Page 1

INSTRUCTIONS

FOR

INSTALLATION

USE AND

MAINTENANCE

FOR COOKING

- GB -

Page 2

F

Fig. 2

1/2"

HOSE ATTACHMENT

A=

FOR LIQUID GAS

FLEXIBLE PIPE

T=

C

G

F

Fig. 3

BACK SIDE

HOSE ATTACHMENT

B=

FOR NATURAL GAS

(AND TOWN GAS

EXTRA E.E.C.

COUNTRY ONLY)

T=

FLEXIBLE PIPE

Flexible

tube

entry

Fig. 13

Fig. 15

1

8

1

2

3

4

8

7

5

6

2

7

3

6

4

5

Fig. 14

G

A

Fig. 16

Fig. 4

BACK SIDE

B

Fig. 5B

3

4

2

Fig. 7

BARS

Inflexible

tube

entry

170

Fig. 8

A

Fig. 5A

Fig. 6

NO NO YES

T

Z

Fig. 17

230 V ~

L1

N

E

E = GREEN and Yellow / N = BLUE / L1-L2-L3 = BROWN

400 V 2N~ 400 V 3N~

L1

1

2

L2

3

4

N

5

E

L1

1

L2

2

L3

3

4

N

5

Fig. 17B

BURNER PAN

FAST 12÷18 cm

SEMI FAST

18÷24 cm

Fig. 19

Fig. 17A

1

2

3

4

5

Max

E

Off

Low

Fig. 18

A

Fig. 20

Max

Fig. 9

Fig. 11

Low

Off

Fig. 10

Fig. 12

1

2

3

4

5

Fig. 21

V

B

F

8

7

6

Fig. 22

P

S

Fig. 23

2

Fig. 24

Page 3

Getting to know your new cooker

Thank you for choosing one of our products.

Our cookers are of simple, rational design. They are constructed to the best

standards to ensure good service and outstanding safety.

Please read this manual carefully; it will provide all the advice needed to allow

you to obtain the best results from the very first day.

These instructions for use are divided into two sections:

1st section: for the qualified technician

2nd section: for the user

1ST SECTION

FOR THE QUALIFIED TECHNICIAN

INSTALLATION

IMPORTANT: The gas and electricity connections and any adjustments must

be made by skilled staff. The manufacturer refuses all liability for

damage of any kind resulting from failure to comply with current

regulations or negligent installation of the appliance.

