.

6. To reduce the risk of fire or electric shock, do not use this range hood

with an additional speed control device.

7. Ducted fans must always be vented to the outdoors.

8. To reduce the risk of fire, use only metal ductwork.

9. Use with approved cord-connection kit only.

10. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings. Boilovers cause

smoking and greasy spillovers that may ignite. Heat oils slowly on low or

medium settings.

2. Always turn hood ON when cooking at high heat or when cooking flaming

foods.

3. Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate for the size of

the surface element.

TO REDUCE THE RISK OF INJURY T O PERSONS IN THE EVENT OF A

RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray,

then turn off the burner. BE CAREFUL TO PREVENT BURNS. If the

flames do not go out immediately, EVACUATE AND CALL THE FIRE

DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN — You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent steam

explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already

know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

!!

CAUTION

1. For general ventilating use only. Do not use to exhaust hazardous or

explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall spray, construction dust, etc. off power unit.

3. For best capture of cooking impurities, your range hood should be

mounted so that the top of the hood is 24-30” above the cooking surface.

4. Please read specification label on product for further information and

requirements.

Installer: Leave this manual with

the homeowner.

Homeowner: Operating and

Cleaning information on page 6.

NOTE If hood is to be installed Non-Ducted:

• Purchase a set of (2) non-ducted filters from your

local distributor or retailer and attach them to the

aluminum mesh filters.

TABLE OF CONTENTS

This manual is divided into sections as follows:

• “PREPARE HOOD LOCATION”

Run ductwork from roof or wall cap, and electrical wiring from service

panel - to installation location

• “PREPARE THE HOOD”

Get your hood ready for installation

• “CONNECT WIRING”

Make electrical wiring connections to hood

• “INSTALL HOOD”

Secure hood to cabinet and ductwork - install bulbs and filters

• “OPERATION”

How to use the hood controls

• “CLEANING”

Keep your hood in top working condition

• “SERVICE PARTS”

Key numbers and exploded view of hood components

• “WARRANTY”

One-year limited warranty and how to contact us

1

!

Page 2

HOOD

PREPARE HOOD LOCATION

PREPARE HOOD LOCATION

ROOF CAP

SOFFIT

CABINET

24" - 30" ABOVE

COOKING SURFACE

HOOD

HOOD

3¼" X 10" or

7" ROUND DUCT

(For vertical

discharge)

HOUSE WIRING

(Top or Back of hood)

WALL CAP

3¼" X 10" DUCT

(For horizontal discharge)

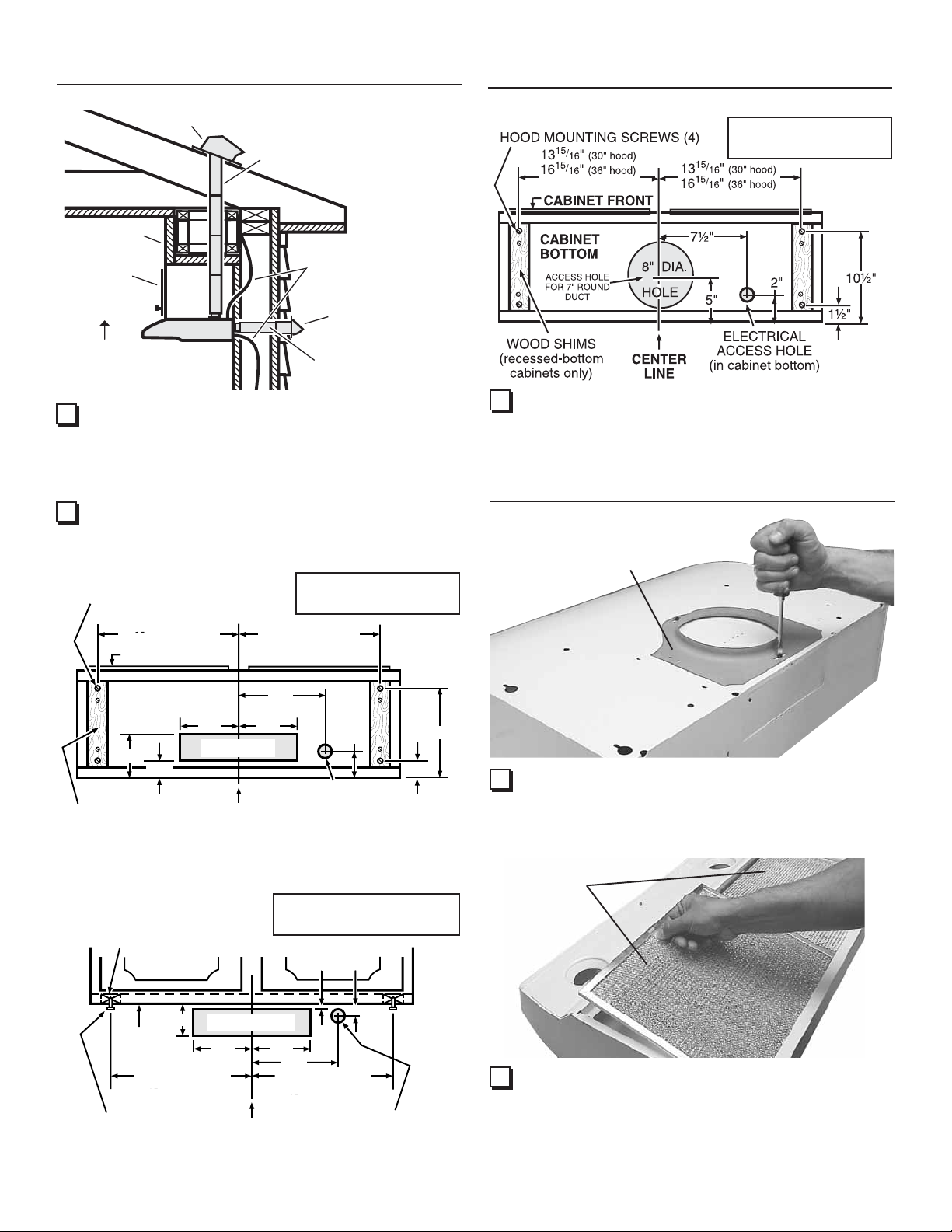

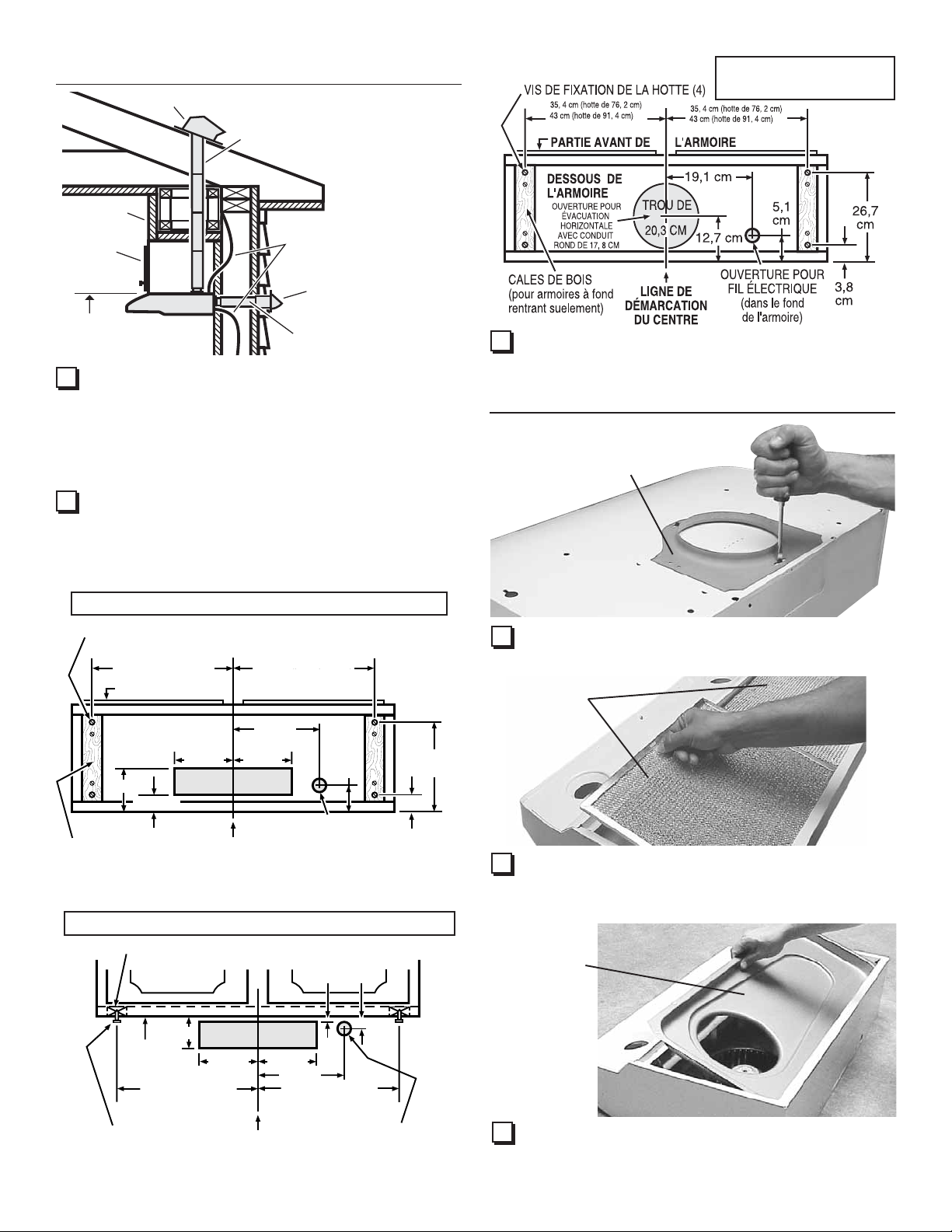

1 Determine whether hood will discharge vertically (3¼” x 10”

or 7” Round), or horizontally (3¼” x 10” only). For vertical or

horizontal discharge, run ductwork between the hood location and a roof cap or wall cap. For best results, use a minimum number of transitons and elbows.

