Page 1

LAVAMAT W 1030

Washing Machine

User information

Page 2

Dear Customer,

Please read this user information carefully.

Pay particular attention to the section "Safety" on the first Info pages.

Please keep this user information in a safe place for later reference.

Pass it on to any future owners of the unit.

The warning triangle and /or signal words (Warning!, Caution!, Impor-

1

tant!) emphasise information which is important for your safety or for

the unit's functional reliability. It is imperative that this information is

observed.

0 1. This symbol guides you step by step through the operation of the appli-

ance.

2. ...

Next to this symbol you will find additional information and practical

3

tips on using the appliance.

Tips and information on economical and environmentally responsible

2

use of the unit are identified with the clover leaf.

For any faults which occur, this user information contains information

on how to remedy these faults yourself. See the section "What to do

if ..."

Printed on recycled paper.

Thinking ecologically means acting ecologically.

2

Page 3

Contents

CONTENTS

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Environmental tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

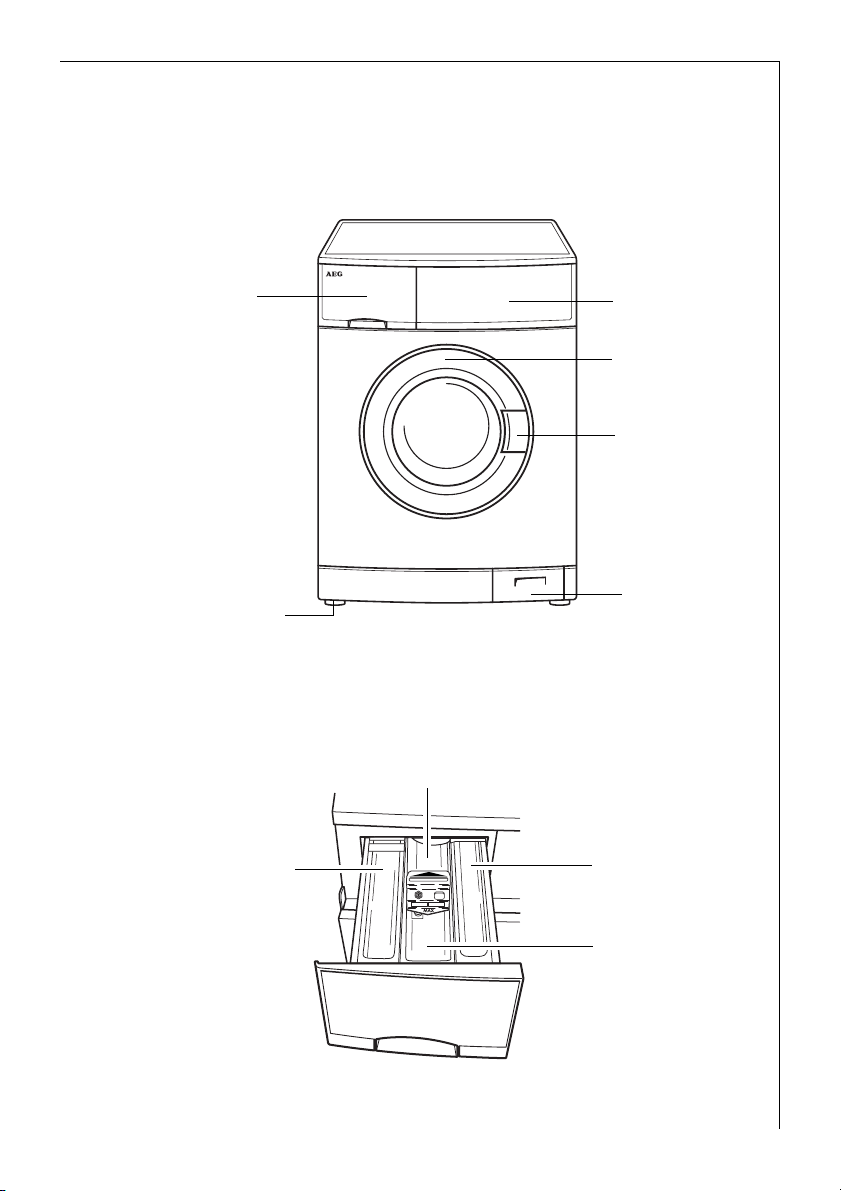

Unit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Drawer for Washing Powder and Care Agent . . . . . . . . . . . . . . . . . . . . . . . 9

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Programme Knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Temperature Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Additional Programme Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ON/OFF button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Consumption values and time requirements . . . . . . . . . . . . . . . . . . . . . . 14

Before the First Wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Prepare washing cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sort washing and prepare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Washing Types and Care Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Washing Detergents and Care Agents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Which detergent and care agent? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

How much detergent and care agent? . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Water Softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Running a Wash Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Brief Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Add the washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Add Washing Detergent and/Care Agent . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setting the Wash Programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Changing the Spin Speed/Selecting Rinse Hold . . . . . . . . . . . . . . . . . . . . . . 21

Start the Wash Programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Wash Programme Progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Changing/Interrupting the Wash Programme . . . . . . . . . . . . . . . . . . . . . . . 22

Wash Cycle Completed/Removing Washing . . . . . . . . . . . . . . . . . . . . . . . . . 23

3

Page 4

Contents

Programme Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Separate Rinse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Separate Conditioning/Starching/Finishing . . . . . . . . . . . . . . . . . . . . . . . . 25

Separate Spin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cleaning and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Detergent Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Washing Drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Main door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cleaning the drain pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

What to do if ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Remedying Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

If the washing results are not satisfactory . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Carrying out emergency drainage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Child Safety Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installation and connection instructions . . . . . . . . . . . . . . . . 35

Installation Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installation of the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Transporting the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Remove transportation protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Prepare the installation place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Installation on a concrete base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Installation on vibrating floors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Compensate for floor unevenness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4

Page 5

Contents

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Water connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Permissible water pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Water inflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Water drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Delivery heads over 1m . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Warranty conditions / Customer service centres . . . . . . . 44

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5

Page 6

Operating Instructions

Operating Instructions

1 Safety

The safety aspects of AEG electrical appliances comply with accepted

technical standards and the German Appliance Safety Law. However, as

manufacturers we regard it as our responsibility to inform you about

the following safety instructions.

Before Using for the First Time

• Refer to the "Installation and Connection Instructions" further on in

this user information.

• If units are delivered in the winter months at minus temperatures:

Store the washing machine at room temperature for a few hours before putting it into operation.

Correct Use

• The washing machine is only intended for washing normal domestic

washing. If the appliance is used for a wrong purpose or wrongly operated, the manufacturer cannot assume any liability for any damages.

• Additions or modifications to the washing machine are strictly forbidden due to safety reasons.

• Use only detergent which is suitable for washing machines. Refer to

the detergent manufacturer's instructions.

• The washing must not contain any flammable solvents. Also bear this

in mind when washing pre-cleaned washing.

• Do not use the washing machine for dry-cleaning.

• Dyes /dye-removing agents may only be used in the washing machine

if the manufacturer expressly permits use of these products. We cannot accept liability for any damage.

• Use only water from the water mains. Use rain water or service water

only if it meets the requirements defined in DIN 1986 and DIN 1988.

• Frost damage is not covered by the warranty! If the washing machine

is in a room subject to possible frost hazards, emergency emptying

must be carried out if there is a risk of frost (see the Section "Carrying out emergency emptying“).

6

Page 7

Operating Instructions

Child Safety

• Packaging materials (e.g. films, polystyrene) can be dangerous for

children. Risk of suffocation! Keep packaging away from children.

• Children frequently cannot recognise hazards involved in handling

electrical appliances. Therefore, ensure that they are properly supervised during operation and never allow children to play with the

washing machine-there is arisk that they can lock themselves inside it.

• Ensure that children or small animals do not climb into the washing

machine's drum.

• When disposing of washing machines pull out the mains plug, destroy

the door lock, cut off the electrical supply lead and dispose of the

plug and remaining cable. This means that playing children cannot

shut themselves in and cannot encounter a potentially lethal hazard.

General Safety

• Repairs to the washing machine may only be carried out by qualified

specialists. Incorrect repairs may result in significant risk to the user.

If repairs are necessary, consult our customer service or your specialist dealer.

• Never use the washing machine if the mains cable is damaged or the

conrol panel, work surface or base panel area are so badly damaged

that the interior of the unit is openly accessible.

• Switch off the washing machine before carrying out cleaning, care

and maintenance work. Also pull the mains plug out of the socket or,

– if it is permanently connected, – switch off the circuit breaker at

the household power distribution box or completely remove the

screw-in fuse.

