Page 1

Washing machine

User information

105 176 518-01-220305-02

Swissline GL EWF 1082

g

Page 2

Dear customer,

Please read this User Information carefully and keep

it to refer to at a later date.

Pass this User Information on to any subsequent

owner of the appliance.

The following symbols are used in the

text:

1 Safety instructions

Warning: Notes that concern your personal

safety.

Attention: Notes that show how to avoid

damage to the appliance.

3 Useful tips and hints

2 Environmental information

2

Page 3

Contents

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Description of the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Programme overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Overview of terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Before the first wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Preparing and sorting washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Running a washing cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Opening the door/loading washing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Adding detergent/ additives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Switching on the appliance/ selecting a programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Changing the spin speed/selecting rinse hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Selecting the programme options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

EXTRA RINSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

QUICK WASH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PRE WASH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

STAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SENSITIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting the delay timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Starting a programme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Programme progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Interrupting a programme/adding washing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

End of the wash cycle/removing the washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Overdosing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Child safety device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cleaning and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Remedying small malfunctions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

If the wash results are not satisfactory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Carrying out an emergency drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Drain pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Consumption values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installation and connection instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Safety information for the installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Transporting the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Removing the transit packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Where to install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Making the appliance level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connecting to the water supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Water inflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Water drainage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3

Page 4

Operating Instructions

1 Safety

Prior to using for the first time

• Follow the ”Instructions for installation and con-

nection”.

• If the appliance is delivered in the winter months

when there are minus temperatures: Store the

washing machine at room temperature for

24 hours before using for the first time.

Correct use

• The washing machine is only designed for the

washing of normal domestic laundry at home.

• Additions or modifications to the washing machine

are not permitted.

• Use only detergents and additives that are suitable

for use in domestic washing machines.

• The washing must not contain any inflammable so-

lutions. Danger of explosion!

• Do not use the washing machine for dry cleaning.

• Dyes/colour removers may only be used in the

washing machine, if the manufacturer of these

products expressly permits this. We cannot be

held responsible for any damage arising.

Child safety

• Keep packaging away from children. There is a risk

of suffocation.

• Children often do not recognise the hazards asso-

ciated with electrical appliances. Don’t allow children to use the washing machine unsupervised.

• Make sure that children and pets don’t climb into

the drum of the washing machine. Could endanger

life!

General safety

• Repairs to the washing machine must only be carried out by qualified service engineers.

• Never use the washing machine if the mains cable

is damaged; or if the control panel, work top or

plinth area is damaged such that the inside of the

appliance is freely accessible.

• Switch off the washing machine before cleaning,

maintenance and servicing. In addition, pull the

mains plug out of the socket or – in the case of a

permanent connection – switch off the cut-out in

the fuse box or remove the screw fuse completely.

• If operation is stopped, disconnect the appliance

from the mains supply and shut off the water tap.

• Never unplug the appliance by pulling on the cable. Always pull the plug.

• Multi-way plugs, connectors and extension cables

must not be used. This could constitute a fire

hazard through overheating.

• Never wash the washing machine down with a water jet. Danger of electric shock!

• In washing programmes with high temperatures

the glass in the door gets hot. Do not touch it.

• Before emergency emptying of the appliance, before cleaning the drain pump or opening the door

in an emergency, let the water cool down.

• Small animals can nibble at the cables and water

hoses. Danger of electric shock and danger of water damage! Keep small animals away from the

washing machine.

4

Page 5

Description of the appliance

Detergent dispenser drawer

Rating plate

(behind door)

Screw feet

(height adjustable)

Control panel

Plinth flap/

Drain pump

Control panel

SPIN/RINSE HOLD button

DELAY TIMER button

Programme option buttons

Multi-display

DOOR indicator

Programme progress display

Programme knob

START/PAUSE button

OVERDOSING indicator

5

Page 6

Programme overview

Programme options Spin speed

Programme

ENERGY SAVING

COTTONS/LINEN

95, 60, 40, 30

2)

1)

(dry washing)

max. load

RINSE +

QUICK WASH

PRE WASH

STAIN

SENSITIVE

1000

900

700

500

RINSE HOLD

6kg • ••••••••

6kg ••••

3)

••••••

40-60 MIX 6kg • ••••••••

EASY-CARES

60, 50, 40, 30

3kg ••••

3)

••••••

EASY IRON 40 1kg •••• •••••

DELICATES

40, 30

WOOL/SILK H (Handwash)

40, 30, COLD

3kg ••• •••••

2kg •••••

GENTLE RINSE 3kg •••••

DRAIN

SPIN 6kg ••••

REFRESH 3kg •••••

1) A 10 litre bucket holds around 2.5 kg of dry washing (cotton).

2) Programme settings for testing in accordance with or in support of standard EN 60 456 and IEC 60 456, are described in the Chapter “Consumption values”.

3) STAIN can only be selected with wash temperatures of 40°C and above, as stain treatment products are only effective at higher temperatures.