2 Use diagrams, below, for proper placement of ductwork and

electrical cutout in cabinet or wall. For a non-ducted installation, DO NOT cut a duct access hole.

HOOD MOUNTING SCREWS (4)

15

/

13

" (30" hood)

16

15

/

16

" (36" hood)

16

15

/

19

" (42" hood)

16

CABINET FRONT

13

16

19

15

/

16

15

/

16

15

/

16

3¼” X 10”

VERTICAL DUCTING

" (30" hood)

" (36" hood)

" (42" hood)

7” ROUND

VERTICAL DUCTING

3 Run house wiring between service panel and hood

location.

PREPARE THE HOOD

7” ROUND

DUCT PLATE

5"

1¼"

WOOD SHIMS

(recessed-bottom

cabinets only)

WOOD SHIMS

(recessed-bottom

cabinets only)

3¾"

CABINET

BOTTOM

15

13

/

16

15

16

/

16

15

19

/

16

HOOD

MOUNTING

SCREWS (4)

7½"

CABINET BOTTOM

5¼"

VERTICAL DUCT

ACCESS HOLE

5¼"

CENTER

LINE

HORIZONT AL DUCTING

CABINET FRONT

HORIZONTAL DUCT

ACCESS HOLE

5¼"

" (30" hood)

" (36" hood)

" (42" hood)

CENTER

5¼"

13

16

19

LINE

2"

ELECTRICAL

ACCESS HOLE

(in cabinet bottom)

3¼” X 10”

1

"

/

¾"

8

7½"

15

" (30" hood)

/

16

15

" (36" hood)

/

16

15

" (42" hood)

/

16

ELECTRICAL

ACCESS HOLE

(in wall)

1½"

10½"

1 Remove 7” Round Duct Plate from top of hood. Set duct

plate aside - with mounting screws.

FILTERS

2 Remove tape holding Filters in place. Pull down on filter

tabs or finger holes and lift filters out. Set filters aside.

2

Page 3

PREPARE THE HOOD PREPARE THE HOOD

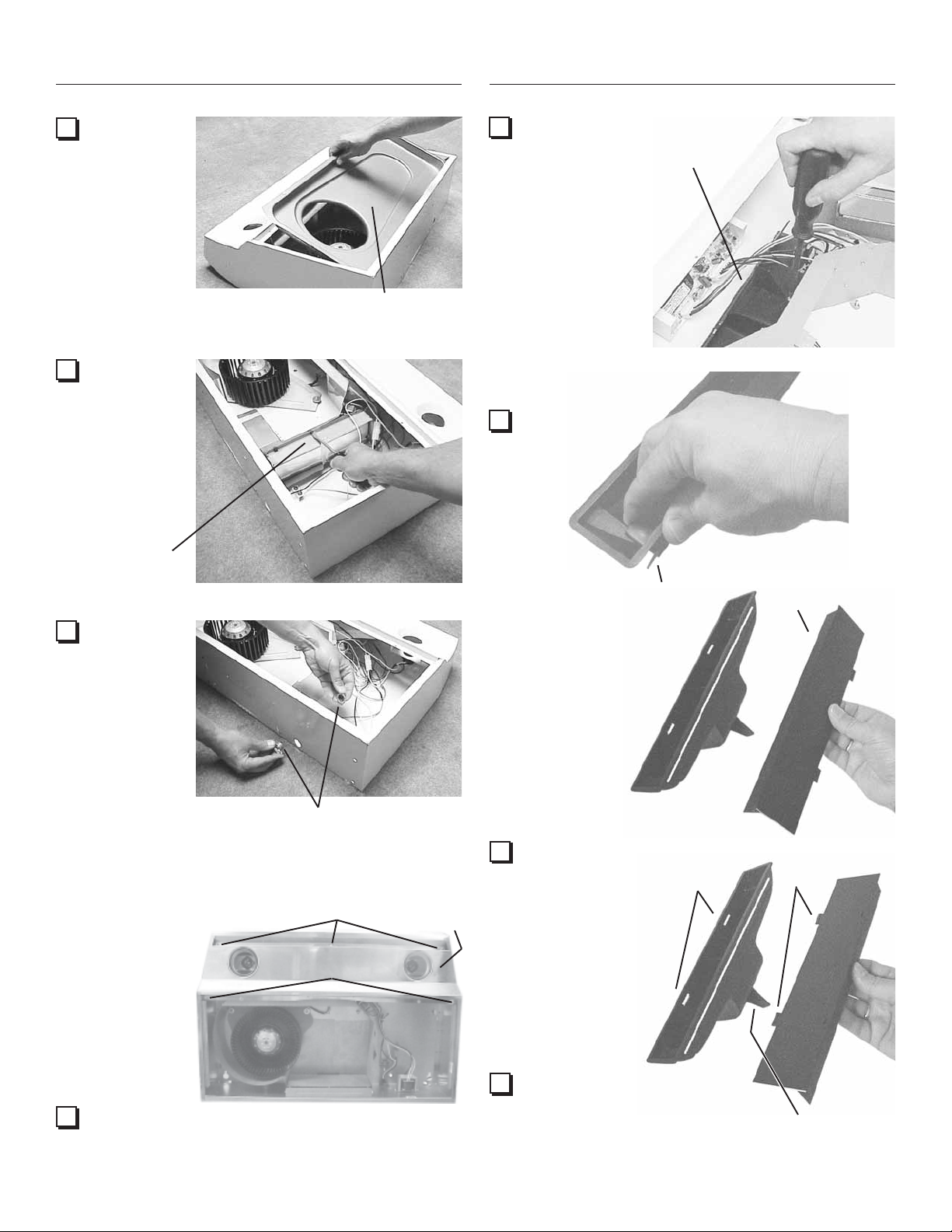

3 Remove

Teflon®-coated

bottom cover

from hood. Set

cover and

mounting screws

aside.

Teflon® is a registered

trademark of DuPont.

4 Remove

Damper/Duct

Connector

from inside

the hood. Set

connector

aside - with

mounting

screws and

parts bag.

DAMPER/

DUCT

CONNECTOR

TEFLON®-COATED BOTTOM COVER

(Held in place with 2 screws)

7 Remove Air

Chute

- held in

place with one

(1) screw.

NOTE: Be

careful not to

disconnect any

wires.

8 Remove Baffle

from air chute.

AIR CHUTE

➠

BAFFLE

BAFFLE

5 Remove

either top or

back wiring

knockout and

install

approved

Electrical

Cable Clamp

.

ELECTRICAL CABLE CLAMP

Non-Ducted Installation - Skip to Step 15.

(3) #8 SCREWS

The following

Steps (6 thru

14) are for

(2) #8 SCREWS

DUCTED

INST ALLATION

ONLY.

LIGHT

PANEL

9 Rotate baffle.

Reinsert baffle into

air chute (as

shown) so that

baffle

tabs fit all the

way into

chute. An audible

“click” will be heard

when fully installed.

This will close off

the air flow through

the non-ducted

slots on top of

hood.

slots in air

➠

SLOTS

➠

TABS

➠

➠

6 Remove Light Panel - held in place with (3) #8 screws and

(2) #8 screws. Disconnect light assembly wire harness

(white connector).

10

Re-install air chute, re-connect wire

harness, and replace light panel.

NOTE: Be careful not to trap wires

between

3

support fin and light panel.

SUPPORT FIN

Page 4

PREPARE THE HOOD

PREPARE THE HOOD

TOP RECTANGULAR

DUCT KNOCKOUT

(Remove for 3¼” x 10”

Vertical & for 7” Round

Discharge)

REAR

RECTANGULAR

DUCT KNOCKOUT

(Remove for 3¼” x 10”

Horizontal Discharge)