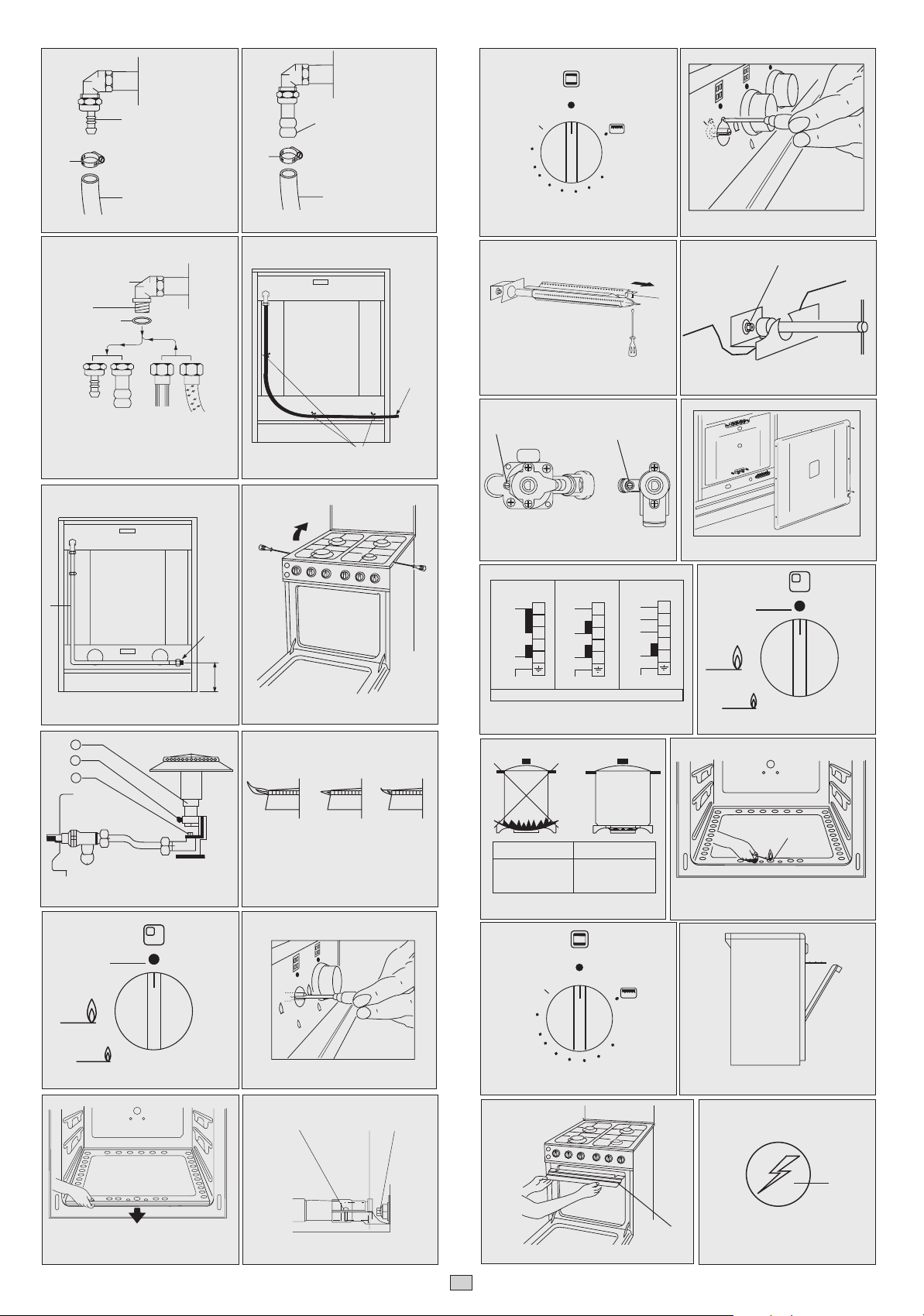

Fig. 1

OVERALL DIMENSIONS

MODEL WIDTH (X)

51 480

52 495

1320

845

X

500

100

TECHNICAL DATA: GAS PART

CHART 1

GAS TYPE

NATURAL

GAS

BUTANE GAS

L.P.G. GAS

PROPANE GAS

TOWN

GAS

OPERATING

PRESSURE

mbar

20

28

30

37

8

NOZZLE

Ø

DESIGNATION

Nº

FAST

135

SEMI-FAST

95

OVEN THERMOSTAT

130

OVEN THERMOMETER

135

105

GRILL

FAST

85

SEMI-FAST

62

OVEN THERMOSTAT

80

OVEN THERMOMETER

85

70

GRILL

265

FAST

170

SEMI-FAST

250

OVEN THERMOSTAT

255

OVEN THERMOMETER

210

GRILL

BURNER

POWER

kW

Max. Min.

0,62

3,09

0,32

1,56

3,00

3,00

1,90

0,62

3,09

0,32

1,56

3,00

3,00

1,90

0,62

3,09

0,32

1,56

3,00

3,00

1,90

FLOW RATE

l/h g/h

Max Min. Max Min.

59

295

30

149

286

286

181

703

355

682

682

432

141

73

225

114

219

219

138

Values for town gas injectors are valid for extra european country only.

TECHNICAL DATA: ELECTRICAL PART

CHART 2

CONVENTIONAL

OVEN

UPPER

ELEMENT

LOWER

ELEMENT

GRILL

ELEMENT

GAS

OVEN

NB.

When gas grill is not fitted

GRILL

ELEMENT

Watt

550

1400

550 +

1400

Watt

1400

CHART 3

ELECTRIC

HOT PLATES

RAPID

STANDARD

RAPID

STANDARD

ø

mm

145

145

180

180

Watt

1500

1000

2000

1500

N.B.: The fast electric hot plates are marked with a red dot.

1) INSTALLING THE COOKER

After removing the external packaging and the internal packaging of the various

moving parts, position the cooker ensuring that the installation area is normally

ventilated without any drafts which might blow out the burners. To ensure perfect

presentation, the stainless steel parts are mounted on the appliance protected

by a plastic covering, which must be removed before using the appliance.

N.B.: The sides of adjoing kitchen units in contact with the cooker must be capable

of withstanding temperatures of approximately 90°C. It is essential that furniture

in contact with the cooker are heat resistant or protected by a similar material.

If the adjacent cabinet top is higher than the cooker hob, a 20 mm, clearance

should be kept between the furniture unless lined with a suitable fireproof material

the clearance above the cooker hot should be at least of 630 mm.

GAS APPLIANCES

This appliance is not connected to a device to vent the combustion products. It must

therefore be installed and connected in conformity with the installation standards in

force. Particular attention must be paid to the standards on ventilation of the room.

1a) VENTILATION OF ROOMS

Remember that this appliance can be installed and work in well-ventilated rooms only,

according to the standards in force, such as to allow, with openings on the external

walls or with special ducts, a correct natural or forced ventilation ensuring permanently

and sufficiently both the entry of the air needed for correct combustion and the removal

of spent air. In particular when there is only this gas appliance in the room, there must

be a hood over the appliance to ensure the natural and direct removal of spent air,

with a vertical straight duct of length equal to at least twice the diameter and a minimum

section of at least 100 cm

must be a similar 100 cm

2

. For the indispensable entry of fresh air into the room there

2

(5,16 cm2 x kW) opening directly to theoutside, situated

at a height near floor level so that it is not blocked either inside or outside the wall and

so as not to cause disturbances to correct burners combustion and to the regular

removal of spent air and with a difference of height with respect to the outlet opening

of at least 180 cm. Remember that the quantity of air necessary for combustion must

never be less than 2m

3

/h for each kW of power (see total power in kW on the appliance

data plate).

In all other cases, i.e. when there are other gas appliances in the same room, or when

43

23

natural direct ventilation is not possible and natural indirect or forced ventilation must

be installed, contact a qualified specialist who will install and make the ventilation

system, scrupulously observing the regulations contained in the standards in force.

