Page 1

User Manual

EFC 9550

Page 2

Dear Customer,

If you follow the recommendations

contained in this Instruction Manual,

your appliance will give you constant

high performance and will remain

efficient for many years to come.

CONTENTS

RECOMMENDATIONS AND SUGGESTIONS 3

CHARACTERISTICS 4

INSTALLATION 6

USE 9

MAINTENANCE 10

2GB

Page 3

RECOMMENDATIONS AND SUGGESTIONS

INSTALLATION

• The manufacturer will not be held liable for any damages resulting

from incorrect or improper installation.

• The minimum safety distance between the cooker top and the

extractor hood is 650 mm.

• Check that the mains voltage corresponds to that indicated on the

rating plate fixed to the inside of the hood.

• For Class 1

guarantees adequate earthing.

• Connect the extractor to the exhaust flue through a pipe of

minimum diameter 120 mm. The route of the flue must be as short

as possible.

• Do not connect the extractor hood to exhaust ducts carrying

combustion fumes (boilers, fireplaces, etc.).

• If the extractor is used in conjunction with non-electrical appliances

(e.g. gas burning appliances), a sufficient degree of aeration must

be guaranteed in the room in order to prevent the backflow of

exhaust gas. The kitchen must have an opening communicating

directly with the open air in order to guarantee the entry of clean

air.

USE

• The extractor hood has been designed exclusively for domestic

use to eliminate kitchen smells.

• Never use the hood for purposes other than for which it has ben

designed.

• Never leave high naked flames under the hood when it is in

operation.

• Adjust the flame intensity to direct it onto the bottom of the pan

only, making sure that it does not engulf the sides.

• Deep fat fryers must be continuously monitored during use:

overheated oil can burst into flames.

• The hood should not be used by children or persons not instructed

in its correct use.

• The appliance is not intended for use by young children or infirm

persons without supervision.

• Young children should be supervised to ensure that they do not

play with the appliance.

a

appliances, check that the domestic power supply

650 mm min.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before

carrying out any maintenance work.

• Clean and/or replace the Filters after the specified time period.

• Clean the hood using a damp cloth and a neutral liquid detergent.

