Page 1

302 D

Cooker Hood

Installation and Operating Instructions

Page 2

Contents

Page 3

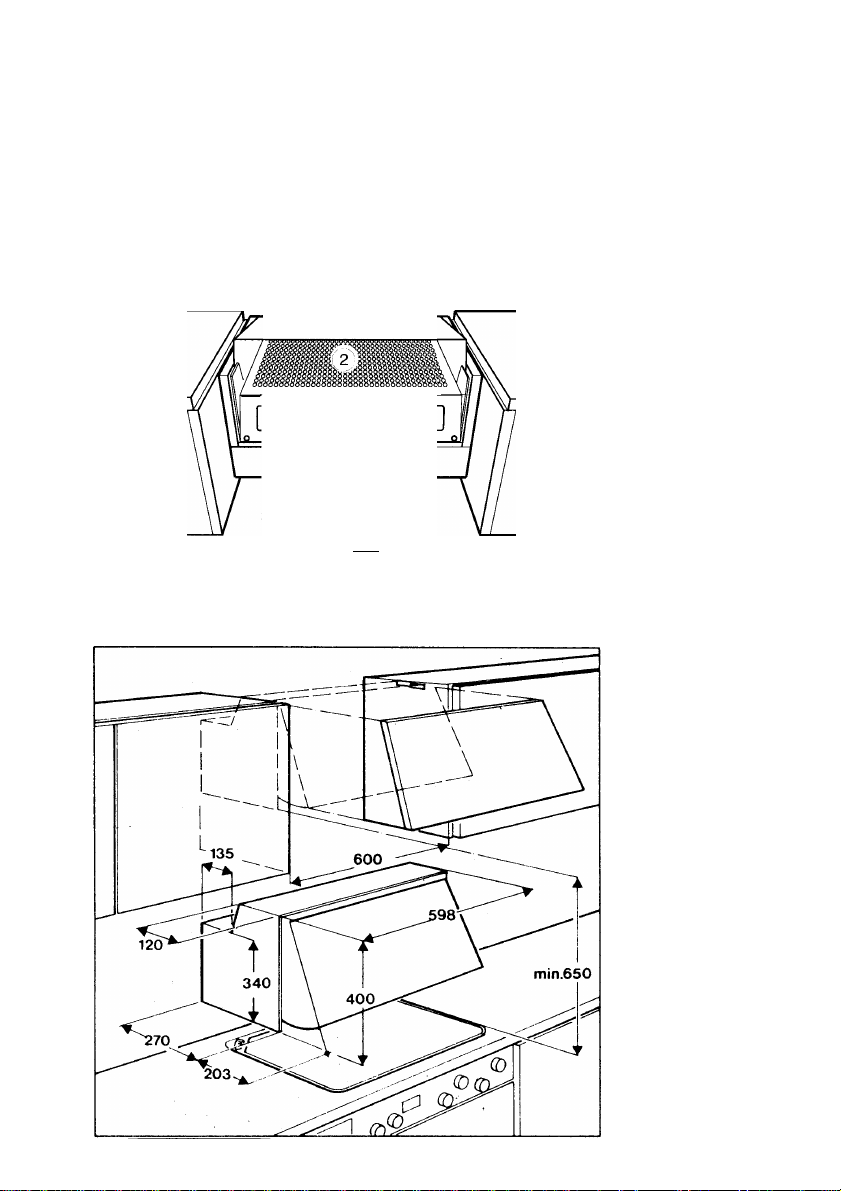

View of the Hood

1) Extendable Vapour Guide

2) Filter Grille

3) Lighting

4) Motor Switch

5) Light Switch

/3^ I i!^°|

41^ 0 I M N1

5 —r-

° ' o

I I Iaeo

Page 4

Page 5

Is..со to

л 1- со со

II II II

л о (О о>

ю

Page 6

^ 529 _

m

1 m

Ю

CO

00_

CO

f-4-

4-

SI

509,5

-4

- 1

Page 7

Page 8

General

The cooker hood can be used :

either as an exhaust air appliance (extraction mode)

or as a return air appliance (recirculation mode)

via a carbon filter (optional extra).

