Page 1

Gebrauchsanweisung , Manuel d'utilisation

Istruzioni per l'uso , User manual

EFC 939.1

EFC 639.1

F ID

UK

Page 2

Contents

Safety warnings 3 0

For kitchen unit installer 3 0

For user 3 0

Description of the appliance 3 1

Mounting of grease filters 3 1

Function 3 1

Extractor version 31

Filter version 3 1

Using the hood 3 2

Control devices for the grease filter and carbon filter 3 2

Grease filter saturation led 3 2

Carbon filter saturation led 3 2

To restore the LED for the filter warnings. 3 2

Correct ventilation 32

Maintenance 3 3

Cleaning 3 3

Metal grease filter 3 3

Open the metal grease filter 3 3

Warning 33

Carbon filter 3 4

Changing the light bulb 3 4

Technic Details 3 5

Special accessories 35

Installation 35

Unpacking 35

Placement 3 5

Electrical connection 35

Wall unit mounting 3 6

Mounting of hood 36

UK

Before you use the cooker hood we recommend that you read through the whole user manual giving a

direct description of the cooker hood and its functions.

To avoid the risks, that are always present when you use a product driven by electricity, it is important

that the cooker hood is installed correctly and that you read the safety instructions carefully to avoid

misuse and hazard.

Save the instruction manual and keep it available at use of the cooker hood

29

Page 3

Safety warnings

For kitchen unit installer

Attention: The air outlet must not be connected

to chimney flues or combustion gas ducts. The

air outlet must under no circumstances be

connected to ventilation ducts for rooms in

which fuel-burning appliances are installed.

• When used as an extractor unit, the hood

must be fitted with a 150mm diameter hose.

• When installing the hood, make sure you

respect the following minimum distance

from the top edge of the cooking hob/ring

surfaces:

electric cookers 600 mm

gas cookers 750 mm

coal and oil cookers 850 mm min.

• If the cooker hood is operating in the suction

version concurrently to other combustion

appliances you will need to ensure that the

depression in the environment of these installations does not exceed the 4PA (4x10

• The air outlet must not be connected to

chimney flues or combustion gas ducts. The

air outlet must under no circumstances be

connected to ventilation ducts for rooms in

which fuel-burning appliances are installed.

• It is advisable to apply for authorization from

the relevant controlling authority when

connecting the outlet to an unused chimney

flue or combustion gas duct.

The air outlet installation must comply with

the regulations laid down by the relevant

authorities.

• When the unit is used in its extractor version,

a sufficiently large ventilation hole must be

provided, with dimensions that are approximately the same as the outlet hole.

• National and regional building regulations

impose a number of restrictions on using

hoods and fuel-burning appliances connected

to a chimney, such as coal or oil roomheaters and gas fires, in the same room.

• Since the rule for rooms with fuel burning

appliances is “outlet hole of the same size as

the ventilation hole”, a hole of 500-600 cm2,

which is to say a larger hole, could reduce

the performance of the extractor hood.

-5

bar).

• If the hood is used in its filtering function, it

will operate simply and safely in the above

conditions without the need for any of the

aforementioned measures.

• When the hood is used in its extractor function, the following rules must be followed to

obtain optimal operation:

— short and straight outlet hose

— keep bends in outlet hose to a minimum

— never install the hoses with an acute

angle, they must always follow a gentle

curve only

— keep the hose as large as possible (prefer-

ably the same diameter as the outlet hole).

• Failure to observe these basic rules will

drastically reduce the performance and

increase the noise levels of the extractor

hood.

For user

• Always cover lighted elements, to prevent

excess heat from damaging the appliance. In

the case of oil, gas and coal fired cookers it is

essential to avoid open flames.

• Also, when frying, keep the deep frying pan

on the cooker top/cooker under careful

control.

• The hot oil in the frying pan might ignite due

to overheating.

• The risk of self-ignition increases when the

oil being used is dirty.

• It is extremely important to note that overheating can cause a fire.

• Never carry out any flambé cooking under

the hood.

• Always disconnect the unit from the power

supply before carrying out any work on the

hood, including replacing the light bulb

(take the cartridge fuse out of the fuse holder

or switch off the automatic circuit breaker).