6

Page 7

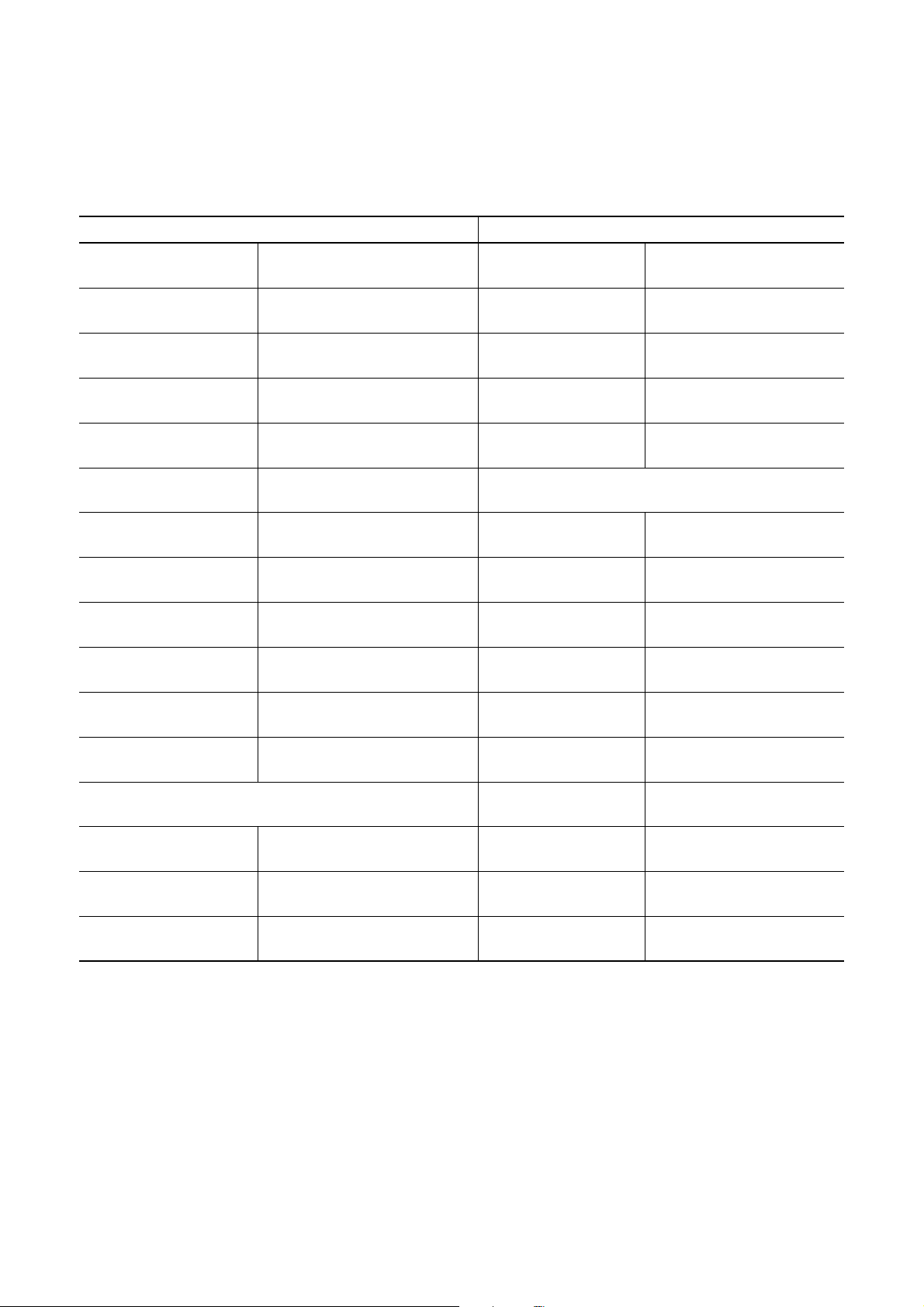

Use/Features Caresymbols

1)

Energy-saving programme at 60 °C for lightly to normally soiled whites/coloureds made of cotton/linen.

Programme for normally to heavily soiled whites and coloureds made of cotton/linen.

Programme for whites and coloureds which are labelled for different wash temperatures. Items,

which according to the care symbols are normally to be washed separately at 40 °C or at 60 °C,

can be washed together in this programme. This makes better use of the drum capacity and thus

saves energy. Through an increased wash time the washing results of a normal 60° programme

are achieved.

Programme for easy-care mixed fibres and synthetics.

Special programme at 40 °C for easy-care fabrics which, after this programme, need no or very

little ironing.

Gentle programme for delicate fabrics such as bonded fabrics, microfibres, synthetics, net curtains (max. load for net curtains 20 to 25 m

mate membrane, e. g., outdoor clothing.

2

). With RINSE HOLD also suitable for fabrics with cli-

M O

J M O

J M

I K N

K N

I K

Particularly delicate programme for machine washable and hand washable wool/silk.

Separate gentle rinse (3 rinses, liquid conditioner is washed in from compartment&, gentle spin).

Pumps water away after a RINSE HOLD.

Pumps water out and spins, e. g. after a RINSE HOLD, or separate spin for hand-washed cottons/linens.

Special programme at 30 °C, approx. 30 minutes, for quickly washing through e. g. once worn,

slightly dirty sports clothing or new clothes.

1) The numbers in the care symbols show the maximum temperatures.

Q L H

I K N

Q L

H

J M O

J M O

I K N

7

Page 8

Overview of terms

The English terms used in this User Information

booklet correspond to the German/French names

below that are to be found on your appliance’s control panel.

Programme selector Buttons

OFF

COTTONS/

LINEN

EASY-CARE

EASY IRON

DELICATES

WOOL/SILK

COLD

GENTLE RINSE

DRAIN

SPIN

REFRESH

AUS

ARRET

KOCH-/BUNTWÄSCHE

BLANC/COULEURS

PFLEGELEICHT

SYNTHETIQUES

LEICHTBÜGELN

FACILE A REPASSER

FEINWÄSCHE

LINGE DELICAT

WOLLE/SEIDE

LAINE/SOIE

KALT

FROID

FEINSPÜLEN

RINCAGE DELICAT

PUMPEN

VIDANGE

SCHLEUDERN

ESSORAGE

SUPERSCHNELL

30 MIN.

PRE WASH

STAIN

SENSITIVE

START/PAUSE

DELAY TIMER

Display

WASH TIME

PRE WASH

MAIN WASH

RINSE

RINSE +

VORWÄSCHE

PRELAVAGE

FLECKEN

TACHES

SENSITIV

SENSIBLE

START/PAUSE

MARCHE/PAUSE

ZEITVORWAHL

DEPART DIFFERE

LAUFZEIT

TEMPS RESTANT

VORWÄSCHE

PRELAVAGE

HAUPTWÄSCHE

LAVAGE

SPÜLEN

RINCAGE

EXTRASPÜLEN

RINCAGE +

ENERGY

SAVING

Buttons END

RINSE HOLD

RINSE +

QUICK WASH

ENERGIESPAREN

ECONOMIQUE

SPÜLSTOPP

ARRET CUVE PLEINE

EXTRASPÜLEN

RINCAGE +

KURZ

COURT

SPIN

OVER DOSING

DOOR

SCHLEUDERN

ESSORAGE

ENDE

FIN

ÜBERDOSIERT

SURDOSAGE

TÜR

PORTE

8

Page 9

Before the first wash

1. Open the detergent dispenser drawer.

2. Pour about 1 litre of water through the detergent

dispenser drawer into the washing machine.

