Page 1

GENERAL INDEX

GB

D

NL

F

SP

................................................ Pag. 1÷9

................................................ Pag. 10÷18

I

................................................ Pag. 19÷27

................................................ Pag. 28÷36

................................................ Pag. 37÷45

................................................ Pag. 46÷54

FORLI' Italy

INDEX

Description Page

1.0 Identification .................................................. 2

1.1 Manufacturer ..................................................... 2

1.2 Definitions .......................................................... 2

1.3 Transport - Handling - storage ........................... 2

1.3.1 Storage conditions ............................................. 2

1.3.2 Weight ............................................................... 2

1.3.3 Overall dimensions ............................................. 2

1.3.4 Handling ............................................................ 2

2.0 Installation...................................................... 2

2.1 Authorised personnel ......................................... 2

2.2 Mounting the generator...................................... 3

2.3 Electrical connections ........................................ 3

2.3.1 Connection of the battery recharger ................... 3

2.3.2 Connection of the starter battery ........................ 3

2.3.3 Connection of the remote control panel ............. 3

2.4 Installing the fuel tank ......................................... 3

Connection to gas canister ................................ 3

3.0 General operation ......................................... 4

3.1 Description of generator and functioning ............ 4

3.2 Safety advice ..................................................... 4

3.3 Noise levels........................................................ 4

4.0 Instructions for use ...................................... 5

4.1 Starting the generator ........................................ 5

4.2 Stopping the generator ...................................... 5

4.3 Inherent risks ..................................................... 5

4.4 Improper use ..................................................... 5

4.5 Useful advices.................................................... 5

4.6 Troubleshooting ................................................. 5

5.0 Maintenance operations .............................. 6

5.1 Nature and frequency of checks ........................ 6

5.2 Maintenance operations which do not

require qualified technicians ............................... 6

5.3 Maintenance operations which require

qualified technicians ........................................... 6

5.3.1 Oil change ......................................................... 7

5.3.2 Air filter maintenance.......................................... 7

5.3.3 Spark plug maintenance .................................... 7

5.3.4 Regulating the voltage........................................ 8

6.0 Inactivity and dismantling ........................... 8

6.1 Dismantling ........................................................ 8

7.0 Dealing with fire hazards............................. 8

8.0 Technical data sheet .................................... 9

8.1 Technical specifications ..................................... 9

8.2 Wiring diagrams .........................................55÷71

© WTA srl -1998

All rights reserved

Printed in Italy

Text and graphics by: VEGA - Forlì

No part of this publication may be reproduced, copied or transmitted in any form or by any means without prior written permission from WTA

srl.

Figures, descriptions, reference and technical data in this manual are given as mere example and are not binding.

Because of WTA policy of continual product and safety improvement, we reserve the right to make changes at any time without notice.

1

Page 2

FORLI' Italy

1.0 IDENTIFICATION

The identification plate of the machine is affixed outside

the plate casing (see fig. 1).

1.1 MANUFACTURER

WTA srl

Via Virgilio, 3

47100 FORLI' - ITALY

P. IVA 00718330400

1.2 DEFINITIONS

In this handbook, three types of “safety graphics” are used

to point out different levels of danger or any other important

information:

DANGER

Draws attention to potentially dangerous situations which

may cause serious personal injury.

CAUTION

Draws attention to potentially dangerous situations which

may cause personal injury or material damage.

