Page 1

Operating Iriotructions

¿/\v &£xsfi IOCS iCiJ

Fully automatic

washing machines

LAVAMAT BELLA 1003/803

AEG

Page 2

The LAVAMAT BB-yV 1003

LAVAMAT 1003 U

and LAVAMAT BELLA 803

E-605 191 902

Your new LAVAMAT Is a modern fully

automatic washing machine.

With a little care and attention, It will give

you many years of faithful service.

This machine offers you the advantage of

compiling the wash programmes exactly

as you like.

It also Incorporates special ’’power

economy” programmes for lightly .«?niied

laundry and economy programm lOr

small load sizes.

In addition, the BELLA 1003 models Incor

porate an extra gentle programr for

woollens.

To enable you to obtain the max im

benefit from your LAVAMAT wa.,..«ng

machine, please read this booklet tho

roughly. This will assist you In becoming

familiar with the controls of the machine

and their functions, thereby ensuring

carefree, happy wash days.

Please remember to remove the transit

bars (see page 5 under installation).

Spinning speed: more

(LAVAMAT BELLA 803:

more than 800 rpm.)

Contents:

than 1000 rpm.

Page

Installation 4

Electrical connection 4

Water supply 4

Water drainage 5

Preparing the laundry 5

Load sizes 6

Washing powder dispenser 6

Controls 8

Wash programmes 9-11

Operation 12

Maintenance 12

What can be the cause when... 13

Page 3

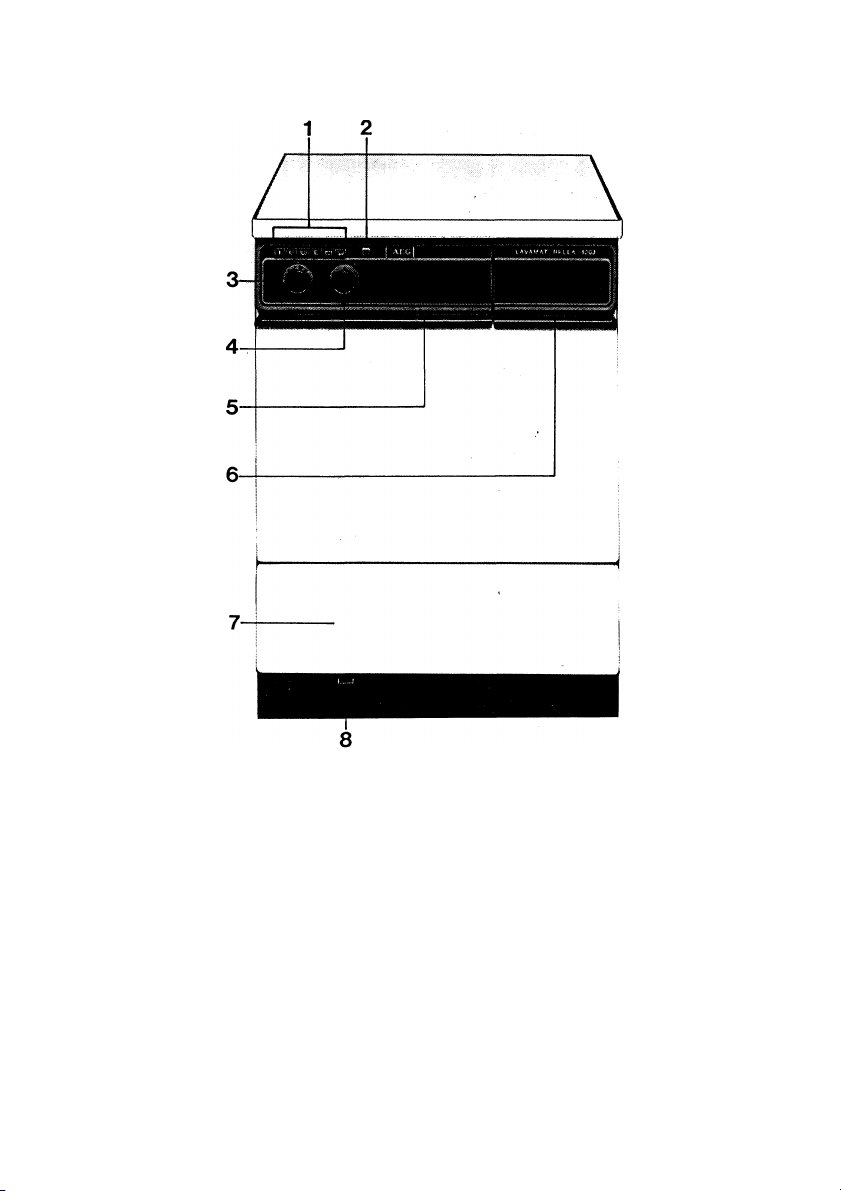

1 = Selector buttons plus ON/OFF-buttons

2 = Pilot lamp

3 = Programme switch

4 = Temperature control

5 = Finger grip for opening

the drop type front door

6 = Finger grip for detergent

dispenser tray

7 = Lower front panel (pull this lower

panel down and the drain fiiter

becomes accessibie).

8 = Fiiter outiet

Page 4

Installation

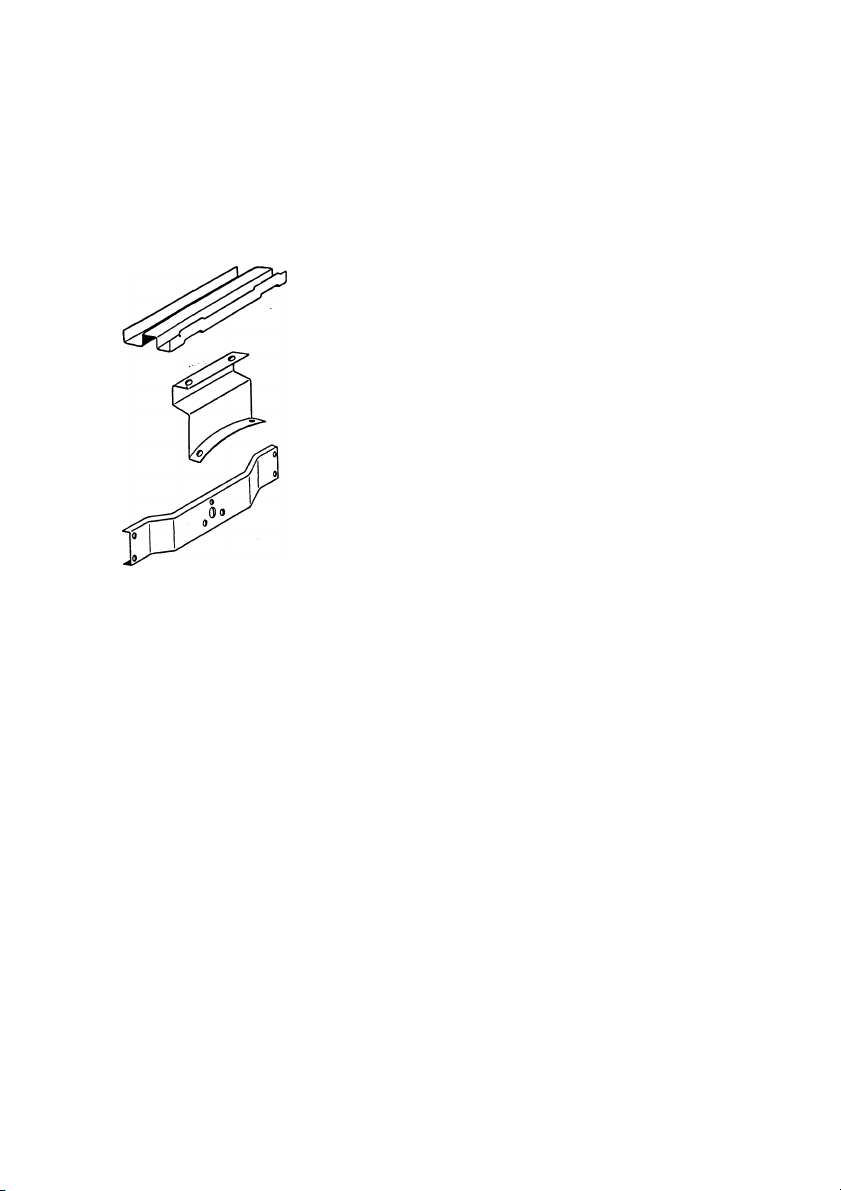

ATTENTION: Having unpacked the

machine, you must first remove the

transit bars. Detailed instructions for this

operation shouid be contained on the

machine in the form of a separate instruc

tion leafiet. Unscrew the worktop and rear

plate and remove 3 parts, 2 bars and

1 bracket (see illustration).

