Page 1

Washing Machine

User Information

822 943 829-01 - 14.07.03-01

EWF 1081

g

Page 2

Dear customer,

Please read this user information carefully.

In particular, pay attention to the section ”Safety” on

the first pages. Keep this user information in a safe

place for later reference. Pass it on to any subsequent owners of the unit.

1

1. This numbers guide you step by step in operating

2. ...

Points which are necessary for your safety

or which are important for the unit's functional capability are highlighted by a warning

triangle and/or signal words (Warning!,

Caution!, Attention!). Always remember.

the unit.

3

2

This user information contains information on remedying any faults which may occur, see the section

”What to do if ...”.

After this symbol you will find detailed information on operation and practical use of the

unit.

The clover leaf indicates tips and information

on the economical and environmentallyresponsible use of the unit.

2

Page 3

Contents

Instructions for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Environment Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Drawer for Washing Powder and Care Agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Program Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Additional Program Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Consumption Data and Wash Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Water Protection Aqua Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Before the First Wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Prepare the Washing Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Sort and Prepare the Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Washing Types and Care Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Washing Detergents and Care Agents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Which washing detergent and care agent? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

How much washing detergent and care agent? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Water Softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Run a Washing Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Brief Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Set the Washing Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Change Spin Speed / Select Rinse Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Set the Delay Timer/Soaking Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Opening and Closing the Filling Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Loading the washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Add Washing Detergent/ Care Agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Start the Washing Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Washing Program Progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Changing a Washing Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Washing Cycle Ended/Remove Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Program Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Separate Conditioning/Starching/Impregnating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Separate Rinse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Separate Spin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cleaning and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Washing Detergent Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Washing Drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Filling Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

What to do if ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Remedying Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

If the washing result is not satisfactory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Carry Out Emergency Emptying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cleaning the drain pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Additional Rinse, RINSE+ (Spülen+/Rinçage+) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Child Safety Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Setting up and connection instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3

Page 4

Technical Data /Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Safety Instructions for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Setting Up the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Transporting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Removing the Transit Bars/Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Prepare the Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Setting Up on a Concrete Pedestal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Setting Up on a Vibrating floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Compensate for Floor Unevenness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Water Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Permissible Water Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Water Inflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Water Drainage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Delivery Heads over 1m . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Servicestellen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Points de Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Servizio dopo vendita . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Garanzia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4

Page 5

Instructions for use

1 Safety

The safety of ELECTROLUX electrical appliances

conforms to the recognised technical regulations

and the legislation covering the safety of appliances.

However, as manufacturers, we still regard it as our

responsibility to inform you of the following safety

information.

Prior to initial start-up

• Refer to the ”Installation and Connection

Instructions” later in this user information.

• When the unit is delivered in winter months with

minus temperatures: Store the washing machine

for 24 hours at room temperature before putting it

into operation.

Correct Use

• The washing machine is only designed for normal

domestic washing. If the unit is used for purposes

other than that for which it is designed, the manufacturer can accept no liability for any resulting

damages.

• For safety reasons, conversions or modifications

to the washing machine are not permissible.

• Use only detergents which are suitable for washing machines. Follow the washing detergent manufacturer's instructions.

• The washing must not contain any flammable solvents. Also remember this when washing precleaned washing.

• Do not use the washing machine for chemical

cleaning.

• Dyes/dye removers may only be used in washing

machines if the manufacturer expressly allows

these products. We cannot be held liable for any

resulting damage.

• Use only water from the water mains. Use rainwater or service water only if it meets the requirements outlined in DIN1986 and DIN1988.

• Frost damage is not covered by the warranty! If

the washing machine is in a room which is at risk

from frost, an emergency emptying operation

must be carried out when there is a frost risk (see

the section ”Carry Out Emergency Emptying”).

Child Safety

• Packaging components (e.g. films, polystyrene)

can be hazardous to children. Risk of suffocation!

Keep packaging away from children.

• Children often cannot recognise the hazards

associated with handling electrical appliances.

Therefore, ensure the necessary supervision during operation and do not allow children to play

with the washing machine – there is a risk that

children can get trapped inside.

• Ensure that children or small animals cannot

climb into the washing machine's drum.

• When disposing of the washing machine: Pull out

the mains plug, destroy the door lock, cut off the

electrical supply lead and throw away the plug

and the left-over cable. This means that children

at play cannot shut themselves inside and in so

doing be in danger.

General Safety

• Repairs to the washing machine may only be carried out by qualified specialists. Incorrect repairs

may result in significant risk to the user. If repairs

are necessary, consult our customer service or

your specialist dealer.

• Never use the washing machine if the mains

cable is damaged or the conrol panel, work surface or base panel area are so badly damaged

that the interior of the unit is openly accessible.

• Switch off the washing machine before carrying

out cleaning, care and maintenance work. Also

pull the mains plug out of the socket or, – if it is

permanently connected, – switch off the circuit

breaker at the household power distribution box

or completely remove the screw-in fuse.

• If operation is stopped, disconnect the appliance

from the mains supply and shut off the tap.

• Never pull the cable to remove the plug from the

socket. Always pull the plug itself.

• Multiple connectors, couplings and extension

cables must not be used. There is a risk of fire

with overheating!

• Do not spray down the washing machine with a

water jet. Risk of electric shock!

• The glass in the door becomes hot in the case of

wash programmes with high temperatures. Do

not touch!

• Allow the washing solution to cool before carrying

out an emergency emptying operation or cleaning

the drain pump.

• Small animals can chew the power cables and

water hoses. Risk of electric shock and danger of

water damage! Keep small animals away from the

washing machine.

5

Page 6

2 Disposal

Dispose the packing material!

Dispose of your washing machine's packaging correctly. All the packaging materials used are harmless

to the environment and can be recycled.

• Plastic parts are marked with standard international abbreviations:

>PE< for polyethylene, e.g. sheet wrapping

material

>PS< for polystyrene, e.g. padding material

(always CFC-free)

>POM< for polyoxymethylene, e.g. plastic clips

• Cardboard packaging is manufactured from recycled paper and should be deposited in the waste

paper collection for recycling.

Dispose the old appliance!

When you finally put your appliance out of operation,

please bring it to your nearest recycling centre or to

your dealer.

2 Environment Tips

• The pre-wash cycle is not required for averagely

dirty washing. This saves washing powder/liquid,

water and time (and does not harm the environment).

• The washing machine is especially economical

when you fully utilise the stated filling quantities.

• For small amounts of washing, use only half to

two thirds the recommended amount of washing

powder/liquid.

• Suitable pretreatment enables stains and small

amounts of dirt to be removed. You can then

wash at a lower temperature.

• Use the energy-saving program to wash garments which are lightly to moderately dirty.

• There is often no need for conditioner. Try it once!

If you use a dryer, your washing will become soft

and velvety even without conditioner.

• In the case of medium to high water hardness,

(hardness range II or higher, see ”Washing and

Care Agents”), you should use water softener.

The washing powder/liquid can then always be

metered for hardness range I (= soft).