This closes the water container when the next programme is started and the economy valve can function properly.

3. In order to remove any residues from the drum and

water container which may have been left during

manufacturing, perform the first wash cycle without any washing in the machine. Programme:

COTTONS/LINEN 60, press QUICK WASH, add 1/

4 of a measuring cup of washing powder.

Preparing and sorting washing

Preparing washing

• Empty pockets. Remove foreign bodies (e. g.

coins, paper clips, nails, etc.).

• Do up zips, button up covers to prevent damage to

washing.

• Remove the runners from net curtains or cover

them with a net or a bag.

• Wash sensitive and small items in a net or a pillow

case, e.g. net curtains, tights, socks, handkerchiefs, bras.

Important! Bras and other items containing wires

should only be washed in a net bag. The wires can

work loose and damage the appliance.

Sorting washing

• By colour: Wash white and coloured washing separately. Washing can run.

• By temperature, type of washing and care symbol.

Important! Do not wash fabrics with care symbol

G (= do not wash!) in the washing machine.

9

Page 10

Running a washing cycle

Opening the door/loading

washing

1. To open the door: pull the door by the handle.

When the machine is switched on, the DOOR light

and the START/PAUSE light indicate whether the

door can be opened:

DOOR indicator START/PAUSE indicator Can the door be opened?

lit green flashes red or is off yes

lit green lit red

lit red

or is off

2. Unfold washing and load it loosely into the machine. Mix large and small items.

Important! Do not get any washing caught between the door and the rubber seal.

3. Push the door shut firmly. Door catch must audibly

click shut.

flashes red

or lit red

yes, after the START/PAUSE button

has been pressed

no, water level and/or temperature

too high

10

Page 11

Adding detergent/

additives

Important: Use only detergents and additives that

are suitable for use in domestic washing machines.

Dose detergent and additives according to the in-

structions of the detergent and additive manufacturers. Follow the instructions on the packaging.

Dosing depends upon:

– the washing’s degree of soiling,

– the size of the load

– the degree of hardness of the water supply.

• If the manufacturer does not give instructions for

small loads: for a half load, use a third less, for a

very small load, use only half of the detergent that

is recommended for a full load.

• From water hardness 2 (= medium) upwards, water

softener should be used. Detergent can then always be dosed for water hardness 1

(= soft). Your local water company will be able to

give you information about the water hardness in

your area.

1. Pull the detergent dispenser drawer out as far as

the stop.

2. Add the detergent/additives.

3. Push the drawer in fully.

Washing powder/tablets

for the main wash

Softeners/

wash-care products

to preserve the shape

of garments/

starch

Washing powder/tablets for the main wash

If you are using water softener and need the right-

hand compartment for the pre-wash detergent, add

the water softener to the main wash detergent in the

left-hand compartment.

Softeners, wash-care products to preserve the

shape of garments, starch

Do not fill the compartment beyond the MAX mark.

Dilute thick liquid concentrates according to the

manufacturer’s instructions before putting them into

the drawer. Dissolve powder starches.

If you use liquid detergents:

Add liquid detergent using the dosage container provided by the detergent manufacturer.

In-wash stain treatment/tablets

Washing powder/tablets

for the pre-wash

or for water softener

11

Page 12

Switching on the appliance/ selecting a programme

Set the programme and temperature using the programme knob.

3 By selecting a programme, you switch the ap-

pliance on at the same time.

– The programme progress display indicates the

programme steps that the selected programme will

perform.

– In the multi-display the

estimated length of the programme (in minutes)

appears.

Changing the spin speed/

selecting rinse hold

The washing machine suggests the maximum permitted speed that is suitable for the selected programme. You can reduce this speed:

Press the SPIN/RINSE HOLD button repeatedly until

the desired display lights up.

3 The speed for the final spin can still be altered

during the programme. To do this:

1. Press the START/PAUSE button.

2. Change the speed.

3. Press the START/PAUSE button again.

n RINSE HOLD

With n (RINSE HOLD) the washing is left to soak in

the final rinse water. There is no final spin after the intermediate spin(s). Intermediate spins are programme-dependent and cannot be altered.

12

Page 13

Selecting the programme

options

If desired, press the programme option button(s).

The corresponding light lights up.

3 If “Err” flashes in the multi-display, the pro-

gramme option selected cannot be combined

with the wash programme set.

EXTRA RINSE

Two additional rinse cycles are carried out for the

programmes ENERGY SAVING, COTTONS/LINEN,

DELICATES, EASY-CARES and EASY IRON (e. g. in

cases of over-sensitive skin).

QUICK WASH

Shortened wash cycle for lightly soiled washing.

PRE WASH

Warm pre-wash before the main wash, which follows

automatically; intermediate spin in the COTTONS/

LINEN and EASY-CARES programmes; no intermediate spin in the DELICATES programme.

STAIN

For heavily soiled or stained washing. In-wash stain

treatment products are washed in at the optimum

time as the programme progresses.

Can only be set with wash temperatures of 40°C and

above, as stain treatment products are only effective

at higher temperatures.