Preparation for installation

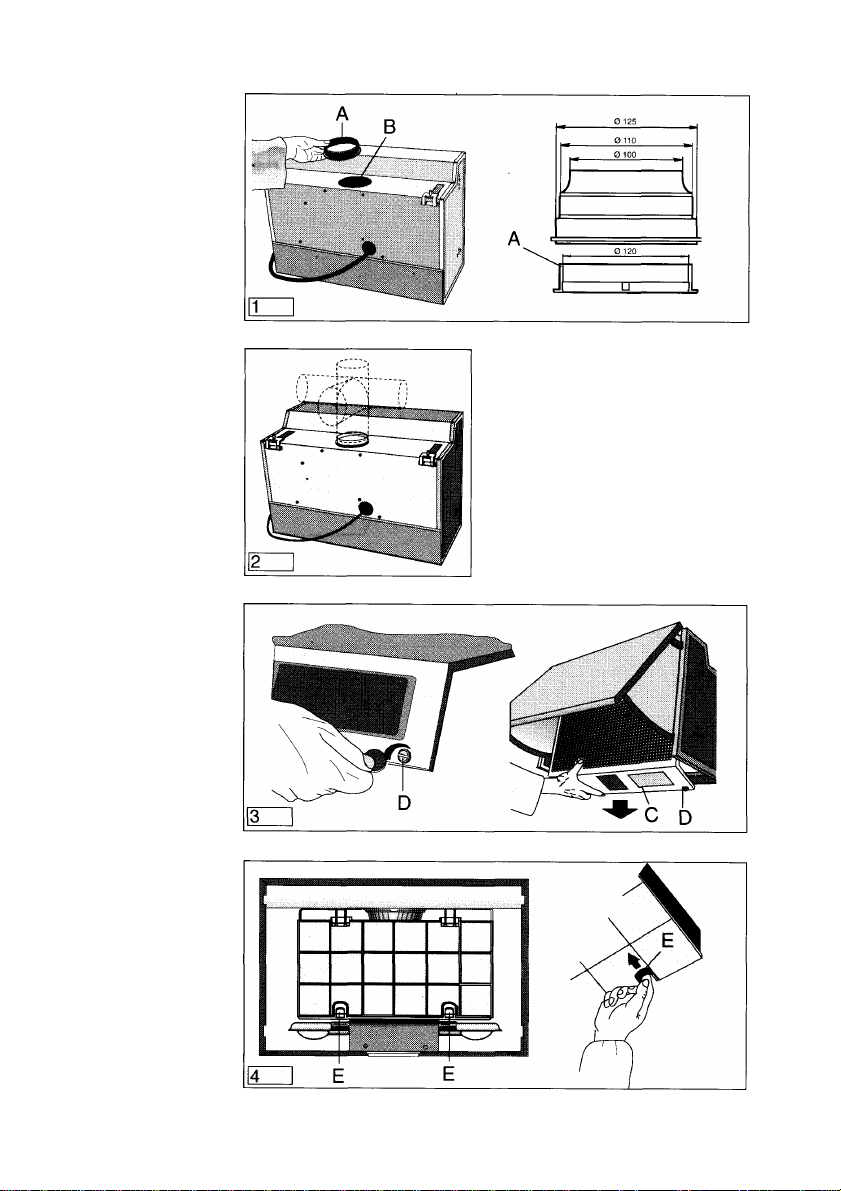

Extraction In this mode the fumes are extracted to the outside via a venting

mode hose connected to the coupling ring A, placed in hole B (fig. 1).

Depending on your installation the hose can be directed either

towards the ceiling or towards the walls(fig. 2).

In the extraction mode the outlet venting hose should to be

120mm in diameter, but 100mm or 110mm venting hoses can be

used by inserting the multiconnector flange (fig. 1), supplied with

the hood on the coupling ring A, before connecting the hood to the

outlet venting hose.

If the venting hose runs horizontal it must be slightly slanted

upwards (about 10°) to ensure the air is vented easily from the

kitchen to the outside.

If the hood is to vent out into the open air through an

external wall, you need a telescopic wall box (optional

extra). Wall box and venting hoses are available via your

AEG Stockist or AEG Spare Parts. Flame retardant venting

hose is available in 120 and 100mm diameter. Other flame

retardant materials such as KA piping can be used.

Optimum operation of the cooker hood in the extraction mode is

assured only if the following points afe observed:

- short, straight exhaust air runs

- as few hose bends as possible

- running of the hose in smooth flat arcs not at sharp angles.

- as large as possible hose diameter

Failure to observe these principles will result in serious power

losses and increased operating noise.

Page 9

In this mode the fumes filter through an active carbon filter

(optional extra) and are returned into the room. ^

To fit the carbon filter remove the grille C by turning locks D and

pull it out downwards (fig. 3). Fit the filter in the seat at the front and

fasten it at the back with the two hooks E (fig. 4). The cover F (fig.

5) must be fitted over the hole B (fig. 1) fixing it with the special

screw provided. This cover deflects the air forwards avoiding

soilage of the rear wall.

Recirculation

mode

Important:

In the extraction mode the exhaust air must not be introduced into

a smoke flue or exhaust gas chimney.Introduction of the exhaust

air into a shaft used for ventilation of the installation spaces of

firerooms is not permitted.

