Page 1

Instruction Manual

Sewing Machine NM 1600/1800

Instruction Manual

Sewing Machine NM 1600/1800

Bedienungsanl.1800/1600 GB 30.08.2004 17:44 Uhr Seite 2

Page 2

Contents

Contents

Page

Page

Important introduction 2

Important instructions 3

Name of Parts 4

Accessory 5

Power supply 5

Change the electric light bulb 5

Change the needle 6

Selection of the right needle 7

Remove and attach presser foot 7

Adjust the threading tension 7

Adjust the lower threading tension 8

Reverse stitch 8

Stitch selection dial 8

Remove the bobbin case 9

Wind the bobbin 10

Thread the upper threading 11

Draw up lower threading 11

Straight sewing and zigzag sewing 12

Start sewing 12

Change sewing direction 12

Strengthen the stitches 12

Tricot stitch 13

Witchcraft or herringbone stitch 13

Zipper insertion 13

Make a buttonhole 14

Hem 15

Button sewing 15

Blind hem sewing 16

Free arm sewing 16

Clean the bobbin case 17

Clean feed dog 17

Oil the machine 18

1

Bedienungsanl.1800/1600 GB 30.08.2004 17:44 Uhr Seite 3

Page 3

Impor

Impor

tant intr

tant intr

oduction

oduction

Before using the machine please read the following instructions carefully.

Take enough time to read it.

By doing that, you’ll get a general idea of functioning and of the function

of the machine what will help you to work more easily and successfully.

The better you familiarize yourself with the work, the straighter you can

use the sewing machine.

This sewing machine has only been produced for use in the home.

2

Bedienungsanl.1800/1600 GB 30.08.2004 17:44 Uhr Seite 4

Page 4

Important instructions!

Important instructions!

Before using the sewing machine, the following instructions should always

be followed:

1. Operate the machine with the adequate caution - because of the needle

going up and down – and keep an eye at the sewing place while working!

2. Always unplug before changing the light bulb, the needle, the sewing foot,

the spool, the needle plate as well as during interruption of work without

supervision or during maintenance for reasons of safety.

Always unplug from the electrical outlet in these cases!

3. The light bulb’s maximal power is 15 watts. The sewing machine is

supplied with a commercial screw light bulb (thread name E14).

