Page 1

Operating and Installation Instructions

Page 2

Contents

Safety warnings 3

for the user 3

for the installer 3

Description of the Appliance 5

Extractor version 5

Filter Version 5

Hood Operation 6

Maintenance and care 7

Metal grease filter 7

Open the metal grease filter 7

Charcoal filter 8

Changing the light bulb 9

Cleaning 10

Mounting accessories included 10

Electrical connection 10

Safety warnings for the electrician 10

Wall unit mounting 11

2

Page 3

Safety warnings

for the user

• Always cover lighted elements, to prevent excess heat from

damaging the appliance. In the case of oil, gas and coal fired

cookers it is essential to avoid open flames.

• Also, when frying, keep the deep frying pan on the cooker top/

cooker under careful control.

• The hot oil in the frying pan might ignite due to overheating.

• The risk of self-ignition increases when the oil being used is dirty .

• It is extremely important to note that overheating can cause a fire.

• Never carry out any flambé cooking under the hood.

• Always disconnect the unit from the power supply before

carrying out any work on the hood, including replacing the

light bulb (take the cartridge fuse out of the fuse holder or switch

off the automatic circuit breaker).

• It is very important to clean the hood and replace the filter at

the recommended intervals. Failure to do so could cause

grease deposits to build up, resulting in a fire hazard.

• The appliance is not intended for use by young children or infirm

persons without supervision.

• Y oung children should be supervised to ensure that they do not play

with the appliance.

• WARNING - Ensure that the appliance is switched of f before

replacing the lamp to avoid the possibility of electric shock.

for the installer

• When used as an extractor unit, the hood must be fitted with a

150mm diameter hose.

• Should there already be a pipe of diameter 125 mm that ducts to

the outside through the walls or roof, it is possible to use the 150/

125 mm reduction flange provided. In this case the hood will be

slightly more noisy .

• When installing the hood, make sure you respect the following

minimum distance from the top edge of the cooking hob/ring

surfaces:

electric cookers 500 mm

gas cookers 650 mm

coal and oil cookers 700 mm min.

• The national Standard on fuel-burning systems specifies a maximum depression of 0.04 bar in such rooms.

• The air outlet must not be connected to chimney flues or combustion gas ducts. The air outlet must under no circumstances be

connected to ventilation ducts for rooms in which fuel-burning

appliances are installed.

3

Page 4

• It is advisable to apply for authorization from the relevant controlling

authority when connecting the outlet to an unused chimney flue or

combustion gas duct.

The air outlet installation must comply with the regulations laid down

by the relevant authorities.

• When the unit is used in its extractor version, a sufficiently large

ventilation hole must be provided, with dimensions that are

approximately the same as the outlet hole.

• National and regional building regulations impose a number of

restrictions on using hoods and fuel-burning appliances connected

to a chimney , such as coal or oil room-heaters and gas fires, in the

same room.

• Hoods can only be used safely with appliances connected to a

chimney if the room and/or flat (air/environment combination) is

ventilated from outside using a suitable ventilation hole approximately 500-600 cm2 large to avoid the possibility of a depression

being created during operation of the hood.

• If you have any doubts, contact the relevant controlling authority or

building inspector’s office.

• Since the rule for rooms with fuel burning appliances is “outlet hole

of the same size as the ventilation hole”, a hole of 500-600 cm2,

which is to say a larger hole, could reduce the performance of the

extractor hood.

• If the hood is used in its filtering function, it will operate simply and

safely in the above conditions without the need for any of the

aforementioned measures.

• When the hood is used in its extractor function, the following rules

must be followed to obtain optimal operation:

— short and straight outlet hose

— keep bends in outlet hose to a minimum

— never install the hoses with an acute angle, they must

always follow a gentle curve only

— keep the hose as large as possible (preferably the same

diameter as the outlet hole).

• Failure to observe these basic instructions will drastically reduce the

performance and increase the noise levels of the extractor hood.