• It is very important to clean the hood and

replace the filter at the recommended

intervals. Failure to do so could cause

grease deposits to build up, causing a fire

hazard.

30

Page 4

Description of the appliance

a

b

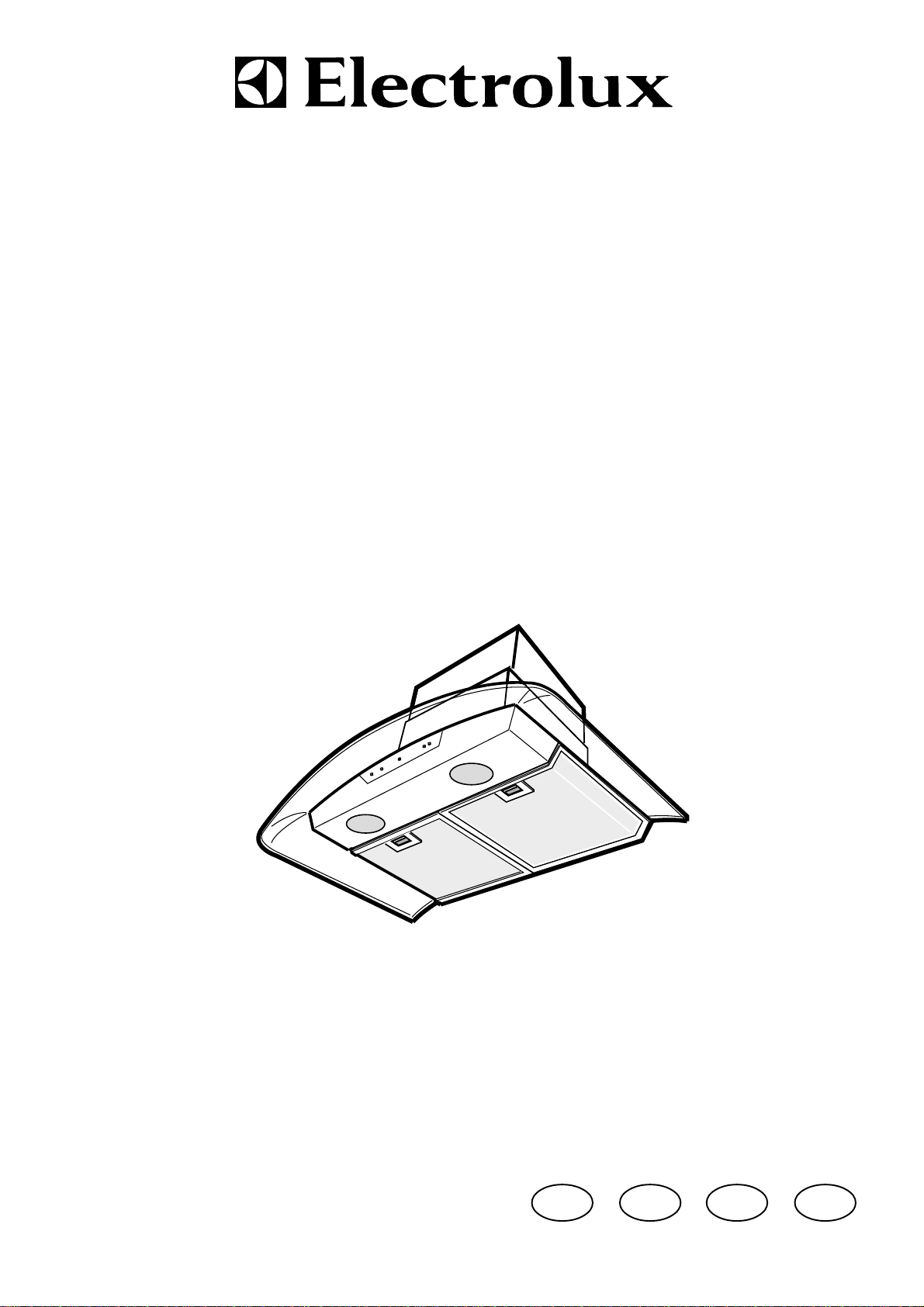

Mounting of grease filters

Attention! The grease filters are supplied not

mounted and packed in order to avoid damages

during transport of the hood.

• Fit the pins of the filter on the slots of the

grease filter housing, then use the handles of

the filter to lock them.

