Page 1

Manual

Compact Reader ARE I2

Installation Guide

for Systems with a

Serial Interface (RS 232)

Page 2

Manual

Page 2 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

Contents

1 INTRODUCTION 5

2 SYSTEM OVERVIEW 5

3 START-UP PROCEDURE 6

4 INSTALLATION 7

4.1 Mounting of the Housing 7

4.2 Grounding of the Reader 7

4.3 Assemblage of the Line Connectors 7

4.3.1 Allowed Diameter of the Used Cables 8

4.3.2 Assembling of the Cable Pipe 8

4.3.3 Mounting of the Power Supply Cable 9

Assembling of the Power Supply and Data Cable (Single Cable Pipe) 10

4.3.5 Final Assembly of the Cable Pipe 11

4.3.6 Plug in of the SAB Cab 11

4.3.7 Using the Service Cable ID 70213 12

4.3.8 Using the Power Supply and Data Cable ID 70212 13

4.4 Power Supply 13

5 VISUAL SIGNAL LAMPS 14

6 SETTINGS OF THE READER / MOST IMPORTANT PARAMETERS 15

6.1 General 15

6.2 Error Codes 16

6.3 CID – Suppression of ID Codes 16

6.4 CN – Suppression of No Reads 17

6.5 NID- Failure Protection 17

6.6 EC- Echo 19

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 3

Manual

Page 3 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

6.7 BD- Baudrate 19

6.8 TOR – Maximum Reading Time 20

6.9 VS- Show Parameter 20

6.10 VSAVE – Save Parameter 20

7 OPERATING MODES OF THE READER 21

7.1 Mode 2 – Triggered by an Software Command 21

7.1.1 Settings of the Reader / Most Used Parameters 22

7.1.2 Basic Data Exchange Process 23

7.1.3 ReadOnly-Transponder 23

7.1.4 R / W –Transponder 23

7.1.4.1 Standard Read Process / Serial Number of the Transponder GT 23

7.1.4.2 Selective Read RD 24

7.1.4.3 Writing Process WD 24

7.2 Operating Mode 0 - Continuous Reading 26

7.2.1 Settings of the Reader / Most Used Parameters 26

8 INSTRUCTIONS 28

8.1 General Instructions 28

8.2 Special Instructions for Using a Read / Write System 29

9 HOTLINE 30

10 REFERENCE DOCUMENTATION 30

11 REVISIONS 30

12 APPENDIX 31

12.1 Best Orientation for an F-Type -Reader 31

12.2 Best Orientation for an L-Type -Reader 32

12.3 Assembling of the SAB Cab 33

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 4

Manual

Page 4 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 5

Manual

Page 5 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

1 Introduction

This document will describe the components of the Compact Reader System ARE I2 / RS 232

and the procedure how to do the first set up of the reader.

The main features of the reader are listed below:

• the antenna is placed inside of the housing (base version)

• there are algorithm available to read nearly all 125 kHz-transponders on market

• the serial RS 232-Interface is placed inside of the housing, allowed baud rate are up to

19200 Bit/s

• the allowed supply voltage is 9 to 30V

• low power consumption of reader < 1.2 Watt

• high reliability for reading and writing within an industrial environment.

• compact housing of the reader with multiple ways for mounting.

• the cabling concept of the reader is optimised to service demands.

• the protection class of the housing is IP65

• there is a set of external antennas available to meet special application demands ( X-tended

version)

