Page 1

Page 2

TOOLS AND

MATERIALS REQUIRED (continued)

PLAN DUCTWORK

INSTALLATION (continued)

For Ductfree Installations Only:

❏ One two-pack HF88 Replacement Filter Kit

For Installation On Kitchen Cabinets With Recessed Bottoms

Only:

❏ Two 1” x 2” x 12” (approximate length) wood strips (purchase

locally)

❏ Four 1-1/4” long flat head wood screws (purchase locally)

to fasten strips to cabinet bottom

PLAN DUCTWORK INSTALLATION

For Ducted Installations Only:

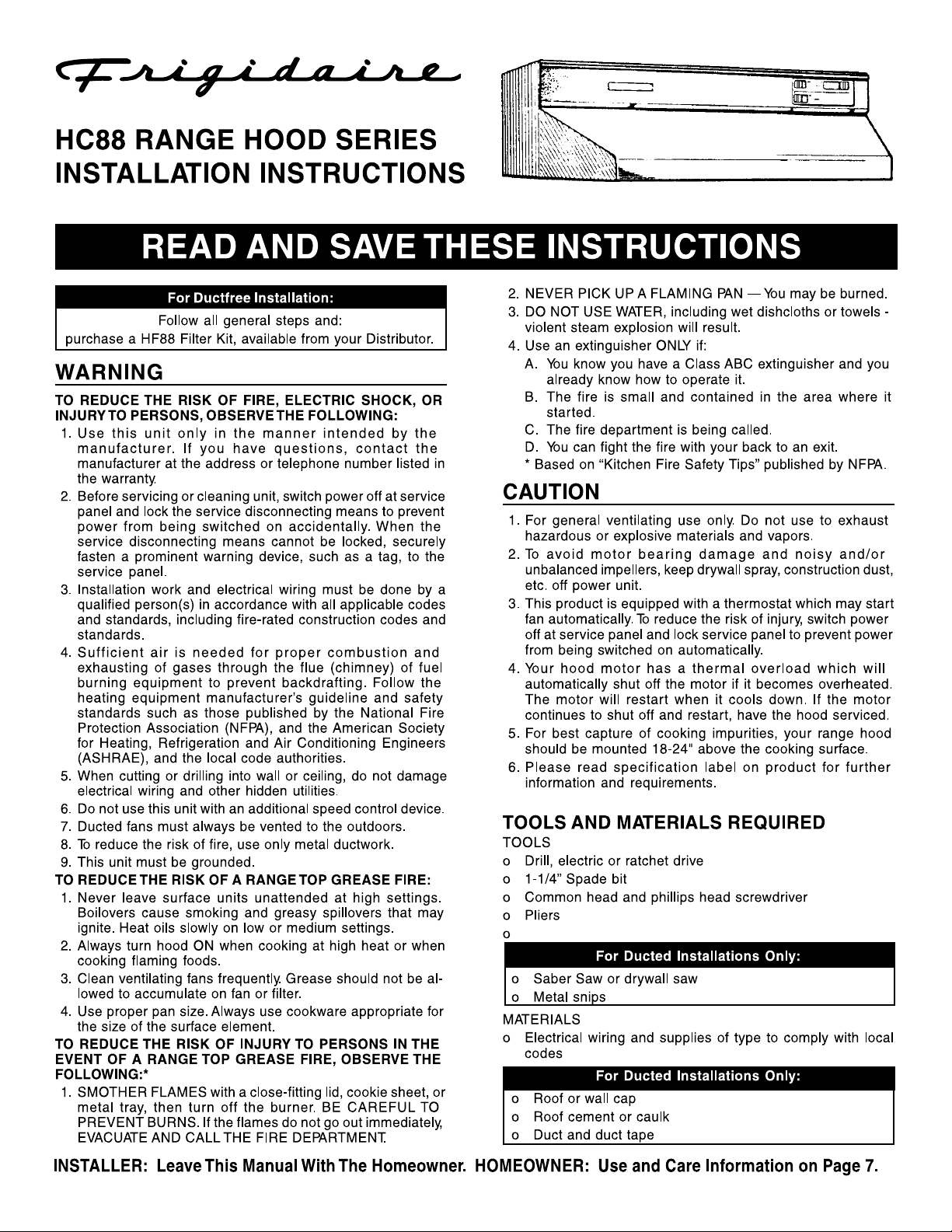

Begin planning ductwork by deciding where duct will run

between hood and outside. For best performance, use

shortest possible duct run and a minimum number of elbows.