• Never pull the cable to remove the plug from the socket. Always

pull the plug itself.

• Multiple connectors, couplings and extension cables must not be

used. There is a risk of fire with overheating!

• Do not spray down the washing machine with a water jet. Risk of

electric shock!

• The glass in the door becomes hot in the case of wash programmes

with high temperatures. Do not touch!

• Allow the washing solution to cool before carrying out an emergency

emptying operation or cleaning the drain pump.

• Small animals can chew the power cables and water hoses. Risk of

electric shock and danger of water damage! Keep small animals away

from the washing machine.

7

Page 8

Operating Instructions

2 Disposal

Disposing of the Packaging Material!

Dispose of the packaging of your washing machine correctly. All pakkaging materials used are environmentally-compatible and recyclable.

• Plastic parts are identified with internationally standardised abbreviations:

>PE< for polyethylene, e.g. packing films.

>PS< for polystyrene, e.g. cushion parts (always CFC-free)

>POM< for polyoxymethylene, e.g. plastic clips.

• Cardboard packaging is manufactured from recycled paper and

should be deposited in the waste paper collection for recycling.

Disposing of your old appliance!

When you put your unit out of operation one day, please bring it to

your nearest recycling centre or to your dealer.

2 Environmental tips

• A pre-wash cycle is not necessary in the case of washing which is not

excessively dirt. This saves detergent, water and time (and is gentle on

the environment.)

• If the indicated load capacities are taken full advantage of, the washing machine is especially efficient.

• For small loads, use only one half to one third of the recommended

detergent quantity.

• Suitable pre-treatment enables marks and limited amounts of dirt to

be removed. You can then wash at a lower temperature.

• Wash slightly to normally dirty cottons with the energy-saving program.

• There is often no need for the softener. Try it once! If you use a drier,

your washing will become soft and fluffy even without a softener.

• In the case of medium to high water hardness (hardness range runs to

upwards, see "Detergent and care agents“), you should use a water

softener. The detergent can then always be metered for hardness

range I (= soft).

8

Page 9

Unit description

Front view

Drawer for detergent and

care agent

Operating Instructions

Control panel

Rating plate (behind filling door)

Main door

Screw feet

(height-adjustable)

Drawer for Washing Powder and Care Agent

Main detergent

(powder) and watersoftener if required

In-wash stain treatment

Flap in front of

drain pump

Pre-wash detergent/

soaking agent

Liquid care agent

(conditioner, finisher,

starch)

9

Page 10

Operating Instructions

Control Panel

Spin speed button

ON/OFF

button with power in-

dicator light

STAIN button

SOAKING button

QUICK WASH

Programme Knob

The programme knob determines

the type of wash cycle (eg. water

level, drum movement, number of

rinses, spin speed) according to

the type of the articles to be

washed.

RINSE HOLD button

button

Program selector

Temperature

selector

10

Important! Only turn the programme knob in a clockwise direction!

Programme group COTTONS/LINEN

PRE WASH

Pre wash for cottons/linen (approx. 30 minutes, temperature limited to

a maximum of 40 °C). The main wash follows immediately afterwards.

MAIN WASH

Main wash cycle for cottons/linen (cold up to 95 °C).

Page 11

Operating Instructions

RINSE

Separate rinse followed by spin or rinse hold, eg. for rinsing handwashed cottons/linen.

Rinse hold means: The washing remains lying in the last rinsing water. It

3

is not spun.

CONDITION

Separate conditioning, separate starching or separate finishing for

damp cottons/linen (1 rinse, liquid care agent is flushed in from the

compartment æ followed by spin or rinse hold).

SPIN

Spin after rinse hold or separate spin for handwashed cottons/linen.

Programme group EASY-CARES

PRE WASH

Pre wash for easy-care textiles (approx. 30 minutes, temperature limited to a maximum of 40 °C). The main wash cycle follows automatically.

EASY-CARES

Main wash cycle for easy-care textiles (cold to 60 °C).

RINSE

Separate rinse followed by spin or rinse hold, eg. for rinsing handwashed easy-care articles.

CONDITION

Separate conditioning, separate starching or separate finishing for

damp easy-care textiless (1 rinse, liquid care agent is flushed in from

the compartment æ followed by spin or rinse hold).

SPIN

Spin after rinse hold or separate spin for handwashed easy-care articles, woollens and delicates.

Programme group WOOL/DELCATES

WOOL

Main wash cycle for machine washable woollens and particularly

delicate textiless (cold to 40 °C).

DELICATES

Main wash cycle for delicates (cold to 40 °C).

11

Page 12

Operating Instructions

GENTLE RINSE

Separate gentle rinse followed by short spin or rinse hold, eg. for rinsing hand-washed woollens or delicates.

CONDITION

Separate gentle conditioning for damp woollens or delicates (1 gentle

rinse, liquid care agent is washed in from the compartment æ followed

by short spin or rinse hold).

PUMP OUT

Water pumped out without spin, eg. after rinse hold.

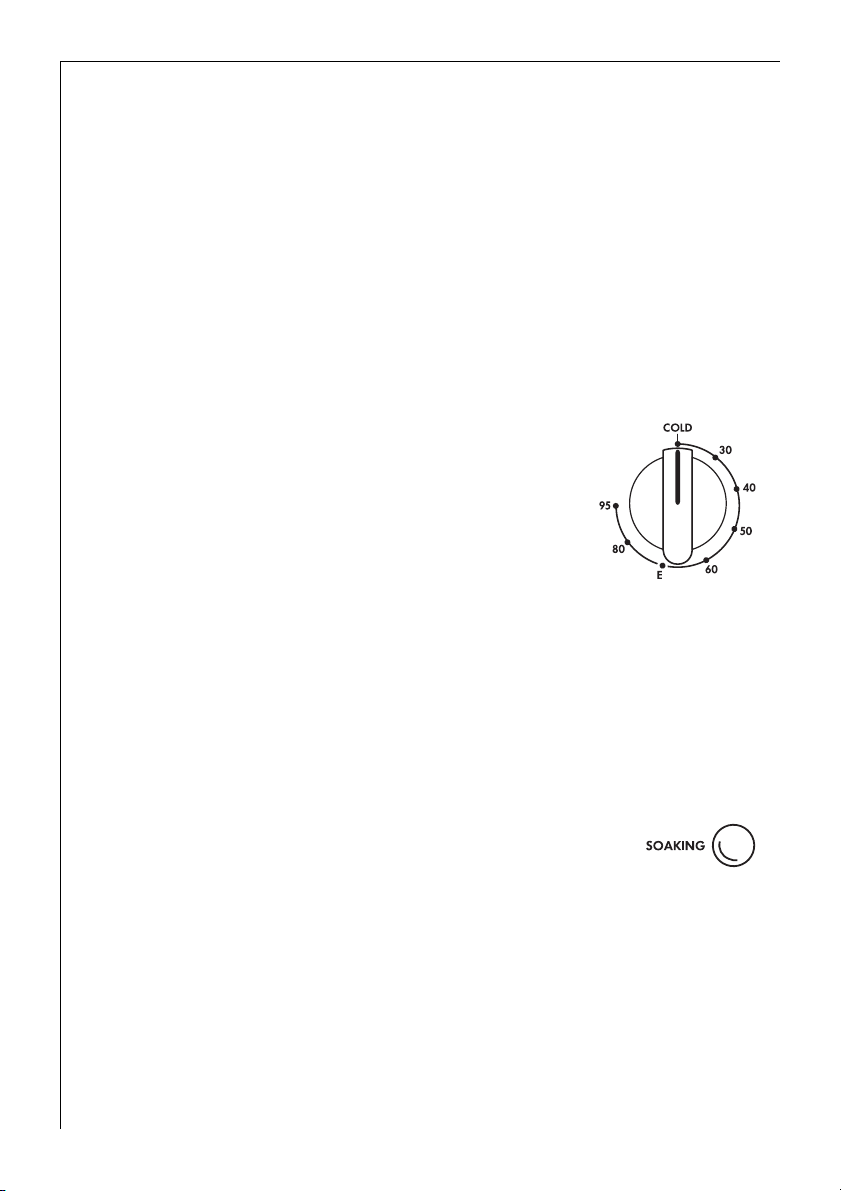

Temperature Selector

The following settings are possible:

COLD, 30, 40, 50, 60, E, 80, 95 °C.

Position E (Energy-saving programme)

2

Instead of a wash cycle at 95 °C the energy-saving programme at approx. 70 °C

can be used for lightly or normally

soiled cottons.

