ÖKO-LAVAMAT 88730 update

The environmentally friendly washing machine

User information

Dear Customer,

Please read this instruction book carefully before using the appliance.

Please ensure you fully understand the safety instructions on the first

pages of this instruction book.

Retain the instruction book for future reference, and pass it on to any

future owners.

The warning triangle and / or key words (Warning!, Caution!, Impor-

1

tant!) give information that is important for your safety or the function of the appliance is highlighted. It is imperative that this

information is observed.

0 1. This symbol guides you step by step through the operation of the

appliance.

2. ...

This symbol gives you additional information and practical tips on using

3

the appliance.

Tips and information about the economical and environmentally

2

friendly use of the machine are marked with the clover leaf.

In the event of a malfunction, these operating instructions contain information on how to remedy these faults yourself. See the section

"What to do if ..."

Printed on recycled paper.

Thinking ecologically means acting ecologically ...

2

Contents

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Environmental tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Description of the Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Detergent dispenser drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Programme selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Programme option buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Consumption data and wash times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Run time display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

What does UPDATE mean? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Anti-flood Aqua Control + Aqua Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Before the first wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Preparing a Wash Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sorting and preparing a wash load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Washing Types and Care Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Detergents and Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Which detergent and conditioner? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

How much detergent and conditioner? . . . . . . . . . . . . . . . . . . . . . . . . . 17

Water softening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Running a washing cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Brief instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setting the Washing Programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Changing the spin speed/Selecting Rinse Hold . . . . . . . . . . . . . . . . . . . . . . 20

Setting the delay timer/soaking duration . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Opening and closing the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Load the washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Add detergent / conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Start the washing programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Washing Programme Progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Washing cycle complete/Removing the washing . . . . . . . . . . . . . . . . . . . . 25

3

Programme tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Separate rinse/conditioning/starching . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Separate spin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Maintenance and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Detergent Dispenser Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Washing Machine Drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Main door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cleaning the drain pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

If the washing results are not satisfactory . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Carrying out an emergency emptying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Emergency unlocking of the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Additional Rinse (RINSE+) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Water Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Additional Rinse and Water Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Programme protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Child Safety Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Installation and connection instructions . . . . . . . . . . . . . . . . 41

Installation Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installation of the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Transporting the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Remove transport packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Installation-Site preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Installation on a Suspended Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Levelling the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Water connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Water pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Inlet Hose Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Water Drainage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Pump head of greater than 1m . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Warranty conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Service & Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5

Operating Instructions

Operating Instructions

1 Safety

The safety features of AEG electrical appliances comply with accepted

technical standards and the German Appliance Safety Law. However, we

also consider it our obligation as a manufacturer to inform you about

the following safety information.

Prior to initial start-up

• Observe the "Installation and Connection Instructions" in this in-

struction book.

• If the appliance is delivered in the winter months and temperatures

are below freezing: Store the washing machine at room temperature

for a few hours before putting it into operation.

Intended Use

• The washing machine is only intended for washing normal domestic

washing. If the appliance is used for any other purpose or incorrectly

operated, the manufacturer accepts no liability for any damages

which may result.

• It is dangerous to alter the specifications or attempt to modify this

product in any way.

• Only use detergents which are suitable for automatic washing machines, and follow the recommendations of the detergent manufacturer.

• Garments which have been in contact with flammable solvents

should not be washed. Also bear this in mind when washing precleaned washing.

• Do not use the washing machine for dry-cleaning.

• Dyes and bleaching agents may only be used if specifically permitted

by the manufacturer of these products. We cannot be held liable for

any damages.

• This appliance must be connected to the cold water supply only.

• Damage due to frost is not covered by the guarantee. If the washing

machine is located in a room in which below freezing temperatures

may occur, emergency emptying must be carried out (see "carrying

out an emergency emptying“).

6

Operating Instructions

Child Safety

• Packaging materials (e.g. films, styrofoam) can be dangerous for children. There is a risk of suffocation! Keep all packaging well away from

children.

• This appliance is designed to be operated by adults. Do not allow

children to tamper with the controls or play with the appliance.

• Pets and children have been known to climb into washing machines.

Please check the drum before use.

• When disposing of the appliance, cut off the mains cable, and destroy

the plug. Disable the door lock to prevent young children being

trapped inside.

General Safety

• Repairs to the washing machine must only be carried out by qualified

personnel. Repairs carried out by inexperienced persons may cause

injury or serious malfunctioning. Contact your local AEG Service

Force Centre.

• Never operate the washing machine if the mains cable is damaged or

the control panel, work top or base area are damaged allowing internal components to be accessible.

• Switch off the appliance and isolate from the mains supply before

carrying out any cleaning or maintenance work.

• Do not use the mains cable to pull the plug out of the socket.

• Adapters and extension cables must not be used. There is a danger

of overheating!

• Do not clean the washing machine with a water jet. There is a danger

of electrical shock!

• During high temperature wash programmes, the glass of the door

may become hot. Do not touch!

• Allow the water to cool down before cleaning the drain pump, carrying out emergency emptying or opening the door in an emergency.

• Small animals/pets can chew on power cables and water hoses. This

can cause the danger of an electrical shock to the animal and water

damage to the appliance and property. Keep small animals away from

the appliance.

7

Operating Instructions

2 Disposal

Packaging

Dispose of the packaging material correctly. All packaging materials

used are environmentally friendly and can be disposed of without any

danger to the environment.

• Plastic parts can be recycled and are identified as follows:

>PE<

>PS< for polystyrene, e.g. padding (always CFC-free)

>POM< for polyoxymethylene, e.g. plastic clips

• Cardboard packaging is manufactured from recycled paper and

should be deposited in the waste paper collection for recycling.

When disposing of the washing machine!

Cut off the mains cable and destroy the plug. Disable the door catch to

prevent young children becoming trapped inside. Use an authorised

disposal site.

for polyethylene, e.g. the outer covering and the bags in

the interior.

2 Environmental tips

To save water and energy, and to help protect the environment, we recommend that you follow these tips.

• Do not use a pre-wash for normally soiled washing.

• It is more economical to wash full loads.

• When washing small loads, reduce the detergent by half to two

thirds.

• Pre-treat stains, and then wash at a lower temperature.

• Use the energy-saving programme when washing light to normally

soiled garments.

• In hard water areas, the use of a water softening agent can reduce

the amount of detergent necessary. See manufacturers recommendations.

8

Description of the Appliance

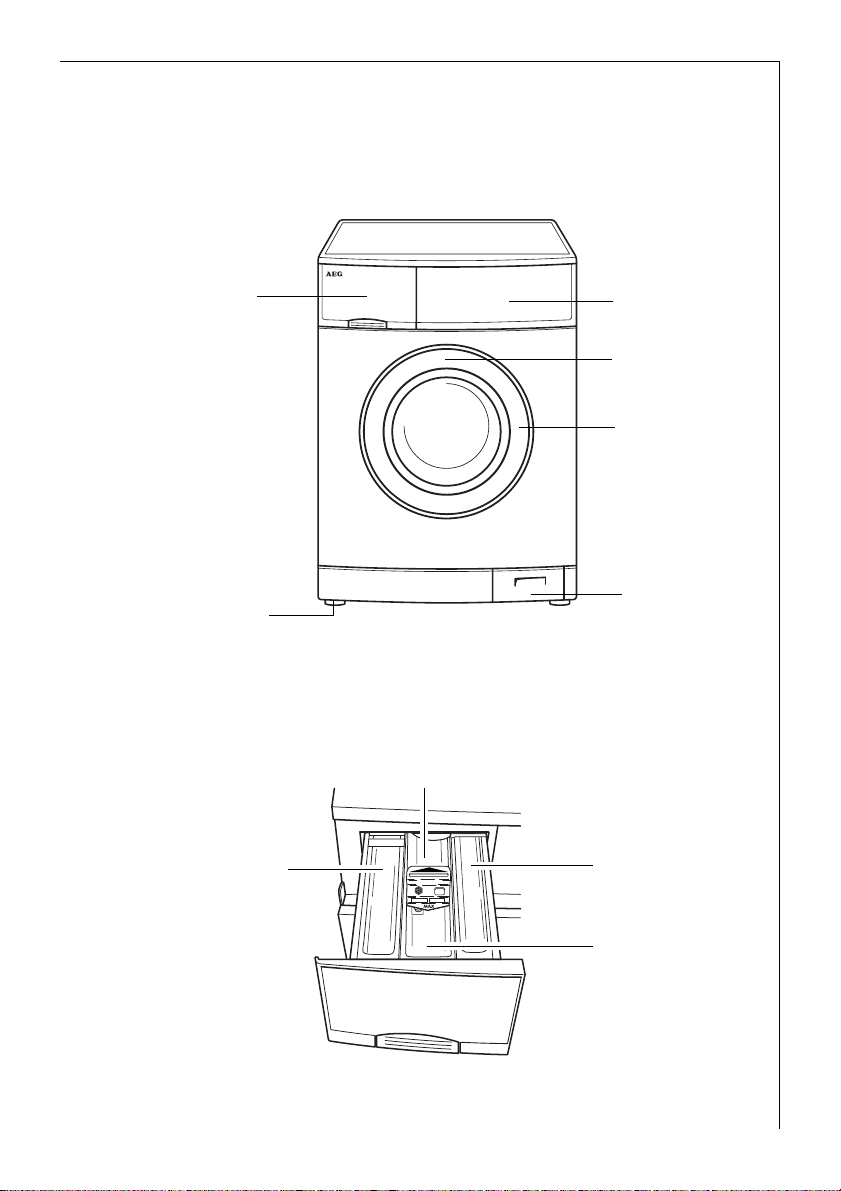

Front view

Detergent

dispenser

drawer

Screw feet

(height-adjustable);

rear left:

Automatic

adjustment foot.