In more complex situations, 3-1/4” x 10” duct can be

converted to round duct by means of a transition. FIGS 1A 1E show several choices.

FIG. 1C

ROOF CAP

3-1/4" X 10" DUCT

FIG. 1C: Ducting straight up through roof using 3-1/4” x 10”

duct. For single story installations.

FIG. 1D

ROOF CAP

FIG. 1A

WALL CAP

FIG. 1A: Ducting directly through outside wall. If wall cap is

used directly off back of hood, check to make sure that

damper flap in damper/duct connector on hood does not

interfere with damper flap in wall cap. If it does, remove flap

on hood damper/duct connector.

FIG. 1B

ELBOW

3-1/4" X 10" DUCT

WALL

CAP

6" ROUND DUCT

3–1/4" X 10" TO 6"

ROUND DUCT

TRANSITION

FIG. 1D: Straight up through roof using round duct.

FIG. 1E

ADJUSTABLE ELBOW

3–1/4" X 10" TO 6"

ROUND DUCT

TRANSITION

6" ROUND

DUCT

WALL CAP

FIG. 1B: At times it will be easier to run duct vertically and

use an elbow.

FIG. 1E: Ducting between ceiling joists for multi-story

installations or through soffits above cabinets where soffit

2

connects to outside walls.

Page 3

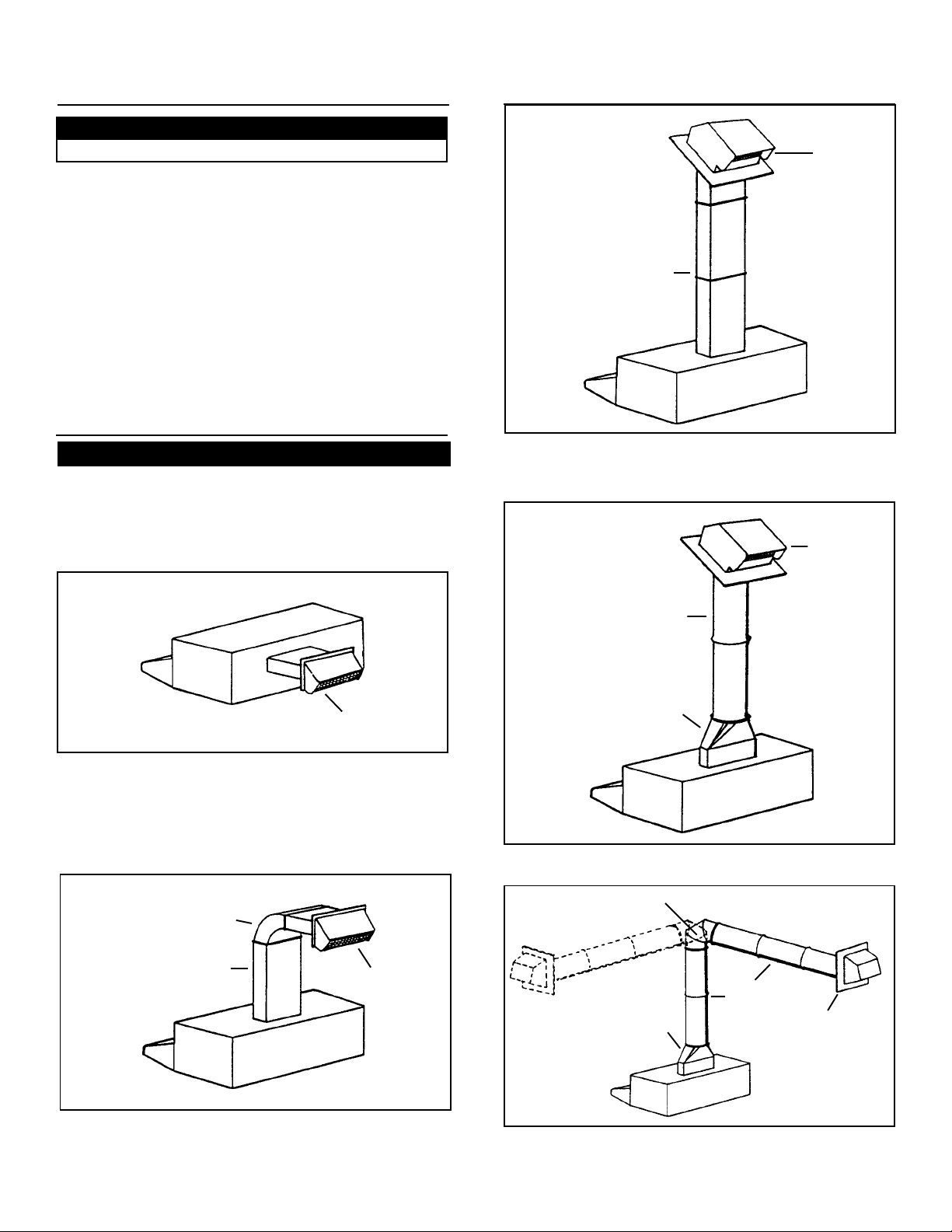

FIG. 2

STEP 4

STEP 3

STEP 2

STEP 6

STEP 5

PREPARE HOOD

1. Unpack hood and check contents. You should receive:

1 - assembled hood

1 - plastic bag, containing:

4 - 7/8” wood screws for mounting hood to cabinet

2 - 1/4” black sheet metal screws for mounting damper/

duct connector to hood

2 - aluminum filters

1 - damper/duct connector