3

Bedienungsanl.1800/1600 GB 30.08.2004 17:44 Uhr Seite 5

Page 5

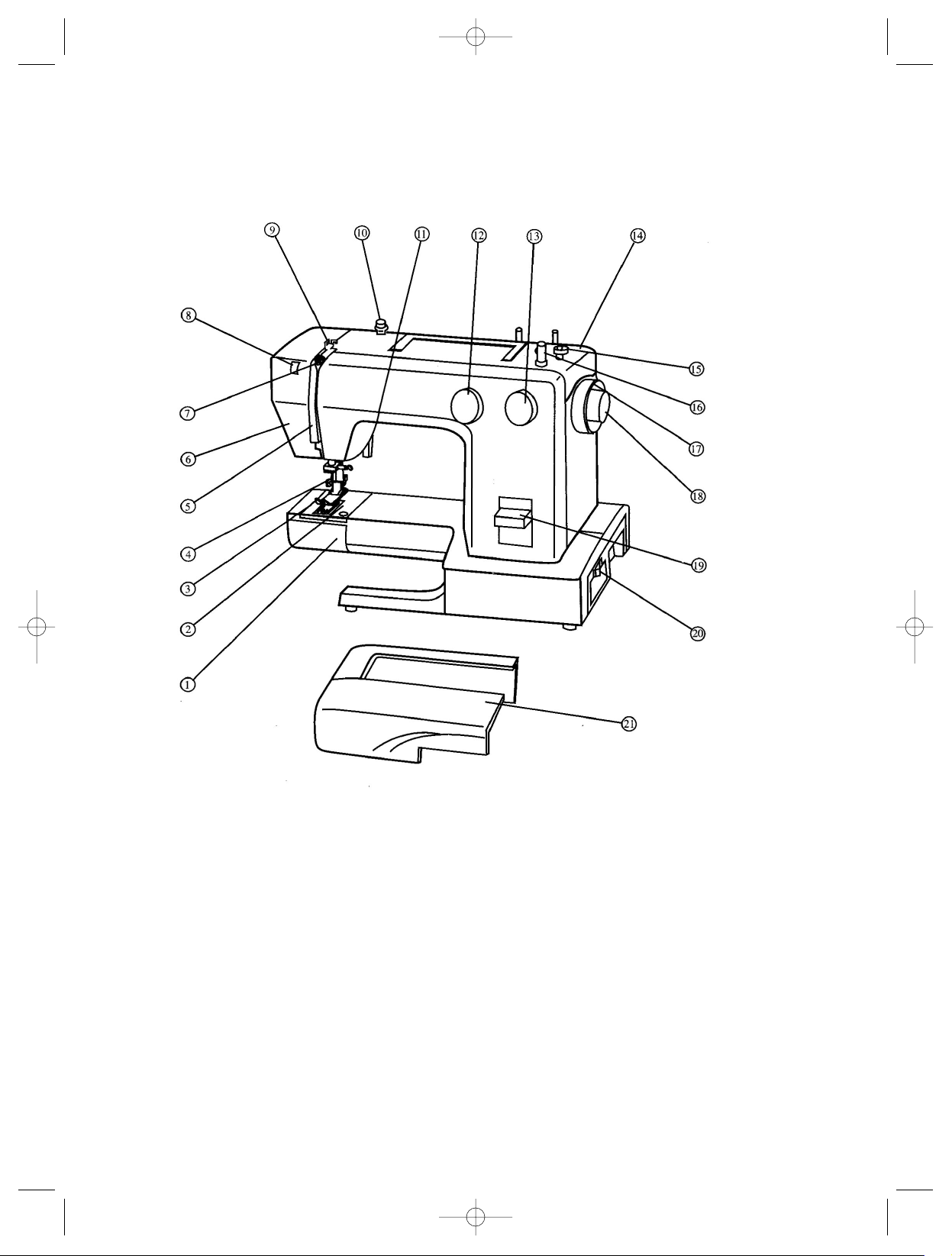

Name of parts

Name of parts

1 Bobbin case cover

2 Needle plate

3 Presser foot

4 Needle

5 Thread cover

6 Front cover, bulb cover

7 Thread take-up leaver

8 Upper threading tension

9 Thread guidance

10 Thread retainer guidance

11 Presser foot lever

4

12 Stitch selection button

13 Stitch length selection button

14 Cover

15 Thread retainer stopper

16 Sewing spool

17 Balance wheel

18 Coupling

19 Reverse button

20 Light switch

21 Cloth plate

Bedienungsanl.1800/1600 GB 30.08.2004 17:44 Uhr Seite 6

Page 6

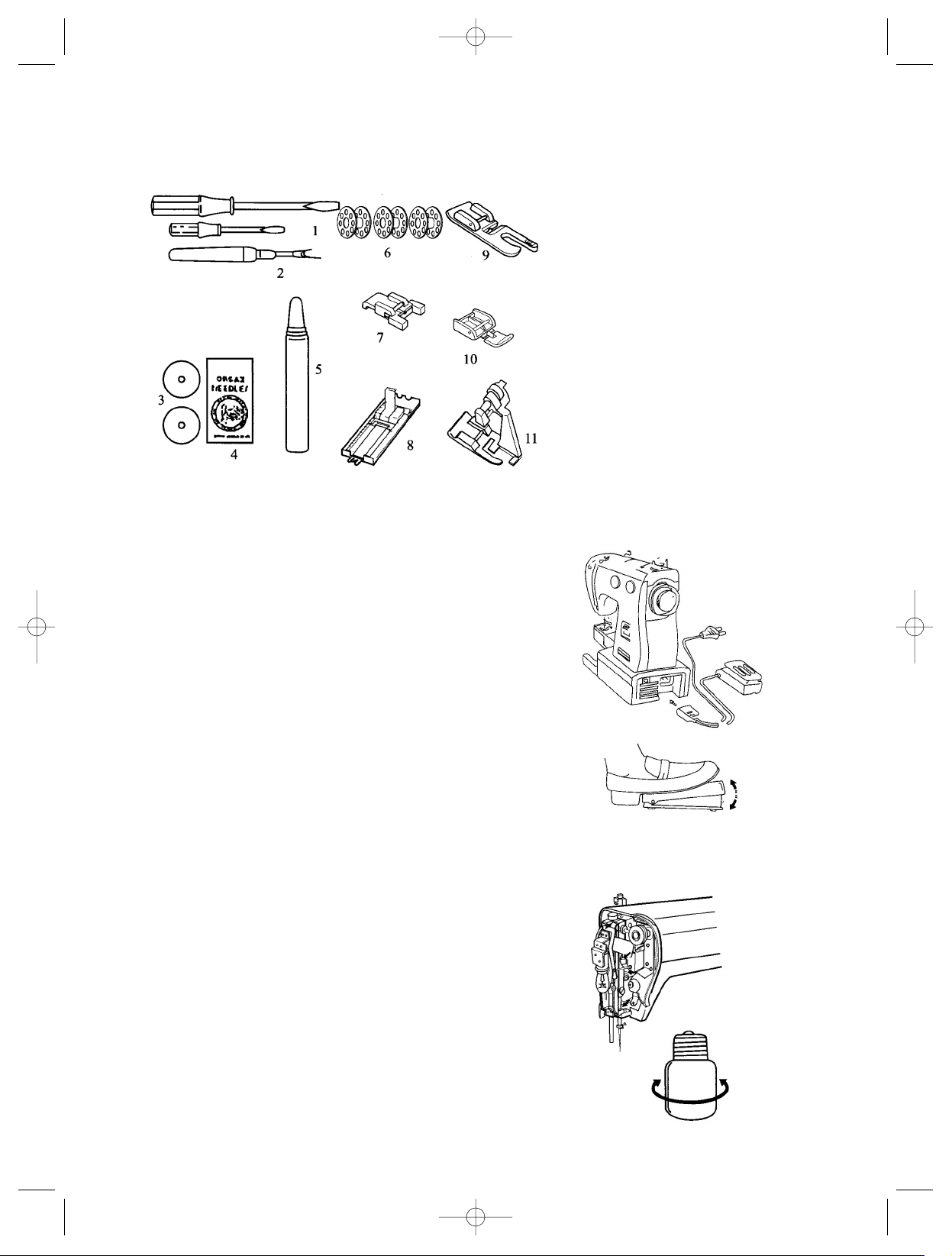

Accessory

Accessory

Power supply

Power supply

Put the coupling plug into the sewing

machine.

Put the plug into the wall socket.

(See figure)

Change the electric light bulb

Change the electric light bulb

The sewing lamp is behind the front cover.

Open the front cover with a screw driver

and unscrew the light bulb.

After that, put in the new light bulb.

WARNING! Pull the plug out of the

wall socket!

5

1. screw driver

2. ripper

3. felt plate

4. needles

5. oilcan

6. shuttles

7. sew on button foot

8. buttonhole foot

9. hem foot

10. zipper foot

11. blind stitch foot

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 7

Page 7

6

Change the needle

Change the needle

Turn the balance wheel into your direction

until the needle is in the highest position.

Loosen the needle screw and remove the

needle from the fixture (see figure).

After that, put the new needle into the fixture

– with its flat side at the back. Press the needle as wide as possible up into the needle fixture. Tighten the needle fixture screw securely again.

Selection of the right needle

Selection of the right needle

The needle’s thickness is displayed

on the shaft.

In any case, do not use a bent or

blunt needle!

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 8

Page 8

7

Remove and attach pr

Remove and attach pr

esser foot

esser foot

Remove:

Turn the hand wheel as wide as you can into

your direction until the needle reaches its highest position.

By lifting the presser foot lever you lift the

presser foot (1).