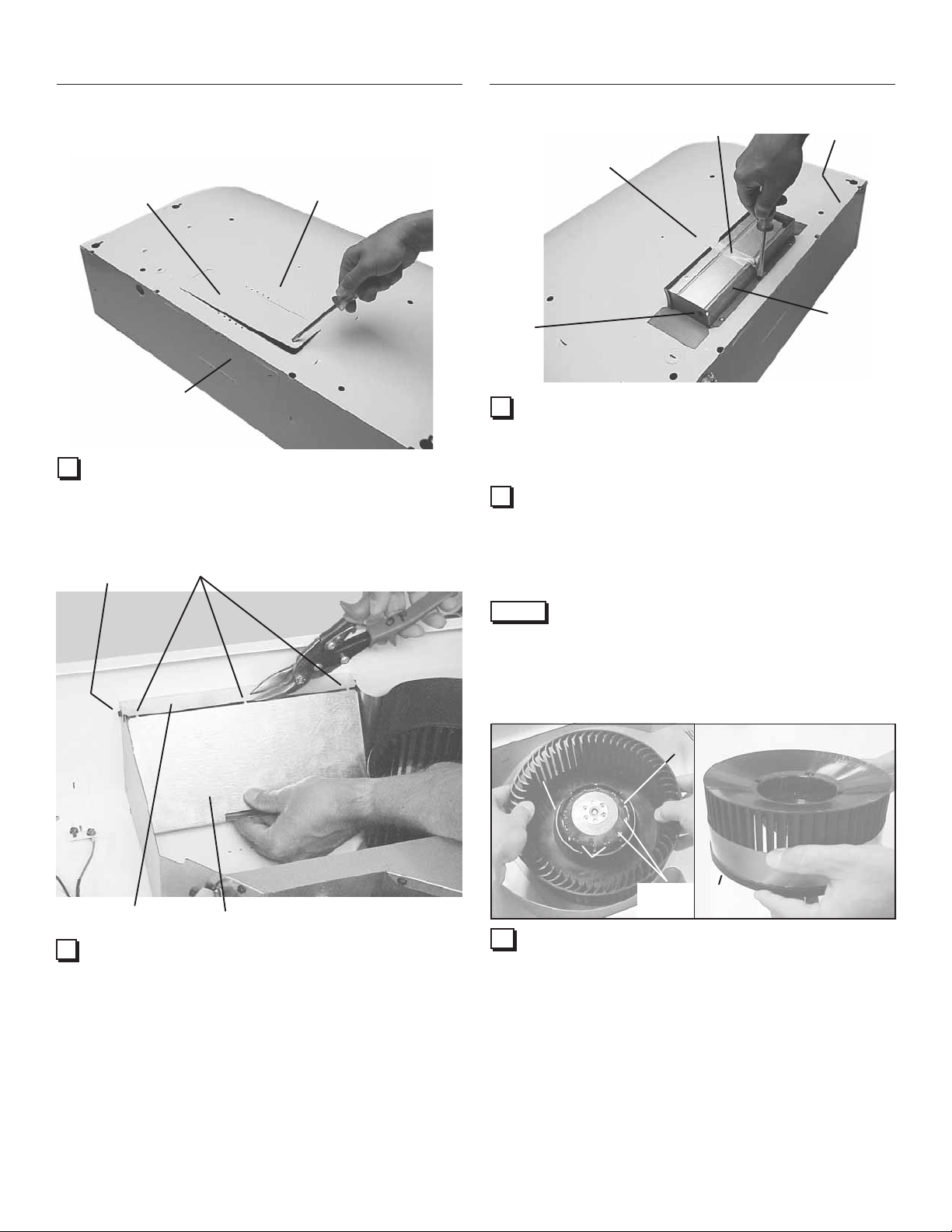

11 Remove appropriate Duct Knockout(s) from top or back of

hood.

SCREW

TIES

SEMI-CIRCULAR

DUCT KNOCKOUT

(Remove for 7” Round

Discharge)

TAPE

UP TO 1”

SIDE-TO-SIDE

ADJUSTMENT

TOP/BACK

EDGE

➙

➙

DAMPER/

PIVOT

13 3¼” x 10” Ducted Discharge Only: Remove Tape from

damper flap and attach

knockout opening with screws removed in Step 4 under

“PREPARE THE HOOD”. Make sure damper

to

Top/Back Edge of hood.

14 7” Round Ducted Discharge Only: Re-install 7” Round Duct

Plate

removed in Step #1 under “PREPARE THE HOOD”.

Install a 7” round damper (purchase separately). Damper flap

must open freely in direction of airflow (away from range

hood).

Damper/Duct Connector over

CONNECTOR

(Vertical discharge

position shown)

Pivot is nearest

DUCT

METAL STRIP

12 Horizontal Discharge Only: Remove the Plate in front of the

horizontal discharge knockout. Cut the

and discard plate. DO NOT REMOVE the

place with two

PLATE

Ties, lift plate out,

Metal Strip held in

Screws.

NOTE

hood center or the 7” Round Duct Plate can be installed up to ½”

on either side of hood center. In extreme off-center installations,

one end of the duct connector may need to be trimmed to clear the

electrical cable clamp.

RETAINING

15 Non-Ducted Installations Only: Require a Performance Ring

To accomodate off-center ductwork, the Damper/Duct

Connector can be installed up to 1-inch on either side of

BLOWER

RING

to be attached to the blower wheel.

To install ring:

1. Remove the

2. Slide the ring onto the

3. Reassemble wheel to motor. Make sure

4. Push wheel down until it is locked in place.

5. Check that wheel is properly positioned as shown. Press

WHEEL

SECTIONS

applying a slight force to pull wheel from motor. Remove

Retaining Ring if necessary.

and down to the

into one of the

Sections into place if necessary. Make sure wheel turns freely.

TAB

SMALL DIAMETER

MOTOR

SLOTS

Blower Wheel by rocking it side to side and

Stop Edge of the wheel.

Motor Slots.

STOP

EDGE

Small Diameter End of the wheel

END

RING

Tab on wheel fits

4

Page 5

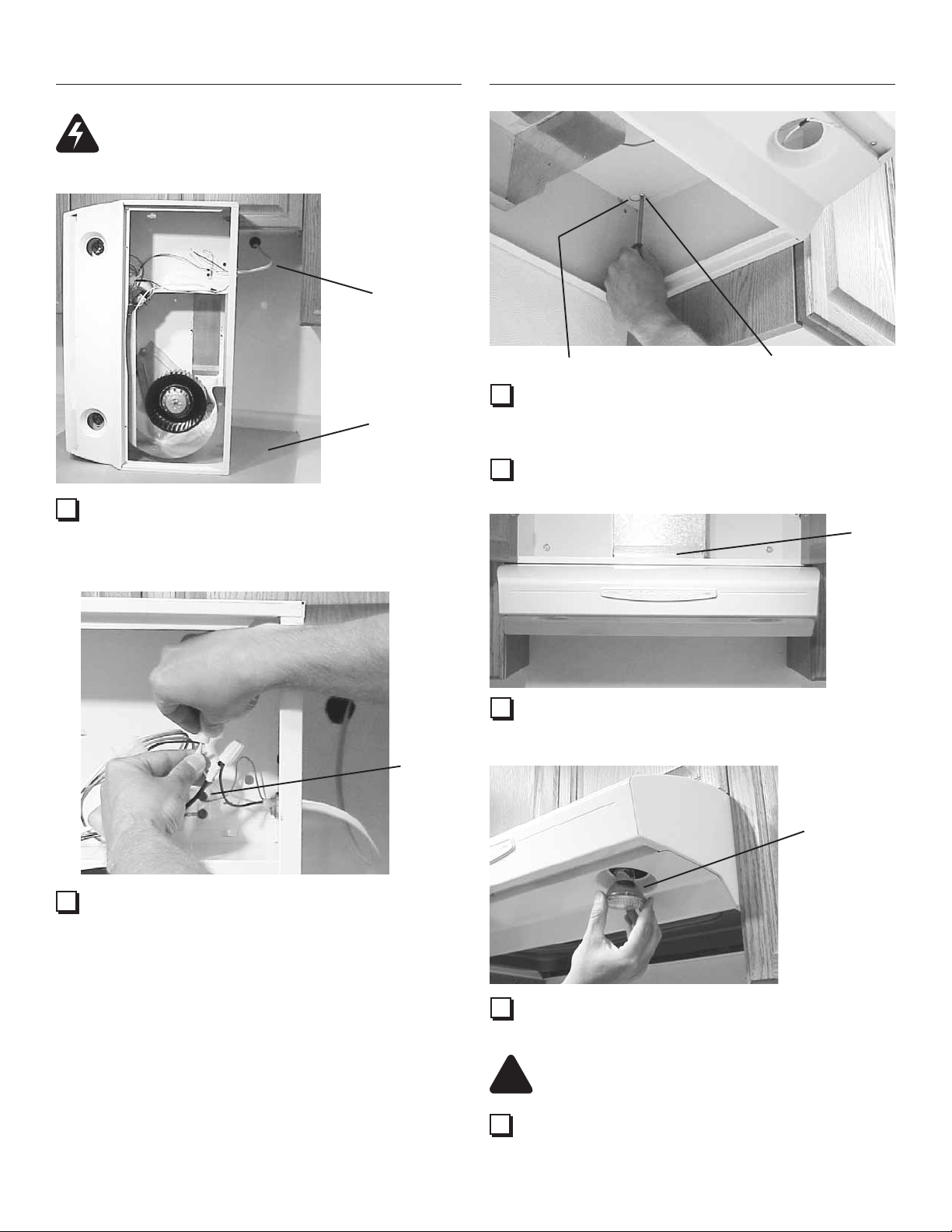

CONNECT WIRING

WARNING: To reduce the risk of electric shock,

make sure power is switched off at the service

panel. Lock or tag service p anel to prevent power

from being switched on accidentally.

INSTALL HOOD

HOUSE

WIRING

(120 VAC)

CARDBOARD

(Use to protect

cooktop)

1 Connect House Wiring (120 VAC) to hood. Use a piece of

Cardboard to protect the cooktop, if necessary.

GREEN

GROUND

SCREW

2 Connect house black to hood black wire, house white to hood

white wire, and house ground under

Securely tighten cable clamp onto house wiring.

Green Ground Screw.