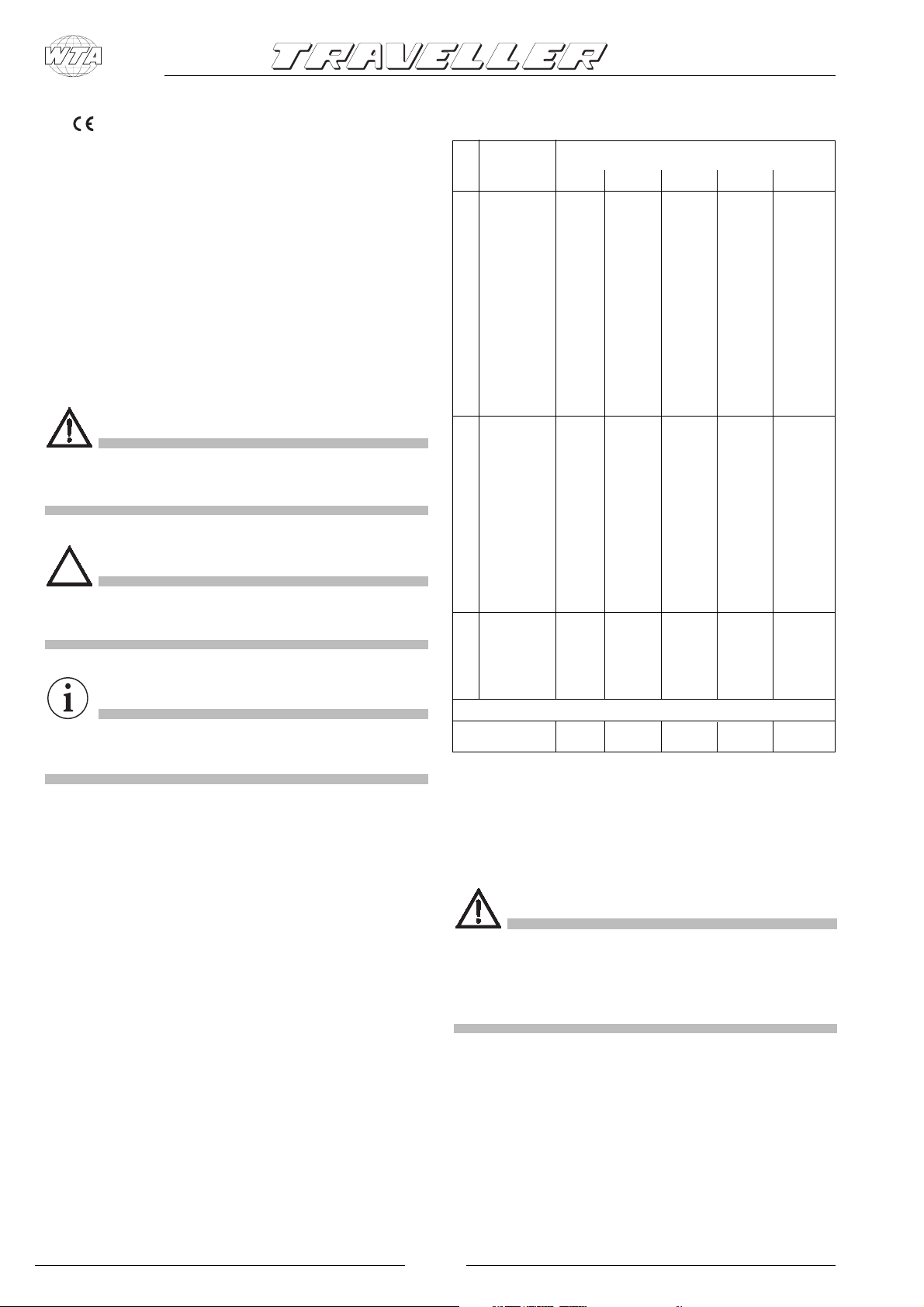

1.3.3 OVERALL DIMENSIONS

See figg. 2, 3, 4 :

Model

1000 2500 3000 4000 5500

A mm 470 530 570 660 700

B mm 535 605 650 740 -C mm 565 640 680 770 -D mm 320 385 385 475 515

E mm 315 290 290 355 510

F mm 260 295 295 310 -Gmm27303062 -H mm -- 360 360 -- --

I mm 65 87 113 78 -Lmm659697265 -M mm 225 222 230 130 -Nmm36282517 -O mm 535 605 650 740 735

Pmm2730306255

TYPE "B" INSTALLATION TYPE "A" INSTALLATION

Q mm 260 295 295 310 370

X mm 590 650 690 780 770

IMPORTANT

Draws attention to situations which may cause

malfunctioning or damage to the machine.

1.3 TRANSPORT - HANDLING - STORAGE

1.3.1 STORAGE CONDITIONS

The generator is protected against sudden impact by

suitable packing consisting of cardboard, polystyrene and

a wooden frame support.

The generator should be stored horizontally in a dry and

well-ventilated room.

1.3.2 WEIGHT

Gross weight (including packing):

Mod. 1000 .......................................... Kg 50

Mod. 2500 .......................................... Kg 62

Mod. 3000 .......................................... Kg 71

Mod. 4000 .......................................... Kg 114

Mod. 5500 .......................................... Kg 140

Y mm 385 430 435 540 505

Z mm 335 305 305 380 550

OPENING DIM.

Air intake area

2

cm

220 220 220 260

1.3.4 HANDLING

The packed generator can be handled by normal means of

lifting and transport.

Boxes are fitted with spacers which enable the use of

manual fork-lifts.

DANGER

Strictly observe the accident prevention precautions and

safety regulations during lifting and transport, and always

use machines

be lifted.

2.0 INSTALLATION

2.1 AUTHORISED PERSONNEL

The generator shall be installed onto the vehicle (caravan,

motorhome or special vehicle) by authorised personnel

only, namely by skilled technicians or workshops, authorised

directly by W.T.A.

If the installation is carried out by non-authorized technicians

with a higher maximum capacity than the load to

2

Page 3

or workshops, W.T.A. disclaims any responsibility for the

safety and efficient running of the generator according to

the M.D. 89/392/EEC.

DANGER

The instructions given in sections 2.2 - 2.3 - 2.4 are

addressed to qualified technicians only.

