Page 1

Instantaneous

IH 18 electronic LCD

Water Heater

IH 21 electronic LCD

IH 24 electronic LCD

Instructions for installation and use

Page 2

Contents Page

Important instructions for the user 3

General 3

Operating the appliance 3

Temperature preselection 3

Hot water flowrate 4

Care and maintenance of the appliance 4

Important instructions for the installer 5

General 5

Appliance constitution 5

Technical data 6

Appliance function 7

Safety temperature and pressure limiter 7

Installing the appliance 8

Dimensioned diagram 8

Appliance installation 9

Hood dismounting 9

Wall mounting 9

Water connection 10

Concealed installation 10

Installation versions 11

Cleaning the strainer insert 12

Flowrate limiter 12

Electrical connection 13

Mains connection 13/14

Circuit diagram 14

Temperature selector range limitation 15

Hood assembly 15

Using the appliance for the first time and checking 16

Fault-finding 17

Fault indications 18

Important for the expert 19

Customer service 20

2

Page 3

Important instructions for the user

IH electronic LCD

General

- Installation and startup should only ever be performed by an approved

installer or authorised installation firm.

- Before using the appliance, please read through these instructions

carefully. The manufacturer cannot accept any liability for damage

resulting from failure to follow these instructions.

- Fittings and connecting pipes may get hot. Therefore keep children well

away.

Operating the appliance

The ELECTROLUX IH electronic instantaneous water heater heats the water

as the latter continuously flows through it. When the hot water tap is opened,

the appliance switches on at a flowrate of around 3 l/min. When the hot water

valve is closed or if the flowrate is reduced below 2.5 l/min, the appliance

switches itself off again. The appliance is suitable for household use and should

only ever be used for heating of drinking water.

One or more tapping points can be supplied with hot water.

Temperature preselection

The electronic system allows

continuous temperature selection in

the range from 30°C to 60°C.

Recommendation for energy-saving

operation:

40°C for washbasin, shower, and bath

(knob tangibly engages).

55°C for kitchen sink. If this

temperature is no longer needed, the

appliance should be reset to the 40°C

energy-saving level.

CAUTION! When operating with prewarmed water (for example solar-energy

plant) the outlet - temperature could be higher than prefixed in the LCDdisplay.

When the appliance is operated with a thermostatic mixer tap, the

temperature setting on the instantaneous water heater must be around 8°C

higher than on the thermostatic mixer tap.