The presser foot falls down if you lift the lever

at the back of the foot switch (2).

Warning: Do not use force!

Attach:

Put the presser foot on the needle plate so

that the groove at the foot is directly situated

under the groove of the foot holder.

Adjust the threading tension

Adjust the threading tension

If you can pull the thread slightly with a small

resistance out of the bobbin, the threading

tension is correct.

As the lower threading tension is already set

by the factory concerning general sewing, it

needs not to be regulated very often.

In the case of very light or heavy materials,

the lower threading has to be regulated.

Adjust the lower threading

Adjust the lower threading

tension:

tension:

Turn the screw clockwise to increase the

tension.

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 9

Page 9

Stitch length selection dial

Stitch length selection dial

To change the stitch length you can

turn the selection dial so that the

number of the desired stitch length

is at the mark.

The numbers stand for the approximate

stitch length in mm.

The lower the number is the shorter the

stitch is.

Reverse stitch

Reverse stitch

Press the button down to use

the reverse stitch.

Stitch selection dial

Stitch selection dial

You can set the desired stitch

using the stitch selection dial.

8

Stich length

selection

button

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 10

Page 10

Remove the bobbin case

Remove the bobbin case

Set up the presser foot, turn the hand wheel

into your direction until the thread take-up

lever is on its position (figure 1).

Open the bobbin cover (figure 2).

After that, open the bobbin case and

take the case out of the machine

(figure 3). As long as you keep the

cover of the bobbin case open, the

bobbin cannot fall out.

As soon as you release the cover,

the bobbin falls out.

9

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 11

Page 11

10

WWind the bobbin

ind the bobbin

Release the hand wheel release by turning the release plate into your direction.

Guide the thread from the thread reel

through the thread retainer (figure 2).

Now, put the end of the thread through

the hole in the bobbin (figure 3).

