Page 1

a-eberle

PQI-DA

Operating Manual

Software - Version:

PQI-DA

Power Quality Interface

& Disturbance Recorder

GB

PQI-DA Operating Manual

Edition 01

Version Feb. 2010

1

Page 2

a-eberle

PQI-DA

PQI-DA

Power Quality Interface & Disturbance Recorder

Operating Manual

Version: October 2009

Copyright 2003 by A. Eberle GmbH & Co. KG

Published by

A. Eberle GmbH & Co. KG

Aalener Straße 30/32

90441 Nuremberg

Germany

Tel.: +49 (0) 911 / 62 81 08 0

Fax: +49 (0) 911 / 62 81 08 96

E-mail: info@a-eberle.de

Internet: www.a-eberle.de

The company A. Eberle GmbH & Co. KG cannot be held liable for any damages

or losses resulting from printing errors or changes in this operating manual.

Furthermore, A. Eberle GmbH&Co. KG does not assume responsibility for any

damages and losses resulting from faulty devices or from devices altered by

the user.

PQI-DA Operating Manual

2

Page 3

a-eberle

PQI-DA

Inhaltsverzeichnis

Information: ................................................................................................................... 7

1. Technical Concept ...................................................................................................

1.1 Application .....................................................................................................8

1.2 Features of the Power-Quality-Interface & Disturbance Recorder ..................

1.3 Description ...................................................................................................

10

10

2. Application ............................................................................................................ 11

2.1 PQI-DA as a Recorder (Fault Recorder) ......................................................... 11

2.1.1 Recorder A ..............................................................................................................11

2.1.2 Recorder B ..............................................................................................................

2.1.3 Recorder C ..............................................................................................................

2.1.4 Events .....................................................................................................................

2.2 PQI-DA as System Component .................................................................... 16

12

14

15

3. Technical Data ...................................................................................................... 17

3.1 Standards ..................................................................................................... 17

3.2 Voltage inputs ...............................................................................................

3.3 Current inputs ...............................................................................................

3.4 Binary inputs (BI) ...........................................................................................

17

18

18

8

3.5 Binary outputs (BO) ......................................................................................

3.6 Limit value monitoring ...................................................................................

3.7 Measurement quantities ...............................................................................

3.8 Reference conditions ....................................................................................

3.9 Measurement data acquisition ......................................................................

3.10 Storage of measured values .........................................................................

3.11 Electromagnetic Compatibility .......................................................................

3.12 Electrical safety .............................................................................................

3.13 Operating voltages .......................................................................................

3.14 Power supply ...............................................................................................

3.15 Environmental conditions ..............................................................................

3.16 Data storage .................................................................................................

19

19

19

20

20

20

21

21

22

22

22

23

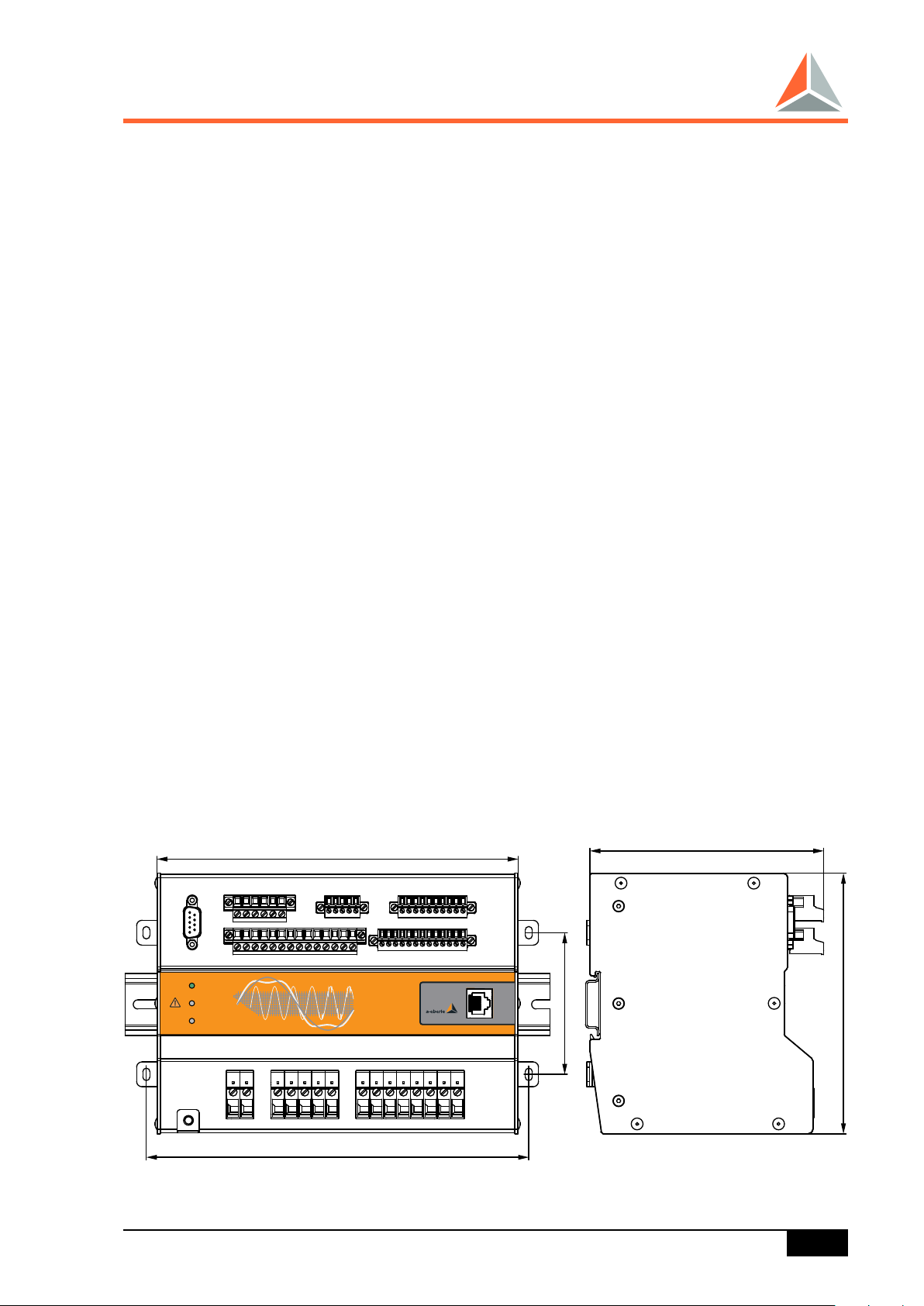

4. Mechanical Design ...............................................................................................23

4.1 Housing ........................................................................................................23

4.1.1 PQI-DA 4U / 4I .........................................................................................................24

4.1.2 PQI-DA 8U ...............................................................................................................

4.1.3 PQI-DA 4U/4I und 8U ............................................................................................

25

26

PQI-DA Operating Manual

3

Page 4

a-eberle

PQI-DA

5. Serial interfaces .................................................................................................... 28

5.1 RS232 interfaces .......................................................................................... 28

5.2 TCP/IP .........................................................................................................

5.3 RS485 Interfaces ..........................................................................................

5.4 E-LAN (Energy - Local Area Network) ...........................................................

5.4.1 Features ...................................................................................................................29

5.4.2 Configuration Information .........................................................................................

28

28

29

29

5.5 Time Synchronisation and Measurement Trigger ........................................... 32

5.5.1 Measurement trigger ................................................................................................33

5.6 Parameterisation ........................................................................................... 34

5.6.1 Parameterising the Device ........................................................................................34

5.6.1.1 Transformer configuration ........................................................................................ 34

5.6.1.2 Measurement range ................................................................................................

5.6.1.3 Network frequency ..................................................................................................

5.6.1.4 System time ............................................................................................................

5.6.1.5 Definition of measurement channels for interval data andevent-triggered measurement

data ......................................................................................................................... 35

5.6.1.6 Configuration of the recording of the measurement data ..........................................

34

35

35

35

5.7 Hardware-orientated device versions ............................................................ 35

5.8 Application Examples (a selection) ................................................................

5.9 Block diagram PQI-DA 4 U/4 I ......................................................................

5.10 Block diagram PQI-DA 8xU .........................................................................

36

37

37

6. Characteristics of the Voltage Supply ................................................................... 38

6.1. Limit Values Specified in EN 50160 ...............................................................38

7. Measurement Circuits ........................................................................................... 40

7.1 Connection Possibilities ................................................................................ 41

7.2 Current Transformer Connections .................................................................

7.2.1 PQI-DA Current Transformer Connection .................................................................43

7.2.2 PQI-DA Current Transformer Connection .................................................................

42

44

7.3 Voltage Transformer Connections .................................................................44

7.3.1 PQI-DA Voltage Transformer Connection..................................................................45

8. Management of Process Data within the Device .................................................. 46

8.1 Classification of the Data .............................................................................. 46

8.2 Monitoring the Voltage Quality and Managing the Process Data ....................

8.2.1 Overview ..................................................................................................................47

8.2.2 Terminology .............................................................................................................

8.2.3 Measurement Data Classes .....................................................................................

8.3 Events .......................................................................................................... 49

8.3.1 Start / Stop Events...................................................................................................50

8.3.2 Interval Events

8.3.3 Linking Events ..........................................................................................................

..........................................................................................................50

47

47

49

51

PQI-DA Operating Manual

4

Page 5

a-eberle

PQI-DA

8.4 Relative Frequency ....................................................................................... 51

8.4.1 Displaying the Week and Year Values ....................................................................... 51

8.5 Availability .....................................................................................................52

8.6 Adherence to the Specified Supply Voltage Range .......................................

8.7 Asymmetry ...................................................................................................

8.8 Harmonics ....................................................................................................

8.9 Flicker ...........................................................................................................

8.10 Frequency, Narrow Range ............................................................................

8.11 Frequency, Wide Range ................................................................................

8.12 Controls for Recording Measurement Data ...................................................

8.13 Interval Status Word .....................................................................................

8.14 Controls for the Event Evaluation ..................................................................

8.15 Event Filtering ...............................................................................................

8.16 Suppressing Interval Events ..........................................................................

8.17 Triggering of Fault Recorders A and B ...........................................................

8.18 Triggering of Fault Recorders A, B and C ......................................................

8.19 Parameterising the Fault Record ...................................................................

8.19.1 Fault Record Sequences ..........................................................................................59

52

54

54

54

55

55

56

56

57

57

58

58

58

59

8.20 Background Memory Recorders A and B ..................................................... 59

8.21 Supply Quality Signals ..................................................................................

60

8.22 Parameterising the Signal Output

8.23 Signal Output Operating Modes

.................................................................. 61

.................................................................... 61

9. Definition of the Measurement Quantities ............................................................ 62

9.1 Sampling, Synchronisation ...........................................................................63

9.2. Primary Sampling Values ..............................................................................

9.2.1 Deduced Sampling Values .......................................................................................64

9.2.1.1 External conductor voltages .................................................................................... 64

9.2.1.2 Neutral earth voltage ............................................................................................... 64

9.2.1.3 Phase voltages towards the virtual phase point ....................................................... 64

9.2.1.4 Outer conductor to earth voltages ........................................................................... 64

9.2.1.5 Outer conductor to phase point voltages ................................................................. 65

9.2.1.6 Linked conductor currents in a three-phase system ................................................. 65

9.2.1.7 Sum current, neutral conductor current ...................................................................65

9.2.1.8 Active power of the phase ....................................................................................... 65

9.2.2 R.M.S. Voltage Values ..............................................................................................66

9.2.2.1 Half-period r.m.s. voltage values .............................................................................. 66

9.2.2.2 10/12-period r.m.s. voltage values ........................................................................... 67

9.2.2.3 150/180-period r.m.s voltage values ........................................................................