3

Page 4

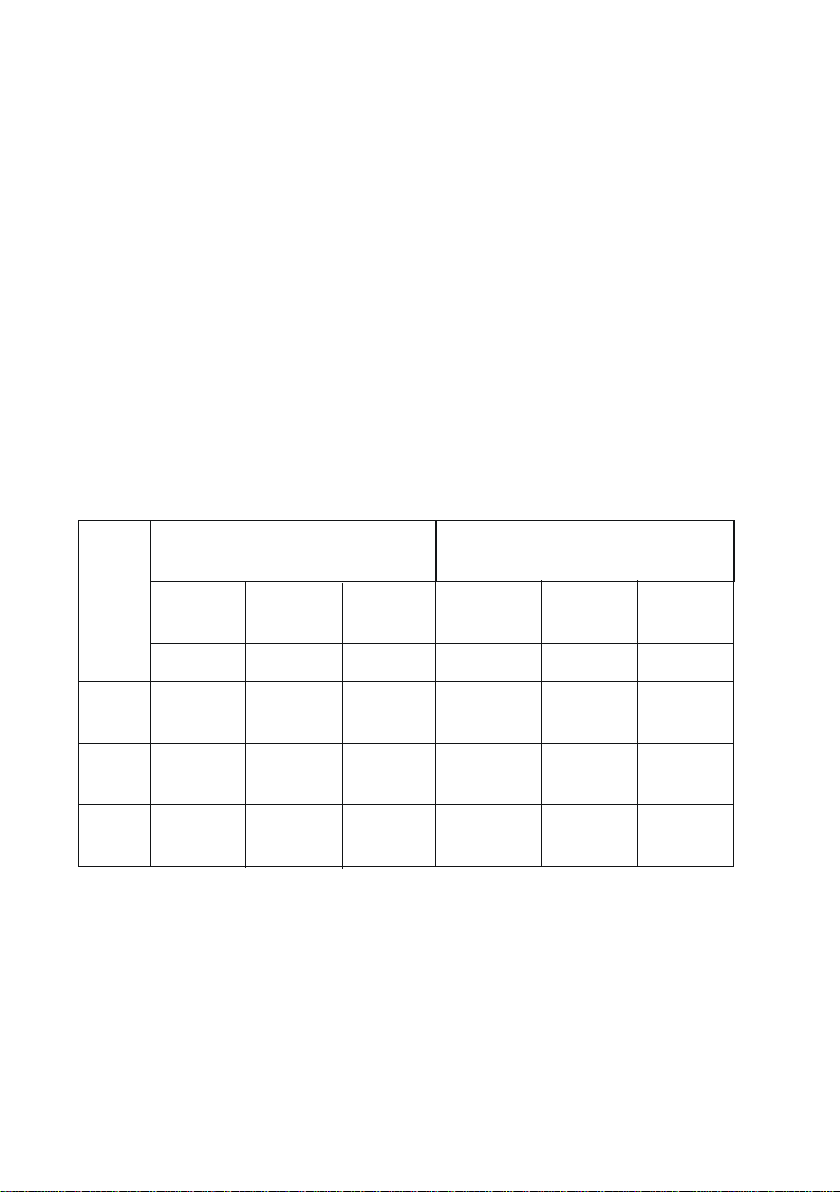

Hot water flowrate

Cold

water

tempe

rature

°C

Outlet temperature

40°C

Outlet temperature

55°C

6

10

14

18 kW

l/min

7,6

8,6

(*8)

9,9

(*8)

21 kW

l/min

8,8

10

(*9)

11,6

(*9)

24 kW

l/min

10,1

11,5

(*10)

13,2

(*10)

18 kW

l/min

5,3

5,7

6,3

21 kW

l/min

6,1

6,7

7,3

24 kW

l/min

7

7,6

8,4

(*) limited to this figure by the built-in flowlimiter

Up to the appliance’s max. power limit, the instantaneous water heater

supplies the set hot water temperature regardless of the water flowrate

selected.

If the hot water temperature is not attained when the hot water valve is

fully opened, more water flows than can be heated by the appliance

power. In this case, the hot water tap must be slightly closed.

The built-in automatic flowlimiter limits the flow in such a way that also with

fully opened warm water outlet valve and low cold water inlet temperatures a

shower-fair outlet temperature (approx. 40°C) remains.

Because of the different inlet temperatures, the hot water output varies

depending on the season.

The following outlet flowrates for bath or shower water (40°C) or washbasin/

sink water (55°C) are attained at the inlet temperatures of 6°C, 10°C,

and 14°C.

Care and maintenance of the appliance

Clean the plastic housing as necessary with a damp cloth and dilute soap

solution. Never use any abrasive, scouring, and solvent-containing detergents.

The instantaneous water heater generally needs no maintenance. Regular

inspection of the appliance by a trained engineer will ensure its operational

reliability and prolong its service life.

bubblers of the fittings or hand shower head must therefore be cleaned from

time to time.