6

Page 7

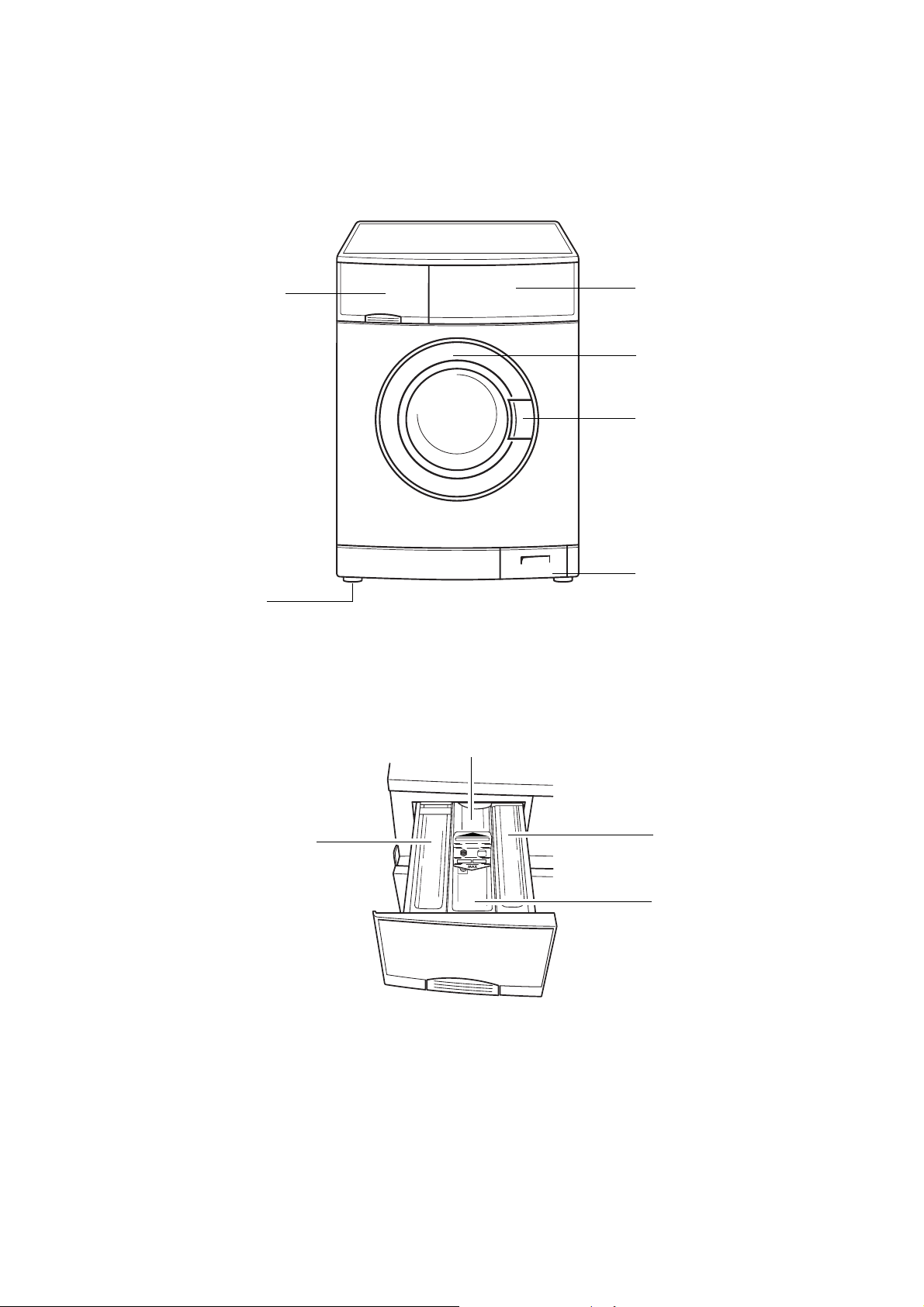

Unit Description

Front View

Drawer for washing

powder and care agent

Screw feet

(height-adjustable)

Control panel

Rating plate

(behind filling door)

Filling door

Flap in front of

drain pump

Drawer for Washing Powder and Care Agent

Main detergent

(powder) and watersoftener if required

In-wash stain treatment

Pre-wash detergent/

soaking agent or

water-softener

Liquid care agent

(conditioner, finisher,

starch)