3GB

Page 4

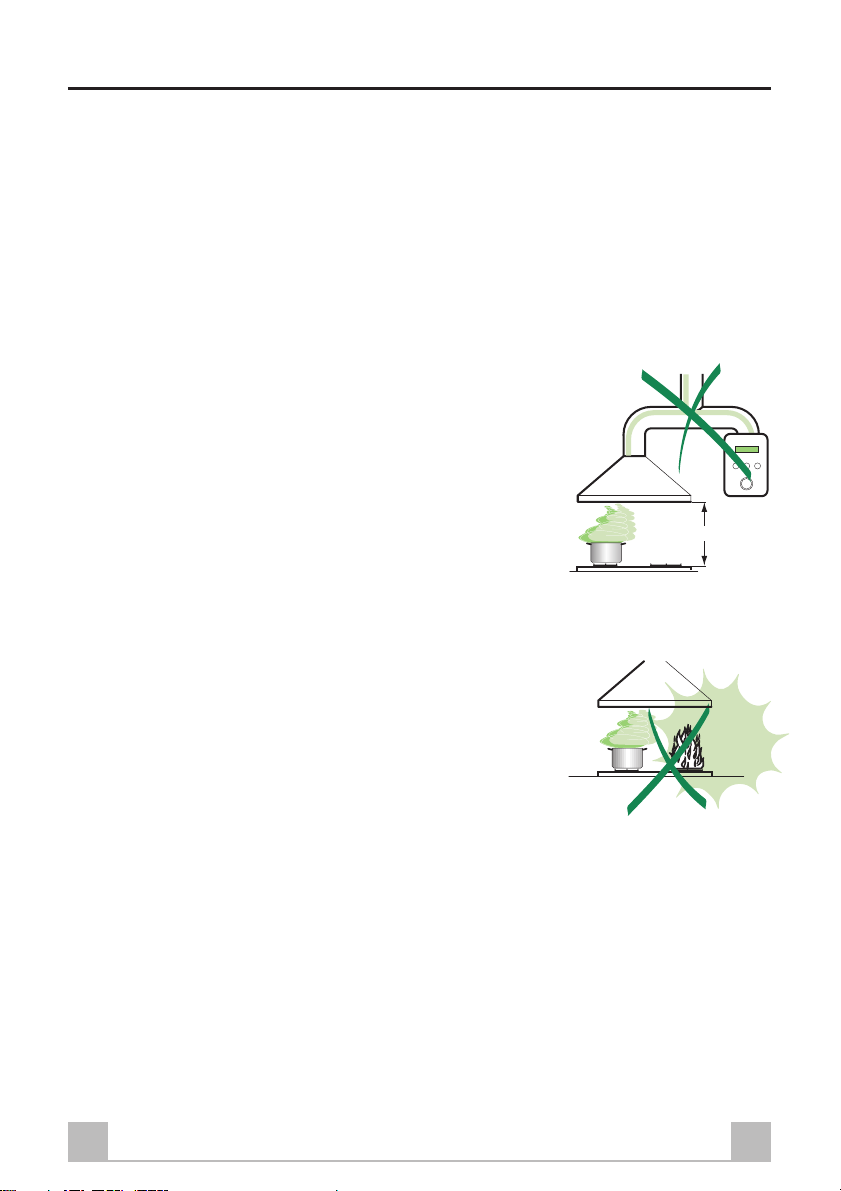

CHARACTERISTICS

Dimensions

740

100

507

108 244

898

300

150

360

max. 1145

min. 850

260

360

60

132

90

433

63

650 min.