Scale deposits in the outlet of fittings reduce the water flowrate. The air

4

Page 5

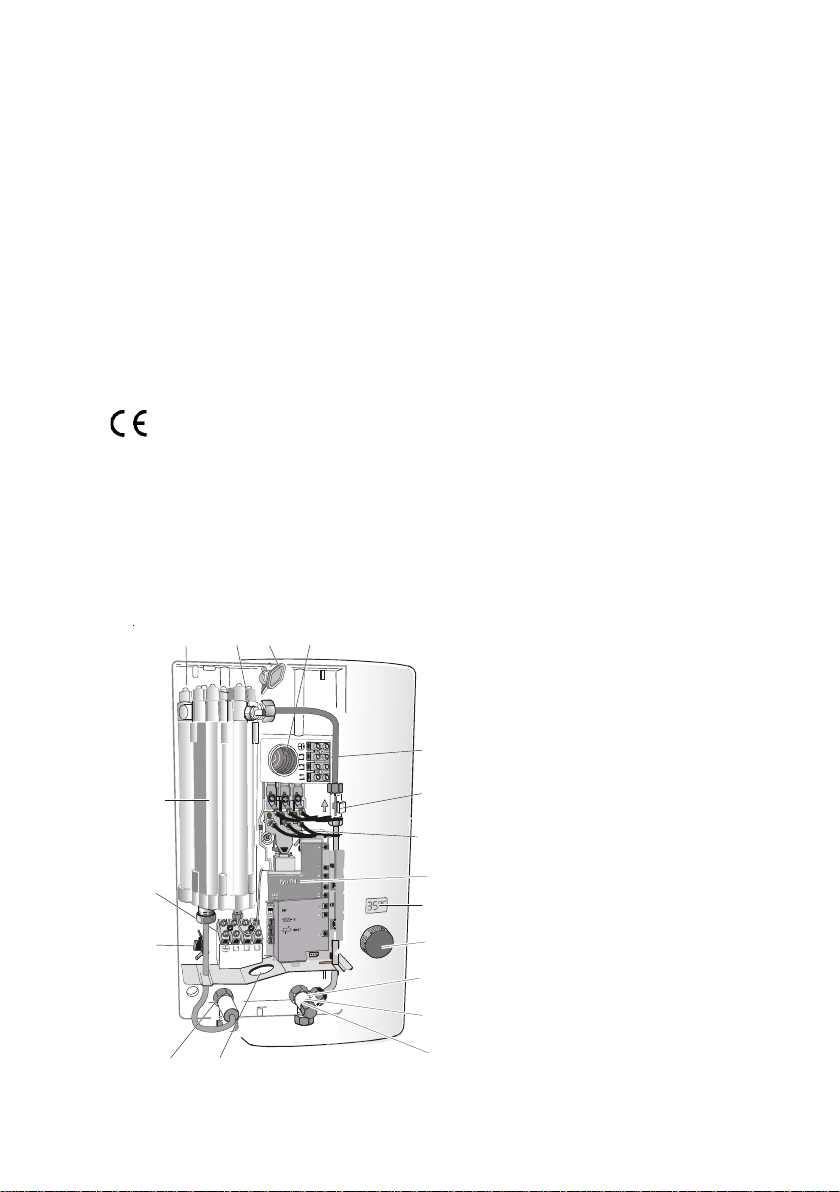

123

4

5

12

13

4a

5a

14

6

7

8

9

10

11

15

16

Important instructions for the installer

General

The instantaneous water heater is manufactured and tested in conformity with

the valid IEC specifications and DIN standards. The appliance complies with

the Appliance Safety Act. The indications given on the rating plate, the technical

connection specifications of the electricity and water companies in the

geographical area concerned, and VDE 0100 and DIN 1988 must be observed

when the appliance is being installed. Before all work on the equipment the

mains voltage supply must be interrupted.

The specific resistance of the water at the installation site should not

be less than 1100

ΩΩ

Ωcm.

