Page 1

LAVAMAT 50610

Washing machine

User information

Page 2

Dear customer,

Please read this User Information carefully and keep it to refer to at a

later date.

Pass this User Information on to any subsequent owner of the appliance.

The following symbols are used in the text:

1 Safety instructions

Warning: Notes that concern your personal safety.

Attention: Notes that show how to avoid damage to the appliance.

3 Useful tips and hints

2 Environmental information

2

Page 3

Contents

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Description of the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Programme overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Before the first wash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Preparing and sorting washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Running a washing cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Opening the door/Loading the washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Adding detergent/ additives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Switching on the appliance/selecting a programme . . . . . . . . . . . . . . . . . . . 13

Changing the spin speed/Selecting rinse hold . . . . . . . . . . . . . . . . . . . . . . . . 13

Selecting programme options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

PRE WASH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

STAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Activating/deactivating RINSE+. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting the delay timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Starting a programme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Interrupting a programme/adding washing . . . . . . . . . . . . . . . . . . . . . . . . . . 15

End of the wash programme/Removing the washing . . . . . . . . . . . . . . . . . . 16

Child safety device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cleaning and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

What to do if.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Remedying minor malfunctions yourself . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

If the wash results are not satisfactory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Carrying out an emergency drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Drain pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Consumption values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3

Page 4

Installation and connection instructions. . . . . . . . . . . . . . . . . 26

Safety information for the installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installing the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Transporting the appliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Where to install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Making the appliance level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connecting to the water supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Water inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Water drainage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Guarantee/Customer Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4

Page 5

Operating Instructions

1 Safety

Prior to using for the first time

• Follow the ”Instructions for installation and connection”.

• If the appliance is delivered in the winter months when there are mi-

nus temperatures: Store the washing machine at room temperature

for 24 hours before using for the first time.

Correct use

• The washing machine is only designed for the washing of normal domestic laundry at home.

• Additions or modifications to the washing machine are not permitted.

• Use only detergents and additives that are suitable for use in domestic washing machines.

• The washing must not contain any inflammable solutions. Danger of

explosion!

• Do not use the washing machine for dry cleaning.

• Dyes/colour removers may only be used in the washing machine, if

the manufacturer of these products expressly permits this. We cannot

be held responsible for any damage arising.

Child safety

• Keep packaging away from children. There is a risk of suffocation.

• Children often do not recognise the hazards associated with electrical

appliances. Don’t allow children to use the washing machine unsupervised.

• Make sure that children and pets don’t climb into the drum of the

washing machine. Could endanger life!

5

Page 6

General safety

• Repairs to the washing machine must only be carried out by qualified

service engineers.

• Never use the washing machine if the mains cable is damaged; or if

the control panel, work top or plinth area is damaged such that the

inside of the appliance is freely accessible.

• Switch off the washing machine before cleaning, maintenance and

servicing. In addition, pull the mains plug out of the socket or – in

the case of a permanent connection – switch off the cut-out in the

fuse box or remove the screw fuse completely.

• If operation is stopped, disconnect the appliance from the mains supply and shut off the water tap.

• Never unplug the appliance by pulling on the cable. Always pull the

plug.

• Multi-way plugs, connectors and extension cables must not be used.

This could constitute a fire hazard through overheating.

• Never wash the washing machine down with a water jet. Danger of

electric shock!

• In washing programmes with high temperatures the glass in the door

gets hot. Do not touch it.

• Before emergency emptying of the appliance, before cleaning the

drain pump or opening the door in an emergency, let the water cool

down.

• Small animals can nibble at the cables and water hoses. Danger of

electric shock and danger of water damage! Keep small animals away

from the washing machine.

