Page 1

FULLY AUTOMATIC

WASHER-DRYER

LAVAMAT 2200 I W-D

Instruction booklet

Subject to alteration

12498.881/^,

11 12/97

AEG

TW/E

AEG

2963

Page 2

Index

Servicing

Page 3- 4

Page 5 Technical specifications

Page 6

Page 7-12

Page 13

Page 14-17 Use of controls

Page 19-20

Page 21-22

Page 23-24

Page 26-28

Page 29-30

Page 31-32 Hints on washing and drying

Page 33-34

Page 35-36

Page 37-39 Door Reversal & Building Under

Page 40-43

Warnings

Your machine

instaiiation instructions

The control panel

The washing and drying programmes

Use of detergent and additives

Washing 4 kg of white cotton at 95°C

Washing 2 kg of delicate synthetic fabrics at 40*^C

Drying 2.25 kg (5 lb) of cotton

Maintenance

Cieaning the filter

Servicing

tn case of any enquiries and fauits, please cali AEG After-Saies Service:

Southern Service Centre

217 Bath Road

SLOUGH

Berkshire

SL1 4AW

Tel: 0753 872506

Scottish Service Centre

Block 11, Unit 1,

Dundyvan Industrial Estate

COATBRIDGE

Lanarkshire ML5 4AQ

Tel: 0236 440387

When calling please state the following:

1. The model number

2. The Prod.'No.

3. The Ser.-No.

Northern Service Centre

Unit 20

Haigh Park

Haigh Avenue

STOCKPORT

Gt. Manchester

SK41QR

Tei: 061 487 2205

The manufacturer reserves the right to make alterations in design and colour in

the interests of technical development without prior notice.

43

Page 3

Servicing

■ PROBLEM • CAUSE ► SOLUTION

■ THE MACHINE DOES

NOT DRY

■ THE DOOR DOES NOT

OPEN

If, after the above checks, there is

still a fault, call your nearest AEG

Service Centre.

Please make sure you give the model

and serial number of the appliance.

This information can be found on the

rating plate (see picture), or on the

guarantee certificate.

Original spare parts can be

purchased from AEG Spare Parts on

Slough 0753 872550.

In-guarantee customers should ensure

that the above checks have been

made as the engineer will make a

charge if the fault is not a

mechanical dr electrical breakdown.

Please note that proof of purchase is

required for any in-guarantee service

calls.

• A drying programme

has not been selected

• The cold water tap is ► Turn the tap on

not on

• The drainage filtei' is

clogged page 35)

• The machine is

overloaded

• The drying time Is not ►

adequate

• The safety device has

locked it

• Water in the wash tub

►

Select a drying

programme

► Clean the filter (see

►

Reduce the load

Refer to the programme

chart and set the

correct time (see pages

19-20)

>

Wait 1 - 2 minutes after

the end of the

programme before

opening the door

► Drain the water by

running the draining

programme (15)

Warnings

It is most important that this instruction book should be retained with the

appliance for future reference. Should the appliance be sold or transferred

to another owner, or should you move house and leave the appliance,

always ensure that the book Is supplied with the appliance In order that

the new owner can get to know the functioning of the appliance and the

relevant warnings.

This appliance Is designed to be

operated by adults. Children should

not be allowed to tamper with the

controls or play with the product.

It Is dangerous to alter the

specifications or attempt to modify

this product in any way.

Any electrical work required to install

this appliance should be carried out

by a qualified electrician or

competent person.

Any plumbing work required to Install

this appliance should be carried out

by a qualified plumber or competent

person.

This product should be serviced by an

authorised AEG Service Centre, and

only genuine spare parts should be

used.

Care must be taken to ensure that the

appliance does not stand on the

electrical supply cable.

Always unplug the appliance and turn

off the water after use.

Do not overload the appliance. See

relevant section in Instruction book.

Always look through the glass door to

check if water has drained before

opening the door. If water is present

do not open door before draining the

water. If in doubt, refer to your

instruction book.

This appliance Is heavy. Care should

be taken when moving it.

All packing and transit bolts must be

removed .before use. Serious damage

can occur to the product and to

property if this is not adhered to. See

relevant section in Instructions.

The glass door becomes very hot

during the washing cycle. Keep

children away from the vicinity of the

appliance whilst it is in operation.

Leave the porthole door slightly ajar

between washes to preserve the door

seal. '

Only wash fabrics which are designed

to be machine washed. Follow the

Instructions given on fabric labels

(see chart «Wash code symbols».

Before washing, ensure that all

pockets are empty and buttons and

zips are fastened. Avoid washing

frayed or torn articles and treat stains

such as paint, Ink, rust, and grass

before^washing. Underwired bras

must not be machine washed.

Any objects such as coins, safety

pins, nails, screws, stones or any

other hard, sharp material can cause

extensive damage and must not be

placed into the appjiance.

42

Page 4

Warnings

Servicing

Before selecting a programme or

changing an ongoing programme the

machine must be switched off by

depressing the ON/OFF push-button.

Garments which have been in contact

with volatile petroleum products

should not be machine washed. If

volatile cleaning fluids are used, care

should be taken to ensure that the

fluid is removed from the garment

before placing in the machine.

Wash small items such as socks,

laces, washable belts etc In a

washing bag or pillow case as it Is

possible for such items to slip down

between the tub and the inner drum.

Only use the advised quantities of

fabric softener. Damage to the fabric

can ensue if you over-fill. Refer to the

manufacturer’s recommendations of

quantities.

As some auvets and eiderdowns

should be washed/dried in large

commercial machines because of

their bulk, please check with the

manufacturer of the item before

washing in a domestic machine, even

if the dry weight of the item is within

the limit advised.

Only tumble dry fabrics which are

designed to be tumble dried.

If it is necessary to open the door

during the drying cycle, take care not

to touch the inside of the glass

porthole as this gets very hot.

Never tumble dry items that have had

contact with chemicals such as dry

cleaning fluid. These are of a volatile

nature and could cause an explosion.

Only tumble dry items which have

been washed in water or require

airing.

The users should always check that

they have not left their gas lighters

(disposable or otherwise) in their

clothing.