7

Page 8

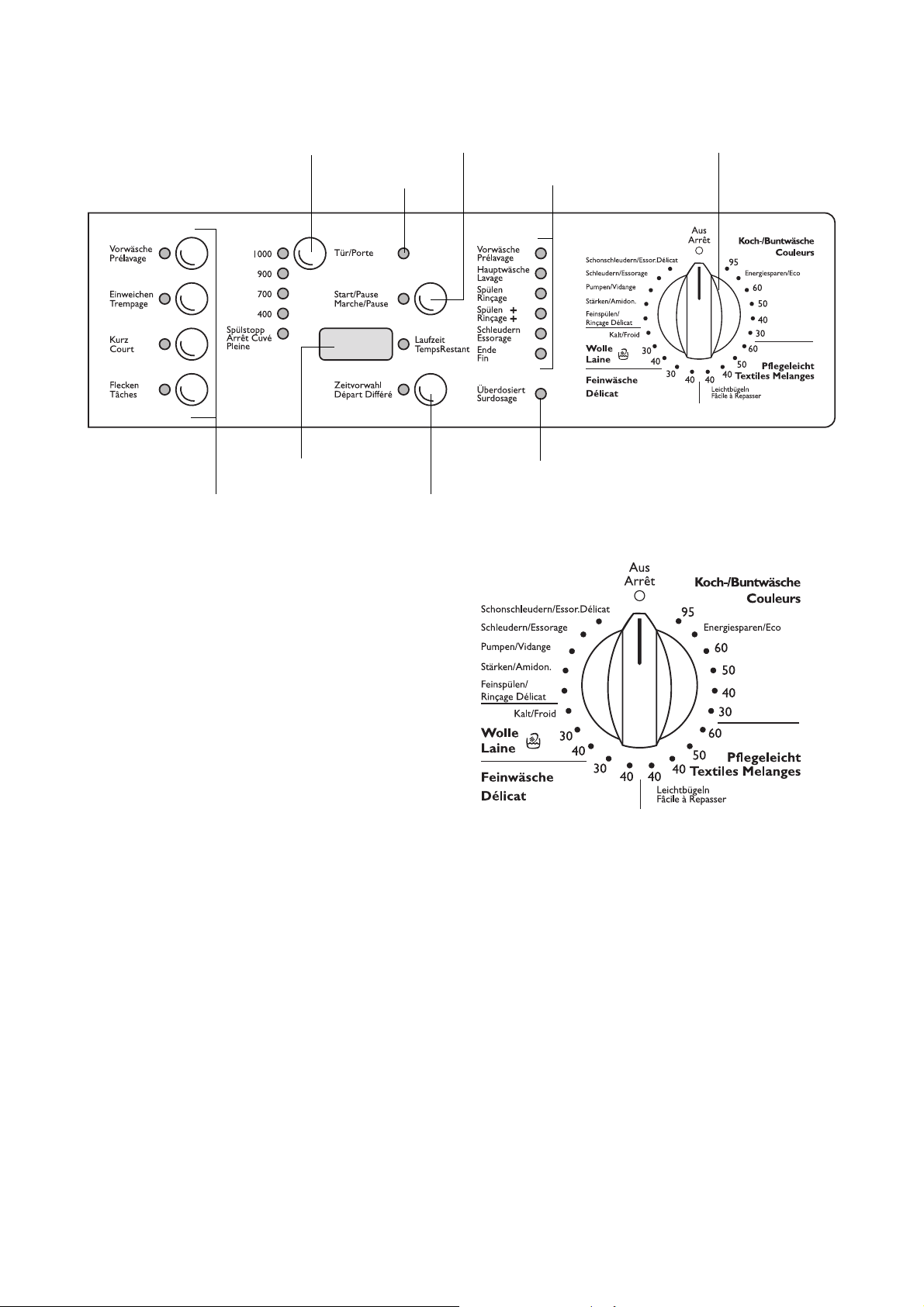

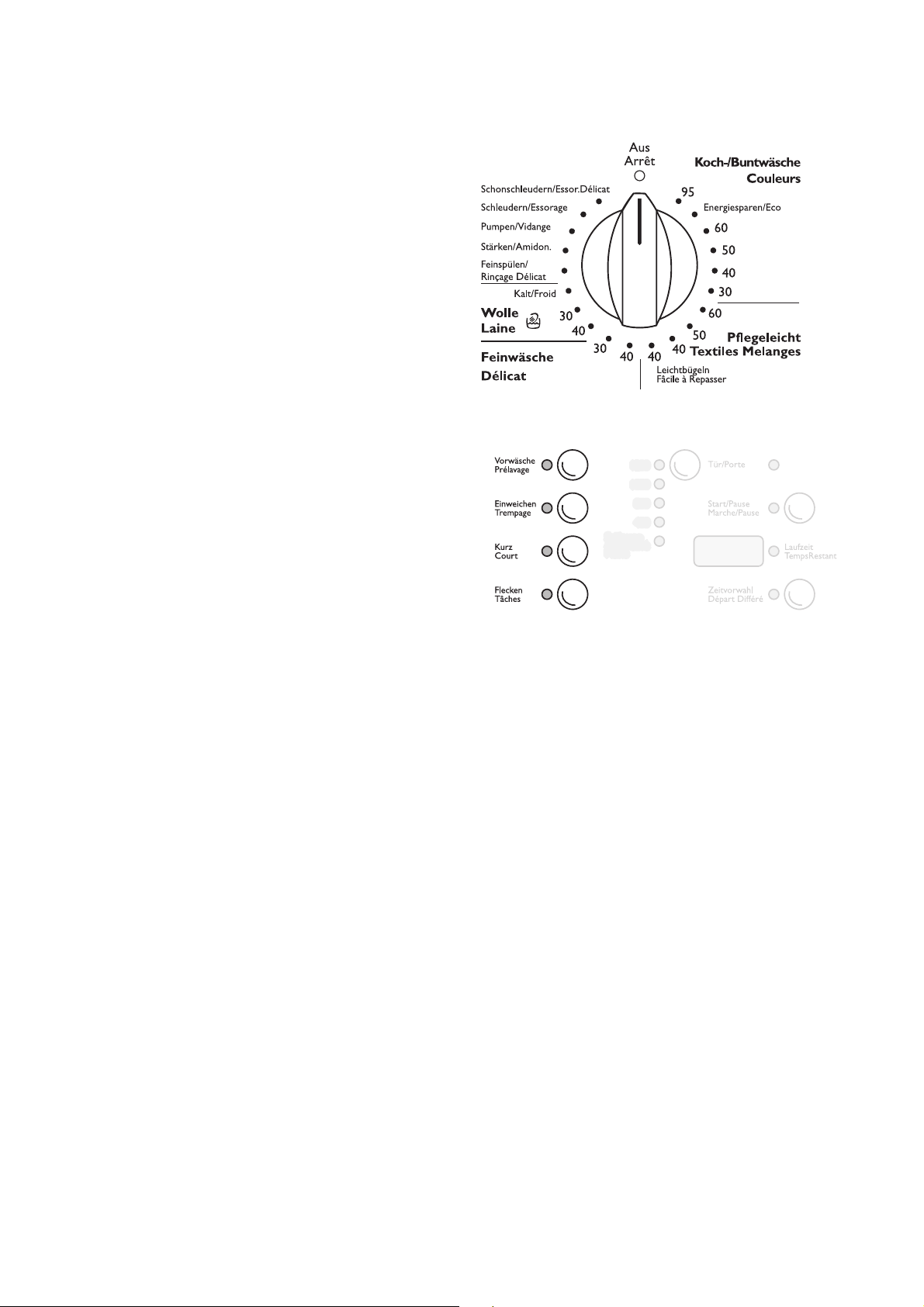

Control Panel

Spin speed/RINSE HOLD button

DOOR display

Multidisplay

START/PAUSE button

DELAY TIMER buttonAdditional program buttons

Program Selector

The program selector determines the type of washing cycle (e.g. water level, drum movement, number

of rinses, spin speed) according to the type of garments being washed, and also the washing solution.

Program selector

Program sequence display

OVER DOSING display

OFF (Aus, Arrêt)

Switches off the washing machine. All other positions are "switched on".

COTTONS/LINEN

(Koch-/Buntwäsche, Couleurs)

Main washing cycle Cottons/Linen at 30 °C to

95 °C.

2

ENERGY SAVING position (Energiesparen/

Eco): Energy-saving program at approx.

67 °C for slightly to normally dirty cottons,

extended washing time. Cannot be combined with QUICK WASH (Kurz, Court) and

STAIN (Flecken, Tâches).

EASY-CARES

(Pflegeleicht, Textiles Melanges)

Main washing cycle for easy-care textiles (mixed fabrics) at 40 °C to 60 °C.

EASY IRON position (Leichtbügeln, Fâcile à

Repasser): Main washing cycle at 40 °C for easycare textiles which, with the aid of this program, only

have to be either gently ironed or not ironed at all.

8

Page 9

DELICATES (Feinwäsche, Délicat)

Main washing cycle for delicates at 30 °C or 40 °C.

WOOL (Wolle, Laine)/ P (Handwash)

Main washing cycle (cold up to 40 °C) for machinewashable woollens and for hand-washable wool textile and silk with the care symbol ï (handwash).

GENTLE RINSE

(Feinspülen, Rinçage Délicat)

Separate gentle rinse e.g. for rinsing hand-washed

textiles (2 rinses, liquid care agent from rinsing compartment æ is added, short spin).

STARCHING (Stärken, Amidon.)

Separate starching, separate conditioner, separate

impregnation of damp washing (1 rinse, liquid care

agent from the rinsing compartment æ is added,

spin).

PUMP OUT (Pumpen, Vidange)

Pumping off the water after a rinse hold (without

spin).

3

Rinse hold (Spülstopp, Arrêt cuve pleine)

means: The washing remains lying in the last

rinsing water. It is not spun.

SPIN (Schleudern, Essorage)

Pumping off the water after a rinse hold and spin, or

separate spin of hand-washed cottons/ linen.

SHORT SPIN

(Schonschleudern, Essorage Délicat)

Pumping off the water after a rinse hold and short

spin or separate short spin of sensitive textiles (easycare washing, delicates, woollens).

Additional Program Buttons

The additional program buttons are for adapting the

washing program to the dirtiness of the washing.

Additional programs are not required for washing

which is not excessively dirty.

Various functions can be combined with each other,

depending on the program.

PRE WASH (Vorwäsche, Prélavage)

Warm pre wash before the main washing cycle which

follows on automatically; with intermediate spin for

COTTONS/LINEN (Koch-/Buntwäsche, Couleurs)

and EASY-CARES (Pflegeleicht, Textiles Melanges),

without intermediate spin for DELICATES (Feinwäsche, Délicat).

If RINSE HOLD (Spülstopp/Arrêt Cuvé Pleine) has

been selected, no spinning will take place at all.

9

Page 10

SOAKING (Einweichen, Trempage)

Approx. 50 minutes at 30 °C. Extendable with the

button DELAY TIMER (Zeitvorwahl, Départ Différé) to

max. 10 hours and approx. 20 minutes. This is followed automatically by the main wash.

QUICK WASH (Kurz, Court)

Shorter washing cycle for slightly dirty washing.

STAIN (Flecken, Tâches)

For treating very dirty washing or stained washing.

In-wash stain treatment is added during the program

on a time-optimized basis. May only be used for

wash temperatures from 40°C as stain removers only

become effective at higher temperatures.

3

With the WOOL (Wolle, Laine)/P (handwash)

program, it is not possible to select the additional programs (any pressed buttons have

no effect).

Consumption Data and Wash Times

The values for selected programs in the following tables were determined under standard conditions. However,

there is a helpful orientation aid for domestic operation.

Program Selector/Temperature

COTTONS/LINEN 95

(Koch-/Buntwäsche, Couleurs)

COTTONS/LINEN 60

(Koch-/Buntwäsche, Couleurs)

COTTONS/LINEN 40

(Koch-/Buntwäsche, Couleurs)

EASY-CARES 40

(Pflegeleicht, Textiles Melanges)

DELICATES 30

(Feinwäsche, Délicat)

WOOL (Wolle, Laine)/P (Handwash) 30 2 48 0.20

1) Note: Program setting for a test in accordance with EN 60 456. The consumption values can deviate from

the stated values depending on the water pressure, water hardness, inlet temperature, room temperature,

type and quantity of washing, the washing powder/liquid used, fluctuations in the mains voltage and selected

additional functions.

1)

Filling Quantity

in kg

5451.70

5420.94

5490.60

2,5 54 0.50

2,5 50 0.30

Water

in litres

Energy

in kWh

10

Page 11

Water Protection Aqua Control

In the event of damage to the supply hose, the system blocks the further supply of water to the unit

directly at the water tap.

If water escapes elsewhere, the drainage pump

automatically pumps off – even if the unit is switched

off. The washing machine merely has to be connected to the electricity mains.

Before the First Wash

Carry out a washing operation without washing.

COTTONS/LINEN 95 °C (Koch-/Buntwäsche, Couleurs), with half the quantity of washing powder.

This removes residues left over from production on

the drum and solution container.

Prepare the Washing Cycle

Sort and Prepare the Washing

• Sort the washing according to care codes and

type (see ”Washing Types and Care Codes”).

• Empty pockets.

• Remove metal parts (paper clips, safety pins

etc.).

• To prevent washing damage and washing snags:

Close zip fasteners, button closed bed covers

and pillow cases, and tie together ribbons, e.g. on

aprons.

• Use clothing made of double-layer fabric (sleeping bag, anorak etc.).

• On knitted, coloured textiles and on wool and textiles with fitted decorations: Turn inside out.

• Wash small and sensitive items (baby socks,

stockings, tights, bras etc.) in a washing net, a

cushion with a zip fastener or in larger socks.

• Treat curtains with particular care. Remove small

metal rollers or small, burred rollers or tie them in

a net or in a bag. We cannot accept any liability

for damage.

• Do not wash coloureds and whites together in

one washing cycle. Otherwise, whites will discolour or turn grey.

• New coloureds often contain surplus dye. It is

best to wash such items separately the first time.

• Mix small and large items of washing! This

speeds up theeffect of washing and the washing

is more favourably distributed during spinning.

• Loosen up the washing before loading it into the

washing machine.

• Put the washing into the drum folded out.

• Pay attention to the care instructions ”Wash sep-

arately” and ”Wash separately several times”!

