Page 1

ENGLISH

For Your Safety

These warnings are provided in the interest of safety. You

or using the appliance. It is most important that this instruction book should be retained with the

appliance for future reference. Should the appliance be sold or transferred, always ensure that the book

is left with the appliance in order that the new owner can get to know the functions of the appliance and

the relevant warnings.

Installation

It is mandatory that all operations required for the

installation are carried out by a qualified or competent

person, in accordance with existing rules and

regulations.

It is dangerous to alter the specification in any way.

Using a gas cooking appliance will produce heat

and moisture in the room which it has been

installed in. Ensure a continuous air supply,

keeping the air vents in good conditions or

installing a cooker hood with discharge tube.

In case of intensive or long time use of the

appliance, make the ventilation more efficient,

by opening a window or increasing the electric

exhaust fan power.

Once you removed all packaging from the appliance,

ensure that it is not damaged and the electric cable is

in perfect conditions. Otherwise, contact your dealer

before proceeding with the installation.

Ensure that the gas supply complies with the gas type

stated on the identification label, placed near the gas

supply pipe.

Ensure a good ventilation around the appliance. A

poor air supply could cause lack of oxygen.

The manufacturer disclaims any responsability

should all the safety measures not be carried out.

Cleaning and Manteinance

For hygiene and safety reasons, this appliance should

Disconnect the appliance from the electrical supply,

Technical assistance

Under no circumstances should you attempt to repair

After installation, please dispose of the packaging

When disposing of an old appliance, make it unusable,

These instructions are only for the countries

stated by the symbol printed on the front cover

of this instruction book.

MUST read them carefully before installing

be kept clean at all times. A build-up of fats or other

foodstuff could result in a fire.

before carrying out any cleaning or manteinance work.

the appliance yourself. Repairs carried out by

unexperienced persons may cause injury or serious

malfunctioning. Refer to your local Service Centre.

Always insist on genuine spare parts.

Environmental Information

with due regard to safety and the environment.

by cutting off the cable.

During Operation

This appliance has been designed for cooking edible

foodstuff and to be used for domestic non-professional

purposes only. It must not be used for any other

purpose.

Ensure that all control knobs are in the OFF position

when not in use.

Should you connect any electrical tool to a plug near

this cooking appliance, ensure that electric cables are

not in contact with it and keep them far enough from

the heated parts of this appliance.

If the appliance is out of order, disconnect it from the

electric supply.

Child safety

This appliance has been designed to be operated by

adults and children under supervision. Young children

MUST NOT be allowed to tamper with the controls or play

near or with the oven.

Accessible parts of this appliance may become hot

when it is in use. Children should be kept away until

it has cooled.

Guide to Use the instructions

The following symbols will be found in the text to guide you

throughout the Instructions:

Safety Instructions

Step by step instructions for an operation

F

Hints and Tips

Environmental information

MANUFACTURER:

ELECTROLUX ZANUSSI S.p.A.

Viale Bologna 298 - 47100 FORLI (Italy)

12

Page 2

Contents

For the user

For Your Safety 12

Instruction for the User 13

Cleaning and Maintenance 14

For the installer

Technical Data 15

Gas connection 15

Electrical Connection 16

Adaptation to different types of gas 17

Building in 18

Instruction for the User

Hob burners control knobs

The hob burners control knobs are situated on the hob

lateral panel. The symbols on the knobs mean that :

l there is no gas supply

there is maximum gas supply

there is minimum gas supply

Lighting the burners

For easier lighting, proceed before putting a pan on

the pan support.