4

Page 5

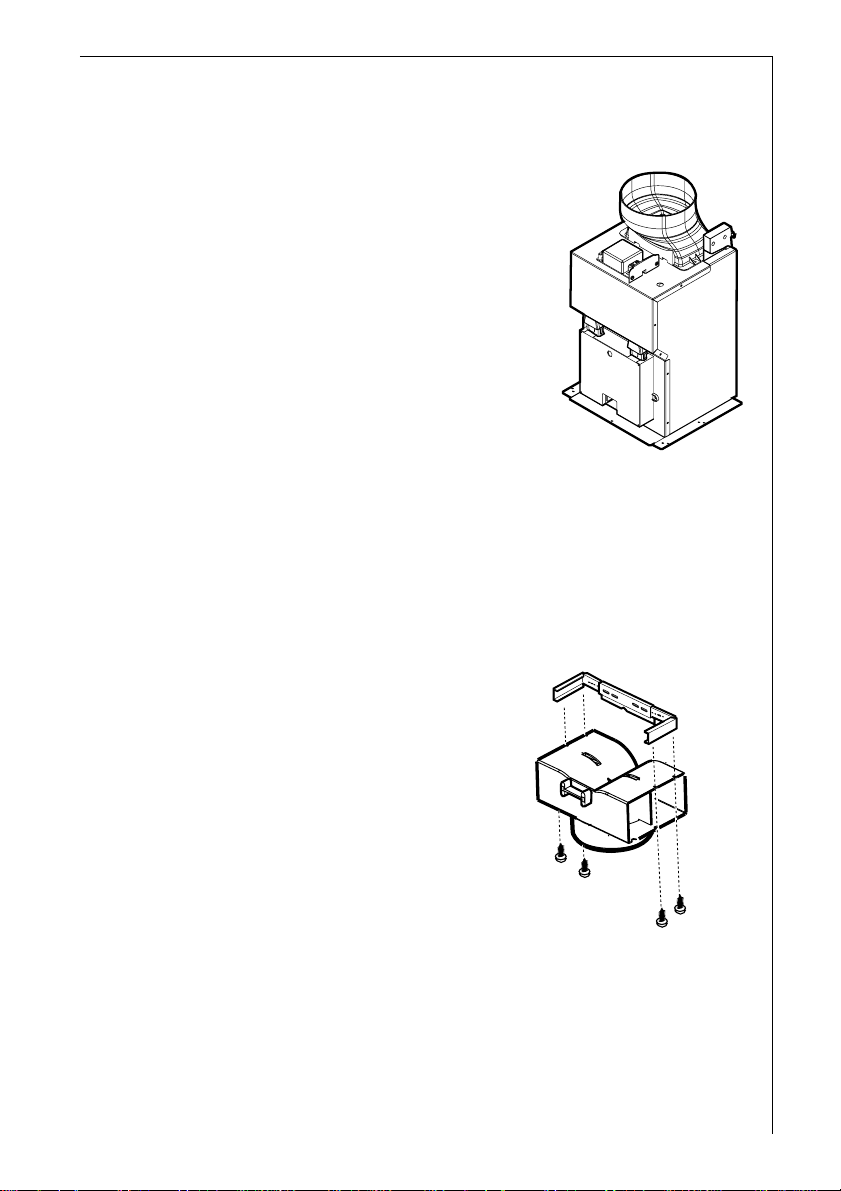

Description of the Appliance

Extractor version

• The hood is supplied as an extractor unit

and can also be used with a filtering

function by fitting one charcoal filter.

• You will need a charcoal filter for this

function.

• The air is discharged to the outside

through a pipe, which must be fitted to

connection flange D. Fig. 1.

• In order to obtain the best performance the

hose should have a diameter equal to the

outlet hole.

Should there already be a pipe of diameter

125 mm that ducts to the outside through

the walls or roof, it is possible to use the

150/125 mm reduction flange provided. In

this case the hood will be slightly more

noisy .

Filter Version

• The air is filtered through an charcoal

filter and returned to the kitchen through

the top grill of the outlet pipe.

• You will need a charcoal filter for the

filtering function.

• Fix the deflector using 4 screws . Fig. 2.