9.2.2.4 10-minute r.m.s. voltage values ...............................................................................

9.2.2.5 2-hour r.m.s. voltage values ..................................................................................... 68

9.2.3 R.M.S. Current Values ..............................................................................................68

9.2.3.1 10/12-period r.m.s. current values ........................................................................... 68

9.2.3.2 150/180-period r.m.s. current values ....................................................................... 69

9.2.3.3 10-minute r.m.s. current values

9.2.3.4 2-hour r.m.s. current values ..................................................................................... 69

9.2.4 Linear Average Values .............................................................................................. 70

................................................................................ 69

64

67

68

PQI-DA Operating Manual

5

Page 6

a-eberle

PQI-DA

9.2.5 Network Frequency ..................................................................................................71

9.2.6 Spectral Analysis ......................................................................................................

9.2.7 Active Powers ..........................................................................................................77

9.2.8 Active Energies ........................................................................................................

9.2.9 Reactive Energies ....................................................................................................

9.2.10 Interval Average Values of the Active Powers ...........................................................

9.2.11 Average Value of the Conductor Currents with the Sign of the Active Power of the Net

9.2.12 Apparent Powers .....................................................................................................

9.2.13 Reactive Powers ......................................................................................................

9.2.14 Active Factors ..........................................................................................................

9.2.15 Reactive Factors ......................................................................................................

9.2.16 Active Factor Display Function .................................................................................

9.2.17 Flicker Magnitude .....................................................................................................

9.2.18 Asymmetrical Voltage ...............................................................................................

9.2.4.1 10/12-period average values ................................................................................... 70

9.2.4.2 150/180-period average values ............................................................................... 70

9.2.4.3 10-minute average values ........................................................................................ 70

9.2.4.4 2-hour average values ............................................................................................. 71

71

9.2.6.1 Complex harmonics ................................................................................................ 72

9.2.6.2 Phase difference between the reference voltge and the measurementvoltage (basic

frequency) ............................................................................................................... 73

9.2.6.3 Direction of the power flow of the harmonics ...........................................................74

9.2.6.4 R.m.s. values of the harmonics ................................................................................ 74

9.2.6.5 R.m.s. values of the interharmonics .........................................................................

9.2.6.6 R.m.s. values of all the harmonics ...........................................................................

9.2.6.7 Total Harmonic Distortion THD................................................................................. 75

9.2.6.8 Phase difference between the voltage and the current(basic frequency) ................... 75

9.2.6.9 Direction of the rotating field .................................................................................... 76

work ........................................................................................................................80

74

74

78

78

79

80

81

81

81

82

82

82

-

10. Commissioning ..................................................................................................... 83

10.1 Safety Information ......................................................................................... 83

10.2 Procedure .....................................................................................................

83

11. Applications .......................................................................................................... 84

11.1 Application-Specific Programming ................................................................ 84

12. Updating the Firmware ......................................................................................... 84

13. Scope of Delivery ..................................................................................................

14. Storage Information ..............................................................................................

15. Guarantee .............................................................................................................

16. Ordering Information .............................................................................................

85

85

85

86

PQI-DA Operating Manual

6

Page 7

a-eberle

PQI-DA

Information:

Please note that the following operating manual cannot describe the latest

version of the device in all cases. For example, if you download a more recent

version of the firmware from the internet, the following description is no longer

accurate in every point.

In this case, either contact us directly or refer to the most recent version of the

operating manual available on our website (www.a-eberle.de).

PQI-DA Operating Manual

7

Page 8

a-eberle

PQI-DA

1. Technical Concept

1.1 Application

The Power Quality-Interface for low-, medium- and high-voltage networks PQI-DA

is the central component of a system, which executes all the measurement tasks

in electrical networks.

The PQI-DA can be used both as Power Quality-Interface according DIN EN 50160

and as measuring device for all physically defined measured variables in threephase systems.

The unit is mainly adapted for monitoring and recording certain supply qualities

or quality objectives between utility and customer and, furthermore to provide the

data for evaluation and storage.

Modern voltage-quality measurement devices operate according to IEC 61000-4-30.

This standard defines measuring methods in order to establish a comparable basis

for the user.

Devices from different manufacturers, operating according to this standard, have

to provide approximately the same measurement results.

The standard distinguishes between two classes of measurement devices.

Class A measurement devices are mainly used for contractual measurements in

customer-supplier relations, whereas class B measurement devices can be used

to determine statistical quality values. For measurements according to EN50160

a class B device is sufficient.

For the following parameters PQI-DA fulfills the requirements of IEC 61000-4-30

for class A devices.

Parameter Class

• Accuracy of voltage measurement A

• Determination of time intervals A

• Marking of measured values at events A

• Harmonics, interharmonics A

• Frequency A

• Voltage asymmetry A

• Event recording A

• Time synchronization A

In addition, three different fault recorders can be used.

(with DCF77 or GPS)

The oscilloscope recorder collects fault records consisting of 100 µs-sampling

values whose length (pre-event and post-event history) is freely selectable.

The r.m.s. recorder collects fault records consisting of r.m.s. values of half-period

values (10ms). The length of the fault record (pre-event and post-event history) is

also freely selectable.

PQI-DA Operating Manual

8

Page 9

a-eberle

PQI-DA

When exceeding a limiting value (harmonic or THD of a voltage), the harmonic

recorder registers the corresponding spectrum of all harmonics from 2nd to 50

harmonic.

All fault records are triggered by a freely definable event. Phase-phase and phaseearth events can be recorded simultaneously.

The signal-voltage-recorder registers a freely adjustable frequency (e.g. ripple

control frequency) over a period that can be selected.

Limit violations can be signalled via relays, if required.

On the input-side (U, I) the interface is available in different hardware-versions.

Current inputs are available for the measuring circuit (C20, C30) and for the protection circuit (C21, C31).

The following input characteristics can be selected:

• 4 voltage transformers for common power-quality applications

• 8 voltage transformers for power-quality applications in double-busbar systems

(code C10)

• 4 voltage transformers and 4 current transformers for power quality and general

measuring tasks (code C20, C21, C30, C31)

(code C00)

th

Theoretically, up to 255 devices can be interlinked via the system bus (E-LAN).

Even connections to devices of the voltage regulator system REGSys™, the Peterson-coil controller REG-DP, the earthfault detection system EORSys and the

collapse prediction system CPSys are possible.

Each device offers two RS 232 interfaces (COM1 and COM2) and two E-LAN

(Energy Local Area Network) interfaces.

Optional the PQI-DA can be equipped with an integrated TCP/IP-interface. In this

case COM 2 is not available.

Possible firmware-updates can be easily made via a pushbutton, prevented against

unintentional touch.

PQI-DA Operating Manual

9

Page 10

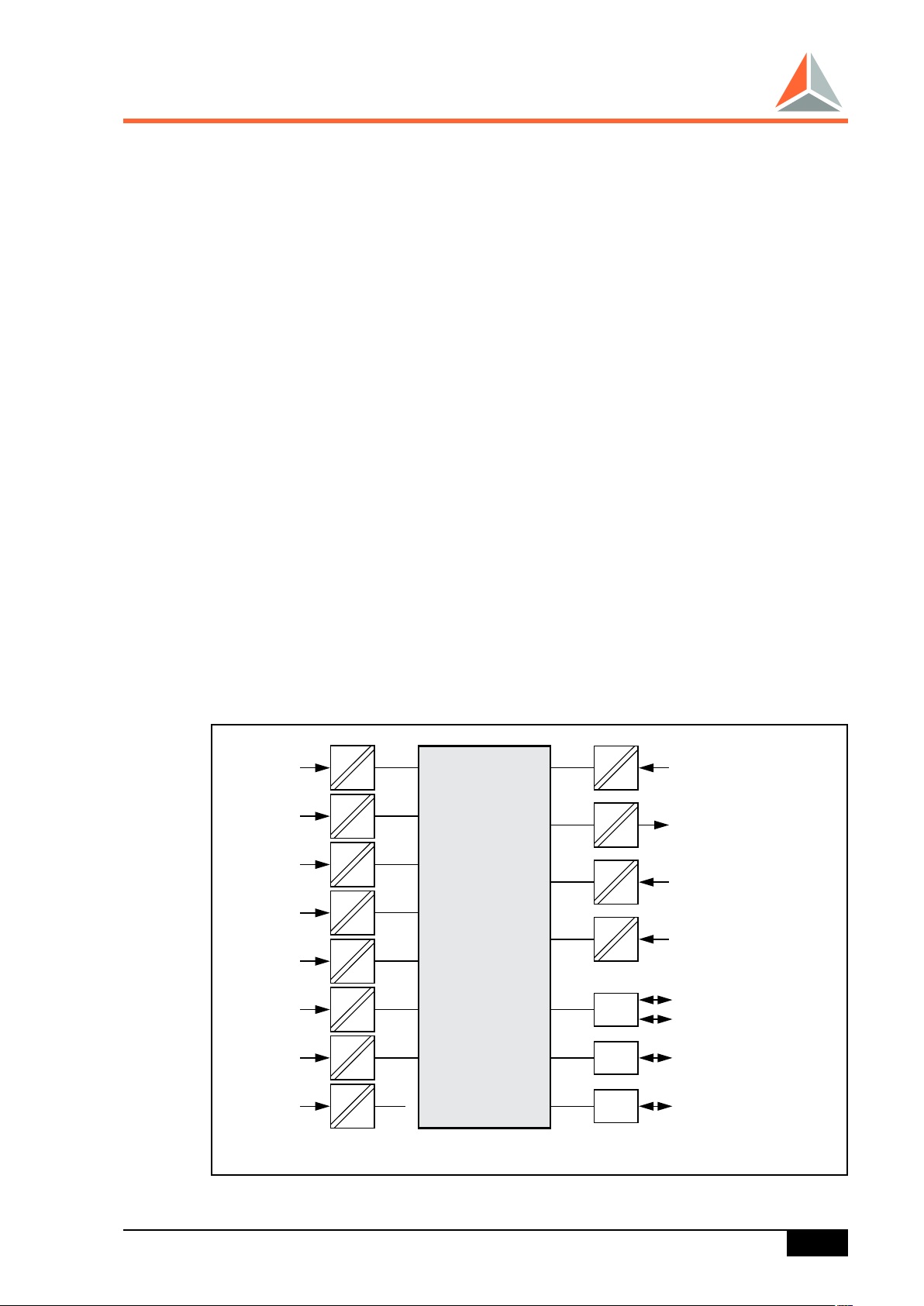

RS232

RS232

COM 1

COM 2 / RJ 45 (TCP / IP)

U1

U2

U3

UNE

DSP*

µP

LCD

LED´s

RAM

ROM

CLOCK

E-LAN-L

E-LAN-R

Binary inputs (BI)

Binary outputs (BO)

DCF 77

Trigger input

E-LAN

I1 (U1)

I2 (U2)

I3 (U3)

I0 (U4)

* DSP : digital signal processor

a-eberle

PQI-DA

1.2 Features of the Power-Quality-Interface & Disturbance Recorder PQI-DA

• Recording of the voltage quality according to DIN EN 50160

• Class A device according to IEC 61000-4-30

• Sampling frequency 10,24 kHz

• Fault recording function up to 20 x In

• Phase-phase and phase-earth measurements are possible simultaneously

• Voltage measurement channels for U

• Measurement of currents I1, I2, I3, I

• Acquisition of more than 3000 measured values

• Freely programmable limiting values and output via insulated contacts.