Operating Instructions

Control panel

Rating plate

(behind door)

Main door

Flap in front of

drain pump

Detergent dispenser drawer

Main wash detergent

in powder form and

water softening

agent if required.

Stain removers

Pre-wash detergent/

soaking agent or

water softening

agent if used.

Liquid conditioners

(fabric softener,

starch)

9

Operating Instructions

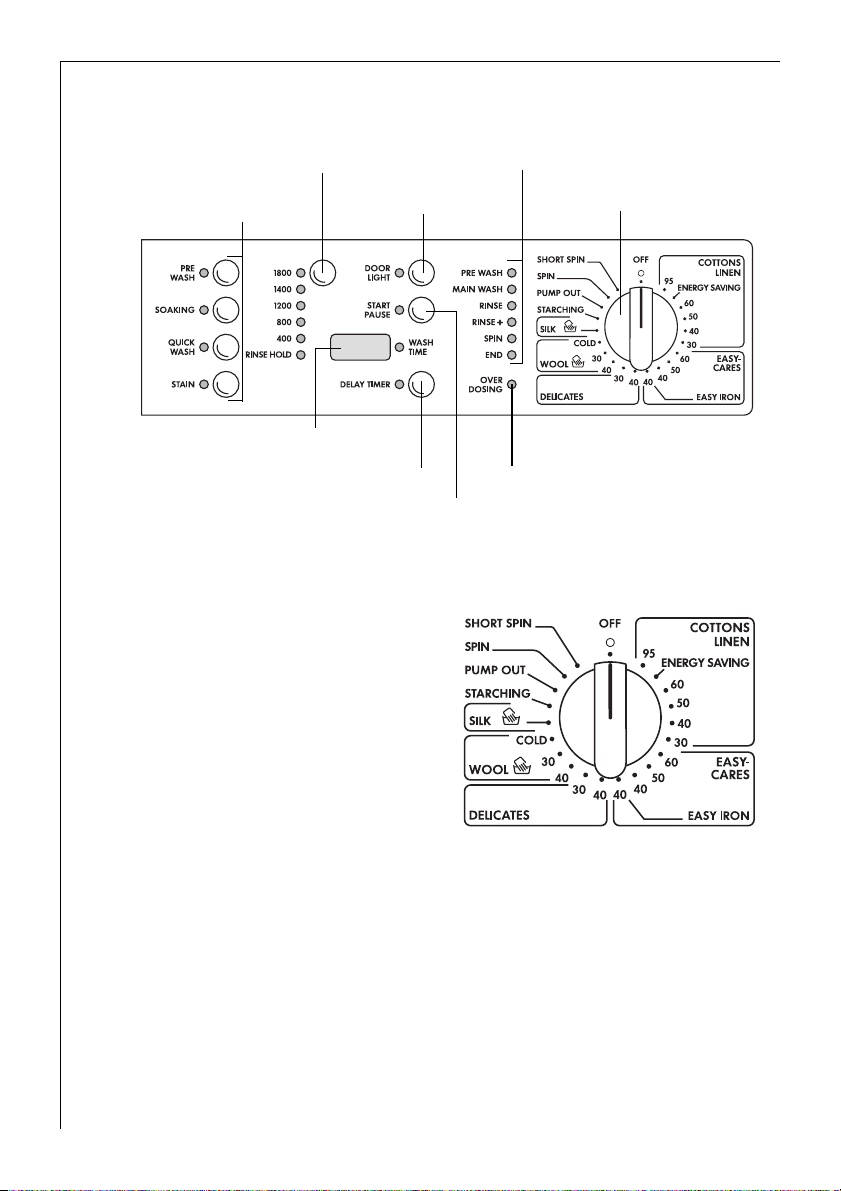

Control panel

Spin speed / RINSE HOLD

button

Programme option

buttons

DOOR/LIGHT button

Multi-display

DELAY TIMER button

START/PAUSE button

Programme selector

The programme selector defines

the nature of the washing cycle

(e.g. water level, drum movement, number of rinses, spin

speed) to suit the type of washing, as well as the wash temperature.

Programme progress

display

Programme selector

OVER DOSING indicator

10

OFF

Switches the washing machine

off, the machine is switched on

at all other positions.

COTTONS/ LINEN

Main washing cycle Cottons / Linen (Cottons / Linen) at 30 °C to 95 °C.

ENERGY SAVING position: Energy-saving programme at approximately

2

67 °C for lightly to normally soiled cottons, extended washing time

(cannot be combined with QUICK WASH and STAIN)

EASY-CARES

Main washing cycle for easy-care textiles (mixed fabrics) at 40 °C to

60 °C.

Operating Instructions

EASY IRON position: Main washing cycle at 40 °C for easy-care fabrics

which, with the aid of this programme, only require a gentle iron, if any

ironing at all.

DELICATES

Main washing cycle for delicates at 30 °C or 40 °C.

WOOLLENS / P (hand wash)

Washing cycle (cold up to 40 °C) for machine-washable woollens and

for hand-washable woollen fabrics with the care symbol ï (hand

wash).

SILK / P (hand wash)

Main washing cycle 30 °C for hand-washable and machine-washable

silk.

As silk is a very sensitive fabric, we recommend that you only wash one

3

item of clothing at a time, and that such items never be washed with

other rough fabrics. A very gentle wash is possible using the QUICK

WASH button for extremely sensitive silk fabrics.

STARCHING

Separate starching, separate softening, separate conditioning of wet

washing (one rinse cycle, liquid conditioner is washed in from the æ

compartment, and a spin - max. spin 1800 rpm).

If a separate rinse cycle is required, this can be carried out by omitting

the conditioner from the æ compartment.

PUMP OUT

Pumping out the water after a rinse hold (without spinning).

Rinse hold means the washing remains in the last rinsing water and is

3

not spun.

SPIN

Pumping out the water after a rinse hold and spinning, or separate

spinning of hand-washed cottons/linen (max. spin 1200 rpm).

SHORT SPIN

Pumping out the water at the end of a rinse hold and short spin, or

separate short spin for delicate fabrics (easy-care washing, delicates,

wool).