6

Page 7

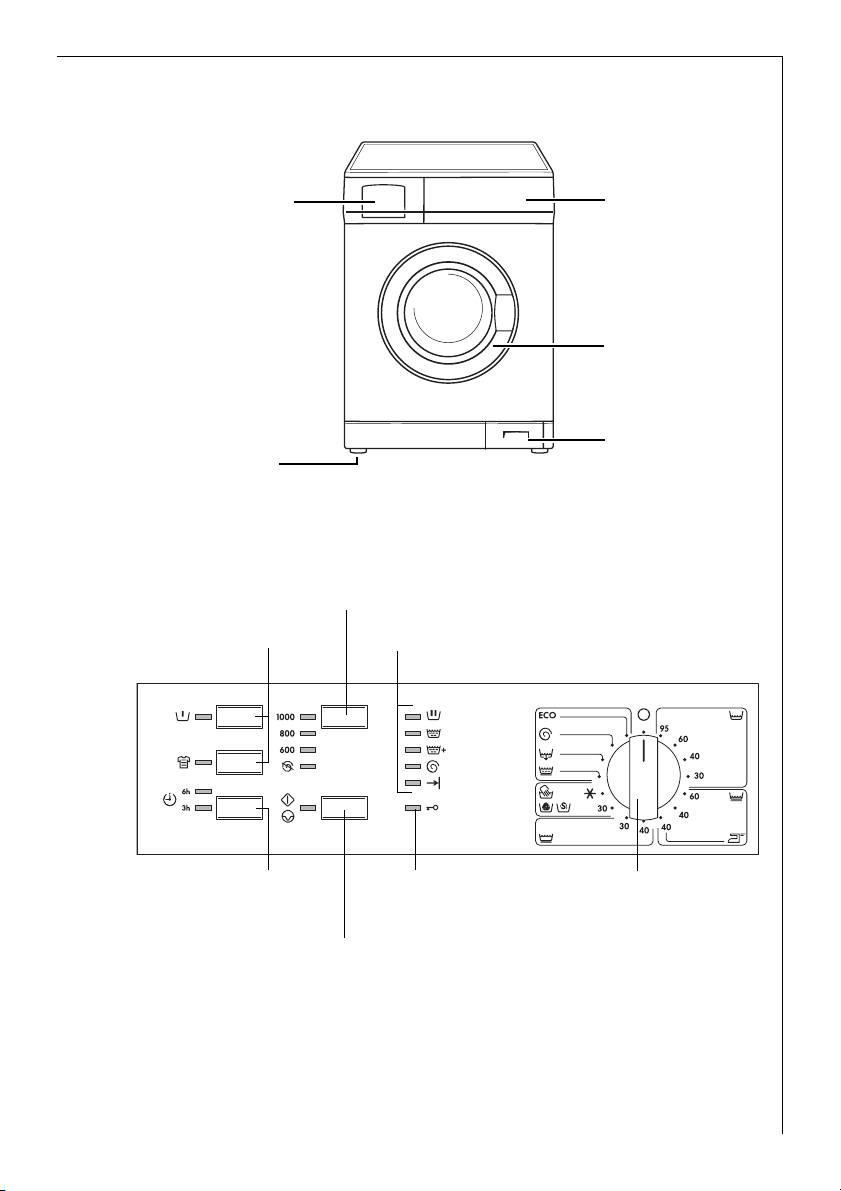

Description of the appliance

Detergent dispenser

drawer

Screw feet

(height adjustable)

Control Panel

SPIN/RINSE HOLD button

Programme option buttons

Control panel

Rating plate

(behind door)

Plinth flap/

Drain pump

Programme Progress display

DELAY TIMER button

START/PAUSE button

DOOR indicator

Programme knob

7

Page 8

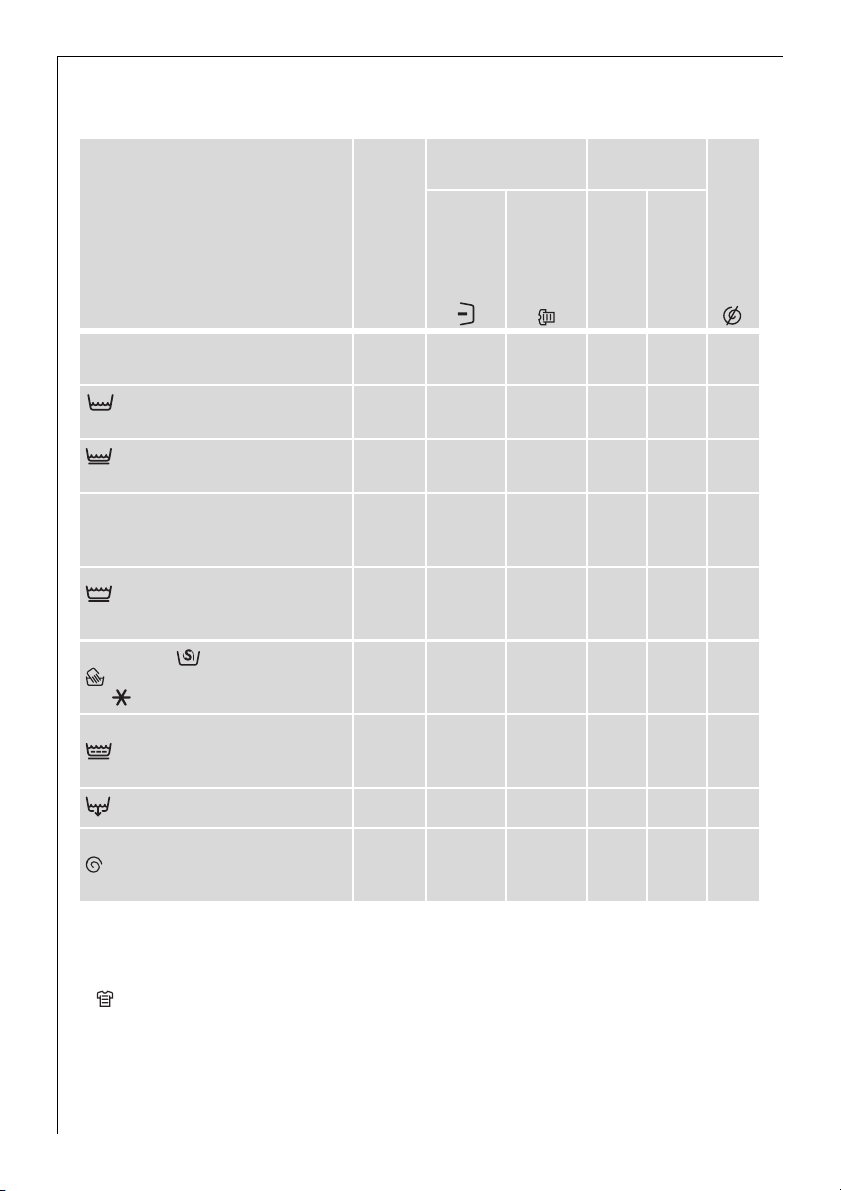

Programme overview

Programme options Spin speed

Programme

ECO (ENERGY SAVING)

(COTTONS/LINEN)

95, 60, 40, 30

(EASY-CARE)

60, 40

l (EASY IRON) 40 1kg • • • • •

(DELICATE)

40, 30

s (WOOL)/ (SILK)

(Handwashing)

30, (COLD)

(GENTLE RINSE) 3kg • • •

(DRAIN)

2)

1)

(PRE WASH)

(dry washing)

max. load

6kg • • • • •

6kg • •3)

3kg • • • • •

3kg • • • •

2kg • • •

(STAIN)

4)

1000 (L 50612)

850 (L 50212)

600

• • •

(RINSE HOLD)

(SPIN) 6kg • •

1) A 10 litre bucket contains approximately 2.5 kg of dry washing (cotton)

2) Programme settings for tests in accordance with or in the style of EN 60 456 and IEC 60 456 are

described in the section ”Consumption values”.