Before the drying cycle always

remove reusable plastic detergent

dispenser designed to be placed

inside the drum with the clothes as

the plastic used is not designed to

withstand the heat of the drying

cycle.

Pets and children have been known to

climb into washing machines. Please

check your drum before use.

If the machine is situated on a

carpeted floor, please adjust the feet

to ensure that air can circulate freely.

Under no circumstances should you

attempt to repair the machine

yourself. Repairs carried out by

inexperienced persons may cause

injury or more serious malfunctioning.

Contact your local AEG Service

Centre. Always Insist on genuine AEG

spare parts.

■ PROBLEM

■ THE MACHINE DOES

NOT DRAIN OR SPIN

■ THE MACHINE LEAKS

OR OVERFLOWS

■ THE MACHINE

VIBRATES OR IS NOISY

• CAUSE

• You have pressed the

«Rinse Hold» button

• The drain filter is

clogged

• The drain hose is bent

• The drainage system

pipes are blocked

• The drain hose

extension is incorrect

• The wash load

is unbalanced

• Too much washing ► Reduce the quantities

powder

• Unsuitable washing

powder

• The inlet hose ring is ► Tighten the ring (see

loose page 10)

• The detergent dispenser ► Clean the drawer and

drawer or recess are recess (see page 33-34)

clogged

• The end of the drain ► Position the drain hose

hose is not securely correctly

positioned

• The internal packing

has not been removed

• The machine is not Adjust the feet (see

level page 12)

• The machine is in

contact with the wall or

furniture feet

• The washing load is

badly distributed

• The machine is ► Run the draining

overloaded programme (15), reduce

► SOLUTION

► Press this button again

to drain the water

► Clean the filter. Before

doing this see page 35 '

► Straighten the hose out

► Consult a qualified

plumber

^ Consult a qualified

plumber

► Redistribute the clothes

inside the drum to ailow

the machine to spin

of washing powder

► Only use washing

powder suitable for

automatic machines

► Remove internal

packing (see p. 7)

^ Move the machine; it

should rest freely on its

► Remember to shake out

large items (e.g. sheets)

when loading

the load and continue

41

Page 5

Servicing

Technical specifications

Certain problems are due to lack of simple maintenance or oversights and can

be solved easily without having to call the AEG Service Department.

PROBLEM

THE MACHINE DOES

NOT START UP

{with pilot light off)

(with pilot light on)

■ THE MACHINE DOES • The water taps are not on

NOT FILL

CAUSE

The On-Off button is

not pressed

The door is not closed

properly

The appliance is not

plugged in

There is no electric

supply from the wall

socket

The programme selector

is not correctly

positioned

No water is entering the

machine

• The water supply has

been cut off supply is restored

• The inlet hoses are bent

• The water pressure is

too low

• The water inlet filter is

clogged

► SOLUTION

► Press the On-Off button

► Close the door

► Plug the appliance in

► Check the fuse

>

Consult a qualified

electrician

► Turn the programme

selector to the required

programme

^ See solutions to the

problem: THE MACHINE

DOES NOT FILL

►

Turn the taps on

►

Wait until the water

►

Straighten the bend out

►

If this occurs often.

consult a qualified

plumber

►

Clean the filter (see

page 35)

Dimensions

Width

Height

Depth

Electrical connection

Voltage 220/240V - 50Hz

Maximum power

absorbed 2550 W (13A)

Water pressure

Minimum (hot)

Minimum (cold)

Maximum

Maximum recommended

load for washing

Cotton, linen

Synthetics,

delicate fabrics

Wool

Maximum recommended

load for drying

Cotton, linen 2.25 kg (5 lb)

Synthetics 1.5 kg (3 lb)

Spin speed

Maximum

60 cm (23.6”)

82 cm (32.3”)

54 cm (21.3”)

5 psi

7 psi

110 psi

4.5 kg (10 lb)

2 kg (4.5 lb)

1 kg (2.2 lb)

1200 r.p.m.

The washing programme "2" at 60°C and

the drying programme "cupboard dry" are

the references programmes for the Energy

label according to EEC Directive 92/75.

Consumptions to wash and dry a full

capacity wash load (4,5 kg cotton items) at

60°C, degree of drying required "cupboard

dry": 4.40 kWh, 134 litres.

■ THE MACHINE • The end of the drain

EMPTIES AS IT FILLS

40

hose is too low

• The end of the drain

hose is submerged in

water submerged

• Drain pipe without

vent-hole

Position the drain hose

►

at the correct height

(between 60 and 90 cm)