4GB

Page 5

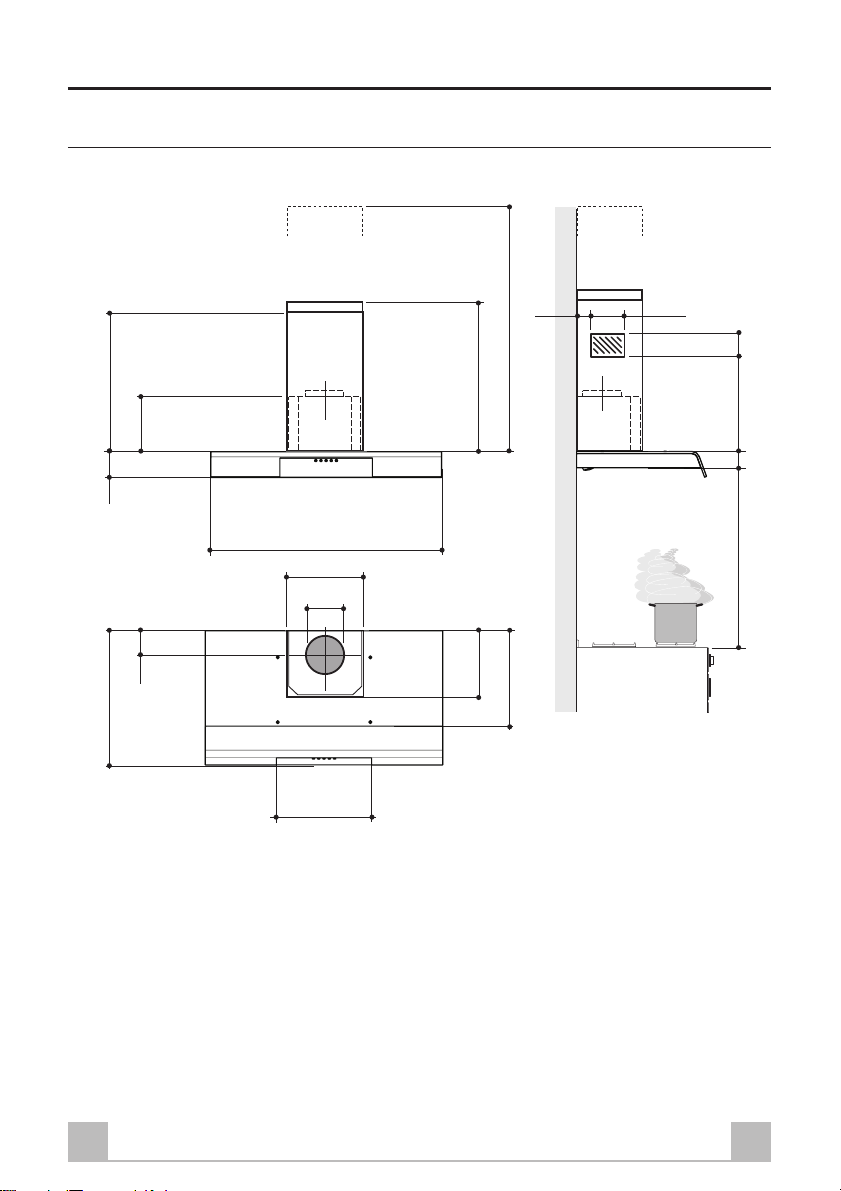

Components

15

14.1

12a

7.2.1 11

14

9

2.1

12c

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light,

Blower, Filters

2 1 Telescopic Chimney comprising:

2.1 1 Upper Section

2.2 1 Lower Section

8a 1 Right Air Outlet Grill

8b 1 Left Air Outlet Grill

9 1 Reducer Flange ø 150-120 mm

14 1 Hood Body Air Outlet Extension Piece consisting

of two Half Shells

14.1 2 Air Outlet Connection Extension

15 1 Air Outlet Connection

2

2.2

8b

8a

Ref. Q.ty Installation Components

7.2.1 2 Upper Chimney Section Fixing Brackets

11 6 Wall Plugs

12a 6 Screws 4,2 x 44,4

12c 4 Screws 2,9 x 9,5

11

12a

Q.ty Documentation

1 Instruction Manual

1

5GB

Page 6

INSTALLATION

Wall drilling and bracket fixing

1÷2

7.2.1

11

12a

650 min.

Wall marking:

• Draw a vertical line on the supporting wall up to the ceiling, or as high as practical, at the centre

of the area in which the hood will be installed.

• Draw a horizontal line at 650 mm above the hob.

• Place bracket 7.2.1 on the wall as shown about 1-2 mm from the ceiling or upper limit aligning

the centre (notch) with the vertical reference line.

• Mark the wall at the centres of the holes in the bracket.

• Place bracket 7.2.1 on the wall as shown at X mm below the first bracket (X = height of the upper

chimney section supplied), aligning the centre (notch) with the vertical line.

• Mark the wall at the centres of the holes in the bracket.

• Mark a reference point as indicated at 116 mm from the vertical reference line and 323 mm above

the horizontal reference line.

• Repeat this operation on the other side.

• Drill ø 8 mm holes at all the centre points marked.

• Insert the wall plugs 11 in the holes.

• Fix the brackets using the 12a (4,2 x 44,4) screws supplied.

• Insert the two screws 12a (4,2 x 44,4) supplied in the hood body fixing holes, leaving a gap of 56 mm between the wall and the head of the screw.

116

116

X

323

6GB

Page 7

12a

Vr

9

ø 120ø 150

Mounting the hood body

• Before attaching the hood body, tighten the two

screws Vr located on the hood body mounting

points.

• Hook the hood body onto the screws 12a

• Fully tighten support screws 12a

• Adjust screws Vr to level the hood body

Connections

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect the hood to the chimney using either a flexible or rigid

pipe ø 150 or 120 mm, the choice of which is left to the installer.

• To install a ø 120 mm air exhaust connection,

insert the reducer flange 9 on the hood body

outlet.