Additional Programme Buttons

The additional programme buttons are for suiting the wash programme

to the dirtiness of the washing. Additional programmes are not required for washing which is not excessively dirty.

The additional programmes can only be used in conjunction with pro-

3

grammes for the programme groups COTTONS/LINEN and EASY-CARES.

SOAKING

Soaking time approx. 35 minutes;

Temperature limited to a maximum of 40 °C.

SOAKING can be used in conjunction with

programme knob settings:

– PRE WASH COTTONS/LINEN;

– PRE WASH EASY-CARES.

At the end of the soaking programme the washing will remain in the

washing solution until you release the SOAKING button by pressing

again. The main wash cycle for COTTONS/LINEN or EASY-CARES will

follow.

12

Page 13

STAIN

For dealing with heavily soiled or stained

washing (in-wash stain treatment is added at

the optimum time during the course of the

programme).

STAIN can be used in conjunction with the

programme knob settings:

– PRE WASH COTTONS/LINEN;

– MAIN WASH;

– PRE WASH EASY-CARES;

– EASY-CARES.

QUICK WASH

Shorter washing cycle for lightly soiled

washing.

QUICK WASH can be used in conjunction with

the programme knob settings:

– MAIN WASH;

– EASY-CARES.

ON/OFF button

Operating Instructions

Pressing the ON/OFF button switches the

washing machine on and starts the selected

programme. Pressing the button again

switches the washing machine off.

13

Page 14

Operating Instructions

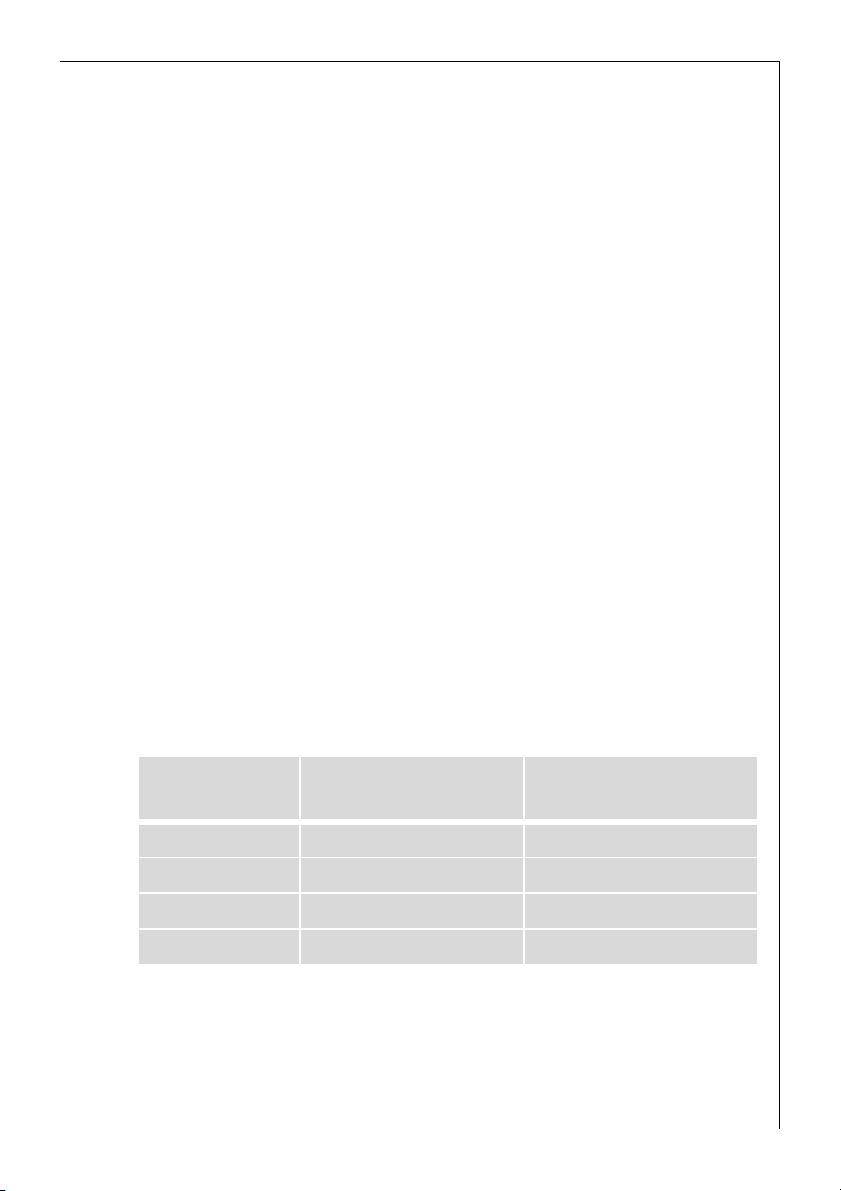

Consumption values and time requirements

The values for selected programmes in the following tables were determined under standardized conditions. They are nonetheless a useful

guide for domestic use.

Programme knob

MAIN WASH 95 5 57 1.90 140

MAIN WASH

MAIN WASH 40 5 54 0.60 11 5

EASY-CARES 40 2.5 45 0.40 65

DELICATES 30 2.5 40 0.25 40

WOOL 30 2 43 0.25 50

1) Information: Programme setting for a test in accordance with EN 60 456. The

consumption values can deviate from the stated values depending on the water

pressure, hardness, inlet temperature, room temperature, type and quantity of

washing, the detergent powder/liquid used, fluctuations in the mains voltage

and selected additional functions.

Temperature

selector

1)

60

Filling

quantity

in kg

5 54 0.95 128

Water

in litres

Energy

in kWh

Time in

minutes

14

Page 15

Operating Instructions

Before the First Wash

0 1. Pull the washing powder drawer out slightly.

2. Pour about 1 litre of water through the washing powder drawer into

the washing machine. The next time a programme is started the solution container will be closed and the eco-sluice can function correctly.

3. Run one wash cycle without washing:

– Programme knob on position MAIN WASH;

– Temperature 95 °C;

– Only add half the quantity of detergent recommended by the manu-

facturer for a full load.

This removes residues left over from manufacture on the drum and solution container.

Prepare washing cycle

Sort washing and prepare

• Sort the washing according to the care symbol and type (see "Wash-

ing types and care codes").

• Empty all pockets.

• Remove metal objects (paper clips, safety pins etc.).

• To prevent damage to the washing and tangled washing: Close zip

fasteners, button bed and pillow covers closed, tie up loose strings

e.g. of aprons.

• Turn articles with double layered textiles inside out (sleeping bags,

anoraks etc.).

• In the case of knitted coloured textiles and also with wool and tex-

tiles with jewelry attached: turn inside out.

• Wash small and sensitive items (e.g. baby socks, tights and stockings,

bras etc.) in a washing net, a cushion with a zip fastener or in larger

socks.

• Handle curtains with particular care. Metal rollers or burred, plastic

rollers must be removed or tied into a net or bag. We cannot accept

liability for damage.

• Coloureds and white items must not be washed together in a washing

cycle. This could discolour white washing or turn it grey.

• There is often excess dye in new, coloured items. It is best to wash

such items separately the first time.

15

Page 16

Operating Instructions

• Mix small and large items. This improves the washing effect and the

washing is more favourably distributed during spinning.

• Fluff washing before placing into the washing machine.

• Do not place folded washing into the drum.

• Pay attention to the care instruction "wash separately" and "wash

separately several times".

Washing Types and Care Symbols

The care symbols help you choose the correct wash programme. The

washing should be sorted according to type and care symbol. The temperatures stated in the care symbols are all maximum values.

Cottons ç

Textiles made of cotton and linen with this care symbol are resistant to

mechanical stress and high temperatures. The COTTONS/LINEN programme is suitable for this type of washing.

Linen è ë

Textiles made of cotton and linen with this care symbol are resistant to

mechanical stress. The COTTONS/LINEN programme is suitable for this

type of washing.

16

Easy-care washing ê í

Textilies such as finished cotton, cotton mixtures, viscose and synthetics with these care symbols require gentler mechanical treatment. The

EASY-CARES programme is suitable for this type of washing.

Delicates ì

Textiles such as fibre blends, microfibres, viscose, synthetics and net curtains with this care symbol need particularly gentle treatment. The

DELICATES programme is suitable for this type of washing.

Woollens and particularly delicate washing 9 ì

Textiles such as wool, wool mixtures and silk with these care symbols

are especially sensitive to mechanical stress. The WOOL programme is

suitable for this type of textile.

