Page 1

i

I N F O

INSTRUCTION MANUAL

BUILT-IN HOB

Models: EHG678* • EHG978* • EHM684* • EHM984* • EHG977* • EHG983* • EHG682* • EHG982*

*Denotes colour: W=White, X=Stainless Steel

Page 2

1

I N S T R U C T I O N M A N U A L

Congratulations and thank you for choosing an Electrolux Product. We are sure you will find your new

cooktop a pleasure to use and a great asset to your cooking. Before you use the cooktop, we recommend

that you read through the whole user manual which provides the description of the cooktop and its

functions. To avoid the risks that are always present when you use a gas or electric appliance, it is important

that the cooktop is installed correctly and that you read the safety instructions carefully to avoid misuse and

hazards. For future reference, please store this booklet in a safe place.

G E N E R A L I N F O R M A T I O N

MODEL AND SERIAL NUMBERS

These are shown on the data plate which is located under the burner box at the front right.

CONVERSION FOR USE WITH A DIFFERENT GAS

This appliance is adjusted for use with the particular gas shown on the gas-type label. However, it can be

converted for use with other gases, please refer to conversion section of this booklet.

AEROSOL SPRAYS

Do not spray aerosols in the vicinity of this appliance while it is in operation as aerosols can contain

flammable propellants.

WARNINGS

• The appliance is not intended for use by young children or infirm persons without supervision

• Young children should be supervised to ensure that they do not play with the appliance

• A steam cleaner is not to be used

• For appliance with supply cord:

• If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a

similarly qualified person in order to avoid a hazard

• It is necessary to have plug accessible after installation

• This appliance must not be used as a space heater

• The use of a gas cooking appliance results in the production of heat and moisture in the room in which it

is installed. Ensure that the kitchen is well ventilated: keep natural ventilation holes open or install a

mechanical ventilation device (mechanical extractor hood).

• Prolonged intensive use of the appliance may call for additional ventilation, for example opening of a window,

or more effective ventilation, for example increasing the level of mechanical ventilation where present.