The end of the drain

►

hose must NOT be

►

Consult a qualified

plumber

Page 6

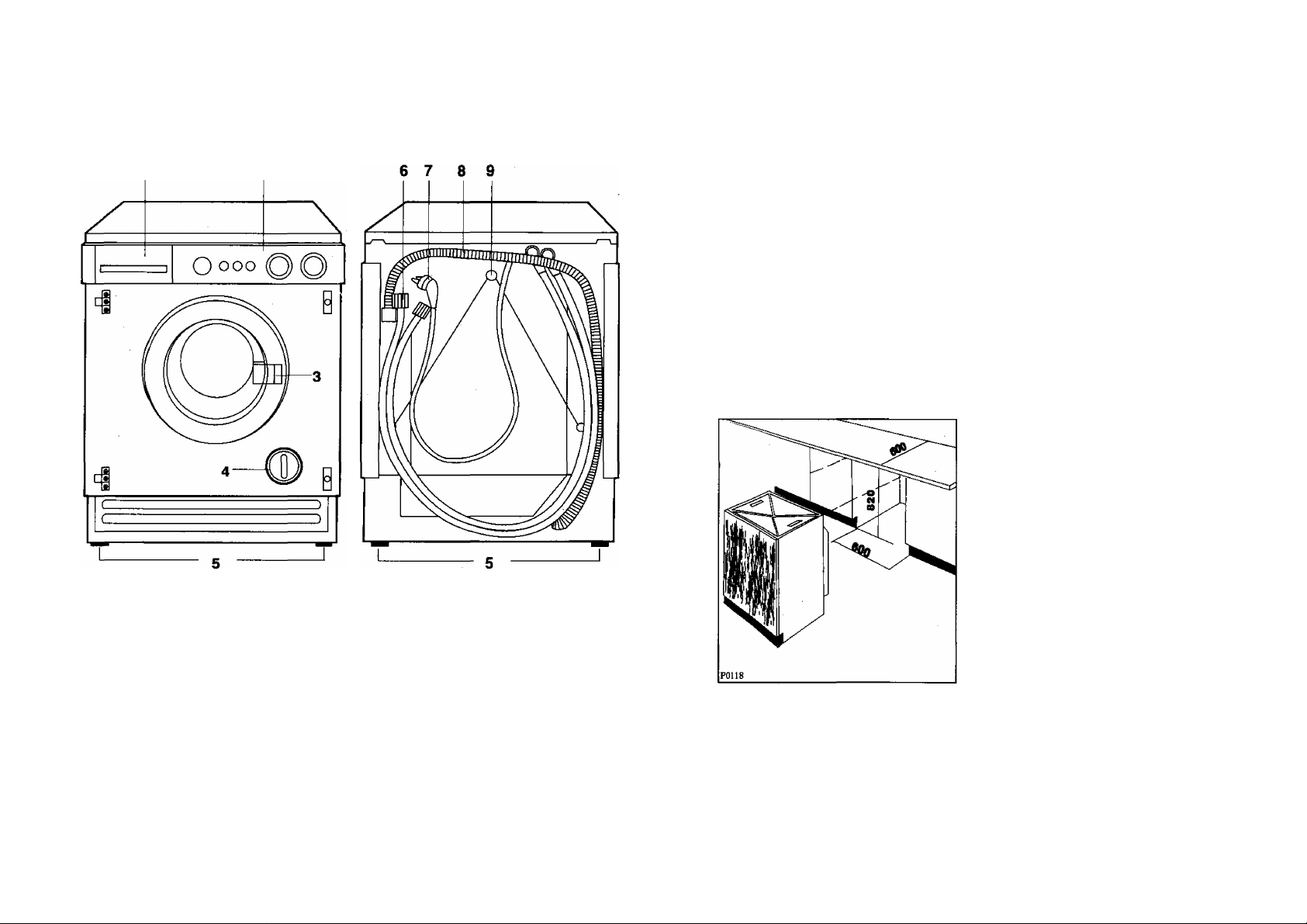

Your machine

Door reversal & building-under

Instructions for building in

under a counter

This appliance is designed to be built

Into a kitchen unit due to its standard

dimensions.

The machine should be inserted into

a recess having the dimensions

shown in the picture, making sure

that the fill and drain hoses are not

bent or kinked in such a way as to

obstruct the normal water flow.

As for water & electricity connection,

please follow the rules given in this

operator's handbook.

Furthermore, we strongly recommend

that the water & electricity supply cut

off controls remain easily accessible.