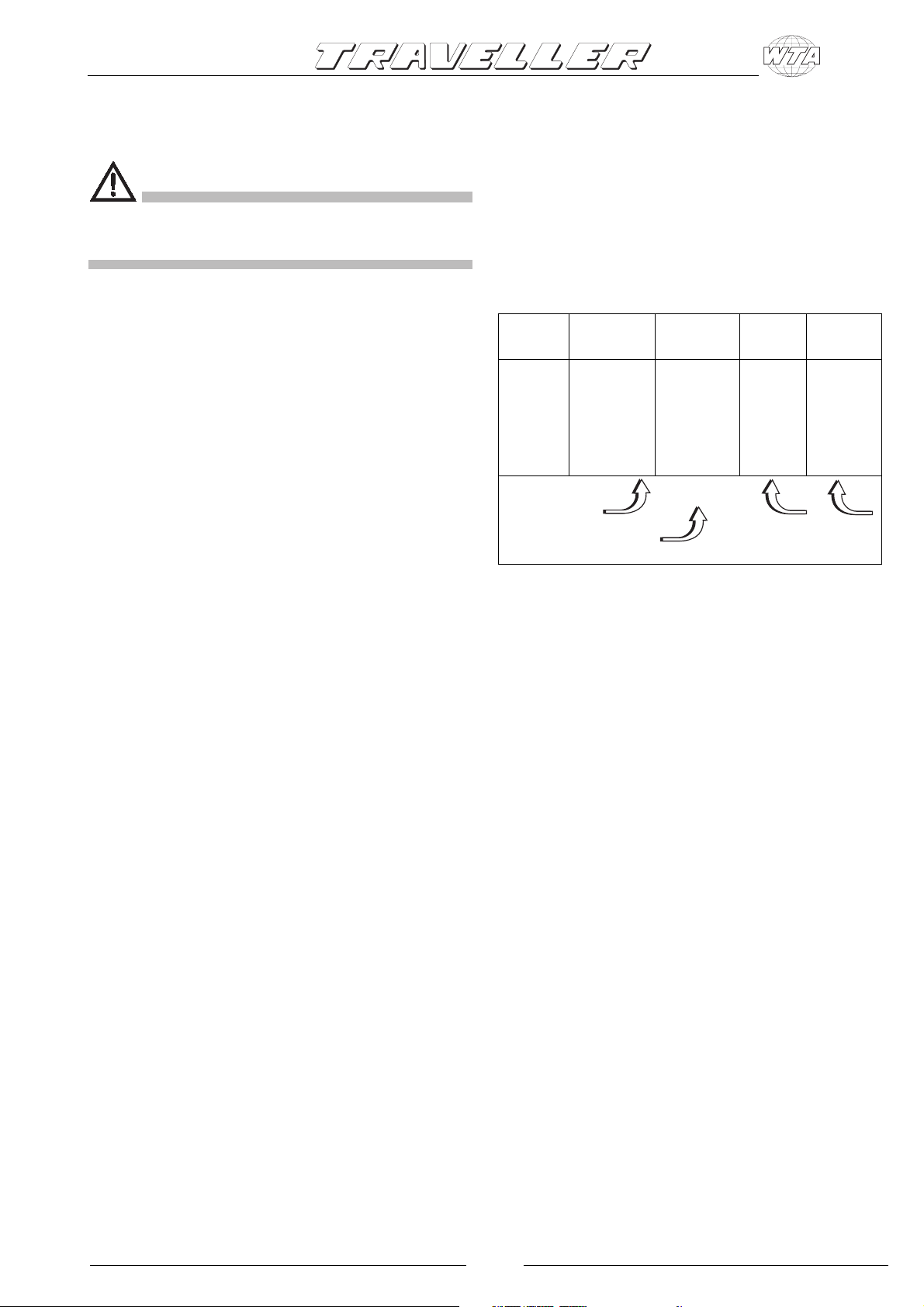

2.2 MOUNTING THE GENERATOR

Generators mod. 1000 - 2500 - 3000 - 4000 are provided

with fixing brackets,vibration dampers and petrol filter to be

placed on the fuel feed hose to the generator. Brackets

allow either suspended type "A” mounting (see fig. 3) or

traditional type "B” mounting (see fig. 4).

This is made possible by the supporting frame of the outer

casing.

Generator mod. 5500 is provided with brackets for fixing

the external seal, brackets for anchoring the unit, vibration

dampers, silencer (pos. 29 fig. 16) to be coupled to the

exhaust hose delivered as accessory AG 125 (pos. 34 fig.

16), and fuel filter which is standard installed inside the

casing (pos. 33 fig. 15). The brackets (pos. 31 fig. 16) which

allow to fix the seal (pos. 35 fig. 16) allow to mount the

generator complete with seal inside the arranged

compartment and to perfectly seal the vehicle side. The

exhaust hose can be positioned at will as shown in fig. 16

by rotating the curve inwards to either upper position or

lower position. By removing the curve, it is also possible to

directly fit the exhaust pipe by crossing the casing on its lefthand side. The prearranged floor must tolerate both the

generator mass and the vibrations due to the motion of the

vehicle ("TYPE B” mounting).

The type “A” mounting (suspended installation) offers the

following advantages: reduced overall dimensions, quick

installation, easy access for both ordinary and extraordinary

maintenance operations.

Make sure there is enough space around the generator

casing for air to pass freely (for cooling). It is also necessary

to leave at least 20 mm distance between the casing and the

surrounding parts.

If the breathing manifold is positioned behind one of the

vehicle's wheels, make sure that the tyre is prevented from

throwing water into the casing when travelling on wet roads.

For the type “A” mounting, use the plate supports provided

to ensure that the genset is fixed securely. If type “B”

mounting is preferred (traditional installation), a watertight

compartment (fig. 2), set towards the vehicle interior and

having the dimensions given in section 1.3.3, needs to be

prearranged, with exhaust holes and air inlets drilled into the

floor and door. In addition, use an exhaust union (fig. 4),

supplied as accessory, to be fixed directly onto the generator

casing with screws or rivets. In order to prevent the exhaust

gas recycling within the compartment, place flameproof

sealing around the exhaust union.