• Freely programmable binary inputs to start or stop measurements

• Data analysis via WinPQ software, using a mySQL-supported database

• Version with integrated TCP/IP-interface available

• Connection to SCADA according IEC 870-5-101

• Connection to SCADA according IEC 61850 in preparation

1.3 Description

, U23, U31, U

12

0

NE

Function of Power Quality-Interfaces

PQI-DA Operating Manual

10

Page 11

a-eberle

PQI-DA

2. Application

2.1 PQI-DA as a Recorder (Fault Recorder)

Fault records are stored in the recorders A, B and C each time a fault occurs.

Trigger condition is either the falling below or exceeding a voltage limit or an external trigger signal. When the system is triggered, the pre-event and the post-event

history of the voltage and current shape is recorded. You can choose between

three different recorders.

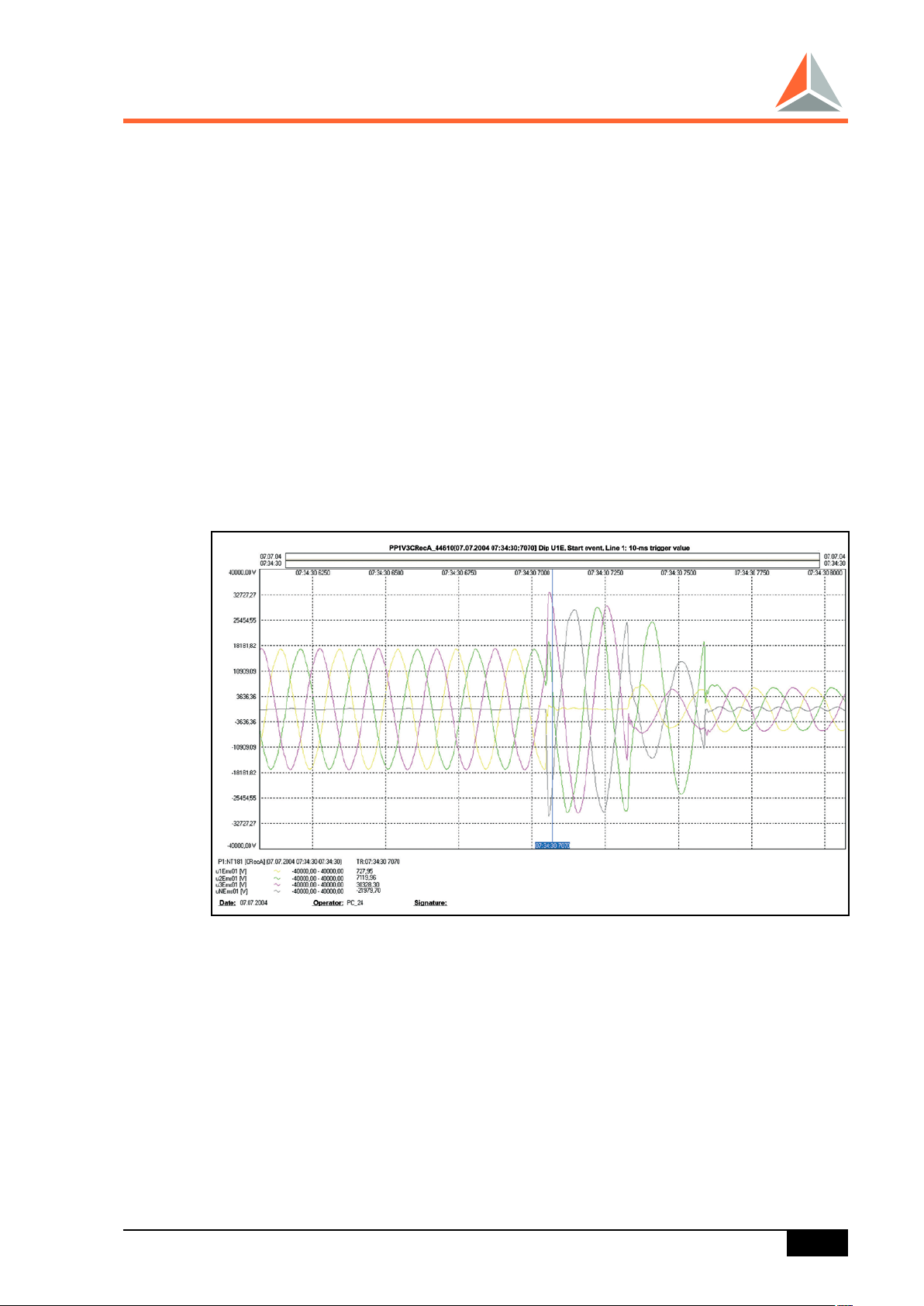

2.1.1 Recorder A

Recorder A stores fault records of the events before and after the fault occurs using,

for example, 2048 sampling values for each of the 8 measurement channels (1024

before, 1024 after). The measurement value acquired in each channel is dependent

on the configuration of the transformer and the version of the device.

Recorder A

8 voltages are sampled if 8 voltage inputs are used. If the measurement task

requires four voltage inputs and four current inputs, then four voltages and four

currents are measured accordingly.

8 simultaneously sampled momentary values are available every 100 µs, based

on a sampling frequency of 10.24 kHz. These can be used to reconstruct a

“fingerprint” of a particular event.

The number of events, the total recording time and the position of the trigger point

within the time slice can all be individually specified.

PQI-DA Operating Manual

11

Page 12

a-eberle

PQI-DA

The selection of the trigger point specifies how many periods (seconds) of information before the fault and how many periods of information after the fault should

be recorded per event.

Example: The total length of the record is specified as 2000 sampling points

(approximately 200 ms). This represents 10 periods for a network frequency of

50 Hz. If the pre-trigger is set to 1000, the information before the event and the

information after the event are both 5 periods, or 100 ms, long.

The total number of permissible trigger events must be chosen carefully since

records stored with recorder A require a very large amount of memory.

If the specified number of events is exceeded, either the oldest events will be

overwritten or no further records will be stored.

The desired behaviour can be chosen using Win PQ.

The trigger conditions which cause recorder A to be used can also be freely specified, i.e. they are not constrained to the limit values specified in EN 50160.

The trigger condition is created by linking selected events together with OR conditions.

The record shows the single-pole earth fault, which changes to a 2-pole earth

fault a short time later.

This could be caused by the events described in the following account.

A mistake occurred in the cable duct: a hydraulic cutter was used to cut a cable

which was still connected to a voltage supply instead of one that was disconnected.

As the edge of the blade touched the first phase, it caused a single-pole earth

fault and an increase in the neutral earth voltage. A short time later, two phases

were short-circuited by the blade (phase-phase fault).

The subsequent progress of the fault process is explained in conjunction with

recorder B.

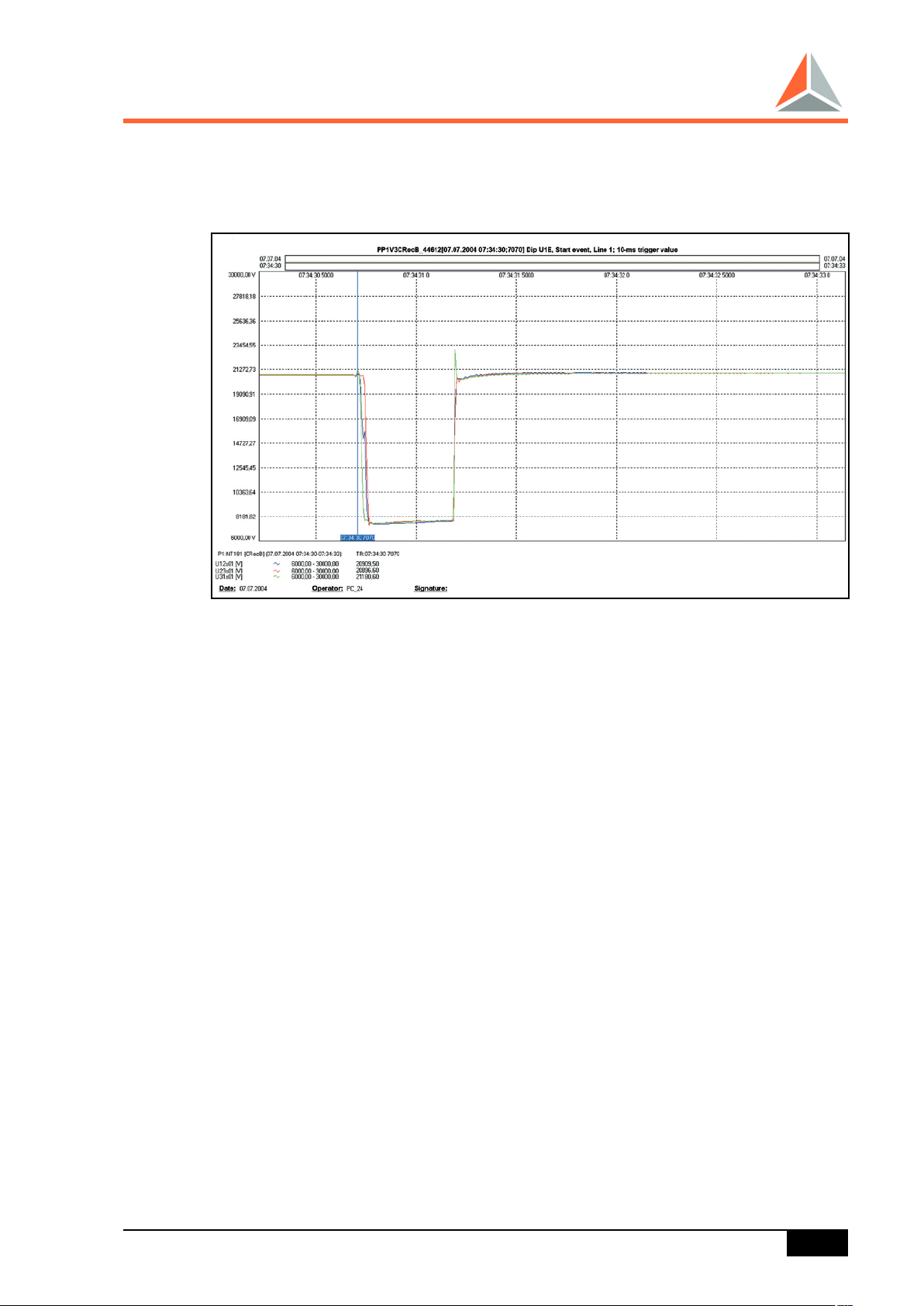

2.1.2 Recorder B

Recorder B stores fault records for the 1/2-period r.m.s. (root mean square) values

of phase and delta voltages. A record consists of a specifiable number of 1/2period r.m.s. values. Thus 10-ms values are recorded if the operating frequency

is 50 Hz.