KEYHOLE (4)

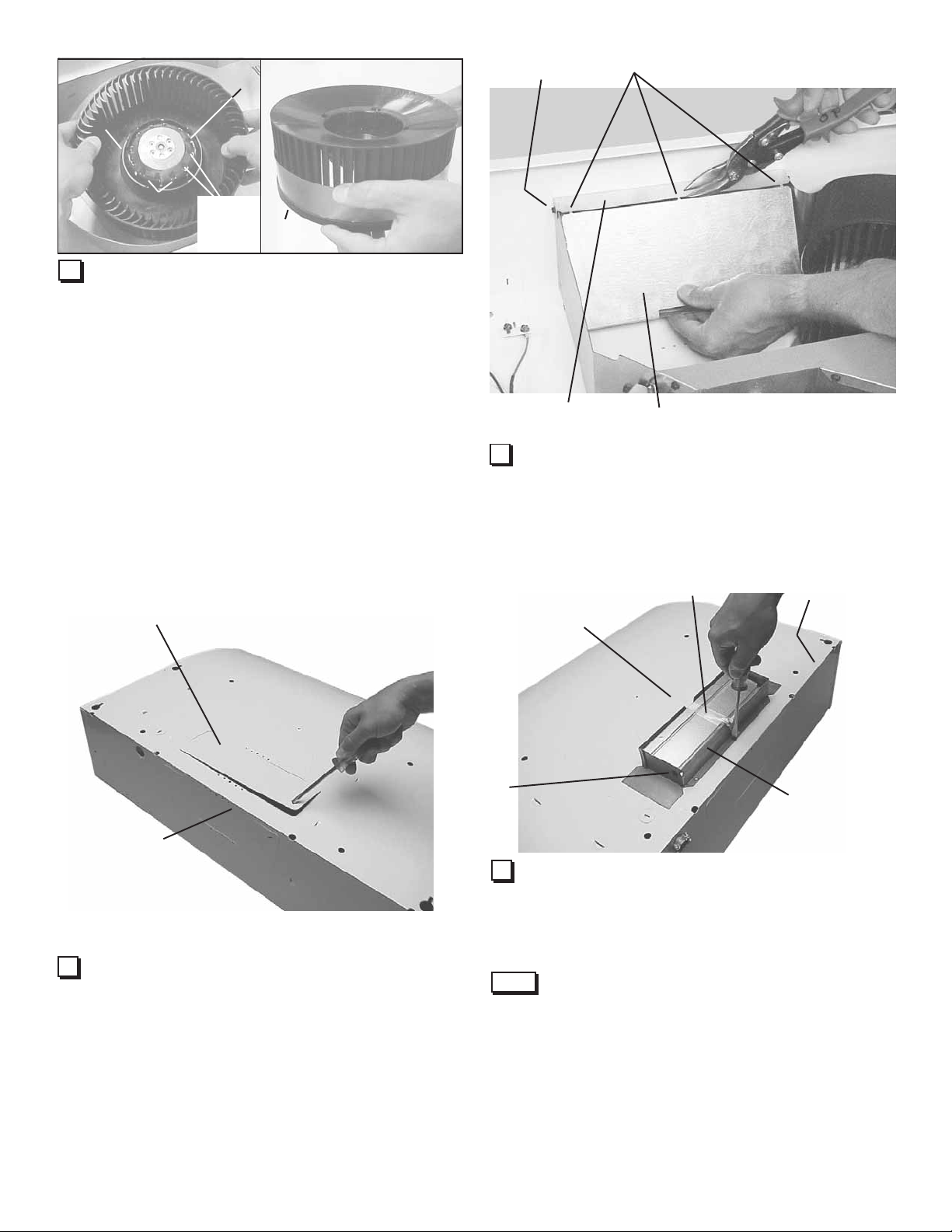

1 Hang hood from (4) Mounting Screws. Slide hood towards

wall until mounting screws are engaged in narrow end of (4)

Keyholes. Tighten mounting screws securely. A long

screwdriver works best.

2 Replace bottom cover.

3 Connect ductwork to hood. Use Duct Tape to make joints

secure and air tight.

MOUNTING SCREW (4)

DUCT

TAPE

PAR20,

50W MAX.

HALOGEN

BULB (2)

- or R16,

40W MAX.

INCANDESCENT

BULB (2)

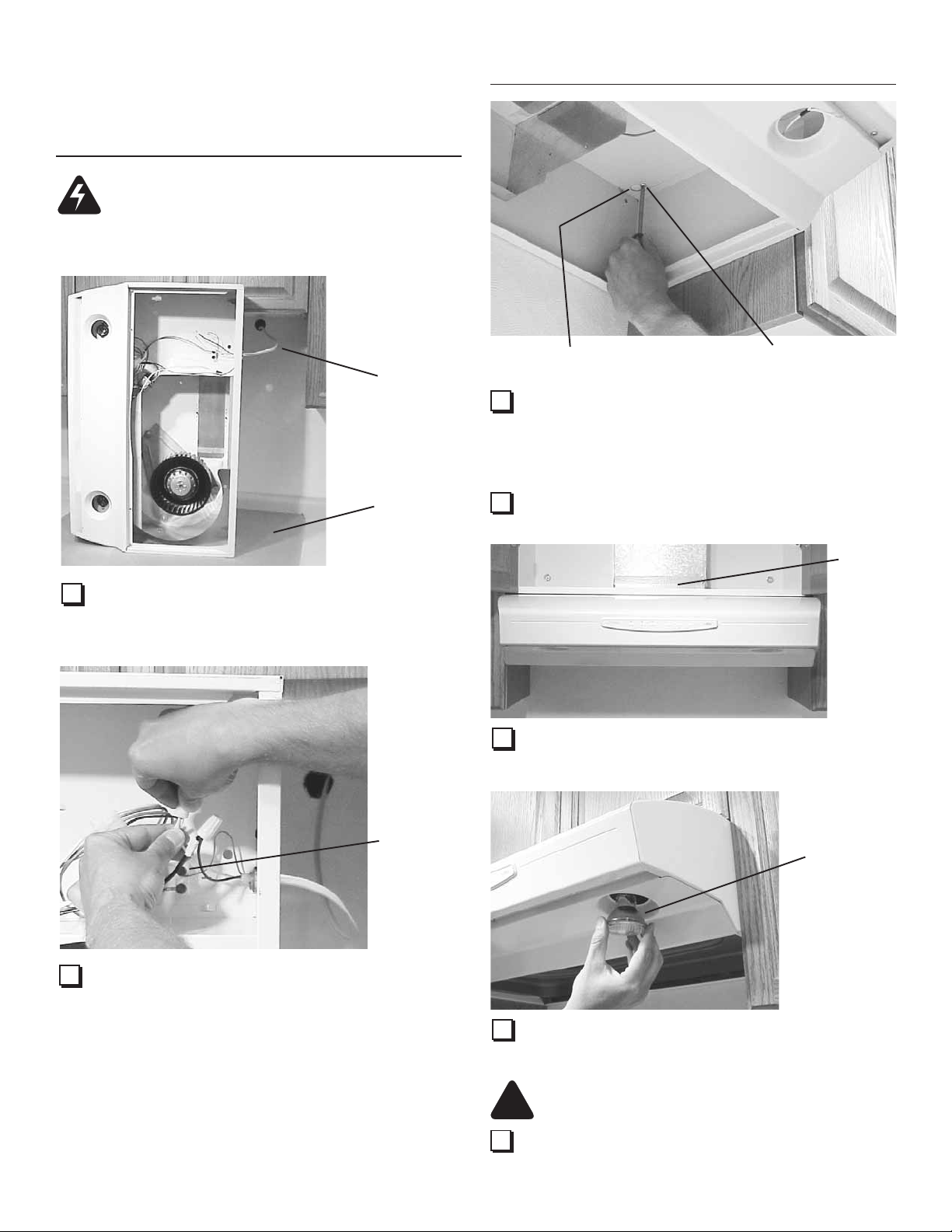

4 Install (2) PAR20, 50 W Maximum Halogen Bulbs or (2) R16,

40 W Maximum

separately.

Incandescent Bulbs. Purchase bulbs

CAUTION: Bulbs may be hot! Refer to bulb packag-

!

ing for further information.

5 Replace filters, turn on power at service panel, and test for

proper operation.

5

Page 6

NON-DUCTED FILTERS

If hood is to be installed Non-Ducted:

Purchase a set of (2) Non-Ducted Filters from your local

distributor or retailer and attach them to the aluminum mesh

filters.

NOTE: For models that are installed in the non-ducted mode, the

most effective operation is achieved at speeds 1 and 2.

These speeds provide the most efficient and quiet

operation during cooking, while maximizing the benefits

of the recirculating filtration system.

OPERATION

Fan and Lights: 3 push button switches for each. Push any button

to select one of 3 fan speeds or one of 3 light levels. Push the

same button to turn fan or light off. Press another button to change

fan speed or light level. A light above each fan button indicates the

fan speed.

Heat Sentry: Your range hood is equipped with the Heat Sentry

feature, which monitors temperature. The Heat Sentry will automatically turn the fan on at its highest speed when the temperature

is above normal.

1) If a fan setting is selected when the Heat Sentry in on, the light

above the fan button will flash on and off.

2) If the fan setting is off when the Heat Sentry is on, the light

above fan button 3 will flash on and off rapidly.

After the temperature has lowered to normal, the fan will change to

the setting prior to the Heat Sentry turning on.

Fuse: The hood control contains a fuse to protect it from power

surges. If the fuse has opened (blown), the green fan-level indicators will operate properly when the fan buttons/switches are pressed

- but the fan and lights will not turn on.

The fuse is a 5 x 20 mm, 10 Amp, Fast-Acting, 125V (min.). Com-

mon manufacturer and part numbers are: Littlefuse, 217010;

Bussmann, GMA10A; Wickmann, 1942100. Radio Shack, Digikey

(1-800-344-4539), and most electronic supply stores have them in

stock.

To replace the fuse:

1. Disconnect power at service entrance.

2. Remove filters, bottom panel, light wire harness, and air chute.

3. Remove and inspect fuse. If it is

diagnostics need to be done.

4. Install new fuse.

5. Re-assemble air chute, light wire harness, bottom panel, and

filters.

6. Turn on power and check hood/control operation.

not open (blown), additional

CLEANING

WARNING: To reduce the risk of electric shock, disconnect from power supply before cleaning.

Aluminum mesh filters: Clean frequently using hot water and a

mild detergent. Filters are dishwasher safe.