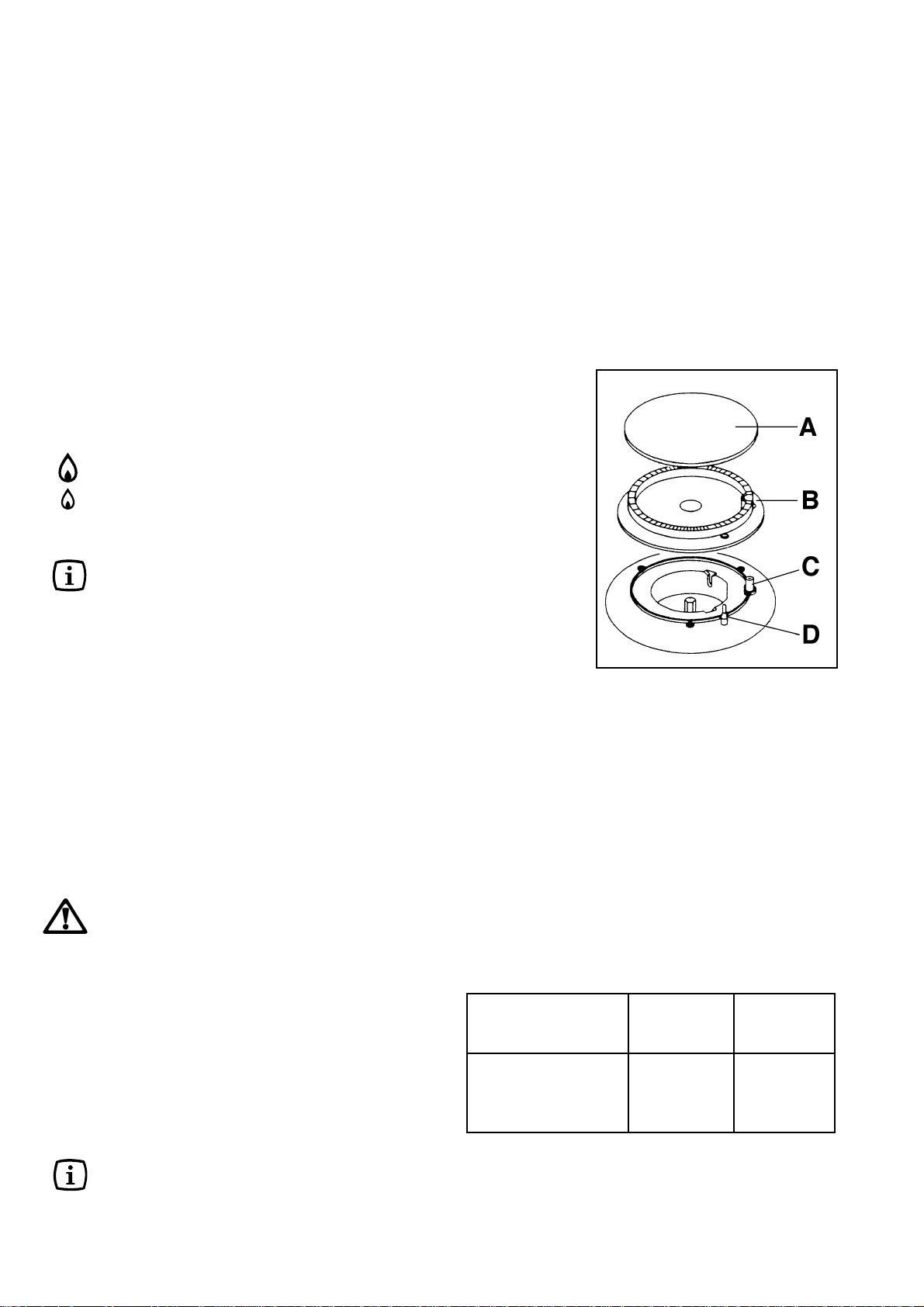

l To light a burner, push in the relevant control

F

knob and turn it anti-clockwise to "maximum"

position.

l Upon ignition, keep the knob pushed down for

about 5 seconds. This will allow the

"thermocouple" (Fig. 1 lett. D) to be heated and

the safety device to be switched off, otherwise

the gas supply would be interrupted.Then,

check the flame is regular and adjust it as

required.

l If you cannot light the flame even after several

attempts, check the "cap" (Fig. 1 lett. A) and

the "crown" (Fig. 1 lett. B) are in the correct

position.

l To put the flame out, turn the knob to the

symbol l.

Always turn the flame down or put it out

before taking the pans off the burner.

Using the hob correctly

To ensure maximum burner efficiency, it is strongly

recommended that you use only pots and pans with a flat

bottom fitting the size of the burner used, so that flame will

not spread beyond the bottom of the vessel (see the table

beside).

It is also advisable, as soon as a liquid starts boiling, to

turn down the flame so that it will barely keep the liquid

simmering.

Fig. 1

Burner minimum maximum

Big (rapid) 180 mm. 260 mm.

Medium (semirapid) 120 mm. 220 mm.

Small (Auxiliary) 80 mm. 160 mm.

FO 0204

A -Burner cap

B -Burner crown

C -Ignition candle

D - Thermocouple

diameter diameter

Carefully supervise cookings with fats or oil,

since these types of foodstuff can result in a

fire, if over-heated.

13

Page 3

Cleaning and Maintenance

Disconnect the appliance from the electrical

supply, before carrying out any cleaning or

manteinance work.

General cleaning

Wash the enamelled components with warm soapy

water. Never use abrasive cleaners.

Frequently wash the "caps" and the "crowns" with hot

soapy water, carefully taking away any built-up of food.