11

Operating Instructions

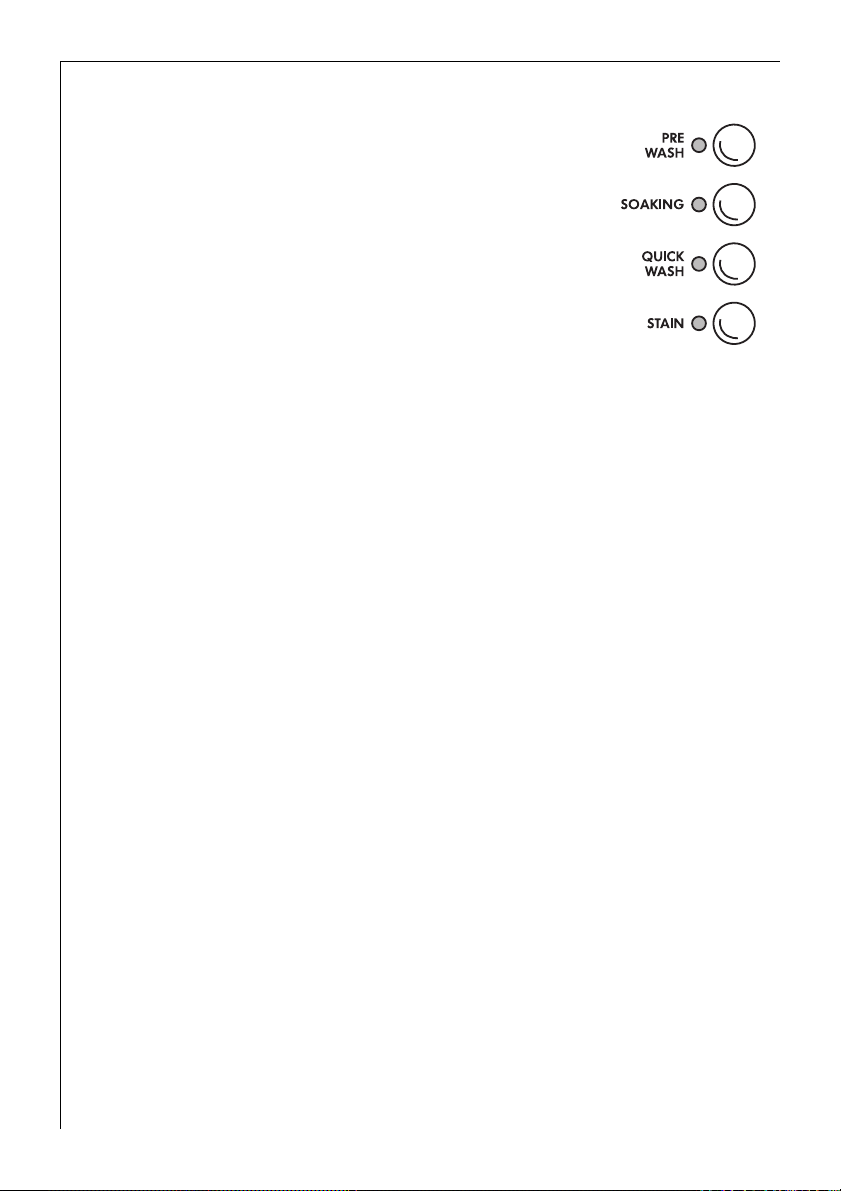

Programme option buttons

The programme option buttons are used to adapt

the washing programme to suit the degree of

soiling of the washing. Programme options are not

required for normally soiled washing.

The different functions can be combined together

depending on the programme.

PRE WASH

You can select the pre-wash before the main wash

on the following programmes: COTTONS / LINEN,

EASY CARE and DELICATES. There is a short spin between the pre-wash and the COTTONS / LINEN

main wash.

The EASY CARE and DELICATES main wash follow

the pre-wash without a spin.

SOAKING

Approx. 1 hour at 30 °C or 40 °C depending upon the wash programme

set. Can be extended to a maximum of 19 hours with the DELAY TIMER

button. The main washing programme then follows automatically.

QUICK WASH

Short main washing cycle for lightly soiled washing.

12

STAINS

For treating heavily soiled washing or stained washing. (In-wash stain

treatment is washed in from the æ compartment at the optimal part in

the programme cycle.)

When the WOOLLENS /P (hand washing) setting is chosen, the pro-

3

gramme options cannot be selected (any buttons pressed have no effect).

Operating Instructions

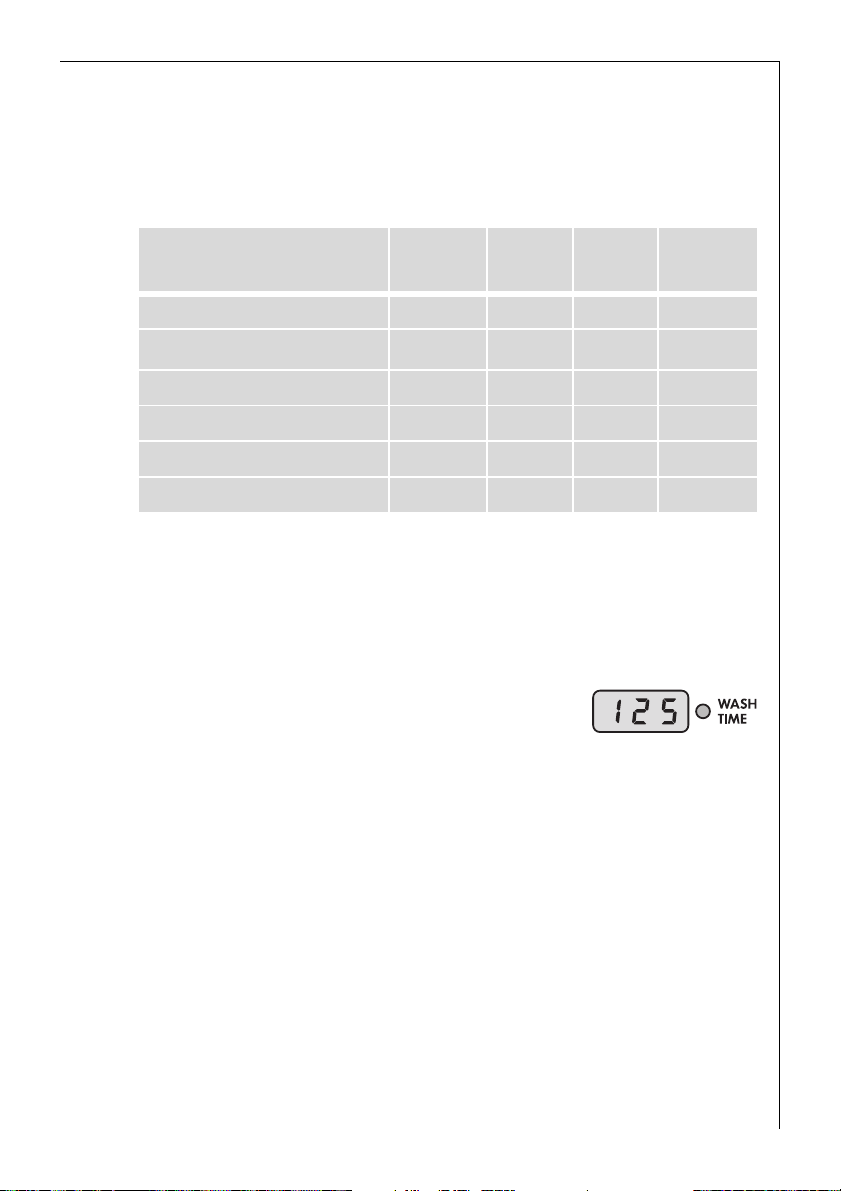

Consumption data and wash times

The values given in the following table for selected programmes were

calculated under standard conditions. They provide a useful guide for

operation in the home.

Programme selector/

temperature

COTTONS/LINEN 95 5 39 1.65 137

COTTONS-/LINEN 60

COTTONS-/LINEN 40 5 44 0.55 122

EASY-CARES 40 2.5 45 0.42 102

DELICATES 30 2.5 49 0.40 68

WOOLLENS/ P (hand wash) 30 2 42 0.20 37

1) Note: The selected programme is tested in accordance with EN 60 456. The consumption values, however, can deviate depending on the following: water pressure, water hardness, water inlet temperature, room temperature, washing type

and washing quantity, the detergent used, and the selected programme options.

1)

Load in kg

5 39 0.89 125

Water

in litres

Energy

in kWh

Run time display

The multi-display indicates the estimated

3

duration, in minutes, of the programme.

These timings are estimates and vary.

During the programme countdown the remaining time can be recalculated due to any of the following: incoming water temperature, type and quantity of laundry, out of balance spin

detection and foam detection.

Time in

minutes

13

Operating Instructions

What does UPDATE mean?

The control system of your machine is fully electronic. The software

which determines this control system can be reprogrammed. If a further improvement to washing technology is introduced by AEG then

your machine can be updated.

The cost of the update will be advised at the time of the request. For

further information regarding this please contact the AEG Customer

Care Department.

Anti-flood Aqua Control + Aqua Alarm

The inlet hose has a mechanical built in safety device. In the event of

the filling hose failing, the safety device will automatically shut off the

water supply.

In the event of a leak within the machine the float switch, which is

mounted in the base of the appliance, will operate the drain pump and

an audible signal will be heard

The system will operate as long as the appliance is connected to the

mains electricity supply, even if the programme selector is in the off

position.

14

Operating Instructions

Before the first wash

0 Run a washing cycle without washing (COTTONS 95, with half the

amount of detergent).

This removes any residues from the drum which may have been left

during manufacturing.

Preparing a Wash Load

Sorting and preparing a wash load

• Sort washing according to the care symbol and type (see "Washing

types and care symbols").

• Empty all pockets.

• Remove metal objects (paper clips, safety pins etc.).

• In order to prevent bunching up of washing and damage to washing,

close zippers, button up duvet covers and pillow cases, and tie up

loose straps such as from aprons.

• Turn articles with double layered textiles inside out (sleeping bags,

anoraks etc.).

• Coloured, knitted fabrics, as well as wool and fabrics with appliqués

should be turned inside out.

• Place small and delicate items (e.g. socks, tights and stockings, bras

etc.) in a washing net, or pillow case.