FORLI' Italy

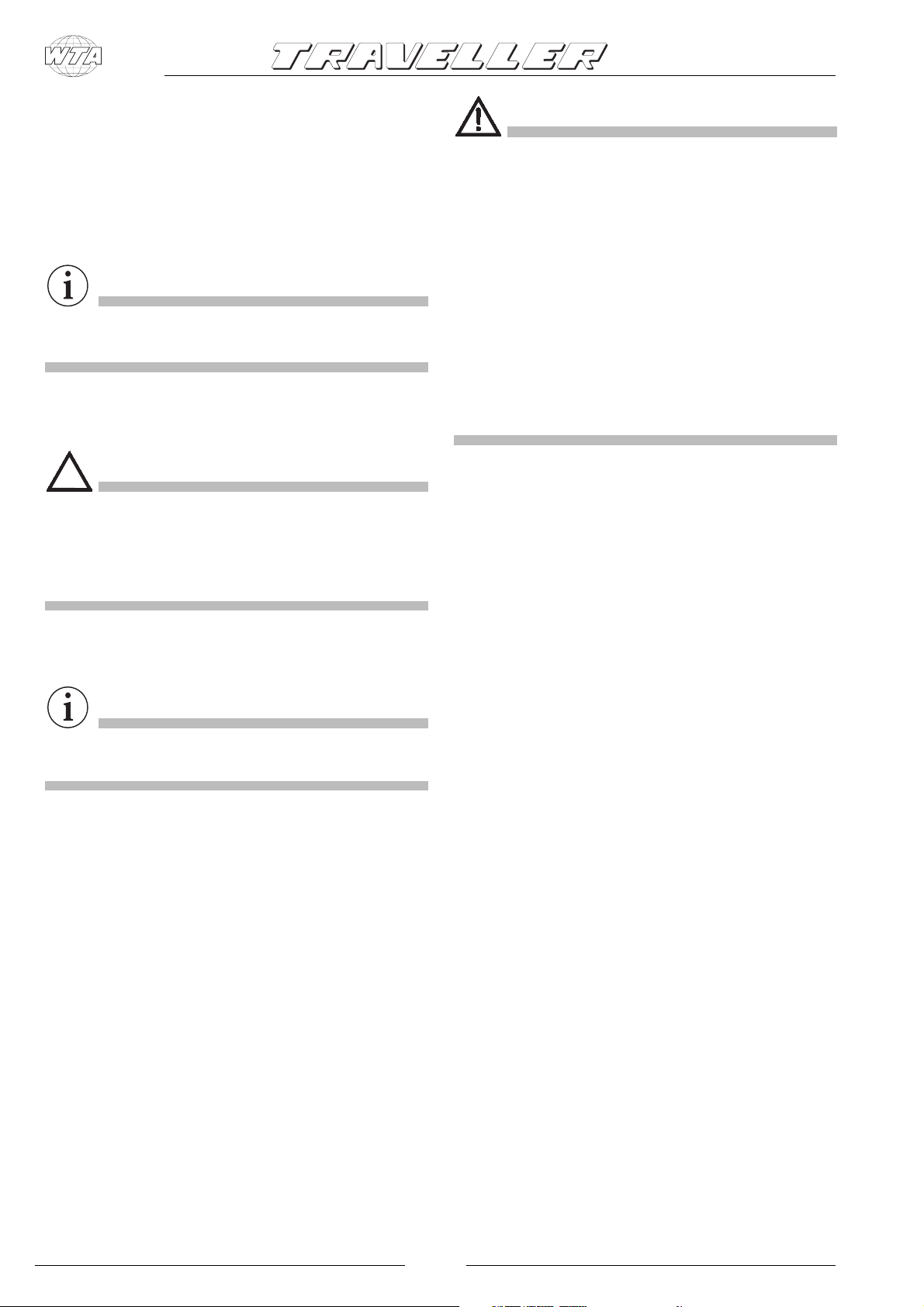

2.3 ELECTRICAL CONNECTIONS

For the 230V use a standard cable with cross-section

according to table 1 below. Pass it inside the casing via the

airlead (pos. 30 fig. 7 and 9) and connect to the terminals

(pos. 17/18 fig. 6 and 14). Connect the earth wire to pos. 15.

The electrical circuit should have a relay or change-over

switch (such as accessory AG102/AG113), so as to prevent

any damage to the generator when the camper is connected

to an external mains supply (precedence is automatically

given to the mains).

Mod.

Cross-section Cross-section

mm2 -230 V mm2-12 V

1000 1.5 6 10 16

2500 2.5 2.5 10 16

3000 2.5 2.5 10 16

4000 4 2.5 10 16

5500 4 2.5 16 25

Power cables

Battery recharger

6 m > 6 m

Battery connection

TAB. 1

2.3.1 CONNECTION OF BATTERY

RECHARGER

Use a wire with minimum cross-section according to table

1 above to connect the terminal (pos. 16 fig. 6 and 14) to

the positive lead of the battery to be recharged.

Insert the AG111 voltage regulator, or alternatively a switch,

to interrupt recharging when complete.

(See wiring diagrams, pages 55 ÷ 71).

2.3.2 CONNECTION OF STARTER BATTERY

For starting the generator, connect the positive terminal of

the vehicle's starter battery to pos. 12 fig. 6 and 14 using a

flame-resistant sheathed cable having a cross-section

according to table 1 above.

The earth cable should have the same cross-section and be

connected from pos. 13 to the vehicle chassis. Make sure

that a clean, rust-free contact is made (i.e. rub down surface

if painted), and protect with grease.

2.3.3 CONNECTION OF REMOTE CONTROL

PANEL

Fix the control panel in desired position inside the vehicle

and use the individually-tested AG103 extension cable to

connect it to the genset by means of the connector pos. 14

fig. 6 and 14.

2.4 INSTALLING THE FUEL TANK

Install the fuel tank as near as possible to the generator and

if possible on the same horizontal level, or up to 30cm

below. As well as reducing the length of fuel pipe as much

as possible, make sure it is not bent or squashed. Do not

put the tank near sources of heat, and make sure that water

3

Page 4

FORLI' Italy

cannot infiltrate.

Use LOCTITE 577 to make all connections, so as to prevent

fuel leakages.

To connect the fuel tank to the generator, use a 6x13mm

rubber-coated tube, of the same type used for the genset

and suitable for unleaded petrol. For the extension, use the

ties and filter provided. It is advisable to use fuel hose

AG118 (accessory) for the connection from tank to refuellingmouth.

IMPORTANT

Model 5500 does not need fuel tank, since it is standard

fitted inside the genset casing.