The openings must be so positioned that there are no draughts of air which cannot

be tolerated by the occupants.

2) GAS CONNECTIONS

The installation must be in accordance with regulations set by the local gas Authority.

This appliance belongs to class "1" against fire dangers (see N.B.). Between the cooker

and gas supply line is required a gas shut off valve (easy of access) to be kept closed

when the cooker is not in use. The pressure regulators for Lpg must be in accordance

with the requirements.

2a) CONNECTION TO GAS CYLINDER

Cooker working with Lpg gas can be connected with a flexible pipe (T ø 8 mm) fixed

to inlet connector A (fig. 2). The pipe must always comply with the regulations in force

in the country where the appliance is installed. Both ends must always be secured by

means of a hose clamp F (fig. 2).

2b) COOKER SET FOR NATURAL GAS AND (TOWN GAS EXTRA E.E.C. COUNTRY)

The flexible pipe (T ø 13 mm) must comply with the rules in force in the country in

question. The pipe must be fixed to the inlet connector B (fig. 3) and to the main gas

tap. Both end be secured with hose clamp F (fig. 3).

WARNING

The flexible pipe must never reach, in any point a temperature higher than 50°C above

the ambient temperature. Do not submit it to torsion or tension efforts. It must not

present strangling or sharp bent. It is advisable to replace it periodically.

Pipe connection

Make the connection using an iron (R) or copper pipe (S) starting from attachment

3

Page 4

C in (fig. 4). Remove hose attachment B using a 23 mm spanner. When making

the connection include an accessible ensure that the seal G is always placed

between the hose attachment and union C (fig. 4). When the connection is complete,

always check that there are no gas leaks from the union.

N.B. The connection between the end of the gas train and the supply can be made

on the right so that the gas pipe does not have to pass behind the cooker. In case

of connection on the left please relate to what already described in paragraph gas

connection having care to let the flexible tube pass through a holder see (fig. 5A)

in case of inflexible connection, see (fig. 5B).

3) ELECTRICAL CONNECTION

The appliance belong to class "X" against fire dangers (see N.B par. 1).

Connection of the appliance to the power mains should be done by a licensed

electrician familiar with local safety regulations.

- This appliance must be earthed by law.

- Before connecting the appliance to the electrical supply, check that the

earth system in your house is working correctly.

- Check that unit voltage and power, marked on the rating plate applied on the

appliance, are correct for the supply;

- It is necessary that the feeding network is protected by a powerful switch able

to disconnect completely the network with a contacts separation of at least 3

mm.

Be sure that the earth wire green/yellow is not interrupted by the switch.

Important: The wires in the mains lead are so coloured:

- green/yellow = earth “ ”

- blue = neutral “N”

- brown = live “L”

- The supply cable must not come into contact with any component the temperature

of which exceeds the ambient temperature by 50°C;

- If a plug is used for connection, the plug to be connected to the supply cable

and the socket to which it is connected must be of the same type (conforming

to the standards).

- Easy access to the plug or the switch is ensured once the appliance is installed;

- Ensure that there is sufficient cable allowed for any subsequent removal of the

unit.

The manufacturer declines all responsibility for any damage to persons or

things caused by failure to observe the rules indicated above.

4) CONVERSION FOR DIFFERENT TYPES OF GAS

The cooker carries a label specifying the type of gas for which it has been preset.

If it is to be used with a different type of gas, convert as follows with:

— Replacement of the hose attachment as in the previous section "Gas connection"

— Replacement of the nozzles and air adjustment.

When using liquid gas this screw must be fully tightened.

After making this adjustment check that the burner remains on when switched

rapidly from full on to minimum position and viceversa.

4c) Gas grill Burner

The figure 15 represent the gas grill burner

The nozzle is replaced as described below:

— Open the oven door.

— Unscrew the screw A which fasten the grill burner to the oven ceiling

and estract the burner from the oven (fig. 15)

— Introduce in the nozzle-holder a 10 mm socket spanner and remove the nozzle G (fig. 16) replacing

it with the new one suitable for the new gas type (see Chart 1)

— Once executed such operation reset the burner and check that it remains on.

In case of problem, move the burner back or before placing it in position for

to get a correct combustion and a good regulation of the air.

— Minimum setting

Since the grill burner always operates at full flame, there is no need to regulate

the minimum setting.

— Important

Once the procedure for adapting the cooker to one type of gas or another

is complete, we strongly advise staff to check using soapy water that

there are no leaks from the unions used to make the conversion.

4d) Burners with safety valve

The procedure for regulating the minimum flame on cookers with safety valves

on the hob burners, oven and grill burners is as described in paragraphs 4a,

4b and 4c. However, in this case the minimum setting screw Tor Z is on the

left of the rod of the gas tap or the thermostat (fig. 17).