D

Fig. 1

Fig. 2

5

Page 6

Hood Operation

• Best results are obtained by using a low speed for normal

conditions and high speed when odours are more concentrated.

Turn the hood on a few minutes before you start cooking then you

will get an underpressure in the kitchen. It should be left on after

cooking for about 15 minutes or until all odours have disappeared.

The control switches are located on the unit’s front panel:

• Light switch: this switch is used to turn the light fitted in the hood

on and off.

• Extractor fan switch: used to turn the fan off.

• Push-button 1: used to set the fan to speed 1.

• Push-button 2: used to set the fan to speed 2.

• Push-button 3: used to set the fan to speed 3.

Push-button 3

Push-button 2

Push-button 1

Extractor fan switch

Light switch

0123

6

Page 7

Maintenance and care

• The hood must always be disconnected from the electricity

supply before beginning any maintenance work.

Metal grease filter

• The purpose of the grease filters is to aspirate grease particles

which form during cooking and it must always be used, either in the

external evacuation or internal recycling function.

Attention: the metal grease filters must be removed and washed,

either by hand or in the dishwasher, every four weeks.

Open the metal grease filter

• First, push the metal grease filter stop backwards, then extract the

filter, pulling downwards. Fig. 3.

Hand washing

Soak grease filters for about

one hour in hot water with a

grease-loosening cleaner,

then rinse off thoroughly with

hot water. Repeat the

process if necessary . Refit

the grease filters when they

are dry .

Dishwasher machine

Place grease filters in dish

washer. Select most powerful

washing programme and

highest temperature, at least

65°C. Repeat the process.

Refit the grease filters when

they are dry .

When washing the metal grease filter in the dishwasher a slight

discoloration of the filter can occur, this does not have any impact

on its performance.

• Clean the inner housing using a hot detergent solution only (never

use caustic detergents, abrasive powders or brushes).

Fig. 3

7

Page 8

Charcoal filter

• The charcoal filter should only be used if you want to use the hood

in its filtering function.

• To do this you will need a charcoal filter.

• Cleaning/replacing the charcoal filter

Unlike other charcoal filters, the LONGLIFE charcoal filter can be

cleaned and reactivated. At normal use the filter should be cleaned

every second month (when using the hood 2,5 hours per day , in

avarage). The best way to clean the filter is in the dishwasher. Use

normal detergent and choose the highest temperature (65º C).

Wash the filter separately so that no food parts gets stuck on the

filter and later causes bad odours. To reactivate the charcoal, the

filter should be dried in an oven for 10 minutes with a temperature

of maximum 100º C.

After approximately three years of use, the charcoal filter should be

replaced with a new, as the odour reduction capacity will be

reduced.

• Mounting

Remove the frame b which supports the filter c by turning 90° the

two knobs a, Fig.4. Insert the coal mattress inside the frame and

put all parts back in their place d.

• To dismount proceed in reverse order.

• Always specify the hood model code number and serial number

when ordering replacement filters. This information is shown on the

registration plate located on the inside of the unit.

• The charcoal filter can be ordered from the technical assistance

service.

a

d

a

c

b

Fig. 4

a

a

8

Page 9

Warning

• Failure to observe the instructions on cleaning the unit and

changing the filters will cause a fire hazard. You are therefore

strongly recommended to follow these instructions.

• The manufacturer declines all responsibility for any damage to the

motor or any fire damage linked to inappropriate maintenance or

failure to observe the above safety recommendations.

Changing the light bulb

• Disconnect the cooker hood from the main supply .

• Remove the lamp cover, use a screw driver as a lever. Fig. 5.

• Replace the old bulb with a new one of the same type.

• Remount the lamp cover.

• If the light does not come on, make sure the bulb has been inserted

in correctly before contacting the technical assistance service.

Fig. 5

9

Page 10

Cleaning

• Warning: always disconnect the hood from the mains power supply

before cleaning it.

Never insert pointed objects in the motor’s protective grid.

• Wash the outside surfaces using a delicate detergent solution.

Never use caustic detergents or abrasive brushes or powders.