1 Washing powder dispenser drawer

2 Control panel

3 Door catch

4 Drain Filter

5 Adjustable feet

6 Water inlet hoses

7 Mains lead with plug

8 Drain hose

9 Transport safety screws

39

Page 7

Door reversal & building-under

Installation instructions

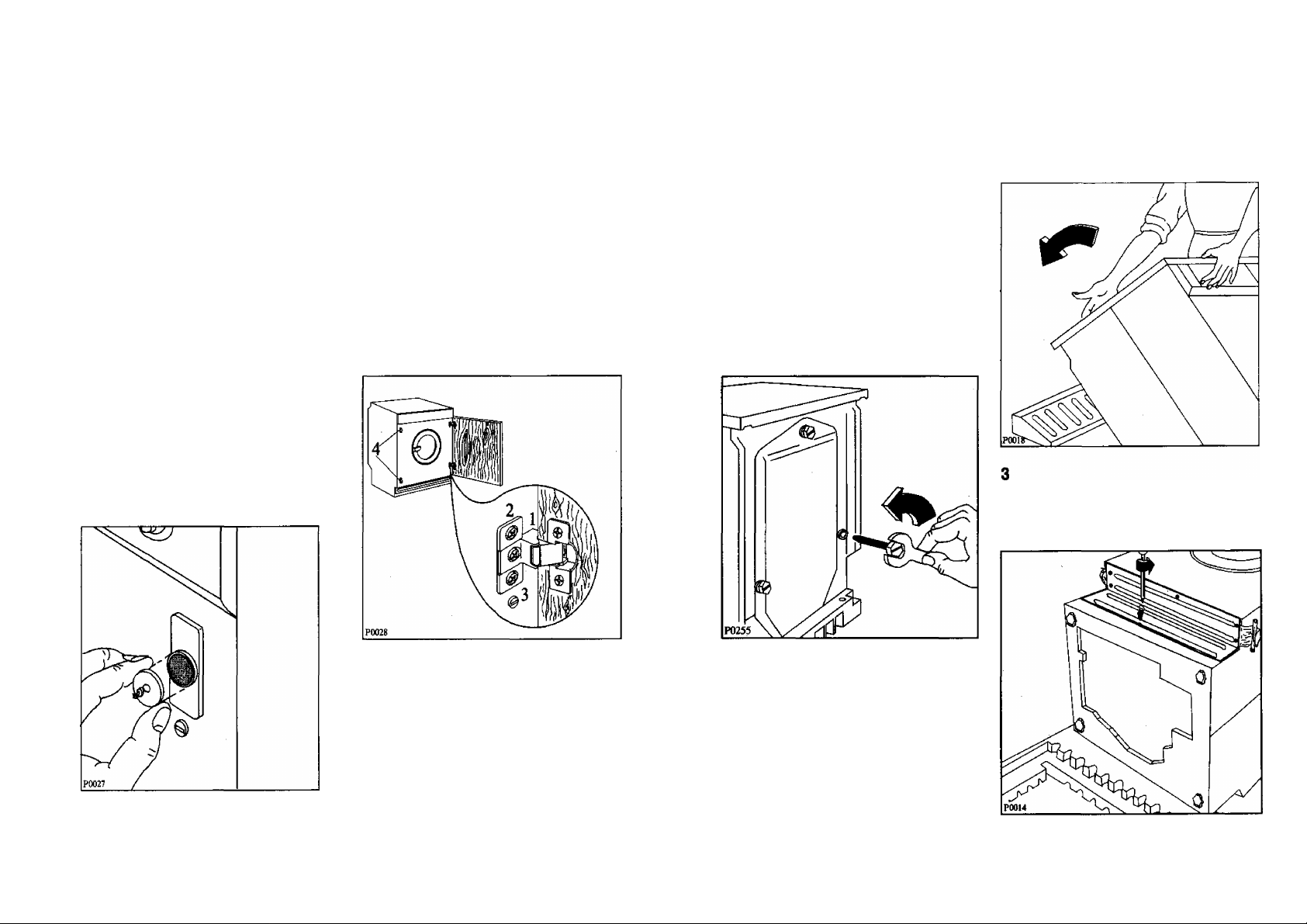

Mounting the door

Now fix the hinges to the machine by

means of the M 5 x 8 mm screws. To

compensate for possible uneven

thickness of the door the hinges can

be adjusted horizontaiiy.

To aiign the door perfectiy it may

sometimes be necessary to adjust the

height of the piates {2). This can be

done by ioosening the piastic screw

(3).

Counter-Magnet (5)

The door is kept ciosed by a

magnetic closure.

To enabie the ciosure to operate a

counter-magnet must be screwed into

the door inner side (steei disk with

rubber ring).

its position must correspond with the

magnet on the appiiance (see

picture).

Change of door opening

direction

Shouid a change of the opening

direction to the left side be required,

operate as foitows:

• Unscrew the door magnet (4) and

the rubber buffer (4) and take out the

plastic inserts.

• Fit the hinge fastening piates (2)

on the right side.

• Fit the magnet, the rubber buffer

and the piastic inserts on the ieft

side.

Caution

Before starting the machine up, the

packing must be removed as follows.

Note

You are advised to keep ali the

packing for re-use in case the

machine has to be transported again.

1

Using a spanner unscrew and remove

the rear right screw.

Lay the machine on its back making

sure that the hoses are not squashed.

Remove the polystyrene base and

take off the bottom panel by

unscrewing the central screw.

38

Page 8

Installation instructions

Door reversal & building-under

Carefully remove the right polythene

bag.

Carefylly remove the central and left

polythene bags.

6

Re-fit the bottom panel using the 4

screws supplied with the booklet and

the previously removed screw.

Set the machine upright and unscrew

the two remaining rear screws.

Preparation and assembiy of

the door

It is possible to change the door

opening side so as to match it

perfectly with the rest of the kitchen

furniture.

The machine is originally pre-arranged

for assembly of a door with right side

opening.

in this case it is sufficient to screw-in

on the door the two hinges (1) and

the oounter-magnet (5) in the right

position.

To mount the hinges on the door it is

necessary to drili 2 holes (dia. 35 mm,

depth 14 mm) on the door’s inner

side.

The distance between the hoies must

be 416 mm.

The dimension (B) (from upper edge

of the door to the center of the hole)

cannot be given, since it depends on

the adjacent cabinets’ dimensions.

The required dimensions are given in

the picture.

The hinges will be fixed to the door

by means of the 4x16 mm screws.

Cabinet’s door

The dimensions of the cabinet’s door

shouid be:

width

thickness

The height (C) cannot be given, since

It depends on the height of the

adjacent furniture, e.g. height of the

kick plate of the kitchen unit.

if necessary, the piastic seaiing

profiles underneath the controi panei

can be removed by unscrewing the

two screws.

595-i-3 mm

16 to 22 mm

37

Page 9

Cleaning the filter

Installation instructions

Warning

When the appliance is in use and

depending on the programme

selected there can be hot water in the

filler. Never remove the filter during a

wash cycle, always wait until the

appliance has finished the cycle, and

is empty. When replacing the filter,

ensure it is securely retightened. This

will prevent leaks and also stop

young children being able to remove

the filter.

The water inlet filters

If your water is very hard or contains

traces of lime deposit, the water inlet

filters may become clogged.

It is therefore a good idea to clean

them from time to time.

Turn off the water taps. Unscrew the

water inlet hoses.

Replace the filters and tighten up the

inlet hoses.

8

Slide out the 3 plastic pins and stop

the holes with the plastic plugs

supplied with the instruction booklet.

Your new AEG washing machine has

been designed to be permanently

plumbed in to your home’s water

supply and drainage system. How

ever, if this is not possible, it may be

connected to suitable existing taps,

with the drain hose discharging into a

sink.

The appliance has two inlet valves,

hot and cold, with female 3/4” BSP

thread connectors. If this connection

size is not compatible with the

plumbing of the existing installation,

a variety of connectors are available

from good hardware stores and

plumbers merchants to suit most

domestic plumbing. Any alterations to

your existing plumbing must be

carried out by a competent person, or

qualified plumber.

10

The inlets on the back of the

appliance are colour coded, blue for

cold, red for hot.

Before connecting the hoses be sure

to fit the mesh filters supplied as per

diagram.

If only a cold water supply is

available, connect the two hoses to a

cold water outlet by means of a «Y»

connection piece.

Installation should comply with local

water authority and building

regulations’ requirements.

The appliance must be given a

separate cold water supply and not

be connected to a mixer tap, a single

outlet water heater or a booster

pump. A minimum water pressure of

7 psi is required for safe operation of

the appliance.

If you cannot make the cold water

connection direct from the rising

mains, you may be able to operate

the appliance from your cold water

storage system.

36

Page 10

Installation instructions

Cleaning the filter

There should be a minimum distance

of 5.02 m (16V2 ft) between the

appliance’s inlet and the bottom of

the tank.

There will be sufficient pressure for

the hot water supply from the hot

water cylinder if the height between

the appliance’s inlet and the bottom

of the cold water storage cistern (not

between the appliance and hot water

cylinder) is at least 2.74 m (9 ft).

11

Set the hose correctly by loosening

the ring nut. After positioning the

Inlet hose, be sure to tighten the ring

nut again to prevent leaks.

12

if you intend the drain hose from the

machine to empty into a sink, make

sure the sink is empty and that the

plug hole is not blocked.

If the machine is permanently

plumbed in, hook the end of the hose

into a standpipe installed for the

purpose.