Dismount the filter the opposite way.

• Pull the handles backwards to loosen the

filter (Fig. 1).

Function

The hood may be used as follows:

- Extractor version

- Filter version

EFC 639

b

Extractor version

The air is vented outdoors by a 150 mm duct

which must be connected to connecting ring

on top of the motor package.

Filter version

The air is filtered through an activated charcoal

filter and returned to the kitchen through the top

grill of the outlet pipe (fig. 2).

This version is used when there is no exhaust

duct for venting outdoors or when it is impossible to install one.

EFC 939

a

Fig. 1

Fig. 2

31

Page 5

Using the hood

The hood has one variable speed motor. For the

best performance, we recommend using the low

speeds in normal conditions and the high

speeds in particular cases of strong odour and

vapour concentration.

We recommend starting up the hood a few

minutes before cooking and keeping it running

until all the odours have been eliminated.

0 123

A

A – Motor OFF button

B – ON button and motor speed selection

E – Speed 1 LED

F – Speed 2 LED and grease filter saturation

C – Speed 3 LED and carbon filter saturation

D – Intensive speed indicator LED

G – Intensive speed ON switch

H – OFF lamp button

I – ON lamp button

If the hood fails to operate correctly, briefly

disconnect it from the mains power supply for

almost 5 sec. by pulling out the plug. Then plug

it in again and try once more before contacting

the Technical Assistance Service.

BEFCD

button 1 - 2 - 3 - 1 - 2 - . . . .

LED (flashes)

LED (flashes)

This speed should be used when the

concentration of cooking fumes or odours

is particularly strong (for example when

frying, cooking fish etc.).

The fast speed will run for about 5 minutes and then return to the speed previously set automatically (1, 2 or 3), or

switch off if no speed was selected. To

turn off the fast speed, before the end of

the 5 minutes, press button A or button B.

FC

5 MIN

0I

H

G

I

Control devices for the grease

filter and carbon filter

This hood has a device which warns you when

to clean the grease filter or replace the carbon

filter (in the case of the air recircultion version).

This hood is delivered without a carbon filter.

For this reason the warning signal to replace the

carbon filter is not connected.

If the hood will be used for recirculation of air,

with carbon filter, the warning signal have to be

connected as follows: Press the buttons B and G

at the same time for about 3 seconds. The LED

marked F lights up.

When the LED marked C lights up, the warning

signal is connected.

To disconnect the warning signal, press the

buttons B and G at the same time for about 3

seconds until the LED marked C goes out.

Grease filter saturation led

The LED marked F warns you when the grease

filter needs to be cleaned.

This LED flashes to warn you that the grease

filters must be cleaned.

Generally, these must be cleaned after 40 hours

of use.

Read the maintenance instructions provided for

the grease filters.

Carbon filter saturation led

The LED marked C indicates carbon filter needs

to be replaced.

This must be done after approximately 160

hours of use.

Read the instructions provided for replacing the

carbon filter.

To restore the LED for the filter

warnings.

After cleaning of the grease filter and exchange

of the carbon filter, press button A for about 3

seconds until the LED F stops flashing.

Correct ventilation

To have the cooker hood working correctly

the windows in the kitchen should be closed.

In stead a window in an adjacent room

should be open.

32

Page 6

Maintenance

The hood must always be disconnected

from the mains power supply before

beginning any maintenance work.

Cleaning

• Warning: always disconnect the hood from

the mains power supply before cleaning it.

Never insert pointed objects in the motor’s

protective grid.

• Wash the outside surfaces using a delicate

detergent solution. Never use caustic detergents or abrasive brushes or powders.

• Only ever clean the switch panel and filter

grille using a damp cloth and delicate detergents.

• It is extremely important to clean the unit and

change the filters at the recommended intervals. Failure to do so will cause grease deposits to build up that could constitute a fire

hazard.

Warning

• Failure to observe the instructions on cleaning the unit and changing the filters will

cause a fire hazard. You are therefore

strongly recommended to follow these instructions.

• The manufacturer declines all responsibility

for any damage to the motor or any fire

damage linked to inappropriate maintenance

or failure to observe the above safety recommendations.