If the exhaust air is introduced into a operational smoke flue or

exhaust gas chimney, it is advisable to seek the advice of a

competent chimney-sweep. The official exhaust air guidance

regulations are to be complied with.

During operation in the extraction mode, an adequate air opening

of approximately the same size as the exhaust air opening should

be ensured.

According to the Provincial Building Regulations, the joint operation

of fume extractor hoods and chimney-linked fireplaces, such as

coal or oil-fired ovens and gas heaters, in the same space is

subject to specific restrictions. In such spaces, the Fireplace

Regulations only allow an underpressure of max. 0.04 mbar. The

safe joint operation of chimney-linked appliances and fume

extractor hoods is only guaranteed if space and/or dwelling

(space/air interaction) are externally vented by a suitable supply

air opening of around 500-600cm2 and an underpressure thereby

avoided when the cooker hood is running. In doubtful cases,

please seek the advice and consent of a competent chimney

sweep or the local building authorities.

Notes prior to

installation

In spaces without a fireplace, the rule is: “Supply an air opening

as large as the exhaust air opening”, the efficiency of the hood in

the extraction mode may be impaired by a greater opening.

Operation of the hood in the recirculation mode in such

circumstances is safe and is not subject to the regulations above.

When installed, the minimum distance from the hob to the

lower edge of the cooker hood must be 65cm for electric hobs

or 75cm in the case of gas or mixed fuel hobs

Page 10

Electrical connections

Voltage and

current

Important

# Please ensure that the voltage and current indicated on the rating

plate agree with the voltage of your electricity supply.

If your appliance has been equipped with a mains lead with a

moulded-on type plug, you must comply with the following

regulations:

The plug moulded on to the lead incorporates a fuse. For

replacement, use a 5 amp BS1362 fuse. Only ASTA approved or

certified fuses should be used. If the fuse cover/carrier is lost, a

replacement cover/carried must be obtained from an electrical

goods retailer. If the socket outlets in your home are not suitable

for the plug fitted to the appliance, then the plug must be cut off and

destroyed for safety reasons, and an appropriate plug fitted.

When wiring the plug ensure that all strands of wire aré securely

retained in each terminal. Do not forget to tighten the mains lead

clamp on the plug.

This appliance complies with the following directives:

— 89/336/EEC of 03.05.1989 (including amendments 92/31/

EEC of 28.04.1992 and 93/68/EEC of 22.07.1993),

EMC directive.

Electrical connections

230 V - using fixed power supply line with plug.

240 V - using fixed power supply line (Great Britain).

Fuse rating 13 amps

(The unit should only be connected up by an authorized electrician).

See rating plate for further information.

It is recommended that the socket for the plug is sited above the

cooker hood or above the overhead cabinet.

This has 2 advantages:

1 ) The socket is not visible.

2) The appliance can easily be unplugged when necessary.

If a fixed connection is required the cooker hood should be

connected by an electrical installer registered with a competent

electricity company. An isolating device is to be provided on the

fixed wiring side. Switches with a contact opening of more than

3mm apply as isolating devices.

These include-automatic cut-out switches, fuses and contactors

(VDE0730, s. 7, Parti).