The standpipe must have an internal

diameter of at least 30 mm (1 Vz in),

in order that there is an air gap

between the drain hose and

standpipe. Make sure, that it is

designed in such a way, that the end

of the drain hose cannot be covered

with water.

Important: Before connecting up the

machine to new pipework or to

pipework that has not been used for

some time, run off a reasonable

amount of water to flush out any

debris that may have collected In the

pipes.

Whether discharging into a sink or a

standpipe check that the end of the

drain hose is neither too high nor too

low. The top of the curve In the

hose’s end should be no more than

90 cm (35.4”) and no less than 60 cfn

(23.6”) above floor level.

The water drain filter

A clean filter is important for correct

functioning of the machine, and

should therefore be cleaned after

every wash.

Place a container underneath to

catch any spillage.

Unscrew the filter.

If the filter is blocked and the

machine is unable to drain you will

need to drain the water from the

machine at this stage.

To do this, unhook the drain hose

from the standpipe or sink and hold

the end of the hose over a bowl on

the floor. The water should drain by

gravity into the bowl. When the bowl

is full, hook the hose back up and

empty the bowl. Repeat the procedure

until the water stops flowing out.

Clean carefully under a fast-running

tap.

10

35

Page 11

Maintenance

Installation instructions

Cleaning the drawer recess

Having removed the drawer, use a

small brush to clean the recess

ensuring that all washing powder

residue is removed from the upper

part of the recess. Replace the

drawer and run programme 4 for a

few minutes and then the drain cycle

15 to clear any residues.

The dangers of freezing

If the machine is exposed to

temperatures below 0°C, certàin

precautions should be taken.

Turn off the water taps and unscrew

the inlet hoses.

Select a wash programme and run for

a few seconds.

Unhook the drain hose from the rear

support and position the end in a

bowl. Run the draining programme for

a few seconds.

When you intend to start the machine

up again, make sure that the room

temperature is above 0°C.

13

Electrical connection

WARNING:

THIS APPLIANCE

MUST BE EARTHED

The manufacturer declines any

liability should this safety measure

not be observed.

If the plug that is fitted to your

appliance is not suitable for your

socket outlet, it must be cut off and

the appropriate plug fitted.

The cut off plug should be disposed

of to prevent the hazard of electric

shocks in case it should be plugged

into a 13 Amp socket in another part

of your home.

Important

The wires in this mains lead are

coloured in accordance with the

following code;

GREEN AND

YELLOW

BLUE

BROWN

If you fit your own plug, the colours

of the wires in the mains lead of your

appliance may not correspond with

the markings identifying the terminals

in your plug, this is what you have to

do:

Connect the green and yellow (earth)

wire to the terminal in the plug which

is marked with the letter «E» or the

earth symbol or coloured green,

or green and yellow.

EARTH

NEUTRAL

LIVE

GtjiMieai me blue (neutral) wire to the

terminal in the plug which is marked

with the letter «N» or coloured black.

Connect the brown (live) wire to the

terminal which is marked with the

letter «L» or coloured red.

The plug moulded on to the cord

incorporates a fuse. For replacement,

use a 13 Amp BS 1362 fuse.

Only ASTA approved fuses should be

used.

The fuse cover/carrier must be

replaced in the event of changing

fuse.

The right fuse cover/carrier colour is

the one shown by the coloured insert

at the base of the plug.

The plug must not be used if the fuse

cover/carrier is lost.

A replacement cover/carrier must be

obtained from AEG Service Agents.

This appliance complies with

a

- 73/23 EEC of 19.2.73 (Low Voltage

- 89 / 336 EEC of 3.5.89 (Electromagnetic

the following E.E.C. Directives:

Directive) and subsequent modifica

tions;

Compatibility Directive) and subse

quent modifications.

34

11

Page 12

Instaltation instructions

Maintenance

14

Level the washing nnachine by

loosening or tightening the feet.

Accurate levelling prevents vibration,

noise and displacement of the

machine during operation. After

levelling the machine, secure the feet

by tightening the ring nuts.

Some vibration is inevitable,

especially if mounted on a wooden

floor.

sprung wooden floors are particularly

susceptible to vibration. For advice,

consult a builder. If possible, always

place the machine on a solid floor.

Note

Please ensure that when the

appliance is installed It is eaSily

accessible for the engineer in the

event of a breakdown.

AM plumbing and efectrical work

required to Install this appliance must

be carried out by competent persons

or qualified plumbers or electricians.

Successful washing and smooth

running of your machine depend on a

series of routine maintenance

operations which should be carried

out from time to time.

Important

Before carrying out any maintenance

or cleaning you MUST disconnect the

appliance from the eiectricity supply.

Décalcification

The water we normally use contains

lime. From time to time, and more

often for hard water, it is a good idea

to use a water softening powder in

the machine. Add this powder

according to the manufacturer’s

instructions. This will prevent the

formation of lime deposits.

After each wash

Leave the door open for a while.

This helps prevent mould and

stagnant smells forming inside the

appliance.

Cleaning the drawer

From time to time the washing

powder and additive dispenser drawer

should be cleaned.

under a tap.

The upper part of the additives

compartment can be removed for

easier cleaning.

12

Externai cieaning

Use soap and water only and then dry

thoroughly.

33

Page 13

Washing hints and drying

Do not leave the damp laundry load

in a heap too long before drying.

Avoid drying dark clothes with light

coloured fluffy items such as towels

as these can attract the fluff.

If you overdry the laundry, besides

wasting energy, any subsequent

ironing may become more difficult

because the fabric couid be heavily

crumpled.

Remove the laundry when the

appliance has finished drying.

To avoid a static charge when drying

is completed, use either a fabric

softener when you are washing the

laundry or a fabric conditioner

specifically for tumble dryers.

For drying, follow the indications

given on the manufacturers’ labels.

Drying at high

e

temperature

Drying at reduced

□

temperature

Do not tumble dry

The controi panei

1

Programme chart (inside the

drawer handle)

2

Dryer indicator light

3

Drying time control

4

«Heavy soil» push button

5

«Rinse hold» push button

6 On/Off-push-button

7

Operating pilot light

8 Thermostat control

9

Programme control

Once you have finished using the

machine, you are advised to unplug it

and turn off the water taps.