The trigger condition is created by linking selected events together with OR conditions.

The number of events, the total recording time and the position of the trigger point

within the time slice can all be individually specified.

PQI-DA Operating Manual

12

Page 13

a-eberle

PQI-DA

The selection of the trigger point specifies how many half-period values (10-ms

values) should be recorded before and after the fault per event.

Recorder B

Example:

The total length of the record is specified as 500 10-ms values (approximately 5 s).

If the pre-trigger is set to 250, the information before the event and the information

after the event are both approximately 2.5 s long.

The total number of permissible trigger events must be chosen carefully. Records

stored with recorder B require a large amount of memory.

If the specified number of events is exceeded, either the oldest events will be

overwritten or no further records will be stored.

The desired behaviour can be selected using Win PQ.

The trigger conditions which cause recorder B to be used can be freely specified,

i.e. they are not constrained to the limit values specified in EN 50160.

The record (see page 13) shows the fault illustrated on page 10 with a reduced

resolution (10-ms r.m.s. value).

Due to the resolution it is no longer possible to recognise the path to the fault, i.e.

the route from a single-pole to a 2-pole fault. However, one can see the effect of

the overcurrent relay which disconnected the faulty cable from the busbar after

approximately 400 ms.

PQI-DA Operating Manual

13

Page 14

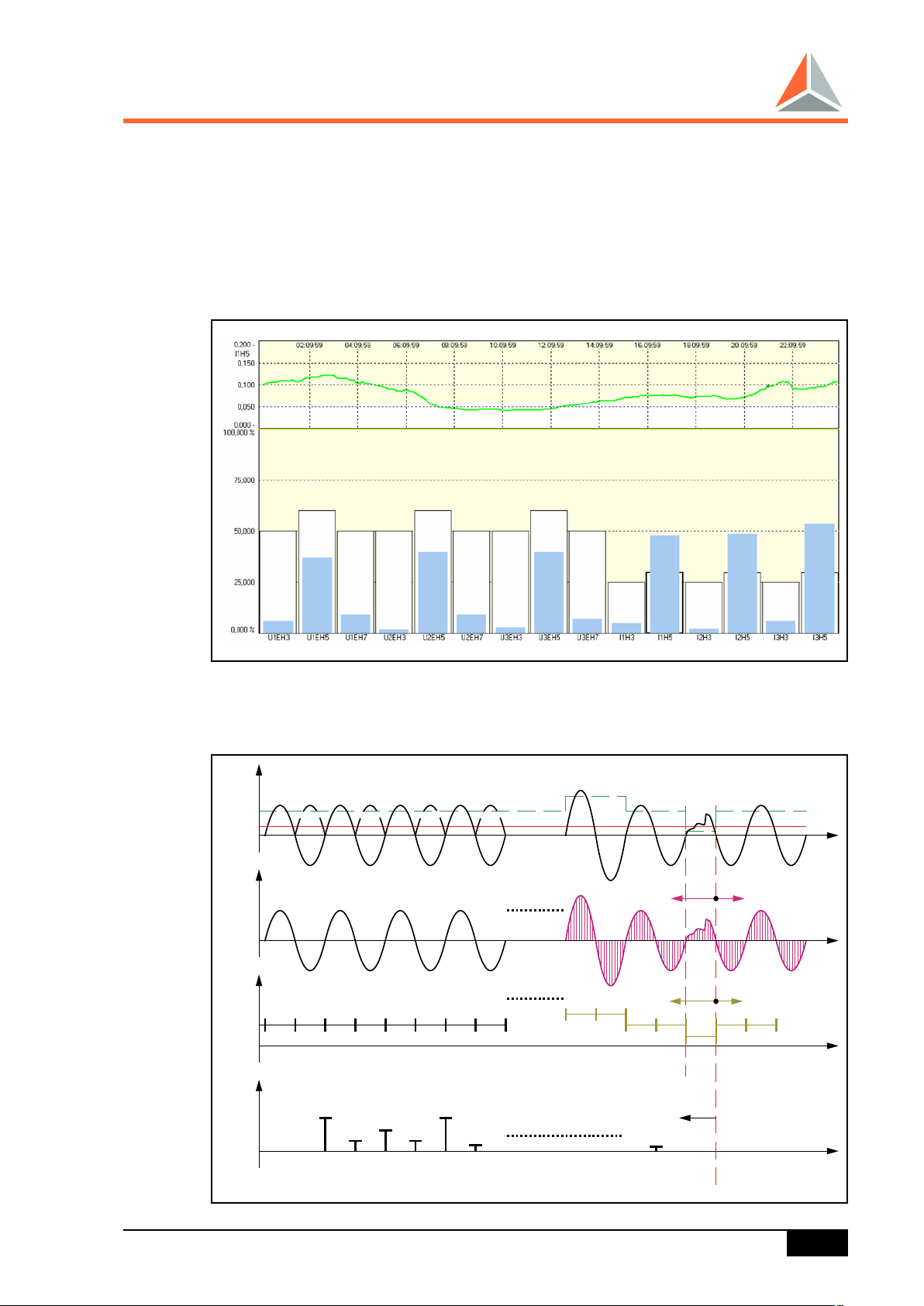

Rec A

Rec B

Rec C

2. 3. 5. 7. 9. 11. 40.

t

0-1

t

0

t

0-1

t

0

TRMS

Event

Input signal

After the eventBefor the event

10-minute average values

of the harmonics

LV

After the eventBefor the event

T.R.M.S. = True Root Mean Square value, LV = limit value

a-eberle

PQI-DA

2.1.3 Recorder C

Recorder C stores the corresponding harmonic spectrum (10-minute harmonic

values) of a voltage if a harmonic limit or the THD (Total Harmonic Distortion,

10-minute value) of the voltage is exceeded.

The trigger condition is created by linking selected events together with OR conditions.

Recorder C

The comparison shows the three recorders A, B and C again as they are triggered

by a dip in the voltage between time t

and time t0.

0-1

PQI-DA Operating Manual

14

Page 15

a-eberle

PQI-DA

After the zero point (t0), recorders A and B store information regarding the time

period before and after the event, whereas recorder C only stores the 10-minute

harmonics values of the information before the event.

2.1.4 Events

By definition, an “event” occurs every time a measurement quantity exceeds the

threshold value specified in EN 50160 or any other predefined value

Each event is stored in the event memory along with the start and stop time.

Events which permanently exceed the threshold value are re-triggered at the end

of every 10-minute or 2-hour interval.

On the other hand, events which permanently exceed the threshold value are not

re-triggered at the end of every 10-ms interval or at the end of 1/2, 10, 12, 150

or 180-period values.

In these cases, only a stop event is recorded when the threshold value is no longer

exceeded.

To create time sums in these cases, the duration of the event is calculated from

the difference between the start and the stop time of the event, and is then stored

in the event memory.

PQI-DA Operating Manual

15

Page 16

a-eberle

PQI-DA

2.2 PQI-DA as System Component

The PQI-DA can be connected to all devices in the XXX-DX series (REG-D, REG-DA,

REG-DM, PAN-D, REG-DP, MMU-D, EOR-D etc.) from A. Eberle GmbH&Co KG

to create a measurement-, registration- and/or control-system.

The individual devices are connected to each other via the E-LAN system bus, and

up to 255 different devices can communicate with each other via one E-LAN.

If multiple transformers feed energy into a network in a transformer station and

each is equipped with a PQI-DA, the partial power of the individual transformers

can also be measured by the corresponding PQI-DAs. They transmit the partial

power to a particular PQI-DA via E-LAN, which then outputs the total power using

a virtual measurement channel.

Furthermore, freely programmable binary inputs can be linked with measurement

values or limit values, and also output as a binary signal.