Metal grease filter

• The purpose of the grease filters is to aspirate

grease particles which form during cooking

and it must always be used, either in the

external evacuation or internal recycling

function.

Attention: the metal grease filters must be

removed and washed, either by hand or in

the dishwasher, every four weeks.

Open the metal grease filter

• Pull the handles backwards to loosen the

filter. Fig. 3.

Hand washing

Soak grease filters for about one hour in hot

water with a grease-loosening cleaner, then

rinse off thoroughly with hot water. Repeat

the process if necessary. Refit the grease

filters when it are dry.

Dishwasher machine

Place grease filters in dish washer. Select

most powerful washing programme and

highest temperature, at least 65°C. Repeat the

process. Refit the grease filters when it are

dry.

When washing the metal grease filter in the

dishwasher a slight discoloration of the filter

can occur, this does not have any impact on

its performance.

• Clean the inner housing using a hot detergent solution only (never use caustic detergents, abrasive powders or brushes).

Fig. 3

33

Page 7

Carbon filter

The active carbon filter absorbs the cooking

vapors formed in the kitchen.

Normally the filter should be replaced once a

year. The active carbon filter should not be

washed under any circumstances. In order to

substitute the filter remove the screws (fig. 4)

and slide the filter downwards.

Note: the activated carbon filter must normally

be replaced at least once a year. This filter

cannot be washed or regenerated. To guarantee

proper absorption of odours the working volume of the activated carbon must be proportionate to the hood air flow. In this case the high

quality of the activated carbon will ensure

efficient odour removal for approximately one

year, assuming that the hood is used normally.

For this reason you should always use original

Electrolux filters only, making sure they are

replaced when necessary.

Fig. 4

Changing the light bulb

• Disconnect the cooker hood from the main

supply.

• Remove the lamp cover, use a screw driver as

a lever. Fig. 5.

• Replace the old bulb with a new one of the

same type.

• Remount the lamp cover.

• If the light does not come on, make sure the

bulb has been inserted in correctly before

contacting the technical assistance service.

Fig. 5

34

Page 8

Technic Details

Model EFC 939.1 EFC 639.1

Dimensions height 590 - 910 mm 590 - 910 mm

width 898 mm 598 mm

depth 490 mm 490 mm

Lighting 2 x 20 W 2 x 20 W

Grease filter 2 1

max absorbed power 200 W 200 W

We reserve the right to generate constructive and chromatic modifications as required by technological

growth.

Special accessories

Carbon filter 942 120 182

Installation

Unpacking

Check that the cooker hood has no damages.

Transportation damages should immediately be

reported to the one responsible for the transport

Damages, faults and eventually missing details

should immediately be reported to the seller.

Take care of the packing material so that small

children cannot play with it.

Min

60 cm

Min

75 cm

Placement

The hood is to be mounted on the wall.

When installed, the hood must be not less than

60 cm. above electric burners or 75 cm. above

gas or mixed-fuel burners (fig. 6).

Electrical connection

The hood has a power cord with moulded plug

with earth connection to be connected to a wall

outlet of 230 V.

The power outlet should be pre-mounted in

such a way that the power cord is invisible

when the hood is fully mounted.

The power cord length is 1,25 m.

Safety warnings for the electrician

Before connecting the appliance to the power

supply, check that the voltage indicated on the

rating plate corresponds to the mains power

supply available. Appliances fitted with a plug

can be connected to any standard power socket

within easy access.

Should it be necessary to provide a fixed connection, the hood must only be installed by an

electrician authorised by the local electricity

board. When installing, an omnipolar

Fig. 6

disconnector with a distance of at least 3 mm

between contacts must be provided.

This disconnector may be for example a switch,

fuses (plug fuses must be removed from the

fuse box, fault current switches and remote

switches with a distance of over 3 mm between

contacts.

The manufacture declines all responsibility for

malfunctions resulting from failure to comply

with the above instructions.

If the power socket is applied directly above the

hood this gives two advantages:

1. the socket is not visible.

2. the appliance can be disconnected at need

merely be removing the plug.

Electrical connection

220-240 V – by means of fixed power cable

with plug.

(Fixed connection of the appliance must only be

carried out by an authorised electrician.)