If the marks are particularly difficult to remove, use

common non-abrasive cleaners or specific products.

Never use steel wool pads or acids.

Automatic ignition

The automatic ignition of the gas burners is obtained

through a ceramic "candle" and a metal electrode (fig. 1

lett. C). Keep these components well clean, to avoid

difficult lighting, and check that the burner crown holes

(lett. B) are not obstructed.

FO 2030

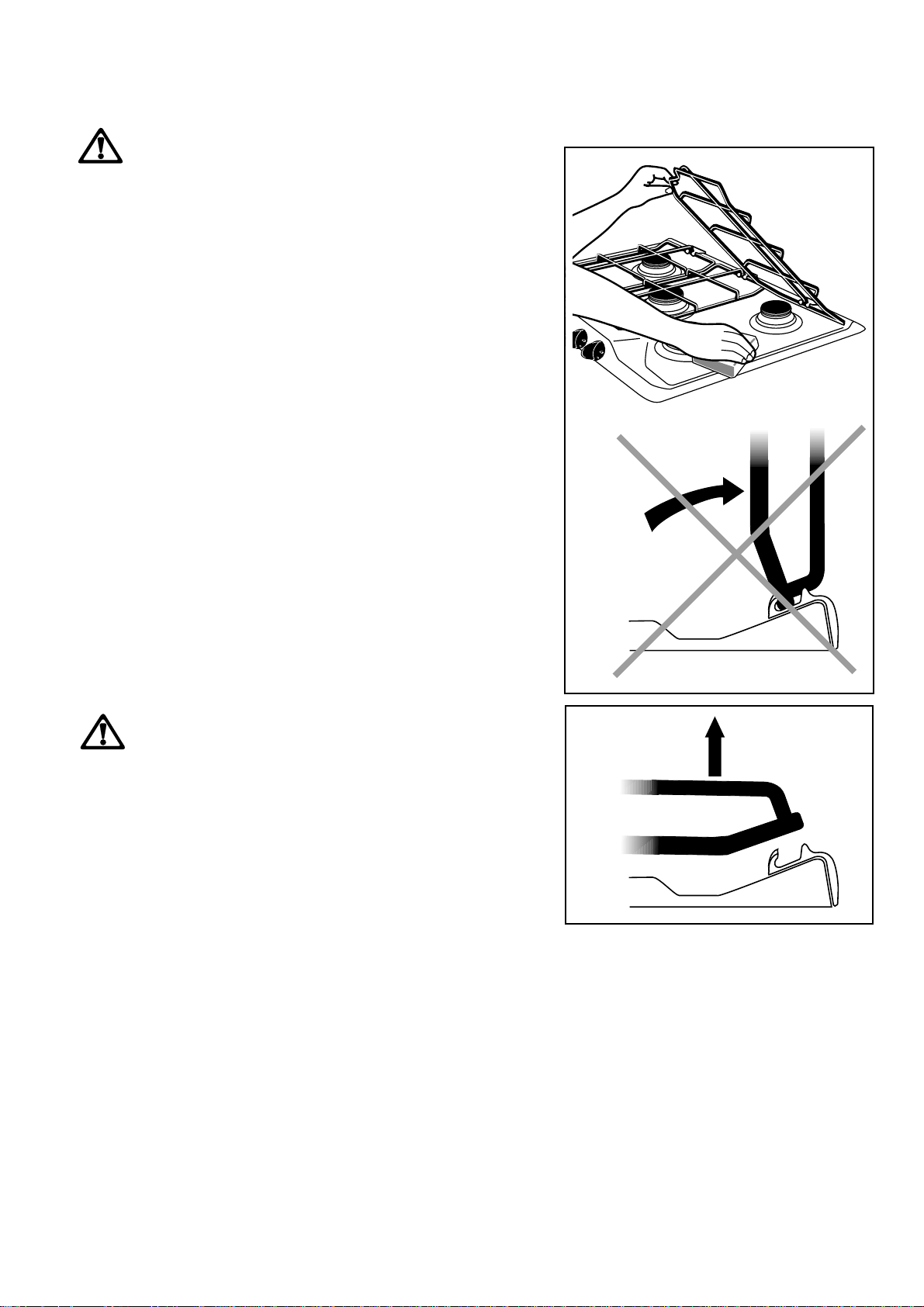

Pan supports

To keep the pan supports in the right position, they are

hooked to a couple of special hinges in the back of the hob.

Thanks to these hooks, you can lift the pan supports for

easier cleaning, as shown in fig. 2.