Please keep these transit bars, in case

you have to move the appliance for any

distance, e.g. moving house.

You can now position the machine into

place, as required.

Dimensions: Height 85 cm

(without worktop 82 cm)

Width 59.5 cm

Depth 60 cm

Weight: 100 kg approx.

Your machine features a three-point

support system so that no adjustment of

the feet shouid be necessary. However,

should levelling become necessary — e.g.

when incorporating the machine into a

fitted kitchen system, then adjustable

feet are available as an optional extra.

Part Number E 605 899 821.

Fuse protection fp^ 03 kW = 16 A,

for 2.08 kW = 10 >-..^JK version please fit

a 13 amp fuse or 15 amp plug).

WARNING: This appliance must be

earthed.

This appliance complies with the require

ments laid out in the EEC Directive

76/889.

Important

The wires in the mains lead are coloured

in accordance with the following code:

1. green and yeilow = earth

2. biue = neutral

3. brown = live

Fit the mains lead with a 3 pin 13 or 15

amp plug.

As the coiours of the wires in the ,ns

lead of the appliance may not correp'^ind

with the coloured marking identifyii ne

terminais in your plug, please proceed as

follows:

1. The wire which is coioured green and

yellow must be connected to the earth ter

minal in your plug, which is marked with

the ietter ’E’ or by the earth symboi or

coloured green yellow, or green and

yellow.

2. The wire which is coioured brown must

be connected to the live terminai which is

marked with the letter ’L’ or coloured red.

3. The wire which is coloured blue must

be connected to the neutral terminal

which is marked with the letter ’N’ or

coloured black.

When \yjring the plug ensure tt. all

strands of .wire are securely retained in

each terminal. Do not forget to tightp" the

mains lead clamp on the plug. If y^ in

stallation is fitted with 2 pin socket out

lets, or if you are in doubt, please c ult

a qualified electrician.

Electrical connection

Voltage: 220 V AC only (UK versions 240 V)

Connected load 3.03 kW which may be

changed over to 2.08 kW

A

Water supply

Your washing machine is fitted with a

high quality pressure hose Va inch bore

with a y* inch BSP screw connector for

connection to a water tap with male

Page 5

thread. The necessajrv washers are en

closed. (Please do : use any other

washers as they may prove to be of an

unsatisfactory quality). Hand tightening

of the nut is sufficient ~ be very careful

when using tools.

Please do not connect the machine to a

hot water supply, as this has an adverse

effect on the washing performance of the

machine.

Notes for plumber

Minimum water pressure: about 1 bar

excess pressure (= 1 atu, = 1 kp/cm^,

“ ^>'cm2 = 15 p.s.i.)

Mv lum permissible water pressure

about 10 bar. Where the supply pressure

exceeds 10 bar, it is necessary to fit a

pr jre relief valve type AD 723 (Part

Nuijioer E 612 896 723).

Sf ’d you require a longer water supply

hoovi than that provided, please use only a

continuous high-pressure hose (at least

60 bar) of suitable length. Do not extend

the existing hose.

On no account must you use cheap gar

den hose or similar hose. Please ensure

that suitable clamps are used for at

taching the hose to the connector fitting.

Please ensure that you comply with any

drinking water regulations of your local

water board.

At the completion of each wash pro

gramme, please close the tap.

Should you wish to soak laundry for a

lop^'^^r period, we recommend that you

cl the tap after the temperature has

been reached (at the end of the drum

movement).

S! !d you discover some residual water

in vour machine, after unpacking, please

df worry. It does not mean that the

ma^nine has been used before, it is due

to the very thorough quality control that

the machine undergoes in our factory.

aeiivers me waier lo a neau ui i.» n

through the drain hose fitted at the back

of the machine.

