Page 1

Waschautomaten

Automatic Washing Machines

Lave-linge

Lavatrici

Wasautomaat

Lavadoras

Aufstell- und Anschlußanweisung

für Waschautomaten mit gewölbter Blende

Installation and connection instructions

for automatic washing machines with

vaulted front cover

Installation et raccordements

des lave-linge à bandeau bombé

Instruzioni di installazione e collegamento

per lavatrici con pannello rigonfiato

Opstellings- en aansluitvoorschrift

voor wasautomaten met gewelfd voorpaneel

Instrucciones para la instalación y la conexión

de lavadoras con panel curvado

Page 2

Contents

Pri

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Appliance Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Front and Side Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Appliance Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Appliance Transit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Removing Transit Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installation-Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Levelling the Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Self Adjusting Foot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Water Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Water Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Inlet Hose Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Water Drainage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

AEG Service Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

14

nted on environment-friendly paper.

AEG – putting words into action.

Page 3

1 Important Safety Information

The safety of AEG appliances is in accordance with recognised technological standards and appliance safety legislation. We nevertheless feel

that it is important to acquaint you with the following safety guidelines.

• This appliance is heavy, care should be taken when moving it.

• When moving, do not tip the washing machine onto it’s front or left

hand side (viewed from the front). This is to prevent the possibility of

electrical components becoming wet.

• Before installation inspect the machine for transport damage. Do not

connect the appliance if it is damaged – contact your retailer.

• Ensure all packaging and transit bolts/bar have been removed, see

„Removing of Transit Packaging“. Failure to remove packaging and

transit bolt/bar may cause serious damage to the product or property.

• Any plumbing work required to install this appliance should be

carried out by a qualified plumber or competent person.

• Any electrical work required to install this appliance should be carried

out by a qualified electrician or competent person.

• Check the electricity supply is the same as that indicated on the

rating plate of the appliance.

• Should the appliance mains cable need to be adapted for any reason

this should only be carried out by a qualified/competent person.

• In the case of a permanent connection it is necessary that you install

a double pole switch between the appliance and the electricity supply

(mains), with a minimum gap of 3 mm between the switch contacts

and of a type suitable for the required load in compliance with the

electrical regulations.

• The switch must not break the yellow and green earth cable at any

point.

• Care must be taken to ensure that the appliance does not stand on

the electrical supply cable.

• The installation should comply with local water authority and

building regulations requirements.

• Appliances designed for cold water connection must not be

connected to hot water.