For Ductfree Installations Only:

Discard damper/duct connector and two black sheet metal

screws.

For Steps 2 - 6 below, refer to FIG. 2.

2. Set hood upside down and remove bottom cover and

screws.

3. Remove filters.

4. Remove wiring box cover and screws.

5. To make hood lighter and easier to handle, remove blower

assembly.

a.) Unplug blower.

b.) Loosen knurled nuts on mounting rods and slip rods

out of blower mounting brackets. Do not remove nuts

completely from rods.

c.) Lift out blower and set blower aside.

CAUTION

DO NOT GRASP BLOWER BY BLOWER WHEELS.

WHEELS MAY BE DAMAGED.

6. Remove light lens. Squeeze sides of lens toward center of

hood and lift lens out.

7. Remove either top or rear electrical knockout. (FIG. 3)

For Ducted Installations Only:

7. Remove either top or rear duct knockout. (FIG. 3)

Fasten damper/duct connector to hood over opening.

Use two black sheet metal screws provided in parts bag.

(FIG. 3)

FIG. 3

VERTICAL DUCTING*

ELECTRICAL

KNOCKOUTS

HORIZONTAL DUCTING*

HINGE

PINS

* FOR DUCTED INSTALLATIONS ONLY.

3

HINGE

PINS

DUCT

KNOCKOUTS*

Page 4

PREPARE THE

INST ALLA TION LOCA TION

NOTE

IF DISTANCE BETWEEN W ALL AND FRONT OF CABINET

FACE FRAME IS MORE THAN 12”, THERE WILL BE A

GAP BETWEEN BACK OF HOOD AND WALL. THIS IS

NORMAL. TOP FRONT EDGE OF HOOD SHOULD BE

FLUSH WITH FRONT OF CABINET FACE FRAME. OMIT

STEP 1 IF HOOD WILL BE INST ALLED UNDER CABINETS

WITH FLUSH BOTTOM.