CONNECTION TO GAS CANISTER

DANGER

• The unit shall be used only and exclusively with the door

closed.

• Keep inflammable substances like petrol, paints, solvents,

etc. away from the generator.

• Do not let hot parts of the genset come into contact with

inflammable materials.

• Do not fill up with the engine running if the tank is placed

close to the generator.

• Do not touch the generator or its connections with wet

hands.

• Do not replace the fuses or thermal switches with new

ones of higher amperage.

• Any check of the electrical parts shall be made with

engine stopped and by authorised technicians only.

CAUTION

For the LPG genset, withdraw the gas from the upright

canister before the vehicle's service regulator and from the

upper part, so that gas enters the genset at high pressure

and in the gaseous state.

(Minimum recommended pressure: 0.7- 0.9 bar)

3.0 GENERAL OPERATION

IMPORTANT

The firm disclaims any responsability for damages arising

from malfunctioning of the generator.

3.1 DESCRIPTION OF GENERATOR AND

FUNCTIONING

The generator consists of an endothermic petrol engine

connected to an alternator which produces both alternate

and direct current.

The unit comes in a soundproof casing made of pressed

steel plate and insulated with special deadening materials.

Fuel comes to the combustion engine through a pump

which is standard fitted on the unit itself.

The generator is manufactured according to the safety rules

given in the Conformity Declaration.

3.3 NOISE LEVELS

The generator has been submitted to a noise emission test

at a qualified ISTEDIL lab, where all the necessary tests were

carried out and EC Certificate No.I-225/92 issued, stating

following results:

Measured according to: EC DIRECTIVE 84/536

NOISE LEVEL:

Mod. 1000 .......................................... LwA 81

Mod. 2500 .......................................... LwA 85

Mod. 3000 .......................................... LwA 85

Mod. 4000 .......................................... LwA 87

Mod. 5500 .......................................... LwA 87

3.2 SAFETY ADVICE

The unit is housed within a perfectly closed casing. Therefore,

there is no danger of accidental contacts with hot or moving

parts or wires under voltage.

The door of the unit is fitted with lock and key and should

not be left within the reach of children or non-authorised

persons.

4

Page 5

FORLI' Italy

4.0 INSTRUCTIONS FOR USE

4.1 STARTING THE GENERATOR

Normally the vehicle's 12V battery is used to start the

genset.

First press the red button (pos. 27 fig. 5) on the control panel

into the “I” position.

To start the genset from cold, press and hold down the

green START button (pos. 25 fig. 5) together with the white

CHOKE button (pos. 26 fig. 5) for max. 5 seconds.

When starting the LPG generator from cold, press the

green button (pos. 25 fig. 5) and at the same time "blip" the

white button (pos. 26 fig. 5) for about a second at intervals

of around 3 seconds. As soon as the engine fires, release

both buttons.

If the engine does not start, wait a few seconds, then repeat

the operation.

CAUTION

Do not make prolonged or repeated (more than 5 consecutive) attempts to start the genset, as this may damage the

starter motor.

4.4 IMPROPER USE

DANGER

The generator is to be installed by qualified technicians only,

according to the manufacturer’s instructions.

The generator is to be used only and exclusively for producing

current for mobile vehicles, fitted with a standard electrical

circuit in keeping with the power supplied by the generator.

4.5 USEFUL ADVICES

To use the genset at best, we remember you that little, but

prolonged, overloads may cut off thermal switches pos. 10

and 11 shown in fig. 6 and 14.

During running-in, it is advisable that the new engine is not

subjected to loads exceeding its nominal load by 70%, at

least during the first 50 running hours.

4.6 TROUBLESHOOTING

We have listed below some problems which may occur,

along with their respective causes and possible solutions.

In the case of problems which are not listed below, please

seek advice from an authorised after-sales service centre.

To start the genset when already warmed-up, or during the

summer, when the outside temperature is high, press the

green “START” button (pos. 25 fig. 5) only.

In an emergency the genset can be started manually using

the pull-cord handle (pos. 4 fig. 8 and 15) and holding the

choke magnet (pos. 36 fig. 8 and 15) shut with one hand

if the engine is cold.

The green LED on the control panel ((pos. 23 fig. 5) indicates

that the genset is running correctly.

4.2 STOPPING THE GENERATOR

Push the red “STOP” button (pos. 27 fig. 5) on control panel

into the ”0" position. Alternatively use the safety switch on

the genset itself (pos. 7 fig. 6 and 14) for models 2500 - 3000

- 4000 - 5500.

4.3 INHERENT RISKS

DANGER

The generator is fitted with a combustion engine, and

therefore runs on highly inflammable fuelstuffs.

Exhaust gases are conveyed under the casing and, although

mixed with cooling air, they are inevitably hot.

Do not touch the parts of the casing close to the exhaust

and do not place your hands or other objects within the

duct.

1 When the green “START” button (pos. 25 fig. 5)

on the control board is pressed, the generator

does not work.

Causes and Solutions:

1.1 Check that the red switch (pos. 27 fig. 5) is in the “I”

position.

1.2 Electrical wires loose or disconnected.

(Have checked by qualified personnel).

1.3 No power supplied to starter-motor.

(Have checked by qualified personnel).

1.4 Earth wire of generator disconnected.

(Have checked by qualified personnel).

2 The starter-motor turns, but the generator does

not start.

Causes and Solutions:

2.1 No fuel: check.

2.2 No oil in engine.

Check if the red warning light (pos. 6 fig. 5) on the

control board blinks during the starting phase.

Check the oil level and top up if necessary (see

Maintenance section).

