AEG-Electrolux EWS850 User Manual

Possible causeProblem

The door can not open :

Spinning starts late or the laundry

is not spun enough :

visible in the machine? The machine,

which is the result of modern technology, runs

in a very economical way with low water

Water is not

consumption. Performance is

nevertheless excellent.

The program is still running and the drum is turning.

The door lock has not yet released.

The water level is above the bottom edge of the door.

The machine is heating the water, and the water

temperature is higher than 55

The door can only be opened when the relevant light

has gone out.

The electronic unbalance detection device has cut

in because the laundry is not evenly distributed in

the drum.The laundry is redistributed by reverse

rotation of the drum.This may happen several times

before the unbalance disappears and normal spinning

can resume.if ,after few minutes,the laundry is still

not evenly distributed in the drum,the machine will

spin at a lower speed or will not spin.If at the end of

the programme the laundry is not spun enough,

redistriute the load manually and select the spin

programme.

The machine makes an unusual

noise? The machine is fitted with a commutator

motor which improves machine

performance.

If you are unable to identify or solve the problem,contact our service centre. Before telephoning, make a note of

the model, serial number and purchase date of your machine: the Service Centre will require this information.

Contents of this user manual may be modified without informing you.

120

4

4

Something is not working?

Problems which you can resolve yourself

3

4

12

13 -14

15

16

During machine operation it is possible that one of the End light starts to flash:

4 flashes= the door has not been closed

2 flashes= the machine does not empty

1 flash= the machine does not fill.

Once the problem has been eliminated, press the START/PAUSE button to restart the programme. If

after all checks, the problem persists, contact your local Service Centre.

5

8

10

10

10

10

10

10

10

11

11

17

5

5

6

5

6

6

7

7

7

7

8

8

17

17

17

17

18

18

18

19- 20

The machine does not start up:

The machine does not fill:

The machine fills them empties

immediately:

The machine does not empty

and/or does not spin:

There is water on the floor:

Unsatisfactory washing results:

The machine vibrates or is noisy:

The door is not firmly closed.

The machine is not plugged in or there is no power at

the socket.

The main fuse or the fuse in the plug has blown.

The Start/Pause button has not been pressed.

The Delay option has been selected.

The water tap is closed.

The inlet hose is squashed or kinked.

The filter in the inlet hose is blocked.

The door is not properly closed.

The end of the drain hose is too low. Refer to relevant

paragraph in drainage section.

The drain hose is squashed or kinked.

The drain pump is clogged.

The laundry is not evenly distributed in the drum.

The Rinse Hold or No Spin option has been selected

Too much detergent or unsuitable detergent (creates

too much foam) has been used.

Check whether there are any leaks from one of the

inlet hose fittings. It is not always easy to see this as

the water runs down the hose ; check to see if it is

damp.

The drain hose is damaged.

Check that the filter has been fastened.

Too little detergent or unsuitable detergent has Been

used.

Stubborn stains have not been treated prior to washing.

The correct program or temperature was not selected.

Excessive laundry load.

The transit bolts and packing have not been removed.

The support feet have not been adjusted.

The laundry in drum has not been evenly distributed.

Too little laundry is washed.

Possible causeProblem

2 19

Remove any objects from the pump impeller by

rotating it.

Put the cap back on the emergency emptying hose

and place the latter back in its seat.

Screw the pump fully in.

Close the pump door.