3) Recommended load for short progammes is 3kg; full loading is possible however with somewhat reduced cleaning results.

4) (STAIN) can be set at 40° and upwards only, as stain treatments are effective only at higher tempera-

tures.

8

Page 9

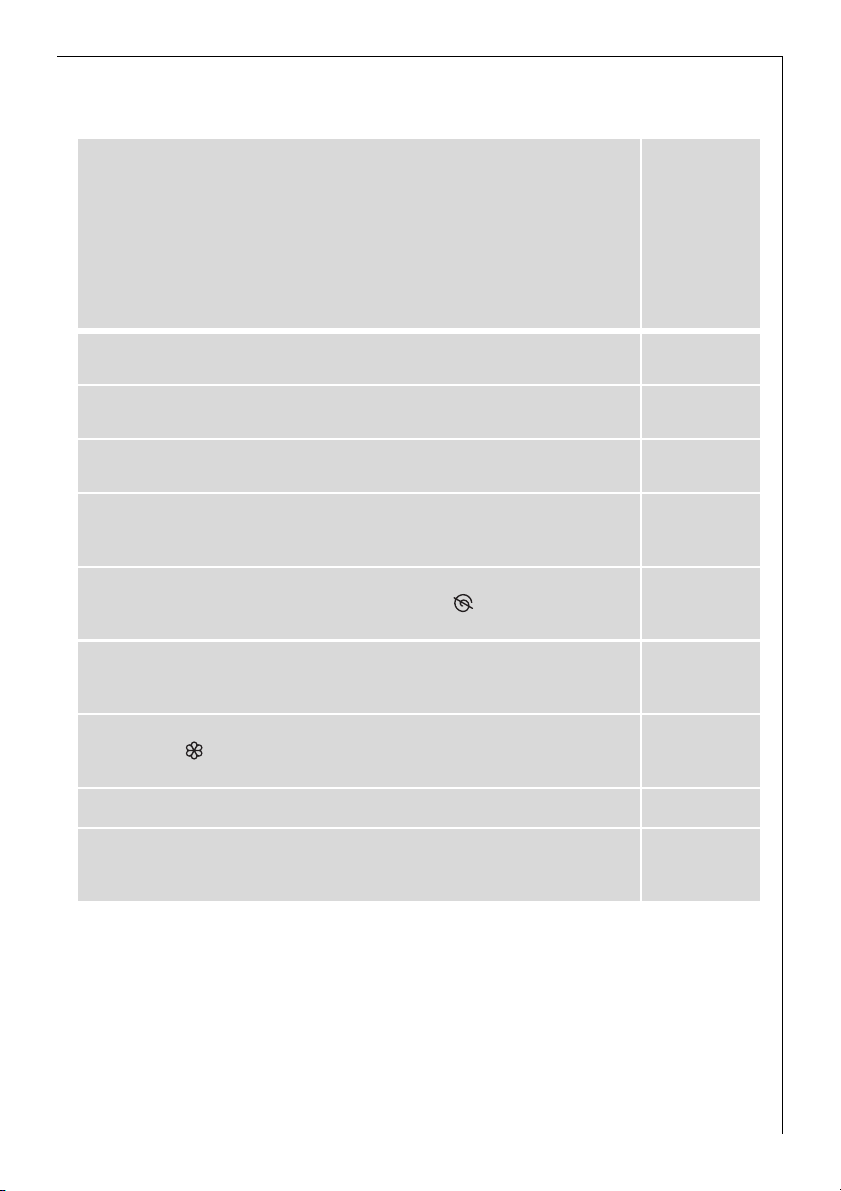

Application/Features

Care

symbols

1)

Energy saving programme which washes at 60 °C for lightly to normally

soiled whites/coloureds made of cotton/linen.

Programme for normally to heavily soiled whites/coloureds made of cotton/

linen.

Programme for easy-care mixed fibres and synthetics.

Wash programme which washes at 40 °C for easy-care fabrics which after

being washed using this programme need to be ironed only lightly or not at

all.

Gentle programme for fine fabrics such as layered fibres, micro-fibres, synthetics, curtains (load max. 20 to 25 m

also suitable for items with a climatic membrane, e.g. outdoor clothing.

Particularly gentle programme for machine washable and hand washable

wool/silk.

Separate gentle rinse (3 rinse cycles, liquid conditioner is washed in from

compartment , spin). Not suitable for wool. Reduce the spin speed when

rinsing easy-care and delicate items.

Pumps water away after a rinse hold.

Draining and spinning e.g. following rinse hold, or separate spinning of handwashed cottons/linen. Reduce the spin speed when rinsing easy-care, delicate

and wool items.

1) The figures in the care symbols indicate the maximum temperatures.