ΩΩ

This appliance complies with the following EC Directives:

- the ”Low-Voltage Directive” 72/23/EEC of 19.02.1973, including

Amendment Directive 93/68/EEC

- the”Electromagnetic Compatibility” Directive 89/336/EEC of

03.05.1989 including Amendment Directive 92/31/EEC

Appliance constitution

1 = Back wall

2 = Thermal sensor

3 = Quick fastener for appliance

mounting

4 = Upper cable bushing

4a =Lower cable bushing

5 = Upper mains connection

terminal (factory-prefitted)

5a = Lower mains connection

terminal (transpose mains

connection terminal)

6 = Flowrate sensor

7 = Safety temperature and

pressure limiter

8 = Electronic module

9 = Temperature Display

10 =Temperature selector knob

11 =Flowrate limiter

12 = Strainer insert, connection

for direct tapping fitting

13 =Cold water connection

14 = Hot water connection

15 = Thermostat

16 = Heating block

5

Page 6

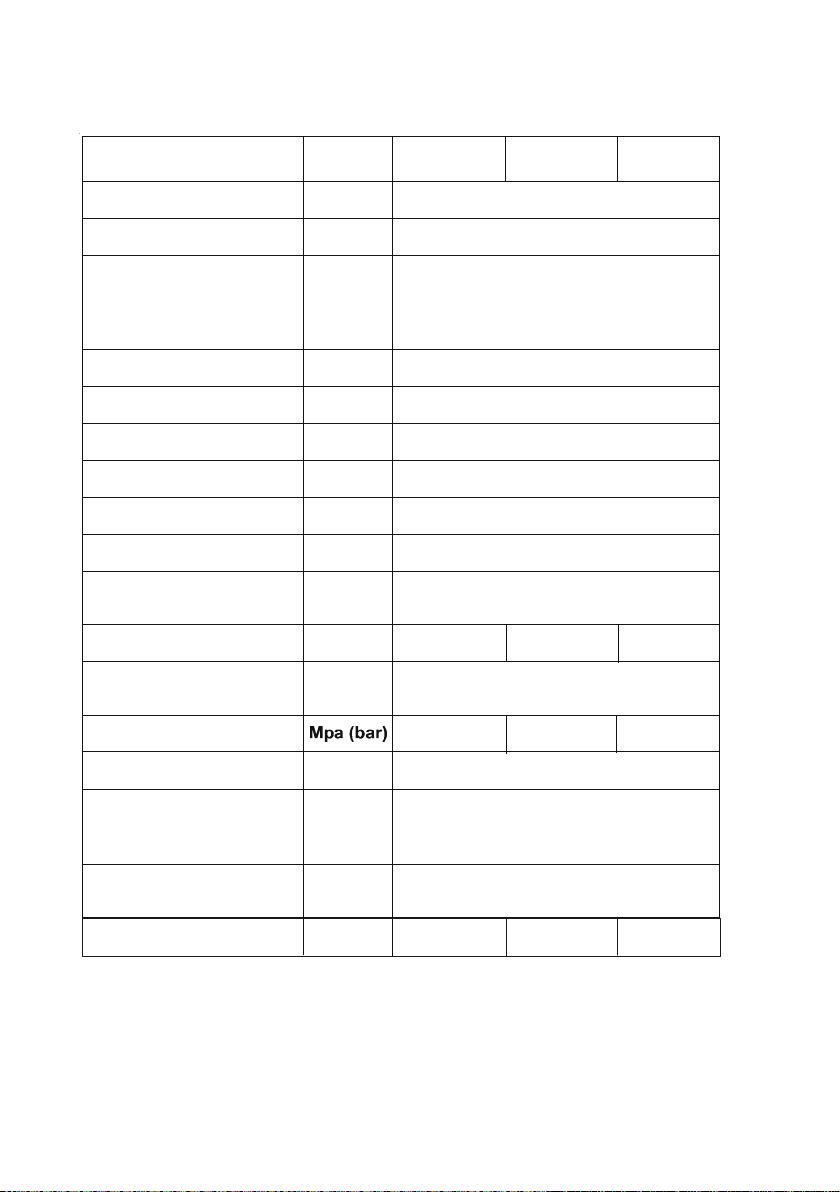

Technical data

Model

Type

unvented

Nominal capacity

Liters

0,4

Dimensions

Width

Height

Depth

mm

226

469

95

Weight

kg

3,9

Nominal overpressure

Mpa (bar)