10

Page 11

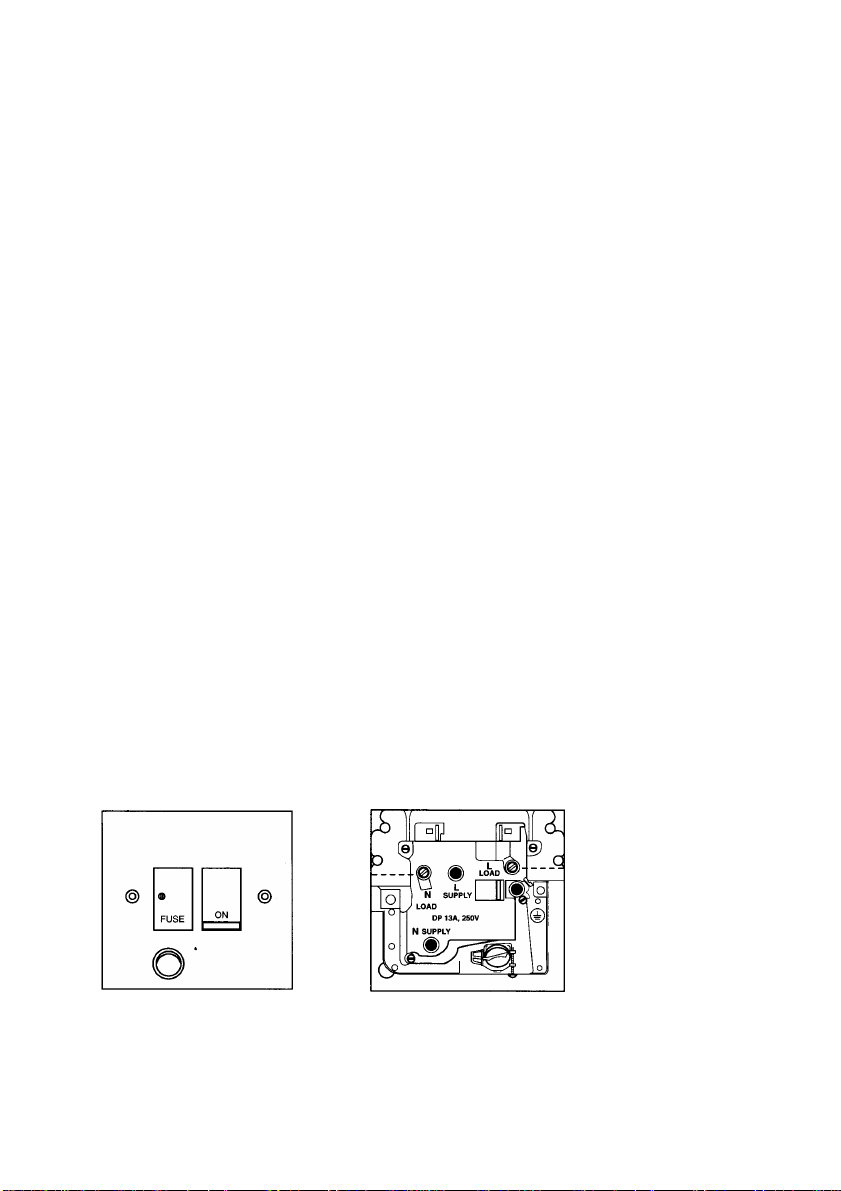

Your appliance must be connected to fixed wiring via the use of

a double pole swiched fused spur outlet with or without pilot lamp.

We strongly recommend the appliance is connected by a quali

fied electrician who is a member of the NICEIC who will comply

with the lEE and any local regulations.

NOTE:

The terminology “DOUBLE POLE” means that both the live

and neutral supplies are swiched and disconnected at the

same time.

The terminations labelled SUPPLY are for the connection for the

internal house wiring and the terminations labelled LOAD are for

the appliance.

IMPORTANT

The wires of the mains lead supplied with this appliance are

coloured in accordance with the following code:

Blue-Neutrai

Brown-Live

As the coiours of the flexible cord of this appliance may not

correspond with the coloured markings identifying the ter

minals in your plug, proceed as follows: The whire which is

coloured brown must be connected to the terminal which is

marked with the ietter L or coloured red.

The wire which is coloured blue must be connected to the

terminal which is marked with the letter N or coloured black.

Appliances

with 2 wires

---BLUE

(NEUTRAL)