Put the bobbin onto the bobbin thorn so

that the end of the thread is on top of the

bobbin.

Press the bobbin thorn to the right until

you can hear a clicking. Hold the end of

the thread tight and start the machine.

As soon as the bobbin is winded up a little bit you can let the end of the thread

go (figure 4).

If the sewing spool stops, remove the

bobbin and cut the thread (figure 5).

Now, tighten the release plate again.

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 12

Page 12

Thread the upper threading

Thread the upper threading

Put the thread reel on the reel holder so

that the thread comes backwards from

the reel.

Hold onto the reel with your right hand

and lead the thread downwards through

the two tension plates from top to bottom.

Lead the thread to the top through the

thread giver. Lead the thread giver with

a slight pull through the hole of the thread giver. Lead the thread to the needle

and thread the needle from front to

back.

Draw up lower threading

Draw up lower threading

Put the sewing foot on its highest position. Now, turn the hand wheel with your

right hand into your direction until the

needle moves down and then it moves

up again.

Stop the hand wheel as soon as the

needle is on its highest position.

Hold on the end of the upper stitch with

your left hand.

Pull the upper stitch slightly to the top

so that the lower stitch forms a loop

(figure 2).

Now, pull out around 5 cm of both threads under the sewing foot to the back

(figure 3).

11

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 13

Page 13

12

Straight sewing and zigzag sewing

Straight sewing and zigzag sewing

Presser foot: zigzag foot (figure)

Stitch selection: 1 or

2 for straight sewing

3-10 for zigzag sewing

Stitch length selection dial: 0.3 – 4

Start sewing

Start sewing

Make sure that both threads are under the presser foot. While holding the threads with your left

hand, turn the hand wheel into your direction and

put the needle in the position on the material

where you want to start sewing. Lower the presser foot, step slightly on the foot controller and

start sewing. To bolt the stitch end you have to

sew a few reverse stitches first.

Change sewing direction

Change sewing direction

1. Stop the machine; turn the hand wheel into

your direction to put the needle into the

material. Lift the presser foot.

2. Turn the material in the desired direction.

3. Lower the presser foot and continue sewing.

Strengthen the stitches

Strengthen the stitches

1. Press the reverse button; sew a few reverse

stitches to bolt the stitches.

2. To remove the material you have to take up

the presser foot and to move the material

away into the other direction.

3. The thread cutter is at the backside of the

presser foot.

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 14

Page 14

TTricot stitch

ricot stitch

This stitch is especially suitable for darning tears. It

is also used to strengthen stretching materials and

to sew on applications.

Presser foot: zigzag foot

Stitch selection: 8

Stitch length: 0.3 – 4

WWitchcraft and herringbone stitch

itchcraft and herringbone stitch

You can sew stretching materials using this very

elastic stitch. The witchcraft stitch is suitable for

lycra swimsuits, etc, as a margin stitch for belts or

as a decorative stitch.

Presser foot: zigzag foot

Stitch selection:

Stitch length: s.s. (stretch stitch)

Zipper insertion

Zipper insertion

Presser foot: zipper foot

Stitch selection: 1

Stitch length: 1 – 4

Sew in right side

If the foot is clicked into place at the foot holder with

the left foot fixture, the needle pricks through the left

foot pinhole. By doing that, the right side of the zipper

gets sewed on.

Sew on right side

Sew on right side

If you sewed on the right side of the zipper, you

have to change the foot into the right position and

sew on the left side.

13

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 15

Page 15

Make a button hole

Make a button hole

Presser foot: button hole foot

Stitch selection: “A” “B’’ ‘’C’’

Stitch length: 0.3 – 1

1. Pull the button hole sole completely

forward and start with the symbol:

Now, you sew forward the left

button hole caterpillar according to

the desired length (see 1).

2. Switch on symbol:

while the needle is outside the material.

You sew the first row with 3-4 stitches (see 2).

3. Switch on symbol:

while the needle is outside the material.

Now, you sew the right caterpillar automatically

backwards (see 3).

4. Here, you stop the machine while the needle

is outside the material and switch on

symbol:

Sew the back row with 4-6 stitches. The button

hole is now sewed and can be opened with a

dividing knife (see 4).

14

WWarning:

arning:

Sometimes it is better to

Sometimes it is better to

repeat the sewing pro

repeat the sewing pro--

cess to get a better fixed

cess to get a better fixed

button hole. Before start

button hole. Before start--

ing sewing a button hole

ing sewing a button hole

you should do trial runs

you should do trial runs

and sew one or more

and sew one or more

button holes on the cor

button holes on the cor--

responding material.

responding material.