2.3 The safety switch (pos. 7 fig. 6 and 14) is in the "0"

position.

Check and press in the “I” position.

2.4 Check that the engine's spark-plug nipple is fully

inserted.

2.5 No current to the spark plug.

(Have checked by qualified personnel).

2.6 No fuel getting to the carburettor.

(Have checked by qualified personnel).

5

Page 6

FORLI' Italy

3 The generator tends to stall.

Causes and Solutions:

3.1 No more fuel left in the tank: refill.

3.2 Low oil level.

Check and top up.

(See Maintenance section).

3.3 Air filter is dirty.

(Have checked by qualified personnel).

4 The generator does not produce current

Causes and Solutions:

4.1 Thermal switch off.

Set it to 'on' by pushing the switches (pos. 10 fig. 6

and 14) for 230V A.C., (pos. 11 fig. 6 and 14) for 12V

D.C.

4.2 Condenser (pos. 19 fig. 8) damaged.

(Have checked by qualified personnel).

4.3 Diode rectifier (pos. 21 fig. 8) damaged.

In this case, only the 12V D.C. and the green LED on

the control board are not working.

(Have checked by qualified personnel).

4.4 Rotor diodes damaged.

(Have checked by qualified personnel).

4.5 Frequency too low.

(Have checked by qualified personnel).

5 The unloaded current produced oscillates.

Causes and Solutions:

5.1 Too much oil in the engine: check.

5.2 Defective carburation.

Have the carburettor cleaned by qualified personnel.

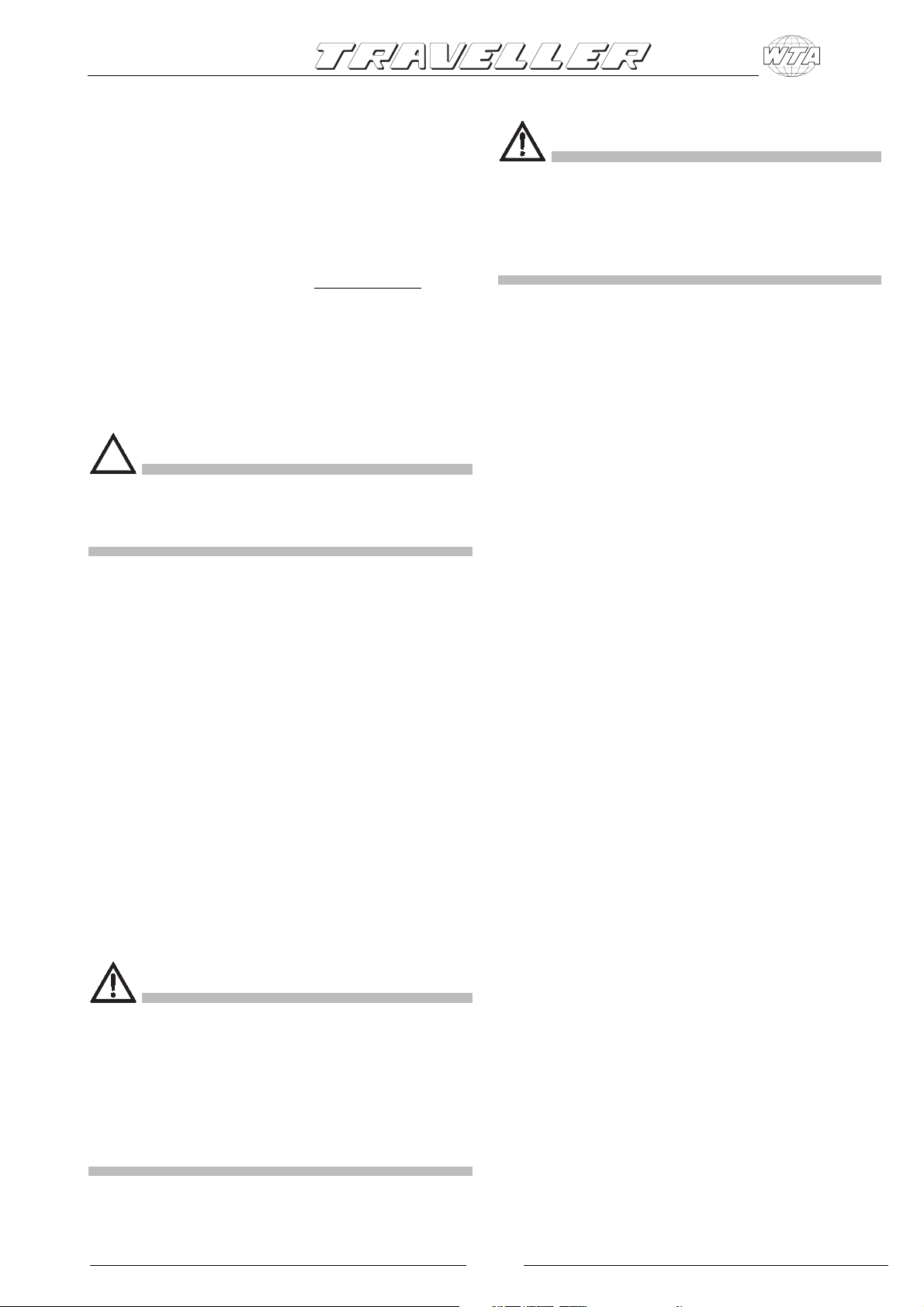

5.1 NATURE AND FREQUENCY OF CHECKS

ORDINARY MAINTENANCE INTERVAL

carry out at the intervals or after the running

hours given in the table, depending on which

occurs first.