PQI-DA Operating Manual

16

Page 17

a-eberle

PQI-DA

3. Technical Data

3.1 Standards

IEC 61010-1 / DIN EN 61010-1

IEC 60255-4 / DIN EN 60255-4

IEC 61326-1 / DIN EN 61326-1

IEC 60529 / DIN EN 60529

IEC 60068-1 / DIN EN 60068-1

IEC 60688 / DIN EN 60688

IEC 61000-6-2 / DIN EN 61000-6-2

IEC 61000-6-4 / DIN EN 61000-6-4

3.2 Voltage inputs

Option*) E1 E2

Un 100V 230V

Full scale range

(FSR),sinus

Impedance 360 kΩ 810 kΩ

Fundamental magnitude

error limit

Fundamental phase error limit ± 0.15°

Bandwidth DC…3kHz

Harmonics 2nd..50

error limit

Interharmonics 2nd..49

error limit

Insulation CAT III / 300V

th

th

200V 460V

±0.1% of U

over 10% ~ 150% of U

over 50% ~ 150% of U

over f

±5% of reading over Um = 1% ~ 16% of U

±0.05% of U

±5% of reading over Um = 1% ~ 16% of U

±0.05% of U

over Um < 1% of U

din

over Um < 1% of U

din

nom

din

din

din

±15%

din

din

din

din

PQI-DA Operating Manual

17

Page 18

a-eberle

PQI-DA

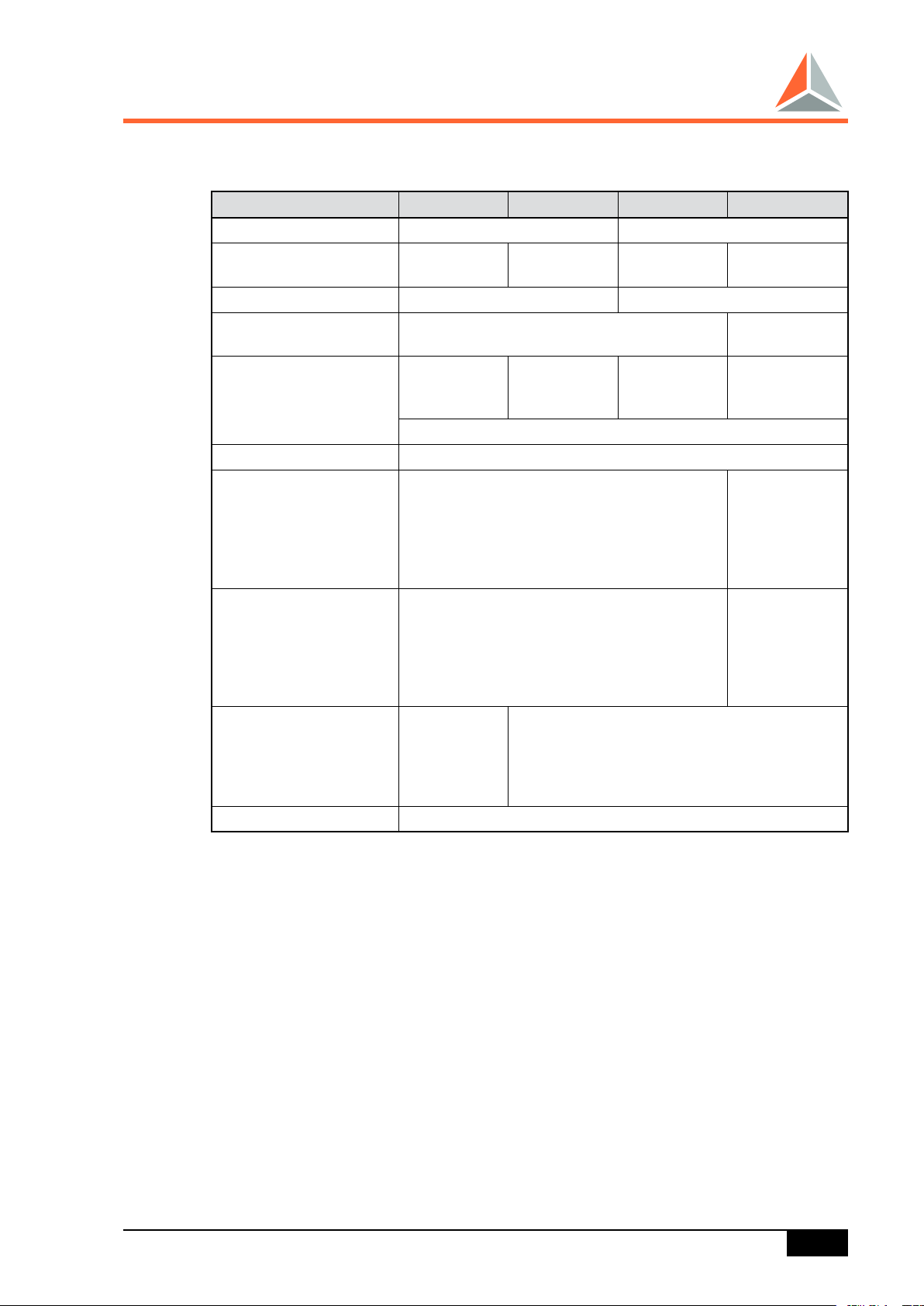

3.3 Current inputs

Option*) C20 C21 C30 C31

In 1A 5A

Full scale range (FSR)

sinus

Load (In) < 0.1 VA < 0.5 VA

Fundamental magnitude

error limit

Fundamental phase

error limit

Bandwidth 25Hz…3kHz

Harmonics 2nd...50

error limit

Interharmonics 2nd...49

error limit

Overload capacity

Continuous

≤ 10s

≤ 1s

≤ 5ms

Insulation CAT III / 300V

th

th

0 < I ≤ 2A 0 < I ≤ 20A 0 < I ≤ 10A 0 < I ≤ 100A

± 0.1% of FSR

over FSR

± 0.15° over

10% ~ 100%

of FSR

±5% of reading over Im = 1% ~ 16% of In

±0.05% of In over Im < 1% of I

±5% of reading over Im = 1% ~ 16% of In

±0.05% of In over Im < 1% of In

5A

10A

30A

100A

± 0.15° over

5% ~ 50%

of FSR

over f

± 0.15° over

10% ~ 100%

of FSR

±15%

nom

n

10A

30A

100A

500A

± 0.2% of FSR

over FSR

± 1.0° over

5% ~ 10%

of FSR

±10% of reading

over

Im = 1% ~ 16%

of In ±0.1%

of In over

Im < 1% of In

±10% of reading

over

Im = 1% ~ 16%

of In ±0.1%

of In over

Im < 1% of In

*) Note:

Codese.g.“E1,E2,C20,C31…“;seecharacteristicsonpage86

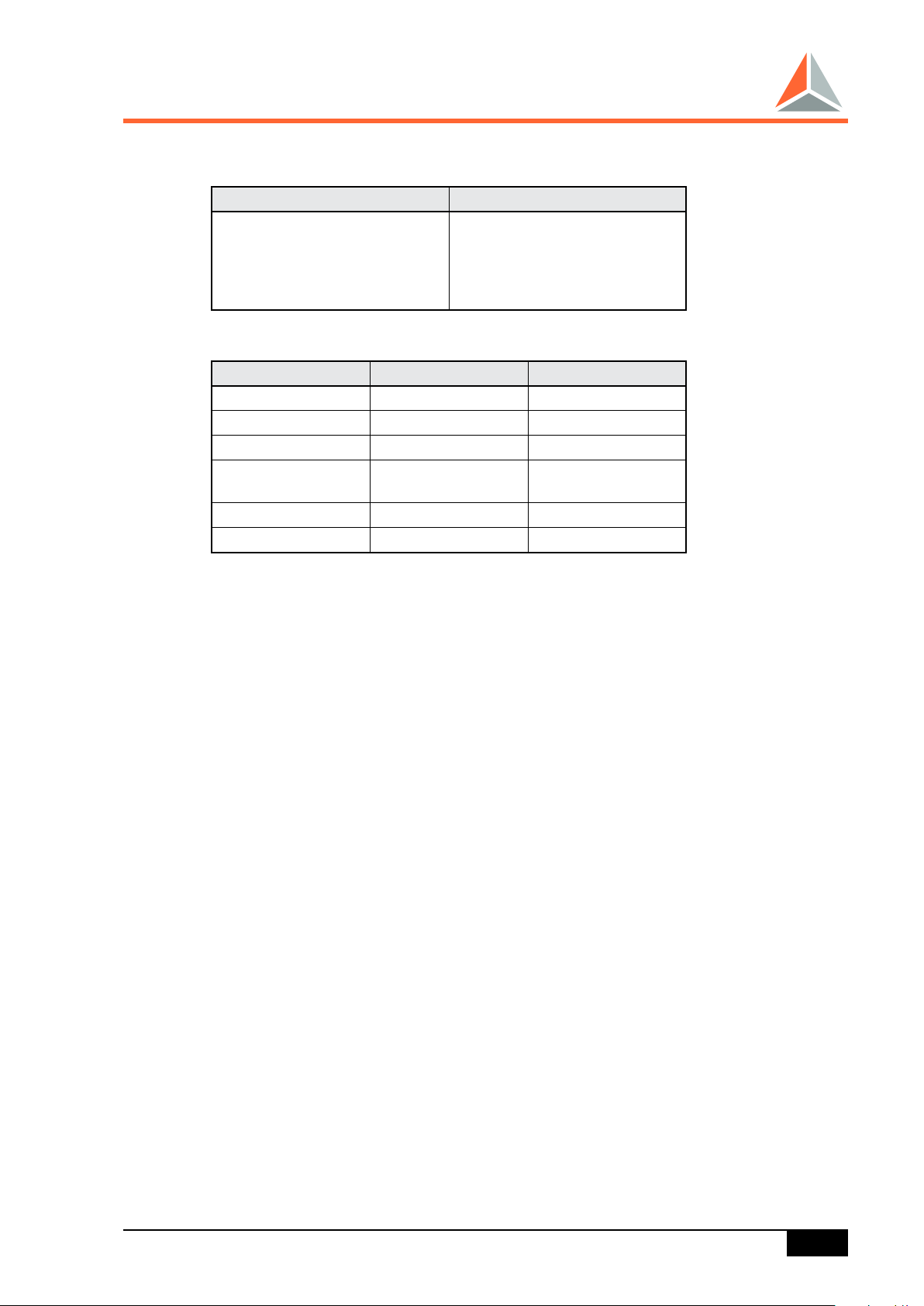

3.4 Binary inputs (BI)

Control signals Ust In the range

48 V ... 230 V AC/DC

Waveform Rectangular, sinusoidal

H – Level > 35 V

L – Level < 20 V

Signal frequency up to 60 Hz DC

Switching delay Selectable from 1...999 s

Input resistance 108 k

Electrical isolation Optocoupler; always two earthed

PQI-DA Operating Manual

Ω

18

Page 19

a-eberle

PQI-DA

3.5 Binary outputs (BO)

Electrical isolation isolated from all internally potentials

Type of relay Changeover contact Status,

R2, R3 Galvanically isolated from each other

R4, R5 Earthed

Contact load AC: 250 V, 5 A (cos

AC: 250 V, 3 A (cos

DC: 220 V, 150 W

switching capacity

No. of switching operations

LED display

Operation Green

Error Red

3.6 Limit value monitoring

Limit values Programmable

Response times Programmable

ϕ = 1.0)

ϕ = 0.4)

≥ 1.104 electrical

3.7 Measurement

(selection from over 3000 measurement quantities)

TRMS voltages U

TRMS current I1, I2, I3, I

Active power P

Reactive power Q

Apparent power S

Power factors cos

Harmonics U/I up to the 50

Interharmonics U/I up to the 49th

Frequency f

Flicker Pst, Plt

Dips, Swells, Interruptions

Voltage unbalance

Mains signalling voltages

, U2N, U3N, UNE, U12, U23, U

1N

0

ϕ

th

31

PQI-DA Operating Manual

19

Page 20

a-eberle

PQI-DA

Aggregation intervals:

½-cycle

10/12-cycle (fnom = 50/60Hz)

150/180-cycle (fnom = 50/60Hz)

5 / 6 / 6.67 / 7.5 / 10

2 h

Error limits:

Frequency: ± 5mHz over f

Flicker, Pst,Plt: ±5% of reading over 0.02% ~ 20% of

Dip residual voltage: ±0.2% of U

Dip duration: ±20ms over 10% ~ 100% of U

Swell residual voltage: ±0.2% of U

Swell duration: ±20ms over 100% ~ 150% of U

Interruption duration: ±20ms over 1% ~ 100% of U

Voltage unbalance: ±0.15% over 1% ~ 5% of reading

Mains signalling voltage: ±5% of reading over U

±0.15% of U

3.8 Reference conditions

Reference temperature 23°C ± 1 K

/ 12 / 15 / 20 / 30 min

±15% (f

nom

over 10% ~ 100% of U

din

over 100% ~ 150% of U

din

m

over Um = 1% ~ 3% of U

din

= 50Hz/60Hz)

nom

din

din

din

= 3% ~ 15% of U

∆U/U

din

din

din

din

Input parameters U = Un ± 10%

I = In ± 10%

Auxiliary voltage H = H

Frequency = f

Other IEC 60688 - Part 1

3.9 Measurement data acquisition

Sampling rate: 10240 Hz

ADC resolution: 24bit

Anti-Aliasing-Filters: Analog filter : 3

Digital filter : sinc

Nominal frequency: f

Fundamental frequency range: f

3.10 Storage of measured values

Permanent 4 MB

± 1%

n

± 1%

nom

= 50Hz, 60Hz

nom

±15 % (f

nom

rd

order Butterworth filter

5

decimation filter (ADC)