35

Page 9

Wall unit mounting

Standard accessories included:

• Screws for mounting

• Drilling scheme

• No return valve (mounted on air outlet)

Mounting of hood

• Fit the drilling scheme onto the wall at the

right height. (Fig. 7).

The lower edge of the scheme correspond to

the lower edge of the cooker hood.

• On the drilling scheme is printed a line

corresponding to the centre of the appliance;

with a pencil draw a line up to the ceiling,

this will aid installation procedures. (Fig. 7).

Fig. 7

• Drill as indicated on the scheme and fit two

dowels, two hooks and two screws 5x45.

(Fig. 7).

• Hang the hood, adjust the position using the

screws on the hooks of the hood. (Fig. 8).

• Release the grease filters. (Fig. 3).

• From the inside of the hood mark on the wall

the point corresponding to the hole which

will be used to fix definitively the hood. (Fig.

9).

• Remove the hood.

• Drill two hole (Ø 8mm) and fit two dowels.

(Fig. 9).

• Hang the hood again on the hooks.

• From inside of the hood insert the definitive

fixing screws. (Fig. 9).

Fig. 8

36

Fig. 9

Page 10

Wall unit mounting

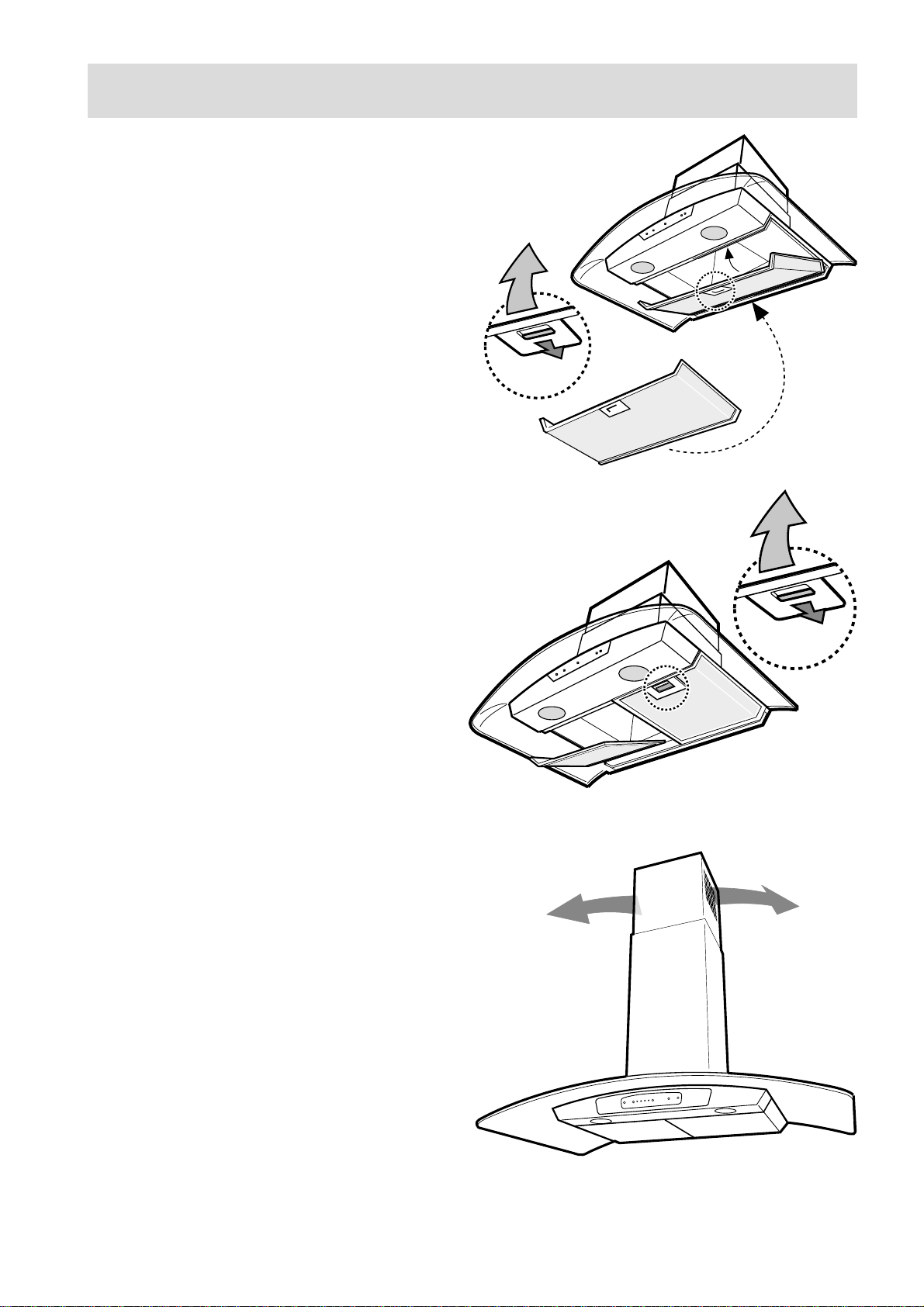

• To mount the chimney you must first affix

the chimney support with the screws and

screw anchors provided (Ø 8 mm) on the

highest point of the wall that meets the ceiling, perpendicular in respect to the lowest

connector of the chimney (fig. 10).

The power plug must be disconnected

from the mains during the mounting

procedure.

b

Extractor version

• Fit a Ø 150 mm exhausting pipe or flex tube

on the hood outlet on top of the motor housing and connect it to the wall or roof outlet

pipe.

Recirculating version

• If not already fitted, fit the connection ring (a

- Fig. 10) supplied (bajonett attachment - turn

clockwise and fix with a screw) on the deflector b.

• Insert the deflector in the chimney support

and fix it with two screws (Fig. 10).

• Fit a Ø 150 mm exhausting pipe on the

motor outlet connection ring sufficiently long

to reach the connection ring on the deflector.

For both versions:

• Now connect the power plug to the wall