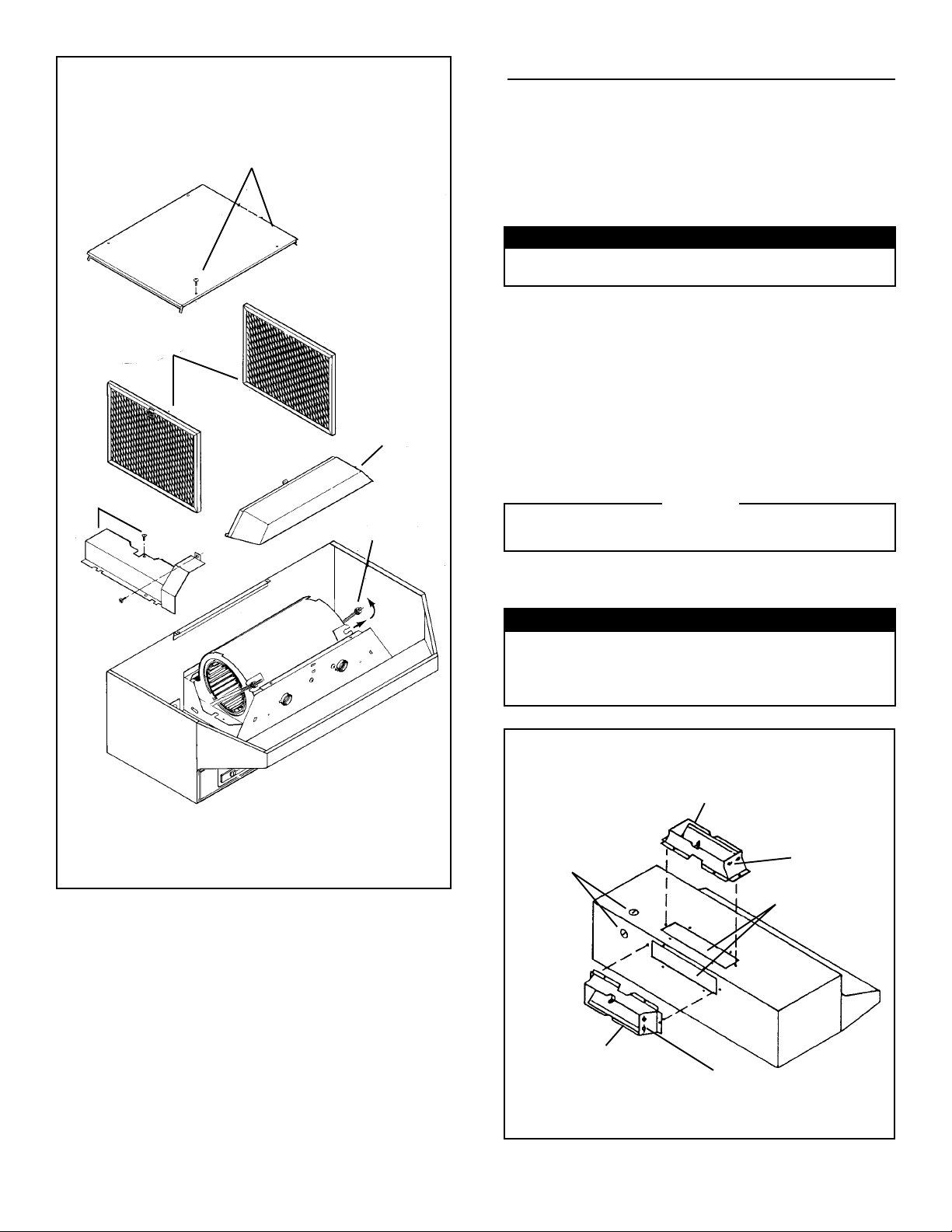

1. For Cabinets With Recessed Bottoms ONLY: (FIG. 4)

Install wood filler strips on each side of recessed area under

cabinet. Use two 1” x 2” strips cut to length (use thicker

strips if necessary). Fasten strips with wood screws about

3” in from each end.

2. Measure and mark the following: (FIG. 5)

a.) electrical wiring opening

For Ducted Installations Only:

b.) duct opening

3. Cut duct opening in wall or cabinet bottom.

4. Drill 1-1/4” electrical wiring opening in wall cabinet bottom.

5. Hold hood up against cabinet bottom and trace keyhole

slots onto cabinet bottom or filler strips. For larger hoods:

Two ¼" dia. holes are provided for secure mounting. They

are located in top of hood approx. 8” each side of center.

Add filler strips for these as necessary . A void blocking hood’s

vertical electrical knockout.

6. Screw four 7/8” wood screws from parts bag into exact

center of narrow end of keyhole slots marked on cabinet

bottom. Allow 3/8” of screws to project, so hood can be

fitted into place later.

7. Run electric wiring through hole drilled in wall or cabinet.

Provide 6” leads and install proper connector for type of

wire used.

FIG. 4

CUT STRIPS TO FIT

DUCT

OPENINGS*

WIDTH OF RANGE

HOOD

* FOR DUCTED INSTALLATIONS ONLY.