DC

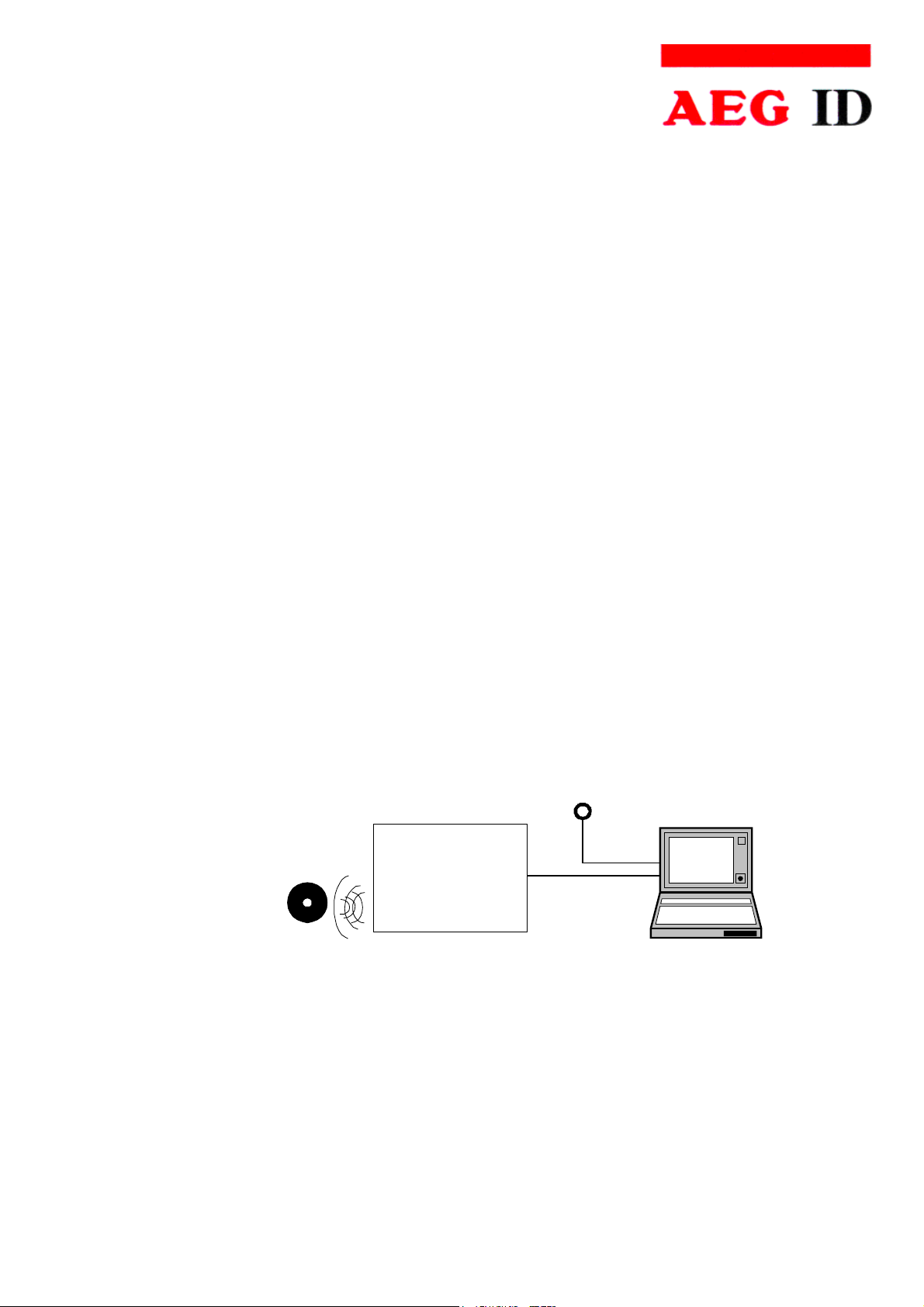

2 System Overview

In the base version all electronic components of the reader is placed inside of a small plastic

housing.

Transponder

Integrated Antenna

Figure 2-1: Concept of the Reading System

Reader with

ARE I2

(9-Pin SubD)

24V

RS232

DC

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 6

Manual

Page 6 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

The connection of the cables (power supply and data transfer) is done inside of the connection

cab (SAB Cab). Together with an sealing element a protection classification of IP 65 is guaranteed.

By means of the integrated antenna the reader generates an alternating magnetic field, which

powers the transponder. Coded signals sent back from the transponder are received and decoded by the reader

The reader is fully controlled by an Master with RS 232 data port, while using the integrated

serial RS 232 Interface of the reader.

The side of the housing showing the antenna symbol must not be brought next to a metal surface. This could lead to a significant change of the properties of the antenna circuit, which in

turn reduces the reading range considerably.

Environmental electromagnetic noise may also reduce the specified reading performance.

Special hints to overcome these problems are documented in Chapter 8.

3 Start-up Procedure

The start-up procedure of the reader system is split up to following steps:

• mounting of the reader and pin connection (cabling), see Chapter 4

• operational instructions, see Chapter 7

To get a feeling how the IdentSystem will work, first start the reader controlled by the serial interface (RS 232) of an isolated PC.

The next step is to integrate the reader to the operating network.

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 7

Manual

Page 7 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

4 Installation

To get the specified reading performance it is necessary to do the installation carefully step by

step as it is described in the following Chapters. All the work must be done by well educated

people.

4.1 Mounting of the Housing

The reader can be mounted to any other mechanic construction. It is recommended to protect

the housing against heavy mechanical interactions.

Attention!

The side of the housing showing the antenna symbol must not be brought next to a metal

surface. This could lead to a significant change of the properties of the antenna circuit,

which in turn reduces the reading range considerably.

With the help of the plastic bars, the reader can mounted or screwed on to the most fastening

elements without open the housing of the device.

4.2 Grounding of the Reader

To get reliable reading results, the reader must be grounded. The connector is place at the side

of the housing (6.35 mm flat contact).

To avoid EMV-problems, the cable to ground ought to be very short with low impedance.

Attention! The topology of the ground wires must be done in the right way (according state of

art).

4.3 Assemblage of the Line Connectors

The connection of the power supply and data transfer cables are done by using the connectors

of the SAB Cab. The Assemblage inside of the SAB Cab is described in Chapter 4.3.1 to

4.3.7.

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 8

Manual

Page 8 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

Inside of the SAB Cap there are the pins of following connections:

• power supply

• data link to the serial interface RS232

The codes to order the SAB Cabs and preassembled cables are listed below:

ID 70212 SAB-Cab incl. one PG9 cable pipe and 5 wire cable (standard cable)

ID 70213 SAB-Cab incl. one PG9 cable pipe and 5 wire cable / Sub D 9 Connector

(Service Cable)

ID 70221 SAB-Cab incl. one PG9 cable pipe

ID 70215 SAB-Cab incl. two PG9 cable pipes

ID 70219 SAB Cab without any cable pipe. The cabling is done by the customer himself.

4.3.1 Allowed Diameter of the Used Cables

The allowed diameters of the cables used for data link and power supply must be in the range

from ∅3,5 to ∅8mm. For this case, IP 65 is reached.