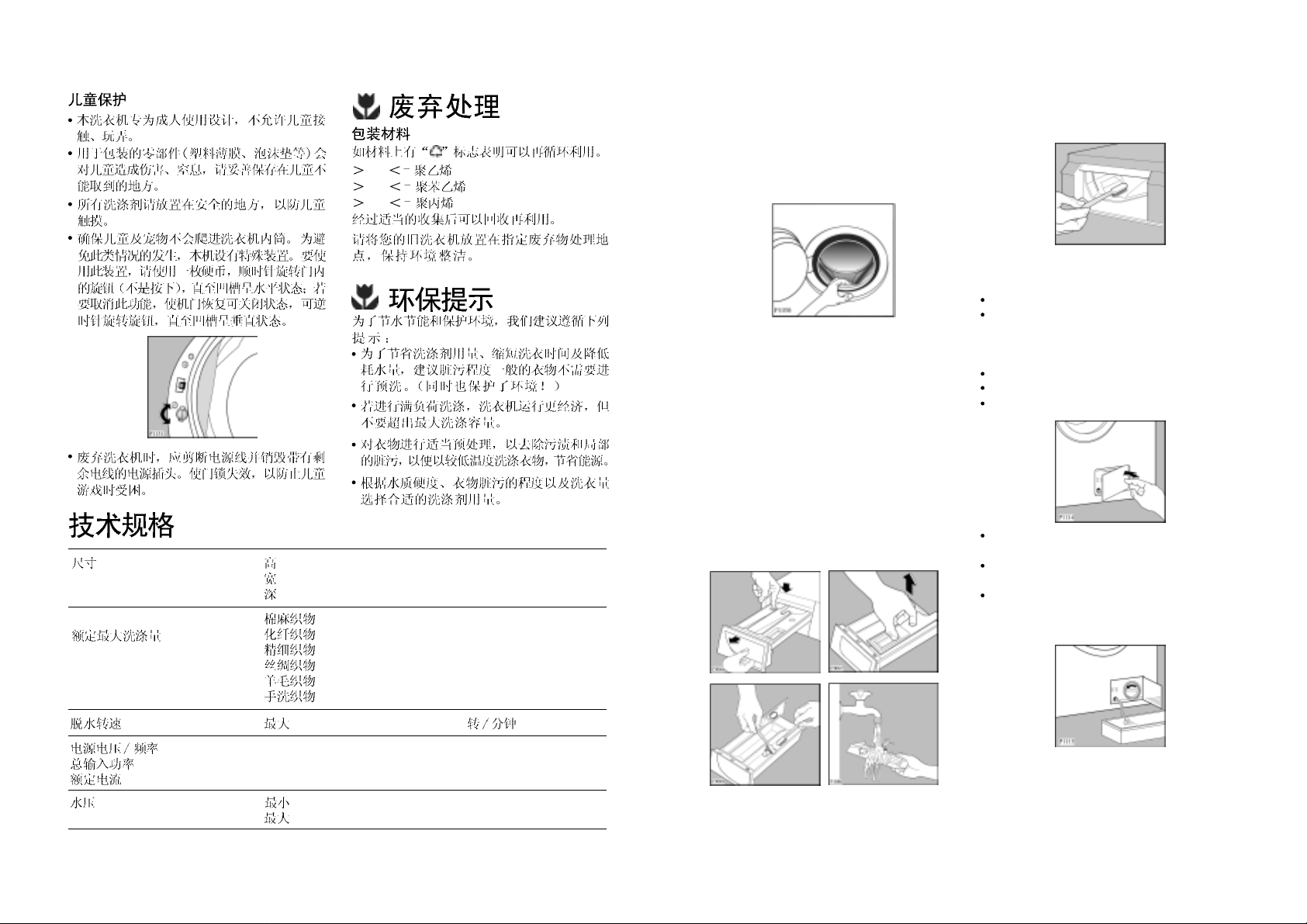

5. Water inlet filter

If you notice that the machine is taking longer to fill,

check that the filter in the water inlet valve is not

blocked:

Turn off the water tap.

Take off the inlet hose from water tap. Drain water in

this hose.

Unscrew the hose from the inlet valve.

Clean the filter with a stiff brush.

Put on the hose back onto the tap and the inlet

valve.

6. Emergency emptying out

If the water is not discharged , proceed as follows to

empty out the machine:

Pull out the plug from the power socket;

Close the water tap;

If necessary, wait until the water has cooled down;

Open the pump door;

Place a bowl on the floor and place the end of the

emergency emptying hose into the bowl. Remove

its cap. The water should drain by gravity into the

bowl.Whe the bowl is full,put the cap back on the

hose. Empty the bowl. Repeat the procedure until

water stops flowing ou;

Clean the pump if necessary as previously described.

Replace the emergency emptying hose in its seat

after having plugged it.

Screw the pump again and close the door.

7. Frost precautions

If the machine is installed in a place where the temperature could drop below 0 , proceed as follows:

Remove the plug from the socket.