Charcoal filters: Clean filter surfaces frequently with a damp cloth

and a mild detergent. DO NOT immerse filters in water or put in

dishwasher. The special “Clean Sense” feature indicates when the

filter is to be replaced. The blue and yellow strips will blend to

green when it is time to change the filter. The “Clean Sense” feature works best when facing toward the cooking surface.

To clean hood: Remove filters. Use a damp cloth and a mild detergent to wipe all grease-laden surfaces. Do not use abrasive cloth,

steel wool pads, or scouring powder on the Teflon

cover or on any painted surface. Use care when cleaning blower

wheel - it must not become bent or misaligned. DO NOT ALLOW

WATER TO ENTER MOTOR. Make sure all surfaces are completely dry before re-installing filters and restoring power.

Motor is permanently lubricated. Do not oil or disassemble motor.

®

Teflon

is a registered trademark of DuPont.

6

®

-coated bottom

Page 7

SERVICE PARTS

KEY NO. DESCRIPTION

1 7” Round Duct Plate (includes hardware)

2 Damper/Duct Connector (includes hardware)

3 Screw, #8-18 x ¼ Hex* (2 in package)

4 Motor Capacitor (includes wire nuts & hardware)

5 Isolation Transformer

6 Nameplate

7 Control Panel (includes Key No. 6 & hardware)

8 Screw for Plastic, #6 x ½ Flat Hd. (3 in package)

9 Screw, #8-18 x 3/8 (2 in package)

10 Ground Screw

11 Scroll Cover, Outlet (includes hardware)

12 Scroll Cover, Front (includes hardware)

13

14

15 Baffle

16 Screw, Metric M4 x 6mm (4 in package)

17 Motor Plate (Includes Key No. 18)

18 Motor Plate Mounting Kit (3 of each part)

19 Motor (includes Key No. 16)

20 Blower Wheel (Includes Key No. 21)

21 Retaining Ring

22 Lamp Socket Assembly

23 Light Panel

24 Hole Plug (1 req.)

25 Pop Rivet, .125D (3 req.)

26 Filter Spring Kit

27 Bottom Cover (includes Key Nos. 9, 25, & 26)

28 Autotransformer (includes hardware)

29 Aluminum Mesh Filter (2 in package)

30 Non-Ducted Blower Wheel Assembly

** Non-ducted Filter Kit

** Wire Harness

** Control Fuse, 10-Amp

Order replacement parts by KEY NO.

* Standard hardware - may be purchased locally.

** Not illustrated - purchase separately.

Control Assembly (includes Key Nos. 6, 7 & hardware)

Air Chute Assembly (includes Key No. 15 & hardware)

(includes Key Nos. 20 & 21)

15

14

7

13

16

17

19

18

1

12

9

27

3

3

23

4

3

5

11

2

9

10

28

22

9

9

9

26

3

6

24

8

29

20

21

7

30

Page 8

Major Appliance Warranty Information

Your appliance is covered by a one year limited warranty. For one year from your original date of

purchase, Electrolux will pay all costs for repairing or replacing any parts of this appliance that prove to

be defective in materials or workmanship when such appliance is installed, used and maintained in

accordance with the provided instructions.

Exclusions

This warranty does not cover the following:

1. Products with original serial numbers that have been removed, altered or cannot be readily determined.

2. Product that has been transferred from its original owner to another party or removed outside the USA or

Canada.

3. Rust on the interior or exterior of the unit.

4. Products purchased "as-is" are not covered by this warranty.

5. Food loss due to any refrigerator or freezer failures.

6. Products used in a commercial setting.

7. Service calls which do not involve malfunction or defects in materials or workmanship, or for appliances

not in ordinary household use or used other than in accordance with the provided instructions.

8. Service calls to correct the installation of your appliance or to instruct you how to use your appliance.

9. Expenses for making the appliance accessible for servicing, such as removal of trim, cupboards, shelves,

etc.,which are not a part of the appliance when it is shipped from the factory.

10. Service calls to repair or replace appliance light bulbs, air filters, water filters, other consumables, or

knobs, handles, or other cosmetic parts.

11. Surcharges including, but not limited to, any after hour, weekend, or holiday service calls, tolls, ferry trip

charges, or mileage expense for service calls to remote areas, including the state of Alaska.

12. Damages to the finish of appliance or home incurred during installation, including but not limited to floors,

cabinets, walls, etc.

13. Damages caused by: services performed by unauthorized service companies; use of parts other than

genuine Electrolux parts or parts obtained from persons other than authorized service companies; or

external causes such as abuse, misuse, inadequate power supply, accidents, fires, or acts of God.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF REMEDIES

CUSTOMER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT

REPAIR OR REPLACEMENT AS PROVIDED HEREIN. CLAIMS BASED ON IMPLIED WARRANTIES,

INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE

LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW, BUT NOT LESS THAN ONE YEAR.

ELECTROLUX SHALL NOT BE LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES SUCH AS

PROPERTY DAMAGE AND INCIDENTAL EXPENSES RESULTING FROM ANY BREACH OF THIS WRITTEN

LIMITED WARRANTY OR ANY IMPLIED WARRANTY. SOME STATES AND PROVINCES DO NOT ALLOW THE

EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE

DURATION OF IMPLIED WARRANTIES, SO THESE LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO

YOU. THIS WRITTEN WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY ALSO HAVE OTHER

RIGHTS THAT VARY FROM STATE TO STATE.

If You Need

Service

This warranty only applies in the USA and Canada. In the USA, your appliance is warranted by Electrolux Major Appliances

North America, a division of Electrolux Home Products, Inc. In Canada, your appliance is warranted by Electrolux Canada

Corp. Electrolux authorizes no person to change or add to any obligations under this warranty. Obligations for service and

parts under this warranty must be performed by Electrolux or an authorized service company. Product features or

specifications as described or illustrated are subject to change without notice.

USA

1.800.944.9044

Electrolux Major Appliances

North America

P.O. Box 212378

Augusta, GA 30907

Keep your receipt, delivery slip, or some other appropriate payment record to establish the warranty period

should service be required. If service is performed, it is in your best interest to obtain and keep all receipts.

Service under this warranty must be obtained by contacting Electrolux at the addresses or phone

numbers below.

Canada

Electrolux Canada Corp.

Mississauga, Ontario, Canada

8

1.800.668.4606

5855 Terry Fox Way

L5V 3E4

628015A

Page 9

Nombre de brevet: US D450, 829 S

LISEZ ET CONSERVEZ CES DIRECTIVES

SÉRIE PROFESSIONNEL MODÈLES

PL30WC4IEC

PL36WC4IEC

SÉRIE GALERIE MODÈLES

GL30WC4IES

GL36WC4IES

GL30WC4IEB

GL36WC4IEB

!!

À LA CUISINE DOMESTIQUE SEULEMENT

AVERTISSEMENT

AFIN DE DIMINUER LES RISQUES D’INCENDIE, D’ÉLECTROCUTION OU

DE BLESSURES, SUIVEZ CES DIRECTIVES:

1. Utilisez ce produit en suivant les recommandations du manufacturier. Pour

toute question, contactez le manufacturier à l’adresse ou au numéro de

téléphone indiqués dans la garantie.

2. Avant de réparer ou de nettoyer cette hotte, coupez le courant au panneau

d’alimentation et verrouillez-en l’accès afin d’éviter que le courant ne soit

accidentellement remis en fonction. S’il vous est impossible de le verrouiller,

apposez un indicateur voyant sur le panneau comme, par exemple, une

étiquette de couleur vive.

3. L’installation de la hotte ainsi que le câblage électrique doivent être effectués

par une ou des personnes compétentes selon les normes et les règles en

vigueur, incluant celles qui régissent la prévention des incendies.

4. Une circulation d’air efficace est requise afin d’assurer la combustion et

l’évacuation complète des gaz par le tuyau d’évacuation (cheminée) des

équipements à combustion et pour prévenir les retours d’air. Conformezvous aux normes et mesures de sécurité pour les manufacturiers d’appareils

de chauffage publiées par la “National Fire Protection Association (NFPA)” et

par la “American Society for Heating, Refregiration and Air Conditioning Engineers (ASHRAE)”, ainsi qu’aux normes en vigueur dans votre région.

5. Lorsque vous coupez ou percez un mur ou un plafond, prenez garde

d’endommager les fils électriques ou autres installations qui pourraient y être

dissimulés.

6. Pour réduire les risques d’incendie ou de décharge électrique, ne pas utiliser

ce ventilateur avec un régulateur de vitesse à transistors.

7. Les installations ventilées doivent toujours être reliées à des conduits rejetant

l’air à l’extérieur.

8. Afin de diminuer les risques d’incendie, n’utilisez que des conduits de ventilation en métal.

9. Utilisation avec le kit approuvé de corde-raccordement seulement.

10. Ce ventilateur doit être relié à une mise à la terre.

AFIN DE DIMINUER LES RISQUES D’INCENDIE POUVANT SE

DÉCLENCHER SUR LA SURFACE DE CUISSON:

1. Ne jamais laisser sans surveillance des unités de surface réglées à feu vif. En

plus de générer de la fumée, les débordements de graisse peuvent prendre

feu. Chauffer les huiles lentement à feu doux ou moyen.

2. Toujours mettre en marche la hotte durant la cuisson à feu vif ou la cuisson

d’aliments à flamber.

3. Nettoyer régulièrement les ventilateurs d’aération. On ne doit tolérer aucune

accumulation de graisse sur le ventilateur ou sur le filtre.

4. Utiliser une casserole de grosseur appropriée. Toujours utiliser une batterie

de cuisine proportionnelle à l’élément de surface.