CONTROLS AND OPERATION

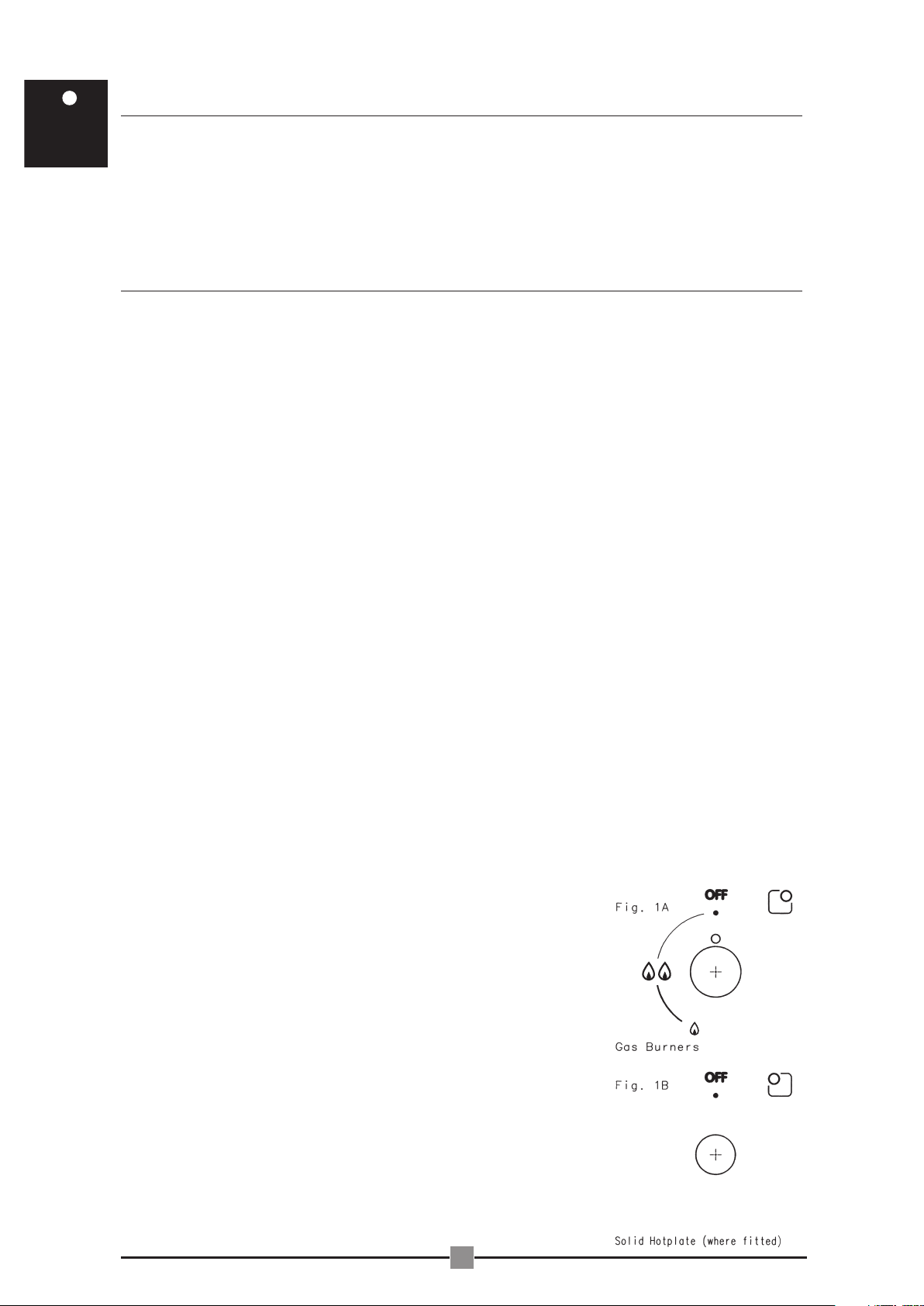

• Each burner is controlled by a valve which is activated by a control knob that diagrammatically shows

high to low (Fig 1A).

• Where a solid hotplate is fitted it is controlled by an infinite control knob which gives a range from high to

low using the numbers 6 to 1 as a guide (Fig 1B). This varies the amount of heat that the element delivers.

The control can be turned either clockwise or counter-clockwise to the desired position. There is a click

felt at the maximum point, number 6, to indicate high position.

LIGHTING BURNERS

These cooktops are fitted with battery or mains powered ignition. When the appliance has been connected and the

power is switched on, depressing any knob will release sparks to all burners. To

light a burner turn the corresponding knob to the ‘High’ position while depressing

the knob. For standard models the knob may be released once the flame is

established. For Flame Safeguard Models the knob must be held down for 5-10

seconds once the burner is ignited. If the flame goes out when the knob is

depressed simply depress the knob again and hold it down for the required

length of time. The height of the flame can be varied by turning the control knob

toward the ‘Low’ position. In the absence of electrical power, carry out the

ignition directly to the burner with a match or taper.

Caution:- In the event of the burner flame being accidentally

extinguished, turn off the burner control and do not attempt to

re-ignite the burner for at least 1 minute.

CHOICE OF BURNER

There are four burner sizes or three burners and an electric hotplate

(where fitted) for your convenience.

• A small burner for special low heat and slow cooking OR solid hotplate

(models with an electric element fitted).

• A medium burner for normal cooking and simmering.

• A large burner for fast heating and large utensils.

• A Wok burner for very fast heating using a Wok or large utensil.

To conserve gas, place the pan centrally over the burner and adjust the

flame so that it does not extend past the edge of the pan (Fig. 2).

i

1

3

2

4

5

6

Page 3

i

2

Do not boil food too rapidly. A strong boil will not cook food any faster, and will waste energy.

UTENSILS

All normally available utensils; aluminium, stainless steel, cast iron, ceramic, etc., may be used on your new

gas or electric element model cooktop. Ensure that the utensils are steady and have flat bases to avoid

dangerous spill-over of hot liquids and wasted energy. Do not use hollow based or oversized utensils i.e.

utensils which have a greater diameter base than the hotplate (Fig. 3). Woks should only be used on the

wok burner and the wok support trivet.

C L E A N I N G A N D C A R E

ENAMEL

Persistent stains may require vigorous rubbing with nylon scourer or creamed powder cleansers. Household

enamel cleaners are available, follow the manufacturer’s instructions in their use. Harsh abrasive cleaners,

powder cleaners, steam cleaners, steel wool or wax polishes should not be used.

STAINLESS STEEL

All grades of stainless steel may stain, discolour or attain an adhering layer of grime in normal operation. To

achieve maximum surface appearance, stainless steel must be kept clean by regularly using the following

cleaning procedures, thus ensuring good performance and long service life. Wash with warm soapy water

and rinse with clean water. For an enhanced appearance wipe the surface with light oil (eg. sewing

machine), then wipe the surface dry with a soft, clean, lintless cloth, being sure to follow the polish or

brushing lines.