To take the pan supports completely off the hob, proceed

as shown in fig. 3.

Cast iron pan supports

Caution! When removing the cast iron pan

supports, lift them up as shown in fig. 3. Never

turn the pan supports on the hinges as shown

in fig. 2, since this could damage them.

Periodic Maintenance

Periodically ask your local Service Centre to check the

conditions of the gas supply pipe and the pressure

adjuster, if fitted.

To ensure the good operation of the hob and its safety

features, it is necessary that the taps are periodically

lubricated.

NO

Fig. 2

YES

Fig. 3

l The periodic lubrication of the taps must be

carried out by qualified personnel, which you

must refer to also in case of malfunctioning.

Mainteinance - Technical

Assistance

ORIGINAL SPARE PARTS

This machine, before leaving the factory, has been

tested and studied by many experts and specialists, in

order to give you the best results.

Any repair work which needs to be carried out should

be done with the utmost care and attention.

14

For this reason we reccomend that for any problem you

contact the dealer who sold it to you, or our nearest

authorized Service Centre, specifying the nature of the

problem and the particular model which you own.

Page 4

Technical Data

Gas Burners Rating

Rapid Burner 3 kW (Natural gas) / 2,8 (LPG)

Semirapid Burner

Auxiliary Burner 1 kW

Category II2H3+

Setting Natural Gas 20 mbar

Electric Supply 220 V 60 Hz

2 kW

Hob recess dimensions

Length 560 mm.

Width 480 mm.

Instruction for the Installer

l The following instructions about installation and

maintenance must be carried out by qualified

personnel in compliance with the regulation in

force.

l The side walls of the unit in which the hob is

going to be installed, must not exceed the height

of the working top.

l Avoid installing the appliance in the proximity of

inflammable materials (e.g. curtains, tea towels

etc.).

l The appliance must be electrically disconnected

before all interventions. If any electric supply to

the appliance is required to carry out the work,

ensure all the necessary precautions are followed.

Gas connection

Choose fixed connections or use a flexible pipe in

stainless steel.

If using flexible metallic pipes, be careful they do not

come in contact with mobile parts or they are not

squeezed. Use the same attention when the hob is

combinated with an oven.

IMPORTANT - To ensure a correct operation, a saving

of energy and the long-life of the appliance, the voltage

pressure of the appliance must correspond to the

recommended values.

IMPORTANT - When the final connection has been

made, it is essential that a thorough leak test is carried

out on the hob and installation. Use some soapy water,

never a flame.

Fig. 4

A

B

A - Ramp

B - Connection

15

Page 5

Electrical Connection

The appliance is designed to be connected to 220 V

monophase electricity supply.

The connection must be carried out in compliance with

the laws and regulations in force.

Before the appliance is connected:

1) check that the main fuse and the domestic installation

can support the load (see the rating label);

2) check that the power supply is properly earthed in

compliance with the current rules;

3) check the socket or the double pole switch used for

the electrical connection can be easily reached with

the appliance built in the forniture unit.

Connect the plug, able to support the load marked on the

identification plate, to the cable (Fig. 5). The plug has to

be fitted in a proper socket.

If connecting the appliance directly to the electric system,

it is necessary that you install a double pole switch

between the appliance and the electricity supply, with a

minimum gap of 3 mm. between the switch contacts and

of a type suitable for the required load in compliance with

the current rules.

The earth cable (yellow/green) must not be interrupted by

the interrupter.

The connection cable has to be placed in order that, in

each part, it cannot reach a temperature of 90 °C.

The brown coloured phase cable (fitted in the terminal

block contact marked with "L") must always be connected

to the network phase.

Fig. 5

Neutral

Earth (yellow/green)

FO 0073

Replacement of the voltage

cable

The connection of the voltage cable to the appliance's

terminal block is of type "Y". This means that its

replacement requires the specific equipment of a

technician.

In this case, only cable type H05V2V2-F T90 must be

used. The cable section must be suitable to the voltage

and the working temperature.

The yellow/green earth wire must be approximately 2

cm. longer than the phase wires (Fig. 6).

To open the terminal block and reach the terminals,

proceed as follows:

l insert the point of a screwdriver into the visible

protrunding part of the terminal block;

l exert a light pressure and lift (Fig. 6)

Fig. 6

FO 0257

16

Page 6

Adaptation to different types of gas

Replacement of injectors

Remove the pan supports.

Remove the burner's caps and crowns.

With a socket spanner 7 unscrew and remove the

injectors (Fig. 7), and replace them with the ones

required for the type of gas in use (see table on the

next page).