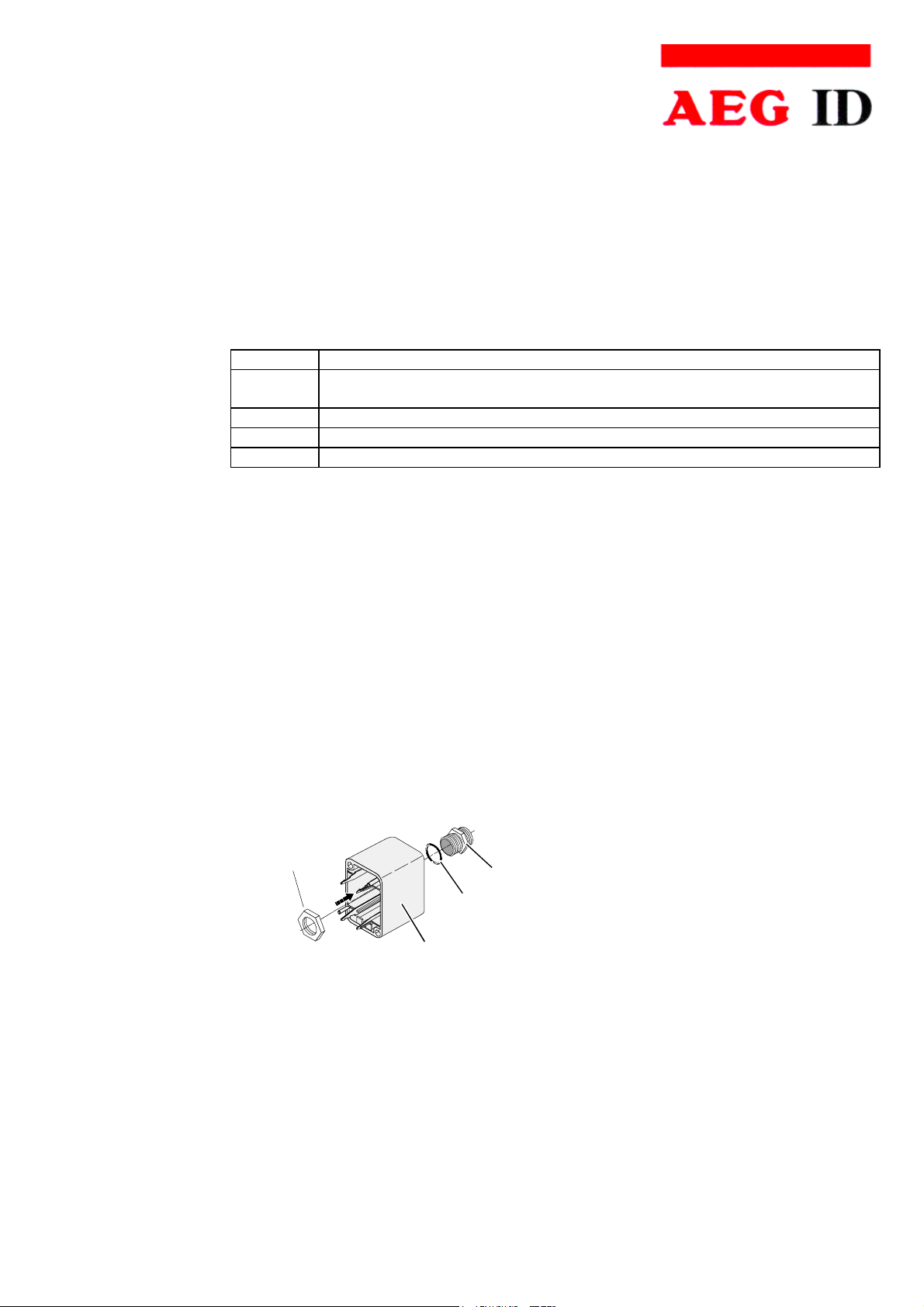

4.3.2 Assembling of the Cable Pipe

If no preassembled SAB Cab are used (Best-Nr. ID 70214), the assembling must be done in

following way:

• Breakthrough the prepared areas at the surface of the SAB Cabs. There are two prepared

areas seen at the SAB Cab: central and at one side of the cab.

• The sealing must be done in the correct way O-Ring (3) at the cable pipe (4) (see also

Figure 4-1.

2

1

Figure 4-1:Assembling oft the Cable Pipe

4

3

• Bring the nut (2) of the cable pipe inside of the SAB Cab (1).

• To fasten the nut please use the right tool (17mm)..