SENSITIVE

Enhanced rinse action through an additional rinse

cycle together with decreased drum movement (improved fabric care). Ideal when frequent washes are

necessary, e. g. in cases of over-sensitive skin.

13

Page 14

Setting the delay timer

3 With the TIME DELAY button you can post-

pone the start of a programme by 30 minutes

(30') to a maximum of 23 hours (23h).

1. Select programme.

2. Continue pressing the TIME DELAY button until the

desired start delay is displayed in the multi-display,

for example12h, if the start of the programme is to

be delayed by 12 hours. TIME DELAY light is lit.

3 If the display is showing 23h and you press the

button again, the time delay will be cancelled.

0' appears followed by the duration of the set

wash programme.

3. To activate the time delay, press the START/PAUSE

button. The remaining time till the programme start

is being shown (e. g. 12h, 11h, 10h, ... 30

Starting a programme

' etc.).

Interrupting a programme/

adding washing

Interrupting a programme

• A washing programme can be interrupted at any

time by pressing the START/PAUSE button. It is

then re-started by pressing the START/PAUSE button again.

• To stop the washing machine before the programme has ended, turn the programme knob to

OFF. Important! Be careful if there is water in the

appliance!

Adding washing

It is possible to add washing, as long as the DOOR

light is lit green.

1.Press the START/PAUSE button. The door can be

opened.

2.Shut the door and press the START/PAUSE button

again. The programme continues.

1. Check that the tap is turned on.

2. Press the START/PAUSE button. The programme

is started or starts after the time delay set has

elapsed.

3 If after the START/PAUSE button has been

pressed E40 flashes in the multi-display, the

END indicator flashes 4 times and at the same

time an acoustic signal sounds 4 times, the

door is not closed properly. Push the door

firmly closed and press the START/PAUSE

button again.

Programme progress

• The programme progress display shows the programme step that is currently being performed.

• The multi-display indicates the estimated time remaining (in minutes) until the end of the programme.

3 During the washing cycle the remaining time

may be increased or stay the same for a while

as the programme adjusts itself to different

conditions (e. g. type and quantity of laundry,

out of balance spin detection, special rinses,

etc.).

End of the wash cycle/

removing the washing

At the end of the programme, END lights up on the

programme progress display. The door can be

opened as soon as the DOOR indicator is lit green.

1.Open the loading door and remove the washing.

2.Turn the programme knob to OFF.

3.After washing, pull out the detergent drawer a little

to enable it to dry out. Keep the loading door very

slightly open so that the washing machine can air.

If n (RINSE HOLD) has been selected:

After the rinse hold, END lights up on the programme

progress display.

The water must first be drained:

– Either turn the programme knob to OFF, then to

DRAIN and press the START/PAUSE button (the

water is drained without spinning),

– or turn the programme knob to OFF and then to

SPIN. Change the spin speed if necessary and

press the START/PAUSE button (the water is

drained and the washing spun).

Overdosing

14

3 If the OVERDOSING indicator is lit, too much

detergent was used in the previous programme. The next time you wash, observe the

dosing recommendations of the detergent

manufacturer and the load sizes.