Important! Textiles with care symbols ï (handwash) or ñ (Do not

wash!) must not be washed in the washing machine!

Page 17

Operating Instructions

Washing Detergents and Care Agents

Which detergent and care agent?

Use only detergents and care agents which are suitable for use in washing machines. Always follow the manufacturer's instructions.

How much detergent and care agent?

The amount to be used depends on:

• the dirtiness of the washing

• the hardness category of the mains water supply

• the quantity of washing

If the detergent manufacturer does not include dosing instructions for

2

reduced loads, use one third less for half loads and only half of the full

load detergent quantity for very small loads.

Refer to the detergent/care agent manufacturer's instructions on use

and dosage.

Water Softener

For medium to high water hardness (hardness category II or higher) you

should use water softener. Pay attention to the manufacturer's instructions. Always then meter detergent for hardness category I (= soft). The

responsible water works can provide information on the local water

hardness.

Water Hardness Details

Hardness Category

I – soft 0 - 7 up to 1.3

II – medium hard 7 - 14 1.3 - 2.5

III – hard 14 - 21 2.5 - 3.8

IV – very hard over 21 over 3.8

Water Hardness °dH

(degrees German hardness)

Water Hardness in mmol / l

(millimol per litre)

17

Page 18

Operating Instructions

Running a Wash Cycle

Brief Instructions

To run a wash cycle:

0 1. Open the door and fill with washing.

2. Close the door.

3. Add washing detergent / care agent.

4. Set the wash programme

– Set the programme using the programme knob;

– Set the temperature using the temperature selector;

– Set any additional programme required.

5. If necessary, change the spin speed or select RINSE HOLD.

You can alter this setting and the temperature at any time during the

wash.

6. Press ON/OFF button. Power indicator light comes on. The washing machine has been switched on. The wash programme will start.

When the wash programme has been completed:

Important! If the wash cycle ends on rinse hold run PUMP OUT or SPIN

before opening the door.

For safety reasons, the door remains locked for 1-2 minutes after the

3

end of the programme.

7. Open the door and remove the washing.

8. Press ON/OFF button. The power indicator light will go out.

The washing machine is switched off.

Add the washing

For the maximum filling quantities, see the "Program tables".

3

See "Sort and prepare washing" for information on correctly preparing

the washing.

0 1. Sort and prepare the washing according to type.

2. Open the filling door: Pull on the handle of the filling door.

3. Fill with washing.

Important! When closing the door, make sure no items of washing get

stuck! This could damage textiles and the unit.

4. Close the filling door securely.

18

Page 19

Operating Instructions

Add Washing Detergent and/ Care Agent

Refer to the information on washing detergents and care agents, see

3

section entitled “Washing Detergents and Care Agents“.

0 1. Pull out the washing powder drawer as far as it will go.

2. Fill with washing detergent / care agent

Compartment for in-wash

stain treatment

only for additional programme

STAIN

Compartment for main wash

detergent (powder only) and

water softener if required

(If you are using water softener, add it

to the main wash detergent.)

Compartment for liquid care agent

(Conditioner, finisher, starch)

Important! Do not fill the compartment above the MAX mark. If necessary,

dilute viscous agent up to the MAX mark,

and dissolve starch powder.

Note: It is normal for a small amount of water

to be left in the compartment for liquid conditioner;

this will not affect the wash results.

Compartment for pre-wash detergent/

soaking agent

only for PRE WASH or SOAKING programmes

3. Push the drawer in fully.

If using liquid detergent / tablets:

3

Use containers supplied by the detergent manufacturers to add liquid

detergent or tablets. Follow the instructions on the washing detergent

package.

19

Page 20

Operating Instructions

Setting the Wash Programme

For a suitable programme, the right temperature and possible addi-

3

tional programmes for the relevant type of wash, refer to the “Programme Tables“.

Important! Only turn the programme knob in a clockwise direction.

0 1. Set the programme knob to the

desired wash programme.

2. Set the temperature selector to

the desired temperature.

3. Select additional programme if required:

• SOAKING may be used in conjunction with

programme knob settings:

– PRE WASH COTTONS/LINEN;

– PRE WASH EASY-CARES.

• STAIN may be used in conjunction with

programme knob settings:

– PRE WASH COTTONS/LINEN;

– MAIN WASH;

– PRE WASH EASY-CARES;

– EASY-CARES.

• QUICK WASH may be used in conjunction

with programme knob settings:

– MAIN WASH;

– EASY-CARES.

20

Page 21

Operating Instructions

Changing the Spin Speed/Selecting Rinse Hold

0 If required, change the spin speed for the final

spin speed or select RINSE HOLD:

– Press the spin speed button or

– press RINSE HOLD button.

If RINSE HOLD is selected the washing will remain

in the last rinse water; it will not be spun.

If the set spin speed is too high for the selected

3

wash program, the final spin speed will be adjusted automatically:

– COTTONS/LINEN 1000 revolutions per minute

– EASY-CARES 850 revolutions per minute

– DELICATES 650 revolutions per minute

– WOOL 850 revolutions per minute

The speed of the intermediate spin is dependent on the program selected and cannot be changed.

Start the Wash Programme

0 1. Check that the water valve is open.

2. Press the ON /OFF button. The power indicator

light will come on.

The washing machine has been switched on. The

wash programme will start.

21

Page 22

Operating Instructions

Wash Programme Progress

Programme progress display

The programme knob is also a

programme progress display. It

turns clockwise as the programme

progresses until it ends, showing

the stage of the programme that

is currently being carried out.

The speed at which the programme knob turns varies.

Changing/Interrupting the Wash Programme

Changing settings

While the wash programme is in progress you can

– change the spin speed

– select RINSE HOLD;

To select a different programme you must first interrupt the

programme that is running and then re-set.

Interrupting the wash programme

0 1. Press the ON/OFF button. The power indicator light will go out.

2. Turn the programme knob clockwise either to PUMP OUT or to SPIN.

3. Press the ON / OFF button again. The power indicator light will come on.

Water is:

– pumped out or

– pumped out and the washing then spun.

22

Page 23

Operating Instructions

Wash Cycle Completed/Removing Washing

A wash programme normally ends with the final spin.

If SOAKING has been selected:

0 Release SOAKING button. Main wash for COTTONS/LINEN or EASY-

CARES will run.

If RINSE HOLD has been selected:

The water must first be pumped out or the washing must still be spun.

0 Either release the RINSE HOLD button

(water is pumped out and the washing spun according to the programme that has been run; the spin speed can still be changed even

during the spin),

or

turn the programme knob clockwise to PUMP OUT

(water is pumped out without spinning),

or

turn the programme knob clockwise to SPIN

(the water is pumped out and the washing spun at the set speed; the

spin speed can still be changed even during the spin).

Once the programme is completed:

For safety reasons, the door remains locked for 1-2 minutes after the

3

end of the programme.

1. Open the door.

2. Remove the washing.

3. Press the ON /OFF button. The power indicator light will go out.

The washing machine is switched off.

4. Close the water valve.

5. Pull the washing powder drawer out slightly to allow it to dry. Leave

the door just slightly ajar so that the washing machine can air.

Important! If the washing machine is not used for a long time:

Close the water tap and disconnect the washing machine from the

electricity mains.

23

Page 24

Operating Instructions

Programme Tables

Not all possible settings are listed below - only the most appropriate

and those most commonly used in everyday operation.

Washing

Type of

Washing,

Care Symbols

Cottons

ç

Energy-saving

programme:

Cottons ç

Linen

èë

Easy-cares

êí

Delicates

ì

Woollens

9ì

2)

Maximum

Filling Quantity

(dry weight)

5kg

5kg

5kg

2.5kg

2.5kg

(or 15-20m

net curtains)

2kg WOOL COLD to 40

Programme Knob

1

PRE WASH

COTTONS/LINEN

MAIN WASH 60 to 95

PRE WASH

COTTONS/LINEN

MAIN WASH

PRE WASH

COTTONS/LINEN

MAIN WASH 30 to 60

PRE WASH

EASY-CARES

EASY-CARES 30 to 60

2

DELICATES COLD to 40

Temperature

Selector

60 to 95

E

30 to 60

30 to 60

Additional

Buttons Possible

SOAKING

STAIN

STAIN

QUICK WASH

SOAKING

STAIN

STAIN

QUICK WASH

SOAKING

STAIN

STAIN

QUICK WASH

SOAKING

STAIN

STAIN

QUICK WASH

1) A 10 litre bucket holds approximately 2.5kg of dry washing (wool).