TRANSFORMATION OF ELECTRIC FEED TYPE

Some cookers, even if manufactured for working at 230V~, can be feeded with

threephases systems. For their transformation you have to disconnect current,

remove the back side of the cooker (fig. 17A) and settle the movable connectars

in terminals block (see fig. 17B)

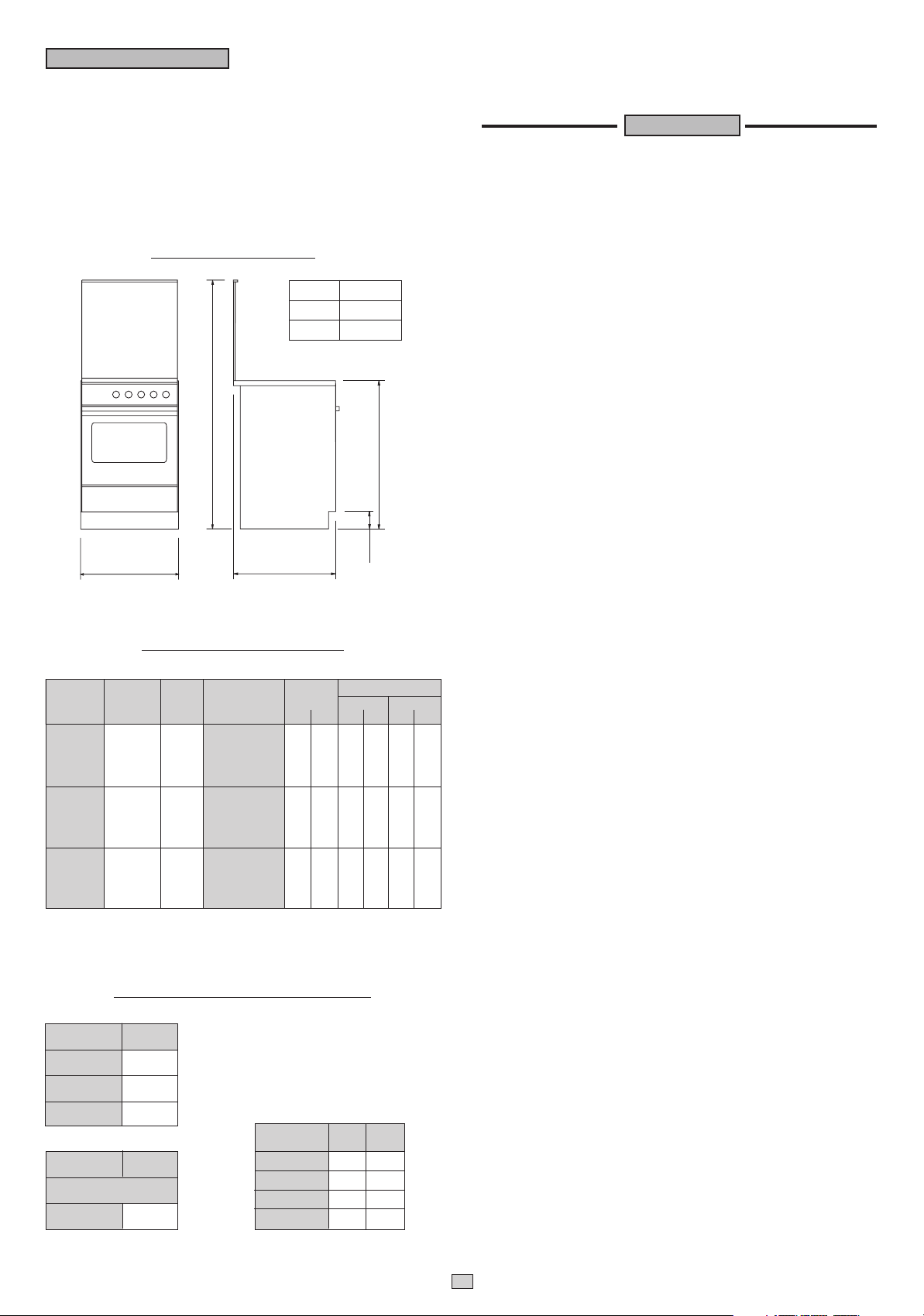

Chart 4

Type of

cooker

Full gas

Full gas with elect. grill

Full gas with 1 elect. plate

Full gas with el. oven

1 electric plate

Single phase connections 230V~

Main cable Features

Caoutchout H05 RR-F

Caoutchout H05 RR-F

Caoutchout H05 RR-F

Caoutchout H05 RR-F

3 x 0,75 mm

3 x 1 mm

3 x 1 mm

3 x 1,5 mm

2

2

2

2

4a) Hob

The nozzles are replaced as described below:

— Disconnect the electricity supply plug if present and close the gas tap installed

upstream of the appliance.

— Remove the hob pan stands, flame caps and burner cups.

— With a screwdriver remove the two screws locking the hob, raise it up and

secure it to prevent from falling back down (see fig. 6)

— Remove the nozzle (2 fig. 7) and screw on the new one suitable for the new

gas type (see chart 1).

— Regulate the flame by backing off the screw (4 fig. 7). Raise or lower the pipe

(3 fig. 7). The best flame conditions are shown in (fig. 8) (regulate with burners

hot if possible).

— Reassemble all components, following the above sequence in reverse order.

— Low flame setting (olso for oven with thermometer)

To obtain this, set the knob in the position where the gas tap opening is

minimum (this position is indicated by a small flame screen-printed on to the

fascia in fig. 9). Slide the knob off and adjust the inside screw coaxial with the

rod of the gas tap (hole in the centre of the knob mounting rod, fig. 10).