2

curtains). If (RINSE HOLD) is used,

M O

J M O

I K N

K N

I K

Q L H

J M O

J M O

9

Page 10

Before the first wash

1. Open the detergent dispenser drawer.

2. Pour about 2 litres of water through the detergent dispenser drawer

into the washing machine.

This closes the water container when the next programme is started

and the economy valve can function properly.

3. In order to remove any residues from the drum and water container

which may have been left during manufacturing, perform the first

wash cycle without any washing in the machine. Programme:

(COTTONS/LINEN) 95, add 1/4 of a measuring cup of washing powder.

Preparing and sorting washing

Preparing washing

• Empty pockets. Remove foreign bodies (e. g. coins, paper clips, nails,

etc.).

• Do up zips, button up covers to prevent damage to washing.

• Remove the runners from net curtains or cover them with a net or a

bag.

• Wash sensitive and small items in a net or a pillow case, e.g. net cur-

tains, tights, socks, handkerchiefs, bras.

Important! Bras and other items containing wires should only be

washed in a net bag. The wires can work loose and damage the appliance.

10

Sorting washing

• By colour: Wash white and coloured washing separately. Washing can

run.

• By temperature, type of washing and care symbol.

Important! Do not wash fabrics with care symbol G (= do not wash!)

in the washing machine.

Page 11

Running a washing cycle

Opening the door/Loading the washing

1. To open the door: pull the door’s handle.

When the appliance is switched on, the K(DOOR) and (START/

PAUSE) indicators show whether the door can be opened:

K

(DOOR) indicator

flashing flashing

illuminated illuminated

off flashing yes

(START/PAUSE)

indicator

Can the door be opened?

yes, after approx.

2minutes

no, water level and/or

temperature too high

2. Separate individual items and load

washing loosely into the machine.

Mix large and small items.

Important: Do not allow items of

clothing to get caught between the

door and the rubber seal.

3. Press the door firmly shut. The catch

must audibly latch.

Adding detergent/additives

Warning! Use only detergents and additives that are suitable for use in

domestic washing machines.

1 For USA and Canada only!

Important! Only LOW-SUDSING detergent suitable for a front-loading

washing machine can be used in this machine. This machine can heat

the water up to 95 degrees celsius, or 200 degrees fahrenheit, and care

should be taken to ensure that the correct washing powder is used. If

you have any doubt, check with your dealer or the distributor.

WARRANTY AND CONSEQUENTIAL DAMAGES ARE VOIDED IF A LOW

SUDSING DETERGENT IS NOT USED.

Dose detergent and additives according to the instructions of the detergent and additive manufacturers. Follow the advice on the packaging.

11

Page 12

Dosing depends upon:

– the washing’s degree of soiling,

– the size of the load

– the degree of hardness of the water supply.

• If the manufacturer does not give instructions for small loads: for a

half load, use a third less, for a very small load, use only half of the

detergent that is recommended for a full load.

• From water hardness 2 (= medium) upwards, water softener should

be used. Detergent can then always be dosed for water hardness 1

(= soft). Your local water company will be able to give you information about the water hardness in your area.

1. Pull the detergent dispenser drawer out as far as the stop.

2. Add the detergent/additives.

3. Push the drawer in fully.

Washing powder/tablets

for the main wash

Softeners/

wash-care products

to preserve the shape

of garments/

starch

Washing powder/tablets

for the pre-wash or inwash stain treatment

Washing powder/tablets for the main wash

If you are using water softener and need the right-hand compartment

for the pre-wash/stain treatment agent, add the water softener to the

main wash detergent in the left compartment.

Softeners, wash-care products to preserve the shape of garments,

starch

Do not fill the compartment beyond the MAX mark. Dilute thick liquid

concentrates according to the manufacturer’s instructions before

putting them into the drawer. Dissolve powder starches.

If you use liquid detergents:

Add liquid detergent using the dosage containers provided by the detergent manufacturer.

12

Page 13

Switching on the appliance/selecting a programme

Set the programme and temperature using the programme knob.

3 By selecting a programme, you

switch the appliance on at the

same time.

The programme progress display

indicates the programme steps

that the selected programme will

perform.

Changing the spin speed/Selecting rinse hold

The washing machine suggests the

maximum permitted spin speed

that is suitable for the selected programme. You can reduce this spin

speed:

To do this press the Spin/ (RINSE

HOLD) button repeatedly until the

desired indicator lights up.

3 The speed for the final spin can still be altered during the programme.

To do this:

1. Press the (START/PAUSE) button.

2. Change the spin speed.

3. Press the (START/PAUSE) button again.

(RINSE HOLD)

If (RINSE HOLD) is used, the washing remains submerged in the final

rinse water. There is no final spin, only an intermediate spin. The intermediate spin cycle depends on the selected programme and cannot be

changed.

13

Page 14

Selecting programme options

If desired, press the programme option button(s). The corresponding

indicator lights up.

PRE WASH

Warm pre-wash before the main

wash that follows automatically; with intermediate spin for

(COTTONS/LINEN) and (EASY-CARE)/

l (EASY IRON), without

intermediate spin for (DELICATES).

STAIN

For treating heavily soiled or stained washing. In-wash stain treatments

are washed in at the optimum time as the programme progresses.

Activating/deactivating RINSE+

If (RINSE+) is activated, two additional rinse cycles take place

during the (COTTONS/LINEN), (EASY-CARE)/

(DELICATE) and (GENTLE RINSE) programmes. (RINSE+)

remains permanently programmed – even after the appliance has been

switched off.