• Handle curtains with care. Metal rollers or burred, plastic rollers must

be removed or tied into a net or bag. We cannot accept liability for

damage.

• Do not wash coloured and white washing together. This could discolour white washing or turn it grey.

• New, coloured washing often contains excessive dye. Wash these separately the first time.

• Mix small and large items of washing. This improves washing efficiency and the washing is more evenly distributed during the spinning cycle.

• Shake out washing before placing into the washing machine.

• Do not place folded washing into the drum.

• Observe tips such as "wash separately“ and "wash separately several

times".

15

Operating Instructions

Washing Types and Care Symbols

The care symbols help you choose the correct washing programme.

Washing should be sorted according to type and care symbol. The temperatures indicated in the care symbols are maximum values.

Cottons ç

Fabrics made from cotton and linen with this care symbol will withstand maximum wash actions and high temperatures. The programme

COTTONS/LINEN is appropriate for this type of washing.

Linens èë

Fabrics made from cottons and linens with this care symbol will withstand maximum wash actions. The programme COTTONS/LINEN is appropriate for this type of washing.

Easy-care washing êí

Fabrics such as treated cotton, cotton mixed fabrics, viscose and synthetics with this care symbol require chemically more gentle treatment.

The programme EASY CARES/EASY IRON is suitable for this type of

washing.

Delicates ì

Fabrics such as those with layered fibres, micro fibres, viscose, as well as

synthetics and Curtains with this care symbol require particularly careful handling. The DELICATES programme is suitable for this type of

washing.

16

Wool, silk and particularly sensitive washing 9ìï

Fabrics such as wool, wool mixtures and silk which carry this care symbol are particularly sensitive to mechanical stress. The programmes

WOOLLENS /P (hand wash) and SILK/P (hand wash) are suitable for

this type of fabric.

Important! Fabrics with this care symbol ñ (do not wash) must not

be washed in the washing machines.

Operating Instructions

Detergents and Conditioners

Which detergent and conditioner?

Use only detergents and conditioners which are suitable for use in automatic washing machines. Always follow the manufacturer's instructions.

How much detergent and conditioner?

The required quantity depends upon:

• the extent of soiling of the washing

• the hardness class of the mains water

• the amount of washing

Should the detergent manufacturer not specify the dosage quantity for

2

less than full loads, reduce the detergent accordingly: For a half load

reduce the quantity by 1/3. For a small load or an EASY IRON programme reduce the quantity by 1/2.

Observe the instructions for use and dosing provided by the detergent

and conditioner manufacturer.

Water softening

For medium to high water hardness (hardness class II upwards) a water

softening agent can be used. Refer to the manufacturer's instructions.

Then always add the appropriate amount of detergent (underdosing)

for hardness class I (soft). Your local Water Authority can advise you on

the hardness of the water in your area.

Water hardness details

Hardness class

I - soft 0 - 7 to 125

II - medium hard 7 - 14 125 - 250

III - hard 14 - 21 250 - 375

IV - very hard greater than 21 greater than 375

Water hardness in °dH

(German hardness scale)

Water hardness in ppm

(Parts Per Million)

17

Operating Instructions

Running a washing cycle

Brief instructions

A washing cycle consists of the following steps:

0 1. Set the correct washing programme:

– Select the programme and temperature with the programme selector.

– Select any programme options if required.

2. If necessary, change the spin speed/select RINSE HOLD.

3. Set the DELAY TIMER if required.

4. Open the door and load the washing.

5. Close the door.

6. Add the detergent/conditioner.

7. Start the washing programme with the START/PAUSE button.

When the washing programme has ended:

Important! If the washing cycle ended with a rinse hold, carry out

PUMP OUT, SPIN, or SHORT SPIN before opening the door.

8. Open the door and remove the washing.

9. Switch off the washing machine: Set the programmes selector to OFF.

18

Operating Instructions

Setting the Washing Programme

See "Programme tables" for a suitable programme, correct temperature

3

and possible programme options to suit the type of washing.

0 1. Set the programme selector to

the desired washing programme

with the desired temperature.

The expected duration of the

programme selected is displayed

in the multi display in minutes.

2. If required, select programme option(s):

The indicator of the programme selected lights up.

– To change the selection press another button.

– To cancel a selection, press the button again.

19

Operating Instructions

Changing the spin speed/Selecting Rinse Hold

0 If necessary, change the spin speed for the final

spin/select RINSE HOLD:

Press the Spin speed/RINSE HOLD button

repeatedly until the indicator of the required

spin speed or of RINSE HOLD illuminates.

If RINSE HOLD is selected, the washing remains in

the final rinse water. It is not spun.

If you do not change the spin speed, the final spin

3

is automatically adjusted to suit the washing programme.

– COTTONS/LINEN 1800 revolutions per minute

– EASY CARES /EASY IRON 1200 revolutions per minute

– DELICATES 1200 revolutions per minute

– WOOLLENS/P (hand wash) 1200 revolutions per minute

– SILK /P (hand wash) 1200 revolutions per minute

The speed of the intermediate spin is dependent on the selected

programme and cannot be changed.

Setting the delay timer/soaking duration

Delay timer

The DELAY TIMER button allows the start of a washing programme to

be delayed by 1 hour up to a maximum of 19 hours.

0 To do this, press the DELAY TIMER button

repeatedly until the desired start delay

is shown in the multi-display, e.g. 12h for

a 12 hour delay.

If 19h is displayed and you press again, the duration of the washing programme set appears

(displayed in minutes, e.g. 125). In this state

the start delay timer is not set.

Soaking duration

When the SOAKING button is pressed, you can extend the soaking period from 1 hour to a maximum of 19 hours with the DELAY TIMER button.

Without a time delay, the soaking period is approximately 1 hour.

3

20

Operating Instructions

Opening and closing the door

0 Open: Press the DOOR/LIGHT button. The door springs

open.

0 Close: Press the door firmly closed.

When the unit is switched on, the DOOR/LIGHT display shows whether

the door can be opened:

– green: The door can be opened (not when programming is acti-

vated, see the section "Program

– off: Door cannot be opened

– red: Door is open

The washing drum is illuminated when the door is open. The light goes

3

out automatically after approx. 3 minutes.

me protection“ for details)

Load the washing

See the "Programme tables" for the maximum load quantities.

3

For information on the correct preparation of the washing, see "Sorting

and preparing washing“.

0 1. Sort and prepare the washing according to type

2. Open the door: Press the DOOR/LIGHT button. Door springs open.

3. Load the washing.

Important: Do not trap washing when closing the door. The fabrics and

the machine could be damaged!

4. Close the door firmly.

21

Operating Instructions

Add detergent / conditioner

For instructions concerning detergent

3

and conditioners, see "Detergents and

conditioners".

0 1. Open the detergent dispenser drawer.

press in the flap on the drawer so as to

be able to grasp the handle(1), and pull

out the drawer (2).

2. Adding detergent / conditioner

Compartment for in-wash

stain treatment

Compartment for powder

main detergent

(If you use water softening agent and

require the right compartment for the

pre-wash/soaking detergent , add the

water softening agent to the main detergent in the left compartment.)

Compartment for liquid conditioner

(Softener, finisher, starch)

Important! Do not fill above the MAX mark. When using

thick concentrated fabric conditioners and starches we

recommend you dilute the concentrate with water to ensure

trouble-free dispensing. If using starch powder dissolve

according to the manufacturer´s instructions.

Note: It is normal for a small amount of water to be left in

the compartment for liquid conditioner; this will not affect

the wash results.

Compartment for pre-wash/soaking detergent

(Only for program

or for water softening agent

3. Push the detergent dispenser drawer fully in.

If using liquid detergent / tablets

3

Add liquid detergent / tablets in the quantity recommended by the

washing detergent manufacturer. Add liquid detergent with dosage

containers provided by the detergent manufacturer.

22

me options PRE WASH/SOAKING)

Operating Instructions

Start the washing programme

0 1. Check that the water tap is open.

2. Start the washing programme: Press the START/PAUSE

button.

The washing programme is started, or starts at the end

of the time delay set.

If the display DOOR/LIGHT flashes red when the START/PAUSE button is

3

pressed, the door is not closed correctly. Press the door firmly and press

the START/PAUSE button again.

If the time preselection is set:

The start time delay set on the time delay counts down; the remaining

time until the programme starts is displayed on the multi-display (in

hours remaining). During this time you can add washing and change or

stop the delay timer.

• Load the washing: Press the START/PAUSE button. The door can be

opened. Then close the door and press the START/PAUSE button

again.

• Changing or stopping delay timer: Press the DELAY TIMER button re-

peatedly until the desired time is displayed; when the programme duration is displayed (shown in minutes e.g. 125), the wash programme

starts without delay.