11

Page 12

Washing Types and Care Codes

The care codes help you choose the correct washing

program. The washing should be sorted according to

type and care code. The temperatures stated in the

care codes are all maximum values.

Cottons ç

Textiles made of cotton and linen with this care code

are insensitive to mechanical stress and high temperatures. The program COTTONS/LINEN (Koch-/

Buntwäsche, Couleurs) is suitable for this type of

washing.

Linen èë

Textiles made of cotton and linen with this care code

are insensitive to mechanical stresses. The program

COTTONS/LINEN (Koch-/Buntwäsche, Couleurs) is

suitable for this type of washing.

Easy-Care Garments êí

Textiles such as finished cottons, cotton mixtures,

viscose and synthetics with this care code require

mechanically more mild treatment. The program

EASY-CARES/EASY IRON (Pflegeleicht, Textiles

Melanges/Leichtbügeln, Fâcile à Repasser) is suitable for this type of washing.

Delicates ì

Textiles such as layered fibres, microfibres, viscose,

synthetics and curtains with this care code require

very gentle treatment. The program DELICATES

(Feinwäsche, Délicat) is suitable for this type of

washing.

Wool and Very Sensitive Washing

9ìï

Textiles such as wool, wool mixtures and silk with

this care code are especially sensitive to mechanical

stresses. The program WOOL (Wolle, Laine)/P

(handwash) is suitable for this type of textiles.

Attention! Textiles with the care code ñ (Do not

wash!) must not be washed in the washing machine!

12

Page 13

Washing Detergents and Care Agents

Which washing detergent and care

agent?

Use only washing detergents and care agents which

are suitable for use in washing machines. Always follow the manufacturer's instructions.

How much washing detergent and

care agent?

The amount to be used depends on:

• the dirtiness of the washing

• the hardness category of the mains water supply

• the filling quantity

Water Softener

For medium to high water hardness (hardness category II or higher) you should use water softener. Pay

attention to the manufacturer's instructions. Always

then meter detergent for hardness category I (= soft).

The responsible water works can provide information

on the local water hardness.

2

Refer to the detergent/care agent manufacturer's

instructions on use and dosage.

2

If the detergent manufacturer gives no

details of the dosing quantities for minimum

loads, add one third less for half loads and,

in the case of very small loads and for EASY

IRON (Leichtbügeln, Fâcile à Repasser), only

half the amount of detergent recommended

for a full load.

Since the water softener is added before the

main washing detergent, (water pre-softening), eighty percent of the softener quantity

stated on the package is sufficient.

Water Hardness Details

Hardness Category

I – soft 0 - 7 up to 1.3

II – medium hard 7 - 14 1.3 - 2.5

III – hard 14 - 21 2.5 - 3.8

IV – very hard over 21 over 3.8

Water Hardness °dH

(degrees German hardness)

Water Hardness in mmol /l

(millimol per litre)

13

Page 14

Run a Washing Cycle

Brief Instructions

A washing cycle is run in the following steps:

1. Set the correct washing program:

– Set the program and temperature with the pro-

gram selector

– Set any additional program(s) if required

2. Change the spin speed if necessary / select

RINSE HOLD (Spülstopp, Arrêt Cuvé Pleine).

3. Set DELAY TIMER (Zeitvorwahl, Départ Différé) if

necessary.

4. Open the filling door and fill with washing.

5. Close the filling door.

6. Add washing detergent/care agent.

7. Start the washing program.

After the Washing Program Ends:

Attention! If the washing cycle ended with RINSE

HOLD (Spülstopp, Arrêt Cuvé Pleine), before opening the filling door carry out PUMP OUT (Pumpen,

Vidange), SPIN (Schleudern, Essorage) or SHORT

SPIN (Schonschleudern, Essorage Délicat).

8. Open the filling door and remove the washing.

9. Switch off the washing machine: Set the program

selector to OFF (Aus, Arrêt).

14

Page 15

Set the Washing Program

3

1. Set the program selector to the required washing

2. Select any additional program(s) if required:

For a suitable program, the right temperature and possible additional programs for

the relevant washing type, refer to the ”Program Tables”.

program with the required temperature.

The probable duration of the set program in minutes is shown in the multi-display.

The indicator for the selected additional program

lights up.

– To change the selection, press another button.

– Press the button again to deselect.

15

Page 16

Change Spin Speed / Select Rinse Hold

If necessary, change the spin speed for the final spin/

select RINSE HOLD (Spülstopp, Arrêt Cuvé Pleine):

Change the spin speed

Continue pressing the spin speed/RINSE HOLD

(Spülstopp, Arrêt Cuvé Pleine) button until the indicator for the desired spin speed is illuminated.

3

If you do not change the spin speed, the

final spin will be adjusted automatically

depending on the type of wash cycle:

– COTTONS/LINEN

(Koch-/Buntwäsche, Couleurs)

– EASY-CARES/EASY IRON

(Pflegeleicht, Textiles Melanges/

Leichtbügeln, Fâcile à Repasser)

– DELICATES (Feinwäsche, Délicat) 700 rpm

– WOOL (Wolle, Laine)/P (Handwasch) 900 rpm

The speed for the intermediate spin cycle is

dependent on the wash cycle selected and

cannot be altered.

1000 rpm

900 rpm

Select RINSE HOLD

Continue pressing the spin speed/RINSE HOLD

(Spülstopp, Arrêt Cuvé Pleine) button until the RINSE

HOLD (Spülstopp, Arrêt Cuvé Pleine) indicator is illuminated.

3

If RINSE HOLD (Spülstopp, Arrêt Cuvé

Pleine) is selected, the washing will remain in

the final rinse water and will not be spun.

The washing will not be spun throughout the

entire wash cycle. As a result the cycle is a

very quiet one. RINSE HOLD (Spülstopp,

Arrêt Cuvé Pleine) is therefore especially

suitable for washing at night.

Note: The laundry remains lying in the water

until you drain or spin (see section “Washing

Cycle Ended”). After 18 hours however, it is

automatically drained and pumped.

16

Page 17

Set the Delay Timer/Soaking Duration

Delay Timer

The button DELAY TIMER allows the start of a washing program to be advanced by 1 to a maximum of

19 hours.

To do this, press the button DELAY TIMER (Zeitvorwahl, Départ Différé) as often as necessary until the

required start delay is shown in the multidisplay,

e.g.12h in the form for a program start delay of 12

hours.

If19h is shown and you press again, 0h and afterwards the run time of the set washing program

appears (display in minutes, e. g.126). In this state,

the delay timer is not set.

Soaking Duration

With the SOAKING (Einweichen, Trempage) button

pressed, you can extend the soaking duration with

the button DELAY TIMER (Zeitvorwahl, Départ

Différé). Maximum 10 hours and approx. 20 min.

3

To set, press the button DELAY TIMER (Zeitvorwahl,

Départ Différé) as often as necessary until the

required soaking duration is shown in the multidisplay, e.g.1h (= 1 hour).

After approx. 2 seconds, the multidisplay shows the

run time in minutes.

Without delay timer, the soaking duration is

approx. 30 minutes, plus a pre-wash time of

approx. 20 minutes.

This run time is comprised as follows:

selected soaking period e. g. 1h =60 minutes

+ heating up/prewash

period

+ run time of the selected

washing program

= displayed value e. g. approx. 206 minutes

3

While SOAKING (Einweichen, Trempage) is

running, PRE WASH (Vorwäsche, Prélavage) lights up on the program sequence display.

e. g. approx. 20 minutes

e. g. approx. 126 minutes

17

Page 18

Opening and Closing the Filling Door

• Open: Pull on the handle of the filling door.

• Close: Press the filling door firmly closed.

The displays DOOR (Tür/Porte) and START/PAUSE

(Marche/Pause) show whether the door can be

opened while the appliance is switched on:

Display

DOOR

(Tür/Porte)

Glows

green

Glows

green

Is off

1) The main door is locked because of a high water

level or a high temperature.

3

If

– the display DOOR (Tür/Porte) flashes red

– then the error code E40 flashes in the

multidisplay

– and the display MAIN WASH (Haupt-

wäsche, Lavage) flashes

you tried to start a washing program without

first closing the main door properly. In this

case push the door shut firmly and restart

the washing program.

Display

START/PAUSE

(Marche/Pause)

Flashes red Yes

Glows red

Flashes or

glows red

Opening door

after pressing button START/PAUSE

(Marche/Pause)

possible?

Yes,

1)

No

Loading the washing

3

1. Sort and prepare the washing according to type.

2. Open the door: pull the handle on the loading

3. Load the washing.

4. Close the door firmly.

For maximum load amounts, see “Programme Tables”. For instructions on how to

correctly prepare the washing, see the

"Sorting and preparing the washing”.

door.