Page 15

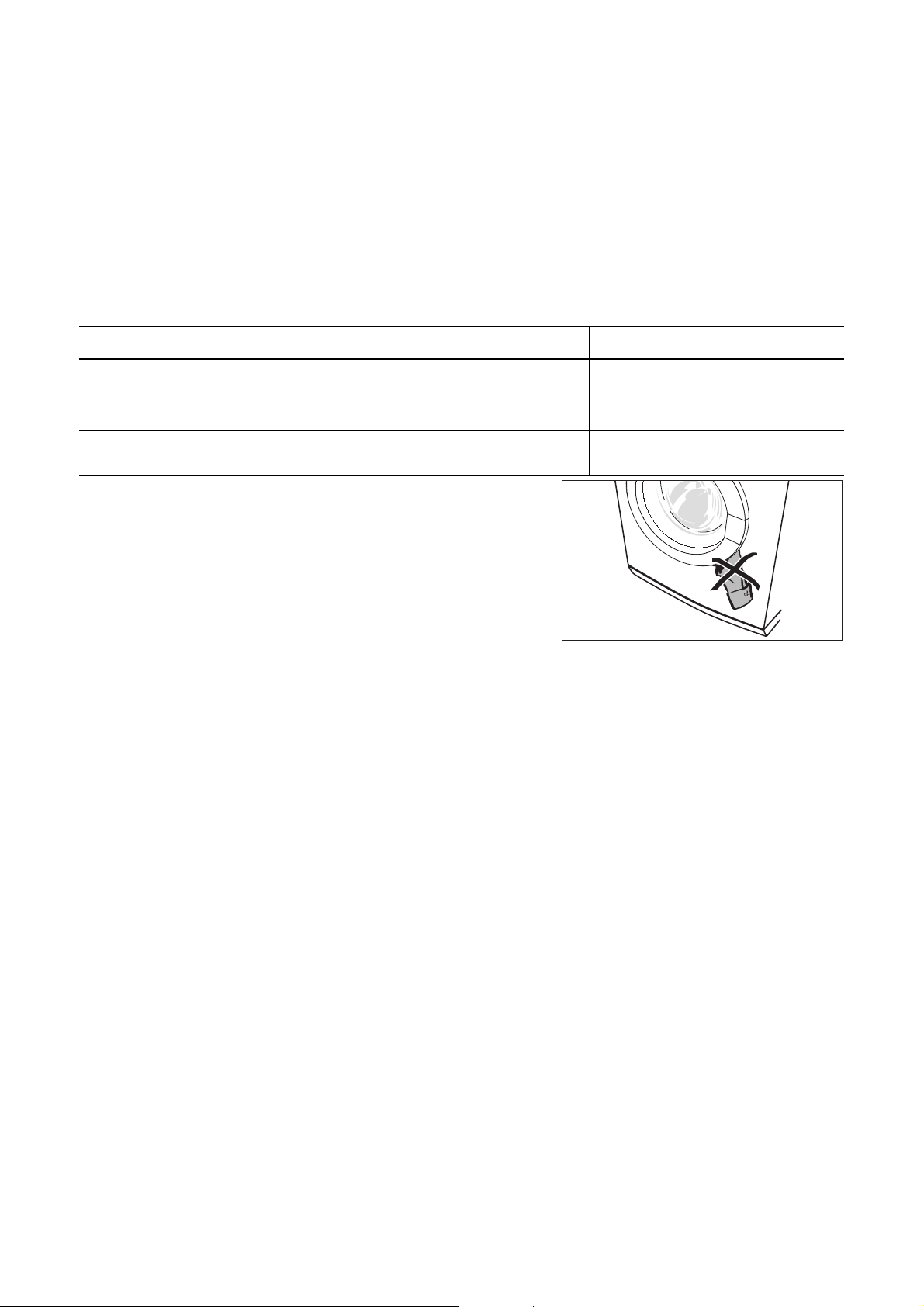

Child safety device

When the child safety device is set, the door can no

longer be closed.

Setting the child safety device:

Use a coin to turn the knob (on the inside of the

door) in a clockwise direction as far as it will go.

1 Warning! The knob must not be sunk-in after

being set, otherwise the child safety device is

not active. The knob must stand proud as

shown in the illustration.

Releasing the child safety device:

Turn the knob anti-clockwise as far as it will go.

15

Page 16

Cleaning and maintenance

Important! Do not use furniture care products or ag-

gressive cleaners to clean the appliance.

Wipe control panel and body with a damp cloth.

Detergent dispenser drawer

The detergent dispenser drawer should be cleaned

regularly.

1. Remove the detergent dispenser drawer by pulling

it firmly.

2. Remove the conditioner insert from the middle

compartment.

3. Clean all parts with water.

4. Put the conditioner insert in as far as it will go, so

that it is firmly in place.

5. Clean all parts of the washing machine, especially

the nozzles in the top of the washing-in chamber,

with a brush.

6. Insert the detergent dispenser drawer in the guide

rails and push it in.

Washing drum

Rust deposits in the drum may occur due to rusting

foreign bodies in the washing or tap water containing

iron.

Important! Do not clean the drum with acidic descaling agents, scouring agents containing chlorine or

iron or steel wool.

1. Remove any rust deposits on the drum with a

cleaning agent for stainless steel.

2. Run a washing cycle without any washing to clean

off any cleaning agent residues. Programme: COTTONS/LINEN 60, press QUICK WASH button, add

approx. 1/4 of a measuring cup of washing powder.

Door and rubber collar

Regularly check whether deposits or foreign bodies

are present in the folds of the rubber collar or on the

inside of the glass door.

Clean the glass in the door and the rubber collar regularly.

16

Page 17

What to do if...

Remedying small malfunctions

If one of the following fault codes is displayed in the

multi-display during operation:

– E10 (Problems with water inlet),

– E20 (Problems with water drainage),

– E40 (door open),

please have a look at the following table.

When the fault is remedied, press the START/PAUSE

button.

Problem Possible cause Remedy

Mains plug not plugged in or fuse not

working.

Washing machine does not

work.

Door cannot be closed. Child safety device engaged. Release child safety device.

When a button is pressed, Err

appears in the multi-display.

E40 appears.

END indicator flashes 4x, at the

same time an acoustic signal

sounds 4x.

Door not closed properly.

START/PAUSE button was not

pressed for long enough.

The selected function cannot be

combined with the programme set.

Door is not closed properly.

In the event of other faults (E plus a number or a letter): Switch the appliance off and on again. Re-set

the programme. Press the START/PAUSE button.

If the fault is displayed again, please contact the

Customer Care Department and inform them of the

fault code.

Plug in mains plug. Check fuse.

Close door - there should be an audible click.

Press START/PAUSE button for longer.

Make another selection.

Close door properly. Start programme

again.

E10 appears.

END indicator flashes 1x, at the

same time an acoustic signal

sounds 1x.

(Problems with water inflow.)

Washing machine vibrates

when operating or is noisy.

Water is leaking out underneath

the washing machine.

Tap turned off. Turn the tap on.

Filter in the screw connection of the

inlet hose is blocked.

Water tap is blocked with limescale

or faulty.

Transit packaging has not been re-

moved.

Screw feet not correctly adjusted.

There is very little washing in the

drum (e.g., just one bathrobe).

Screw connection on the inlet hose

is leaking.

Drain hose is leaking. Replace drain hose.

Drain pump cover is not closed

properly.

Washing was caught in the door.

Emergency drain hose is leaking.

Turn off the water tap. Unscrew hose,

take out filter and clean it.

Check the water tap and have it repaired if necessary.

Remove transit packaging.

Adjust feet according to the Installation and Connection instructions.

This does not affect how the machine

operates.

Tighten inlet hose.

Close cover properly.

Load washing carefully for the next

wash.

Close off emergency drain hose properly.

17

Page 18

Problem Possible cause Remedy

EF0 appears. END indicator

flashes 15x, at the same time

an acoustic signal sounds 15x.

The drain pump runs constantly, even when the machine is

switched off.

Washing water is foaming excessively. At the end of the

washing cycle, the spin stops.

OVER DOSING indicator is lit.

The Aqua Control anti-flood system

has responded.

Probably too much detergent has

been used.

Kink in the drain hose. Remove kink.

Turn off the tap, remove the mains

plug from the socket and contact the

Customer Care Department.

Dose detergent exactly as instructed

by manufacturer.

E20 appears.

END indicator flashes 2x, at the

same time an acoustic signal

sounds 2x.

(Problems with water outflow.)

Conditioner not rinsed in, w

compartment for additives is

filled with water.

Door cannot be opened when

appliance is switched on.

Washing is heavily creased.

Maximum pumping height of 1m exceeded.

Drain pump is blocked.