1 (10)

Protection class to VDE

I

Protection type to VDE

IP 25 (splash-water protected)

Test mark

See rating plate

Water connection

G 1/2 A

Electrical connection

3 / PE ~ 380 V

Nominal output

kW1821

24

Spec. water resistance at

15 °C

Ohm cm

> 1100

Switch-on flow pressure*)

0.035 (0,35)

Switch-on flowrate

l/min

3

Mains retroactive effect

Free from any mains retroactive effect

to DIN EN 60555/VDE 0838

VDEW Approval

Maximum inlet

temperature

°C

< 70 (power engagement up to 45 °C)

IH E

24 LCD

IH E

21 LCD

IH E

18 LCD

Flowrate limitation l/min 8 9 10

0.03 (0,3)

0.04 (0,4)

*) In addition to the flow pressures of the instantaneous water heater itself, consideration

must be given to the pressure losses in the household pipework.

6

Page 7

Appliance function

The fully electronically controlled ELECTROLUX IH instant water heater is a

pressurised appliance for the supply of one or more tapping points and heats

the water as the latter continuously flows through it. A flowrate sensor switches

on the heating at a flowrate of around 3 l/min and off again at around 2,5 l/min.

The microprocessor controlled electronic system automatically adapts the

heating power with regard for the inlet temperature, the temperature set on the

temperature selector knob, and the water flowrate. The user thus has hot

water available in an energy-saving system giving the exact temperature required

without any time limitation whatever.

The nominal operating pressure is 1MPa. If this value is exceeded, a pressure

reducing valve should be provided in the household pipework. A safety valve is

not necessary.

The bare wire resistance heating system has a high efficiency. Its low weight

and extremely low water content also make it suitable for hard, lime-containing

water qualities.

Safety temperature and pressure limiter

In the event of a fault, the inbuilt safety

temperature and pressure limiter isolates the

appliance from the mains supply on all

contacts.

Before the appliance is switched back on, a

trained engineer must ascertain and eliminate

the cause of the fault (see page 17). Then

carefully press in the contact rocker with a

screwdriver until it audibly engages.

Important: Don't block up the contact rocker!

Pressurepoint

for screwdriver

Important! The safety temperature and pressure limiter should never

be adapted or modified in any way!

7

Page 8

Installing the appliance

1

2

3

4

4a

3a

5

6

226

190

100

95

37,5

5

4

6

9

2

9

3

395

21

30

The appliance should only ever be installed or stored in frost-free

premises.

Dimensioned diagram

1 = Quick fastener for appliance mounting

2 = Wall mounting

3 = Upper connection terminal (factory-set)

3a = Lower connection terminal for electrical connection

4 = Upper cable bushing

4a = Lower cable bushing for electrical connection

5 = Cold water connection with strainer insert

6 = Hot water outlet

8

Page 9

Appliance installation

1

2

3

Carefully unpack and take out the enclosed pack.

Prepare the appliance for assembly.

Hood dismounting

Press in the engagement lug on the underside of

the appliance from above or from the front with a

screwdriver and take off the hood. Pull out the

connection lead of the temperature set-point

pickup on the electronic system.

The rotational range of the temperature selector

knob can be limited (see page 15).

Wall mounting

Mark out wall-plug holes with the

mounting template supplied,

insert wall-plugs, and screw on

fixing rail (1). Take out threaded

pin (2) from the enclosed pack

and screw in. Then prepare water

connections, mount appliance on

threaded pin and retaining rail,

and fix by turning the quick

fastener (3) one quarter revolution.

9

Page 10

Water connection

The water inlet temperature on the cold water connection should be

max. 70°C. Upwards of 45°C, the appliance system is arranged not to

apply any more heating power.

If plastic pipe systems are used as installation material, the pipe

manufacturer must expressly and unreservedly confirm the

applicability and quality of his pipes for this application.