AFIN DE DIMINUER LES RISQUES DE BLESSURES POUVANT SUR VENIR

LORSQU’UN FEU SE DÉCLENCHE SUR LA SURF ACE DE CUISSON, SUIVEZ

CES DIRECTIVES:

1. ÉTOUFFEZ LES FLAMMES avec un couvercle hermétique, une tôle à biscuits ou un plateau en métal puis éteignez la cuisinière. PRENEZ GARDE

AUX BRÛLURES. Si vous ne parvenez pas à éteindre immédiatement les

flammes, ÉVACUEZ LES LIEUX ET CONTACTEZ VOTRE POSTE LOCAL

DE LUTTE CONTRE LES INCENDIES.

2. NE VOUS EMPAREZ JAMAIS D’UN PLAT QUI S’EST ENFLAMMÉ – Vous

risqueriez de vous brûler.

3. N’UTILISEZ JAMAIS D’EAU, incluant les linges à vaisselles ou serviettes

mouillés car cela peut provoquer une violente explosion de vapeur.

4. Utilisez un extincteur SEULEMENT si:

A. Il s’agit d’un extincteur de classe ABC et que vous savez comment

vous en servir.

B. Il s’agit d’un petit feu qui ne se propage pas ailleurs que sur l a

cuisinière.

C. Vous avez appelé votre poste local de lutte contre les incendies.

D. Vous pouvez combattre le feu tout en ayant accès à une sortie.

* Basé sur “Kitchen Fire Safety Tips” édité par NFPA.

!!

ATTENTION

1. N’utilisez cet appareil que pour la ventilation des surfaces de cuisson. Ne

l’utilisez pas pour ventiler des matières ou des vapeurs de nature

dangereuse ou explosive.

2. Afin d’éviter d’endommager le mécanisme du moteur et de débalancer

et/ou de rendre bruyant le fonctionnement des hélices, protégez l’appareil

des poussières de placoplâtre et de construction.

3. Pour obtenir de meilleurs résultats de ventilation, votre hotte de cuisinière

devrait être installée à une distance de 60 cm à 76 cm au-dessus de la

surface de cuisson.

4. Veuillez lire toutes les étiquettes apposées sur le produit pour obtenir

plus d’information et connaître les spécifications d’installation.

Avis à l’installateur: Veuillez remettre ce guide

au propriétaire de la hotte.

Avis au propriétaire de la hotte: Vous trouverez

les directives concernant le fonctionnement et le

nettoyage de cet appareil à la page 14 du présent

guide.

NOTA Si la hotte est installée sans conduit (installation non

ventilée) :

• Procurez-vous un ensemble de 2 filtres pour installation

non ventilée chez le distributeur de votre région ou chez

le marchand qui vous et fixez-les sur les filtres

d’aluminium.

TABLE DES MATIÈRES

Ce guide est divisé en huit sections:

• “PRÉPAREZ L’EMPLACEMENT”

Installez les conduits depuis le capuchon de toit ou le capuchon de

mur ainsi que les fils électriques depuis le panneau d’alimentation

jusqu’à l’emplacement d’installation.

• “PRÉPAREZ LA HOTTE”

Effectuez les préparatifs nécessaires pour l’installation de votre

hotte.

• “BRANCHEZ LES FILS D’ALIMENTATION ÉLECTRIQUE”

Raccordez les fils électriques à la hotte.

• “INSTALLEZ LA HOTTE”

Fixez la hotte sous l’armoire et reliez-la au conduit - installez les

ampoules et les filtres.

• “FONCTIONNEMENT”

Comment faire fonctionner votre hotte.

• “ENTRETIEN”

Conseils pour maintenir votre hotte en parfait état de marche.

• “PIÈCES DE REMPLACEMENT”

Liste des pièces de remplacement avec leur numéro d’identification

et schéma détaillé des composantes de la hotte.

• “GARANTIE”

9

Garantie limitée d’un an et coordonnées pour communiquer avec

notre service à la clientèle.

!

Page 10

HOTTE

PRÉPAREZ L’EMPLACEMENT

CAPUCHON DE TOIT

CONDUIT DE 8, 3 CM X 25,4 CM

(Pour évacuation verticale)

CONDUIT VERTICAL

DE 17,8 CM ROND

SOFFITE

ARMOIRE

HOTTE

HOTTE

0 CM À 76 CM

U-DESSUS DE LA SURFACE

E CUISSON

FIL DU PANNEAU D'ALIMENTATION

ÉLECTRIQUE (Branché sur le dessus

ou à l'arrière de la hotte)

CAPUCHON DE MUR

CONDUIT DE 8, 3 CM X 25, 4 CM

(Pour évacuation horizontale)

1 Choisissez entre une évacuation verticale (conduit de 8,3

cm x 25,4 cm), une évacuation horizontale (conduit de 8,3

cm x 25,4 cm) et une installation sans conduit. Pour les installations à évacuation horizontale ou verticale, reliez la hotte

à un capuchon de mur ou à un capuchon de toit à l’aide de

conduits appropriés. Pour obtenir de meilleurs résultats,

évitez, dans la mesure du possible, d’utiliser des transitions

ou des coudes.

2 Consultez les schémas ci-dessous pour savoir où percer les

ouvertures dans les armoires ou les murs pour les conduits

et les fils électriques. Dans le cas d’une installation non

ventilée, NE PERCEZ PAS d’ouverture pour un conduit de

rejet d’air.

CONDUIT VERTICAL DE 8,3 CM X 25,4 CM

VIS DE FIXATION DE LA HOTTE (4)

35, 4 cm (hotte de 76, 2 cm)

43 cm (hotte de 91, 4 cm)

50, 6 cm, (hotte de 106,7)

PARTIE AVANTE DE L'ARMOIRE

35, 4 cm (hotte de 76, 2 cm)

43 cm (hotte de 91, 4 cm)

50, 6 cm, (hotte de 106,7)

3 Amenez le fil électrique depuis le panneau d’alimentation

jusqu’à l’emplacement prévu pour la hotte.

PRÉPAREZ LA HOTTE

PLAT ROND DE

CONDUIT DE 17,8 CM

1 Enlevez le plat rond de conduit de 17,8 cm du dessus du

hotte. Placez le plat de conduit de côté - avec des vis de

support.

FILTRES

19,1 cm

12,7 cm

DESSOUS DE L'ARMOIRE

13,3 cm 13,3 cm

OUVERTURE POUR

ÉVACUATION VERTICALE

5,1

cm

3,2 cm

CALES DE BOIS

(pour armoires à fond de

rentant seulement)

DÉMARCATION

LIGNE DE

DU CENTRE

OUVERTURE POUR FIL

ÉLECTRIQUE

(dans le fond

de l'armiore)

3,8

cm

CONDUIT HORIZONTAL DE 8,3 CM X 25,4 CM

CALES DE BOIS (pour armoires à fond rentrant seulement)

PARTIE AVANT DE L'ARMOIRE

9,5 cm

DESSOUS

DE L'ARMOIRE

35, 4 cm (hotte de 76, 2 cm)

43 cm (hotte de 91, 4 cm)

50, 6 cm (hotte de 106, 7 cm)

VIS DE FIXATION

DE LA HOTTE (4)

OUVERTURE POUR

ÉVACUATION HORIZONTALE

13,3 cm13,3 cm

19,1 cm

35, 4 cm (hotte de 76, 2 cm)

43 cm (hotte de 91, 4 cm)

50, 6 cm (hotte de 106, 7 cm)

LIGNE DE

DÉMARCATION

DU CENTRE

19

3,2 mm

mm

OUVERTURE POUR

FIL ÉLECTRIQUE

(dans le mur)

26,7

cm

2 Retirez le ruban adhésif qui sert à maintenir les filtres en

place. Tirez sur les languettes des filtres et soulevez ces

derniers. Mettez les filtres de côté.

COUVERCLE

PROTECTEUR

SITUÉ SOUS

LA HOTTE À

ENDUIT

TEFLON

®

(fixé à l’aide

de 2 vis))

3 Retirez le Couvercle protecteur situé sous la hotte à enduit

Teflon® est une marque déposée de DuPont.

10

®

. Mettez-le de côté avec les vis d’assemblage.

Teflon

Page 11

RACCORD

DU CONDUIT

AVEC LE

REGISTRE

4 Retirez le raccord du conduit avec le registre de la hotte.

Mettez-le de côté avec les vis d’assemblage et le sac

contenant les pièces.

CHUTE D’AIR

7 Enlevez le

chute d’air -

maintenue par

une (1) vis.

REMARQUE :

Prendre garde

de ne

débrancher

aucun fil.

8 Enlevez le

déflecteur de la

chute d’air.

➠

COLLET DE FIXATION DU CÂBLE

D’ALIMENTATION

5 Retirez l’une des deux débouchures d’accès du câble

d’alimentation (sur le dessus de la hotte ou à l’arrière) et

installez un collet de fixation répondant aux normes

régissant les installations électriques.

Installation sans conduit - Passez à l’étape 11.

Les étapes suivantes (5 à 10) ne concernent

que les INSTALLATIONS AVEC CONDUIT.

(3) #8 VIS

(2) #8 VIS

6 Enlevez le panneau d’éclairage- mainenu par cinq (3) #8

vis et (2) #8 vis.

PANNEAU

D’ÉCLAIRAGE

9 Faites pivoter le

déflecteur.

Réinsérez le

déflecteur dans la

chute d’air (comme

montré) de sorte que

les

onglets toute la

manière dans des

fentes dans la chute

d’air. Un “clic”

audible

sera entendu

quand il est

entièrement

installé. Ceci

dirigera l’air

traversant les fentes

non-canalisées sur

le dessus du hotte.