23

Operating Instructions

Washing Programme Progress

Programme progress display

Prior to the start, the programme steps chosen are

displayed by the programme progress display. During

the washing programme the current programme step is

displayed.

Multi-display

The expected time remaining (in minutes) to

the end of the programme is shown in the

multi-display.

The multi-display indicates the estimated duration, in minutes, of the

3

programme. These timings are estimates and can be varied and influenced by incoming water temperature, type and quantity of laundry,

out of balance spin detection and foam detection. During the programme countdown the remaining time can be recalculated due to any

of the above factors.

Changing the Spin Speed

During the washing programme, the spin speed can still be changed or

the RINSE HOLD can be set.

Other settings cannot be changed.

Stopping the programme

0 Turn the programme selector to OFF in order to stop the washing pro-

gramme prematurely.

The washing programme can be interrupted at any time with the

3

START/PAUSE button and can be continued again by pressing this button again.

24

Operating Instructions

Washing cycle complete/Removing the washing

Once the washing programme has come to an end, END illuminates on

the programme progress display.

• If the EASY IRON programme was selected, an anti-creasing phase of

approximately 30 minutes follows the programme end. Here, the

multi-display still shows a remaining time and the END indicator

lights up. During the anti-creasing phase, you can open the door at

any time and remove the washing.

• If RINSE HOLD was selected, the display beside the START/PAUSE

button flashes.

0 1. After a rinse hold, the water must first be pumped out:

– Either press the START/PAUSE button (the water is pumped out and

the washing is spun according to the completed programme; with the

spin speed/RINSE HOLD button, it is possible to change the spin speed

during spinning),

or

– turn the programme selector to PUMP OUT and press the START/

PAUSE button (the water is pumped out without spinning),

or

– turn the programme selector to SPIN or GENTLE SPIN and press the

START/ PAUSE button (the water is pumped out and the washing is

spun or gently spun).

At the end of this programme step, the END TIME indicator will

illuminate.

2. Open the door.

As soon as the indicator next to the DOOR/LIGHT button lights up

green, the door can be opened (not if Programme protection is activated, for details see "Programme protection“).

3. Remove the washing.

4. Turn the programme selector to OFF.

5. After washing, pull out the washing detergent drawer slightly so that it

can dry out. Leave the door ajar so that air can circulate in the drum.

If the OVERDOSING indicator illuminates, then too much

3

detergent was used in the washing programme just

completed. Observe the dosing recommendations of the

detergent manufacturer as well as the load quantity for the next wash.

Important: If the washing machine is not to be used for a long period:

Close the water tap and disconnect the washing machine from the

electricity mains. (Anti-flood: The Aqua Control with Aqua Alarm does

not function if the power supply is interrupted).

25

Operating Instructions

Programme tables

Washing

Not all possible settings are listed below, only those which are useful

and meaningful in everyday use.

Washing type,

care symbol

Cottons

ç

Energy-saving

programme:

Cottons ç

Cottons

èë

Easy cares

êí

Delicates

ì

Max. Load

(dry weight)

5kg

5kg

5kg

2.5kg

1kg

2.5kg

(or 15-20m

curtains)

Programme

1)

2

selector

Temperature

COTTONS/LINEN

95

COTTONS/LINEN

ENERGY SAVING

COTTONS/LINEN

30 to 60

EASY CARES

40 to 60

EASY IRON

40

DELICATES

30, 40

Possible

programme

options

PREWASH

SOAKING

QUICK WASH

STAIN

PRE WASH

SOAKING

PRE WASH

SOAKING

QUICK WASH

STAIN

PRE WASH

SOAKING

2)

QUICK WASH

STAIN

PRE WASH

SOAKING

QUICK WASH

STAIN

26

Woollens/handwash

9ìï

Silk/handwash

ï

1) A 10-litre bucket holds approximately 2.5kg of dry washing (cottons).

2) Creases in the washing are largely prevented only by maintaining the load

quantity of 1kg.

5 to 7 easy-care men's shirts are equivalent to approximately 1kg of dry washing.

2kg

1 kg

WOOLLENS/P

COLD up to 40

SILK/P

30

QUICK WASH

This machine is capable of washing 5.5 kg, however, to achieve optimum wash results it is recommended that the wash loads quoted in this

instruction book are adhered to.

Separate rinse/conditioning/starching

Operating Instructions

Type of washing

Cottons/ Linen 5kg STARCHING

Max. Load

(dry weight)

Separate spin

Type of washing

Cottons/ Linen 5kg SPIN

Easy-cares 2.5kg

Delicates 2.5kg

Woollens/hand wash 2kg

Silk/handwash 1 kg

Max. Load

(dry weight)

Programme selector

Programme selector

SHORT SPIN

27

Operating Instructions

Maintenance and Cleaning

Control panel

Important! Do not use household furniture polish or abrasive cleaners

to clean panel and operating parts.

0 Wipe over the operating panels with a damp cloth. Use warm water.

Detergent Dispenser Drawer

The detergent dispenser drawer should be cleaned from time to time.

0 1. Pull the detergent dispenser drawer out as far as it will go.

2. Remove the detergent dispenser drawer by pulling sharply.

3. Take the conditioner insert out of the

middle compartment.

4. Clean the conditioner insert under

running water.

5. Clean the separate compartments

with warm water. It is best to use

a flat brush.

6. Push on the conditioner insert

as far as it will go so that it is

securely in place.

28

Operating Instructions

7. Use a brush to clean the entire

compartment area of the washing

machine, particularly also the

nozzles on the top side of the

compartment.

8. Set the detergent dispensing

drawer into the guide tracks and

push it in.

Washing Machine Drum

The washing machine drum is made from rust-free stainless steel. Any

objects left in the laundry which are likely to rust can stain the drum.

Important! Do not clean the stainless steel drum with descaling agents

containing acids, scouring agents containing chlorine or iron, or steel

wool. Your local AEG Service Force Centre has suitable agents available.

0 Remove any rust stains on the drum using a stainless steel cleaning

agent.

Maintenance Wash

With the use of low temperature washes it is possible to get a build up

3

of residues inside the drum.

We recommend that a maintenance wash be performed on a regular

basis.

To run a maintenance wash:

The drum should be empty of laundry.

0 1. Select the hottest cotton wash programme.

2. Use a normal measure of detergent, must be a powder.

Main door

0 Regularly check to see if there are deposits or foreign objects in the

rubber seal behind the door, and remove them.

29

Operating Instructions

Cleaning the drain pump

Paper clips, nails and so on can sometimes get into the washing machine with the washing and remain in the drain pump casing. Fluff and

strands of fabric can gather on these items and block the drain pump.

Therefore the drain pump should be cleaned at least once a year.

Warning! Switch off the washing machine and pull out the mains plug

1

before cleaning the drain pump.

0 1. First carry out emergency emptying (see section "Carrying out emer-

gency emptying“).

2. Place a towel on the floor in front of the cover of the drain pump.

Surplus water may flow out.

3. Unscrew the drain pump cover anticlockwise and pull it out.

4. Remove any foreign bodies from the

pump housing.

5. Replace the cover. Insert the webs on

the cover laterally into the guide slots

and screw on the cover securely clockwise.

6. Close the emergency emptying hose and

place it in the holder.

7. Close the flap.

30

Operating Instructions

What to do if...

Trouble Shooting

If the appliance is not working correctly, please carry out the following

checks before contacting your local Service Force Centre. Important: If

you call out an engineer to a fault listed below or to repair a fault

caused by incorrect use or installation, a charge will be made even if

the appliance is in guarantee.

• If the fault code C1 oder C2 is shown in the

multi-display, you may be able to remedy

the fault yourself (see the Fault table below).

After clearing the fault, press the START/PAUSE button. If the fault

code is shown again, contact your local Service Force Centre.

• For all other faults displayed in the multi-display, please contact your

local AEG Service Force Centre, stating the fault code.

Problem Possible Cause Remedy

The washing machine

does not work.

The door cannot be

closed.

Water is not running.

Error code

pears.

(1 ap-

The mains plug is not

plugged in.

The house fuse has blown. Replace the fuse.

The door is not correctly

closed.

START/ PAUSE button not

pressed long enough.

The child safety feature is set

Water tap closed. Open the water tap.

Filter in screw connection of

the inlet hose is blocked.

Water tap is blocked with

limescale or is faulty.

Plug in the mains plug.

Close the door; The lock must

engage audibly.

Keep the START/PAUSE button pressed until the programme begins.

Cancel the child safety feature (see Section "Child

Safety Feature“).

Close the water tap. Unscrew

the hose from the tap, remove the filter and clean under running water

Check water tap and have it

repaired if necessary.

31

Operating Instructions

Problem Possible Cause Remedy

The washing machine

vibrates during operation or is unstable.

Excessive foaming during the main wash.