15

Page 4

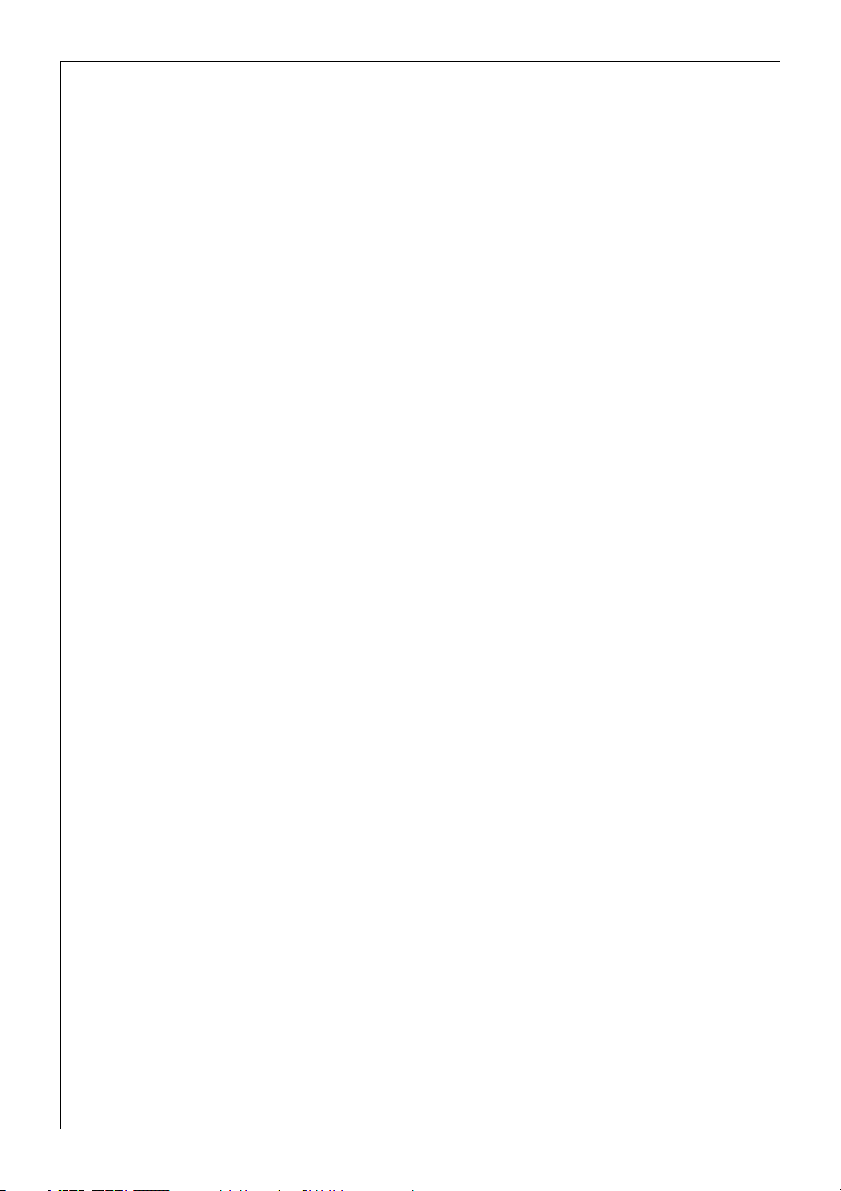

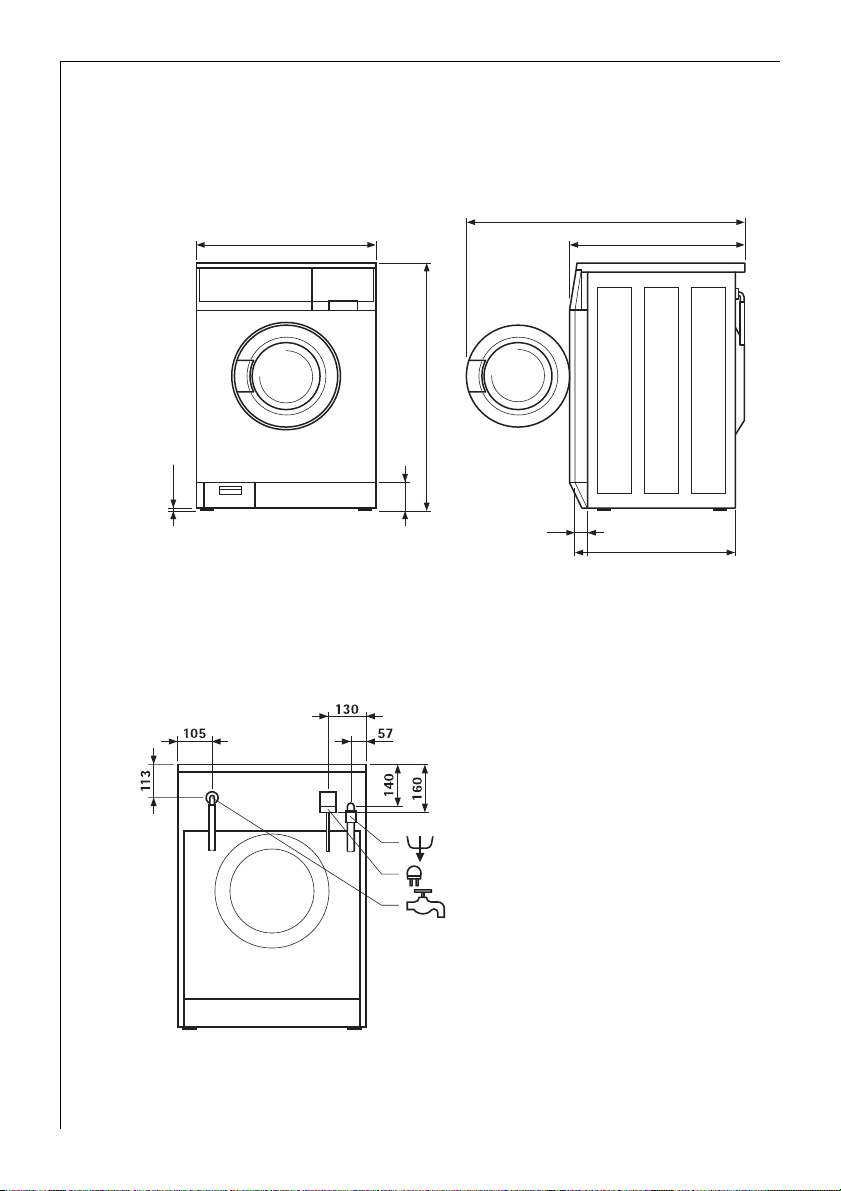

Appliance Dimensions

Front and Side Views

598

+10

-5

850

+10

-5

10

Rear View

Appliances with cold water connection only

100

950

592

50

575

16

Page 5

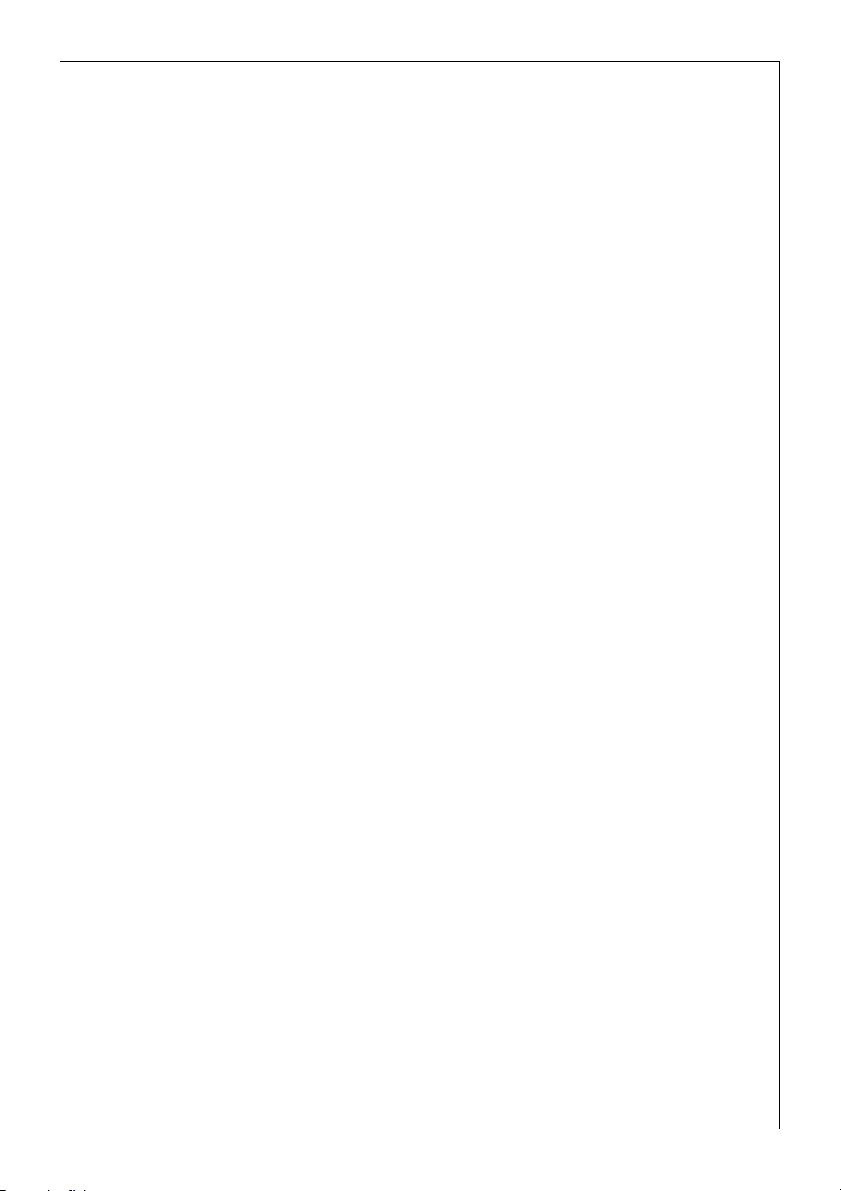

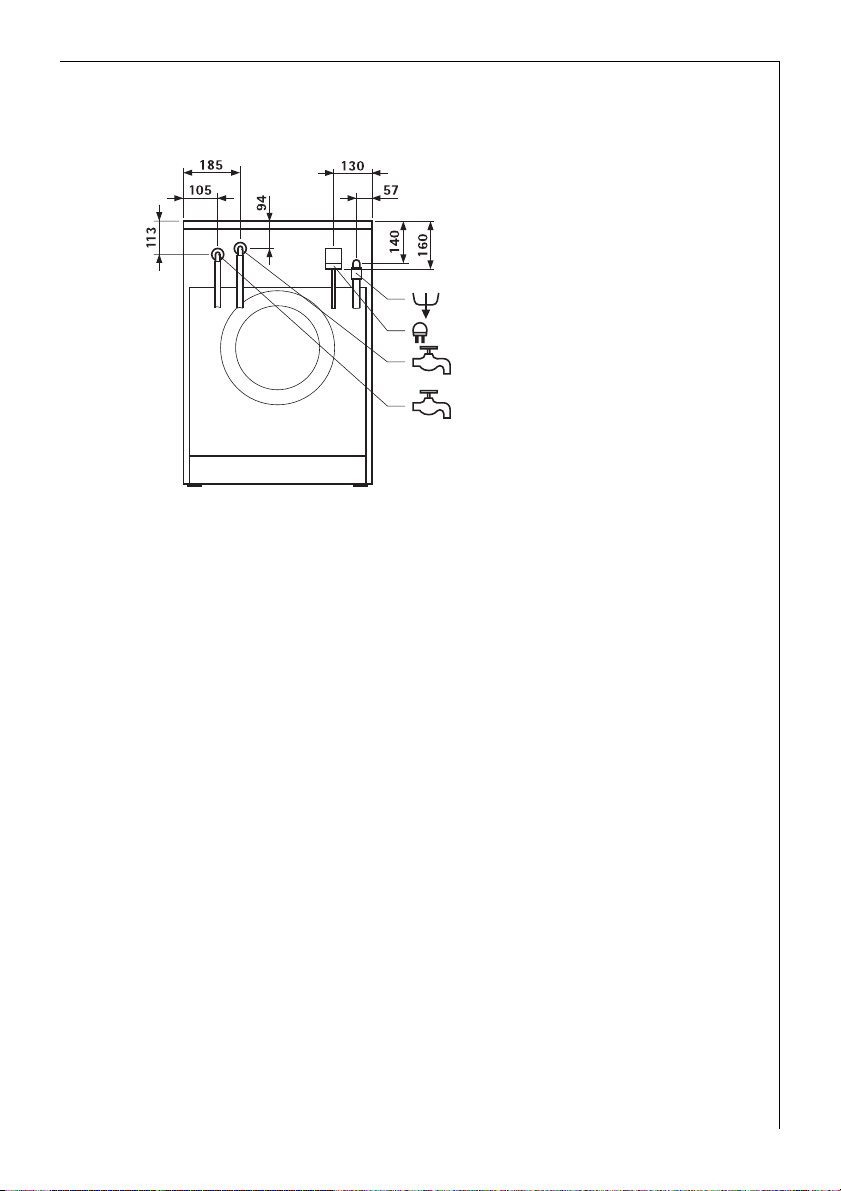

Appliances with hot and cold water connections

Hot water inlet

Cold water inlet

Appliance Installation

The appliance worktop must not be removed to gain a height reduction

3

when installing under a kitchen worktop.

Appliance Transit

• To prevent electrical components becoming wet when moving the

appliance, do not tip the washing machine onto it’s front or the left

hand side (viewed from the front).

• Do not transport the appliance without the transit packaging/bolts/

bar in place. Transporting the appliance without the transport

packaging/bolts/bar in place may cause damage to the product.

• Never lift the appliance by the door.

• The appliance is heavy, care must be taken when moving it.