Close the water tap and unscrew the water inlet hose

from the tap.

Place the end of the emergency emptying hose and

that of the inlet hose in a bowl placed on the floor

and let water drain out.

Screw the water inlet hose back on and reposition the

emergency emptying hose after having put the cap

on again.

By doing this, any water remaining in the machine is

removed, avoiding the formation of ice and,

consequently, breakage of the affected parts.When

you use the machine again, make sure that the ambient temperature is above 0

.

318

PE

PS

PP

85 cm

60 cm

49 cm

5 kg

2 kg

2 kg

2 kg

1 kg

1 kg

Maintenance

1. Door seal

Check from time to time the door seal and eliminate

eventual possible objects that could be trapped in the

fold.

2. Bodywork

Clean the outside of the machine with warm water and

a neutral, non-abrasive household detergent. Rinse

with clean water and dry with a soft cloth.

Important: do not use methylated spirits, solvents or

similar products to clean the bodywork.

3. Detergent dispenser drawer

After a while, detergents and fabric softeners leave

deposits in the drawer.

Clean the drawer from time to time by rinsing it under

a running tap. To remove the drawer from themachine,

press the button in the rear left-hand corner.To facilitate cleaning, the top part of the additive compartment can be removed.

Detergent can also accumulate inside the drawer

recess: clean it with an old toothbrush. Refit the drawer

after cleaning.

4. Drain pump

The drain pump should be inspected if:

The machine does not empty and/or spin.

The machine makes an unusual noise during draining

due to objects such as safety pins,coins etc.

blocking the pump.

Proceed as follows:

Disconnect the appliance.

If necessary wait until the water has cooled down.

Open the pump door.

Place a container close to the pump to collect any

spillage.

Release the emergency emptying hose, place it in

the container and remove its cap.

When no more water comes out, unscrew the pump

and remove it. Always keep a rag nearby to dry up

spillage of water when removing the pump.

850

AC 220V/50Hz

2000 W

10A

50 kPa

800 kPa

174

Special Programme table

7

Programme

selector dial

programme

position

11

Cold wash

12

Refresh

13

Rinses

14

Spin

15

Drain

O

Reset/Off

For cotton and

Synthetic

This programme can be

used for softening hand

washed garments

For rinsing hand washed

items

Separate spin for

all fabrics

For emptying out the

water of the last rinse

of programmes that end

with water in the tub

For cancelling the

programme which is

running or to switch the

machine off

Note without Rinsehold function

Programme

description

Wash with cold water

1 rinse,with fabric softener,if required short spin (Cannot use

detergent)

3 rinses with liquid additive,if

required short spin at max.