Important: When shutting the door, be sure that

no items are caught in it. This could result in damage to both machine and clothes.

18

Page 19

Add Washing Detergent/Care Agent

3

1. Open the washing detergent drawer: grip inside

2. Fill with washing detergent/care agent.

Refer to the information on washing detergents and care agents, see section ”Washing Detergents and Care Agents”.

the flap on the drawer at the bottom (1) and pull

out the drawer as far as it will go (2).

–

Compartment for in-wash stain

treatment

– Compartment for main washing

powder

(If you use water softener and need the right

compartment for the pre-wash/soaking agent,

add the water softener to the main washing

detergent in the left compartment.)

–

Compartment for liquid care agent

(Conditioner, finisher, starch)

Attention! Fill the compartment up to the MAX

mark. If necessary, dilute viscous agent up to

the MAX mark, and dissolve powder starch.

Note: It is normal for a small amount of water

to be left in the compartment for liquid conditioner; this will not affect the wash results.

–

Compartment for pre-wash agent/

soaking agent

Only for additonal programs PRE WASH (Vorwäsche, Prélavage) and SOAKING (Einweichen, Trempage)

or for water softener

In-wash Stain Treatment

Main Washing

Powder

Liquid Care Agent

Pre-Wash Agent/

Soaking Agent

or Water Softener

3. Push the drawer fully in.

3

If using Liquid Detergent/Tabs:

Add liquid detergent/tabs in the amount recommended by the washing detergent industry. Follow the instructions on the detergent

package.

19

Page 20

Start the Washing Program

1. Check that the water valve is open.

2. Start the washing program: Press the button

START/PAUSE. The washing program is started

or it starts after the set time expires.

3

If the time preselection is set:

A set time preselection runs and the remaining time

until the program start is displayed (in each case in

full hours, e.g. 5h). During this time you can load

washing or change/abort the time preselection.

• Load washing: Press the button START/PAUSE.

• Change or abort time preselection: Press the but-

The filling door is not correctly closed if,

when the button START/PAUSE is pressed,

– the indicator DOOR (Tür, Porte) flashes

red

– the fault code E40 in the multidisplay

flashes

– and the indicator MAIN WASH (Haupt-

wäsche, Lavage) flashes.

In this case, press the filling door firmly

closed and again press the button START/

PAUSE.

The filling door can be opened. Next, close the

door and again press the button START/ PAUSE.

ton DELAY TIMER (Zeitvorwahl, Départ Différé) as

often as necessary until the required time is displayed; when the program run time is displayed

(display in minutes, e.g.126), the washing program starts without delay.

Washing Program Progress

Program Sequence Display

Prior to the start, the program steps chosen are

displayed by the program sequence display. During

the washing program the current program step is

displayed.

Multi-display

The expected time remaining (in minutes) to the end

of the program is shown in the multi-display.

3

The multi-display indicates the estimated

duration, in minutes, of the program. These

timings are estimates and can be varied and

influenced by incoming water temperature,

type and quantity of laundry, out of balance

spin detection and foam detection. During

the program countdown the remaining time

can be recalculated due to any of the above

factors.

20

Page 21

Changing a Washing Program

Changing or aborting a program

1. Press button START/PAUSE (Marche/Pause).

2. Turn programme knob to OFF (Aus, Arrêt). The

washing program is aborted.

3. If required, set a new washing program. Otherwise turn the programme knob to PUMP OUT

(Pumpen, Vidange) and then press the button

START/PAUSE (Marche/Pause).

3

The washing program can be interrupted at

any time with the button START/PAUSE

(Marche/Pause) and continued by pressing

the button again. Changing the washing program is possible only after the programme

knob was turned to OFF (Aus, Arrêt).

Select the Additional Program

The additional programs QUICK WASH (Kurz, Court)

or STAIN (Flecken, Tâches) can also be selected

after the program start.

1. Press the button START/PAUSE (Aus, Arrêt).

2. Press the button QUICK WASH (Kurz, Court) or

the button STAIN (Flecken, Tâches).

3. Press the button START/PAUSE (Marche/Pause)

again. The washing program is continued.

Change the Spin Speed

During the washing program, the spin speed can still

be changed or RINSE HOLD (Spülstopp, Arrêt cuve

pleine) can be set.

1. Press the button START/PAUSE (Marche/Pause).

2. Change the speed with the button Spin Speed/

RINSE HOLD (Spülstopp, Arrêt cuve pleine).

3. Press the button START/PAUSE (Marche/Pause)

again. The washing program is continued.

21

Page 22

Washing Cycle Ended /Remove Washing

After a washing program has ended, END (Ende, Fin)

lights up on the program sequence display.

If you selected RINSE HOLD (Spülstopp, Arrêt cuve

pleine), the indicator next to the button START/

PAUSE (Marche/Pause) flashes.

1. After a rinse hold, it is first necessary to pump off

the water:

– Press either the button START/PAUSE

(Marche/Pause)

(water is pumped off and the washing is spun

according to the program which has just run;

after pressing the button START/PAUSE

(Marche/Pause) again, the spin speed can also

still be changed during spinning),

or

– first turn the programme selector to OFF (Aus,

.

Arrêt)

Then turn the program selector to PUMP OUT

(Pumpen, Vidange) and press the button

START/PAUSE (Marche/Pause)

(water is pumped off without spinning)

or

– first turn the programme selector to OFF (Aus,

.

Arrêt)

Then turn the program selector to SPIN (Schleudern, Essorage) or SHORT SPIN (Schonschleudern, Essorage Délicat) and press the

button START/ PAUSE (Marche/Pause)

(water is pumped off and the washing is spun

or gently spun).

After the end of this program step, the indicator END

(Ende, Fin) lights up.

2. Open the filling door.

As soon as the indicator DOOR (Tür, Porte) lights

up green, the filling door can be opened.

3. Remove the washing.

4. Turn the program selector to OFF (Aus, Arrêt).

5. After washing, pull out the washing detergent

drawer slightly so that it can dry out. Only lean the

door against the washing machine so that the latter can air out.

3

Attention! If the washing machine is not used for a

long time: Close the water tap and disconnect the

washing machine from the electricity mains. (The

Aqua Control water protection does not function if

the power supply is interrupted).

If the display OVER DOSING (Überdosiert,

Surdosage) lights up, too much washing

detergent was used in the washing program

just ended. During the next wash, pay attention to the dosing information of the washing

detergent manufacturer and pay attention to

the filling quantity!

22

Page 23

Program Tables

Washing

Not all possible settings are listed below - only the ones most commonly used in everyday operation and the

most appropriate ones.

Type of Washing,

Care Codes

Cottons

ç

Energy-Saving

Program:

Cottons ç

Linen

èë

Easy-Cares

êí

Max. Filling

Quantity

(dry weight)

1

5kg

5kg

5kg

2.5kg

1kg

)

2)

COTTONS/LINEN

(Koch-/Buntwäsche, Couleurs)

95

COTTONS/LINEN

(Koch-/Buntwäsche, Couleurs)

ENERGY SAVING

(Energiesparen/Eco)

COTTONS/LINEN

(Koch-/Buntwäsche, Couleurs)

30 to 60

EASY-CARES

(Pflegeleicht, Textiles Melanges)

40 to 60

EASY IRON

(Leichtbügeln, Fâcile à Repasser)

40

Program Selector

Te mp er at ure

5)

Possible

Additional Programs

PRE WASH (Vorwäsche, Prélavage)

SOAKING (Einweichen, Trempage)

QUICK WASH (Kurz, Court)

STAIN (Flecken, Tâches)

PRE WASH (Vorwäsche, Prélavage)

SOAKING (Einweichen, Trempage)

STAIN (Flecken, Tâches)

PRE WASH (Vorwäsche, Prélavage)

SOAKING (Einweichen, Trempage)

3

QUICK WASH (Kurz, Court)

STAIN (Flecken, Tâches)

PRE WASH (Vorwäsche, Prélavage)

SOAKING (Einweichen, Trempage)

QUICK WASH (Kurz, Court)

STAIN (Flecken, Tâches)

)

4)

Delicates

ì

Woollens/Handwash

9ìï

1) The load amount inquiry operates in accordance with the EN 60456 standard load.

2) A 10-litre bucket holds approx. 2.5kg of dry washing (cottons).

3) QUICK WASH cannot be selected if washing at 50°C.

4) In the case of the STAINS, a minimum temperature of 40°C is required for the stain remover to become ef-

fective.