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 9

Manual

Page 9 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

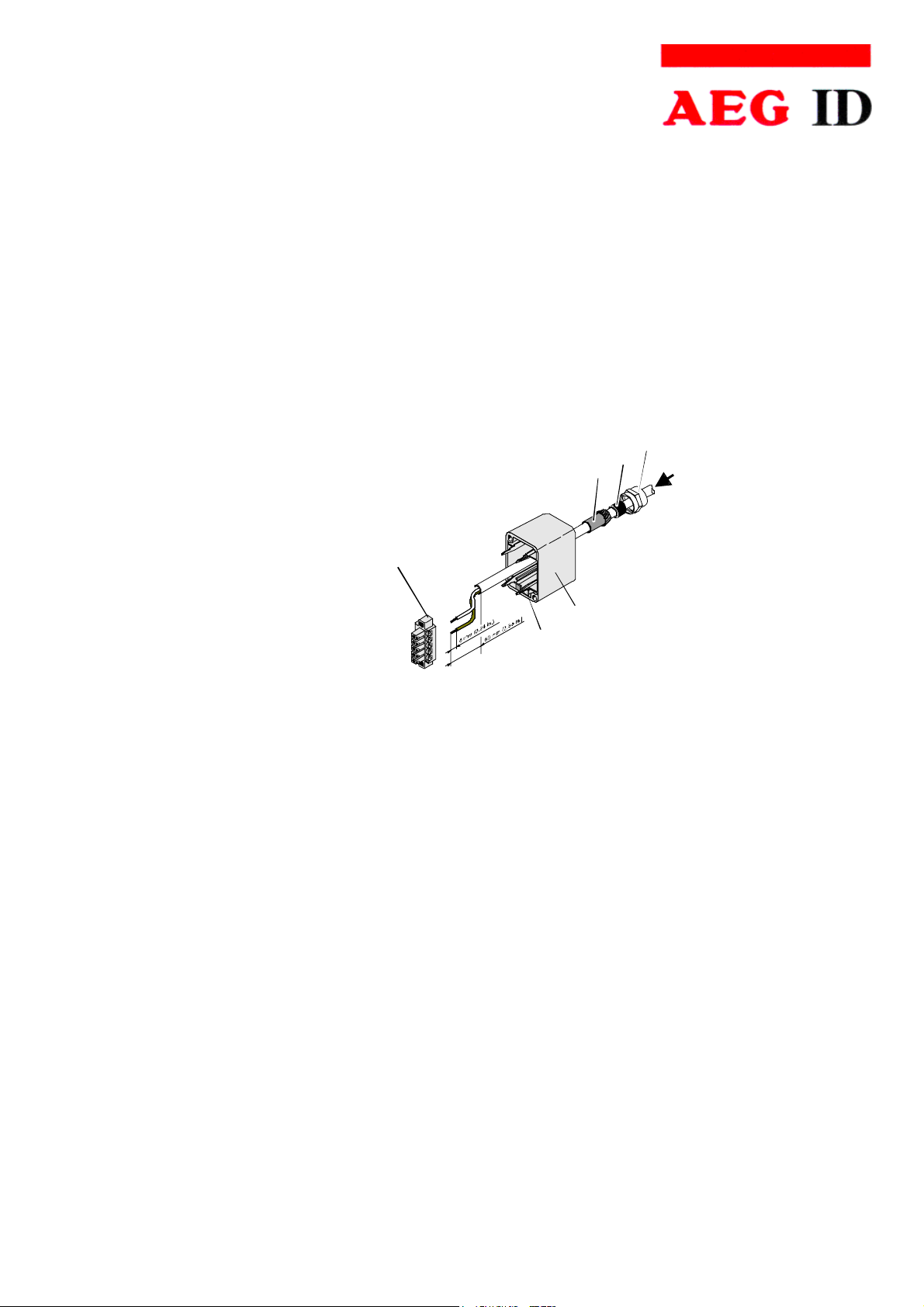

4.3.3 Mounting of the Power Supply Cable

The power supply cable must be mounted in following steps:

• Remove all inner parts from the cable pipe at the SAB Cab (1) ( nut (5), pipe(4) and cable

fastener (3)) (see Figure 4-2)

• Put all the removed parts ( nut (5), pipe (4), cable fastener (3)) and the cable pipe of the

SAB Cab as well (1 to 4) to the cable.

5

4

3

Cable

6

1

7

Figure 4-2: Arranged Parts for Mounting

• Remove the outer isolation of the cable at a length of 6cm .

• Remove the isolation of the wires at a length of 6 [mm] and stick a covering hull to the litz

wire.

• Put the cable to the cable pipe. The length of the cable coming out the SAB Cab must long

enough to do all further installation steps in an easy way.

• Stick the pipe (4) into the cable fastener (3).

• Stick the cable fastener (3) into the cable pipe.

• Connect the power supply cable into the right places of the MINI-COMBICON-Connector

(see Figure 4-2 Part (6)).

• The pin assignment is shown in the figure below.