Where the stainless steel has become extremely dirty with signs of surface discolouration, (due to periods of

neglect or misuse) use a stainless steel cleaner. When removing these stains be sure to follow the polish or

brushing lines.

BURNER-CAPS AND CROWNS

These can all be lifted off and removed for separate cleaning. Ensure burner caps and crowns are

thoroughly dried after cleaning or spillage.

When cleaning the burner crowns, ensure that all the flame ports and other holes are free of any blockage.

If necessary, use a matchstick or brush to clear ports.

NOTE: When refitting the burner caps and crowns, ensure that they are correctly seated.

Burner minimum maximum

diameter diameter

Ultra-rapid

(Triple crown) 180 mm. 260 mm.

Large (rapid) 180 mm. 260 mm.

Medium (semi-rapid) 120 mm. 220 mm.

Small (Auxiliary) 80 mm. 160 mm.

UTENSIL SIZES

Page 4

SOLID HOTPLATE (Where fitted)

It is most important that the sealed

hotplate is kept clean and correctly

conditioned. If spillage occurs clean off

immediately after the hotplate has

cooled and warm hotplate for

approximately 30 seconds to dry

surface. At weekly intervals clean

hotplate with a nylon scouring pad and

soap. Use a damp cloth to wipe clean

and warm hotplate as described

previously.

Never use asbestos mats, wire mats or

grids, aluminium foil, woks or similar

utensils on the hotplate as it can lead to

overheating and permanent damage.

SERVICE

If a fault develops in your hotplate,

please check the points listed in Table

1.0 before calling for service as it may

be possible to avoid a service call and

therefore keep the appliance in use.

I N S T A L L A T I O N I N S T R U C T I O N S

This is a Category II, Class 3 appliance.

This appliance must be installed by an authorised person and in compliance with:

i. The local gas fitting regulations, municipal building codes, electrical wiring regulations and any other

relevant statutory regulations.

ii. The particular instructions as given below. Before commencing installation, check to ensure that the

appliance gas type given on label next to gas connection on appliance corresponds with the type of gas to

which it is intended the appliance be connected.

iii. This appliance is not connected to a combustion products evacuation device. It shall be installed and

connected in accordance with current installation regulations. Particular attention shall be given to the

relevant requirements regarding ventilation.

During installation the following points should be noted.

1. THE BENCH CUTOUT should be made as per ‘BENCH CUTOUT SIZE’ table (Fig. 4).

2. ADJACENT WALLS, CUPBOARDS AND PROTECTION FOR COMBUSTIBLE MATERIALS:

Ensure that overhead cupboards and any combustible material e.g. curtains are a minimum of 1000mm

from the cooktop. The minimum distance from exhaust fans is 750mm, the minimum distance from

rangehoods is 650mm and the minimum distance from the edge of the cooktop to any nearby wall should

be as specified in Fig.5. The distance between a rear or side wall can be reduced from 110mm and

210mm, providing the walls are covered with a non-combustible material, ie: Gib / Board (Fire line),

minimum thickness 19mm, covered with 5mm thick ceramic tiles, or sheet metal to a minimum height, not

less than 150mm. The surface temperature of a combustible surface must not exceed 50˚C above ambient

temperature.

3. PULL DOWN CLAMPS (four supplied) are supplied in a parts bag with their corresponding screws (four

supplied). To assemble attach the 4 clamps to each corner of the burner box via the screws provided.

When placing the appliance in the cutout, swing the clamps parallel with the box to avoid interference with

the cutout.

4. SAFETY BARRIER A barrier can be installed to prevent accidental contact with the cooktop base, where

the base of the cooktop is accessible from below (ie inside a cupboard, etc).

Impressions have been incorporated into the base to ensure a minimum clearance of 10mm is maintained

between the base and the barrier. This barrier may be made of any rigid material.

i

3

FAULT POSSIBLE CAUSE REMEDY

Burner will not light even though the Gas supply valve turned off. Turn on gas supply to

sparker is working. appliance.

Port blockage in ignition Ensure that ports in ignition

area. area both upper and lower

are clean and dry.

Sparking at wrong point Ensure that crown is seated

because of incorrectly fitted properly, so that the spark

burner crown. fires to the receiving point in

the burner crown.

No spark is obtained when control Electricity supply is Switch on electricity or

knob is activated. disconnected or switched off. check fuses.

Spark plug wet or dirty. Dry or clean spark plug.