Activating (RINSE+):

1. Turn programme knob to (COTTONS/LINEN), (EASY-CARE)/

l (EASY IRON) or (DELICATE) (at any temperature).

2. Press the (PRE WASH) and (DELAY TIMER) buttons simultaneous-

ly until (RINSE) and (RINSE+) are illuminated in the programme progress display. (RINSE+) is now permanently activated.

(RINSE+) is illuminated in the programme progress display prior

to the start of a programme and while the additional rinse cycles are

taking place.

l (EASY IRON),

Deactivating (RINSE+):

1. Turn programme knob to (COTTONS/LINEN), (EASY-CARE)/

l (EASY IRON) or (DELICATE) (at any temperature).

2. Press the (PRE WASH) and (DELAY TIMER) buttons simultaneous-

ly until (RINSE+) is no longer illuminated in the programme

progress display. (RINSE+) is now permanently deactivated.

14

Page 15

Setting the delay timer

The (DELAY TIMER) button allows you to delay the start of a

programme.

1. Select a programme.

2. Press the (DELAY TIMER) button once if you would like the wash

programme to begin in 6 hours. The 6h indicator will illuminate. Press

the (DELAY TIMER) button twice if you would like the wash programme to begin in 3 hours. The 3h indicator will illuminate.

3 If you press the (DELAY TIMER) button once again the delay timer

setting is cancelled. The indicator goes out.

3. To activate the delay timer, press the (START/PAUSE) button.

Note: If a start delay of 6 hours is selected, the 6h indicator will illumi-

nate. After 3 hours the indicator will change and 3h will illuminate. Af-

ter a total of 6 hours the wash programme will begin.

Starting a programme

1. Check that the tap is turned on.

2. Press the (START/PAUSE) button. The programme starts or will

start after the delay timer has elapsed as set.

During the wash programme the current stage of the programme is

shown in the programme progress display.

3 If after pressing the (START/PAUSE) button the (END) display

flashes 4x, the door has not been closed properly. Push the door firmly

closed and press the (START/PAUSE) button again.

Interrupting a programme/adding washing

Interrupting a programme

• A washing programme can be interrupted at any time by pressing the

(START/PAUSE) button. It is then re-started by pressing the

(START/PAUSE) button again.

• To stop the washing machine before the programme has ended, turn

the programme knob to (OFF). Important! Be careful if there is

water in the appliance!

Adding washing

It is possible to add washing, as long as the (DOOR) light is not lit.

1. Press the (START/PAUSE) button. The door can be opened.

2. Shut door and press the (START/PAUSE) button again. The pro-

gramme continues.

15

Page 16

End of the wash programme/ Removing the washing

When the programme has finished, (END) will illuminate in the programme progress display. As soon as the (DOOR) indicator has gone

out and the (END) indicator is illuminated, the door can be opened.

1. Open the door and remove the washing.

2. Turn the programme knob to (OFF).

3. Turn off the tap.

4. After the machine has finished washing, pull out the detergent drawer

a little to let it dry out. Keep the door very slightly open so that the

washing machine can air.

If (RINSE HOLD) was selected:

After a rinse hold (DOOR) and (END) will illuminate in the programme progress display.

The water must first be drained:

– Either turn the programme selector to (OFF), then to (DRAIN)

and press the (START /PAUSE) button (water is drained and

there is no spin cycle),

– or turn the programme selector to (OFF) and then to (SPIN). De-

pending on the type of washing, if required reduce the spin speed

and press the (START /PAUSE) button (water is drained and

there is a spin cycle).

16

Page 17

Child safety device

When the child safety device is set, the door can no longer be closed.

Setting the child safety device:

Use a coin to turn the knob (on the

inside of the door) in a clockwise direction as far as it will go.

1 Warning! The knob must not be

sunk-in after being set, otherwise

the child safety device is not active.

The knob must stand out as shown

in the illustration.

Releasing the child safety device:

Turn the knob anti-clockwise as far

as it will go.

Cleaning and maintenance

Important! Do not use furniture care products or aggressive cleaners to

clean the appliance.

Wipe control panel and body with a damp cloth.

Cleaning procedure

If you plan to wash mainly at low temperature, you should run a hot

programme from time to time. This will reduce any deposits and clean

the appliance from the inside.

17

Page 18

Detergent dispenser drawer

The detergent dispenser drawer should be cleaned regularly.

1. Remove the detergent dispenser drawer by pulling it firmly.

2. Remove the conditioner insert from

the middle compartment.

3. Clean all parts with water.

4. Put the conditioner insert in as far as

it will go, so that it is firmly in place.

5. Clean all parts of the washing machine, especially the nozzles in the

top of the washing-in chamber, with

a brush.

6. Insert the detergent dispenser drawer in the guide rails and push it in.

Washing drum

Rust deposits in the drum may occur due to rusting foreign bodies in

the washing or tap water containing iron.

Important! Do not clean the drum with acidic descaling agents, scouring agents containing chlorine or iron or steel wool.

1. Remove any rust deposits on the drum with a cleaning agent for stainless steel.

2. Run a washing cycle without any washing to clean off any cleaning

agent residues. Programme: (COTTONS/LINEN) 95, add approx. 1/4

measuring cup of washing powder.

18

Door and rubber collar

Regularly check whether deposits or foreign bodies are present in the

folds of the rubber collar or on the inside of the glass door.

Clean the glass in the door and the rubber collar regularly.

Page 19

What to do if...