• Only ever clean the switch panel and filter grille using a damp cloth

and delicate detergents.

• It is extremely important to clean the unit and change the filters at

the recommended intervals. Failure to do so will cause grease

deposits to build up that could constitute a fire hazard.

Mounting accessories included

1 deflector (3 pieces to assemble)

2 metal screws 3,5 x 13 (to assemble the deflector)

1 chimney support (3 pieces to assemble)

4 metal screws 4 x 8 (to assemble the chimney support)

4 metal screws 3,5 x 9,5 (to affix the deflector to the support)

1 reduction flange Ø 125-120 mm

1 support bracket

6 wood-screws 5 x 45 mm (for wall mounting)

6 wall plugs Ø 8 mm (for wall mounting)

2 metal screws 2,9 x 6,5 (for upper chimney mounting)

8 metal screws 3 x 10 (to affix the screen and lower chimney to the

cooker hood)

1 allen spanner (for TORX screws)

Electrical connection

Safety warnings for the electrician

Before connecting the appliance to the power supply, check that the

voltage indicated on the rating plate corresponds to the mains power

supply available. Appliances fitted with a plug can be connected to any

standard power socket within easy access.

Should it be necessary to provide a fixed connection, the hood must only

be installed by an electrician authorised by the local electricity board.

When installing, an omnipolar disconnector with a distance of at least

3mm between contacts must be provided.

The manufacture declines all responsibility for malfunctions resulting from

failure to comply with the above instructions.

Electrical connection

220-240 V – by means of fixed power cable with plug.

(Fixed connection of the appliance must only be carried out by an authorised electrician.)

10

Page 11

Wall unit mounting - Fig. 6

=

=

X

X

H

G

• Only for extractor version: position the upper section of the

chimney so that the oulet slots H are not visible (see also A-B-C

sequence on on Fig. 6).

• Assembling the chimney flue support/bracket (3 parts):

The three parts should be fixed with 4 screws, the support

extension is adjustable and should correspond to the internal width

of the telescopic chimney flue. Fig. 6.

Fig. 6

11

Page 12

Wall unit mounting - Fig. 7

• Fix each other both parts of the hood (1), make all connections

between the two parts (2) and fix with 6 screws (3).

• Mark the wall with a centre line, this will aid mounting (4), position

the template so that the mid line printed on the template matches

with the center line previously drawn, the lower side of the template

corresponds to the lower side of the hood once mounted (5).

• Drill two holes Ø 8mm and fix the support bracket with two wall

plugs and screws (6). Hang the hood (7) and adjust its position (8-

9).

• From the inside of the hood mark two points for final fixing (10).

• Remove the hood (11) and drill two holes Ø 8mm (12), fit two wall

plugs (13).

• Rest the chimney support bracket G against the wall, touching the

ceiling. Use the support bracket as a drilling template and mark 2

holes with a pencil (14), dril the holes insert 2 wall plugs, fix the

chimney support bracket to the wall using two screws (15) (If the

hood is to be used in filter version, fix deflector F to the chimney

support bracket G using 4 screws).

• Hang the hood again (16) and fix it with two screws (17).

• Connect an exhaust pipe to the outlet hole of the hood B (18) for

direct discharge of fumes to the outside (Extractor version) or to be

connected to the connection ring located on the bottom of the

deflector F (Filter version).

• Make the electrical connections (19).

• Fit the chimney sections and fix them at the top to the chimney

support G (20b) using 2 screws (20a), slide the bottom section of

the chimney down until it completely covers the suction unit and

slots into the housing provided on top of the hood (21) and fix with 2

screws (22).

12

Page 13

20a

4

13

20a

G

7-16

11

9

8

20b

F

12

H

1

21

18

19

1

1

B

9

8

8

9

2

2

10

15

13

14

7-16

11

14

20b

6

5

12

10

17

NOTE: 18 not supplied

Fig. 7

17

1

1

3

3

22

3

3

22

13

Page 14

14

Page 15

15

Page 16

LI1Z4A Ed. 07/02

Loading...

Loading...