5) Only if a filling quantity of 1kg is observed are creases in the washing largely avoided.

5 to 7 easy-care men's shirts are equivalent to about 1kg of dry washing.

2.5kg

(or 15-20m

curtains)

2kg

DELICATES

2

(Feinwäsche, Délicat)

30, 40

P

WOOL (Wolle, Laine)

COLD (Kalt, Froid

) to 40

PRE WASH (Vorwäsche, Prélavage)

SOAKING (Einweichen, Trempage)

QUICK WASH (Kurz, Court)

STAIN (Flecken, Tâches)

4)

23

Page 24

Separate Conditioning/Starching/Impregnating

Type o f Wa s h ing

Cottons/Linen 5kg

Max. Filling Quantity

(dry weight)

Separate Rinse

Type o f Wa s h ing

Cottons/Linen 5kg

Easy-Cares 2.5kg

Delicates 2.5kg

Woollens/Handwash 2kg

Max. Filling Quantity

(dry weight)

Separate Spin

Type o f Wa s h ing

Max. Filling Quantity

(dry weight)

Program Selector

STARCHING

(Stärken, Amidon.)

Program Selector

GENTLE RINSE

(Feinspülen, Rinçage Délicat)

Program Selector

Cottons/Linen 5kg

Easy-Cares 2.5kg

Delicates 2.5kg

Woollens/Handwash 2kg

SPIN

(Schleudern, Essorage)

SHORT SPIN

(Schonschleudern, Essorage Délicat)

24

Page 25

Cleaning and Care

Control Panel

Attention! For cleaning panels and control parts, do

not use furniture polish or any aggressive cleaning

agents.

Wipe off control panels with a damp cloth. Use warm

water to do this.

Washing Detergent Drawer

The washing detergent drawer should be cleaned

from time to time.

1. Pull out the washing detergent drawer as far as it

will go.

2. Remove the washing detergent drawer with a firm

pull.

3. Remove the softener insert from the middle com-

partment.

4. Clean the softener insert under running water

5. Clean the compartments from the rear with warm

water.

It is best to use a bottle brush.

6. Push on the softener insert as far as it will go so

that it is secure.

7. Use a brush to clean the entire rinsing-in part of

the washing machine, especially the nozzles on

the top side of the rinsing-in chamber.

.

8. Insert the washing detergent drawer into the

guide rails and push it in.

25

Page 26

Washing Drum

The washing drum is made of high-quality stainless

steel. Rust deposits on the drum can occur due to

foreign bodies in the washing which can cause rust.

Attention! Do not clean the stainless steel drum with

acidic antiliming agents, scouring agents containing

chlorine or iron or steel wool. Our Customer Service

Department has suitable agents available.

Remove any rust deposits on the drum using a stainless steel cleaning agent.

Filling Door

Check regularly whether there are deposits or foreign

bodies in the rubber sleeve behind the filling door

and, if so, remove them.

26

Page 27

What to do if ...

Remedying Faults

In the event of a fault, try to solve the problem yourself with the aid of the information provided here. If

you call Customer Service to deal with one of the

faults listed here or to remedy an operating fault, the

customer service technician's visit will not be free of

charge, even during the warranty period.

• If the fault code E10, E20 or E40 is shown in the

multidisplay, you may be able to remedy the fault

yourself (see Faults Table below). After remedying

the fault, press the button START/PAUSE.

• With all other displayed faults (E plus number or

letter): switch appliance off and on again. Reset

the wash programme and press the START/

PAUSE button.

If the fault code is displayed again, please contact

the Customer Service department quoting the fault

code.

Problem Possible Cause Remedy

The washing machine does

not work.

The filling door cannot be

closed.

Fault code

indicator MAIN WASH (Hauptwäsche, Lavage) flashes.

No water runs in.

Fault code

indicator RINSE+ (Spülen+,

Rinçage+) flashes.

E40 appears. The

E10 appears. The

The mains plug is not plugged in. Plug in the mains plug.

The fuse of the building's wiring is not

in order.

The filling door is not correctly closed.

The button START/PAUSE (Marche/

Pause) was not pressed for long

enough.

The child lock is set.

The filling door is not correctly closed.

Water tap is closed. Open the water tap.

Filter in screw connection of the

intake hose is blocked.

Water tap is blocked with limescale or

is faulty.

Replace the fuse.

Close the filling door; the lock must

engage audibly.

Press the button START/PAUSE

(Marche/Pause) until the program

begins.

Cancel the child lock (see section

“Child Safety Feature").

Close the filling door correctly. Restart

the program.

Close the water tap. Unscrew the

hose from the water tap, remove the

filter and clean it under running water.

Check water tap and have it repaired

if necessary.

27

Page 28

Problem Possible Cause Remedy

The washing machine vibrates

during operation or it is on an

uneven surface.

The washing solution of the

main wash froths up a lot.

Water runs out under the

washing machine.

The transport safeguard has not been

removed.

The height-adjustable screw feet are

not correctly set.

There is not much washing in the

drum (e.g. only one dressing gown).

The water could not be completely

pumped off before spinning because

the drainage hose is bent

or

the solution pump is blocked.

Too much detergent was probably

used.

The screw connection on the intake

hose is leaky.

The drainage hose is leaky.

The washing solution pump cover is

not correctly closed.

Washing stuck in the filling door.

Remove transport safeguard as indicated in the instructions for installation and connection.

Adjust in accordance with the installation and connection instructions.

This does not impair the operation of

the machine.

Check the laying of the drainage hose

and eliminate the bend if necessary,

or clean the solution pump and, if

required, remove foreign bodies from

the pump housing.

Meter the detergent exactly in accordance with the manufacturer's information.

Tighten the intake hose screw connection.

Check the drainage hose and replace

it if necessary.

Close cover correctly.

Stop the program, remove washing

from the filling door, start a new program.

The emergency drain hose is not

properly shut off or it is not watertight.

Fault code EF0 appears.

The drain pump for the washing machine runs constantly even when the appliance is

switched off.

Conditioner not added, compartment æ for care agent full

of water.

Washing heavily creased. Too mush washing probably put in.

The washing has not been

spun as dry as usual.

The Aqua Control anti-flood system

has been activated.

Softener insert in the compartment for

care agent not correctly attached or is

blocked.

The washing was not able to be distributed evenly in the drum prior to

spinning.

Shut the emergency drain hose off

properly (see section "Performing an

Emergency Drain"). Call your aftersales service if the emergency drain

hose is not water-tight.

Turn off the tap, then remove the plug

from the mains and inform Customer

Service.

Clean the detergent drawer and firmly

attach the softener insert.

Pay attention to the maximum filling

quantity (see Program Tables). For

easy-care textiles, select the program

EASY IRON (Leichtbügeln, Fâcile à

Repasser).

Always load the drum as full as possible with a combination of large and

small items.

28

Page 29

Problem Possible Cause Remedy

Drainage hose bent. Remove the bend.

Washing not well spun. Residual water still visible in the

drum.

Fault code

indicator RINSE (Spülen,

Rinçage) flashes.

The main door cannot be

opened while the appliance is

turned on.

E20 appears. The

Maximum pump head (outlet head

1m from unit's floor surface)

exceeded.

Solution pump blocked.

If a siphon is connected: Siphon

blocked.

The main door is locked because of a

high water level or a high temperature. The display DOOR (Tür, Porte) is

not lit.

Power failure!

(All displays have gone off.)

For safety reasons the door remains

locked for 4 to 5 minutes.

Consult Customer Service. They can

supply a retrofit kit as a special accessory for delivery heads of more than

1m.

Switch off the unit and pull out the

mains plug. Clean the solution pump.

Clean the siphon.

Wait until the display DOOR (Tür,

Porte) lights up green.

Should it nevertheless be necessary

to open the main door:

Turn the programme knob to OFF

(Aus, Arrêt); turn the programme knob

to PUMP OUT (Pumpen, Vidange).

Press button START/PAUSE (Marche/

Pause) . The main door can be

opened after the water has been

pumped out.

If water can be seen through the window in the door, first carry out emergency emptying (see section

“Carrying out Emergency Emptying

Operation").

After approx. 4 to 5 minutes the door

can be opened again by pulling the

handle.

Washing detergent residues

form in the washing detergent

drawer.

The rinsing water is murky.

The corresponding display

does not light up when one of

the additional program buttons

is pressed.

Water tap not fully opened. Open the water tap fully.

Filter in the screw connection of the

intake hose on the water tap or on the

unit is blocked.

The cause is probably a detergent

with a high silicate content.

The selected additional program cannot be combined with the set program.

Close the water tap. Unscrew the

intake hose from the water tap and

from the unit. Clean the filter.