Remedying minor malfunctions yourself

If the programme progress display shows one of the following error

messages during operation:

– (END) flashes 1x (problem with water inflow),

– (END) flashes 2x (problem with water outflow),

– (END) flashes 4x (door open),

please refer to the following table.

After the error has been remedied, press the (START/PAUSE) button.

For other error messages (one or more flashing indicators in the programme progress display):

Switch the appliance off and then on again. Reset the programme.

Press the (START/PAUSE) button.

If the error is displayed again, please contact customer service.

Problem Possible cause Remedy

Washing machine is not

working.

The door cannot be

closed.

The (END) indicator

flashes 4x.

The (END) indicator

flashes 1x.

(Problems with water

inflow)

The washing machine

vibrates when operating

or is not stable.

Mains plug not plugged in

or fuse not working.

Door not closed properly.

The (START/ PAUSE)

button was not pressed for

long enough.

Child safety device has been

activated.

The door is not closed properly.

Tap turned off. Turn on the tap.

The filter in the screw connection on the inlet hose is

blocked.

Water tap is furred with

lime scale or is faulty.

The transportation lock has

not been removed.

The screw feet are not correctly adjusted.

Connect the plug to a mains

socket. Check fuse.

Close door until the catch

audibly latches.

Press the (START/

PAUSE) button for longer.

Deactivate the child safety

device.

Close the door properly. Restart the programme.

Turn off the tap. Unscrew the

hose, remove the filter and

clean it.

Check the tap and have it repaired if necessary.

Remove the transportation

lock.

Adjust the feet as described

in the installation and connection instructions.

19

Page 20

Problem Possible cause Remedy

Washing has not been

spun.

Water is running out

from under the washing

machine.

Wash water is foaming

excessively.

The (END) indicator

flashes 2x.

(Problems with water

outflow.)

Fabric softener not

rinsed in,

w compartment for

conditioners is filled

with water.

Only a few large items of

washing in the drum.

Screw connection on the inlet hose is leaking.

Drain hose is leaking. Replace drain hose.

Drain pump cover is not

closed properly.

Washing was caught in the

door.

Emergency drain hose is

leaking.

Too much detergent has

probably been used.

Kink in drain hose. Straighten the hose.

Maximum pumping height

of 1m has been exceeded.

Drain pump is blocked.

For sink spigot connections:

The sink spigot is blocked.

Fabric softener insert in the

compartment for conditioners is not correctly inserted

or is blocked.

Always load the drum as full

as possible. Mix large and

small items.

Screw the inlet hose on

tightly.

Close the cover properly.

Load washing carefully for

the next wash.

Close off emergency drain

hose properly.

Follow the manufacturer's

instructions exactly when

measuring out detergent.

Please contact customer

service.

Switch off the appliance. Remove the mains plug.

Clean the drain pump. Remove any foreign objects

from the pump housing.

Clean the sink spigot.

Clean the detergent drawer,

insert the fabric softener

insert firmly.

20

Page 21

Problem Possible cause Remedy

Wait until the (DOOR) indicator has gone out and the

(END) indicator is illumi-

nated.

The programme will continue

when the power cut is over.

To remove washing:

If water can be seen in the

appliance, first drain the water before opening the door

(see section ”Carrying out an

emergency drain”).

Observe maximum loads.

The door cannot be

opened when the washing machine is switched

on.

Washing is very creased.

Door locked.

There has been a power cut.

(All indicators are off.)

The door will remain locked

for approx. 2 minutes.

Too much washing may

have been loaded.

If the wash results are not satisfactory

Washing is grey and scale is being deposited in the drum

• Too little detergent is being used.

• The right detergent was not used.

• Special soiling was not pre-treated.

• Programme or temperature was not correctly set.

There are grey stains on the washing.

• Washing soiled with ointment, grease or oil was washed with too lit-

tle detergent.

• It was washed at too low a temperature.

• A common cause is that fabric conditioner – especially a concentrate

– has got onto the washing. Such stains should be washed out as

quickly as possible and make sure that you are careful when using

fabric conditioner.

After the last rinse foam can still be seen.

• Modern detergents may create foam even in the last rinse cycle. The

washing is however sufficiently rinsed.

There are white residues on the washing.

• This is due to the insoluble ingredients in modern detergents.

They are not caused by insufficient rinsing.

Shake or brush the washing. If possible turn the washing inside out

before washing. Check your choice of detergent. Especially with dark

colours it is advisable to use liquid detergents.

21

Page 22

Carrying out an emergency drain

1 Warning! Before emergency draining, switch off the washing machine

and remove the mains plug from the socket.

Warning! The water that comes out of the emergency drain hose may

be hot. There is a risk of scalding. Let the water cool before performing

an emergency drain.

1. Open the plinth flap and remove it.

2. Take out the emergency drain hose.

3. Place a shallow container under-

neath it. Then loosen the drain plug

by turning it in an anti-clockwise

direction and pull it out.

4. The water runs out. If it is necessary

to empty the container more than

once, seal up the emergency drain

hose with the drain plug while you

are doing so.

When the water has all drained away:

5. Push the drain plug firmly into the emergency drain hose and screw it

tight in a clockwise direction.

6. Place the emergency drain hose back in the support.

7. Insert the plinth flap and close it.

22

Page 23

Drain pump

The drain pump is maintenance-free. It is only necessary to open the

pump cover if there is a malfunction and water is no longer being

pumped out, e. g. if the pump wheel is blocked.

Please make sure before loading the washing that there are no foreign

bodies in the pockets or caught between the washing. Paperclips, nails,

etc. that may have got into the washing machine with the washing remain in the pump housing (foreign body trap that protects the pump

wheel).