17

Page 6

Appliance Installation

Removing Transit Packaging

• Ensure all transit packaging is removed prior to installation.

• Retain transit packaging for future use.

F

G

E

C

C

B

B

D

H

A

The appliance is supplied with a spanner (H) and plastic caps (E) (2 pcs.)

3

and (G) (1 pc).

0 Remove the hose holder (A).

0 Remove the 2 screws (B) with the spanner supplied (H).

0 Remove the 4 screws (C).

0 Remove the transit bar (D).

0 Cover the holes left by screws (B) the 2 plastic caps (E).

0 Replace the 4 screws (C), for safe keeping.

0 Remove the screw and compression spring (F) with the spanner (H),

cover the hole with plastic cap (G).

Important: When fitting the plastic caps, press until they snap into the

rear panel securely.

18

Page 7

Appliance Installation

Installation-Site Preparation

• The installation surface must be clean, dry and level.

• Do not install on deep pile carpet.

• If the appliance ist installed next to heat source (e. g. cooking

appliance), a heat insulating pad (85 x 57 cm) must be placed

between the washing machine and the heat source.

• Do not install the appliance in locations where the temperature may

fall below freezing.

• Please ensure that when the appliance is installed it is easily

accessible for the engineer in the event of a breakdown.

Installation on a Suspended Floor

Suspended wooden floors are particularly susceptible to vibration. To

help prevent vibration we recommend you place a waterproof wood

panel, at least 15 mm thick under the appliance, secured to at least 2

floor beams with screws. If possible install the appliance in one of the

corners of the room, where the floor is more stable.

Levelling the Appliance

• The appliance must be levelled using the adjustable feet.

• Adjust the feet using the spanner provided.

• Ensure the spanner is securely pushed onto the hex head on the feet

of the appliance.

• Adjust the feet so that the appliance is level. The appliance must not

rock when weight is applied.

• Check the appliance level using a spirit level.

• Never use strips or shims of wood or cardboard etc to compensate for

any uneveness in the floor. Always use the adjustable feet.

Self Adjusting Foot

Appliances with a spin speed of 1400 r. p. m. and over have a self

adjusting foot fitted (rear right).

• If the appliance vibrates or is unstable during a spin cycle of

1400 r. p. m.: Set the three adjustable feet to length of 10 mm.

• If the self adjusting foot (rear right) does not reach the floor:

Manually extend the self adjusting foot to the required length.

19

Page 8

Electrical Connection

Any electrical work required to install this appliance should be carried

out by a qualified electrician or competent person.

WARNING - THIS APPLIANCE MUST BE EARTHED.

1

The manufacturer declines any liability should these safety

measures not be observed.

Before switching on, make sure the electricity supply voltage is the

same as that indicated on the appliance rating plate. The rating plate is

located at the top of the rim of the open door.

The appliance is supplied with a 13amp plug fitted. In the event of

having to change the fuse in the plug supplied, a 13amp ASTA

approved (BS 1362) fuse must be used.

20

Should the plug need to be

replaced for any reason. The

wires in the mains lead are

coloured in accordance with

the following code:

Green and Yellow : Earth

Blue : Neutral

Brown : Live

Blue

Green

& Yellow

Brown

Cord Clamp

Page 9

Electrical Connection

• The wire coloured green and yellow must be connected to the

terminal marked with the letter “E“ or by the earth symbol or

coloured green and yellow.

• The wire coloured blue must be connected to the terminal “N“ or

coloured black.

• The wire coloured brown must be connected to the terminal marked

“L“ or coloured red.

• Upon completion there must be not cut, or stray strands of wire

present and the cord clamp must be secure over the outer sheath.

WARNING: A cut off plug inserted into a 13 amp socket is a serious

1

safety (shock) hazard. Ensure that the cut off plug is disposed of

safely.

Permanent connection

In the case of a permanent connection it is necessary that you install a

double pole switch between the appliance and the electricity supply

(mains), with a minimum gap of 3 mm between the switch contacts

and of a type suitable for the required load in compliance with the

current electrical regulations.

The switch must not break the yellow and green earth cable at any

point.