2) Woollen articles with a woolmark may only be washed in the machine if the label also

states “does not mat“, “non-matting“ or “machine-washable“.

24

Page 25

Separate Rinse

Operating Instructions

Type of Washing

Cottons/ Linen 5kg

Easy-cares 2.5kg

Delicates 2.5kg

Woollens 2kg

Max. Filling Quantity

(dry weight)

Programme Knob

COTTONS/LINEN

EASY-CARES

GENTLE RINSE

DELICATES/WOOL

Separate Conditioning/Starching/Finishing

Type of Washing

Cottons/ Linen 5kg

Easy-cares 2.5kg

Delicates 2.5kg

Woollens 2kg

Max. Filling Qantity

(dry weight)

Programme Knob

CONDITION

COTTONS/LINEN

CONDITION

EASY-CARES

CONDITION

DELICATES/WOOL

RINSE

RINSE

Separate Spin

Type of Washing

Cottons/ Linen 5kg

Easy-cares 2.5kg

Delicates 2.5kg

Woollens 2kg

Max. Filling Quantity

(dry weight)

Programme Knob

SPIN

COTTONS/LINEN

SPIN

EASY-CARES

25

Page 26

Operating Instructions

Cleaning and Care

Control panel

Important! Do not use any furniture cleaning agents or aggressive

cleaning agents in order to clean panel and control parts.

0 Wipe control panels with a damp cloth. When doing so, use warm wa-

ter.

Detergent Drawer

The detergent drawer should be cleaned from time to time.

0 1. Pull the detergent drawer out as far as it will go.

2. Remove the detergent drawer by pulling sharply.

3. Take the conditioner insert out of the

middle compartment.

4. Clean the conditioner insert under

running water.

5. Clean the compartments with warm

water from the rear side. It is best to

use a flat brush.

6. Push on the conditioner insert as far as it will go so that it is securely in

place.

26

Page 27

Operating Instructions

7. Use a brush to clean the entire

rinsing-in section of the washing

machine, particularly also the nozzles on the top side of the rinsingin chamber.

8. Set the detergent drawer into the

guide tracks and push in.

Washing Drum

The washing drum is made of stainless steel. Rusting foreign bodies in

the washing can cause rust deposits on the drum.

Important! Do not clean the stainless steel drum with decalcifying

agents containing acids, scouring agents containing chlorine or iron, or

steel wool. Our Customer Service can provide suitable agents.

0 Remove any rust deposits on the drum using a stainless steel cleaning

agent.

Main door

0 Check on a regular basis to see if deposits or foreign objects are present

in or at the rubber sleeve behind the door, and remove.

27

Page 28

Operating Instructions

Cleaning the drain pump

Paper clips, nails and so on can sometimes get into the washing machine with the washing and remain in the drain pump casing. Fluff and

strands of fabric can gather on these items and block the drain pump.

Therefore the drain pump should be cleaned at least once a year.

Warning! Switch off the washing machine and pull out the mains plug

1

before cleaning the drain pump!

0 1. First carry out emergency emptying (see section "Carrying out emer-

gency emptying").

2. Place a towel on the floor in front of the cover of the drain pump. Residual water can run out.

3. Unscrew the drain pump cover anticlockwise and pull it out.

4. Remove any foreign bodies from the

pump housing.

5. Replace the cover. Insert the webs on

the cover laterally into the guide slots

and screw on the cover securely clockwise.

6. Close the emergency emptying hose and

place it in the holder.

7. Close the flap.

28

Page 29

Operating Instructions

What to do if ...

Remedying Faults

In the event of a fault, try to solve the problem yourself with the aid of

the information provided here. If you call Customer Service to deal

with one of the faults listed here or to remedy an operating fault, the

customer service technician's visit will not be free of charge, even during the warranty period.

Problem Possible Cause Remedy

The washing machine

does not work.

The door cannot be

closed.

The machine does not

take in water.

The mains plug is not

plugged in.

The circuit breaker at the

household power distribution box has tripped or a fuse

at the household fuse box

has blown.

The door is not correctly

closed.

The child safety feature is

set.

The door is not correctly

closed.

Water valve is closed. Open the water valve.

Filter in screw connection of

the inlet hose is blocked.

Water valve is blocked with

limescale or is faulty.

Plug in the mains plug.

Re-set the circuit breaker or

replace the fuse.

Close the door; The lock must

engage audibly.

Cancel the child safety feature (see the section “Child

Safety Feature“).

Close the door; The lock must

engage audibly.

Close the water valve. Unscrew the hose from the water valve, remove the filter

and clean it under running

water.

Check water valve and have

it repaired if necessary.

The washing solution

of the main wash produces a great deal of

lather.

Too much washing powder/

liquid was probably used.

Use the exact quantities recommended by the detergent

manufacturer.

29

Page 30

Operating Instructions

Problem Possible Cause Remedy

The washing machine

vibrates during operation or wobbles.

Water runs out under

the washing machine.

The transport packaging has

not been removed.

The height-adjustable screw

feet are not correctly set.

There is very little washing in

the drum (e.g. only one

dressing gown).

The water could not be completely pumped out before

spinning because

the drain hose is bent or

the drain pump is blocked.

The screw connection on the

inlet hose is leaky.

The drain hose leaks.

The drain pump cover is not

correctly closed.

Washing is stuck in the door.

Remove transport packaging

according to the installation

and connection instructions.

Adjust the feet according to

the instructions for installation and connection.

This does not impair the

function.

Check along the drain hose

and remove any kinks

present, or clean the drain

pump and, if necessary, remove foreign bodies from

the pump housing.

Tighten the inlet hose screw

connection.

Check the drain hose and replace it if necessary.

Close cover correctly.

Interrupt the programme

and remove washing from

the door. Start the programme again.

30

The washing machine

does not spin; there is

water in the drum.

Emergency drain hose is not

correctly sealed or is leaking.

RINSE HOLD has been selected.

Soaking programme has finished.

Seal the emergency drain

hose correctly (see section

“Carrying out an Emergency

Emptying Operation“). If the

emergency drain hose leaks

contact customer service.

Cancel RINSE HOLD.

Release SOAKING button

(main wash programme will

follow).

Page 31

Operating Instructions

Problem Possible Cause Remedy

Softener has not been

flushed into machine;

drawer æ for care

agent is filled with water.

Washing is heavily

creased.

Washing has not been

spun properly. Residual

water is still visible in

the drum.

Detergent deposits

form in the washing

powder drawer.

The softener insert has not

been correctly positioned inside the care agent compartment or is blocked.

Probably too much washing

was packed into the drum.

The drain hose is bent. Remove the bend.

Maximum pump head (outlet

head 1m from unit's floor

surface) exceeded.

Drain pump is blocked.

Where a siphon is connected:

siphon is blocked.

Water valve is not fully

opened.

Filter in the screw connection of the inlet hose on the

water valve or on the unit is

blocked.

Wash the washing powder

drawer and position the softener insert firmly.

Follow instructions for the

maximum filling quantity

(see Programme Tables).

Contact customer service; a

retrofit kit is available as a

special accessory for pump

heads over 1m.

Switch off the unit and pull

out the mains plug. Clean

the drain pump.

Clean the siphon.

Open the water valve fully.

Close the water valve. Unscrew the inlet hose from the

water tap and from the unit.

Clean the filter.

The rinsing water is

murky.

Door cannot be

opened.

The cause is probably a

washing powder/liquid with

a high silicate content.

Door is locked for safety reasons.

No negative influence on the

rinse results; perhaps use liquid washing agent.

Wait for 1 or 2 minutes after

the end of the programme.

31

Page 32

Operating Instructions

If the washing results are not satisfactory

If the washing has turned grey and if limescale is deposited in the

drum, then

• Too little detergent was used.

• The wrong detergent was used.

• Special soiling was not pre-treated.

• Program or temperature not set correctly.

• If multi-component detergents are used, the individual components

were not used in the correct ratio.

If there are still grey spots on the washing,

• Washing soiled with ointments, grease or oils was washed with too

little detergent.

• Too lower temperature was used for washing.

• A frequent cause is that softener - particularly that in concentrated

form - has reached the washing. Wash out such spots quickly and use

the softener concerned carefully.

If at the end of the last rinse foam is still visible

• Modern detergents can also cause foam in the last rinse. However,

the washing is still sufficiently rinsed.

32

If there are white remnants on the washing

• These are insoluble components of modern detergents. They are not

the result of an insufficient rinsing effect.