Engine oil

Air filter Cleaning

Spark plug

Valve adjustment Check - adjust ▲

Fuel filter and tank

R.p.m.

or frequency Adjust ▲

Suspension points for

vibration dampers Inspection ▲

Fuel hoses Check (replace,

REMARK (1):Clean more frequently when used in dusty areas

(2): Get this work done by a specialist only

Inspection

Change

Inspection

-Cleaning ▲

Cleaning ▲

if necessary)

Every

use

▲

First

3 months

month

or

50 hours

20 hours

▲

(2)

(1)▲(2)

(2)

Every two years

Every

or

Every

6 months

or

100 hours

▲

(2)

(2)

(2)

Every

year

or

300 hours

(2)

(2)

▲

(2)

(2)

5.2 MAINTENANCE OPERATIONS WHICH

DO NOT REQUIRE QUALIFIED

TECHNICIANS

To carry out these operations, the generator door first

needs to be opened. Therefore, the following measures

should be taken:

1) The generator must be stopped with all parts cold.

2) Let the unit cool.

3) Set the safety switch to the “0” position.

N.B.Remember to set it to the “I” position again after check!

5.0 MAINTENANCE OPERATIONS

IMPORTANT

Use only genuine spare parts. The generator may get

damaged if other than genuine parts having a different

quality standard are used.

To make sure that the generator keeps working to maximum

efficiency, it is essential that it is properly and regularly

maintained. Additionally, a proper maintenance grants the

generator a longer lifetime.

DANGER

Before carrying out any check or maintenance operation on

the genset, rotate safety switch (pos. 7 fig. 6 and 14) to "0"

position to prevent any accidental startings of the unit.

For mod. 1000, it is necessary to disconnect the spark-plug

nipple (pos. 1 fig. 8), since no safety switch is fitted.

OIL LEVEL CHECK

1) Remove the oil filling cap (pos. 9 fig. 8) and clean the

dipstick.

2) Re-introduce the dipstick by screwing it in fully.

3) Remove the dipstick and check that the oil level is

between min. and max. levels.

If not, top up with the recommended oil.

4) Refit the cap.

IMPORTANT

All checks should be carried out with the genset horizontal.

5.3 MAINTENANCE OPERATIONS WHICH

REQUIRE QUALIFIED TECHNICIANS

For some maintenance operations you need to slide the unit

out on its runners (pos. 28 fig. 7 and 15) after first loosening

the fixing screws.

6

Page 7

FORLI' Italy

5.3.1 OIL CHANGE

MULTIGRADE

SG / SF

-30° -20° -10° 010° 20° 30° 40°

Room Temperature

15W 50

10W 30

Use detergent oil for four-stroke engines, class API SG or SF

(indicated on the oil can) with SAE viscosity suitable for the

climate (see table).

To allow the oil to drain out easier, run the engine for about

3÷5 minutes. Then discharge the oil when the engine is still

warm so that the emptying is quicker and more complete via

the drainage hose (pos. 2 fig. 8 and 15) by removing the

drain cap (pos. 8 fig. 8 and 15).

Top up with oil of the recommended type via the filling cap

(pos. 9 fig. 8).

Table 2 shows the amount of oil in the oil pan.

Mod. Liters

1000 0.45

2500 0.6

3000 0.6

4000 1.1

5500 1.1

Hot climates

Cold climates

5.3.2 AIR FILTER MAINTENANCE

IMPORTANT

A dirty air filter reduces the air flow to the carburettor. To

keep the carburettor working properly, check it often. Check

more frequently if the engine is used in dusty areas.

DANGER

Never use diesel oil or solvents with a low evaporation point

for cleaning the air filter, since this may lead to danger of

flames or explosion.

Never let the engine run without the air filter. It would get

damaged in a short space of time.

1. Carefully check both cartridges. Replace them if there

are holes or tears (mod. 1000 H/HG is fitted with a single

cartridge).

2. Sponge cartridge: wash it with a neutral detergent

solution and rinse carefully. Let the cartridge dry

completely, then soak it in clean engine oil and wring out

the excess.

3. Paper cartridge: smoothly beat it several times on a hard

surface to remove any dirt, or blow compressed air

through the filter from inside to out. Do not brush the dirt:

this operation would just push it into the fibres. If the

paper cartridge is too dirty, replace it.

TAB. 2

DANGER

• Warm oil may burn you.

• Running the engine with a poor amount of oil can

seriously damage the engine itself.

• Check the oil level when engine is stopped.

IMPORTANT

Used oils must never be poured on the ground. They shall

be collected and consigned to qualified companies for the

disposal in accordance with any local regulations.

5.3.3 SPARK PLUG MAINTENANCE

RECOMMENDED SPARK PLUG:

Mod. 1000 BMR-4A (980073-54744) NGK

BPMR4A-10 (98073-54941) NGK

Mod. 2500/3000/4000/5500

BP6ES, BPR6ES NGK

W20EP-U, W20EPR-U ND

Never use a spark plug with a different thermal degree.

1. Remove the spark plug nipple (pos. 1 fig. 8) and use a

suitable wrench to remove the spark plug.

2. Visually check the spark plug. If it is worn or if the

insulator is broken or chipped, replace it. Clean the

spark plug with an iron brush if it is to be used again.

3. Measure the electrode distance by means of a thickness

gauge.

The distance should be 0.7-0.8 mm.

Adjust, if necessary, by bending the side electrode.

4. Check that the spark plug washer is in good condition

and screw it manually to prevent it being set at an angle.

5. Once mounted, tighten the spark plug using a wrench

with the right driving torque.