With connection to sink outlet: sink

outlet is blocked.

Conditioner insert in the compartment for additives is not correctly attached or is blocked.

Door locked. Wait until DOOR indicator is lit green.

Power cut. (All display indicators are

off.)

Door remains locked for 4 to 10 minutes.

Possibly too much washing was

loaded.

Please contact the Customer Care

Department.

Switch off appliance. Pull out mains

plug.

Clean drain pump. Remove foreign

bodies from pump housing.

Clean out sink outlet.

Clean detergent dispenser drawer, insert conditioner insert firmly.

Programme continues, when power

cut is over.

To re m ove w a shin g:

If water can be seen in the appliance,

before opening the door, first drain off

the water. (See section “Carrying out

an emergency drain”.)

Observe maximum loads.

If the wash results are not

satisfactory

Washing is grey and scale is being deposited in the drum

• Too little detergent is being used.

• The right detergent was not used.

• Special soiling was not pre-treated.

• Programme or temperature was not correctly set.

There are grey stains on the washing.

• Washing soiled with ointment, grease or oil was

washed with too little detergent.

• It was washed at too low a temperature.

• A common cause is that fabric conditioner – espe-

cially a concentrate – has got onto the washing.

Such stains should be washed out as quickly as

possible and make sure that you are careful when

using fabric conditioner.

18

After the last rinse foam can still be seen.

• Modern detergents may create foam even in the

last rinse cycle. The washing is however sufficiently rinsed.

There are white residues on the washing.

• This is due to the insoluble ingredients in modern

detergents.

They are not caused by insufficient rinsing.

Shake or brush the washing. If possible turn the

washing inside out before washing. Check your

choice of detergent. Especially with dark colours it

is advisable to use liquid detergents.

Page 19

Carrying out an emergency drain

1 Warning! Before emergency draining, switch

off the washing machine and remove the

mains plug from the socket.

Warning! The water that comes out of the emergency drain hose may be hot. There is a risk of scalding.

Let the water cool before performing an emergency

drain.

1. Open the plinth flap and remove it.

2. Take out the emergency drain hose.

3. Place a shallow container underneath it. Then

loosen the drain plug by turning it in an anti-clockwise direction and pull it out.

4. The water runs out. If it is necessary to empty the

container more than once, seal up the emergency

drain hose with the drain plug while you are doing

so.

When the water has all drained away:

5. Push the drain plug firmly into the emergency drain

hose and screw it tight in a clockwise direction.

6. Place the emergency drain hose back in the support.

7. Insert the plinth flap and close it.

19

Page 20

Drain pump

The drain pump is maintenance-free. It is only necessary to open the pump cover if there is a malfunction

and water is no longer being pumped out, e. g. if the

pump wheel is blocked.

Please make sure before loading the washing that

there are no foreign bodies in the pockets or caught

between the washing. Paperclips, nails, etc. that

may have got into the washing machine with the

washing remain in the pump housing (foreign body

trap that protects the pump wheel).

1 Warning! Before opening the pump cover,

switch off the washing machine and remove

the mains plug from the socket.

1. First carry out an emergency drain.

2. Place a cloth on the floor in front of the drain pump

cover.

Residual water runs out.

3. Unscrew the pump cover in an anti-clockwise direction and remove it.

4. Remove foreign bodies and fluff from the pump

housing and from the pump wheel.

5. Check whether the pump wheel right at the back of

the pump housing can turn. (It is normal for the

pumping wheel to turn jerkily.) If the pumping

wheel cannot be turned, please contact the Customer Care Department.

6. Insert the pump cover. Insert the guides at the

sides of the cover into the guide slots and tighten

the cover by turning in a clockwise direction.

7. Close off the emergency drain hose and place it in

the support.

8. Close plinth flap.

20

Page 21

Disposal

2

Packaging material

The packaging materials are environmentally

friendly and can be recycled. The plastic components are identified by markings, e.g. >PE<,

>PS<, etc. Please dispose of the packaging

materials in the appropriate container at the

community waste disposal facilities.

2 Old appliance

The symbol W on the product or on its pack-

aging indicates that this product may not be

treated as household waste. Instead it shall be

handed over to the applicable collection point

for the recycling of electrical and electronic

equipment. By ensuring this product is disposed of correctly, you will help prevent potential negative consequences for the

environment and human health, which could

otherwise be caused by inappropriate waste

handling of this product. For more detailed information about recycling of this product,

please contact your local city office, your

household waste disposal service or the shop

where you purchased the product.

21

Page 22

Technical data

5

This appliance conforms with the following EU

Directives:

– 73/23/EEC dated 19.02.1973 Low Voltage Direc-

tive

– 89/336/EEC dated 03.05.1989 EMC Directive in-

clusive of Amending Directive 92/31/EEC

– 93/68/EEC dated 22.07.1993 CE Marking Directive

Height x Width x

Depth

Depth when door is

open

Height adjustment approx. +10/-5mm

Load (depending on

programme)

Area of use Domestic

Drum spin speed see Rating Plate

Water pressure

850 x 598 x 640 mm

1017 mm

Max. 6kg

1-10bar (=10–100N/

2

cm

=0.1–1.0MPa)

Consumption values

The consumption values were obtained under standardised conditions. They may vary when operating in

domestic conditions.

Programme knob

(Temperature)

Load

in kg

1)

Water

in litres

Energy

in kWh

COTTONS/LINEN 95 6 62 2,20

ENERGY SAVING

COTTONS/LINEN 40 6 58 0,70

EASY-CARES 40 3 58 0,52

DELICATES 30 3 58 0,42

WOOL/SILK H (Handwash) 30 2 54 0,35

1) The load is determined in accordance with EN 60456 standard loads.

2) Note: Programme setting for testing in accordance with or in support of EN 60 456 and IEC 60 456.