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

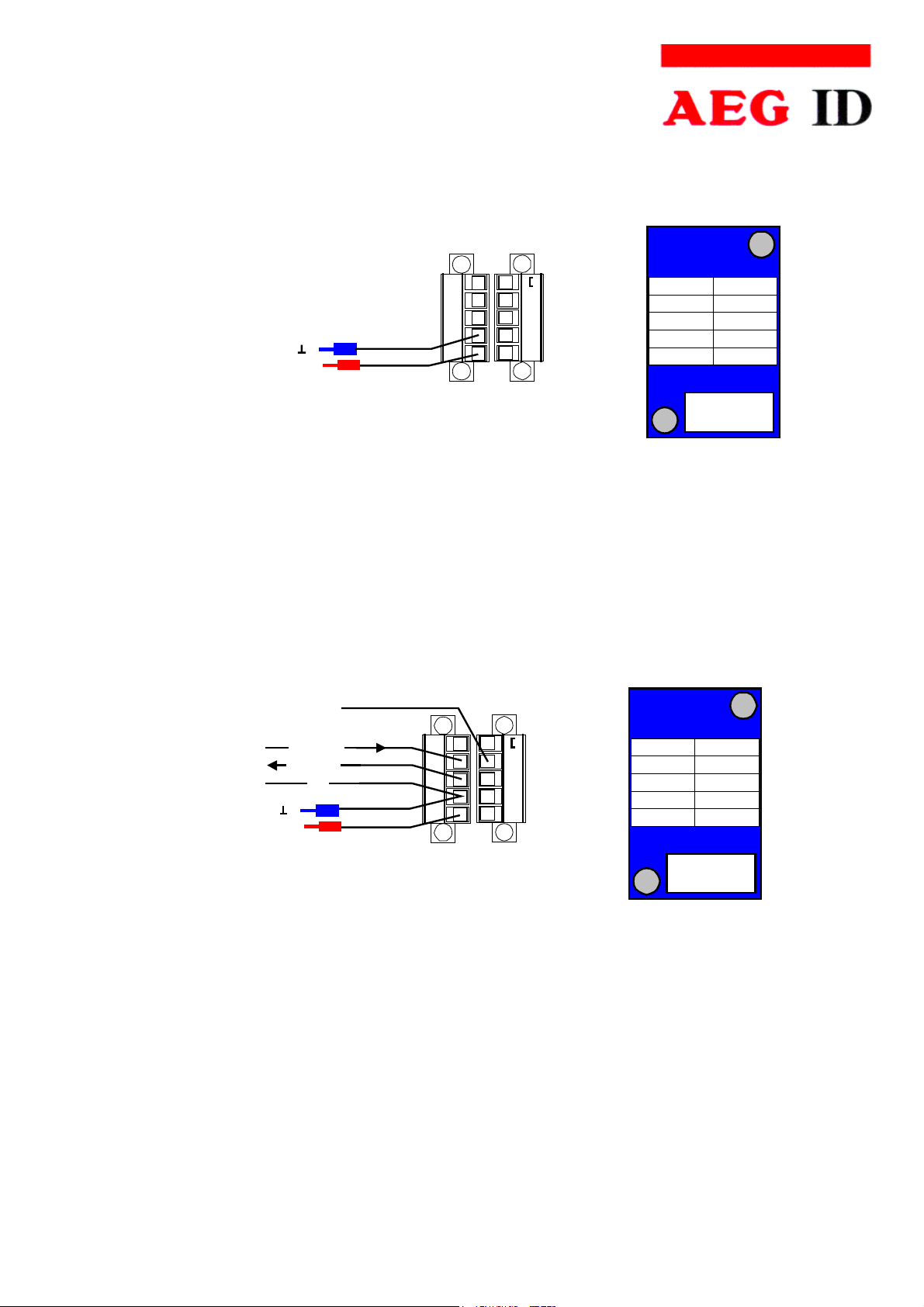

Page 10

Manual

Page 10 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

green

B

A

C

D

V+

DC

E

black

+U

S

-U

-

+

S

L

U

L

NC

RXD

TXD

GND (0V)

+9..30V

shielding

NC

DC

ARE I2

4.3.4 Assembling of the Power Supply and Data Cable (Single Cable Pipe)

The connection of the cable is also done inside of the SAB Cab. Instead of an 2-wire power

supply cable there is now an 5-wire data cable needed. The diameter of the inner wires must

be big enough to keep the voltage drop in the specified range.

The steps to mount the cable is decried in Chapter 4.3.3.

shielding

RxD (reader)

TxD (reader)

V+

DC

GND

green

B

A

D

C

E

black

+U

S

-U

-

+

S

L

U

L

NC

RXD

TXD

GND (0V)

+9..30V

shielding

NC

DC

ARE I2

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 11

Manual

Page 11 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

4.3.5 Final Assembly of the Cable Pipe

• Pull by and by all the cable back, until the isolation of the cables are near to beginning of

the cable pipes.

• Fasten nuts (5) of the cable pipes with the right tool (17mm).

• Do this carefully, to ensure the tightness of the protection class of IP 65..

• Plug the finished assembled MINI-COMBICON-Connector to the SAB Cab. Take care of

the correct coding ((7) in Figure 4-2) of the connectors.

4.3.6 Plug in of the SAB Cab

Attention:

Before plugging the SAB Cab to the connectors of the reader, make sure that the

grounding of the device is well done. Otherwise the electronic may be destroyed by electrostatic discharge (ESD).

1

B

A

Figure 4-3: Plug on the SAB Cab

2

• Put on the sealing 2 to the SAB Cab (A).

• Plug in the SAB Cab to the connector at the bottom of the reader device (B).

• There is only one way to plug in the SAB Cab to the connector rim of the reader.

• Fasten the SAB Cab with the help of the screws.

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 12

Manual

Page 12 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

4.3.7 Using the Service Cable ID 70213

Using the Service Cable, no special assembly work inside of the SAB Cab has be done by the

customer. After making the link to a power supply and plug in the Sub D 9 Connector to the

Com Data Port of an PC, the reader is ready to work.

:

power supply: brown = + 9 ...30 Volt

white = Ground

RS232

( 9 Pins Sub-D female)

1

2

3

4

5

6

7

8

9

RxD (reader)

GND

V+

DC

TxD (reader)

RXD

TXD

GND (0V)

V+ (+24V)

green

B

A

D

C

E

shielding

ARE I2

black

+U

S1

-U

S1

+U

S2

-U

S2

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 13

Manual

Page 13 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

4.3.8 Using the Power Supply and Data Cable ID 70212

Using the Power Supply and Data Cable, no special assembly work inside of the SAB Cab has

be done by the customer. After making the link to a power supply and to the connector block

of Serial Data Port, the reader is ready to work.

power supply: brown = + 9 ...30 Volt

white = Ground

serial Interface: green = RxD ( reader receives data‘s )

RS 232 yellow = TxD ( reader sends data‘s )

grey = ground

4.4 Power Supply

The device is designed for DC Current with an voltage in the range between 9. to .30VDC. The

minimum power of the power supply is 1.2 Watt. There no need to use special cable to supply

the device.

Attention!

The minimum voltage at the at the readers input mustn’t be lower then 9V.

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 14

Manual

Page 14 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

5 Visual Signal Lamps

To show the operational state or results there are 5 LED at the

side of the housing.