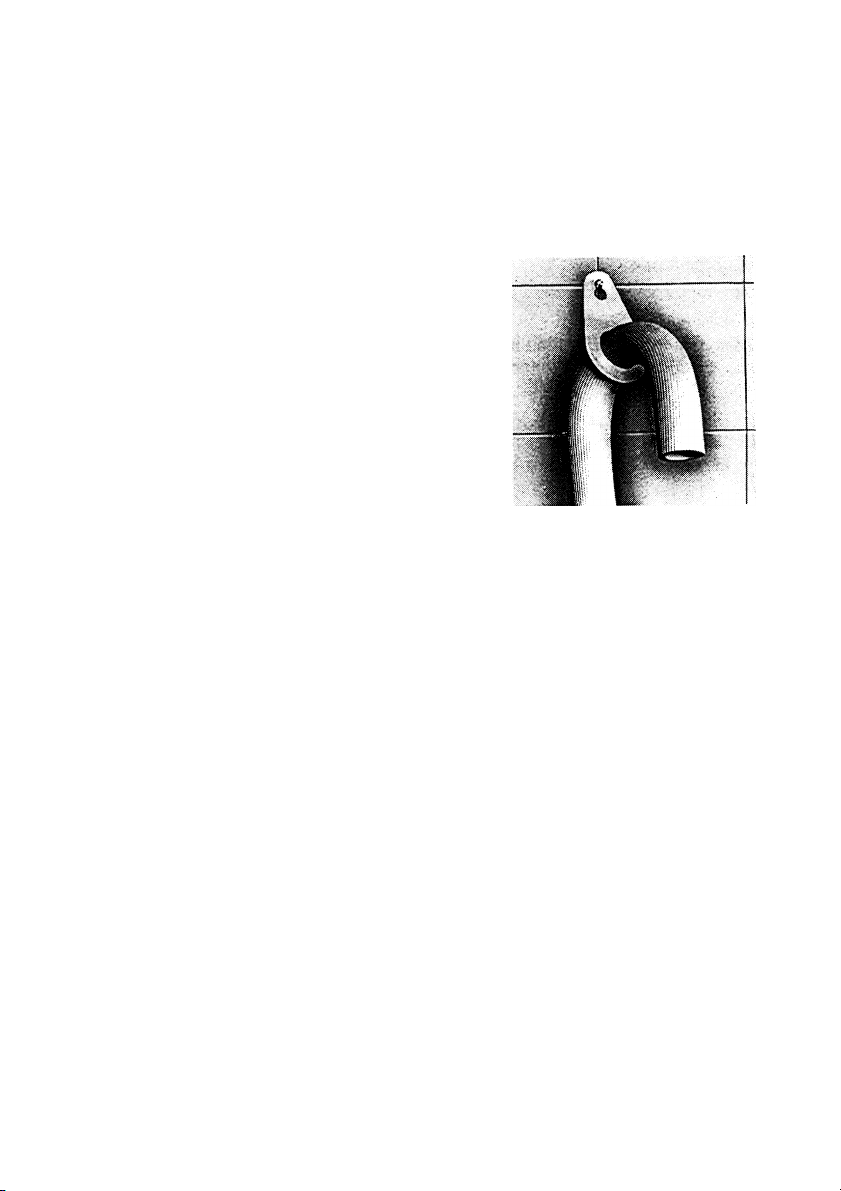

The drain hose (i/D 19 mm max.) is bent at

the end for hooking over a sink edge or si

milar receptacle. Please secure this bent

end in such a way that it cannot siip off

(especialiy where the sink or basin edge

is very wide).

If permanent connection to a siphon is re

quired, you can shohen the drain hose as

necessary (in this case the hose must be

ventilated. The necessary ventilating

valve or breather Is available from the

AEG Service Department).

When installing the machine In a room

with floor drainage (i. e. a gulley in a

laundry room), you can place the hose

directly onto the floor after cutting off the

bent part, which should be cut at an

angle. The hose has been routed inside

the machine in such a way that no water

can drain off unintentionally when the

hose is placed on the floor.

If necessary (e.g. in the case of a power

failure) the water can be drained from the

machine by carefully opening the

drainage filter. The laundry cah then be

removed from the drum as normal.

Preparing the laundry

Water drainage

To drain the machine of all soap and rinse

water, the machine is fitted with a pump,

which Is controlled by the programme. It

Preparation of your laundry prior to com

mencing washing, can be of immense be

nefit to you. Take a little time and sort

your laundry according to colour and type

of fabric. Please check the manufacturers

5

Page 6

washing label inside each garment.