10

Réinstallez la chute d’air et la vis, l’harnais pour fils, et le

panneau d’éclairage.

REMARQUE : Prendre garde de ne pas coincer les fils

11

entre la

DÉFLECTEUR

DÉFLECTEUR

➠

➠

ONGLETS

FENTES

➠

➠

LANGUETTE DE

SUPPORT

languette de support et le panneau d’éclairage.

Page 12

ANNEAU

DE

ROUE DU

VENTILATEUR

COMPRESSION

PATTE

EXTRÉMITÉ DE

FAIBLE DIAMÈTRE

VIS

ATTACHES

SECTIONS

FENTES

DU

MOTEUR

11 Pour installations sans conduit seulement : Vous devez

installer un anneau de puissance sur la roue du ventilateur.

Pour installer cet anneau :

1. Retirez la roue du ventilateur en tirant de façon modérée

et en la bougeant pour la désengager du moteur. Retirez

anneau de compression si nécessaire.

2. Faites glisser l’anneau par-dessus l’extrémité de faible

diamètre de la roue jusqu’à ce qu’il atteigne le bord limite

de la roue.

3. Réinstallez la roue sur le moteur. Assurez-vous que la

patte de la roue s’insère dans l’une des fentes du moteur.

4. Poussez sur la roue jusqu’à ce qu’elle s’enclenche.

5. Vérifiez que la roue soit bien installée, tel qu’illustré.

Appuyez sur les sections pour les engager, si nécessaire.

Assurez-vous que la roue tourne librement.

ANNEAU

BORD

LIMITE

DÉBOUCHURE SUPÉRIEURE POUR CONDUIT

RECTANGULAIRE (Retirez pour installer un conduit de

rejet d’air à la verticale de 8,3 cm x 25,4 cm)

LANGQUETTE

DE MÉTAL

13 Pour évacuation horizontale seulement : Retirez la plaque

qui protège la débouchure pour évacuation horizontale.

Coupez les attaches puis retirez et jetez la plaque. NE

RETIREZ PAS la languette de métal maintenue en place

par les deux vis.

AJUSTEMENT

LATÉRAL POSSIBLE

JUSQU’À 2,5 CM

PLAQUE

RUBAN

ADHÉSIF

CÔTÉ

SUPÉRIEUR

ARRIÈRE

DÉBOUCHURE

LATÉRALE POUR

CONDUIT

RECTANGULAIRE

(Retirez pour installer un conduit

de rejet d’air à l’horizontale de 8,3

cm x 25,4 cm)

12 Retirez la débouchure appropriée sur le dessus ou à l’arrière

de la hotte.

➙

➙

PIVOT

14 Pour les installations avec un conduit de rejet d’air de 8,3 cm

x 25,4 cm seulement : Retirez le ruban adhésif du volet du

registre et fixez le raccord du conduit avec le registre sur

l’ouverture (débouchure) choisie avec les vis que vous avez

retirées lors de l’étape 4 de cette section. Assurez-vous que

le pivot du registre soit installé près du côté supérieur

arrière de la hotte.

NOTA Le raccord du conduit avec le registre et peuvent être

installés avec un jeu de 2,5 cm de part et d’autre de la

ligne de démarcation centrale pour s’adapter aux conduits

qui ne sont pas parfaitement centrés. Dans certains cas

extrêmes, il peut être nécessaire de tailler l’une des

extrémités du raccord de conduit pour permettre un

dégagement du collet de fixation du câble d’alimentation.

RACCORD DU

CONDUIT AVEC LE

REGISTRE (le

schéma montre une

installation pour un

rejet à la verticale)

12

Page 13

BRANCHEZ LES FILS

D’ALIMENTATION

ÉLECTRIQUE

AVERTISSEMENT: Afin de prévenir les risques

d’électrocution, assurez-vous que le courant ait été

interrompu au panneau d’alimentation principal.

Verrouillez ce dernier ou apposez un indicateur voyant

pour éviter que quelqu’un ne remette

accidentellement le courant en marche.

CÂBLE

D’ALIMENT ATION

DU PANNEAU

PRINCIPAL

(120 V, courant

alternatif)

MORCEAU DE

CARTON (pour

protéger la

surface de

cuisson)

1 Branchez le câble d’alimentation du panneau principal

(120 V, courant alternatif) à la hotte. Si nécessaire, utilisez

un morceau de carton pour protéger la surface de cuisson.

INSTALLEZ LA HOTTE

OUVERTURE EN FORME DE

TROU DE SERRURE (4)

1 Utilisez les 4 vis d’assemblage (que vous retrouverez dans

le sac contenant les pièces) pour suspendre la hotte. Faites

glisser la hotte vers le mur pour engager les vis dans la partie

étroite des 4 ouvertures en forme de trou de serrure.

Serrez solidement les vis d’assemblage. Utilisez un tournevis

long.

2 Remettez en place le couvercle protecteur sous la hotte.

OUVERTURE EN FORME DE

TROU DE SERRURE (4)

RUBAN

ADHÉSIF

POUR

SCELLER

LES CON-

DUITS

VIS VERTE

DE MISE

À LA

TERRE

2 Branchez le fil noir du panneau principal au fil noir de la hotte,

le fil blanc du panneau principal au fil blanc de la hotte et le fil

de mise à la terre du panneau principal à la vis verte de

mise à la terre. Utilisez le collet de fixation pour maintenir

solidement en place le câble d’alimentation.

3 Raccordez le conduit à la hotte. Utilisez du ruban adhésif

pour sceller les conduits pour rendre votre installation

étanche.

AMPOULES

HALOGÈNES (2)

PAR 20, 50

WATTS MAXIMUM

AMPOULES

RÉGULIÈRES (2)

WATTS MAXIMUM

4 Installez 2 ampoules halogènes PAR20 de 50 W maximum

ou 2 ampoules régulières R16 de 40 W maximum (ampoules

vendues séparément).

Avertissement : Les ampoules peuvent devenir très

chaudes ! Consultez les directives sur l’emballage

!

pour plus d’information.

5 Remettez les filtres en place, remettez le courant en marche

depuis le panneau principal et effectuez un test pour vous

13

assurer du bon fonctionnement.

OU

R16, 40

Page 14

FILTRES SANS CONDUIT

Si la hotte est installée sans conduit:

Procurez-vous un ensemble de 2 filtres pour installation non

ventilée et fixez-les aux filtres d’aluminium. Ces filtres sont

disponibles chez le distributeur de votre région ou chez le

marchand qui vous a vendu la hotte.

NOTA: Pour les modèles installés sans mise à l’air libre, le

fonctionnement le plus efficace est obtenu aux régimes 1

et 2. Ceux-ci offrent un meilleur rendement et un

fonctionnernent silencieux pendant la cuisson, tout en

maximisant les avantages du sytème de filtration par

recyclage.

FONCTIONNEMENT

Ventilateur et éclairage : Chacune de ces fonctions est contrôlée à l’aide

de 3 boutons. Appuyez sur l’un de ces 3 boutons pour choisir l’une des trois

intensités du ventilateur ou l’une des trois intensités d’éclairage. Appuyez

sur ce même bouton pour éteindre le ventilateur ou l’éclairage. Appuyez sur

un autre bouton pour changer l’intensité du ventilateur ou de l’éclairage. Un

indicateur lumineux au-dessus de chacun des boutons du ventilateur indique

à quelle intensité le ventilateur a été réglé.

Détecteur de chaleur: Votre hotte de cuisine est équipée d’une fonction de

détecteur de chaleur qui surveille la température. Le détecteur de chaleur

met automatiquement le ventilateur en marche à la vitesse maximale lorsque

la température excède la normale.

1) Si l’un des réglages du ventilateur est sélectionné alors que le détecteur

de chaleur est activé, le voyant lumineux situé au-dessus du bouton du

ventilateur se met à clignoter.

2) Si le ventilateur est réglé sur “ arrêt ” alors que le détecteur de chaleur est

activé, le voyant lumineux situé au-dessus du bouton 3 se met à clignoter

rapidement.

Une fois la température revenue à la normale, le ventilateur reprend

automatiquement le réglage choisi avant l’entrée en fonction du détecteur

de chaleur.

Fusible: La commande de la hotte contient un fusible pour la protéger contre

les surtensions. Si le fusible a sauté (grillé), les voyants verts indiquant la

force du ventilateur s’allument normalement lorsque l’on appuie sur les

boutons et les interrupteurs, mais ni le ventilateur ni la lumière ne fonctionnent.

Le fusible est de 5 x 20 mm, 10 A, à action rapide, 125 V (min.). Les principaux

fabricants et numéros de pièce sont : Littlefuse, 217010 ; Bussmann,

GMA10A ; Wickmann, 1942100. Radio Shack, Digikey (1-800-344-4539)

et la plupart des magasins d’électronique ont ces fusibles en stock.

Pour remplacer le fusible :

1. Couper le courant au panneau électrique.

2. Enlever les filtres, le panneau inférieur, le connecteur de la lumière et le

volet d’évacuation.

3. Enlever et inspecter le fusible. S’il n’a

plus poussé doit être effectué.

4. Installer le nouveau fusible.

5. Remonter le volet d’évacuation, le connecteur de la lumière, le panneau

inférieur et les filtres.

6. Rétablir le courant et vérifier le fonctionnement de la hotte et des

commandes.

pas sauté (grillé), un diagnostic

ENTRETIEN

AVERTISSEMENT : Afin de prévenir les risques

d’électrocution, interrompez le courant avant de procéder

à l’entretien de la hotte.

Filtres d’aluminium: Nettoyez régulièrement à l’eau chaude avec un

peu de détergent doux. Vous pouvez également les nettoyer au lavevaisselle.