= 50 Hz / 60 Hz)

nom

Volatile 48 MB

PQI-DA Operating Manual

20

Page 21

a-eberle

PQI-DA

3.11 Electromagnetic Compatibility

CE conformity

- Electromagnetic Immunity

EN 61326

EN 61000-6-2

- Emitted interference

EN 61326

EN 61000-6-4

ESD

IEC 61000-4-2 8 kV / 16 kV

IEC 60 255-22-2

Electromagnetic fields

IEC 61000-4-3 10 V/m

IEC 60 255-22-3

Burst

IEC 61000-4-4 4 kV / 2 kV

IEC 60 255-22-4

Surge 1 MHz burst

IEC 61000-4-5 4 kV / 2 kV

IEC 61000-4-12 2.5 kV, class III

IEC 60 255-22-1

Conducted high frequency magnetic fields

IEC 61000-4-6 10 V, 150 kHz ... 80 MHz

IEC 61000-4-8 100 A/m continuous

All positions 1000 A/m 1 s

Voltage dips

IEC 61000-4-11 30 % 0.02s, 60 % 1 s

Emitted interference

EN 61326

EN 61000-6-4

- Housing

At a distance of 10 m 30 ... 230 MHz, 40 dB

230 ... 1000 MHz, 47 dB

- AC supply connection

At a distance of 10 m 0.15 ... 0.5 MHz, 79 dB

0.5 ... 5 MHz, 73 dB

5 ... 30 MHz, 73 dB

3.12 Electrical safety

Degree of protection I

Degree of pollution 2

Measuring category CAT III / 300 V

Optional CAT III / 500 V

PQI-DA Operating Manual

21

Page 22

a-eberle

PQI-DA

3.13 Operating voltages

50 V 230 V

E-LAN,

COM-Server,

COM1 ... COM2

Time- /

Trigger- BUS

3.14 Power supply

Feature H0 H1

AC (internal) - -

AC 85 … 264 V -

DC 88 … 280 V 18 … 72 V

Power

consumption

Frequency 40 … 70 Hz -

Miniature fuse T1 250 V T2 250 V

Auxiliary voltage

Binary inputs

Relay outputs

≤ 15 W ≤ 15 W

The following applies to all features:

Voltage interruptions ≤ 80 ms do not cause a fault or loss of data.

3.15 Environmental conditions

Temperature range

Function -15 ... +55°C

Transport und storage -25 ... +65°C

Humidity

No condensation

on 30 days/year 95 % rel.

Dry, cold

IEC 60068-2-1 -15°C / 16 h

Dry, hot

IEC 60068-2-2 +55°C / 16 h

Constant humid heat

IEC 60068-2-3 + 40 °C/93 % / 2 days

Cyclical humid heat

IEC 60068-2-30 12+12h, 6 cycles, +55°C/93%

Toppling

IEC 60068-2-31 100 mm drop, unwrapped

Vibration

IEC 60255-21-1 Class 1

Impact

IEC 60255-21-2 Class 1

PQI-DA Operating Manual

22

Page 23

132.05

204

216

80

147.2

www.a-eberle.de

PQI-DA

SERVICE

FAULT

RESET

class A

a-eberle

PQI-DA

3.16 Data storage

Device settings Serial EEPROM with

≥ 1000 k read/write cycles

RAM data Li battery laser-welded

4. Mechanical Design

4.1 Housing

The Power Quality-Interface PQI-DA is kept in a rugged stainless steel case.

All connections are accessible via Phoenix terminals. The connections are made

in plug-in/clamping technology, except the current and voltage inputs.

If the option COM-Server (code T1) is selected, a RJ 45-connection is available.

The PQI-DA is applicable both as wall mountable as well as DIN rail mountable

housing.

Material stainless steel

Degree of protection

Housing IP 40

Terminals IP 20

Mass

≤ 2 kg

Dimensions see fig. below

Connection elements Screw terminals

Dimensions

PQI-DA Operating Manual

23

Page 24

4

6

1

3

7

9

10

12

I

3k

I

2k

I

1k

I

3l

I

2l

I

1l

I4kI

4l

x3

U L(+)HU L(-)

H

14 15

x1

2

5

8

11 13

U

1

U

2

U

3

x2

U

4

GND

PE

14 15

x1 x3

1

3

4 6

7

9 10

12

30 31

32 33 34 35

x7

59

606162

63

x8

36

37

38

39

40

41424344

45

x9

16

17

18 19

20

21 222324

25 26

27

28 29

x5

46 47

48

49

50

5152 53545556 57

58

x6

x2

2

5

8

11 13

a-eberle

PQI-DA

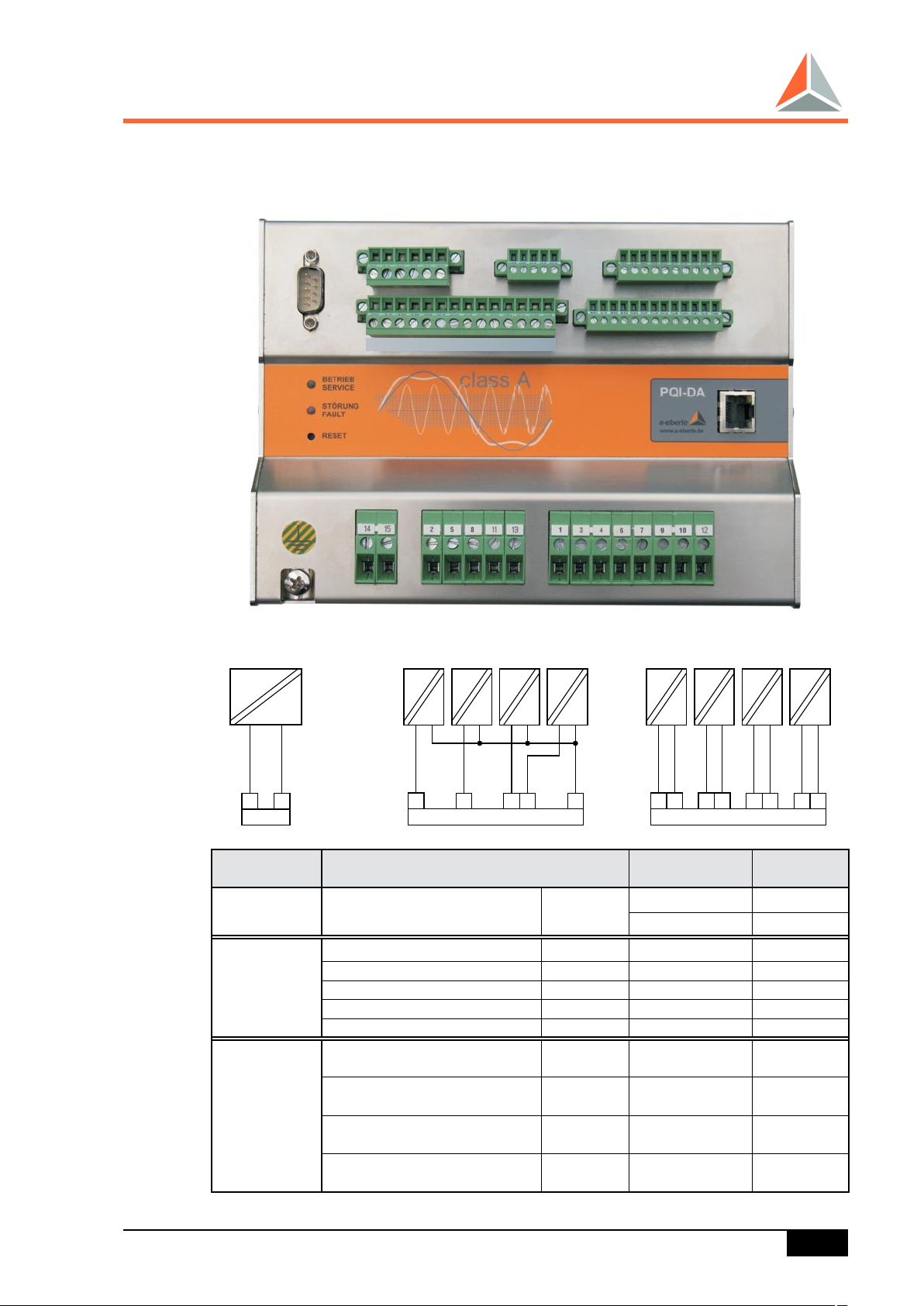

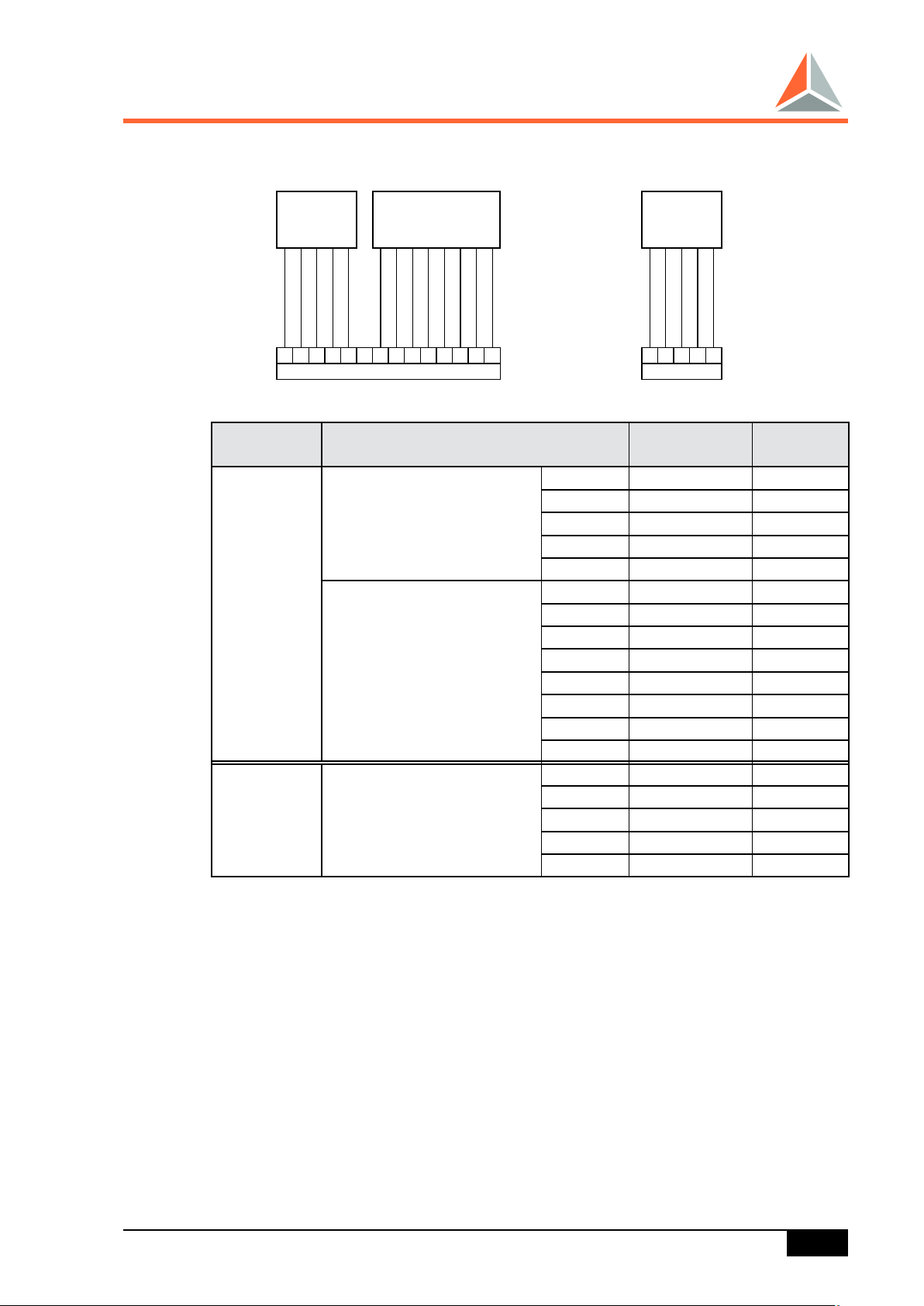

4.1.1 PQI-DA 4U / 4I

Assignment of the terminal blocks x1 … x3

Terminal

block no.