1 Warning! Before opening the pump cover, switch off the washing ma-

chine and remove the mains plug from the socket.

1. First carry out an emergency drain.

2. Place a cloth on the floor in front of the drain pump cover.

Residual water runs out.

3. Unscrew the pump cover in an anticlockwise direction and remove it.

4. Remove foreign bodies and fluff

from the pump housing and from

the pump wheel.

5. Check whether the pump wheel

right at the back of the pump housing can turn. (It is normal for the

pumping wheel to turn jerkily.) If

the pumping wheel cannot be

turned, please contact the Customer

Care Department.

6. Insert the pump cover. Insert the

guides at the sides of the cover into

the guide slots and tighten the cover by turning in a clockwise

direction.

7. Close off the emergency drain hose

and place it in the support.

8. Close plinth flap.

23

Page 24

Disposal

Packaging material

2

The packaging materials are environmentally friendly and can be recycled. The plastic components are identified by markings, e.g. >PE<,

>PS<, etc. Please dispose of the packaging materials in the appropriate

container at the community waste disposal facilities.

2 Old appliance

The symbol

product may not be treated as household waste. Instead it shall be

handed over to the applicable collection point for the recycling of electrical and electronic equipment. By ensuring this product is disposed of

correctly, you will help prevent potential negative consequences for the

environment and human health, which could otherwise be caused by

inappropriate waste handling of this product. For more detailed information about recycling of this product, please contact your local city

office, your household waste disposal service or the shop where you

purchased the product.

W on the product or on its packaging indicates that this

1 Warning! When an appliance is finished with, remove the plug from

the mains socket. Cut off the cable and plug and dispose of them.

Destroy the door lock. This prevents children from trapping themselves

inside and endangering their lives.

24

Page 25

Technical data

This appliance conforms with the following EU Directives:

5

– 73/23/EEC dated 19.02.1973 Low Voltage Directive

– 89/336/EEC dated 03.05.1989 EMC Directive inclusive of Amending

Directive 92/31/EEC

– 93/68/EEC dated 22.07.1993 CE Marking Directive

Height x Width x Depth 850 x 598 x 603 mm

Depth when door is open 980 mm

Height adjustment approx. +10/-5mm

Load (depending on programme) Max. 6 kg

Area of use Domestic

Drum spin speed see programme overview

Water pressure 1-10bar (=10–100N/cm2=0.1–1.0MPa)

Consumption values

The consumption values were obtained under standardised conditions.

They may vary when operating in domestic conditions.

Programme selector

(Temperature)

(COTTONS/LINEN) 95 6 62 2,20 146

ECO (ENERGY SAVING)

(COTTONS/LINEN) 40 6 58 0,70 129

(EASY-CARE) 40 3 58 0,52 80

(DELICATE) 30 3 58 0,42 66

s (WOOL)/ Ñ (SILK)

(Handwashing)30

1) The load size is determined in accordance with the EN 60 456 standard load.

2) Note: Programme setting for testing in accordance with or in the style of EN 60 456

and IEC 60 456.

Consumption values will vary from those given depending on the pressure and hardness of the water and its initial temperature, the room temperature, type and quantity of washing, detergent used, fluctuations in mains voltage and options selected.

2)

Load size

in kg

6 49 1,12 125

2 54 0,45 54

Water

1)

in litres

Energy

in kWh

Time in

minutes

25

Page 26

Installation and connection instructions

1 Safety information for the installation

• This washing machine cannot be built-in.

• Before using for the first time, check the appliance for damage sus-

tained while it was being transported. Do not under any circumstances connect an appliance that is damaged. In the case of damage,

please contact your supplier.

• Before using for the first time, all parts of the transport lock must be

removed. Otherwise when spinning damage may be caused to the appliance or to neighbouring units or furniture.

• Before using the appliance for the first time, splash protection must

be completed. (See “Removing the transit packaging”.)

• Always plug the mains plug into a correctly installed shockproof

socket.

• Permanent connection: a permanent connection must only be in-

stalled by a trained electrician.

• Prior to using the appliance for the first time, ensure that the rated

voltage and type of supply on the rating plate match that of the supply where the appliance is to be installed. The fuse rating is also to be

found on the rating plate.

• If work on the plumbing is required for the proper connection of the

washing machine to the water supply, this must be undertaken by a

registered plumber.

• If work on the electricity supply system is required for the proper

connection of the washing machine to the electricity supply, this

must be undertaken by a registered electrician.

• The washing machine’s cable must only be replaced by the Customer

Care Department or a registered electrician.

Installing the appliance

Transporting the appliance

1 Warning! The washing machine is very heavy. Risk of injury. Be careful

when lifting.

• Do not lay the appliance on its front nor on its right side (as seen

from the front). Electrical components may get wet.

26

Page 27

• Never transport the appliance without its transport lock. Only remove

the transport lock when the appliance is in its place of installation.

Transporting the appliance without its transport lock can lead to

damage to the appliance.

• Never lift the appliance by the door when it is open nor by the plinth.

When moving using a sack trolley:

• Only use the sack trolley on the side of the appliance.

Unpacking

1 The transport safeguard must be removed before putting the appliance

into operation.

Important!

You are advised to keep all the packaging for re-use in case the

machine is to be transported again.

1. After removing all the packaging,

with assistance carefully lay machine on it’s back to remove the polystyrene base from the bottom.