Tighten or back off the screw until the flame is brought down to the level

required. This adjustment must be made with the burner on.

When using liquid gas this screw must be fully tightened. After making

this adjustment check that the burner remains on when switched rapidly from

full heat to minimum position and viceversa.

4b) Gas oven burner

— Remove the oven bottom (fig. 11).

— Unscrew the screws V (fig. 12) and remove the upper collar fixing the air muff

fig. 12) in order to have easier access to the nozzle.

B (

— Remove the nozzle (F fig. 12) and screw on the one which is suitable for the

new type of gas (see chart 1).

— Regulate the flame by backing off the screws (V fig. 12) and move the pipe

(B fig. 12) backwards or forwards.

— Regulating the thermostat low flame position.

To do this, turn the oven to full heat (8) for about 10 minutes, then bring the

knob back to the minimum setting, position 1 (fig. 13). Remove the knob and

use the screw on the body of the thermostat (fig. 14) to set the flame size.

Type of

cooker

4 el. plates and elect. oven

Features

Keeping in consideration the simultainety coefficient of 0,75.

Single phase

connection

230 V~

Caoutchout H05 RR-F

3 x 4 mm2 4 x 2,5 mm2 5 x 1,5 mm

Three phases

connection

400V 2N~

230V 3~

Caoutchout H05 RR-F Caoutchout H05 RR-F

Three phases

connection

400V 3N~

2

FACIA PANELS

The below facia panels and hobs present the most of our productions.

For further information please consult this booklet following paragraphs.

FACIA PANELS DESCRIPTIONS

1) Knob for burner A and for electric plate A

2) Knob for burner B and for electric plate E-B

3) Knob for burner C and electric plate C

4) Knob for burner D and electric plate D

5) Knob for gas oven or electric oven

6) Knob for Timer (Optional)

7) Ignition button (Optional)

8) Oven light button (Optional)

9) Grill/turnspit button (Optional)

10) Warning light for electric plates.

4

Page 5

ENAMELLED FACIA PANELS

9 3462 51 78

2 10 1 5 3746

If the appliance is supplied with it, the functioning of the heating element is

highlighted by the illumination of the oven light, otherwise it will be indicated

by a warning light placed on the facia-panel.

6a) Lighting the burner manually

Open the oven door and place a lighted match against the hole in the centre

of the oven bottom A (fig. 20). Turn the oven knob anticlockwise until the

pointer reaches (8) (full heat) (Fig. 21). Look at the holes in the oven bottom

to check that the burner has ignited, close the door and position the knob as

required (Chart B). To switch the burner off turn the knob clockwise until the

pointer is vertical on ( ) (fig. 21).

CHART B

9342 51 7 8

Knob Position

1 140 °C

2 150 °C

3 160 °C

4 170 °C

5 190 °C

6 210 °C

7 230 °C

8 250 °C

Temperature °C

OVEN WITH THERMOMETER

The oven knob is of the same model of the ones of the hob's burners (fig. 18).

The thermometer, situated on the oven door, signals the temperature of the oven.

Only the utilisation will consent you to find a perfect regulation of the knob, in order

to obtain the temperature required.

BC

DA

EC

DA

BC

DA

C

DA

2nd Section

USE

WARNING:

Children should be kept away while the oven or grill (gas or electric) is

in use since accessible parts become hot.

- Do not use oven base panel as a shelf, make use of the oven shelves.

- To avoid splattering and smoke, position collecting tray under the turnspit with

some water in it.

- Never close the drop down tempered glass lid when burners or electric hot-

plates are on or they are still hot, wait until they cool down and then close lid.

- Always turn pan handles to the side or to the back of the hob. If they are left

out intothe room they can easily be hit or reached by children, this knocking

the pan off the hob.

- Don't let children sit down or play with the oven door. Do not use the drop

down door as a stool to reach above cabinets.

- Once your cooking is oven make sure to close the main gas supply.

The gas taps are fitted with a safety device prevent them from being opened

accidentally

5) GAS HOB

5a) Lighting burners manually

Open the gas tap on the metre or the gas cylinder, light a match and place

it against the burner to be lit. Then press the relative knob and turn it

anticlockwise until the flame setting required is reached (fig. 18). Over each

knob, the fascia panel is screen-printed with a diagram indicating the relative

burner. To turn off the burner turn the knob clockwise to ( ) (fig. 18).

The minimum position is at the end anti-clockwise rotation of the knob. All

operation positions must be chosen between the positions of max. and min.,

never choose them between max. and off.

5b) Using hob burners

The hob consists of burners of different sizes.

To ensure optimum efficiency in use of gas, with minimum consumption, follow

the hints given below:

— Each burner must be used with a suitably sized pan (fig. 19) so that the

flames do not project beyond the pan bottom.

— Once the contents are boiling, turn the knob down to minimum (low flame

fig. 18).

— Always put the lid on the pan.

6) GAS OVEN

For reasons concerning safety and regulations in force, the simultaneous use

of the gas oven burner together with electrical:gas grill is forbidden (EEC

normes). In case of gas oven with gas grill, see knob with double selection

fig. 21. In case of gas oven with electrical grill, the gas oven burner cannot

be switched on by pushing the grill button (fig. 31) and if it is in function it will

turn off.