CENTER

LINE

3"

ELECTRICAL

WIRING

OPENING

3"

FIG. 5

1–1/2"

HORIZONTAL DUCT OPENING

FRONT OF CABINET

3–7/8"

3/8"

6–1/4"

CABINET BOTTOM

6-7/8"

9"

10-5/8"

6–1/4"

BACK WALL

6–1/4"

6–1/4"

1/8"

7–1/2"

7–1/2"

3/4"

1–1/2"

9–7/8"

9"

VERTICAL DUCT OPENING

4

Page 5

INSTALL THE DUCTWORK

For Ducted Installations Only:

NOTE

THESE INSTRUCTIONS WILL FOLLOW THE PLANS

MADE ON PAGE 2. START ON THE OUTSIDE AND

WORK BACK TOWARD HOOD. FOLLOW

APPROPRIATE DIRECTIONS FOR TYPE OF DUCT

SYSTEM YOU ARE INSTALLING.

FIG. 6

WALL CAPS (FIG. 6)

Use a saber saw to cut a hole slightly larger than duct so

duct will line up easily with hood. Install casing strips on

outside walls finished in siding. Assemble the ductwork and

tape all joints. Run ductwork back to hood. Fasten wall cap

to last section of duct and nail or screw cap to wall. Seal all

around flange on wall cap with caulking compound. Make

sure that enough duct runs into the room so that the duct

will overlap the damper/duct connector by 3/4” when the

hood is installed.

FIG. 7A

FIG. 7B

INSTALL HOOD

1. Position hood so that: (FIG. 8)

FIG. 8

ELECTRICAL LINE

a.) electrical wiring runs through opening in top or back of

hood.

b.) large part of keyhole slots fit over hood mounting screws

For Ducted Installations Only:

c.) damper/duct connector slides into ductwork.

2. Push hood back so that mounting screws slide into narrow

end of keyhole slots. When mounting larger hoods, run (2)

screws through the 1/4” dia. holes (in hood top and 8” each

side of center) and into the cabinet bottom or added filler

strips. Tighten all screws firmly.

3. Install locknut on electrical connector and tighten securely.

4. Make electrical connections. Connect white to white, black

to black, and green or bare wire to green ground screw.

(FIG. 9)

3/4"

PLASTIC ROOF

CEMENT

FIG. 7C FIG. 7D

DO NOT CAULK AROUND BOTTOM

OF FLANGE FOR DRAINAGE

NAIL

ROOF CAPS (FIGS. 7A - 7D)

Cut hole in roof slightly larger than duct so duct will line up

easily with hood. Trim shingles around hole so that they will

fit snugly around hood of cap when cap is installed. Assemble

the ductwork and tape all joints. Run the ductwork down to

hood. Trim duct parallel to roof pitch, leaving 3/4” of duct

projecting above roof (FIG. 7A). Seal all around duct with

roof cement. (FIG 7B) Install roof cap, inserting back edge

of cap under shingles. (FIG 7C) Seal around roof cap with

roof cement and seal all nail heads and shingles which were

cut or lifted. (FIG. 7D)

Make sure that enough duct runs into the room so that the

duct will overlap the damper/duct connector by 3/4” when

the hood is put into place.

FIG. 9

BLACK

BLACK

WHITE

WHITE

BLACK

WHITE

GREEN

GROUND

(BARE OR

GREEN WIRE)

GREEN

WHITE

BLACK

5. Replace wiring box cover and screws. Make sure that wires

are not pinched between cover and hood.

6. Install two 75 watt max. bulbs, or one 75 watt bulb and one

25 watt bulb for night-light use. Install 25 watt bulb in righthand socket.

5

Page 6

INSTALL HOOD (Continued)

INST ALL HOOD (Continued)

For Ducted Installations Only:

FIG. 10

BLOWER DISCHARGE

VERTICAL DUCTINGHORIZONTAL DUCTING

7. Reinstall blower. Do not grasp blower by blower wheels.

Position blower so that blower discharge lines up with

damper/duct connector and slip rods into mounting brackets on blower assembly. (FIG. 10) Tighten knurled nuts

securely, and plug in blower.

For Ductfree Installations Only:

FIG. 11

BLOWER

DISCHARGE

LOUVER COVER

For Ductfree Installations Only:

9. Snap aluminum filter onto front of replacement filter. (FIG.

13) Make sure that tab on aluminum filter lines up with

finger pull on replacement filter.

FIG. 13

Push filter assembly into hood. Flaps on filter will flex

against top and sides of opening. (FIG. 14) Push

assembly up until bottom of assembly clears lip on bottom

cover. Insert bottom of filter and pull assembly down,

collapsing pull ring against aluminum filters.