BFH

Moderne elektronische

Objekterkennung und Verfolgung

ID

L1: twinkles, if the processor works.

L2: lit, if the latest reading process was successful

L3: lit, if the latest reading process was a NoRead

L4: lit, if the reader receives data’s at the serial data

port ( Rx )

L5: lit, if the reader sends data’s at the serial data port

( Tx )

ARE I2

L 1

L2

L3

L4

L5

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 15

Manual

Page 15 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

6 Settings of the Reader / Most Important Parameters

The default value of the operating mode parameter is 2..

• MD 2 triggered by an software command – default value

• MD 0 continuos mode

6.1 General

The command set described below defines the transfer of data on the serial interface.

The commands consist of a command code and optionally of a parameter value. Commands

are terminated by the control character <CR> (13h). The control character serves as command line terminator.

Command codes and parameters, that means all letters and numerical values, are principally transmitted as a sequence of ASCII characters (the value 255 (decimal) consequently

as 32H, 35H, 35H; the command RST as 52H, 53H, 54H).

The protocol format is as follows

command <SP> parameter <CR>

The space character <SP> separates commands from parameters and the <CR> character

acts as command line terminator.

For commands without parameter values (e.g. GT ) the <SP> character and parameter values are omitted. The command line is as short as this:

command <CR>.

Generally, every input terminated by <CR> is acknowledged by the reader. The following

response protocols are different:

Generally, every input terminated by <CR> is acknowledged by the reader. The following

response protocols are different:

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 16

Manual

Page 16 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

After entering a valid command together with a parameter value, the system answers by

sending the parameter value and <CR>. Example:

After entering an invalid parameter value, the system answers with the corresponding error

code

Parameter settings can be queried by sending the command without adding an parameter

value. Example:

Command: MD <SP> 2 <CR>

Output: 2 <CR>

Command: MD <CR>

Output: 1 <CR>

If a single <CR> is input, the reader answers with a single <CR>. Example:

Command: <CR>

Output: <CR>

Please note: If echo mode is active, a single <CR> forces the reader to output <CR> <CR>

(echo plus output).

6.2 Error Codes

If a command is not entered correctly, the reader sends one of the following error codes:

Wrong command: <NAK> #00 <CR>

Wrong parameter: <NAK> #02 <CR>

6.3 CID – Suppression of ID Codes

With CID=1 only the first of in succession identical transponder numbers is output on the

serial interface. The possibly following identical transponder numbers are suppressed, as

long as no new valid transponder number is received, processed and output. NoReads do

not influence the data filtering.

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 17

Manual

Page 17 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

Input format: CID <SP> parameter <CR>

Parameter:

Value

Function

0 no filter function , (default value)

1 suppression of repeatedly read IDs

Please note: The CID parameter is only active, if the GT-Command is applied or the reader is

in the Continuos Reading Mode. In the MD 2 anyway a <CR> is sent to the master.

6.4 CN – Suppression of No Reads

Through the setting CN=1 all NoRead results are suppressed on the serial interface..

Input format: CN <SP> parameter <CR>

Parameter:

Value

Function

0 issue NoReads on serial interface; (default value)

1 suppress NoReads on interface

Output (example): 0 <CR>

Please note: The CN parameter is only active, if the GT-Command is applied or the reader is in

the Continuos Reading Mode. In the MD 2 any way a <CR> is sent to the master.

6.5 NID- Failure Protection

NID specifies the number of identical transponder numbers, which have to appear for the

result “successful reading“ within a reading cycle. In the setting NID = 1, two successive

readings have to show the same transponder number.

Input format: NID <SP> parameter <CR>

Parameter:

Value

Function

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 18

Manual

Page 18 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

0 one out of one (no effect)

1 two out of two ; (default value)

Output (example): 1 <CR>

Sequence of readings Length of the reading cycle Result of the reading cycle

NoRead 1 reading NoRead

0000125ED1, 0000125ED1 2 readings 0000125ED1

0000125ED1, 0000126ED1 2 readings NoRead

Schedule 6-: example for a reading cycle with NID=1

Example: A, B, C are specific different transponder numbers, N is NoRead:

Sequence of reading cycles Output sequence after

filtering with CN=0 and

CID=1

N, N, ......,N, A, A, A, ....A, N,N, ......... N, N, ......,N, A, N, N,

.......

N. N, N, A, A, A, N, A, A, B, A, C, C, C, ....... N. N, N, A, N, B, A, C,

.....

N, N, B, B, B, B, B, N, N, N, B, B, B, B, N,

N, N, B, N, N, N, N, N,... B

N,...

N, N, N, B, B, B, B, B, N, B, B, B, B, N, N, N,

....

N, N, N, B, N, N, N, N,

....

Table 6-: example for the effect of the CID function

Annotation: The internal reference number is deleted in the following conditions:

• after a cold start

• after a warm start

• after entering the command line CID <SP> 1 <CR>

This causes that the next transponder code is output definitely.

Caution: The filter function CID picks up the results of the complete reading

cycles, while the parameter NID proceeds from the results of single

readings! The filter function CID has effect on the serial interface

only.

Output sequence after

filtering with CN=1 and

CID=1

A

A, B, A, C

B

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 19

Manual

Page 19 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

6.6 EC- Echo

The command EC changes of the echo function setting.

Input format: EC <SP> parameter <CR>

Parameter:

Output (example): 0 <CR>

v Function

0 echo on

1 echo off

Note: The default value of the parameter EC depends on the particular

6.7 BD- Baudrate

The command BD enables the change of the baud rate. The settings are effective after a warm

start using the RST command.