Shake or brush out the washing. In future, perhaps you should turn

the washing inside out before washing it. Examine your choice of detergent and if necessary use liquid detergent.

Page 33

Operating Instructions

Carrying out emergency drainage

• If the washing machine no longer pumps off the washing solution,

emergency drainage must be performed.

• If the washing machine is in a room where there is a risk of frost,

emergency drainage must be performed if there is a possibility of

frost.

In addition: unscrew the inlet hose form the water tap and place it on

the floor. Empty the drainage hose.

Warning! Switch off the washing machine before performing emer-

1

gency drainage and pull out the mains plug.

Caution! The washing solution escaping from the emergency drainage

hose may be hot. There is a risk of scalding! Allow the washing solution

to cool down before performing emergency drainage.

0 1. Place a flat collecting vessel in order to collect the washing solution

which is draining off.

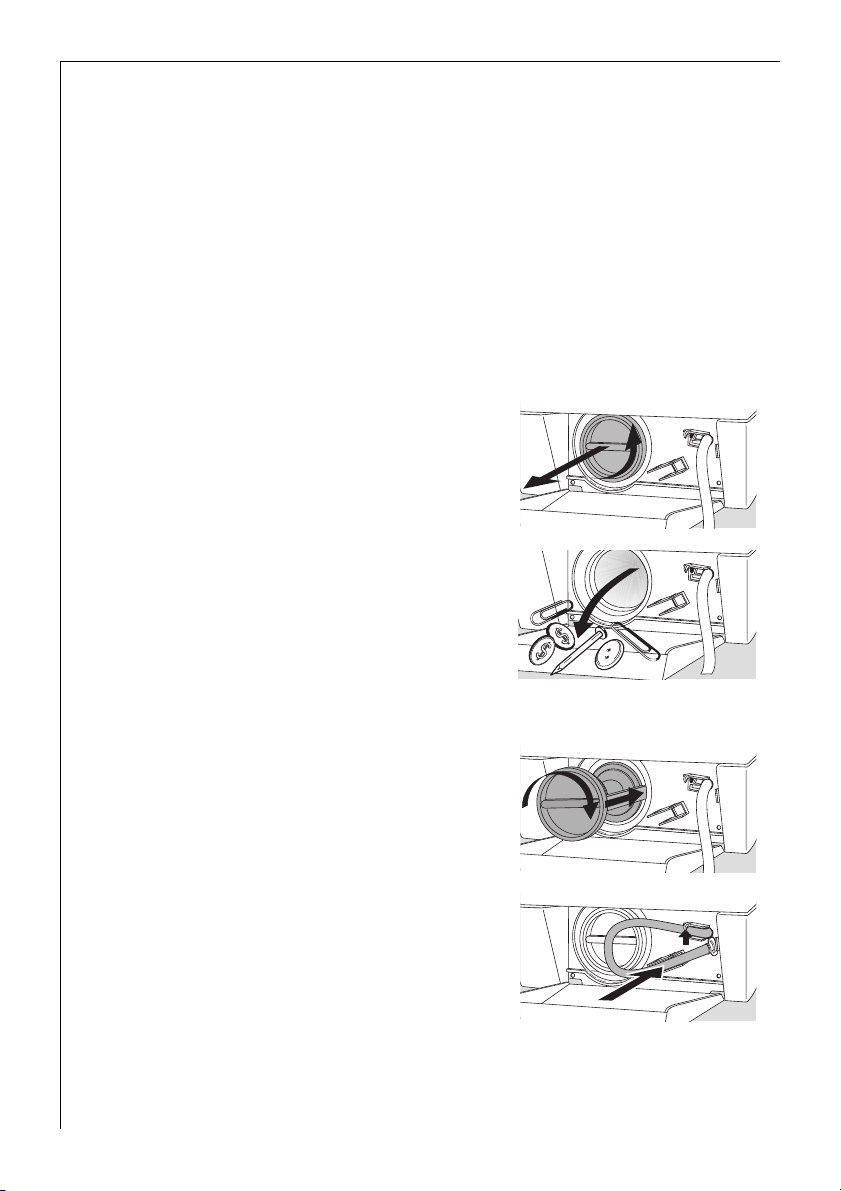

2. Fold open the flap in the right section

of the base outwards and pull it off.

3. Remove the emergency drainage hose

from its holder.

4. Place the container under the hose.

5. Detach the plug of the emergency

drainage hose by turning it anticlockwise and pull it out.

The washing solution runs out. Depending on the amount of solution, it may

be necessary to empty the collecting

vessel several times. To do this, close the

emergency drainage hose temporarily

with the plug.

33

Page 34

Operating Instructions

When the water is completely drained:

6. Push the plug securely into the emergency drainage hose and turn it

clockwise to secure it.

7. Replace the emergency drainage hose in its holder.

8. Put on the flap and close.

Child Safety Feature

If the child safety feature is set,

the filling door can no longer be

closed and no washing program

can be started.

Setting the child safety feature

0 Use a coin to turn the rotary knob

on the inside of the filling door

clockwise as far as it will go.

Warning! The rotary knob must

1

not be in a vertical position after

adjustment, otherwise the child

safety feature is not active. The rotary knob must project as shown in

the diagram

Cancelling the child safety

feature

0 Turn the rotary knob anticlockwise

as far as it will go.

34

Page 35

Installation and connection instructions

Installation and connection instructions

Installation Safety Precautions

• Do not tilt the washing machine onto its front or onto its right side

(viewed from the front). Electronic components can get wet.

• Check the washing machine for transport damages. A damaged unit

must never be put into operation under any circumstances. In the

event of damage, please contact your supplier.

• Ensure that all parts of the transport safeguard are removed and that

the unit is splash protected, see "Removing transport safeguard".

Otherwise, the units or neighbouring furniture can be damaged when

spinning.

• Always insert the plug into a correctly installed earthed socket.

• In the case of permanent connection: A permanent connection may

only be made by an authorised specialist.

• Before putting the machine into operation, ensure that the mains

voltage and current type shown on the unit's rating plate correspond

with those at the place where the machine is being installed. The fuse

rating is also found on the rating plate.

• The mains lead may only be replaced by the customer service or by an

authorised electrician.

35

Page 36

Installation and connection instructions

Installation of the appliance

Washing machines with curved panels are not suitable for installing

3

under units.

Transporting the appliance

• Do not place the washing machine on its front or on its right side

(viewed from the front). Otherwise, electrical components can get

wet.

• Never transport the unit without the transport safeguard. Do not re-

move the transport safeguard until the appliance is at the installation

location. Transporting the unit without the transport safeguard can

damage it.

• Lift the appliance neither by an open filling door nor by the base.

• When transporting the unit with a sack trolley: Attach the sack trol-

ley only at the side.

Remove transportation protection

Important! It is essential to re-

move the transport safeguard before putting the unit into

operation. Keep all parts of the

transport safeguard in a safe

place for possible later transport

(moving).

0 1. Open both hose holders on the

unit's rear side and remove the

hoses and mains cable.

36

Page 37

2. Pull both hose holders off the

unit with a strong pull.

The special key E and the caps D

3

(2 each) and G (1 each) are supplied with it.

3. Unscrew the two screws with the

special spanner.

4. Unscrew the 4 screws B with special spanner E.

5. Remove the transport rail C.

6. Screw the 4 screws B back in.

7. Close the 2 large holes with the

caps D.

Important! Press in the caps with

sufficient strength so that they

engage in the rear panel (protects

the inside of the units against

splash water).

8. Remove the screw F, including the

compression spring, with the special spanner E.

9. Close the hole with the cap G.

Important! Press in the cap with

sufficient strength so that it engages in the rear panel (protects

the inside of the unit against

splash water).

Installation and connection instructions

37

Page 38

Installation and connection instructions

Prepare the installation place

• The installation surface must be clean and dry, free of floor polish

residues and other greasy coatings so that the unit does not slip

away. Do not use lubricants as a sliding aid.

• Installation on a high-veil carpet or floor tiles with soft sponge backs

is not recommended because the standing safety of the appliance is

then no longer ensured.

• By installation surfaces with small-format tiles, lay a conventional

rubber mat underneath.

• Minor unevenness of the floor surface should never be levelled out by

laying pieces of wood, card or similar materials, but rather should always be compensated for by adjusting the screw feet.

• If, for space reasons, it is not possible to avoid setting up the unit di-

rectly next to a gas or coal-fired cooker: install a thermal insulation

panel between the cooker and washing machine (85 x 57cm) which

must have an aluminium film on the side against the cooker.

• The washing machine must not be set up in a room where there is a

danger of frost. Frost hazard!