7

Page 8

FORLI' Italy

IMPORTANT

When mounting a new spark plug, tighten it a half-turn after

it has compressed the washer. When re-using the same

spark plug, tighten it 1/8-1/4 turn after the washer

compression.

CAUTION

The spark plug should be tightened carefully. A loose spark

plug can get very hot and damage the engine.

5.3.4 REGULATING THE VOLTAGE

This regulation should be carried out with the engine warm

and the generator running without a load.

Check the generator voltage using a tester or voltmeter

connected to the vehicle's 230V socket or to the terminals

(pos. 17-18 fig. 6 and 14) of the generator terminal board.

The voltage should be between 230 and 240 Volts.

If these values are not obtained, adjust the current regulation

screw (pos. 32 fig. 10 and 15) until they are.

Rotate clockwise to increase the voltage.

Rotate anticlockwise to decrease both r.p.m. und voltage.

6.00 INACTIVITY AND DISMANTLING

6.01 DISMANTLING

If the unit must be dismantled, get the work done by

authorised workshops.

7.0 DEALING WITH FIRE HAZARDS

In case of fire, do not open the generator casing and use

type-approved fire-extinguishers.

8

Page 9

FORLI' Italy

8.0 TECHNICAL DATA

8.1 TECHNICAL SPECIFICATIONS

ENGINE 1000H 2500H 3000H 4000H 5500H

Type Single-cylinder

four-stroke Single-cylinder, four-stroke, overhead valves

side valves

Honda model G100K2 GX 160 GX 200 GX 270 GX 390

Displacement cm

Stroke x bore mm 52x46 68x45 68x54 77x58 88x64

Consumption gkW/h 300 230 230 230 235

Fuel Lead-free petrol

Starter system Electronic

Spark plug NGK / ND NGK NGK NGK NGK

Engine-oil sump capacity litres 0,45 0,6 0,6 1,1 1,1

Frequency regulator Automatic with centrifugal masses

ALTERNATOR 1000H 2500H 3000H 4000H 5500H

3

97 163 196 270 389

Type

Synchronous, single-phase, self-regulated, self-energized, two-pole, brushless

Peak max. power W 900 2200 2700 3800 5300

For continuous utilization W 800 2000 2400 3500 4500

Voltage/frequence 230V 50Hz

D.C. power 12V 25A 12V 10A 12V 10A 12V 10A 12V 10A

Rotor insulation class H H H H H H

Stator insulation class F F F F F F

Cooling Centrifugal fan

GENERATOR 1000H 2500H 3000H 4000H 5500H

Total weight Kg 39 50 59 102 132

Overall dimensions (LxWxH) mm 470x320x315 530x385x290 570x385x290 660x475x355 700x520x510

Ignition Electric/man.

Fuel pump Vacuum

Remote control Separate control board with:

push-button starter

push-button choke

stop switch

low fuel LED

running LED

low oil LED (automatic stop)

hour meter

9

Page 10

WIRING DIAGRAMS

SCHEMI ELETTRICI

ELEKTROPLÄNE

STROOMSCHEMA'S

SCHEMAS ELECTRIQUES

FORLI' Italy

ESQUEMAS ELÉCTRICOS

55

Page 11

s.r.l.

Via Virgilio 3, 47100 Villanova - Forlì (Italy)

Tel. 0543/754213 - Telefax 0543/756631

AN ELECTROLUX COMPANY

Page 12

AN ELECTROLUX COMPANY

1000 H/HG

2500 H/HG

3000 H/HG

4000 H/HG

5500 H/HG

Ed. 02/1998

Operating and Maintenance Handbook

Libretto Istruzioni Uso e Manutenzione

Bedienungs- und Wartungsanleitung

Bedienings- en onderhoudshandleiding

Livret d'Usage et d'Entretien

Manual de instrucciones de uso y mantenimiento

Prima di utilizzare il generatore leggere attentamente le istruzioni e le indicazioni riportate nel seguente manuale.

Vor dem Gebrauch des Generators diese Bedienungs- und Wartungsanleitung aufmerksam lesen.

Lees alle aanwijzingen en adviezen in deze handleiding nauwkeurig door voordat u de generator in gebruik neemt

Avant d’utiliser le générateur, lire attentivement les instructions et les renseignements du présent livret.

Antes de utilizar el generador, leer con cuidado las instrucciones y las indicaciones del manual.

Read all instructions and advice given in this handbook carefully before use.

Page 13

FORLI' Italy

FIG. 1

Z

Y

X

FIG. 5

230 V

230 V

12 V

18

17

16

15

22

7

23

6 24

00000

25

17

( )

26

18

START

1h

.

I

0

27

14

FIG. 2

E

FIG. 3

C

B

A

H

G

10

11

FIG. 6

D

F

28

16

30

13

1215

FIG. 7

19 20

1

21

5

FIG. 4

M

36

P

4

Q

O

9

I

L

N

FIG. 8

8

2

3

Page 14

FIG. 9

FORLI' Italy

30

00000

1h

.

START

I

(

)

FIG. 13

17 16 1518

FIG. 10

FIG. 11

32

12

220

220

O

1

14

7

12

B

B

B

R

R

R

T

T

T

E

E

E

I

I

I

A

A

A

U

U

U

K

K

K

C

C

C

E

E

E

R

R

R

R

R

R

I

C

P

T

T

T

R

E

E

E

E

S

S

S

S

S

S

E

E

E

S

S

S

R

R

R

T

T

T

O

O

O

131110

FIG. 14

I

I

C

C

P

P

R

R

E

E

32

36

8

2

4

3

FIG. 15

28

33

3

FIG. 12

32

230

230

31

29

35

12

FIG. 16

34

Loading...

Loading...