Flames uneven or tending to lift. Flame ports blocked or wet. Clean or dry flame ports.

Flame not staying on when knob Knob not held down long Repeat lighting procedure

released. enough for flame safeguard.

and hold knob down for 5-10

seconds.

Dirt or spillage on flame Clean flame safeguard

safeguard sensor. sensor tip.

Electric element not working. Controls incorrectly set. Check that the controls are

set correctly.

Household fuse blown or Replace fuse/check supply.

power supply off.

Smoking hotplate. Hotplate cleaner is curing. The cleaner will cure and

there will be no more smoke.

Low heat, slow cooking. Incorrect cooking utensil Refer to Fig. 2,3.

being used.

Flame won’t turn down sufficiently. Incorrect injector or gas Contact installer.

control valve incorrectly

adjusted.

Benchtop overheating. Incorrect cooking utensil Check Fig.3 for correct

used. utensil to be used.

Seal not installed. Install seal .

Flame goes out on low setting. Gas pressure too low. Contact installer to correctly

adjust regulator.

Gas valve needs adjustment. Contact service to adjust

by-pass screw.

Yellow flame with Wok burner. Can be normal. If soot deposits are evident

on wok contact service to

reduce injector size.

Table 1.0 SERVICING INSTRUCTIONS

Page 5

i

4

When the appliance is in position swing the clamps

under the bench top and lightly tighten. (Fig. 6)

5. RUBBER SEAL This is to be applied around the

edge of the hob (Fig. 7) leaving a 400mm cutout on

a hidden edge of the unit. This gap is to allow air to

enter for ventilation. NOTE: the rubber seal has talc

powder applied to its surface which should be

wiped off with a damp cloth after the unit has been

installed.

GAS CONNECTION:

Cylinder or network connection must be carried out

according to the relevant local standards.

Flexible Connection.

The supply hose must be visible for its entire length

(max. one metre) and must be secured with a hose

clamp A (Fig. 8A). The hose shall be fitted in such a

way that it cannot come into contact with a moveable

part of the housing unit (eg. drawer) and does not

pass through any space susceptible to becoming

congested. The sealing washer must be fitted.

Rigid Connection.

Connect by using an iron or copper pipe, starting

from the threaded outlet of elbow B (Fig. 8B).

Include an accessible, demountable pipe union in

the connection.

Elbow Positioning.

It is possible to reposition the elbow if required by

loosening the locking nut and elbow by using two

spanners. Retighten the entire assembly after the

elbow has been repositioned.

ELECTRICAL CONNECTION:

Before installing this appliance, the flexible cord must be connected to an approved plug by an authorised

person. The connection of the appliance to mains is effected via a cable located underneath.

This appliance is fitted with an earth connection. This must be connected to a domestic earth. The domestic

power outlet should be located within 600mm of the flexible cord connection point (ref Fig. 4). Whenever

thesocket or the installation does not have available an earthing connection, such connection must be

provided according to the local standards.

APPLIANCE DIMENSIONS

MODEL A B C

Square Models 600 535 45

Rectangular Models 860 510 45

BENCH CUT-OUT SIZE

MODEL X Y

Square Models 570 490

Rectangular Models 830 470

*GAS & ELECTRIC CONNECTION POINT

NOTE: It will be necessary for Servicing

purposes to disconnect the electrical

power supply.

WEIGHT of the unit is printed on the

appliance identification label.

TESTING APPLIANCE OPERATION:

After installation, test the appliance and

ensure that it operates correctly before

handing it over to the customer. The

following procedure is recommended:

1. Turn on the gas and electricity supply

(if applicable) and attempt ignition. (For

correct procedure, refer to the OPERATING

INSTRUCTIONS). Note that the additional time

needs to be allowed for the initial lighting as

air has to be purged from the pipes.

BATTERY HOLDER INSTALLATION INSTRUCTIONS

COMPONENTS:

1. BATTERY HOLDER (212-2-78)

2. MOUNTING BRACKET (30-24-103)

3. PLASTIC NUT

4. BATTERY 1.5V (659-1-5)

5. SPRING

6. RETAINING CAP

7. 2 SCREWS (701-2-103)

INSTALLATION NOTES:

1. MOUNT THE BRACKET IN AN EASILY ACCESSIBLE

LOCATION UNDER THE BENCHTOP, USING THE TWO

SCREWS PROVIDED.

2. REMOVE THE CAP AND PLASTIC NUT FROM THE

BATTERY HOLDER.