Water runs out from

under the washing machine.

The transport packaging has

not been removed.

The machine is not level.

There is very little washing in

the drum (e.g. only one

dressing gown).

The water could not be completely pumped out before

spinning because the drainage hose is kinked or

the drain pump is blocked.

Probably too much detergent

was used.

The screw connection on the

inlet hose is leaking.

The drainage hose is leaking.

The drain pump cover is not

correctly closed.

Washing is caught in the

door.

Remove transport packaging

according to the installation

and connection instructions.

Adjust the feet according to

the installation and connection instructions.

This does not impair the

function.

Check the drain hose and remove any kink if necessary,

or clean the drain pump and,

if required, remove foreign

bodies from the pump housing.

Measure the detergent exactly in accordance with the

manufacturer's information.

Tighten the inlet hose screw

connection.

Check the drainage hose and

replace it if necessary.

Close cover correctly.

Stop the programme, remove

the washing caught in the

door. Restart the programme.

32

The emergency emptying

hose is not correctly closed

or is leaking.

Close the emergency emptying hose correctly (see the

section "Carry out emergency emptying“). Call your

local Service Force Centre if

the emergency emptying

hose leaks.

Operating Instructions

Problem Possible Cause Remedy

The drain pump for the

washing machine runs

constantly - even when

the appliance is

switched off.

Fabric softener was not

rinsed in, compartment æ for conditioners is filled with water.

Washing heavily

creased

The washing is not sufficiently spun. Water is

left in the drum.

Error code

(2 appears.

Turn off the tap, then reThe Aqua Control anti-flood

system has been activated.

The conditioner insert in the

compartment for the conditioner is not correctly attached or is blocked.

Probably too much washing

put in the drum.

Drain hose is kinked. Remove the kink.

Maximum pump head (discharge height 1m from the

unit's floor) is exceeded.

Drain pump blocked.

move the plug from the

mains and inform Customer

Service.

Clean the detergent dis-

penser drawer and attach the

conditioner insert securely.

Pay attention to the maxi-

mum load quantity (see Pro-

gramme tables). In the case

of easy-care fabrics, select

the EASY IRON programme.

Contact your local Service

Force Centre. For pumping

heights over 1m a conver-

sion kit is available as a spe-

cial accessory.

Switch off the appliance and

pull out the mains plug.

Clean the drain pump.

The door cannot be

opened when the appliance is switched on.

Remnants of detergent

are building up in the

detergent drawer.

The rinsing water is

cloudy.

The door is locked for safety

reasons (DOOR/LIGHT display

is off).

The programme protection

function is set.

Water tap not fully opened. Open the water tap fully.

The inlet hose filter in the

coupling of the inlet hose at

the tap is blocked.

The cause is probably a detergent with a high silicate

content.

Wait until the DOOR/LIGHT

display lights up green.

Cancel programme protec-

tion (see the section "Pro-

gramme protection“).

Close the water tap. Unscrew

the inlet hose from the water

tap and the appliance and

clean the filter.

No negative influence on the

rinsing results, use a liquid

detergent if necessary.

33

Operating Instructions

Problem Possible Cause Remedy

When pressing a programme option button

the corresponding display does not light up.

The programme

progress indicator

flashes constantly.

The selected programme option cannot be combined

with the set programme.

Programme safeguard

switched on; The programme selector was accidentally moved during the

washing cycle.

Make another selection.

Turn the programme selec-

tor back to the original posi-

tion (see "Programme

protection“).

If the washing results are not satisfactory

If the washing turns greyish and limescale deposits are present in

the drum

• Insufficient detergent has been added.

• Incorrect detergent was used.

• Stains were not pre-treated.

• Programme or temperature was not set correctly.

• If using modular detergents, the individual components were not

used in the correct ratio.

If there are still grey stains on the washing

• Soiled garments with ointments, grease or oils were washed with insufficient detergent.

• The temperature selected for the wash was too low.

• A frequent cause is that fabric softener - particularly a concentrated

one - has come into contact with the washing. Wash out these types

of stains as soon as possible and use the fabric softener carefully.

34

If after the last rinse foam is still visible

• Modern detergents can still cause foam in the final rinse cycle. However, the washing is still sufficiently rinsed.

If there are white residues on the washing

• These are insoluble contents of modern detergents. They are not the

result of an insufficient rinse. Shake out the washing or brush it off.

Turn the washing inside out before washing it. Review your choice of

detergent and if necessary use liquid detergent.

Operating Instructions

Carrying out an emergency emptying

• If the washing machine no longer pumps out the water, emergency

emptying must be carried out.

• If the washing machine is located in a room in which below freezing

temperatures might occur, emergency emptying must be carried out.

Furthermore: unscrew the inlet hose from the water tap and drain off

the water. Empty the drainage hose.

Warning! Switch off the washing machine and pull out the mains plug

1

prior to performing emergency emptying.

Warning! The water, which flows out of the emergency emptying hose

can be hot. First allow the water to cool down before you carry out the

emergency emptying.

0 1. Have a flat container on hand to catch the water.

2. Pull down the flap in the right corner of

the base strip outwards and pull it off.

3. Remove the emergency emptying hose

from its holder.

4. Place the container under the hose.

5. Detach the plug of the emergency emp-

tying hose by turning it anticlockwise

and pull it out.

The water runs out. Depending on the

amount of water, it may be necessary to

empty the collecting vessel several

times. To do this, close the emergency

emptying hose temporarily with the

plug.

Discard the water from the container, replace it under the emergency

emptying hose and remove the plug from the hose.

35

Operating Instructions

When the water is completely drained:

6. Push the plug securely into the emergency emptying hose and turn it

clockwise to secure it.

7. Replace the emergency emptying hose in its holder.

8. Put on the flap and close.

Emergency unlocking of the door

If the door cannot be opened, it can be opened using the emergency

unlock feature.

Warning! If it is necessary to unlock the door manually, always ensure

1

that the washing machine has been disconnected from the electricity

supply first.

0 1. If water can be seen in the window of the door, first perform and emer-

gency emptying (see section "Carry out emergency emptying“).

2. Pull down the flap in the right hand

side of the base panel.

3. Turn the rotary knob clockwise using a

coin. The door springs open.

36

Operating Instructions

Additional Rinse (RINSE+)

The washing machine is set for very economical water consumption.

However, for persons who suffer from allergies to detergents, it can be

helpful to rinse with extra water.

If RINSE + is set, an additional rinse cycle is carried out with the COT-

3

TONS/LINEN, EASY CARES/EASY IRON and DELICATES programmes.

When the appliance is supplied from the factory, the additional rinse

function is not set.

Setting the additional rinse function:

0 1. Turn the programmeselector to SHORT SPIN.

2. Press the SOAKING button for at least 5 seconds.

After the button has been pressed for 5 seconds, RINSE

the programme progress display for 5 seconds.

3. Release the SOAKING button while RINSE

After it has stopped flashing, the additional rinse cycle has been set. It

remains set until it is manually cancelled.

When the additional rinse cycle is set, the indicator RINSE

on the programme progress display before the programme start and

during the additional rinse cycle.

4. If you wish to check whether the additional rinse function is enabled:

– Turn the programme selector to SHORT SPIN.

– Press the SOAKING button briefly.

If RINSE

rinse cycle is set.

+ flashes on the programme progress display, the additional

+ flashes.

+ flashes on

+ lights up

Cancelling the additional rinse function:

0 1. Turn the programme selector to SHORT SPIN.

2. Press the SOAKING button for at least 5 seconds.

RINSE

+ flashes on the programme progress display as soon as the but-

ton is pressed. After 5 seconds, RINSE

constantly for a further 5 seconds.

3. Release the SOAKING button while RINSE

After RINSE

celled.

An additional rinse cycle increases water consumption and the pro-

3

gramme duration.

+ has stopped lighting up, the additional rinse cycle is can-

+ stops flashing and lights up

+ lights up constantly.

37

Operating Instructions

Water Cooling

It may be necessary to cool down the water before pumping it out in

order to prevent thermal damage to the plastic drainage pipes.

The water is cooled down before pumping out at the end of the main

3

washing cycle (by adding cold water).

(This setting is only active for COTTONS/LINEN with a temperature of

over 40 °C.).

When the appliance is supplied from the factory, the water cooling

function is not set.

Setting the water cooling function:

0 1. Turn the programme selector to SHORT SPIN.

2. Press the PRE WASH button for at least 5 seconds.

After the button has been pressed for 5 seconds, MAIN WASH flashes

on the programme progress display for 5 seconds.

3. Release the PRE WASH button while MAIN WASH is flashing.

After it has stopped flashing, the water cooling function is set. It remains set until it is manually cancelled.

4. If you wish to check whether the water cooling function is set:

– Turn the programme selector to SHORT SPIN.