Input format: BD <SP> parameter <CR>

Parameter:

Parameter

0 4800 baud

1 9600 baud

2 19200 baud

Output (example): 2 <CR>

reader.

Function

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 20

Manual

Page 20 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

6.8 TOR – Maximum Reading Time

Timeout for the reader. TOR is used in operation mode 2 as maximum gating time for a

reading process . The length of the maximum gating time results from the equation gating_time = TOR * TB.

The time constant TB (Time Base) has always the default value 100ms.

Input format: TOR <SP> parameter <CR>

Parameter:

Function

0 limits the reading process duration to exactly one reading cycle

1 limits the reading process duration to maximum 1 times TB

2 limits the reading process duration to maximum 2 times TB

...

255 limits the reading process duration to maximum 256 times TB

Output (example): 2 <CR>

6.9 VS- Show Parameter

The command VS lists all current parameter settings.

Input format: VS <CR>

Output (example): EC <SP> 0 <CR>

BD <SP> 2 <CR>

MD <SP> 2 <CR>

6.10 VSAVE – Save Parameter

All operating parameters temporarily stored are saved permanently using VSAVE.

Input format: VSAVE <CR>

Output: ok <CR>

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 21

Manual

Page 21 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

7 Operating Modes of the Reader

There are two operational modes defined:

• Mode 2 The reading process is triggered by an software command coming

from the serial interface.

• Mode 0 Continuos read.

If there is an read/write transponder used, the serial number of

. the transponder is always read.

7.1 Mode 2 – Triggered by an Software Command

In operating mode 2, the exciter is always turned off. Triggered by the software command

(GT; RD ; WD), the exciter is activated. After successful reading or writing of a transponder

number the exciter is turned off automatically.

exciter

processor

interfac e

Figure 7.1.1- Software triggered reading operation

If the first reading cycle yields no result (NoRead), the on-time of the exciter is limited by

the parameter TOR (time out reader): Reading cycles are continuously started until either a

transponder is read successfully or the time span corresponding to the value of the parameter TOR has expired. The reader will not interrupt the last running readout cycle. If no

transponder number has been read, a NoRead is output.

GT

reading cycle

ID

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 22

Manual

Page 22 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

exciter

TOR

processor

interfac e

Figure 7.1.2 : Software triggered reading operation with TOR>0

reading cycle reading cycle reading cycle

GT

reading process

NoRead

Please note: The TOR parameter is only active, if the GT-Command is applied. Within the

time span defined by the value of TOR no NoRead will be output on the interface!

7.1.1 Settings of the Reader / Most Used Parameters

The default operation mode is changed by sending a software command to the reader.

In combination with an R / W transponder, the serial number of the transponder device is read

out only.

MD 2 - triggerd by an software command

most used parameters.

• CID 0 - no suppression of repeatedly read Ids

• CN 0 - no suppression of NoReads

• NID 1 failure protection.; selection guide 2 out 2 transponder codes

• TOR XYZ maximum reading time after the standard read command

is applied to the reader. The chosen value must match the

timing demands of the production process.

TOR 5 Default value

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 23

Manual

Page 23 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

7.1.2 Basic Data Exchange Process

The master has to send an software command to start an read or write process of the reader.

After doing all the necessary work at the readers site, the result of the reading or writing process or an failure code is sent back to the master.

If there is used an read/write transponder, only the serial number of the transponder will be

read if the basic read command „Get Tag“ („GT <CR>“) is applied.

The data exchange of the whole memory can only be done, if the reader is set to the Mode 2 (

„selective Read (RD) “ and „write (WD)“).

7.1.3 ReadOnly-Transponder

• Start the reader with the command GT (plus <CR>)

• Wait for the answer( max. time to wait is given by the value of TOR Parameter)

• Analyse the received answer:10 characters plus <CR>

The reading result may also been judged according the LED’s.

• LED L2 lit, if there was a successful read.

• LED L3 lit, if there was a No Read.

7.1.4 R / W –Transponder

7.1.4.1 Standard Read Process / Serial Number of the Transponder GT

• Start the reader with the command GT (plus <CR>)

• Wait for the answer( max. time to wait is given by the value of TOR Parameter)

• Analyse the received answer: 8 characters plus <CR>

The reading result may also been judged according the LED’s.

• LED L2 lit, if there was a successful read.

• LED L3 lit, if there was a No Read.

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 24

Manual

Page 24 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

7.1.4.2 Selective Read RD

• Start the reader with the command RD plus Parameters ( plus <CR>). see example

below.

- You can read out one block of the transponders memory, if the address of only one

. block is sent to the reader.

– You can read out several blocks, if the first and the last block to read is sent to the

reader. So it’s also possible to read out the whole memory of the transponder.

• Wait for the answer

• Analyse the received answer: 8 characters plus <CR>. Allowed characters 0 to F.

The NoRead Code is set to ( „XXXXXXXX“) ..

The result of the reading process may also be seen at the LED’s.

• LED L2 lit, if there was a successful read.

• LED L3 lit, if there was a No Read.

Example RD <SP> 20 <CR> read block 20

RD <SP> 16 <SP> 33 <CR> read all blocks from 16 to 33

Allowed Values (block numbers of the transponder IC):

ALGO 9 (1kBit Memory) 3 .... 33

Serial Number block 32

ALGO 6 (2kBit Memory) 16 ... 63

Serial Number block 1

7.1.4.3 Writing Process WD

The memory of the transponder is organised in blocks, containing 32 bits. The data’s of every

single block must be changed separately.