Next check the pockets of each garment

for foreign bodies e. g. pins, needles,

paper clips, paper etc., close all zips.

Loosely tie long apron strings or pyjama

cords.

Please note: White fabrics should never

be washed vi/ith coloured items. If you do,

the white items will gradually become

grey in colour.

New items being washed for the first time

should always be washed separately.

This is because they tend to lose some of

their colour duringlheir first wash.

Wool: Woollen articles should only be

washed in your LAVAMAT if they are

labelled ’’Machine Washable”.

Curtains: Curtains of synthetic fibres are

very delicate and can easily be damaged

when taken down, or put back up. In most

cases the damage shows only after

washing (pulled threads etc.). We cannot

accept any responsibility for curtains so

damaged. If your curtains are particularly

delicate, then we recommend that they be

hand washed.

Washing pow^r dispenser

The washing powder dispenser operates

automatically. You can add the washing

powder for prewash and main wash, as

well as the fabric conditioner at the start

of the programme, namely

compartment A (centre) for the prewash,

compartment B (front) for the main wash,

compartment C (rear) for after-care.

Please use only liquids in compartment C

(e. g. fabric conditioner) and do not add

more than up to the level of the red mark

in compartment C.

Red mark = load limit

Load sizes

Washing

Normally soiled whites or coloureds —

Maximum 5 kg (11 lbs) dry laundry weight.

The drum has been correctly loaded when

you can still turn your hand freely bet

ween drum wall and the laundry.

Heavily soiled whites or coloureds (cot

tons and linens) — up to 4 kg (9 lbs) dry

laundry weight. (Items like work clothes,

overalls etc). The reason for the reduced

load is that heavily soiled garments need

the additional space for good wash re

sults.

Easy care fabrics, synthetics and wool

lens — up to 1.5 kg {Vi lbs) dry laundry

weight. This is the equivalent to 6-8shirts.

In this case the reason for the reduced

load is that these types of fabric float in

the water to minimise creasing.

If you want to use a fabric conditioner in

powder form, such as starch, then this

should be dissolved in accordance with

the manufacturer’s instructions and

poured directly into the drum. Alternative

ly, pull out the dispenser and po he

starch slowly into compartment B.

Piease ensure that the dispens'^*^^ is

pushed home fuiiy after ioading i ith

washing powder etc. As otherwise' no

water can come into the machine.

Wash powders

There are many different types of washing

powders on the market today. Please do

not use ordinary powders like Ariel,

Radiant, Daz etc., in your new AEG

LAVAMAT. The reason for this is very

simpie, these powders produce so much

Page 7

lather that the clothes are prevented from

tumbling freely durr the washing cycle,

therefore they do wt get a thorough

wash.

Do use the right powder. To get the best

results, we recommend the use of PERSIL

AUTOMATIC. Like'all modern automatic

machines the LAVAMAT works at peak

efficiency with a low lather product.

PERSIL AUTOMATIC'S balanced lather is

specially designed to complement the

cleaning action of the machine. Do use

enough powder. Follow the manufactu

rer’s recommended dosage. Please bear

in id that the correct amount of powder

de,. .ids on a number of factors — the

hardness of the water, the size of the load

an'“ *he amount of soiling of the laundry.

Pi' 'se note: On ’Economy’ programmes

fc nail loads (using button Vz). These do

not require the full amount of powder. Use

about 30 to 40 % less than for a normal

programme with a full wash load.

Overfoaming can be caused by several

things:

1. wrong type of powder

2. too much washing powder in conjunc

tion with soft water

3. when washing very small loads.

To correct overfoaming (1) use a powder

specially formulated for front loading

automatics, (2) and (3) reduce the amount

of '«ashing powder used.

Page 8

Controls

Selector buttons Control lamp

2) Temperature cojpl<pl

With the temper^.dre control is in posi

tion ’0’ you can actually wash cold

(woollens for example). Between 30°C

and 95°C the temperature is infinitely

variable.

Please note the washing instructions

on the labels Inside your garments.