This appliance is in accordance with the following EU Guidelines:

;

– Low Voltage Guidelines 73/23 EEC dated 19 February 1973, include

Guideline Change Notice 93/68 EEC

– EMC Guideline 89/336 EEC dated 3 May 1989, including Guideline

Change Notice 92/31 EEC.

This appliance complies with the requirements laid out in the EEC

Directive 76/899.

Voltage 240 V AC Fuse rating 13 amps

See rating plate for further information.

This appliance meets VDE requirements.

Particular regulations of local electricity authorities must be observed.

This appliance conforms to EEC Directive No. 82/499/EWG on radio

interference.

WARNING: Repairs to electrical appliances may only be performed by

1

trained personnel. Improper repairs may lead to serious risks for the

user.

21

Page 10

Water Connection

The washing machine is provided with safety devices preventing back-

3

contamination of the water supply and complies with local water

authority requirements.

This appliance is designed to be permanently plumbed into your home’s

water supply.

Before connecting up the machine to new pipework or to pipework

that has not been used for some time, run off a reasonable amount of

water to flush out any debris that may have collected in the pipes.

Water Pressure

The appliance is designed to operate within the following water

pressure limits:

– minimum 1 bar (14.5 p. s. i.)

– maximum 10 bar (145 p. s. i.)

IMPORTANT

• At more than 10 bar (145 p. s. i.): Install pressure-reducing valve.

• At less than 1 bar (14.5 p. s. i.): Unscrew the inlet hose from the

appliance at the inlet solenoid valve and remove the flow regulator

(to do this, remove the sieve with needle-nose pliers and remove

rubber washer behind the sieve). Replace sieve. Retain the washer for

future use.

Inlet Hose Connection

The inlet hose provided is 1.2 or 1.3 metres depending on the model. If

a longer inlet hose is required contact your AEG Service Force Centre.

Under no circumstances should hoses be connected together to provide

a longer length.

The rubber washers are either set into the inlet hose threaded

connection or supplied separately in the installation kit. These washers

must be fitted to ensure water tight seals. Do not use any other washer.

22

Page 11

0 Connect the hose to the machine with

the right angled connector.

IMPORTANT:

Do not overtighten the plastic nuts on

the threaded connectors.

Rubber Washer

0 Connect the hose end with a straight

connector to the water supply tap with

an 3/4" thread.

Rubber Washer

IMPORTANT:

Do not overtighten the plastic nuts on

Fine Filter

the inlet hose threaded connectors.

WARNING:

Open the water taps slowly and check the connections are

watertight before final positioning of the machine.

23

Page 12

Water Connection

Appliances with hot and cold water fill

Washing machines with hot and cold fill should be connected as shown

below.

hot

cold

hot

WARNING: The incoming hot water temperature must not

exceed 70°C.

If only a cold water supply is available, connect the two hoses to the cold

water outlet by means of a “Y“ connection piece. (A “Y“ piece is available

from your AEG Service Force Centre, part number 645430709).

24

Page 13

Water Connection

Water Drainage

The appliance drain hose should hook into a standpipe, the hook in the

drain hose is formed using the plastic “U-Piece“ supplied, with an

internal diameter of approximately 38 mm (see diagram) thus ensuring

there is an air break between the drain hose and standpipe.

When discharging into a standpipe ensure that the top of the

curve in the hose end is no more

that 90 cm (35.4’’) and no less

than 60 cm (23.6’’) above floor

level.

Max 90 cm (35,4“)

Min 60 cm (23,6“)

The upright standpipe should

have a minimum, length of

30 cm (12’’) from the bottom of

the elbow to the top of the pipe

(see diagram). Make sure that it

is designed in such a way that

the end of the drain hose

cannot be covered with water.

Longer drain hoses are available

in lengths of 2.7 and 4 metres

from your AEG Service Force

Centre.

If you intend the drain hose

from the washing machine to

empty into a sink, make sure

that the sink is empty and the

plug hose is not blocked. Use

the plastic “U-Piece“ supplied.

38mm (11/2“)

diameter standpipe

Min 30 cm (12“)

25

Page 14

AEG Service Force

If you wish to contact your local AEG Service Force Centre for advice or

spare parts, telephone:

0990 234234

26

Loading...

Loading...