3. PLACE THE THREADED END OF THE BATTERY HOLDER

THROUGH THE LARGE HOLE IN THE BRACKET.

4. SCREW THE PLASTIC NUT ONTO THE BATTERY HOLDER.

5. ENSURE THE BATTERY AND SPRING REMAIN IN THE

HOLDER AND SCREW THE RETAINING CAP ON.

CONNECTED TO

PRODUCT

Page 6

i

5

2. Observe the flame appearance on each

burner. If it is much larger or much smaller

than expected, the injector size requires

checking. If it is too soft or too sharp the

aeration setting may need adjustment. Where

a flame is unsatisfactory, refer to the

SERVICING INSTRUCTIONS and correct the

fault, if possible.

3. When all the foregoing is satisfactory,

check the turndown setting on each burner,

as this may need adjustment. Flame

safeguard models have a controlling screw in

the spindle. Standard models have a

controlling screw in the body of the valve.

Normally, this will have been correctly set at

the factory and should not require adjustment.

For more details, refer to the SERVICING

INSTRUCTIONS.

4. If the appliance cannot be adjusted to

perform safely, inform the customer of the

problem and affix an appropriate warning

notice to the appliance. If the fault appears to

be dangerous the appliance should be

disconnected. If a minor fault exists, the

customer may wish to use the appliance while

awaiting service. The customer should be

advised that, in the event of a fault, the

Electrolux local Service Organisation or the

retailer from whom the appliance was

purchased should be contacted.

5. When satisfied that the unit is operating

correctly, turn off and instruct the customer on

correct operation as outlined in this booklet.

Ask the customer to operate the controls to

ensure that the correct procedure is understood. Servicing must only be carried out by an authorised

service person. Injector sizes required for various gas types are shown in Table 2.0. The appliance inlet

pressure for each gas type is also shown.

To convert the appliance for use with Citigas follow the conversion procedure.

A Qualified Technician should carry out this procedure and use a Conversion Kit available from Electrolux

The Kit contains -

• One injector for each hotplate burner with the size indicated in the table.

• One aeration calibrator per hotplate burner.

• One wok injector.

• Data Label.

To carry out the conversion or to access components within the appliance for service follow these instructions.

Read all of these instructions before commencing.

Fig. 6

Hob

Benchtop

Clamp Screw

Rubber Seal

BURNER BOX

Page 7

i

6

CONVERSION PROCEDURE

1. Disconnect the appliance from main electrical power supply.

2. Lift off trivets, burner caps, burner crowns, and control knobs.

3. Remove the existing injectors and fit the injectors appropriate for the required gas type as specified in the

table.

4. Fit the Citigas aeration calibrators to the injectors. Aeration calibrators with the large opening must be

fitted to large burner and wok burner. Calibrators with small opening fit medium and small burner.

5. Any faulty or damaged components should be replaced at this point.

6. Adjust the burners to minimum. By turning the screw on the body of the gas control valve (Standard

models) or in the shaft of the gas control valve (Flame safeguard models) Fig.9., adjust the size of the flame

at minimum.

Ensure that the flame does not go out at minimum (Fig. 10).

7. Connect to the main electrical power supply.

8. Check that ignition is satisfactory for all burners.

9. Check proper operation of solid hotplate (if fitted).

10. Stick Citigas data label over LPG information. If the supply cord of this appliance is damaged, it must

only be repIaced by a repair shop appointed by the manufacturer, because special purpose tools are

required. Refer to the local service agency for the correct replacement part. (Part no. 215-2-59)

Any sealing shall be restored after the gas conversion operation.

Table 2.0

LPG (butane) Citigas Natural Gas

*Appliance

Operating

27.5 mbar 10.0 mbar 20.0 mbar

Pressure (p)

Injector Rating - grams/hr. Injector Rating - kW Injector Rating - kW

Size (kW) Size Size

Wok 1.00 290 (4.0) 4.00 4.0 1.50 4.2

Large 0.90 230 (3.2) 2.82 2.9 1.19 3.1

Medium 0.70 130 (1.8) 2.10 2.1 0.96 1.9

Small 0.55 90 (1.2) 1.42 1.1 0.70 1.0

Fig. 9

* Adjust pressure with appliance operating at approximately 50% of maximum kW

Page 8

7

P/No. 342-1-487 ECN 04A076G

MANUFACTURER:

Electrolux Home Products Pty Ltd

P.O. Box 21 Prospect

South Australia 5082

i

Loading...

Loading...