3) Selector buttons

Programme switch Temperature control

1) Programme switch

The programme switch has 8 settings

for the basic programmes:

1 wash programme with prewash

2 wash programme without prewash

3 fabric softening — starching —

spinning

4 pumping — spinning

5 woollens

6 short spin (automatic SL action)

7 soaking — extra prewash

8 pumping

With the exception of woollens, you

can wash ail fabrics with or without

prewash, depending on their degree of

soiling. Wooilens are washed on a

main wash only.

The programme selector should al

ways be operated rn clockwise direc

tion.

Button

Button Q] Switch off

When depressing button you

cancel the function of ail other

buttons.

Button VIll

Economy button for small loads

This economy button means that you

need not to work with the same water,

power and washing powder consump

tion as for full loads. Instead, you can

make savings all round.

Effect: reduced water level during

washing and rinsing. Depending on the

actual programme, you save up to 45 %

of water, up to 45% power and up to

20% time. The amount of washing

powder is also reduced.

Application: for small loads — about

half a drum full (up to 2Vz kg of whites

and coloureds, up to 0.8 kg of

care fabrics and synthetics).

Used with programmes 1, 2, 3.

Please note, that optimal economy . id

that the most favourable consump n

of water, electricity and wash pov jr

can only be achieved when the full

capacity of the drum is used.

Button [e] Energy saving

By selecting this button in conjunction

with programme 1 or 2 the water tem

perature is limited to 60°C and the

length of the wash is extended to that

Switch on

Page 9

of a 95°C wash pi:agrarpme. This

means you can expc the same re

sults as the 95 ®G wash programme,

providing the laundry is only slightly

soiled. Furtherhnore, you save electrici

ty and the wear and tear on your

laundry Is reduced.

Used with programmes 1, 2, 3.

Button \l/2/-t-[E]

Naturally, It Is also possible to com

bine these two buttons when washing

small loads of lightly soiled laundry.

You save even more electricity, water

a'''' ash powder.

You cannot combine the energy saving

button [i] with buttons tzJ ^nd

Bu**">n tZi

water level (rinse water stop)

Effect: The laundry is washed at a

high water level, but with normal

drum movement. The laundry is left

floating in the last rinse water (rinse

water stop).

Application: for synthetics or synthe-

tic/cotton mixtures which require a

high water level, e.g. all outer garments

such as blouses, shirts, skirts, dres

ses, trousers etc. bearing the HLCC

symbols:

Used with programmes 1, 2 and 3.

Bv ^ LJ

Reu^^ed drum movement

Effect: Depression of this button re-

su in a reduced drum movement

(reouced mechanics) coupled with a

nc il water level. In addition, the

lauiiory if left in the last rinse water

(rinse water stop).

Application: for baby clothes, cotton

mixtures or synthetics e. g. sheets,

underwear etc. which do not require a

high water level bearing HLCC sym

Buttons: tH/ -f \ /

High water level combined with re

duced drum movement. For particular

ly delicate fabrics which require a high

water level and a gentle wash action.

Please note:

in the case of programmes where the

last rinsing water or the soak water is

left in the machine (buttons XZJ ,

\u . a + W , as well as

programmes 5 and 7) It Is necessary to

first pump off the water before the door

Is opened. This can be done in diffe

rent. ways, depending on the type of

fabric involved. (See programme chart

’’Additional Programmes”).

Wash programmes

The basic programmes of your LAVAMAT

can be adapted for practically all kinds of

fabric by using the selector buttons and

temperature controls. You can vary the

programmes to suit your particular re

quirements.

Your LAVAMAT is an advanced piece of

technology. We have taken care of the

future — this means any future develop

ments by the textile Industry can be

catered for.

On page 10 and 11 is a table showing the

major programmes. Please study this

table and find out the many possibilities

open to you before putting your washing

machine into operation.

The water symbols used in the table are

explained as follows: —

normal water level

^ high water level

\60*c] \50*c/

Used with programmes 1, 2, 3, 7.

Page 10

Main programmes

Load size

T> )f laundry

Cottons and linens 30® C to

with prewash 95 °C

Cottons and linens 30° C to

without prewash 95°C

fi] Whites 95 °C

'— with prewash

[e] Whites 95 ®C

without prewash

Easy-care fabrics 30°Cto

with prewash tzz/ 95 °C

Easy-care fabrics 30 ° C to

without prewash tzd 95°C

Easy-care fabrics ^ 30®Cto

with prewash tui 60 ® C

Easy-care fabrics 30® to

without prewash tZi/ 60 ® C

Woollens tZi ooldto

30®C

5 kg max. cotton, linen

e.g. bed linen, table linen,

underwear, shirts, towels,

tea cloths, aprons etc.