Actual consumption will vary from the indicated values depending on water pressure, water hardness, water temperature at filling, room temperature, type and quantity of washing, detergent used, variations in mains voltage and any additional programme

functions selected.

22

2)

6451,02

Page 23

Installation and connection instructions

1 Safety information for the installation

• This washing machine cannot be built-in.

• Before using for the first time, check the appliance

for damage sustained while it was being transported. Do not under any circumstances connect an

appliance that is damaged. In the case of damage,

please contact your supplier.

• Before using for the first time, all parts of the transit

packaging must be removed. Otherwise when

spinning damage may be caused to the appliance

or to neighbouring units or furniture.

• Before using the appliance for the first time, splash

protection must be completed. (See “Removing

the transit packaging”.)

• Always plug the mains plug into a correctly installed shockproof socket.

• Permanent connection: a permanent connection

must only be installed by a trained electrician.

Installing the appliance

• Prior to using the appliance for the first time, ensure that the rated voltage and type of supply on

the rating plate match that of the supply where the

appliance is to be installed. The fuse rating is also

to be found on the rating plate.

• If work on the plumbing is required for the proper

connection of the washing machine to the water

supply, this must be undertaken by a registered

plumber.

• If work on the electricity supply system is required

for the proper connection of the washing machine

to the electricity supply, this must be undertaken

by a registered electrician.

• The washing machine’s cable must only be replaced by the Customer Care Department or a registered electrician.

Transporting the appliance

1 Warning! The washing machine is very heavy.

Risk of injury. Be careful when lifting.

• Do not lay the appliance on its front nor on its right

side (as seen from the front). Electrical components may get wet.

• Never transport the appliance without its transit

packaging. Only remove the transit packaging

when the appliance is in its place of installation.

Transporting the appliance without its transit packaging can lead to damage to the appliance.

• Never lift the appliance by the door when it is open

nor by the plinth.

When moving using a sack trolley:

• Only use the sack trolley on the side of the appliance. The sack trolley’s base plate must not be

longer than 24 cm, otherwise parts of the antiflood system may be damaged.

23

Page 24

Removing the transit packaging

Important! Before using the appliance for the first

time, all parts of the transit packaging must be removed! Keep the transit packaging in a safe place, in

case it is needed at a later date when the appliance

is to be moved (e.g. moving house).

1. At the back of the appliance, open both hose clips

and remove both hoses and mains cable.

2. Remove both hose clips from the appliance by

jerking them hard.

3 Special spanner A and sealing caps B (2 off)

and C (1 off) are supplied with the appliance.

3. Remove screw D with its compression spring using

special spanner A.

4. Turn sealing cap C upside down as shown in the illustration.

5. Seal hole using sealing cap C.

24

Page 25

6. Unscrew and remove two screws E using special

spanner A.

7. Unscrew and remove four screws F using special

spanner A.

8. Remove transit bar G.

9. Screw in the four screws F again.

10.Seal the two big holes using sealing caps B.

Important! Press all sealing caps B (2 off) and C

(1 off ) in firmly, so that they snap into place. (Splash

protection).

Where to install

Important! The appliance must not be used in a

room where there is a danger of frost. Frost damage

or impaired operation! Frost damage is not covered

by the warranty.

• The surface on which the appliance is to be installed must be firm and level. Do not install the

appliance on carpets or on soft floor coverings.

• The surface on which the appliance is to be installed must be clean and dry and free from coverings that move, so that the appliance does not

slide.

• If the location in which the appliance is to be installed is fitted with small-format tiles, put a rubber

mat (available in the shops) under the appliance.

If the appliance is to stand on a plinth:

In order for the appliance to be secure on the plinth,

fixing plates*) must be mounted, into which the appliance is inserted.

If the appliance is to stand on floors that

vibrate, e. g. floors of wooden joists with

deal boards:

If possible, install the appliance in one corner of the

room.

1. Screw a water-resistant wooden board (at least 15

mm thick) onto at least 2 of the floor joists.

2. Affix fixing plates *) onto the wooden board, into

which the appliance is inserted.

*) The fixing plates can be obtained from the Customer Care Department.

25

Page 26

Making the appliance level

The four feet of the appliance are pre-adjusted.

Large degrees of unevenness can be compensated

for by individually adjusting the height adjustable

screw feet.

Use the special spanner supplied to do this.

Important! Do not use pieces of wood, cardboard or

such like to level out unevenness in the floor, but adjust the height adjustable screw feet instead.

Electrical connection

Details about the voltage, type of supply and the fuses required are to be found on the rating plate. The

rating plate is next to the doorway.

Connecting to the water supply

Important!

• This appliance must not be connected to the hot

water system.

• When connecting it, use only new hose kits.

• Only connect the appliance to the drinking water

supply. Rain water or water for industrial use may

only be used if it fulfils the requirements of

DIN1986 and DIN1988.

• Do not kink or crush the water inlet hose or drain

hose.

Permitted water pressure

The water pressure must be at least 1bar (=10N/

2

cm

=0.1MPa) and may be a maximum of 10bar

(=100N/cm

– If more than 10bar: Connect a pressure reduction

valve.

– If less than 1bar: Disconnect the appliance end of

the inlet hose from the solenoid inlet valve and remove the flow meter. (In addition remove the filter

using pointed pliers and take out the rubber gasket

behind it.) Re-insert the filter.

2

=1MPa).

26

Page 27

Water inflow

A 1.50 m long pressure hose is supplied with the appliance.

If a longer water inlet hose is required, only original

hoses are to be used. The Customer Care Department stocks hose kits of different lengths.

3 Sealing rings are either inserted in the plastic

nuts of the threaded hose fitting or are included as spare parts . Do not use any other seals.

Important! All threaded hose fittings must only be

tightened by hand.

1. Connect the hose with the right-angle connector to

the machine.

Important! Do not position the inlet hose vertically

downwards. Position it to the right or the left as

shown in the illustration.

2. Connect the hose with the straight connector to a

water tap with an R ¾ (inch) screw thread.