32

Symbols

Symbols provided on the control

panel have the following meaning:

LU Prewash compartment

UU Wash compartment

® Softener compartment

13

Page 14

Use of controls

Washing hints and drying

1

Washing powder dispenser

drawer

The washing powder or liquid and

additives must be placed in this

drawer before starting the

programnne.

A pull-out programme chart is

available inside the drawer handle.

Dryer indicator iight

This light will come on when the

machine is drying.

Drying time control

Press the control knob to pop it out.

This control allows you to choose the

desired drying time according to the

type and quantity of the load to be

dried. It can also be adjusted whilst

the machine is in operation to either

increase or reduce the drying time.

The control incorporates two drying

cycles, both of them up to 80 minutes

duration. The

for cotton and linen items is marked

with a solid line, and the low

temperature range for synthetic

fabrics with a hollow line.

high temperature range

Heavy soil button

By pressing the heavy soil button, the

machine will take in cold water only

on programmes with a water

temperature of 60®C and hotter.

These would normally be hot and

cold, or hot fill only.

The water is then gradually heated to

the required temperature.

The effect is to improve the overall

wash performance, particularly on

biological stains such as egg, blood

and grass stains, and heavily soiled

fabrics, since the longer «cool-soak»

phase as the water heats up provides

the right conditions for the powder

and the water temperature to interact,

and achieve the best possible results.

Rinse hold button

Press this button to leave the water

in the wash tub after the wash cycle

is completed.

This works only on mixed fabrics,

wool or delicate/synthetic

programmes.

The clothes are left suspended in

water after the final rinse to prevent

the formation of creases.

Depress the button to drain the water.

Do not overload the machine. Weigh

the laundry the first few times you

use the appliance.

The average weights of the most

common items are listed below as a

guide:

1000 g = 1 kg (2 lb)

sheet

pillow case

tablecloth

serviette

tea towel

linen hand towel

towelling hand towel

towelling bath towel

bath robe

man’s shirt

apron

Load the laundry loosely alternating

large items with small ones.

Sort the laundry according to the type

of fabric, colour-fastness and how

dirty it is.

Avoid washing unhemmed or torn

items as they may unravel.

Before washing, empty all pockets of

small objects which may have been

left inside (coins, keys, screws etc.),

as these could damage the drain

pump.

When washing curtains, remove the

hooks.

Close poppers and zips and fasten

loose buttons.

It is essential to wash new coloured

items separately when washing for

the first time.

700-1000 g

100- 200 g

400- 500 g

50- 100 g

70- 120 g

100- 150 g

150- 250 g

700-1000 g

1000-1500 g

200- 300 g

150- 200 g

When washing fabrics requiring

different wash temperatures together,

always select the lowest temperature.

White items should not be washed

with coloured items.

Very small items (handkerchiefs,

ribbons, socks etc.) should be washed

in a washing bag or a pillow case.

Use a good quality detergent suitable

for automatic washing machines.

Use the correct quantities of

detergent.

For wool, use gentle detergents only

in small quantities.

Bleach is very corrosive; it should be

used with care and kept out of reach

of children.

Some stains such as fruit, wine,

grass, rust etc. are difficult to remove

and should be treated before washing

with specific products which can be

found in most household shops.

In some cases it may help to soak

the stain before washing with a

special pre-soak product or biological

detergent.

Only wool marked «Pure New Wool washable, preshrunk» can be washed

in the machine using the wool

programme: other types of wool

should be washed by hand or dry

cleaned.

When drying always load well spun

laundry. The higher the spin speed

the lower is electric energy

consumption and the shorter is the

drying time.

14

31

Page 15

Drying 2.25 kg (5 tb) of cotton

Select the time

Following indications given in the

programme chart, turn the selector

dial clockwise on the 40 mins {High

Temperature Range).

Start the machine

Switch on the ON-OFF switch.

The pilot lights and

illuminate and the machine will start

to work.

Stopping the machine

At the end of the programme the

machine stops automatically and the

Dryer Indicator Light will go out.

Depress the ON-OFF button, the light

floes out.

If the laundry is still too damp, select

a further brief drying time, bearing in

mind that during the last 8 minutes

the appliance carries out a cooling

and anti-crease phase.

Use of controls

6

On/Off button

By depressing this button the

machine starts operating. When it is

depressed again, the machine stops.

Operating pilot light

This lights up when the ON/OFF

button is depressed and goes out

when the button is pressed again.

8

Adjustable thermostat dial

Press the dial to pop it out and then

turn to the required temperature.

The most suitable temperatures for

all types of laundry are shown In the

programme charts.

The temperatures shown can be

reduced and even a cold wash can be

used (dial to position ^ ) when your

laundry Is only slightly soiled or

particularly delicate.

In this way you will also save

electricity.

Programme control

To select the required programme,

press the knob to pop It out. Turn the

knob clockwise until the marker at

the top of the dial coincides with the

required programme letter.

Press the knob again if you wish to

return it to its original position.

30

15

Page 16

How and when to use the controls

Drying 2.25 kg (5 lb) of cotton

Start

After loading the laundry and placing

the washing powder or liquid and

additives into the appropriate

compartments, before starting up the

machine check that:

— the appliance is plugged in

— the water supply taps are turned

on

— the drain hose is correctly and

securely positioned

— the door and the washing powder

dispenser drawer are closed.

Depress the required pushbutton(s).

Select the washing temperature via

the adjustable thermostat dial.

Select the required programme by

turning the programme dial clockwise.

Set the drying time if you are using

the Wash ’n’ Dry option.

At this stage, press the ON/OFF

button to start the programme up.

The pilot light will come on and the

programme will start.

Stop

When the programme has finished,

the programme dial will be in the «•»

position and the machine will

automatically stop.

If you have depressed the «Rinse

Hold» button, the water remaining In

the wash tub must be drained by

pressing again the same button

before opening the door.

If necessary, stop the machine by

pressing the ON/OFF button again.

At the end of the programme, all the

buttons must be reset to the «rest»

position {not depressed).

The washing programmes

This washing machine has a wide

range of programmes for optimum

washing of all types of fabrics.