Filtres à charbon actif: Nettoyez souvent la surface des filtres avec un

chiffon mouillé et un détergent doux. NE PLONGEZ PAS ces filtres dans

l’eau et ne les nettoyez pas au lave-vaisselle. L’indicateur spécial “Clean

Sense” s’active lorsqu’il est temps de remplacer le filtre. Les bandes

bleue et jaune se mêlent pour verdir pour vous signaler qu’il est temps

de le remplacer. L’indicateur “Clean Sense” fonctionne mieux lorsqu’il

fait face à la surface de cuisson.

Pour nettoyer la hotte: Retirez les filtres. Utilisez un chiffon mouillé et

un déteNe pas utiliser de chiffon abrasif, ni laine d’acier, ni poudre à

récurer sur le couvercle protecteur situé sous la hotte à enduit Teflon

sur toute surface peinte. Nettoyez délicatement l’hélice du ventilateur

afin d’éviter de l’endommager ou de la déplacer. LE MOTEUR NE DOIT

JAMAIS ÊTRE EXPOSÉ À L’EAU. Assurez-vous que toutes les surfaces soient bien sèches avant de remettre les filtres en place et de rebrancher la hotte.

Le moteur bénéficie d’une lubrification permanente. Ne démontez pas le

moteur et n’essayez pas d’y ajouter de l’huile ou un lubrifiant quelconque.

MD

14

T eflon

une marque déposée enregistrée de DuPont.

®

ni

Page 15

PIÈCES DE REMPLACEMENT

NO. DU

SCHEMA DESCRIPTION

1 Plat rond de conduit de 17,8 cm

2 Raccord du conduit avec le registre

(avec vis d’assemblage)

3 Vis # 8-18 x ¼ six pans* (2)

4 Condensateur pour moteur

(avec serre-fils et vis d’assemblage)

5 Transformateur d’isolement

6 Plaque d’identification

7 Panneau de contrôle

(avec clé #6 et vis d’assemblage)

8 Vis pour déflect. plastique #6 x ½ tête plate (3)

9 Vis # 8-18 x 3/8 (2)

10 Vis de mise à la terre

11 Couvercle de volute, entrée d’alimentation

(avec vis d’assemblage)

12 Couvercle de volute, partie avant

(avec vis d’assemblage)

13 Bloc de contrôle

(avec clés # 6, 7 et vis d’assemblage)

14 Ensemble de déflecteur pour retour d’air

(avec clé # 15 et vis dissemblage)

15 Déflecteur

16 Vis métrique M4 x 6 mm (4)

17 Plaque moteur (avec clé # 18)

18 Ensemble plaque moteur

(3 exemplaires de chaque composante)

19 Moteur (avec clé # 17)

20 Roue du ventilateur (avec clé # 22)

21 Anneau de compression

22 Ensemble de douille de lampe

23 Panneau d’éclairage

24 Prise de trou (1 nécessaire)

25 Rivet 32 mm (3 nécessaires)

26 Ressort pour le filtre

27 Couvercle protecteur sous la hotte

(avec clés # 9, 25 et 26)

28 Autotransformateur (avec vis d’assemblage)

29 Filtre d’aluminium pour hotte (2 par sac)

30 Ensemble de turbine pour hotte sans conduit

(avec clés # 20 et 21)

** Ens. de filtres pour instal. sans conduit

** Harnais pour fils

** Fusible de contrôle, 10-Amp

Commandez les pièces de remplacement en spécifiant le

numéro de pièce et non le numéro du schéma.

* Pièce que vous pouvez vous procurer dans toute bonne

quincaillerie.

** Non illustré

15

14

7

13

17

16

19

21

18

20

1

12

9

27

3

3

23

30

4

3

5

11

2

9

10

28

22

9

9

9

26

29

3

6

24

8

15

Page 16

Informations sur la garantie des gros électroménagers

Votre appareil est couvert par une garantie limitée d’un an. Pendant un an à partir de la date d’achat originale,

Electrolux assumera les coûts des réparations ou du remplacement des pièces de cet appareil qui présente un

défaut de fabrication ou de matériau, si cet appareil est installé, utilisé et entretenu selon les instructions fournies

avec celui-ci.

Exclusions

Si vous avez

besoin d’une

réparation

Cette garantie ne couvre pas ce qui suit :

1. Les produits dont le numéro de série original a été enlevé, modifié ou qui n’est pas facilement déterminable.

2. Les produits qui ont été transférés de leur propriétaire inital à une autre partie ou qui ne sont plus aux États-Unis ou

au Canada.

3. La rouille à l’intérieur ou à l’extérieur de l’appareil.

4. Les produits vendus « tels quels » ne sont pas couverts par cette garantie.

5. Les aliments perdus en raison de pannes du réfrigérateur ou du congélateur.

6. Les produits utilisés dans les établissements commerciaux.

7. Les appels de service qui ne concernent pas un malfonctionnement, un défaut de fabrication ou un vice de matériau

ou pour les appareils qui ne font pas l’objet d’un usage domestique ou qui ne sont pas utilisés conformément aux

instructions fournies.

8. Les appels de service pour vérifier l’installation de votre appareil ou pour obtenir des instructions sur la façon

d’utiliser votre appareil.

9. Les frais qui rendent l’appareil accessible pour une réparation, par exemple enlever des garnitures, les armoires, les

étagères, etc. qui ne faisaient pas partie de l’appareil lorsqu’il a quitté l’usine.

10. Les appels de service au sujet de la réparation ou du remplacement des ampoules, des filtres à air, des filtres à eau,

d’autre matériel ou des boutons, poignées ou autres pièces esthétiques.

11. Les frais supplémentaires, y compris, sans s’y limiter, les appels de service après les heures normales de bureau,

le week-end ou les jours fériés, les droits et péages, les frais de convoyage ou les frais de déplacement pour les

appels de service dans des endroits isolés, notamment l’État de l’Alaska.

12. Les dommages causés au fini de l’appareil ou à la maison pendant l’installation, y compris, sans s’y limiter, aux

planchers, aux armoires, aux murs, etc.

13. Les dommages causés par : des réparations faites par des techniciens non autorisés; l’utilisation de pièces autres

que les pièces Electrolux d’origine qui n’ont pas été obtenues par l’entremise d’un réparateur autorisé; ou les

causes étrangères comme l’abus, l’alimentation électrique inadéquate ou les cas de force majeure.

AVIS DE NON-RESPONSABILITÉ SUR LES GARANTIES IMPLICITES; LIMITATIONS DES RECOURS

L’UNIQUE RECOURS DU CLIENT EN VERTU DE CETTE GARANTIE LIMITÉE EST LA RÉPARATION OU LE

REMPLACEMENT DU PRODUIT COMME DÉCRIT PRÉCÉDEMMENT. LES DEMANDES BASÉES SUR DES

GARANTIES IMPLICITES, Y COMPRIS LES GARANTIES IMPLICITES DE QUALITÉ MARCHANDE ET D’ADAPTATION À

UN USAGE PARTICULIER SONT LIMITÉES À AU MOINS UN AN OU À LA PÉRIODE LA PLUS COURTE PERMISE PAR LA

LOI. ELECTROLUX NE SERA PAS TENUE RESPONSABLE DES DOMMAGES DIRECTS OU INDIRECTS NI DES

DOMMAGES MATÉRIELS ET DES DÉPENSES IMPRÉVUES RÉSULTANT D’UNE VIOLATION DE CETTE GARANTIE

ÉCRITE OU DE TOUTE AUTRE GARANTIE IMPLICITE. CERTAINS ÉTATS ET CERTAINES PROVINCES NE PERMETTENT

PAS DE RESTRICTION OU D’EXEMPTION SUR LES DOMMAGES DIRECTS OU INDIRECTS OU DE RESTRICTION SUR

LES GARANTIES IMPLICITES. DANS CE CAS, CES RESTRICTIONS OU EXEMPTIONS POURRAIENT NE PAS ÊTRE

APPLICABLES. CETTE GARANTIE ÉCRITE VOUS PROCURE DES DROITS LÉGAUX SPÉCIFIQUES. IL SE PEUT QUE

VOUS AYEZ D’AUTRES DROITS QUI VARIENT SELON L’ÉTAT OU LA PROVINCE.

Conservez votre reçu, votre bon de livraison ou une autre preuve valide de paiement pour établir la période de la garantie

dans le cas où vous devriez faire appel aux services d’un technicien autorisé. Si une réparation doit être effectuée,

veuillez obtenir et conserver tous les reçus.

Le service auquel vous avez recours en vertu de cette garantie doit être obtenu en communiquant avec Electrolux à

l’adresse ou aux numéros de téléphone indiqués ci-dessous.

Cette garantie n’est valide qu’aux États-Unis et au Canada. Aux États-Unis, votre appareil est garanti par Electrolux Major Appliances

North America, une division de Electrolux Home Products, Inc. Au Canada, votre appareil est garanti par Electrolux Canada Corp.

Personne n’est autorisé à modifier ou à ajouter aux obligations contenues dans cette garantie. Les obligations de cette garantie

concernant la réparation et les pièces doivent être remplies par Electrolux ou par une compagnie de réparation autorisée. Les

caractéristiques et spécifications décrites ou illustrées peuvent être modifiées sans préavis.

ÉTATS-UNIS

1.800.944.9044

Electrolux Major Appliances

North America

Case postale 212378

Augusta, GA 30907, ÉTATS-UNIS

1.800.668.4606

Electrolux Canada Corp.

5855 Terry Fox Way

Mississauga, Ontario, Canada

16

Canada

L5V 3E4

628015A

Loading...

Loading...