BROWN

(LIVE)--

11

Page 12

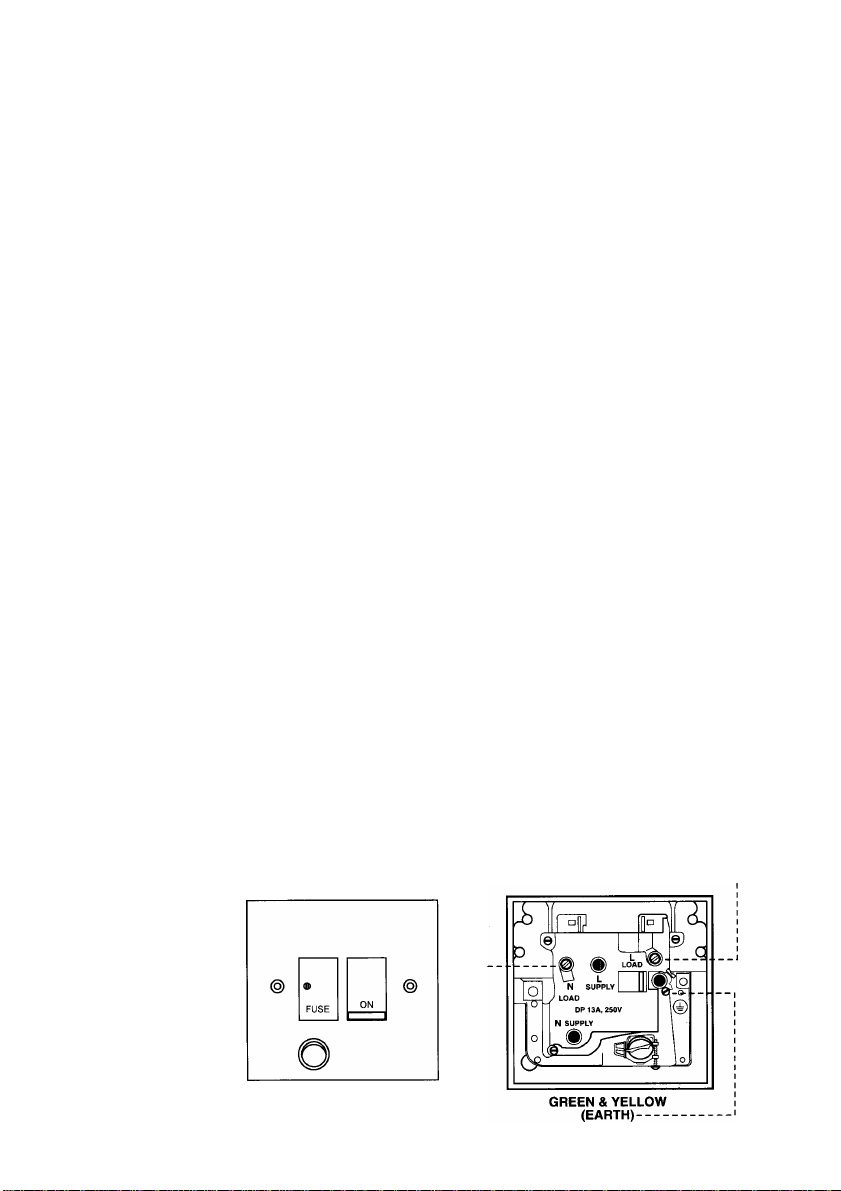

Appliances Your appliance must be connected to fixed wiring via the use of

with 3 wires a double pole swiched fused spur outlet with or without pilot lamp.

We strongly recommend the appliance is connected by a quali

fied electrician who is a member of the NICEIC who will comply

with the I EE and any local regulations.

NOTE: The terminology “DOUBLE POLE” means that both

the live and neutral supplies are swiched and disconnected at

the same time.

The terminations labelled SUPPLY are for the connection for the

internal house wiring and the terminations labelled LOAD are for

the appliance.

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT

The wires in this mains lead are coloured in accordance with the

following code:

Green/Yeiiow - Earth

Blue - Neutral

Brown - Live

As the colours of the wires in the mains lead of this appliance may

not correspond with the coloured markings identifying the termi

nate in your spur box, proceed as follows:

The wire wbii^% coloured green and yellow must be connected

to the terminal which is marked with the letter “E” or by the earth

symbol ^ or coloured green or green and yellow. The wire which

is coioured blue must be connected to the terminal which is

marked with the letter “N” or coloured black.

The wire which is coloured brown must be connected to the

terminal which is marked with the ietter “L” or coloured red.