5 kg max.

\9fc]

5 kg max. cotton, linen etc.

lightly soiled

5 kg max.

1.5 kg max.

1.5 kg max.

@ ^ ®

special finish cotton, cotton mixtures,

synthetics which do not

require a high water level

1.5 kg max.

1,5 kg max.

\60*c7 \^*c/ \40^

nylon, polyester, cotton mixtures,

cotton with special finishes; all

outer garments which require a

high water level

1,5 kg max.

3 4 6

\60*c/ \^/

1.0 kg max.

fabrics of machine-washable wool

or wool mixtures

Additional Programmes

Soft rinsing, starching, spinning 5 kg max. cotton, linen

Soft rinsing, starching tZi/ 1.5 kg max. easy-care fabrics, synthetics

Soaking — (extra) prewash 4.0 kg max.

Pumping, spinning

Pumping, Variomatic spinning

5 kg max.

1,5 kg max.

cotton, linen, very heavily soiled

cotton, linen

easy-care fabrics, synthetics,

delicate cotton fabrics

Pumping — short spinning

1.0 kg max.

woollens, wool mixtures

automatic SL action

Pumping

easy-care fabrics which must

not be spun

10

tzJ = RINSE WATER STOP! First pump off the water before the door Is opened.

Page 11

Programme setting <

Programm« Button Temp,

switch control

\vater Wash

' level powder

dispenser

Programme cycle

1 30°Cto

95 °C

2 30°Cto

95°C

1 [|] 95°C

2 [|] 95°C

1 LJ 30-Cto

95-C

2 LJ 30°Cto

95°C

1 30”Cto

60-c

2 tZ/ 30»Cto

60°C

5 cold to

3o:*c

^ ABC

Q B c

Q ABC

Q Bc

Q A BC

Q BC

^ ABC

^ B c

^ B c

Prewash — main wash at normal water level

cooling — 5 rinses — spinning

Main wash at normal water level — cooling —

5 rinses — spinning

Prewash — main wash at normal water level

60°C — cooling — 5 rinses — spinning

Main wash at normal water level 60°C — cooling

— 5 rinses — spinning

Prewash — main wash with reduced drum move

ment, normal water level — cooling — 4 rinses —

the laundry is left In the last rinse water

Main wash with reduced drum movement,

normal water level — cooling — 4 rinses —

the laundry is left in the last rinse water

Prewash — main wash at high water level —

cooling — 4 rinses — the laundry is left floating

in the last rinse water

Main wash at high water level — cooling —

4 rinses — the laundry is left floating in the last

rinse water

Main wash at high water level and particularly

gentle drum movement — 3 rinses — the laundry

is left floating in the last rinse water

3

4

4 a

6

8

7 upto40°C

9 *

'

# <=

• 0

Rinsing and spinning

Rinsing — the laundry Is left floating in the last

rinse water

Prewash at high water level — the laundry is left

floating in the soap water

Spinning

Gentle spinning — (repeated short spins followed

by loosening action)

Pumping — short spin

Pumping

Page 12

Operating procedure

Washing

ana me programrne seleoior temams in

the relevant cut-< oosition (one of the

breaks in the cycle indicator band).

Plug the machine In or switch on (If permanently connected).

Hook the drain hose over sink edge.

Uniess piumbed in, connect the suppiy

hose to the tap.

Open the tap.

Open the door.

Load with dry iaundry.

Ciose inner and outer doors.

Please ensure that both doors àr« closed

properly as otherwise the programme

cannot start. The outer door must engage.

Puli out the drawer type washing powder

dispenser.

Add washing powder.

Push the dispenser back in.

Select the required temperature.

Rotating the programme selector in

clockwise direction, set it to the required

position.

Press buttons as necessary ( tH/ ,

, \W2y or E).

Press button

The control light goes out.

Return the temperature control to ”0”.

If the programme ends with the laundry in

the last rinse water, remember to pump

off the water before opening the door.