150

MIN

200

250

MAX

6b) Using the gas oven

The first time the oven is used, allow it to heat up for about 30 minutes at

full heat, in order to eliminate any smells or fumes produced by internal

components. To start cooking, turn the pointer of the knob in (fig. 21) to the

temperature required (chart B). Wait at least 15 minutes before placing the

food inside, to cooking times.

CHART C

Food

MEAT PASTRY

ROASTED PORK 185-210 FRUIT CAKE 220

ROASTED BEEF 250 MARGHERITA CAKE 190

ROASTED VEAL 220 BRIOCHES 175

ROASTED LAMB 220 SCONES 235

ROASTED HARE 230 RING-SHAPED CAKE 190

ROASTED RABBIT 235 PUFF-PASTE 200

ROASTED TURKEY 220 GRAPES CAKE 200

ROASTED GOOSE 235 STRUDEL 180

ROASTED DUCK 225 SAVOIA BISCUIT 290

ROASTED CHICKEN 235 APPLE FRITTER 200

ROAST-BEEF 200-225 PUDDING 200

FISH 200-225 TOAST 250

Temperature °C

Food

BREAD 230

Temperature °C

7) GAS GRILL

7a) Lighting the burner manually

To light the grill, simply open the oven door fully, turn the knob clockwise until the

pointer is against the symbol (fig. 21)

and place a lighted match against the grill burner. To switch the burner off turn

the knob anticlockwise until the pointer is vertical on “ ” (fig. 21).

7b) Using the gas grill

After ignition, wait for 5 minutes before placing the food under the grill and leave

the oven door half opened as shown in (fig. 22). To prevent the knobs and gas

taps from overheating, the guard (canopy) S (fig. 23) must be fitted.

Electrical ignition for hob burners (optional)

Follow the initial procedure as described in paragraphs 5a.

In this case no match is required; simple keep button‚ on the facia panels pressed

(fig. 24) to ignite the burner.

8) APPLIANCES WITH SAFETY VALVE

To light the burners proceed as described in the precedent paragraphs.

However, in this case, once the knobs have been turned on they must be pressed

for 10 seconds to heat the thermocouple bulb (fig. 25). If the burner flame goes

out for any reason, the safety valve will automatically intervene and cut off the gas

flow to the burner concerned.

Example of hob burner with thermocouple (T) and electric ignition (C) (

fig. 26).

9) ELECTRIC HOT-PLATES

When an electric hot-plate is used for the first time or after it has been out

of service for a long period, operate on setting 1 for about 20 minutes to

eliminate any moisture from the internal insulating material.

5

Page 6

— Use pans with a thick, flat bottom (fig. 27).

— Never use pans with diameter smaller than that of the hot-plate itself.

— Dry the bottom of the pan before placing it on the hot-plate.

— Do not switch on the power until the pan has been placed on the hot-plate.

— For good maintenance, after use wipe the hot-plate over with a rag dipped

in oil, so that its surface is always clean and shining. This will prevent rusting.

— The hot-plates are independently controlled by a 7-position switch activated

by turning the knob clockwise to the position required (fig. 28).

Over each knob, the fascia panel is screen-printed with a diagram indicating

the relative hot-plate R (fig. 28). A red indicator light shows that one or more

hot-plates are in operation.

— For purely guideline purposes Chart D shows settings. The power values

corresponding to the various knob positions are shown in Chart E.

CHART D

CHART E

Type of electric plates No. position 1 2 3 4 5 6

Ø145 Standard 1000W 6 + 0 100 165 250 500 750 1000

Ø145 Rapid 1500W 6 + 0 135 180 250 625 875 1500

Ø180 Standard 1500W 6 + 0 135 220 300 850 1150 1500

Ø180 Rapid 2000W 6 + 0 175 220 300 850 1150 2000

Rapide

Electric

Plates

Heat

Power

0 Off

1 Slight

2 Mild

3 Slow

4 Medium

5 High

6 Max

Power heating of the electric plates

To melt butter, chocolate etc. To warm up

small amounts of liquid.

To warm up more amounts of liquid. Suitable

for creams and sauces.

To defrost frozen food, for stewed meat, to

reach the boiling temperature, for white meat

or fish.

For food requiring the boiling temperature.

For chops or steaks. For boiled meat

To boil big amounts of liquid. To dry.

Possible Cookings

10) USE OF CONVENTIONAL ELECTRIC OVEN

The first time the oven is used allow it to heat up for about 30 minutes at full

heat, in order to eliminate any smells or fumes produced by internal components.

To start cooking, turn the knob of the electric thermostat for oven/grill (fig.

29) gives possibility to choose the requires oven temperature (chart F) and

to make the oven function and wait at least 15 minutes before placing food

inside.

IMPORTANT

— In this cooker normally the oven lamp functions as an indicator light of the

oven; before using the oven always check that the oven bulb is not burned

out and that is always lighted with the control knob of the oven switched on

in each position

Function selection

Oven switched off

O

Oven Light (only)

Lower electric element on AND OVEN LIGHT

Upper electric element on AND OVEN LIGHT

Grill on (and turnspit when available) AND OVEN LIGHT

NOTE:

After ignition, wait for 5 minutes before placing the food under the grill and leave

the oven door half opened as shown in (fig. 22). To prevent the knobs and gas

taps from overheating, the guard (canopy) S (fig. 23) must be fitted.