No negative influence on the rinsing

result, use liquid detergent if necessary.

Make another selection.

29

Page 30

If the washing result is not satisfactory

If the washing is grey and limescale

forms in the drum

• Not enough washing detergent added.

• The right washing detergent was not used.

• Special types of stain were not pretreated.

• Program or temperature incorrectly set.

• If binary wahing detergents were used, the indi-

vidual components were not added in the correct

ratio.

If there are still grey stains on the washing

• Washing contaminated with creams, grease or

oils was washing with too little detergent.

• Washing at too low temperature.

• A frequent cause is that conditioner – particularly

concentrated form, ended up on the washing.

Wash out such stains as quickly as possible and

carefully use the right conditioner.

If foam is still visible after the final rinse

• Modern washing detergents can still produce

foam, even in the final rinse. The washing is still

sufficiently rinsed.

If there are white residues on the washing

• These are the insoluble components of modern

detergents. They are not the result of an insufficient rinsing effect.

Shake or brush off the washing. Perhaps in future

you should turn the washing before washing it.

Check the choice of detergent and use a liquid

detergent if necessary.

30

Page 31

Carry Out Emergency Emptying

• When the washing machine no longer pumps off

the washing solution, an emergency emptying

operation must be carried out.

• When the washing machine is in a room where

there is a frost risk, an emergency emptying operation must be carried out when there is a frost

risk.

Also: Unscrew the intake hose from the water tap

and lay it on the floor. Empty the drainage hose.

1

1. Provide a flat collecting vessel to catch the wash-

2. Open the flap downwards in the right part of the

Warning! Switch off the washing machine

before carrying out an emergency emptying

operation and pull out the mains plug.

Caution! The washing solution running out

of the emergency emptying hose can be hot.

Risk of scalding! Allow the washing solution

to cool down before carrying out emergency

emptying.

ing solution as it runs out.

base panel and pull it off.

3. Remove the emergency emptying hose from the

holder.

4. Place the collecting vessel underneath.

5. Release and pull out the plug of the emergency

emptying hose by turning it anticlockwise.

The washing solution drains off. Depending on

the amount of solution, it may be necessary to

empty the collecting vessel several times. To do

this, temporarily close the emergency emptying

hose again with the plug.

When all the washing solution has

drained off:

6. Firmly push the plug into the emergency empty-

ing hose and turn it tight clockwise.

7. Put the emergency emptying hose back into the

holder.

8. Insert the flap into the base panel and close.

31

Page 32

Cleaning the drain pump

The drain pump is maintenance-free. Opening the

cover of the drain pump is required only in the event

of a malfunction when no more water is being

pumped out, e.g. if the pump wheel is blocked.

Before loading the machine, please always ensure

that there are no foreign objects present in the pockets or in between the items to be washed. Paper

clips, nails etc. which may find their way into the

washing machine along with the washing will remain

in the drain pump housing (foreign objects remain in

the pump wheel as protection).

To restart the drain pump when it is blocked, please

proceed as follows:

1

1. First carry out an emergency emptying procedure

2. Place a cloth on the floor in front of the cover of

3. Screw off the lid of the drain pump in an anti-

Warning: Prior to cleaning the drain pump,

switch off the washing machine and disconnect the power plug.

(see section “What to do if .../performing an

emergency emptying procedure”).

the drain pump. Residual water may run out.

clockwise direction and remove it.

4. Remove any foreign objects from the drain pump

housing.

5. Replace the cover. Laterally insert the webs on

the cover into the guide slots and screw on the

cover in a clockwise direction.

6. Cap the emergency emptying hose and place it in

the retainer.

7. Close the flap.

32

Page 33

Additional Rinse, RINSE+ (Spülen+/Rinçage+)

The washing machine is set for extremely economical water consumption. However, for persons who

suffer from allergies, it can be helpful to rinse with

more water.

3

Set Additional Rinse:

1. Turn the program selector to COTTONS/LINEN

2. Simultaneously keep the button PRE WASH (Vor-

3

If RINSE+ (Spülen+/Rinçage+) is set, an

additional rinse is performed in the case of

the programs COTTONS/LINEN (Koch-/

Buntwäsche, Couleurs), EASY-CARES

(Pflegeleicht, Textiles Melanges)/EASY IRON

(Leichtbügeln, Fâcile à Repasser) and DELICATES (Feinwäsche, Délicat).

No additional rinse is set when the unit is

delivered.

(Koch-/Buntwäsche, Couleurs), EASY-CARES

(Pflegeleicht, Textiles Melanges)/EASY IRON

(Leichtbügeln, Fâcile à Repasser) or DELICATES

(Feinwäsche, Délicat) with any temperature.

wäsche, Prélavage) and the button QUICK WASH

(Kurz, Court) pressed for at least 2 seconds.

RINSE+ (Spülen+/Rinçage+) lights up on the program run indicator. The additional rinse is set. It

remains saved until you cancel it again.

Water consumption is increased due to the

additional wash cycle.

Cancel Additional Rinse:

1. Again turn the program selector to COTTONS/

LINEN (Koch-/Buntwäsche, Couleurs), EASYCARES (Pflegeleicht, Textiles Melanges)/EASY

IRON (Leichtbügeln, Fâcile à Repasser) or DELICATES (Feinwäsche, Délicat).

2. Simultaneously keep the button PRE WASH (Vorwäsche, Prélavage) and the button QUICK WASH

(Kurz, Court) pressed for at least 2 seconds.

RINSE+ (Spülen+/Rinçage+) goes out in the program run indicator. The additional rinse is cancelled.

33

Page 34

Child Safety Feature

When the child safety feature is used, the filling door

can no longer be closed and no more washing programs can be started.

Setting the Child Safety Feature:

Use a coin to turn the rotary knob (on the inside of

the filling door) clockwise as far as it will go.

1

Cancelling the Child Safety Feature:

Turn the rotary knob anticlockwise as far as it will go.

Warning! The rotary knob must not be

pressed in following adjustment, otherwise

the child safety feature is not active. The

rotary knob must project as shown in the

diagram.

34

Page 35

Setting up and connection instructions

Technical Data /Dimensions

Height adjustment Approx. +10/-5 mm

Filling quantity

(program-dependent)

Use Domestic

Drum speed, spin see rating plate

Water pressure 1-10bar

max. 5kg

(=10–100N/cm

2

= 0.1–1.0MPa)

Safety Instructions for Installation

• Do not tilt the washing machine onto its front or

onto its right side (looking from the front). Electrical components could get wet!

• Check the washing machine for transport damage. Never connect a damaged unit. Consult your

supplier in the event of damage.

• Ensure that all parts of the transport safeguard

have been removed and that the splash guard is

fitted to the unit, see ”Removing the Transport

Safeguard”. Otherwise, damage to the unit or to

adjacent furniture could occur during spinning.

• Always insert the plug into a correctly installed PE

socket.

• In the case of permanent installation: A permanent installation may only be made by an authorised specialist.

• Before putting the unit into operation, ensure that

the rated voltage and current type shown on the

unit's rating plate are the same as the mains voltage and current type at the installation location.

The required electrical fuse is also shown on the

rating plate.

• Should work be carried out on the water supply

installations in order to allow the machine to be

connected properly to the water supply, this work

must be carried out by an authorised installer.

• Should work be carried out on the mains supply

in order to allow the machine to be connected

properly to the electricity supply, this work must

be carried out by an authorised electrician.

• The mains cable may only be replaced by the

Customer Service or by an authorised specialist.

(dimensions in mm)

35

Page 36

Setting Up the Unit

3

Washing machines with curved panels are

not suitable for substructures.

Transporting the Unit

• Do not place the washing machine on its front

side or on its right side (looking from the front).

Otherwise the electrical components can get wet.

• Never transport the unit without using the transport safeguard. Do not remove the transport safeguard until you reach the installation site.

Transporting the unit without the transport safeguard can result in damage to the unit.

• Never lift the unit by the open filling door or by its

base.

When transporting the unit with a sack

trolley:

• Attach the sack trolley only at the side. The scoop

of the sack trolley must not be longer than 24cm,

otherwise the float switch can be destroyed.

36

Page 37

Removing the Transit Bars/Bolts

Important Before the appliance is used for the first

time, the transit bars/bolts must be removed. Keep

all the parts of the transit bars/bolts in a safe place in

case they are needed for a later journey (moving

house).

1. On the back of the appliance open both hose

holders and take out hoses and power cable.

2. Remove both hose holders from the appliance by

pulling hard.