• Flexible feed and drain tubings may not be crinkled or squeezed.

38

Installation on a concrete base

If the unit is set up on a concrete base,

for safety reasons it is essential to fit

stand plates in which the washing machine is adjusted. The stand plates are

available from Customer Service under

the spare parts number 645 425 058.

Installation on vibrating floors

Where the floor vibrates, particularly in the case of wooden beam

floors with pliable boards, securely screw a water-resistant wooden

panel at least 15mm thick onto at least 2 floor planks. If possible, set up

the unit in the corner of a room, as the wooden floor is optimally restrained there and is therefore least likely to be subject to resonance vibrations.

Page 39

Installation and connection instructions

Compensate for floor unevenness

Floor unevenness can be compensated for and the height can be corrected with the four adjustable screw feet. The height can be adjusted

in the range +10 .. -5mm.

To adjust the feet use the special spanner supplied for removing the

transport braces.

0 1. Slide the special key firmly onto

the hexagon head of the threaded foot as far as it will go.

2. Adjust the screw feet so that the

unit is horizontal and stable. The

unit must not wobble over when

loaded.

3. If necessary, check the setting

with a spirit level.

Important! Minor unevenness of

the floor surface should never be

levelled out by laying pieces of

wood, card or similar materials,

but rather should always be compensated for by adjusting the adjustable feet.

39

Page 40

Installation and connection instructions

Electrical connection

Details of the mains voltage, current

type and required fuses can be

found on the rating plate. The rating plate is located at the top

above the filling door.

For permanent electrical connection

within the electrical circuit, provisions must be made which allow for electrical disconnection of the appliance from the mains with a contact opening of at least 3 mm at all

poles. Suitable devices include circuit breakers, fuses (threaded fuses

must be entirely removed from the socket), ground fault circuit interrupters and contactors. Permanent connection may only be carried out

by an authorised electrician.

This appliance complies with the following EC directives:

;

– The "Low Voltage Directive" 72/23/EU with changes

– The "EMC Directive" 89/336/EU with changes

Water connection

The washing machine has safety features which prevent back-contami-

3

nation of the drinking water and which conform to the national regulations of the water authorities (e.g. for Germany: DVGW guidelines).

This means that additional protective measures in the installation are

not necessary.

Important!

– Units for connecting to cold water must not be connected to hot wa-

ter.

– Use only new hose sets for the connection.

Permissible water pressure

The water pressure must be at least 1 bar (= 10 N/cm2 = 0.1 Mpa), maximum 10 bar = 100 N/cm

• If more than 10 bar: Connect a pressure-reduction valve upstream.

• If less than 1 bar: Unscrew the inlet hose on the unit side at the sole-

noid intake valve and remove the flow regulator (to do this, remove

the filter with pointed pliers and take out the rubber washer behind).

Replace the filter.

40

2

= 1 Mpa).

Page 41

Installation and connection instructions

Water inflow

A pressure hose of 1.35m in length is supplied.

If a longer inflow hose is required, only a VDE-approved, complete set

of hoses with fitted hose screw connections offered by our Customer

Service is permissible.

– Hose sets in lengths of 2.2m, 3.5m and 5m are available for washing

machines without Aqua-Control.

– Hose sets in lengths of 2.0m, 2.9m and 3.5m are available for washing

machines with Aqua-Control.

Important! Never cut into pieces in order to extend the hoses!

Sealing rings are supplied either in the plastic

3

nuts of the hose screw connection or in the enclosed pack. Do not use other seals!

0 1. Connect the hose with the angled connection to

the machine.

Important!

– Do not lay the inlet hose verti-

cally downwards, instead run it

to the right or left as shown in

the diagram.

– Tighten the hose screw connec-

tion only by hand.

2. Connect the hose with the

straight connection to a water valve with a

screw thread R 3/4 (inches).

Important! Only tighten the screw connection

manually.

3. By slowly opening the water valve before

putting the washing machine into operation,

check that the connection is free of leaks.

41

Page 42

Installation and connection instructions

Water drain

The drainage hose can either be connected to a siphon or hung in a

wash basin or discharge basin or a bath tub.

Only original hoses may be used for extensions (max. 3m laid on the

floor and then up to 80cm high). Customer Service stocks drainage

hoses in lengths of 2.7 and 4m.

Important! It is essential to lay the drainage hose without kinks.

Water drain-off inside a siphon

The grommet on the hose end fits all

standard siphon types.

0 Secure the connection between the

grommet and siphon with a hose clamp.

Water drain-off inside a basin

Important!

– Small basins are not suitable for

drainage. Water could overflow!

– The end of the drainage hose must not

be submerged in the pumped-out water. Otherwise, the water could be

sucked back into the unit.

– When hanging in a wash basin or a

bath tub, the drainage hose must be

secured with the supplied attachable

bend to prevent it slipping. The backsurge force of the escaping water

could otherwise force the hose out of

the basin.

0 Tie the bend to the tap or the wall using

a piece of string.

42

Page 43

Installation and connection instructions

Delivery heads over 1m

To pump off the washing / rinsing solution, every washing machine has

a drain pump which carries liquids up to a height of 1m via the drainage hose, calculated from the machine's standing surface.

Please contact Customer Service for delivery heads of over 1m.

Technical data

Adjustment possibility Approx. +10 / -5mm

Filling quantity (program-dependent) max. 5kg

Area of use Domestic

Drum speed, spinning See rating plate

Water pressure 1-10 bar (= 10 - 100 N/cm

= 0.1 - 1.0 Mpa)

Dimensions

2

(dimensions in mm)

43

Page 44

Warranty conditions / Customer service centres

Warranty conditions / Customer service

centres

Weitere Kundendienststellen im Ausland

In diesen Ländern gelten die Garantiebedingungen der örtlichen Partner. Diese können

dort eingesehen werden.

Further after-sales service agencies overseas

In these countries our AEG agents’ own guarantee conditions are applicable. Please obtain further details direct.

Autres agences étrangères assurant le service après-vente

Dans ces pays, les conditions de garantie des concessionnaires de la région sont valables. Vous pouvez les consulter sur place.

Otros puntos de Postventa en el extranjero

En estos países rigen las condiciones de nuestros representantes locales. las cuales

pueden ser consultadas allí mismo.

Ulteriori uffici del servizio tecnico assistenza clienti all’estero

In questi paesi sono valide le condizioni di garanzia dei partner locali. Queste condizioni

possono essere esaminante sul luogo.

Serviços de assistência técnica no estrangeiro

Nestes países são válidas as condições de garantia dos concessionários locais, podendo

aí ser consultadas.

44

U.A.E. Abu Dhabi

Universal Trading Company

P.O. Box 43 99

Tel.: 335331

Egypt

Middle East Commercial

Center

P.O. Bo x 19

Kairo-Heliopolis

Tel.: 29917/31634

Australia

ANDI-Co Pty. Ltd

9 Kingston Town Close

Oakleigh VIC 3166

Tel.: (03) 9569 1235

Fax: (03) 9569 1450

Jordan

Jordan Household

Supply Co. Ltd.

P.O. Box 3/68

Amman/Tel.: 69 70 50

Kanada

EURO-LINE Appliances

2150 Winston PARK Drive 20

Oakville, Ontario L6H 5V1

Tel.: 905 829 3980

Fax: 905 829 3985

Korea (South)

Core Incorp.

3/F Chewoo Bldg.

200 Nonhyun-Dong

Kangnam-Ku

Seoul

Telefon 82 2 549 89 61

Malta

ITC

International Trading Company

White House Building

Mountbatte Street

Blata L-Bajda/Tel.: 220644

Mauritius

Happy World Centre Ltd.

P.O. 7 54

1 Chausee Street

Port Louis

Tel.: 25355

Namibia

AEG NAMIBIA (PTY) LIMITED-Jeppe Street

Northern Industrial Area

Windhoek

Tel.: (061) 21-6082/4

Fax: (061) 217838

Page 45

Warranty conditions / Customer service centres

Bahrain/Arabian Gulf

A.A. Zayani & Sons

P.O. Box 9 32

Bahrain

Tel.: 261060

Bulgaria

Electrolux Bulgaria E.O.O.D.

91 Levski Blvd.

1000 Sofia

Tel.: 2 806676

Fax. 2 980 5276

Cyprus

Hadjikyrlakos & Sons Ltd.

Prodromou 121

P.O. Box 21587

Nicosia 1511

Service Telephones:

Nicosia 02 481226

Limassol 05 562182

Larnaca 04 633929

Paphos 06 932 699

Estonia

Electrolux Estonia Ltd.