Concealed installation

Insert connector with shutoff spindle (1) in

cold water connection and double- nipple

(2) in hot water outlet using hemp packing.

The shutoff spindle must point downwards

and the screw slot aligned in the flow

direction of the water. The shutoff unit

must not be used for throttling.

The ELECTROLUX IH electronic can be operated with all pressure fittings

suitable for instantaneous water heater.

10

Page 11

Installation versions

1

2

3

4

For fittings directly on the appliance, the bushing openings pre-embossed in

the appliance hood must be cut out for the extension pipes of the fitting. The

supporting sheet (1) enclosed with the fitting fixes the extension pipes in

position and seals the housing openings. To ensure moisture protection,

the supporting sheet must be fitted.

Fitting must be vertically seated and centrally

under the appliance. Seal appliance

connection to the wall, where necessary, with

G 1/2 A blind plugs (2) (fitting accessory).

If a cold water supply is made to the

appliance, the shutoff adapter (3) should be

replaced by an adapter with a wood screw

(4) for fixing the fitting in place.

The following tapping fittings are suitable:

D 169 - Special mixer tap with swivelling outlet

D 159 - Special shower mixer tap

D 149 - Special bath mixer tap with change-over tub/shower

Important! After completion of the water installation, the appliance

should be thoroughly flushed with cold water (open the hot water valve).

The strainer insert may possibly need cleaning afterwards.

11

Page 12

Cleaning the strainer insert

2

1

3

1

2

If the water flowrate is reduced by dirt from the cold water line, the strainerinsert should be cleaned as follows:

− Shut off cold water on shutoff unit (1)

− Loosen cap nut (2 ) using a spanner

− Take out and clean strainer (3)

− Re-assemble in reverse sequence

− Open cold water on shutoff unit (1); check

tightness

Flow rate limiter

The flow rate limiter (2) is installed in the cold

water connector (1) to allow a constant outlet

temperature at high flow pressures of approx. 40° C,

suitable for showering.

(See table page 4 and 6)

12

Page 13

Electrical connection

1

2

3

max.10

4

20

150

The electrical connection should only ever be made after the water is

connected! The appliance is only suitable for a fixed connection of

380 V 3 ~ (three-phase current) .

The appliance must be connected to the protective conductor.

Important note: The wiring must be arranged so that the appliance can be

de-energised (disconnected from the electricity supply) before any

intervention involving the fuses being unscrewed, the automatic safety

devices being switched off, or similar measures being taken (isolating gap

width of at least 3 mm).

Mains connection lead

The connection cable must project from the wall

over an insulated length of at least 20 mm.

Mains connection on top

Electrical connection terminal (3)

factory-prefitted.

Cut out cable inlet opening (1).

Slide flexible inlet bush (2) over

connection cable, insert it through the

back wall opening, and screw fixing

strap under connection terminal (4).

13

Page 14

Mains connection underneath (alternative)

3

2

1

L1(R)

L2(S)

L3(T)

PE

Heizblock

3

4

2

5

1

W4

W3

W2

W1

3

4

2

5

1

Elektronik

LED

1 2

IN

S2

L1

L2

L3

K

S

D

LCD

For this connection

version, transpose the

mains connection terminal

(1) from top to bottom.

Note the terminal

designation on the back

wall, and do not cross

the connection leads to

the safety temperature

limiter.

Carry out cable inlet opening

(2), inlet bush (3), and bush fixing under the mains connection terminal as

described above for mains connection.

Important! Moisture protection is only guaranteed with the inlet bush

fitted in position.

Circuit diagram

Heating block

Main connection terminal

Safetytemperature

and pressure

limiter

Electronic

system

14

Page 15

Temperature selector range limitation

IN

The maximum temperature able to be set can be limited to 40°C or 45°C.

Important! Before dismantling, set the knob to the minimum

temperature of 30°C.

Detach the temperatur set-point pickup (2) in the appliance hood. Turn the

setting dial (3) so that the printed set-point coincides with the hood mark (1).