The differences between the

programmes are the rotation rhythm

of the drum, the washing

temperature, the water level, use or

not of the spin cycle etc.

Drying

The dryer part of this machine is a

Turbo Condenser Dryer.

During the drying cycle the machine

uses a small amount of water.

The clothes are dried by means of a

continuous flow of hot air which as it

passes through the drum, gradually

reduces the moisture in the laundry.

The moisture is then condensed

within the machine. The condensed

water is then drained away, together

with the cooling water, through the

drain hose. There is no need to

provide special ventilation in the

room in which the machine is

installed.

The duration of the preset drying time

may be shortened or extended during

the drying cycle. Do not extend or

shorten the drying period within the

8-0 minute cycle. During this time

both the machine and the laundry are

cooling off.

During a power failure it is advisable

to remove the laundry from the

machine. After a short mains power

failure the machine will continue with

the selected programme once the

power is restored.

You have for example just machinewashed and spun at 1200 rpm 4.5 kg

(10 lb) of laundry.

They are cotton fabrics of medium

weight which you want to iron as

soon as they are dry.

Switch off the machine.

Then remove the laundry from the

appliance and divide the items to

obtain two loads of approx. 2.25 kg

(5 lb) each.

1

Load the laundry

Load the items you have to dry one at

a time, shaking them out loosely and

close the door.

Select the programme

Turn the programme dial clockwise

until number 6 on the dial coincides

with the grey dot.

16

29

Page 17

Washing 2 kg of synthetic fabrics at 40**С

How and when to use the controls

6

Start up

Check that:

— the appliance is plugged in

— the water taps are on

— the drain hose is correctly

positioned

Then push the ON/OFF- button ®

The pilot light will come on and the

machine will start.

At the end of the programme

The machine automatically stops.

The door Is controlled by a safety

device which releases 1 • 2 minutes

after the end of the progr^me.

Push the ON/OFF-button © again

and the pilot light will go out.

When the programme has finished

you are advised to unplug the

appliance and turn off the water taps.

Important

The washer-dryer operates on the

condensation principle. For this

reason, when drying takes place, the

water tap must be open and the drain

hose must be hooked over the sink If

the machine Is not permanently

plumbed In. The dispenser drawer

must be fully closed.

Only laundry washed in water should

be dried in this machine. In particular,

the following fabrics should not be

loaded into the machine:

Clothes which were dry-cleaned or

cleaned with chemical solvents;

Woollens or mixed woollens which

will shrink with heat;

Extremely delicate fabrics such as

silk and delicate synthetics;

Sponge, rubber and similar items;

Fibre glass items;

Fabrics tending to fray.

Wash ‘n’ dry

It is possible to programme the

machine to run automatically from

the wash programme through to the

drying programme without pausing. In

this case, the wash load must be no

more than 2.25kg (5 lb) for cottons

and a maximum of 1.5kg (2.2 lb) for

synthetics. The drying time should be

selected at the beginning of the wash

programme. This is possible on all

programmes except the Wool, Silk

and Délicates (10-11-12-13-14

programmes).

Drying times

The drying times of all fabrics will

depend on the extent to which they

have been spun as well as the fabric

characteristics. The higher the spin

speed the shorter the drying time.

To alleviate creasing, care should be

taken not to overdry clothes. All

clothes should be removed from the

drum as quickly as possible after

completion of a drying cycle.

Important

Polycottons of less than 70% cotton

should NOT be dried using «High

Temperature» drying.

Only polycottons with more than 70%

cotton content should be dried using

programme 6.

If you are not sure of the cotton

content use «Low Temperature»

drying.

28

17

Page 18

Wash code symbols

Washing 2 kg of synthetic fabrics at 40°C

The familiar wash code symbols

which are found on the care labels in

most clothes will gradually disappear

and a new set of codes will be

introduced. This change Is due to

changes in fabrics and detergents

Old Symbol New Symbol Wash Action Fabric

Ш

yJL é

\Ш

vSU é

yJLy

\Ш

\ш

Ш7

No longer used. White Nylon, Polyester/Cotton mixtures now included in

\Ш

Normal (Maximum) White Cotton or Linen without

Normal (Maximum) Cotton, Linen or Viscose without

Reduced (Medium) Nylon, Polyester/Cotton, Viscose

Normal (Maximum) Cotton, Linen or Viscose

and because people are tending to

use fewer programmes and mix

fabrics in one load. The change will

bring the codes into line with the

labelling used in the rest of Europe.

Special Finishes

Special Finishes

Colourfast at 60° C.

with Special Finishes:.

Cotton/Acrylic Mix.

Colourfast at 40°C but not 60°C.

Measure out the additives

Pour the softener, if required, into the 40®c.

compartment marked ^ ; do not

exceed the MAX level. 5

Close the drawer gently. programme

Select the temperature

Turn the adjustable thermostat dial to

ti/

wZw

\40¥

\Ш

я

\Ш

The new symbols have been used on the Programme Guide of this machine,

and are listed in the Programme Charts on page 19 and 20.

The new wash symbols will also appear on the side of Washing Powder

packets.

18

Ш

No longer used. Silk now included in

printed acetate included in .

No longer used.

Reduced (Medium) Acrylics, Acetate, Triacetate, Wool

mixes, Polyester/wool blends.

Much Reduced Wool, wool mixes. Silks.

(Minimum)

Turn the programme dial clockwise

until number 10 on the dial coincides

with the grey dot.

27

Page 19

Washing 2 kg of synthetic fabrics at 40**C

Programmes for cotton and iinen

Suppose you have 2 kg of synthetic

fabric laundry to wash. They are

rather deiicate fabrics and should not

be washed at a high temperature.

1

Load the iaundry

Open the door by puiiing the catch

outward. Load the items to be

washed one at a time and ciose the

door.

Measure out the washing

powder

Pour the washing powder into

compartment uu , the main wash

compartment.

Washing programmes

Recommended load: max. 4.5 kg (10 lb)

PROGRAMME

\m7

BOILWASH

with prewash

95/ BOILWASH I

HOT

WASH

(*) For an economy wash, if your laundry is not heavily soiled, you can select 60° instead

of 95°C.