12

-BLUE

BROWN

(LIVE)--

Page 13

Installation

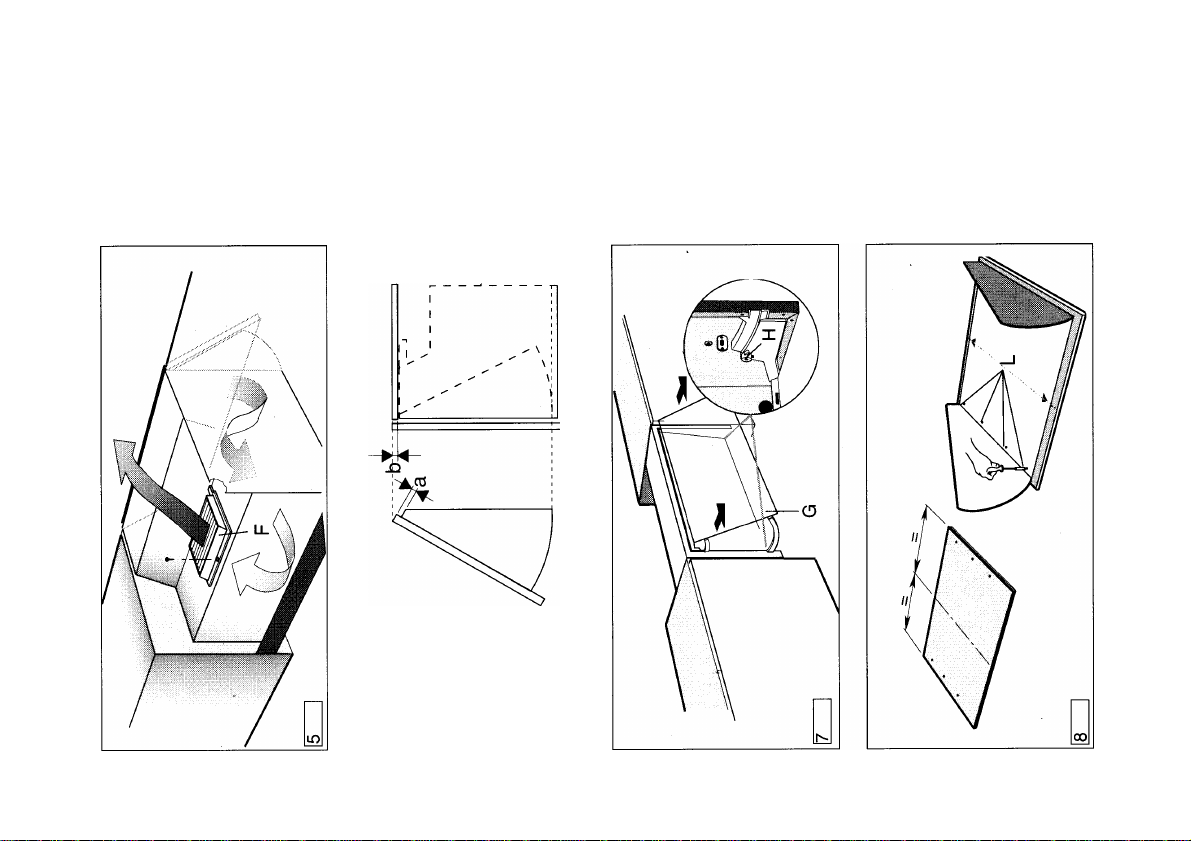

Before fixing the furniture door to the hood, please ensure the

correct distance between the plate and the upper edge of the

cabinet door (depends on the thickness of the material and

whether or not there is an upper shelf) (Fig. 6).

1. Remove the grille filter C by turning the locks D and pull it out

downwards (Fig. 3).

2. Take off the extendable vapour guide G (fig. 7) by turning the

rear locking knobs H (Fig. 7).

3. Draw a line with a pencil on the middle of the internal side of the

furnituture door (Fig. 8).

4. Fit the plate upon the internal side of the furniture door so that

the line previously marked on it, is visible through the two

triangles holes located on the mid upper and lower side of the

plate, having care to respect the distance from the plate to the

higher edge of the furniture door as for the reason mentioned

above.

5. Fasten the plate to the furniture door through the 6 screws L 4,5

X 13 mm supplied (Fig. 8).

6. Replace the complete fume protection plate assembly into the

extractor hood, first inserting it on its upper, then on its lower

guides.

7. Turn the rear unlocking knobs H (Fig. 7) so to avoid the fume

protection plate take off.