• Fix the pipe in position using sufficient pipe

clamps (not supplied).

• Remove any activated charcoal filters.

7GB

Page 8

14

14.115

8a

8b

RECIRCULATION VERSION AIR OUTLET

12c

8a

2.1

2.2

2

8b

7.2.1

12c

• Assemble the two halves of the hood body

extension piece 14.

• Push fit the assembled hood body extension

piece 14 onto the air outlet.

• Push fit connection 15 onto the hood body

extension piece 14.

• Insert the connection extension pieces laterally

14.1 in connection 15.

• Make sure that the outlet of the extension pieces

14.1 is horizontally and vertically aligned with

the chimney outlets. If this is not the case, adjust

the position by either reversing the connection

extension pieces 14.1 or by cutting the hood

body extension 14 along one of the thinner

section channels denoting the pre-fixed lengths,

then reassemble as described previously .

• The air outlet directional grills 8a - 8b must be

fitted after the lower outlet duct has been

installed.

• Ensure that the activated charcoal filters have

been inserted.

ELECTRICAL CONNECTION

• Connect the hood to the mains through a two-pole switch having a contact gap of at least 3 mm.

Flue assembly

Upper exhaust flue

• Slightly widen the two sides of the upper flue

and hook them behind the brackets 7.2.1,

making sure that they are well seated.

• Secure the sides to the brackets using the 4

screws 12c (2,9 x 9,5) supplied.

Lower exhaust flue

• Slightly widen the two sides of the flue and hook

them between the upper flue and the wall,

making sure that they are well seated.

• Fix the lower part laterally to the hood body

using the 2 screws 12c (2,9 x 9,5) supplied.

• On the recirculation version, fit the directional

grids 8a – 8b in their housings making sure that

the directional symbols are towards the top and

front of the hood. Also make sure that they are

correctly inserted in the connection extension

pieces 14.1.

8GB

Page 9

USE

Control panel

L

S

V1 V2 V3

L Light Switches the lighting system on and off.

S Led Motor running led.

V1 Motor Switches the extractor motor on and off at low speed. Used to provide a contin-

uos and silent air change in the presence of light cooking vapours.

V2 Speed Medium speed, suitable for most operating conditions given the optimum treated

air flox/noise level ratio.

V3 Intensive Maximum speed, used for eliminating the highest cooking vapour emission,

including long periods.

9GB

Page 10

MAINTENANCE

Grease filters

CLEANING METAL SELF- SUPPORTING GREASE FILTERS

• The filters must be cleaned every 2 months of

operation, or more frequently for particularly

heavy usage, and can be washed in a dishwasher.

• Remove the filters one at a time by pushing

them towards the back of the group and pulling

down at the same time.

• Wash the filters, taking care not to bend them.

Allow them to dry before refitting.

• When refitting the filters, make sure that the

handle is visible on the outside.

Activated charcoal filter (Recirculation version)

REPLACING THE ACTIVATED CHARCOAL FILTER

• The filter is not washable and cannot be

regenerated, and must be replaced approximately

every 4 months of operation, or more frequently

for particularly heavy usage.

• Remove the metal grease filters

• Remove the saturated activated carbon filter by

releasing the fixing hooks

• Fit the new filter by hooking it into its seating

• Replace the metal grease filters.

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the 2 Screws fixing the Lighting

support, and pull it out of from the Hood.

• Extract the Lamp from the Support.

• Replace with another of the same type, making

sure that the two pins are properly inserted in

the lamp holder socket holes.

• Replace the Support, fixing it in place with the

two Screws removed as above.

10GB

Page 11

Page 12

This appliance conforms to European Low Voltage Directive 73/23/CEE governing electrical safety, European Directive 89/

336/CEE on Electromagnetic Compatibility and Directive 93/68/CEE regarding CE Marking.

436001716 01 - 030311

Loading...

Loading...