– Press the PRE WASH button briefly.

If the MAIN WASH indicator on the programme progress display

flashes, the water cooling function is set.

Cancelling the water cooling function:

0 1. Turn the programme selector to SHORT SPIN.

2. Press the PRE WASH button for at least 5 seconds.

MAIN WASH flashes on the programme progress display as soon as the

button is pressed. After 5 seconds, MAIN WASH stops flashing and illuminates for 5 seconds.

3. Release the PRE WASH button while MAIN WASH is continuously illuminated. Once MAIN WASH has ceased to be illuminated, the water

cooling function is cancelled.

Water cooling increases water consumption and the programme dura-

3

tion.

Additional Rinse and Water Cooling

You can combine the additional rinse cycle and water cooling. The setting is performed as under "Additional rinse cycle“ and "Water cooling“.

38

Operating Instructions

Programme protection

To safeguard a programme setting against unwanted changes (e.g. programme selector turned, option buttons pressed etc., you can set the

Programme protection. This prevents your washing being damaged.

The programme protection can be set and cancelled at any time during

3

a programme.

Select programme protection:

0 1. Select the desired programme settings.

2. To start the programme, press the START/PAUSE button.

3. Keep the PREWASH and SOAKING buttons pressed simultaneously for

5 seconds. The programme progress display flashes for 5 seconds.

The programme protection function is set.

As long as the programme protection is set, you cannot make any other

3

settings. The door cannot be opened with the DOOR/LIGHT button. Also

after the washing cycle has ended, you must first cancel the programme protection before you can open the door.

If you attempt to change the selected setting by pressing a button during the washing cycle, the programme progress display flashes for

5 seconds.

If you attempt to change the selected setting by turning the programme selector, the programme progress display flashes until the original setting of the programme selector is restored. The washing cycle is

not influenced in either case.

The programme selector must be in its original setting before you can

3

cancel the programme protection.

Cancelling programme protection:

0 Keep the PREWASH and SOAKING buttons pressed simultaneously for

5 seconds. The programme progress display flashes for 5 seconds, then

it is illuminated for 5 seconds. Programme protection is cancelled.

39

Operating Instructions

Child Safety Feature

If the child safety feature is set,

the door cannot be closed and no

washing programme can be

started.

Setting the child safety feature

0 Use a coin to turn the rotary knob

on the inside of the door clockwise as far as it will go.

Warning! The rotary knob must

1

not be in a vertical position after

adjustment, otherwise the child

safety feature is not active. The rotary knob must project as shown in

the diagram.

Cancelling the child safety

feature

0 Turn the rotary knob anticlockwise

as far as it will go.

40

Installation and connection instructions

Installation and connection instructions

Installation Safety Precautions

• When moving do not tilt the washing machine onto its front or onto

its right hand side (viewed from the front). This is to prevent the possibility of the electronic components becoming wet.

• Before installation inspect the machine for transport damage. Do not

connect the appliance if it is damaged - contact your retailer.

• Ensure all packaging and transit bolts/bars have been removed, see

„Removal of Transit Packaging“. Failure to remove transit bolts/bars

may cause serious damage to the appliance or property.

• Always insert the plug into a correctly installed earthed socket.

• Any plumbing work required to install this appliance should be

carried out by a plumber or competent person.

• Check that the electricity supply is the same as that indicated on the

appliance´s rating plate.

• Any electrical work required to install this appliance should be carried

out by an electrician or competent person.

41

Installation and connection instructions

Installation of the appliance

Transporting the appliance

• Do not place the washing machine on its front or on its right hand

side (viewed from the front). This is to prevent the possibility of the

electronic components becoming wet.

• Never transport the unit without the transport packaging and bolts/

bars. Do not remove the transport packaging until the appliance is at

the installation location. Transporting the unit without the transport

packaging can damage it.

• Never lift the appliance by the door.

When transporting the unit with a sack trolley:

• Attach the sack trolley only at the side. The shovel of the sack trolley

must not be longer than 24 cm, otherwise the float switch can be destroyed.

Remove transport packaging

Important! It is essential to re-

move the transport packaging before putting the appliance into

operation. Keep all parts of the

transport packaging in a safe

place for future use.

0 1. Open both hose holders on the

appliance's rear side and remove

the hoses and mains cable.

2. Pull both hose holders off the appliance with a strong pull.

42

The special spanner (A) and the

3

caps (B) (2 each) and (C) (1 each)

are supplied with it.

3. Remove the screw D, including

the compression spring with the

special spanner A.

4. Cover the hole with the cap C.

Important! When fitting the

plastic caps, press until they snap

into the rear panel securely.

5. Remove the two screws (E) with

the special spanner (A).

6. Remove the 4 screws (F).

7. Remove the transit bar (G).

8. Screw the 4 screws (F) back in for

safe keeping.

9. Close the 2 large holes with the

caps (B).

Important! When fitting the

plastic caps, press until they snap

into the rear panel securely.

Installation and connection instructions

43

Installation and connection instructions

Installation-Site preparation

• The installation surface must be clean, dry and level. Do not install on

a deep pile carpet.

• Minor unevenness of the floor surface should never be levelled out by

laying pieces of wood, card or similar materials, but should always be

compensated for by adjusting the screw feet.

• If the appliance is installed next to a heat source (e.g. cooking appli-

ance), a heat insulating pad (87 x 57 cm) must be placed between the

appliance and the heat source.

• Do not install the appliance in locations where the temperature may

fall below freezing.

• Please ensure that when the appliance is installed it is easily accessi-

ble for the engineer in the event of a breakdown.

Installation on a Suspended Floor

Suspended wooden floors are particularly susceptible to vibration. To

help prevent vibration we recommend you place a waterproof wood

panel, at least 15 mm thick under the appliance, secured to at least

2 floor beams with screws. If possible install the appliance in one of the

corners of the room, where the floor is more stable.

44

Installation and connection instructions

Levelling the appliance

Self adjusting foot: The rear foot of your washing machine is designed

3

like a spring leg. This makes the machine very stable even at high spin

speeds.

If the washing machine is still not stable during spinning, proceed as

follows:

0 1. Set the three adjustable feet to

the nominal value of 10 mm.

Use the supplied spanner.

If the self adjusting foot does

not reach the floor:

2. Manually extend the self

adjusting foot (rear left) to

the required length.

3. Check the appliance is level using

a spirit level.

Important! Never use strips or

shims of wood or cardboard etc.

to compensate for any unevenness in the floor. Always use

the adjustable feet.

45

Installation and connection instructions

Electrical Connection

Any electrical work required to install this appliance should be carried

out by a qualified electrician or competent person.

WARNING - THIS APPLIANCE MUST BE EARTHED.

1

The manufacturer declines any liability should these safety

measures not be observed.

Before switching on, make sure

the electricity supply voltage is

the same as that indicated on the

appliance rating plate.

The rating plate is located at the

top of the rim of the open door.

The appliance is supplied with a

13amp plug fitted. In the event of

having to change the fuse in the

plug supplied, a 13amp ASTA approved (BS 1362) fuse must be used.

Should the plug need to be replaced

for any reason, proceed as described

below.

The wires in the mains lead are

coloured in accordance with the

following code:

Blue

Green & Yellow

Brown

46

Green and Yellow: Earth

Blue: Neutral

Brown: Live

• The wire coloured green and yellow must be connected to the termi-

nal marked with the letter “E“ or by the earth symbol or coloured

green and yellow.

• The wire coloured blue must be connected to the terminal “N“ or

coloured black.

• The wire coloured brown must be connected to the terminal marked

“L“ or coloured red.

• Upon completion there must be no cut, or stray strands of wire

present and the cord clamp must be secure over the outer sheath.

Cord Clamp

Installation and connection instructions

WARNING! A cut off plug inserted into a 13 amp socket is a

1

serious safety (shock) hazard. Ensure that the cut off plug is

disposed of safely.

Permanent Connection

In the case of a permanent connection it is necessary that you install a

double pole switch between the appliance and the electricity supply

(mains), with a minimum gap of 3 mm between the switch contacts

and of a type suitable for the required load in compliance with the

current electrical regulations.

The switch must not break the yellow and green earth cable at any

point.

This appliance is in accordance with the following EU Guidelines:

;

– Low Voltage Guidelines 73/23 EEC dated 19 February 1973, include

Guideline Change Notice 93/68 EEC

– EMC Guideline 89/336 EEC dated 3 May 1989, including Guideline

Change Notice 92/31 EEC.

This appliance complies with the requirements laid out in the EEC Directive 76/899.

Voltage 240 V AC: Fuse rating 13 amps

See rating plate for further information.

This appliance meets VDE requirements.

Particular regulations of local electricity authorities must be observed.