8. Replace the grille filter.

1. Remove the grille filter (Fig. 3).

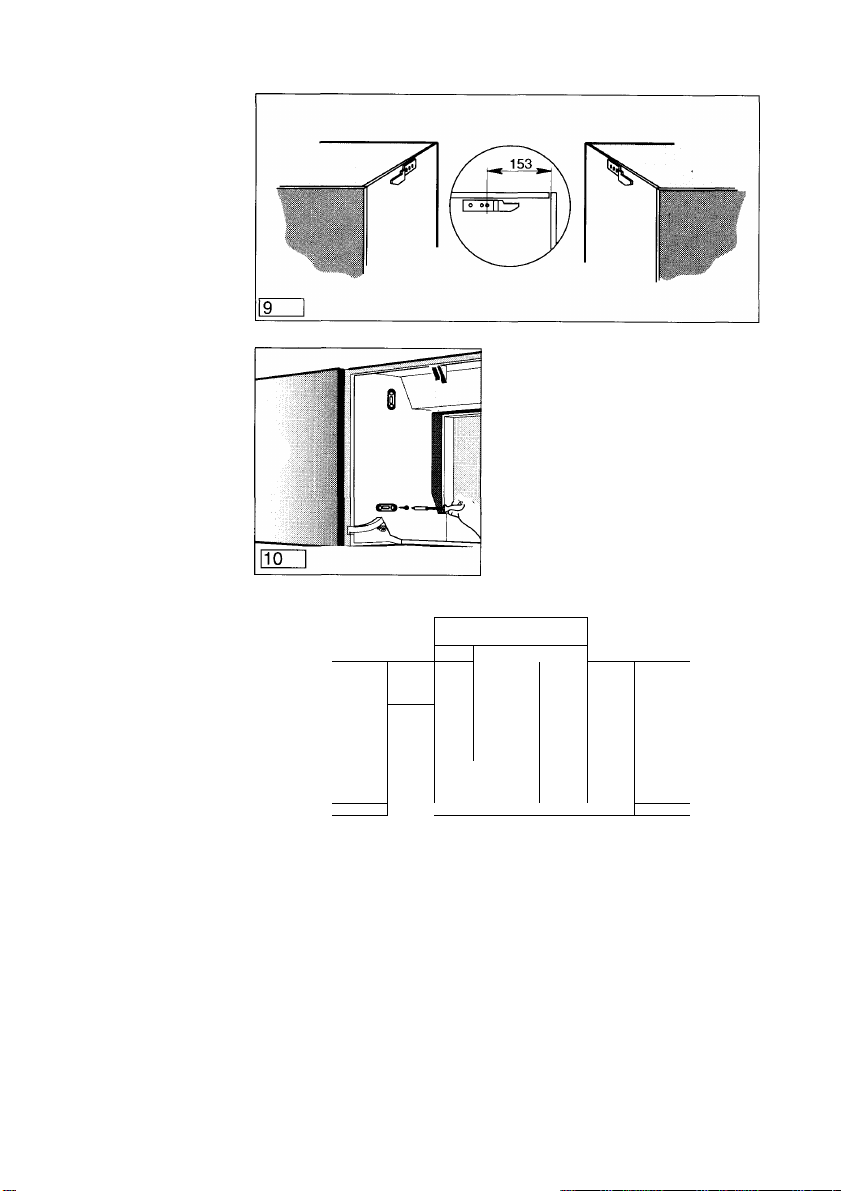

2. Remove the fume protection plate (Fig. 7).

3. Mount the two hanging rails directly underneath the edge of the

cupboard using three screws 4,5 x 16 mm each rail.

Distance from first hole to front edge of the cupboards sides

must be 153 mm (Fig. 9).

4. Push the extractor hood over the two hanging rails, then fix the

hood from its inside to the cupboards sides with two screws (4,5

X 13) through the lower holes of the hood (Fig. 10).

5. Replace the the complete fume protection plate assembly into

the extractor hood.

6. Replace the grille filter. •

7. Ensure that there is not a gap between the back of the hood and

the wall by adjusting the spacer M tightly to the wall, using the

screws O (fig. 12).

Fixing the

furniture

door to the

hood

Installing the

hood between

cupboards with

hanging rails

13

Page 14

Installing the hood

to the wall

It is possible to fix the hood in position, if necessary, by only

attaching it to the rear wall.

Proceed as follows:

1. Drill the four holes on the wall as indicated (Fig. 11).

2. Insert the four rawl plugs supplied into these holes.

3. Screw the two mountings hooks into the top two rawl plugs

(Fig. 12).

4. Dismount the spacer M (Fig. 12) from the body of the hood by

unscrewing completely the two spacer fixing screws O and

washers.

5. Fix the base spacer M to the wall (Fig. 12) with the two screws

R 5x45 provided (Fig. 11) using either the long or the short arm,

depending on the depht of the side cupboards.

Do not tighten the screws fully.

6. Fix the hood to the wall by means of the two hooksP previously

mounted, but first move the upper brackets S (Fig. 11) so that

the front panel of the hood, once mounted, will be in line with

the front edge of the cupboard doors. The two upper brackets

S, located at the top rear edge of the hood may be slid

backwards and forwards by loosening its fixing screws T

adjacent to them on the upper hood surface (Fig. 11).

7. Check that the hood is at the right height. Minor height

adjustments may be made with the screws U embodied in the

brackets (see Fig. 11).

8. Tighten the two wall fixing screws R, through the two access

holes N provided on the inside of the hood (Fig. 12) then fix the

lower sliding frame to the hood with two screws O and washers

previously unscrewed (item 4).

14

Page 15

Using the hood

It is advisable to switch on the cooker hood a few minutes before

starting cooking and then to leave it running fot approximately 15

minutes afterwards to ensure that all odours are extracted.

On the front of the appliance there are control switches

(see page 3).

The switch marked with motor symbol controls fan power.

The switch marked with lamp symbol controls the lighting of the

cooking surface.

The hood is also fitted with an automatic micro switch located on

the right hand side behind the visor, the micro switch will switch

the hood OFF, whatever selection is made with the slider switches

when the visor is closed. When the visor is pulled open the hood

will switch ON at its previous setting.

— If the hood is run at the same time as an ambient-air dependent

burner or fireplace (for example gas, diesel, coal or wood

heaters, water heaters, etc.) be careful, because the hood,

when it extracts air, removes the ambient air the burners of

fireplace need for combustion.

For safe operation and to prevent discharged gas from coming

back into the room, make sure there is an air inlet, which may be

provided through air-recycling doors, windows or wall boxes or

by other technical devices.