With a socket spanner 7 unscrew and remove the

injectors (Fig. 7), and replace them with the ones

required for the type of gas in use (see table 2):

Reassemble the parts, following the same procedure

backwards.

Replace the rating label (placed near the gas supply

pipe) with the relevant one for the new type of gas

supply. You can find this label in the package of the

injectors supplied with the appliance.

Should the feeding gas pressure be different or variable

compared with the required pressure, an appropriate

pressure adjuster (for non-LPG) must be fitted on the gas

supply pipe, in compliance with the rules in force.

Fig. 7

FO 0392

Adjustment of minimum level

To adjust the minimum level of the burners, proceed as

follows:

Light the burner.

By-pass

Fig. 8

screw

Turn the knob on the minimum position.

Remove the knob.

BY-pass diameters

With a thin screwdriver, adjust the by-pass screw (see

Fig. 8). If changing from natural gas to LPG, completely

tighten clockwise the screw, until a small regular

flame is obtained.

Burner Ø By-pass

in 1/100

of mm.

Finally check the flame does not go out when quickly

turning the knob from the maximum position to the

minimum position.

This procedure can easily be carried out, anyhow the hob

has been positioned or built in the working top.

BURNERS

TYPE TYPE OF INJECTORS NOMINAL REDUCED NOMINAL NOMINAL

OF GAS BURNER MARKS POWER POWER POWER PRESSURE

1/100 mm INPUT kW mbar

Auxiliary 28

Semi-rapid 32

Rapid 40

KW m3/h g/h

NATURAL

GAS

(Methane)

LPG

(Buthane/

Propane)

Rapid (large) 119 3,0 0,65 0,286 -

Semi-rapid (medium) 96 2,0 0,45 0,190 - 20

Auxiliary (small) 70 1,0 0,33 0,095 -

Rapid (large) 86 2,8 0,65 - 202

Semi-rapid (medium) 71 2,0 0,45 - 144 29

Auxiliary (small) 50 1,0 0,33 - 72

17

Page 7

Building in

SR

A

SR

R

580

510

Fig. 9

Installation and assembly

These hobs can be installed in a kitchen unit with an

opening for insertion whose dimensions are shown in

Fig. 10.

The edge of the cut out must have a minimum distance

from the rear wall of 55 mm.

If there are side walls, or sides of the furniture unit near

the hob, the cut out edges must have a minimum

distance of 150 mm. as shown in Fig. 10.

Carry out the building in of the hob as follows:

A = Auxiliary burner

SR = Semirapid burner

R = Rapid Burner

These hobs can be inserted in a built-in kitchen unit

whose depth is between 550 and 600 mm. The hobs

dimensions are shown in Fig. 9.

55 min.

480

560

150 min

FO 2038

Fig. 10

FO 2239

put the relevant sealings, supplied with the hob, on the

edges of the cut out, as shown in Fig. 11, taking care

that the sealings meet without overlapping;

place the hob in the cut out, taking care of its centring;

fix the hob with the relevant screws (Fig. 12). The

traction of the screws is able to trace the sealing, any

excess of which can then be easily removed.

The edge of the hob forms a double labyrinth seal which

provides a total guarantee against infiltration of liquids.

Fig. 12

Fig. 11

a

FO 0199

18

a) sealing

Page 8

POSSIBILITIES FOR

INSERTION

Fig. 13

Fig. 14

Kitchen unit with door

Proper arrangements must be

taken in designing the forniture unit,

in order to avoid any contact with

the bottom of the hob which can be

heated when it is operated. The

recommended solution is shown in

Fig. 13.

The panel fitted under the hob

should be easily removable to allow

an easy access if a technical

assistance intervention is needed.

Kitchen unit with oven

The hob recess dimensions must

comply the indication given in Figs.

14 and 17 and must be provided

with brackets to allow a continuous

supply of air.

To avoid overhating, the building in

should be carried out as shown in

Figs. 15 e 16.

The hob's electric connection and

the oven's one must be carried out

separately, both for safety reasons

and to allow the oven to be easily

taken off the unit.

Hanging forniture units or hoods

must be placed at 650 mm.

minimum from the hob (Fig. 18).

30

a

60

20 min

b

FO 2044 FO 2043

a) Removable panel

b) Space possibly useful for

connections

Fig. 15

50 cm

2

Fig. 16

480

380

140

30

591

120 cm

2

Fig. 17

FO 0198

560 min.

550 min.

FO 2041

Fig. 18

FO 2240

360 cm

2

FO 2042

180 cm

2

650 min

19

Page 9

35674-1702 01/01

Grafiche MDM - Forlì

Loading...

Loading...