Description Function

x1 Auxiliary voltage U

Phase voltage L1 (AC) U

Phase voltage L2 U

x2

Phase voltage L3 U

Neutral voltage U

H

1

2

3

4

Terminal

no.

L (+) 14

L (-) 15

L1 2

L2 5

L3 8

N 11

Ground GND E 13

Phase Current L1 I1

Phase Current L2 I2

x3

Phase Current L3 I3

Neutral-current I4

PQI-DA Operating Manual

k 1

l 3

k 4

l 6

k 7

l 9

k 10

l 12

24

Page 25

30 31

32 33 34 35

x7

59

606162

63

x8

36

37

38

39

40

41424344

45

x9

46 47

48

49

50

5152 53545556 57

58

x6

16

17

18 19

20

21 222324

25 26

27

28 29

x5

2.1

5.1

8.1

11.1

x2 / line 1

2.2

5.2

8.2

11.2

x2 / line 2

14 15

x1

PE

GND

U L(+)HU L(-)

H

14 15

x1

2.2

5.2

8.2

11.2

GND

2.1

5.1

8.1

11.1

13

U

1

U

2

U

3

x2

U

1

U

2

U

3

U

4

U

4

a-eberle

PQI-DA

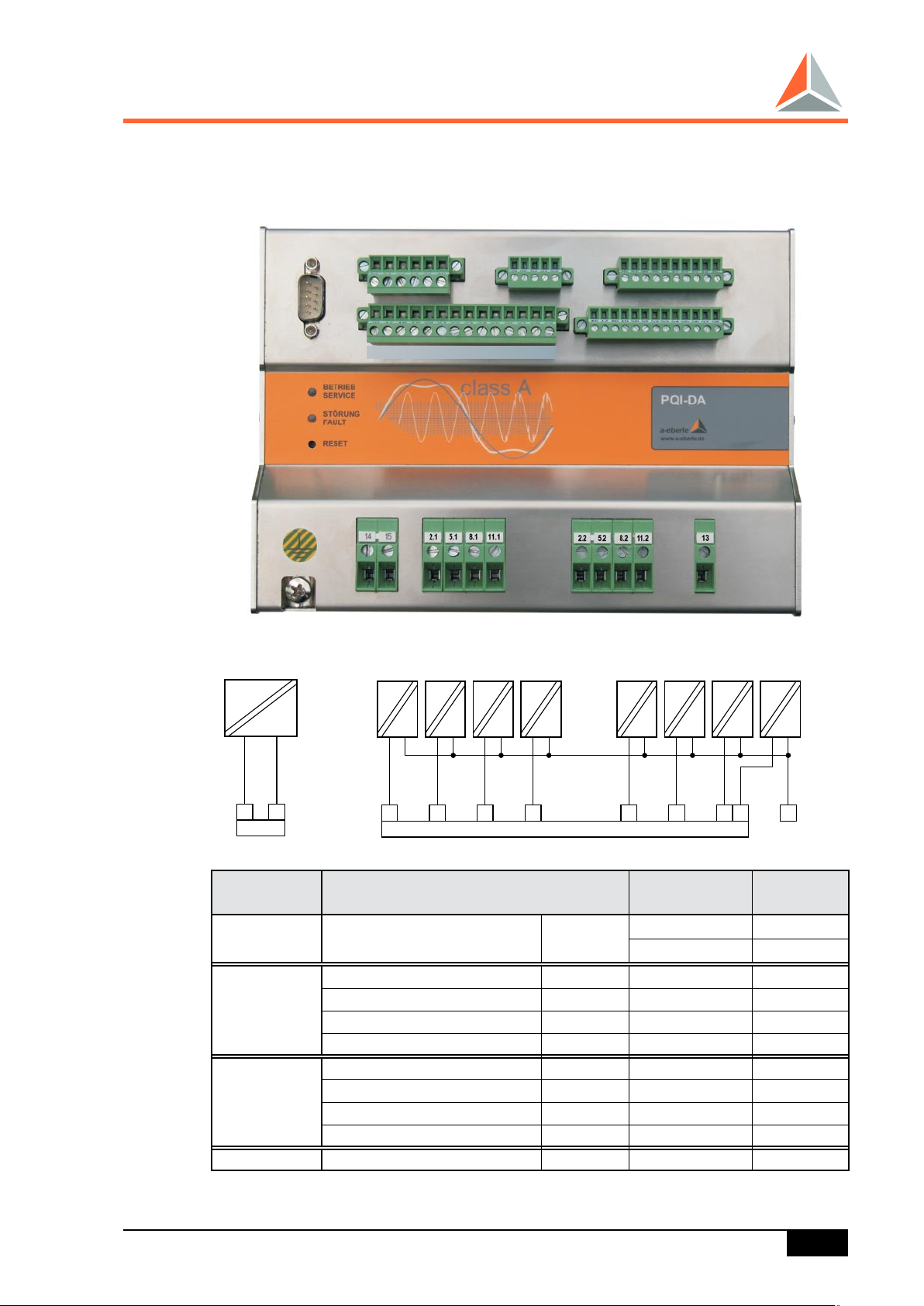

4.1.2 PQI-DA 8U

Assignment of terminal blocks x1 … x2

Terminal

block no.

Description Function

x1 Auxiliary voltage U

Phase voltage U

x2

line 1

Phase voltage U

Phase voltage U

Neutral voltage U

Phase voltage U

x2

line 2

Phase voltage U

Phase voltage U

Neutral voltage U

H

1

2

3

4

1

2

3

4

Terminal

no.

L (+) 14

L (-) 15

L1 2.1

L2 5.1

L3 8.1

N 11.1

L1 2.2

L2 5.2

L3 8.2

N 11.2

Ground GND E 13

PQI-DA Operating Manual

25

Page 26

prog.

prog.

prog.

prog.

R5

Binary outputs 230 V

Status

R2

R3

R4

16 19

22

25

17

20

23

26 28

18

21 24 27 29

x5

R1

Binary inputs 230 V

+-+ + +

- - -

E1 E2 E3 E4

30 31 32 33 34 35

prog.

prog.

prog.

prog.

x7

E-LAN

R

E-LAN

L

414042

39433844374536

E-

GND

E+

EA+

EA-

EA-

EA+

E+

GND

E-

x9

a-eberle

PQI-DA

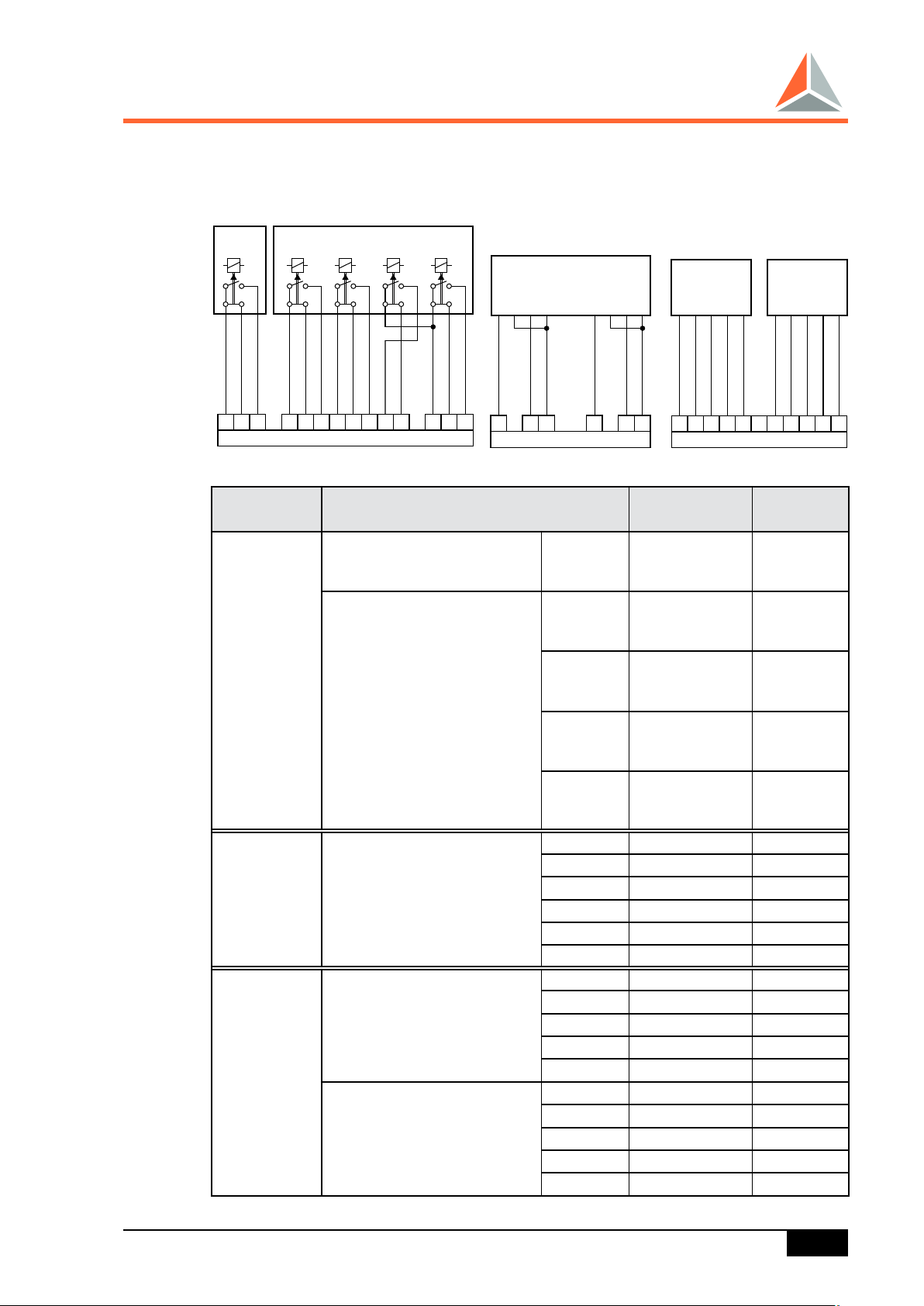

4.1.3 PQI-DA 4U/4I und 8U

Assignment of terminal blocks x5 … x9

PQI-DA Operating Manual

Terminal

block no.

Description Function

Status R1

x5

Binary outputs 230 V

x7 Binary inputs 230 V

E-LAN R (right)) E- 36

x9

E-LAN L (left) E- 41

Terminal

no.