— No food must be cooked flambé underneath the hood. The

use of an unprotected flame is dangerous for the filters and

could cause a fire. Therefore never use an open flame under

the hood. When frying foods, never leave the pan unattended,

the cooking oil could ignite. If contaminated oil is used,

spontaneaous ignition may occur even more readily.

— The hood must not be connected to fuel exhaust flues

(boilers, heating systems, water heaters, etc.).

— The manufacturers do not accept liability for damage to the

hood or its catching fire because of failure to observe the

above instructions.

Where flexible ducting is fitted the length should be no more

than:

— 3 metres with one 90° bend

— 2 metres with two 90° bends.

Bends of more than 90° will reduce the efficiency of the hood

and reduce the air flow.

15

Page 16

Maintenance

Before carrying out any maintenance disconnect the hood from the electricity supply.

Grease filter

Removing the

grease filter

Carbon filter

The grease filter traps the suspended grease particles, and is

used in the hood regardless of whether the hood is in the

extraction or recirculating mode.

The thin synthetic filter (thickness about 1 mm) is installed inside

the filter grille. It is changed when the top colouring appears on the

bottom, i.e. you can see the colour through the filter grille.

To remove the filter:

a) Remove the filter grille (see fig. 3)

b) Take out the saturated filter after removing the clamps

Z (fig. 13).

c) Fit a new grease filter and replace filter grille.

When replacing the grease filter, also wash the filter grille with

warm water and mild detergent i.e. washing-up liquid.

Replacement grease filters are available from AEG Spare Parts

- Telephone (0753) 872550.

The carbon filter is fitted when the hood is used in the recirculating

mode.

This is not washable and cannot be reused.

The carbon filter should be replaced at least once every four

months.

Removing the

carbon filter

Cleaning

16

To remove the carbon filter, push the push-buttons E inwards and

pull the filter downwards (Fig. 4).

Please specify model number and product number when ordering

a replacement filter. This is found on the rating place located

inside the hood. Replacement filters are available from AEG

Spare Parts, Telephone (0753) 872550.

To clean the outside of the hood use a mild solution of washingup liquid and water.

Never use abrasive detergents, brushes or scouring powders.

Important

Always switch off the hood and pull out the plug before

cleaning.

Page 17

ATTENTION

Failure to observe the rules for cleaning the appliance and

changing and cleaning the filters may cause a fire as a result of

grease deposits. Therefore please observe these

recommendations.

1) Disconnect the hood from the electricity supply.

2) Remove the filter grille (fig. 3) - this will then allow inspection/

change of the bulb/s.

3) Unscrew defective bulb and replace with new one. Important:

always use 40W candle lamp (El 4) bulbs.

Before calling the Service Engineer because the hood fails to light

up, make sure the bulbs are screwed in tightly.

Dimensions

Height — 400mm

Width — 599mm

Depth —270mm

Weight

Net 9,7Kg

Connected Load 200W

Fan Motor 120 W

Lighting: 40 Watt Candle Lamp x 2

Lengt of the cable: 140 cm

Changing the

bulbs

Technical Data

Fan speed: 1

Extractor version: 143 m%

Filtre version: 87 m^/h

Special Accessories

Wall/Window Box

Venting Hose 120mm x 2.4M

Venting Hose 100mm x 2.4M

Universal Grease Filter

Carbon Filter KLF 60/80

171 mVh

132 mVh

Number

Performance

Data

234 mVh

167 mVh

647 000 020

647 000 012

647 000 010

660 951 157

610 899 421

17

Page 18

Faults

In case of any enquiries and faults, please call AEG After-Sales Service;

AEG Domestic Appliances Limited Head Office:

217 Bath Road

Slough, Berks SL1 4AW

Tel: 01753 872506

Telefax: 01753512271

AEG Northern Service Centre: AEG Scottish Service Centre:

Unit 20, Haigh Park

Haigh Avenue

Stockport

GL Manchester SK4 1QR

Tel: 0161 487 2205

Telefax: 0161 474 1191

Service Appointments

Bristol: 01179 252880

Norfolk: 01603 765515

When calling please state the following

1. The model number

Block 11, Unit 1

Dundyvan Industrial Estate

Coatbridge

Lanarkshire ML5 4AQ

Tel: 01236 440387

Telefax: 01236 440256

2. The E-Nr.

3. The F-Nr.

The manufacturer reserves the right to make alterations in design

and colour in the interests of technical development without prior

notice.

18

Page 19

AEG Hausgeräte AG

Postfach 1036

D-90327 Nürnberg

© Copyright by AEG

H 260 251 240

L361C Ed.06/95

Loading...

Loading...