37

Page 38

3

3. Remove screw D and the spring with the special

4. Close the hole with the sealing cap C.

5. Undo two screws E with special key A.

6. Undo four screws F with special key A.

7. Remove transit bar G.

8. Screw in the four screws F again.

9. Close the two big holes with sealing cap B.

Special key A and sealing caps B (x 2) and C

(x 1) come with the appliance.

key A.

Important! Press the sealing cap in firmly so that

it engages in the back (protects the inside of the

appliance against splashes).

Important! Press the sealing cap in firmly so that

it engages in the back (protects the inside of the

appliance against splashes).

Prepare the Installation Location

• The installation surface must be clean, dry and

free of floor wax residue and other lubricating

coatings so that the unit does not slide away. Do

not use any lubricants as sliding aids.

• It is not recommended to set up the washing

machine on deep-pile carpets or on floor coverings with soft foam underlays, as this would mean

that the stability of the unit would not be guaranteed.

• Use ordinary rubber mats as underlays in locations with small-format tiles.

• Never use wood, card or similar underlays to

compensate for minor floor unevenness. Always

use the adjustable screw-type feet of the

machine.

• If, for reasons of space, it is not possible to avoid

setting up the unit next to a gas cooker or coal

stove: Insert a thermally-insulating panel between

the washing machine and the cooker (85 x 57cm).

This panel must have an aluminium foil on the

side against the cooker.

• The washing machine must not be set up in a

room where there is a danger of frost. Frost damage!

• The intake and drainage hoses must not be bent

or pinched.

38

Page 39

Setting Up on a Concrete Pedestal

When setting up the washing machine on a concrete

pedestal, it is essential for safety reasons to fit stand

plates in which the washing machine is then

adjusted. The stand plates are available from the

Customer Service Centre.

Setting Up on a Vibrating floor

In the case of vibrating floors, especially wooden

beam floors with flexible boards, securely screw a

water-resistant wooden panel at least 15mm thick

onto at least 2 of the floor beams. If possible, set up

the unit in a corner of the room where the wooden

floor is best firmly installed and is therefore least

likely to be susceptible to vibrations.

Compensate for Floor Unevenness

Floor unevenness can be compensated for and the

height can be corrected with the four adjustable

screw feet. The height can be adjusted in a range of

+10 ... -5 mm.

To adjust the feet use the special spanner supplied

for removing the transport braces.

1. Slide the special key firmly onto the hexagon

head of the threaded foot as far as it will go.

2. Adjust the screw feet so that the unit is horizontal

and stable. The unit must not wobble over when

loaded.

3. If necessary, check the setting with a spirit level.

Attention! Never compensate for minor floor une-

venness with underlays made of wood, card etc.

Always adjust the adjustable feet.

39

Page 40

Electrical Connection

Refer to the rating plate for details of the mains voltage, current type and the necessary fuses. The rating

plate is located at the top behind the filling door.

;

This unit conforms to the following EU

directives:

– the ”Low Voltage Directive" 73/23/EU

with changes

– the ”EMC Directive" 89/336/EWG

with changes

Water Connection

3

Attention!

– Units for connection to cold water must not be

– Use only new sets of hoses for connection!

The washing machine has safety features

which prevent contamination of the drinking

water and which conform to the legal regulations of the water authorities (e.g. for Germany: DVGW regulations). Other protection

measures in the installation are therefore not

necessary.

connected to hot water!

Permissible Water Pressure

The water pressure must be at least 1bar (= 10N/

2

cm

= 0.1MPa), maximum 10bar (= 100N/cm2 =

1MPa).

• In the case of more than 10bar: Connect a pressure-reducing valve upstream.

• In the case of less than 1bar: Unscrew the intake

hose on the unit side on the inlet solenoid valve

and remove the flow regulator (to do this, remove

the filter with pointed pliers and remove the rubber washer behind). Replace the filter.

40

Page 41

Water Inflow

A pressure hose 1.5m in length is supplied.

If a longer inflow hose is required, only a VDEapproved, complete set of hoses with fitted hose

screw connections offered by our Customer Service

is permissible.

– Sets of hoses in lengths of 2.2m, 3.5m and 5m

are available for washing machines without AquaControl.

– Sets of hoses in lengths of 2.0m, 2.9m and 3.9m

are available for washing machines with AquaControl.

Attention! Never cut into pieces in order to extend

the hoses!

3

1. Connect the hose with the angled connection to

Attention!

– Do not lay the supply hose vertically downwards.

– Only tighten the screw connection manually.

2. Connect the hose with the straight connection to

3. By slowly opening the water tap before putting

Sealing rings are supplied either in the plastic nuts of the hose screw connection or in

the enclosed pack. Do not use other seals!

the machine.

Rather, turn it to the right or left as shown in the

diagram.

a water tap with a screw thread of R 3/4 (inches).

Attention! Only tighten the screw connection

manually.

the washing machine into operation, check

whether the connection is free of leaks.

41

Page 42

Water Drainage

The drainage hose can either be connected to a

siphon or hung in a wash basin or bath tub.

Only original hoses may be used for extension purposes (max. 3m on the floor and then up to 80cm

high). The Customer Service stocks hoses in lengths

of 2.7 and 4m.

Attention! It is absolutely essential to install the

drainage hose free of pinches.

Water Drainage into a Siphon

The grommet on the end of the hose fits all commonly used siphon types.

Secure the grommet/siphon connecting point with a

hose clamp.

Draining the water into a basin

Attention!

– Small basins are not suitable for draining the

water into them. Water could overflow!

– It is not permitted to submerge the end of the

drainage hose into the pumped-off water. Water

could be sucked up into the hose!

– When hooked into a wash-basin or a bath tub the

drainage hose must be protected from slipping

out of place by the supplied slip-on elbow. Otherwise the repelling power of the draining water can

press the hose out of the sink.

Fix the elbow to the water tap or to the wall with

string.

Delivery Heads over 1m

To pump off the washing / rinsing agent, every washing machine has a pump which transports liquids via

the drainage hose up to a height of 1m, calculated

from the machine's floor.

For delivery heads over 1m, consult the Customer

Service.

42

Page 43

434445

Page 44

Page 45

Index

A

Aqua Control . . . . . . . . . . . . . . . . . . . . . . 11, 22, 28

C

Care agent . . . . . . . . . . . . . . . . . . . . . . 7, 13, 14, 19

Child safety feature . . . . . . . . . . . . . . . . . . . . 27, 34

Conditioner . . . . . . . . . . . . . . . . . . . . 6, 7, 9, 19, 24

Cottons . . . . . . . . . . . . . . . . . . . . . . . . 8, 12, 23, 24

Curtains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11, 23

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . 26

Customer service . . . . . . . . . . . . . . . . . . . . . . 27, 46

D

Delay timer . . . . . . . . . . . . . . . . . . . . . . . . 10, 17, 20

Delicates . . . . . . . . . . . . . . . . . . . . . . . . . . 9, 12, 23

Detergent . . . . . . . . . . . . . . . . . . . . . . . . . . 7, 13, 19

Detergent dispenser drawer . . . . . . . . . . . . . . . 7, 19

Door opening . . . . . . . . . . . . . . . . . . . . . . 18, 22, 29

Drain pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 7, 32

E

Easy iron . . . . . . . . . . . . . . . . . . . . . . . 8, 12, 23, 28

Easy-cares . . . . . . . . . . . . . . . . . . . . . . . . . 8, 12, 23

Emergency emptying . . . . . . . . . . . . . . . . . . . . . . 31

Energy saving . . . . . . . . . . . . . . . . . . . . . . . . . . 8, 23

F

Filling quantity . . . . . . . . . . . . . . . . . . . . . . . . 10, 23

Frost hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . 5, 31

G

Gentle rinse . . . . . . . . . . . . . . . . . . . . . . . . . . . 9, 24

H

Handwash . . . . . . . . . . . . . . . . . . . . . . . . . 9, 23, 24

I

In-wash stain treatment . . . . . . . . . . . . . . . . . . 7, 19

L

Linen . . . . . . . . . . . . . . . . . . . . . . . . . . 8, 12, 23, 24

M

Multidisplay . . . . . . . . . . . . . . . . . . 8, 17, 20, 27, 46

O

Over-dosed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

P

Pre wash . . . . . . . . . . . . . . . . . . . . . . . . . . 9, 19, 23

Pre wash detergent . . . . . . . . . . . . . . . . . . . . . 7, 19

Program aborting . . . . . . . . . . . . . . . . . . . . . . . . . 21

Program changing . . . . . . . . . . . . . . . . . . . . . . . . 21

Program progress display . . . . . . . . . . . . . . . . . . 20

Pump out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9, 22

Q