3. Open the water tap slowly and check all connec-

tions for water tightness.

27

Page 28

Water drainage

The maximum permitted difference between the

height of the surface on which the appliance is installed and the water outlet is 1 metre.

Only original hoses may be used to extend hoses. (A

maximum of 3 m laid on the floor and then 80 cm

vertically). The Customer Care Department stocks

outlet hoses of different lengths.

Draining water into a sink outlet

Secure the outlet/sink outlet joint with a hose band

clip (available from your dealer).

Draining water into a wash basin/bath

1 Important!

– Small basins are not suitable. Water may overflow.

– The end of the drain hose must not be in the water

that has been pumped out. Otherwise water could

be sucked back into the appliance.

– When draining into a wash basin or a bath, secure

the drain hose with the supplied elbow to stop it

slipping. Otherwise the water running out can force

the hose out of the basin.

– When pumping the water out, check that the water

is running away fast enough.

Pumping heights over 1 m

The washing machine’s drain pump is able to pump

water to a height of 1meter, calculated from the surface on which the appliance is installed.

Warning! If pumping height is over 1 metre, malfunctions and damage to the appliance may arise.

For pumping heights over 1metre a conversion kit

can be obtained. Please contact the Customer Care

Department.

28

Page 29

Servicestellen

Demonstration / Vente

5506 Mägenwil/Zürich

Industriestr. 10

9000 St. Gallen

Vonwilstrasse 15

4127 Birsfelden

Hauptstrasse 52

8604 Volketswil

Hölzliwisenstrasse 12

6032 Emmen

Buholzstrasse 1

7000 Chur

Comercialstrasse 19

3063 Ittigen/Bern

Ey 5

Ersatzteilverkauf

5506 Mägenwil

Industriestrasse 10

0848 848 023

8048 Zürich

Badenerstrase 587

01 405 81 11

Garantie

Nous octroyons sur chaque produit 2 ans de garantie à partir de la date de livraison ou de la mise en

service au consommateur (documenté au moyen

d’une facture, d’un bon de garantie ou d’un justificatif d’achat).

Notre garantie couvre les frais de mains d’œuvres et

de déplacement, ainsi que les pièces de rechange.

Les conditions de garantie ne sont pas valables en

cas d’intervention d’un tiers non autorisé, de l’emploi

de pièces de rechange non originales, d’erreurs de

maniement ou d’installation dues à l’inobservation

du mode d’emploi, et pour des dommages causés

par des influences extérieures ou de force majeure.

Fachberatung / Verkauf

8048 Zürich

Badenerstrasse 587

01 405 81 11

Garantie

Für jedes Produkt gewähren wir ab Verkauf bzw.

Lieferdatum an den Endverbraucher eine Garantie

von 2 Jahren. (Ausweis durch Garantieschein, Faktura oder Verkaufsbeleg).

Die Garantieleistung umfasst die Kosten für Material,

Arbeits- und Reisezeit.

Die Garantieleistung entfällt bei Nichtbeachtung der

Gebrauchsanweisung und Betriebsvorschriften, unsachgerechter Installation, sowie bei Beschädigung

durch äussere Einflüsse, höhere Gewalt, Eingriffe

Dritter und Verwendung von Nicht-Original Teilen.

Points de Service

1028 Préverenges

Le Trési 6

Servizio dopo vendita

6916 Grancia

Zona Industriale E

Vendita pezzi di ricambio

5506 Mägenwil

Industriestrasse 10

0848 848 023

Consulente (cucina) / Vendita

8048 Zürich

Badenerstrasse 587

01 405 81 11

Points de vente de rechange

5506 Mägenwil

Industriestrasse 10

0848 848 023

29

Page 30

Garanzia

Per ogni prodotto concediamo una garanzia di 2 anni

a partire dalla data di consegna o dalla sua messa in

funzione (fa stato la data della fattura, del certificato

di garanzia o dello scontrino d’acquisto).

Nella garanzia sono comprese le spese di manodopera, di viaggio e del materiale.

Dalla copertura sono esclusi il logoramento ed i danni causati da agenti esterni, intervento di terzi, utilizzo di ricambi non originali o dalla inosservanza delle

prescrizioni d’istallazione ed istruzioni per l’uso.

Ersatzteile, Zubehör und Pflegemittel

Schweiz: Sie können Ersatzteile, Zubehör und

Pflegemittel on-line bestellen bei http://www.electrolux.ch

Pièces détachées, accessoires et

produits d'entretien

Pour la Suisse : Vous pouvez commander des pièces

détachées, des accessoires et des produits d'entretien en ligne sur http://www.electrolux.ch

Ricambi, accessori e prodotti di

pulizia

Per la Svizzera: Ricambi, accessori e prodotti di

pulizia si possono ordinare direttamente sul sito internet http://www.electrolux.ch

30

Page 31

Service

In the event of technical faults, please first check

whether you can remedy the problem yourself with

the help of the operating instructions (section “What

to do if…”).

If you were not able to remedy the problem yourself,

please contact the Customer Care Department or

one of our service partners.

In order to be able to assist you quickly, we require

the following information:

– Model description

– Product number (PNC)

– Serial number (S No.)

(for numbers see rating plate)

– Typ e o f f ault

– Any error messages displayed by the appliance

So that you have the necessary reference numbers

from your appliance at hand, we recommend that

you write them in here:

Model description: .....................................

PNC: .....................................

S No: .....................................

31

Page 32

105 176 518-01-220305-02 Subject to change without notice

The Electrolux Group. The world´s No.1 choice.

The Electrolux Group is the world´s largest producer of powered appliances for kitchen, cleaning and outdoor use. More than 55 million Electrolux Group products

(such as refrigerators, cookers, washing machines, vacuum cleaners, chain saws and lawn mowers) are sold each year to a value of approx. USD 14 billion in more

than 150 countries around the world.

Loading...

Loading...