Mustamäe tee 24

EE0006 Tallinn

Tel.: (372) 6 650 090

Fax: (372) 6 650 092

Croatia

Electrolux D.O.O.

Suplova 7

10000 Zagreb

Tel.: 1 61 19512

Fax: 1 61 19513

Kuwait/Arabian Gulf

Ali Al-Ghanim Est.

P.O. Box 10 83

Tel.: 5322463

Fax: 5242114

Lebanon

Adib & Assaferi

P.O. Box 539

Tripoli

Latavia

Electrolux Latavia Ltd.

Terlaton Street 42/44

1011 Riga

Tel.: 371 2 297821

Fax: 371 2 821286

New Zealand

Euro-Life New Zealand Ltd.

Privat Bag

58 Symonds Street

Auckland

Tel.: (09) 525 2222

Nouvelle Caledonie

Socometra N.C.

B.P. 483

Nouman

Tel.: 275444

Oman

Moshin Haider Darwish

P.O. Box 1 35

Muscat

Tel.: 703743

Poland

Electrolux Poland Sp. zo.o.

ul. Domaniewska 41

02-034 Warszawa

tel.: 022 874 33 33

fax: 022 874 33 00

Hongkong

Wo Kee Services Ltd.

585-609 Castle Peak Road

Kwai Chung N.T.

Hongkong

Tel.: 2494 4000

Lthuania

Electrolux Lthuania

Verkui 29

2600 Vilnus

Tel.: 372 272 3326

Fax: 372 272 3366

Russia

Electrolux Russia Ltd.

16 Olympiysky prospekt

129090 Moscow

Tel.: (095) 937 7837

Fax: (095) 926 5513

45

Page 46

Warranty conditions / Customer service centres

Israel

Electricity & Electronic

Services-Evis LTD.

19 Hataasia st.

Raanana,

Industrial area 43654

Tel: 972-9-7448118

Fax: 972-9-7603618

e-mail:evis@evis.co.il

Japan

Electrolux Japan Ltd.

Yasuda Warehouse 4F 3-3-12

Heiwajima Ota-Ku

Tokyo

Tel.: 81 3 3544 3363

Fax: 81 3 3763 6143

Thailand

OLYMPIA Thai Ltd.

44 Ratchadapisek Road

10320 Bangkok

Tel.: 2 513 6111

Fax: 2 513 2574

Malaysia

Arzbergh Engineering

No. 49A/B, Jalan Petaling

Utama 7

4600 Petaling Jaya

Tel.: 3 795 1084

Fax: 3 795 1082

Singapore

Arzbergh Engineering

19 Tanglin Road 06-07

Singapore 247909

Tel.: 65 7356572

Fax: 7351124

Slovakia Rep.

Electrolux Slovakia S.R.O.

Seberiniho 1

821 03 Bratislava

Tel.: 02 4333 4322, 4355

Fax: 02 4333 6976

Saudi Arabia

Alia Trading Corporation

P.O. Box 4101

King Abdul Aziz Street

Riyadh

Tel.: 4645977

Al Nahas Est.

Musaidia Market I

P.O. Box 1 15 29

Jeddah

Tel.: 6606852

Slovenia

Electrolux Slovenia D.O.O.

Traska Ul. 132

1000 Ljubljana

Tel.: 61 1234 137

Fax: 61 1234 238

South Africa

AEG (Pty) Ltd.

55, 12th Road

P.O. Box 1 02 64

Kew/Johannesburg 2000

Tel.: 8069111

46

Hungary

Electrolux Lehel KFT

(AEG Div)

Erzsebet’Kiralyne Utja 87

1142 Budapest

Tel.: 00361/251 84 44

USA

ANDI Co. Appl. Inc. East

65 Campus Plaza

Edison, New Jersey 0837

USA/Tel.: (201) 2258839

Syria

Masri & Shami

P.O. Box 24 96

Damascus

Tel.: 214080

Page 47

474849

Page 48

Page 49

Page 50

Index

INDEX

C

Care agent . . . . . . . . . . . . . . . . . . . . 9, 17, 19

Care symbols

Child safety feature

Conditioner

Conditioning

Cottons

Curtains

Customer Service

. . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . .29, 34

. . . . . . . . . . . . . . . . . . . . . . .9, 19

. . . . . . . . . . . . . . . . . . . . .11, 25

. . . . . . . . . . . . . . . . . . .10, 16, 24, 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . 27, 29, 51

D

Delicates . . . . . . . . . . . . . . . . . . . . . 16, 24, 25

Detergent

Detergent drawer

Drain pump

. . . . . . . . . . . . . . . . . . . . . 9, 17, 19

. . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . .9, 28

E

Easy-cares . . . . . . . . . . . . . . . .11, 16, 24, 25

Eco-sluice

Emergency drainage

Energy-saving programme

. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . 33

. . . . . . . . . .12, 24

F

Filling quantity . . . . . . . . . . . . . . . . . . .14, 24

I

In-wash stain treatment . . . . . . . . . . . . 9, 19

L

Linen . . . . . . . . . . . . . . . . . . . . . . . . 16, 24, 25

M

Main wash . . . . . . . . . . . . . . . . . . . . . . .10, 24

N

Net curtains . . . . . . . . . . . . . . . . . . . . . . . . . 24

O

Opening the door . . . . . . . . . . . . . 18, 23, 31

P

Pre wash . . . . . . . . . . . . . . . . . . . . . 10, 19, 24

Pre-wash detergent

Programme

changing

interrupting

setting

. . . . . . . . . . . . . . . . . . . . . . . .20, 24

Programme progress display

Pump out

. . . . . . . . . . . . . . . . . . . . 18, 22, 23

. . . . . . . . . . . . . . . .9, 19

. . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . 22

Q

Quick wash . . . . . . . . . . . . . . . . . . 13, 20, 24

R

Rating plate . . . . . . . . . . . . . . . . . . . 9, 40, 51

Rinse

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Rinse hold

Risk of frost

. . . . . . . . . . . . . 11, 18, 21, 22, 23

. . . . . . . . . . . . . . . . . . . . . . 6, 33

S

Silk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Soaking

. . . . . . . . . . . . . . .12, 19, 20, 23, 24

Soaking agent

Spin

. . . . . . . . . . . . . . . . . . . . . 18, 21, 22, 25

Stain

. . . . . . . . . . . . . . . . . .8, 13, 20, 24, 32

Starching

. . . . . . . . . . . . . . . . . . . . . . .19

. . . . . . . . . . . . . . . . . . . . . . . . 11, 25

W

Warranty . . . . . . . . . . . . . . . . . . . . . .6, 29, 44

Washing

coloureds

heavily soiled

lightly soiled

normally dirty

sensitive

Washing powder drawer

Water

hardness

pumping out

softener

Woollens

. . . . . . . . . . . . . . . . . . . . . . . . .15

. . . . . . . . . . . . . . . . . . . . . .13

. . . . . . . . . . . . . . . . . . . . 8, 13

. . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . .16

. . . . . . . . . . . . . . .19

. . . . . . . . . . . . . . . . . . . . . . . 8, 17

. . . . . . . . . . . . 12, 18, 22, 23

. . . . . . . . . . . . . . . . . . . . . 8, 17, 19

. . . . . . . . . . . . . . . . . . . . .16, 24, 25

50

Page 51

Service

In the chapter "What to do if...“ , some faults are listed which you can

remedy yourself. Look there first if a fault occurs. If you do not find any

information there, please consult your Customer Service. (You can find

the addresses and telephone numbers in the section "Customer Service

Centres“.)

Always prepare in advance for the discussion. By doing so you will simplify the diagnosis and the decision on whether customer service is

necessary.

Note the PNC number and S. number. You will find both on the rating

plate on the inside of the door of

your washing machine.

PNC .....................................................

S. No. .....................................................

Answer as precisely as possible:

• What form does the fault take?

• Under what circumstances does the fault occur?

Service

When do you incur costs even during the warranty period?

– If you could have remedied the fault yourself with the aid of the fault

table (see the section "What to do if..."),

– If several journeys by the customer service technician are necessary

because for example he did not receive all the important information

before his visit and must collect spare parts. These multiple trips can

be avoided if you prepare your phone call as described above.

51

Page 52

AEG Hausgeräte GmbH

Postfach 1036

D-90327 Nürnberg

http://www.aeg.hausgeraete.de

© Copyright by AEG

822 942 753-01-030402-05

Subject to change without notice

Loading...

Loading...