Open the door (on programmes with

spinning cycle this is not possible until

approx. 1 minute after completion of the

programme — safety feature.)

Remove the iaundry.

if you have nothing else to wash, retóse

the tap, pull the plug out of the so. or

switch off.

Press button [T]

The programme starts.

The left control lamp lights up.

The programme selector begins to rotate.

It stops during heating-up until the re

quired temperature is reached.

Opening of the outer door during opera

tion will immediately interrupt the pro

gramme.

It Is not possible to open the door during

spinning (safety feature).

Please remember that the glass of the

door gets hot during washing (do not

touch). The door features a safety lock

and cannot be opened during a pro

gramme cycle.

On completion of the programme

the machine switches off automatically

12

Maintenance

When you have done all your wa ig,

close the tap and pull the plug out or the

socket or switch off the main switch.

Leave the door open for a short while to

allow the machine to dry out. Remove any

washing powder left in the dispenser. To

do this, hold the dispenser with both

hands, lift and pull out completely, giving

it a short sharp pull.

Page 13

Should your machine show grey deposits

of lime, please do not try to remove them

by unsuitable means, but contact your

AEG Service Department instead.

If there is a danger of frost, empty the

machine beforehand of all water by ope

ning the drain filter. Unscrew the supply

hose and let this drain as well.

What can be the cause when ...

Non-functioning of your automatic

washing machine is mostly due to the

following which you can rectify yourself.

What is important is that you regulariy

ciean the drain filter.

To do this, place a flat dish on the floor

below the filter outlet bottom left. Next

fold down the lower front panel (where the

machine has been built in, you should use

the plastic hook provided for the purpose)

and give the filter cover about a half a turn

in r ‘’-clockwise direction. The water can

no. .rain off. Unscrew the filter com

pletely and clean It. When refitting the fil

ter -^lease ensure that it is Inserted correi in its guides and securely tightenpd.

Oc^ .oionally you should also clean the

filter in the water inlet hose.

What may look like rust stains on drum or

tub is due to ferrous foreign bodies intro

duced with the laundry or the water.

Remove such stains with a stainless steel

cleaning agent. Do not use chlorous or

ferrous scouring powders. Never use

acids, chloride or bleach in the machine.

The programme does not start.

Has the machine been plugged in or

switched on?

Are the fuses in order?

Have the doors of the machin.^ been

closed properly? '

Is button in depressed?^

Too little or no water in coming in.

Has the tap been O/pened?

Has the washing /powder dispenser been

fully pushed home?

Is the filter In thè water supply line

blocked?

It should be cleaned from time to time.

Is'the supply hose kinked?

Is the water pressure too low?

The water is immediately running off

again through the drain hose.

Please note that the discharge end of the

drain hose must not be Immersed In the

pumped-off water (siphon action).

13

Page 14

The programme switch stops during the

programme cycie.

Your fully automatic machine has been

fitted with the Thermo-Chron control

system. This means that the control knob

stops during prewash and main wash

until the required temperature is reached.

The washing powder foams excessiveiy.

Too much washing powder or the wrong

powder has been used. Omit the prewash

from your next programme or reduce the

amount of washing powder used. Use a

low lather powder.

The programme (white or coioureds) has

been compieted without spinning.

The thermal protection device of the

motor has tripped. Possible causes:

blocked drain filter, kinked drain hose.

The spinning cycle will automatically co

me on again after a certain period has

elapsed (up to an hour).

The door cannot be opened immediately

on completion of the programme cycle.

Please wait until the release time of the

door locking mechanism has elapsed

(about 1 minute).

Should you be unable to locate the cause

of a problem in s^ i of the above check

list, then please coTitact your AEG Service

Department. To assist our service staff,

please quote the E-number of your ma

chine which you find on the inside front

cover of this booklet or on the rating plate

of your machine.

If you call a service engineer in connec

tion with one of the aforementioned pro

blems, please note that the cost involved

will have to be passed on even during the

warranty period.

A more comprehensive guaran' is

offered by our AEG Service Club. ■ or a

modest annual premium you can sign a

service agreement with our Tec’ cal

Service to cover your machine.

14

Page 15

Page 16

Subject to change without notice

H 245 256 240 - 07801./31 —

AEG

Loading...

Loading...