The following chart F of the temperatures in the oven doesn't have validity when

using the above mentioned heating functions.

CHART F

Knob Position

150

270

390

4 110

5 130

6 150

7 170

8 190

9 210

10 230

11 250

Static Oven °C

The indicator light for the oven thermostat optionally available is illuminated when

the oven control is switched on in each heating functions. This light goes out the

oven when the selected temperature is reached in the center of the oven, and the

food may be placed inside the oven for cooking. Chart G shows guideline cooking

times.

6

CHART G

Food

MEAT PASTRY

ROASTED PORK 225 FRUIT CAKE 225

ROASTED BEEF 225 MARGHERITA CAKE 175-200

ROASTED VEAL 225 BRIOCHES 175-200

ROASTED LAMP 225 SCONES 220-250

ROASTED HARE 230 RING-SHAPED CAKE 180-200

ROASTED RABBIT 250 PUFF-PASTE 200-220

ROASTED TURKEY 250 GRAPES CAKE 250

ROASTED GOOSE 250 STRUDEL 180

ROASTED DUCK 225 SAVOIA BISCUIT 190

ROASTED CHICKEN 250 APPLE FRITTER 200-220

ROAST-BEEF 250 PUDDING 200-220

FISH 200-225 TOAST 250

Temperature °C

Food

BREAD 220

Temperature °C

12) USING THE ROTISSERIE

— To prevent the knobs and gas taps from overheating, the (canopy) (S fig. 23)

must be fitted as explained in section 7b. The oven door must be kept opened

during cooking.

— Place the chicken or piece of meat for roasting on the spit L (fig. 30), ensuring

that it is gripped securely between the two forks F (fig. 30) and balancing it

properly to avoid unnecessary strain on the gear motor R (fig. 30) at the back

of the oven.

— After having placed the tip of the spit in the driving pivot of the motor P hang

the spit support G inserting and turning it from the inside of the oven as shown

in (fig. 30).

— Unscrew the handle S

— Start the gear motor by pressing the button on the fascia panel (fig. 31) in

gas ovens; on cookers with electric oven this function is provided by selector

(fig. 29)

— Juices can be collected in the dripping-pan, which must be placed on the

lowest level.

13) TIMERS (Optional)

Our cookers may be equipped with two different types of timers.

Minute minder bell: timer with ringing alarm to signal end of cooking time

(fig. 32).

Cooking end timer: automatically switches off oven when cooking is over

(fig. 33).

13a) Minute minder bell

Turn knob G (fig. 32) clockwise, stopping the pointer at the time selected.

The minute timer can be regulated from 1 to 60 minutes. When the preset

time has passed, a ringing alarm signals that the food is cooked.

13b) Cooking end programmer

For use in manual mode, turn the knob G (fig. 33) anticlockwise to the

( ) mark. To programme cooking time, turn clockwise and set a cooking

time using the knob (max. 120 minutes).

When the cooking time is over the oven is automatically switched off.

Now select the temperature required using the thermostat knob (fig. 29).

GENERAL CLEANING

It is advisable always clean off spillage as quickly as possible to prevent

burning on, which will make removal more difficult but cleaning should only

be carried out when the appliance is COOL and SWITCHED OFF AT THE

MAINS SUPPLY.

Do not utilize the optional dish

— Warming compartment to store aerosol bombs or inflammable products.

— When cleaning no water should enter in to the burners holes of the hob or in

to the slots of the bottom of the oven.

Be careful in replacing correctly all the parts removed for better cleaning because

improper positioning will cause damages to the appliance and painful accidents

and mainly:

The burner cup (B) must be deeply inserted in to the proper support in order to

avoid gas leakage.

The burner flame spreader (A) must rest with the studs in the proper seats of the

cup in order to avoid flash back or extinquishing of the flame (fig. 34).

CLEANING ENAMELLED PARTS

To keep the enamelled parts shiny, clean them regularly with lukewarm soapy

water. Do not clean when they are still not and never use abrasive powders. Never

allow vinegar or lemon or tomato juice to stand on enamelled surfaces. One

special feature of the oven is that the inner window A (fig. 35) can be removed

by just unscrewing screws V (fig. 35) to allow their inside surfaces to be cleaned.

Clean the outer glazed surfaces with a damp cloth when the oven is cold, ensuring

that no abrasives are used.

CLEANING ELECTRIC PLATES

It is advisable to clean the electric plates with wet rags and grease them afterwards

with a drop of mineral oil: this prevent rust making on their surface.

Page 7

MAINTENANCE

N.B: BEFORE CARRYING OUT ANY MAINTENANCE DISCONNECT THE

POWER SUPPLY AND CLOSE THE GAS TAP OF THE CYLINDER OR

MAINS LINE.

Check often that gas connection is in good conditions, and when made with rubber

tube replace it at least every two years and always before the expiring date of the

tube.

CHANGING THE OVEN LIGHT BULB

Unscrew the glass guard C (fig. 36) by turning anticlockwise. Replace the oven light

bulb with another rated to resist heat up to 300°C type E 14, 15W 230 V~ (L).