This appliance conforms to EEC Directive No. 82/499/EWG on radio interference.

WARNING! Repairs to electrical appliances must only be carried out by

1

trained personnel. Improper repairs may lead to serious risks for the

user.

47

Installation and connection instructions

Water connection

The washing machine is provided with safety devices preventing back-

3

contamination of the water supply and complies with local water authority requirements.

This appliance is designed to be permanently plumbed into your home’s

water supply.

Before connecting up the machine to new pipework or to pipework

that has not been used for some time, run off a reasonable amount of

water to flush out any debris that may have collected in the pipes.

Important!

– Appliances for connecting to cold water must not be connected to

hot water.

– Only use new hose sets for the connection.

Water pressure

The appliance is designed to operate within the following water

pressure units. Minimum 1 bar (= 10 N/cm

10 bar (= 100 N/cm

• If more than 10 bar: Install a pressure-reduction valve upstream

• If less than 1 bar: Unscrew the inlet hose from the appliance at the

inlet solenoid valve and remove the flow regulator (to do this, remove

the filter with needle nose pliers and remove the rubber washer behind the filter). Replace the filter.

2

= 1 Mpa).

2

= 0.1 Mpa), maximum

48

Installation and connection instructions

Inlet Hose Connection

A pressure hose 1.5m in length is supplied.

If a longer inflow hose is required, only a VDE-approved, complete set

of hoses with fitted hose screw connections offered by your local Service Force Centre is permissible.

– Hose sets in lengths of 2.2m, 3.5m and 5m are available for washing

machines without Aqua Control.

– Hose sets in lengths of 2.0 m, 2.9m and 3.9m are available for wash-

ing machines with Aqua Control.

Important! Never cut hoses into pieces in order to extend them!

Sealing rings are supplied either in the plastic

3

nuts of the hose screw connection or in the

enclosed pack. Do not use other seals!

0 1. Connect the hose with the angled

connection to the machine.

Important!

– Do not lay the inlet hose verti-

cally downwards. Instead, turn

it to the right or left as shown

in the diagram.

– Tighten firmly to prevent

leakage but do not use

excessive force.

2. Connect the hose with a straight connection to a

water tap with a screw thread R 3/4 (inches).

Important! Only tighten the screw connection

manually.

3. By slowly opening the water tap before putting

the washing machine into operation it is possible

to check that the connection is free of leaks.

49

Installation and connection instructions

Water Drainage

The appliance drain hose should hook into a standpipe, the hook in the

drain hose is formed using the plastic “U-Piece“ supplied. The standpipe

should have an internal diameter of approximately 38 mm (see diagram) thus ensuring there is an air break between the drain hose and

standpipe.

Important! It is essential to lay

the drainage hose without kinks.

When discharging into a standpipe ensure that the top of the

curve in the hose end is no more

than 90 cm (35.4’’) and no less

than 60 cm (23.6’’) above floor

level.

50

The upright standpipe should

have a minimum, length of

30 cm (12’’) from the bottom of

the elbow to the top of the pipe

(see diagram). Make sure that it is

designed in such a way that the

end of the drain hose cannot be

covered with water.

Longer drain hoses are available

in lengths of 2.7 and 4 metres

from your AEG Service Force

Centre.

Installation and connection instructions

If you intend the drain hose from

the washing machine to empty

into a sink, make sure that the

sink is empty and the plug hose

is not blocked. Use the plastic

“U-Piece“ supplied.

Important! The end of the

drainage hose must not be

submerged in the pumped-out

water. Otherwise, the water

could be sucked back into the appliance.

Pump head of greater than 1m

Every washing machine includes a wash water pump for the removal of

wash and rinse water, which can pump fluids through the outlet hose

up to a height of 1m, measured from the surface on which the machine

stands.

For pump heads of greater than 1m please contact your local

AEG Service Force Centre.

51

Installation and connection instructions

Technical data

Height Adjustment approx. +10 / -5mm

Load (depending on the

programme)

Area of use Domestic

Drum speed, spinning see rating plate

Water pressure 1-10bar

max. 5kg

(=10-100 N /cm

Dimensions

2

= 0.1-1.0 Mpa)

52

(dimensions in mm)

Warranty conditions

Warranty conditions

Great Britain

Guarantee Conditions

AEG offer the following guarantee to the first purchaser of this appliance.

1. The guarantee is valid for 12 months commencing when the appliance is handed over

to the first retail purchaser, which must be verified by purchase invoice or similar documentation.

The guarantee does not cover commercial use.

2. The guarantee covers all parts or components which fail due to faulty workmanship or

faulty materials. The guarantee does not cover appliances where defects or poor performance are due to misuse, accidental damage, neglect, faulty installation,

unauthorised modification or attempted repair, commercial use or failure to observe

requirements and recommendations set out in the instruction book.

This guarantee does not cover such parts as light bulbs, removable glassware or plastic,

dust bags or filters.

3. Should guarantee repairs be necessary the purchaser must inform the nearest customer

service office (manufacturer´s service or authorised agent). AEG reserves the right to

stipulate the place of the repair (i. e. the customer´s home, place of installation or AEG

workshop).

4. The guarantee or free replacement includes both labour and materials.

5. Repairs carried out under guarantee do not extend the guarantee period for the appli-

ance. Parts removed during guarantee repairs become the property of AEG.

6. The purchaser´s statutory rights are not affected by this guarantee.

European Guarantee

If you should move to another country within Europe then your guarantee moves with

you to your new home subject to the following qualifications:

– The guarantee starts from the date you first purchased your product.

– The guarantee is for the same period and to the same extent for labour and parts as

exist in the new country of use for this brand or range of products.

– This guarantee relates to you and connot be transferred to another user.

– Your new home is within the European Community (EC) or European Free Trade Area.

– The product is installed and used in accordance with our instructions and is only used

domestically, i. e. a normal household.

– The product is installed taking into account regulations in your new country.

Before you move please contact your nearest Customer Care Centre, listed below, to

give them details of your new home. They will then ensure that the local Service Organisation is aware of your move and able to look after you and your appliances.

France Senlis +33 (0) 44 62 29 29

Germany Nürnberg +49 (0) 800 234 7378

Italy Pordenone +39 (0) 800 117511

Sweden Stockholm +46 (0) 8 672 5360

UK Slough +44 (0) 1753 219899

53

Index

Index

A

Aqua Control . . . . . . . . . . . . . . . . . 14, 25, 33

Automatic adjustment foot

. . . . . . . . . . 9, 45

C

Child safety feature . . . . . . . . . . . . . . .31, 40

Circulation pump

Conditioner

Cottons

. . . . . . . . . . . . . . . . . . .10, 16, 26, 27

Curtains

. . . . . . . . . . . . . . . . . . . . . 15, 16, 26

Customer Service

. . . . . . . . . . . . . . . . . .9, 30

. . . . . . . . . . . . . . . . 9, 17, 18, 22

. . . . . . . . . . . . . 29, 31, 55

D

Delay timer . . . . . . . . . . . . . . .10, 12, 20, 23

Delicates

Detergent

Detergent dispenser drawer

. . . . . . . . . . . . . . . . . .11, 16, 26, 27

. . . . . . . . . . . . . . . . . . 9, 17, 18, 22

. . . . . . . . . . 9, 22

E

Easy iron . . . . . . . . . . . . . . . . . .11, 16, 26, 33

Easy-cares

Emergency emptying

Emergency unlocking

Energy saving

. . . . . . . . . . . . . . . .10, 16, 26, 27

. . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . .10, 26

F

Fabric softener . . . . . . . . . . . . . . . . . . . . . . 22

H

Hand wash . . . . . . . . . . . . . . . . . . . 11, 26, 27

L

Linen . . . . . . . . . . . . . . . . . . . . .10, 16, 26, 27

Load

. . . . . . . . . . . . . . . . . . . . . . . . . . . .13, 26

M

Multi-display . . . . . . . . . . 10, 23, 24, 31, 55

O

Open the door . . . . . . . . . . . . . . . . 25, 33, 39

Opening the door

Over-dosed

. . . . . . . . . . . . . . . . .21, 36

. . . . . . . . . . . . . . . . . . . . . . . . . 25

P

Pre wash . . . . . . . . . . . . . . . . . . . . . 12, 22, 26

Pre-wash detergent

Program progress display

Program protection

Pump out

. . . . . . . . . . . . . . . . . . . . . . . .11, 25

. . . . . . . . . . . . . . . .9, 22

. . . . . . . . . . .10, 24

. . . . . . . . . . . 21, 25, 39

Q

Quick wash . . . . . . . . . . . . . . . . . . . . . .12, 26

R

Rating plate . . . . . . . . . . . . . . . 9, 46, 47, 55

Rinse

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Rinse +

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Rinse hold

Risk of frost

Run time