outlet.

• Fix the chimney top part on its support with

two screws (Fig. 10).

• Slide the lower section of the chimney down-

wards and insert it on its proper housing on

the upper side of the hood.

a

Fig. 10

Mounting of carbon filter (for

filter version)

• Remove the grease filter.

• Fix the carbon filter with its two screws (Fig.

11).

• Replace the grease filter.

Fig. 11

37

Page 11

Page 12

Page 13

Kundendienst

LI1VWB Ed. 01/02

Service après-vente

Servizio post-vendita

Servicestellen Points de service Servizio dopo vendita

Zürich/Mägenwil

5506 Mägenwil

Industriestr. 10

9000 St. Gallen

Vonwilstrasse 15

4133 Pratteln

Rheinpark-Center

Netzibodenstr. 23b

8604 Volketswil

Hözliwiesenstrasse 12

6032 Emmen

Buholzstrasse 1

7000 Chur

Comercial str a s s e 19

3063 Ittingen/Bern

Ey 5

1028 Préverenges

Le Trési 6

1950 Sion

Rue de la Piscine

Ersatzteil ver k au f Point de vent e de

rechange

6916 Grancia

Zona Industriale E

Vendita pezzi di

ricambio

5506 Mägenwil

Industriestrasse 10

Tel. 0848 848 023

Kochberatung /

Verkauf

8048 Zürich

Badenerstrasse 587

Tel. 01 405 81 11

5506 Mägenwil

Industriestrasse 10

Tel. 0848 848 023

Demonstration /

Vente

8048 Zürich

Badenerstrasse 587

Tel. 01 405 81 11

5506 Mägenwil

Industriestrasse 10

Tel. 0848 848 023

Consulente (cucina) /

Vendita

8048 Zürich

Badenerstrasse 587

Tel. 01 405 81 11

Garantie Garantie Garanzia

Wir gewähren auf allen

Produkten, die in der Schweiz

gekauft und in Betrieb sind, eine

einjährige Vollgarantie, gerechnet

ab Lieferdatum an den Endverbraucher. Massgebend für den

Garantieanspruch ist die Faktura

oder ein entsprechen-der

Verkaufsbeleg

L'utilisateur final de tout produit

acheté et utilisé en Suisse,

bénéficie d'une garantie complète

d'une année à partir de la date de

livraison. La facture ou le

justificatif d'achat correspondant

fait fo i en la matièr e.

Per questo prodotto concediamo

una garanzia di 12 mesi a partire

della data di vendita. La garanzia

è valida dietro presentazione

della fattura o dello scontrino

d'acquisto.

Loading...

Loading...