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 16

Page 16

Hem

Hem

Presser foot: Hem foot

Stitch selection: “1”

Stitch length: 1-4

1. Replace the normal foot by a hem foot.

2. Turn up the selvage about 3 mm as shown

on the right side.

3. To protect the selvage you have to take in 5

mm from the selvage. For a short moment, stop

the machine with the needle in a horizontal

position.

4. Pull the selvage into the hem foot and start

the automatic hemming.

During hemming, fold the material slightly to the

left and let the selvage run through the foot as

wide as you can.

Button sewing

Button sewing

Presser foot: button foot

Stitch selection: “3” about “7”

Stitch length: 0

The button hole foot is for sewing buttons

up to an average size. Insert the foot.

Clamp the button by lifting and lowering the

presser foot (needle is in a horizontal position).

You have to set the needle stop so that the

button holes were directly hit by the needle.

The first stitches should be steered by the

hand wheel to avoid a damaging of the needle.

15

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 17

Page 17

16

Blind hem sewing

Blind hem sewing

Presser foot: blind hem foot

Stitch selection: “9”

Stitch length: 1-3

1. Fold the material according to the desired

material width (figure 1).

2. On the right side, when you fold back the

hem, there has to remain a selvage with the

width of 4 mm (figure 2).

3. Lay the hem under the blind stitch foot so

that the guidance of the foot goes along the

folded hem (figure 3).

The guidance of the blind stitch foot can be

changed in that way, that the needle only hits

the selvage of the hem using the biggest zigzag over-lock so that you can only see a point

of the thread at the other side (figure 4). You

should complete the hem only slowly to have a

better control.

Free arm sewing

Free arm sewing

By removing the cloth plate you

get a free arm cloth plate.

The free arm makes it possible to

sew tubular components more easily.

Put the sleeves and the trouser

legs onto the free arm.

(See figure on the right)

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 18

Page 18

Clean the bobbin case

Clean the bobbin case

1. Put the needle in the highest position,

otherwise, it is not possible to remove the

shutter. Remove the bobbin case.

2. Turn the snap lever out and remove the

retaining ring.

3. Remove the shuttle by holding the cone in

the middle of the shuttle. Remove all the

dirty parts from the retaining ring and oil all

the parts using a cloth.

4. Put a few drops of oil onto the shuttle.

5. Put the parts together again in

reversed order.

Warning:

Please only use special oil for

sewing machines!

Clean feed dog

Clean feed dog

To guarantee a perfect sewing it is always

necessary to keep the feed dog clean. You

should clean it every 2-3 months if you use

the machine very often.

1. Remove the presser foot and the needle.

2. Open the screws of the needle plate to

remove them from the machine (figure 1).

3. Now, remove the dust and remnants from

the feed dog by using a small brush

(figure 2).

4. Put on the needle plate again.

17

Bobbin

Shuttle

Greiferbahnring

Bobbin

case

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 19

Page 19

18

Oil the machine

Oil the machine

Remove the upper arm cover and

open the bulb cover.

Warning:

Pay attention to the locked cover!

The parts that have to be oiled are

marked with arrows.

Before oiling, you should clean these

parts. You can put one or two drops of

good oil used for sewing machines

onto these parts.

Warning:

Only use oil for sewing machines.

You should oil every second or third

month.

Warning:

After oiling, do not forget to sew a

remnant first to absorb oil that came

out.

Bedienungsanl.1800/1600 GB 30.08.2004 17:45 Uhr Seite 20

Page 20

24 months guarantee

The receipt of purchase with date of purchase is the certificate for the guarantee

(Please always keep carefully)

If you have any questions or problems, please call our service hotline

under phone number

+49 7244 720435

Service (Repair Service)

SDC VERTRIEBS GMBH

AM HASENBIEL 6

D-76297 STUTENSEE

PRODUCT SPECIFICATIONS:

POWER 230 VOLTS 50 HERTZ

POWER INPUT 85 WATTS

INCLUDING ENGINE 70 WATTS

WORKPLACE LIGHTING 15 WATTS (LIGHT BULB SOCKET WITH THREAD E 14, MAX

15 WATTS)

STITCH RATE MAX 800 STITCHES PER MINUTE

Our devices are provided with the CE sign and are safety and GS tested.

We are always available for further information. Please contact:

VERITAS BETEILIGUNGSGESELLSCHAFT

P.O. Box 291347 • D- 47833 Krefeld • Germany

Trademark-License AEG

®

by Licentia Patent-Verwaltungs-GmbH

Bedienungsanl.1800/1600 GB 30.08.2004 17:44 Uhr Seite 1

Loading...

Loading...