Replace the glass guard and screw on clockwise.

GREASING THE TAPS AND THERMOSTAT

This maintenance must be carried out by qualified technician.

— With a screw driver remove the two screws locking the hob, rise it up and secure

it to prevent from falling down (fig. 6). Pull and remove all the facia knobs.

No tools are needed since they are simply pressed on to the rods.

— Open the oven door and unscrew completely the two screws with a screws driver

located on botton bordering of facia panel and the screw located upper the side

of cooker (fig. 37).

— Draw the facia panel following the arrow direction (fig. 37).

1) Remove the body of the tap or thermostat (see fig. 38) following the order shown

in the diagram.

2) Clean the cone and its housing with a rag soaked in solvent.

3) Grease the cone slightly with an appropriate grease.

4) Fit the cone and move through its stroke a few times. Remove again. Wipe off

any excess grease, ensuring that the gas orifices are not blocked.

5) Replace all the pieces, reversing the order given above.

9) Don't let children sit down or play with yhe oven door. Do not use drop down door

as a stool to reach above cabinets.

FOR YOUR SAFETY

1) If you smell gas:

- open the window

- don't touch electrical switches

- extinguish any open flame

- never use a flame to locate such a leak, but soapy water only

- contact a specialized assistent.

2) Keep children away from the appliance; they can suffer serious personal harms

touching the hot parts of the appliance or of the pans.

3) Don't store items that are attractive to children above or near the appliance.

4) Do not store flammable products near the burners as fabric, carton or plastic

boxes and specially aerosol containers.

Do not use aerosol sprays near the unit when the burner is on work.

5) Do not use the appliance as a space heater, especially in a small room, a caravan

or a boat.

6) In order to avoid any unintentional fall down, pan handles should be turned to

the back of the cooker, not out to the room or over adjacent burners.

7) When cooking, don't use clothes with large flaving and flammable sleeves.

8) In case of fire, close immediately the main valve of the gas pipe line and never

pour water on firing oil in any case.

WHEN YOU CALL FOR SERVICE

When you call for service or order parts for your unit, be sure to give:

1. MODEL

2. SERIAL NUMBER

3. COLOUR

4. PART NAME and/or description of problem

5. YOUR FULL NAME, ADDRESS, and HOME TELEPHONE NUMBER and

BUSINESS TELEPHONE NUMBER IF APPROPRIATE.

Fig. 27

Fig. 28

R

Fig. 30

110

100

Fig. 33

120

R

0

1

2

3

P

F

L

S

6

5

11

4

Fig. 29

10

9

8

1

2

3

4

5

6

7

Fig. 31

0

55

50

G

45

40

35

30

G

5

10

15

20

25

Fig. 32

0

stop

90

80

60

70

G

10

20

30

40

50

A

B

Fig. 34

THIS APPLIANCE HAS BEEN CONSTRUCTED AND DISTRIBUTED IN

COMPLIANCE WITH:

— The safety requirements od Directive 73/23/EEC regarding "Low Voltages"

— The requirements of Directive 89/336/EEC regarding "Electromagnetic

Compatibility"

— The safety requirements of Directive 90/396/EEC regarding "Gas Appliances"

— Directive 89/109/EEC regarding "Materials that can touch food"

— Moroever the above mentioned Directives comply with Directive 93/68/EEC.

Fig. 25

C

C= Electric Ignition T= Thermocouple

Fig. 26

T

7

Fig. 35

Fig. 37

V

F

V

C

A

L

Fig. 36

Fig. 38

Page 8

ENVIRONMENTAL NOTES

Disposal of packaging materials

Do not dispose of packaging materials with normal household

waste. These materials are recyclable and should be sorted

(e.g. cardboard, plastic sheeting, polystyrene) and disposed

of in accordance with local regulations.

• The only proper use of this appliance is that for which it

was expressly designed, as a “cooking appliance”.

8

Page 9

Page 10

R

0

1

2

3

11

10

9

8

4

5

6

7

1

2

3

6

5

4

R

0

55

50

45

40

35

30

G

5

10

15

20

25

A

120

B

110

100

P

F

L

S

0

stop

90

80

10

60

70

G

G

20

30

40

50

V

L

V

C

A

F

C

T

C= T=

Page 11

Page 12

9 3462 51 78

10 1 5 3746

2

9342 51 7 8

MIN

150

200

250

MAX

BC

DA

EC

DA

BC

DA

C

DA

Page 13

Page 14

1320

845

X

500

100

Page 15

1

8

2

7

3

6

4

5

1

2

3

4

8

7

5

6

F

B=

F

T=

A=

T=

G

A

1/2"

C

G

Max

Low

Off

T

230 V ~

L1

N

E

E = GREEN and Yellow / N = BLUE / L1-L2-L3 = BROWN

400 V 2N~ 400 V 3N~

L1

1

2

L2

3

4

N

5

E

Z

L1

1

2

3

4

5

1

L2

2

L3

3

4

N

5

E

A

B

BARS

170

3

4

2

A

Off

1

2

3

4

5

8

7

6

V

B

F

Max

Low

P

S

Page 16

Tipolitografia Montagnani - Cod. 533321 1102 - Made in Italy

Loading...

Loading...