• Start the reader with the command WD plus Parameters ( plus <CR>). See also example

below.

The sent parameter consists of the block address and writing data’s (8 ASCII characters).

Note! There must be a blank between the block address and the writing data’s..

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 25

Manual

Page 25 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

• Wait for the answer

• Analyse the received answer: 3 characters plus <CR>.

<ACK> <CR> Writing process was successful

<NAK> <CR> Writing process was not successful.

<NOT> <CR> The response of the transponder was not readable.

The result of the writing process may also seen at the LED’s.

• LED L2 lit, if there was a successful write

• LED L3 lit, if there was no successful write.

Example

WD <SP> 20 <SP> < 0 1 2 7 A C D F > <CR> Write to block 20

Allowed Values (block numbers of the transponder IC):

ALGO 9 (1kBit Memory) 3 .... 31

ALGO 6 (2kBit Memory) 16 ... 63

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 26

Manual

Page 26 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

7.2 Operating Mode 0 - Continuous Reading

When operating continuously the exciter is switched on permanently. The reading cycles

are initiated periodically.

After an accomplished reading cycle the reading information is evaluated. After that data (either transponder number or NoRead code) is output to the serial interface

exciter

processor

interfac e

Figure 7.2: continuous operation

reading cycle

reading cycle reading cycle

ID ID ID

7.2.1 Settings of the Reader / Most Used Parameters

The default operation mode is changed by sending a software command to the reader.

In combination with an R / W transponder, the serial number of the transponder device is read

out only.

MD 0 - continuos read

most used parameters.

• CID 0 - no suppression of repeatedly read Ids

• CN 0 - no suppression of NoReads

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 27

Manual

Page 27 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

• NID 1 failure protection.; selection guide 2 out 2 transponder codes

The result of the reading process may also seen at the LED’s.

• LED L2 lit, if there was a successful read

• LED L3 lit, if there was an NoRead

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 28

Manual

Page 28 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

8 Instructions

8.1 General Instructions

To avoid any reduction of the reading distance of the reader, the housing must not be brought

next to a metal surface. This could lead to a significant change of the properties of the antenna

circuit, which in turn reduces the reading range considerably!

To get reliable readings, the distance between reader and transponder must be within the specified reading volume.

The reading characteristic in front of the reader is not isotropic. It depends also strongly on the

orientation between Reader and Transponder. To get the maximum reading distance, the orientation between reader and transponder must be well suited. The best orientation depends on

the type of antenna inside of the housing ( ferrite – type or plane coil type) and the applied

transponder (disc or glass transponder)

To get a reliable readings or writings, the time of transponder while crossing the sensitive area

of the antenna must be co-ordinated to the data transfer characteristics of transponder

In general the time depends on the speed of the transponder, the size of the transponder and

the way the transponder is mounted on the vehicle and must be verified by field tests.

Environmental electromagnetic noise may also reduce the read and write range considerably.

Arrangement to eliminate such troubles must be done specific to the application by the help of

engineers of the manufacturer.

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 29

Manual

Page 29 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

8.2 Special Instructions for Using a Read / Write System

To transfer the data to the transponder or to control the selective read process, all standard

transponder types uses a 100%-pulse-gap-modulation technique.

The modulation of the magnetic field comming from the transponder and the write pattern done by the base station, shows a lot of similarities. Therefore, read write systems may interfere

each other.

The minimum distance between two antennas mounted next to each other and the size of the

interference must be determined for each application itself.

Below there are listed several parameters that will influence the size of the interaction:

• size of the antennas

• orientation of the antennas (f.e. parallel or rectangular to each other)

• size of transponder; distance between transponder and antenna

• the chronological orders for reading or writing.

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 30

Manual

Page 30 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

9 Hotline

If there are questions or suggestions please be so free an phone:

Fax: ++49 (0)731-933-1855

e-mail: info@aegid.de

http:\ www.aegid.de

10 Reference Documentation

[1]: Manual: ASB 1.0 (AEG ID standard operating system)

11 Revisions

The initial English Edition is based on Revision 1 of the German Manual

Edition Nr - date 19.12.2001 09.09.03

Revision 00 01 02 03

Changes: Rev. 00 Initial Edition.

Rev. 01 Chapter 8.2 added

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 31

Manual

Page 31 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

12 Appendix

12.1 Best Orientation for an F-Type -Reader

F-Typ-Reading Coil-

Best Orientation

1

0

2

0

3

0

8

Rod

Transponder

0

10203

0

25 30

2

0

1

5

1

0

5

Disc

Transponder

Compact Reader ARE I2

Internal Antenna F-Typ

1

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 32

Manual

Page 32 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

12.2 Best Orientation for an L-Type -Reader

L-Typ-Reader Coil-

Best Orientation

1

0

2

0

3

0

8

0

Rod Transponder

10203

0

25 30

DiscTransponder

2

0

1

5

1

0

5

Bauteilname

Compact Reader ARE I2

Internal Antenna L-Typ

1

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Page 33

Manual

Page 33 / 33- Revision 01

ARE I2 / RS 232 – Installation Guide

12.3 Assembling of the SAB Cab

AEG

Identifikationssysteme GmbH

Söflinger Straße 100

D-89077 Ulm

Tel. ++49(0)731-933-1340/1877

Fax ++49(0)731-933-1855

e-mail: info@AEGID.de

Loading...

Loading...