speed

Short spin at max.speed

Water drain

Additional

functions

Prewash

Anti-allergic rinse,Super

quick wash

Spin speed

Spin speed

Anti-allergic Rinse,

Spin speed

Spin speed

1

2

3

A

B

A

4

B

16

C B

5

6

5

60cm

60 90cm

220V/50Hz

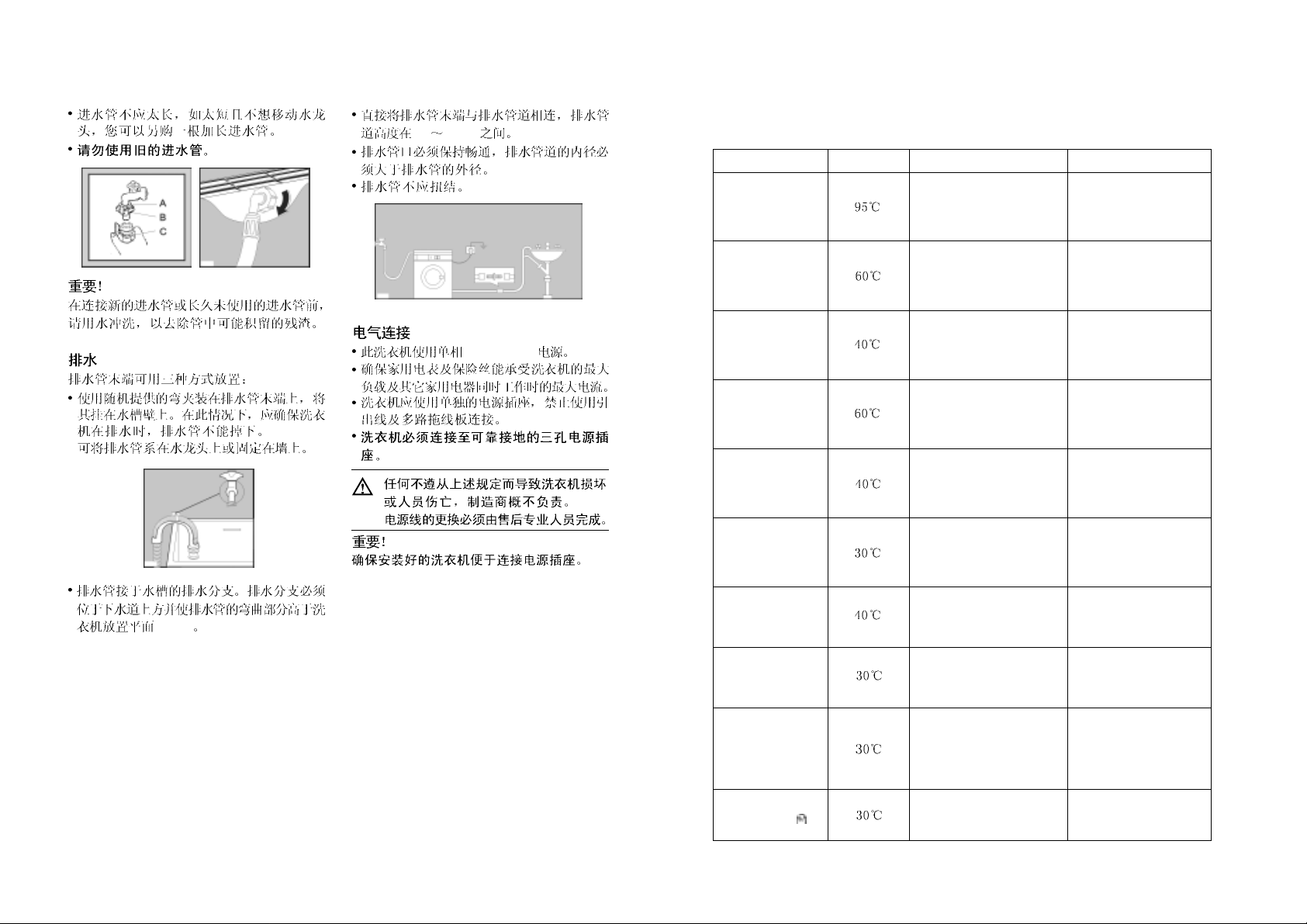

Programme table

Fabrics/programme

1

Cotton

2

Cotton

3

Cotton

4

Synthetic

5

Synthetic

6

Synthetic

7

Delicate

8

Silk

temperature Type of laundry Additional functions

White cotton

White and

coloured

cotton

White and

coloured

cotton

shirts,blouse,

underwear,

mixed fabrics

shirts,blouse,

underwear,

mixed fabrics

shirts,blouse,

underwear,

mixed fabrics

Acrylic, viscose,

polyester items,

curtains

Silk

Prewash

Anti-allergic rinse

Economy

Super quick wash

Spin speed

Prewash

Anti-allergic rinse

Economy

Super quick wash

Spin speed

Prewash

Anti-allergic rinse

Economy

Super quick wash

Spin speed

Prewash

Anti-allergic rinse

Economy

Super quick wash

Spin speed

Prewash

Anti-allergic rinse

Economy

Super quick wash

Spin speed

Prewash

Anti-allergic rinse

Super quick wash

Spin speed

Prewash

Anti-allergic rinse

Super quick wash

Spin speed

Prewash

Anti-allergic rinse

Spin speed

Special programme for gar-

9

Wool

10

Hand wash

6

ments bearing

the “ Pure new wool, nonshrink, machine

washable” label

Special programme for articles of cloths

with hand wash label

15

Spin speed

Spin speed

Loading...

Loading...