Water filling: 40°/50°C programmes • cold water filling; 60°C programmes - hot and cold

filling. 95°C programmes - hot water filling only, unless the heavy soil button is used.

Wash ’n’ Dry Programmes

Recommended load: max. 2.25 kg (5 lb} drying only.

Do NOT use ball dispensers on Wash ’n' Dry programmes. The automatic drying can

be used on programmes 1,2,3,4, Sand 8 by setting the drying time at the beginning

of the wash programme.

DEGREE

SOIL

Heavy

Normal

Normal

COMPARTMENTS

OF

($ if required}

TO USE

u

Ujifi

PROGRAMME

AND TEMP.

DIAL

POSITION

1

95

2

95

T

60

DESCRIPTION

Prewash at 40°C

Wash at 95°C

5 rinses

Spin

Wash at 95°C

5 rinses

Spin

Wash at

5 rinses

Spin

26

Energetic drying programme

Fabric type/ Programme

Spin speed

Cotton and

linen Q

(Long spin at

1200 rpm)

The drying times indicated in this table are for drying cotton towels. By varying the

composition of the load, the drying times indicatecTwill vary.

(0-80 mins ■

Quantity Drying time

2.25 Kg (5 lb)

2.0 Kg (4 lb) 35-45 mins

1.5 Kg (31b) 30-40 mins

1.0 Kg (2 lb) 25-30 mins

■ indicated by continuous line (High Temp.)

Iron dry Cupboard-dry

40-50 mins 60-70 mins

55-65 mins

40-50 mins

35-40 mins

_____________________

19

Page 20

Programmes for synthetics, silk and wool

Washing 4 kg of white cotton at 95**C

Washing programmes

Recommended load: max. 2 kg (4.5 lb); wool max. 1 kg (2.2 lb) washing only.

(*) If the «Rinse Hold» button has been depressed the machine will not proceed

to the spin as indicated, untii the button has been reieased, but wiii have water ieft

in the drum.

PROGRAMME

AND TEMP.

DIAL

POSITION

12

30

13

14

DESCRIPTION

Wash at 30®C

3 rinses

Short spin (*)

3 rinses with

additive if required

Short spin (*)

1 rinse vifith

additive if required

Short spin (*)

PROGRAMME

QUICK

WASH

RINSES

CONDI

TIONER

DEGREE

COMPARTMENTS

OF

SOIL

Light

($ If required)

TO USE

6

Start up

Check that:

— the appliance is plugged in

—• the water taps are on

— the drain hose is correctly

positioned

Then push the ON/OFF- button CD

The pilot light will come on and the

machine will start.

At the end of the programme

The machine automatically stops.

The door is controlled by a safety

device which releases 1 - 2 minutes

after the end of the programme.

Push the ON/OFF-button O again

and the pilot light will go out.

When the programme has finished

you are advised to unplug the

appliance and turn off the water taps.

DRAIN

15

Draining of water

Wash ’n’ Dry Programmes

Automatic drying can be used on programme 7, by setting the drying time at the

beginning of the wash programme.

Delicate Drying Programme (0-80 mins ■ indicated by dotted line (Low Temp).

Fabric type/

Spin speed

Synthetics

(Short spin at

850 rpm)

The drying times given in this table are just an indication of the average drying times.

20

Programme Quantity

9

1.5 Kg (31b)

1.0 Kg (21b)

0.5 Kg (1 lb)

Drying time

Iron dry

Cupboard-dry

75-80 mins

50-60 mins

35-40 mins

25

Page 21

Washing 4 kg of white cotton at 95^C

Use of detergent and additives

Measure out the additives

Pour the softener, if required, into the

compartment marked® ; do not

exceed the MAX levei.

Close the drawer gently.

Seiect the temperature

Turn the adjustable thermostat dial to

95°C.

Select the programme

Choosing the right washing

powder

Always use a low lather powder. This

is important as too much lather

prevents the articles from being

properly cleansed and you may

damage the machine.

Use of washing powder

The washing powder should be

placed in the appropriate

compartments in the washing powder

dispenser drawer before starting the

programme.

How much detergent?

Your washing machine has a unique

water circulation system which runs

continuously. This means that it uses

detergent sparingly.

Initially you are advised to use less

than the quantity specified by the

detergent manufacturer.

Subsequently it is worth

experimenting to see if your laundry

comes out clean with smaller

quantities.

Powder residue left on the clothes at

the end of a wash indicates the use

of too much powder. If the drum is

only half-full, you can obviously use

less detergent.

24

The compartment marked with the

symbol (jj is for the prewash

powder (if required by the

programme).

The compartment marked with the

symbol uu is for the main wash

powder.

Turn the programme dial clockwise

until number 2 on the dial coincides

with the grey dot.

21

Page 22

Use of detergent, and additives

Washing 4 kg of white cotton at 95°C

Use of liquid detergent

Suitable liquid detergent can be used

instead of washing powder.

In this case a progrannme without

prewash must be selected.

Pour the liquid detergent into the

compartment ULI in the dispenser

drawer immediateiy before starting

the programme.

If the detergent has its own dispenser

ball, this should be used according to

the manufacturer’s instructions.

Use of liquid additives

Any liquid additives for softening or

starching the laundry must be poured

into the appropriate compartment of

the washing powder dispenser drawer

before starting the programme.

The compartment marked with the

symbol ^ is for softeners or

starching agents.

Concentrated additives MUST be

diluted before pouring in the

compartment.

Never exceed the MAX ievel.

Important

Before the drying cycle always

remove re-usable plastic detergent

dispensers designed to be placed

inside the drum with the clothes as

the plastic used is not designed to

withstand the heat of the drying

cycle.

Note

Once the dispenser is filled, close it

by pushing it in gently. This is

particularly important if you are using

fabric conditioner because if the

drawer Is slammed it will cause the

conditioner to enter the machine

prematurely.

Suppose you have 4 kg of normally

soiled laundry to wash. It is white

cotton and resistant to high

temperature washing.

Load the iaundry

open the door by pulling the catch

outward. Load the items to be

washed one at a time and close the

door.

Measure out the washing

powder

Pour the washing powder into

compartment Uii , the main wash

compartment.

22

23

Loading...

Loading...