7. Reinstall blower. Do not grasp blower by blower wheels.

Move blower mounting rods to front holes in hood support

channels. (FIG. 11) Position blower so that blower

discharge lines up with louvered opening on hood front.

Slip rods into mounting brackets and tighten knurled nuts

securely. Plug in blower.

Remove louver cover on control panel. Pry cover off with

screwdriver or knife.

8. Reinstall bottom cover and screws. See FIG. 2.

For Ducted Installations Only:

FIG. 12

3

2

FIG. 14

3

2

1

1

9. Reinstall aluminum filters. Make sure tabs are toward

outside and bottom. (FIG. 12)

10. Turn on power and check operation of hood.

6

Page 7

USE AND CARE

CONTROLS (FIG. 15)

FIG. 15

BLOWER - "SPEED"

Infinite speed slide control adjusts blower speed and sound

level for quiet operation

BLOWER - "ON"

Turns blower ON and OFF.

When this control is turned ON, blower will operate at preset

speed of slide control.

LIGHT

Three-position switch

• First position (Normal) - Turns both bulbs ON.

• Second position (Night Light) - Turns right-side bulb ON.

• Third position (OFF) - Turns both bulbs OFF.

DO NOT install bulbs rated higher than 75 watts.

Install a smaller bulb on the right for a night light.

USE AND CARE (Continued)

HOW TO AVOID A COMMON RANGE-TOP GREASE FIRE

• Your range hood provides a protective barrier between

the cooking surface and the cabinets.

• Keep fan, filters and grease laden surfaces CLEAN

according to instructions.

• Always turn hood ON when cooking at high heat to keep

the cooking area and the hood cooler.

• Use high heat settings only when necessary.

• Never leave cooking surface unattended. Boil-over

causes smoking and greasy spillovers that may ignite.

• Always use adequate-sized utensils.

• If preparing flaming foods, such as Cherries Jubilee,

always turn hood ON to HIGH to prevent a high heat

situation which can cause damage or fire.

HOW TO EXTINGUISH A COMMON RANGE-TOP

GREASE FIRE

• Never pick up a flaming pan. If dropped, flames can

spread quickly.

• DO NOT USE WATER! A violent steam explosion may

result. Wet dishcloths or towels are also dangerous.

• Smother flames with a close fitting lid, cookie sheet or

metal tray.

• Flaming grease can also be extinguished with baking

soda or a multi-purpose dry chemical extinguisher.

• Turn off surface units - If you can do so without getting

burned.

HEAT SENTRY™

Your hood is equipped with a Heat Sentry™ thermostat. This

thermostat is a device that will turn on or speed up the blower

if it senses excessive heat above the cooking surface.

1) If blower is OFF - it turns blower ON to HIGH speed.

2) If blower is ON at a lower speed setting - it turns blower up

to HIGH speed.

When the temperature level drops to normal, the blower will

return to its original setting.

FILTER CARE

Remove each filter by grasping the tab at the bottom of filter,

lifting up and swinging filter out to the side.

ALUMINUM FILTERS

Clean filters frequently in a detergent solution. They are

dishwasher safe.

REPLACEMENT

FILTERS

The aluminum filter is the only washable part of the filter system.

Snap it out of its frame and clean it in a detergent solution or

dishwasher.

The particle filter is not washable. It should last up to twelve

months with normal use.

CLEANING

Do not allow an excessive accumulation of grease. Use a mild

detergent suitable for painted surfaces. DO NOT USE

ABRASIVE CLOTH, STEEL WOOL PADS, OR SCOURING

POWDERS. Vacuum blower to clean. Do not immerse blower

in water.

WIRING DIAGRAM

NOTE: If any of the original wire on the hood has to be replaced,

use wire having equivalent insulation and temperature rating

(105°C Thermoplastic AWM, U.L. Listed).

GREEN

6

WHITE

BLACK

WHITE

WHITE

BLACK

ORANGE

BLACK

BLACK

YELLOW

BLACK

CONTROL

BOARD

(SYMBOLIC)

WHITE

M

B

1

2

4

5

8

9

10

120 VAC

LINE IN

WHITE

LAMP "B"

WHITE

THERMOSTAT

BLACK

WHITE

LAMP

"A"

7

Page 8

Loading...

Loading...