2. Remove the power supply cable and

the draining hose from the hose

holders on the rear of the appliance.

27

Page 28

3. With a suitable spanner unscrew and

remove the central rear bolt A. Slide

out the relevant plastic spacer.

4. Unscrew and remove the two large

rear bolts B and the six smaller bolts

C.

5. Remove the bracket D.

6. Tighten up the six smaller bolts C.

28

Page 29

7. Open the porthole and remove the

polystyrene block

.

8. Fill the smaller upper hole and the

two large ones with the corresponding plastic plug caps supplied in the

bag containing the instruction

booklet.

Important!

All the different plug caps are supplied with the appliance in the plastic bag containing the instruction

booklet.

Connect the water inlet hose as described under the paragraph “Water

inlet”.

on the door seal.

Where to install

Important! The appliance must not be used in a room where there is a

danger of frost. Frost damage or impaired operation! Frost damage is

not covered by the warranty.

• The surface on which the appliance is to be installed must be firm

and level. Do not install the appliance on carpets or on soft floor coverings.

• The surface on which the appliance is to be installed must be clean

and dry and free from coverings that move, so that the appliance

does not slide.

• If the location in which the appliance is to be installed is fitted with

small-format tiles, put a rubber mat (available in the shops) under

the appliance.

29

Page 30

Making the appliance level

The four feet of the appliance are

pre-adjusted.

Large degrees of unevenness can be

compensated for by individually adjusting the height adjustable screw

feet.

Use the special spanner supplied to

do this.

Important! Do not use pieces of

wood, cardboard or such like to level out unevenness in the floor, but

adjust the height adjustable screw

feet instead.

Electrical connection

Details about the voltage, type of supply and the fuses required are to

be found on the rating plate. The rating plate is next to the doorway.

Connecting to the water supply

Permitted water pressure

The water pressure must be at least 1 bar (= 10 N/cm2=0.1MPa) and may

be a maximum of 10bar (= 100N/cm

– If more than 10 bar: Connect a pressure reduction valve.

– If less than 1bar: Disconnect the appliance end of the inlet hose from

Water inlet

Attention!

• An inlet hose is supplied and can be found inside the machine drum.

• Do not use the hose from your previous machine to connect to

• This appliance must be connected to a cold water supply.

30

2

=1MPa).

the solenoid inlet valve and remove the flow meter. (In addition remove the filter using pointed pliers and take out the rubber gasket

behind it.) Re-insert the filter.

the water supply.

Page 31

1. Open the porthole and extract the inlet hose.

2. Connect the hose with the angled

connection to the machine.

Important!

Do not place the inlet hose downwards. Angle the hose to the left

or right depending on the position

of your water tap.

3. Set the hose correctly by loosening

the ring nut. After positioning the

inlet hose, be sure to tighten the

ring nut again to prevent leaks.

4. Connect the hose to a tap with a

3/4” thread.

Always use the hose supplied with

the appliance.

Installation should comply with local

water authority and building regulations’ requirements.

A minimum water pressure of 0.05

MPa (0.5 bar) is required for safe operation of the appliance.

If you cannot make the cold water

connection direct from the rising mains, you may be able to operate

the appliance from your cold water storage system.

There should be a minimum distance of 5.02m (16.5 ft) between the

appliance’s inlet and the bottom of the water storage tank.

Aqua Control

The inlet hose is provided with a water stop device, which protects

against damage caused by water

leaks in the hose which could develop due to natural ageing of the

hose. This fault is shown by a red

sector in the window „A”. Should this

occur, turn the water tap off and refer to your Service Centre to replace

the hose.

31

Page 32

Water drainage

The maximum permitted difference between the height of the surface

on which the appliance is installed and the water outlet is 1 metre.

Only original hoses may be used to extend hoses. (A maximum of 3 m

laid on the floor and then 80 cm vertically). The Customer Care Department stocks outlet hoses of different lengths.

Draining water into a sink outlet

Secure the outlet/sink outlet joint

with a hose band clip (available from

your dealer).

Draining water into a wash basin/bath

1 Important!

– Small basins are not suitable. Wa-

ter may overflow.

– The end of the drain hose must

not be in the water that has been

pumped out. Otherwise water

could be sucked back into the appliance.

– When draining into a wash basin

or a bath, secure the drain hose

with the supplied elbow to stop it

slipping. Otherwise the water running out can force the hose out of

the basin.

– When pumping the water out,

check that the water is running

away fast enough.

32

Pumping heights over 1 m

The washing machine’s drain pump is able to pump water to a height of

1meter, calculated from the surface on which the appliance is installed.

Warning! If pumping height is over 1 metre, malfunctions and damage

to the appliance may arise.

For pumping heights over 1metre a conversion kit can be obtained.

Please contact the Customer Care Department.

Page 33

Service

In the event of technical faults, please first check whether you can

remedy the problem yourself with the help of the operating instructions (section “What to do if…”).

If you were not able to remedy the problem yourself, please contact the

Customer Care Department or one of our service partners.

In order to be able to assist you

quickly, we require the following

information:

– Model description

– Product number (PNC)

– Serial number (S No.)

(for numbers see rating plate)

– Type of fault

– Any error messages displayed by

the appliance

So that you have the necessary reference numbers from your appliance

at hand, we recommend that you write them in here:

Model description: .....................................

PNC: .....................................

S No: .....................................

33

Page 34

34

Page 35

35

Page 36

www.electrolux.com

132 973 910-00-302007 Subject to change without notice

Loading...

Loading...