Do not twist the selector axis and plate of the temperature set-point

pickup when reassembling!

Hood dismounting

Plug the connection lead of the

temperature set-point pickup into the

electronic system, suspend the

appliance hood in the upper edge of the

back wall, and swivel it downwards until

it audibly engages.

If necessary, the hood can be supplimentarily fixed with a screw next to

the engagement lug.

15

Page 16

Using the appliance for the first time and checking

The unit must be installed and started up by an approved firm of installers

which accepts liability for safety and proper function.

Before the appliance is energised (connected to the electricity supply),

it should be thoroughly flushed with cold water and the tightness of the screwed

joints checked.

After the instantaneous water heater is energised (connected to the

electricity supply), it should be inspected by a trained engineer to

ensure that it is in proper working order. For protection of the heating

systems, the system is arranged for a switch-on delay of 5 - 25 s at

initial startup and after the appliance has not been live for any length

of time.

Important: After any work carried out on the water supply unit, the

appliance should also be thoroughly flushed with cold water (vented)

before being switched on again. Only then should the appliance be

reconnected to the electricity supply.

After initial startup, the user should be familiarised with operation of

the appliance and the instructions for installation and use handed

over for safekeeping.

16

Page 17

Fault-finding (important instructions for the trained engineer)

In the event of any fault, a check should first be made to ascertain

whether the fuse and line protection switch have tripped.

CauseFault Remedy

- Heating system does

not switch on

- Hot water flowrate too

low

- Safety temperature

and pressure limiter has

tripped

- Active fault indicator

(LED)

- Appliance is not live

- Strainer insert is

clogged

- Soiling or scaling of

bubblers and shower

heads

- Defective heating

system

- Inadmissibly high cold

water inlet tempera ture (over 70 °C)

- Inadmissibly high

outlet temperature

(over 70 °C)

- System fault (see

table on page 18)

Check the voltage

Clean strainer insert (see

page 12)

Dismantle and clean the

bubblers and showers

heads

Inspection and repair only

by the trained engineer

Appliance should not be

operated with preheated

water over 70 °C

Inspection and repair only

by the trained engineer

Inspection and repair only

by the trained engineer

17

Page 18

Fault indications

- L1 or L3 phase missing

- L2 phase missing

Fault

pattern

Idicator Possible faults

LED 1 LED 2

1 No display

Appliance does

not work

- Flowrate sensor not plugged

Defective

Hot water temperature

too low

2

FLASHES

short

FLASHES

long

- Setpoint generator not fitted

3

4

5

6

ON

- Water flow > 20 l/min

No display

warm water temp.37°C

Constant

FLASHES

short

FLASHES

long

degree rgulation

No correct

- Temperature sensor not

plugged / Defective

- Electronic defective

FLASHES

long

FLASHES

short

No heat output

FLASHES

long

OFF

No heat output

- Outlet temperature 70°C>

FLASHES

long

ON

- Inlet temperature > 45°C

No heat output

OFF

18

Page 19

Important for the expert

V

1

2

1 2

Fehleranzeige

The electronic controls the safety-function of the appliance. When a fault is

noticed, the fault indicator (LED) blinks and the heating element is switched

off.

After the fault has been recitified, fault memory will be automatically cancelled.

Instructions for the fault finding see in "Instructions for installation and use"

page 17and 18.

Fault indicator

19

Page 20

Customer service

Serial No..

If your appliance has a fault, please contact your customer service centre for

advice.

Electric appliances should only ever be repaired by a trained

electrician, since the user may be seriously endangered by

improper repairs.

A list of the addresses of customer service centres is attached.

If your appliance requires service, you will need to quote these

numbers indicated on the rating plate.

To save enquiries, copy the data from the rating plate and keep them handy.

Subject to change

267791-K33895-8040

EHT Haustechnik GmbH

Gutenstetter Straße 10

D-90449 Nürnberg GERMANY

Loading...

Loading...