Pole

NC contact

NO contact

Pole

R2

NC contact

NO contact

Pole

R3

NC contact

NO contact

Pole

R4

NC contact

NO contact

Pole

R5

NC contact

NO contact

E1 + 30

E2 + 31

E1 / E2 GND 32

E3 + 33

E4 + 34

E3 / E4 GND 35

E+ 37

EA- 38

EA+ 39

GND 40

E+ 42

EA- 43

EA+ 44

GND 45

16

17

18

19

20

21

22

23

24

27

26

25

27

28

29

26

Page 27

Trigger

GPS

IRIG-A

IRIG-B

58

57

56

55

54

53

5251504948

47

46

GND

Term TxB

TxB

TxA

Term TxA

RxB

Term RxA

RxA

GND

Term B

B

A

Term A

x6

(optional)

COM 2

RS232

63

62616059

TxD

RxD

GND

RTS

CTS

x8

a-eberle

PQI-DA

Terminal

block no.

x6

x8

Description Function

GPS,

IRIG-A

IRIG-B adapter card

Term A 46

Terminal

no.

A 47

B 48

Term B 49

GND 50

Trigger RxA 51

Term RxA 52

RxB 53

Term TxA 54

TxA 55

TxB 56

Term TxB 57

GND 58

COM 2

RS 232

CTS 59

RTS 60

GND 61

RxD 62

TxD 63

PQI-DA Operating Manual

27

Page 28

a-eberle

PQI-DA

5. Serial interfaces

5.1 RS232 interfaces

Each PQI-DA has two RS 232 interfaces referred to as COM 1 and COM 2.

COM 1 can be used as a parameterisation and programming interface via a 9-pole

SUB-D plug.

COM 2 can be wired via a plug-in terminal block.

If option T1 (COM server / TCP/IP) is selected, an RJ 45 connection is available

instead of COM 2.

Connection elements

COM 1 Pin strip, Sub Min D

on the front of the device,

pin assignment as on PC

COM 2 Terminal strip x8

Connection options PC, terminal, modem, PLC

Number of data bits / protocol Parity 8, even, off, odd

Transfer rate bit / s 1200, 2400, 4800, 9600, 19200,

38400, 57600, 76800, 115200

Handshake RTS / CTS or X

5.2 TCP/IP

The TCP/IP or COM server interface is galvanically isolated from all other electrical

circuits.

Communication via this interface is possible with a baud rate of 100 MBaud.

Parameterisation of the connection (IP address etc.) is carried out using the WinPQ

parameterisation software.

5.3 RS485 Interfaces

ON

/ X

OFF

Each PQI-DA is equipped with a double E-LAN interface as standard. It provides the bus connection to PQI-DAs, REG-D voltage regulators, REG-DP

Petersen coil regulators, or an EORSys earth fault locating system.

PQI-DA Operating Manual

28

Page 29

a-eberle

PQI-DA

5.4 E-LAN (Energy - Local Area Network)

5.4.1 Features

• 255 bus stations can be addressed

• Multimaster structure

• Integrated repeater function

• Open ring, bus or combination of bus and ring possible

• Log based on SDLC/HDLC framework

• Transfer rates of 62.5 or 125 kbit/s

• Telegram length 10 to 30 Bytes

• Average throughput approx. 100 telegrams / s

5.4.2 Configuration Information

The E-LAN (Energy- Local- Area- Network)) is a powerful bus which is used to

communicate with all the other bus devices, and which can be operated as either

a 2-wire or a 4-wire bus.

The bus controller can store up to 255 addresses. This means that theoretically

up to 255 A. Eberle GmbH & Co. KG devices can be operated by one E-LAN,

and they can all be read and parameterised using a single COM 1 or COM 2

(RS232) interface.

The transfer speed ranges from 15.6 to 375 kBaud.

It is possible to use either a 2-wire and 4-wire line-to-line connection, or to operate up to 32 devices in parallel using a dedicated 2-wire line like a standard bus

connection.

Mixtures of the two topologies are possible, as is the conversion to other bus

protocols and other physical media (LWL connection, coaxial cable, etc.).

The line-to-line topology has an E-LAN characteristic which is particularly useful

for distributed installed devices.

Two RS485 devices can be separated by up to 1.2 km according to the specification of the RS485 driver.

However, since all PQI-DA, like all other bus components, is equipped with a double

interface (E-LAN left and E-LAN right), each device acts as a repeater, meaning

the distance to be bridged can be increased by a further 1.2 km.

Figure 14 shows a configuration in which four PQI-DAs, with addresses <A> to

<D>, are operating on a dedicated 2-wire line using the standard bus technology.

The distance between these four devices may not exceed 1.2 km.

A second bus line is opened from address <B>. In this example, it leads to two

bus stations – a REG-D voltage regulator (address <E>) and a Peterson coil regulator (address <F>).

PQI-DA Operating Manual

29

Page 30

a-eberle

PQI-DA

In this example, an EOR-D is connected to the right hand E-LAN interface of the

PQI-DA with address <D> using a 4-wire connection.

The question “Which device should be connected to the right interface, and which

to the left interface?” is easily answered: both are acceptable. The system can

detect which sort of device is connected to which interface (left or right) and enters

the corresponding bus station (address, type of device, type of connection) into

its own bus index.

Therefore, the bus type doesn’t have to be taken into consideration when planning

an E-LAN. However, one must ensure that each E-LAN component has a unique

address (A...A9, B...B9, C...C9.....Z...Z4) and that the transfer speed and bus

topology are identical between two devices that are connected with each other.

Furthermore, one must ensure that if a two-wire connection is used, the first and

last bus connection are terminated with a resistance as this prevents reflections

from occurring. The resistances are available in every device (as hardware) and

can be activated or deactivated using WinPQ.

E-LAN connections that are not used should either be terminated or operated in

the 4-wire mode.

PQI-DA Operating Manual

30

Page 31

b8

b6

z8

z6

b8

b6

z8

z6

z8

z6

b8

b6

z8

z10

z12

z6

b8

b6

b10

b12

EOR-D

COM1

Status

Reset

PQI-D

COM1

Status

Reset

PQI-D

COM1

Status

Reset

2 wire BUS

z8

z6

BUS-L

BUS-L

BUS-L

BUS-L

BUS-L

BUS-R

BUS-R

BUS-R

BUS-R

BUS-R

BUS-R

4-wire

line to line

2-wire

line to line

2-wire line to line

<A>

<C>

<B>

<D>

<E>

<F>

<G>

PQI-DA

PQI-DA

PQI-D

PQI-D

REG-D

REG-DP

EOR-D

Example of linking using

E-LAN

<A>

PQI-D

PQI-DA

REG-D

REG-DP

EOR-D

Int. term.

BUS address

Power-Quality-Interface

Power-Quality-Interface &

Disturbance Recorder

Voltage regulator

Peterson coil regulator

Earth-fault locating relay

Interface must be terminated

with a resistance

Int. term.

Int. term.

Suitable for fibre optic cable transmission

lengths and RS 485 boosters

Int. term.

Int. term.

www.a-eberle.de

PQI-DA

BETRIEB

STÖRUNG

RESET

class A

www.a-eberle.de

PQI-DA

BETRIEB

STÖRUNG

RESET

class A

AUTO

local

remote

ESC

MENU

F5

F4

F3

F2

F1

Status

< U

> U

> I

REG-D

COM1

a-eberle

Display

X = 81,15

y = 76,95

B = 67,818 mm

H = 67,818 mm

AUTO

local

remote

ESC

MENU

F5

F4

F3

F2

F1

Status

REG-DP

COM1

a-eberle

M

x9

x9

a-eberle

PQI-DA

PQI-DA Operating Manual

31

Page 32

www.a-eberle.de

PQI-DA

BETRIEB

STÖRUNG

RESET

class A

www.a-eberle.de

PQI-DA

BETRIEB

STÖRUNG

RESET

class A

www.a-eberle.de

PQI-DA

BETRIEB

STÖRUNG

RESET

class A

x6 x6 x6

a-eberle

PQI-DA

5.5 Time Synchronisation and Measurement Trigger

The PQI-DA has an accurate quartz real time clock (RTC), which continues to run

even if the auxiliary voltage is interrupted. The synchronisation of multiple devices

is achieved by linking the PQI-DAs via the so-called time synchronisation bus

(RS 232) and/or E-LAN.

A device defined as the time master cyclically transmits its local time via E-LAN

to all the other PQI-DAs. The master also sends additional pulses each second

via the time synchronisation bus to achieve sub-second accuracy. Thus, the real

time clock of each synchronised PQI-DA will exactly match that of the master

PQI-DA.

If the master PQI-DA is synchronised by connecting a radio time signal (e.g. the

MSF signal in Great Britain), this signal is also applied to all the PQI-DAs it synchronises.

Multiple PQI-DAs can also be synchronised by assigning a radio time signal receiver

or GPS receiver to each PQI-DA.

Figure 15: Bussynchronisation,examplesfor3PQI-DAslinkedbya4-wireline.

PQI-DA Operating Manual

32

Page 33

a-eberle

PQI-DA

5.5.1 Measurement trigger

The PQI-DA can record fault records triggered by events and multiple PQI-DAs can

simultaneously store fault records when they are all connected to the measurement

trigger bus. If an event occurs in a PQI-DA that triggers its internal fault recording

to start, this unit sends a trigger pulse to the measurement trigger bus. This pulse

is then detected by the other PQI-Ds and they will also begin to store fault records,

if external triggering has been enabled.

The time trigger can, for example, also be used to deduce how a particular event

at input 1 affected the voltage quality at output 5.

The measurement trigger should always be activated if the exact time sequence

of events is required. Time differences of a few tens of milliseconds may occur

if time-critical data is transmitted over the E-LAN, due to the running time of the

bus.

From the electrical point of view, the time synchronisation bus and the measurement

trigger bus exhibit the same characteristics as the E-LAN (RS 485). However, in

contrast to the E-LAN, the interfaces of the first two can only be configured using

jumpers.

All PQI-DAs are supplied with the termination switched off.

The default values do not have to be altered if one or more PQI-DAs are operated

in a single housing or 19” mounting rack. The first and last device on the bus must

be correctly terminated if multiple housings or mounting racks are used (causing

the bus length to be longer than 50 cm). For time and measurement signals there

is a difference between active and passive termination.

Active termination terminates the bus with the wave resistance at the start of the

cable and at the same time applies the driving voltage to the appropriate bus

segment. On the other hand, a passively terminated bus station is normally located at the end of the cable, and is simply terminated with the wave resistance in

order to prevent reflections.

Due to this, the first device on the bus must be set to active termination and the

last device to passive termination. The termination remains switched off for all the

intermediate devices, i.e. they remain in the default status.

The jumpers for the two signals are located on an additional board which is mounted on the circuit board CPU (see Figure 16).

This method can be used to connect up to 32 devices to each other.

The specification of RS 485 drivers stipulates that the maximum separation of two

devices should not exceed 1.2 km.

PQI-DA Operating Manual

33

Page 34

a-eberle

PQI-DA

5.6 Parameterisation

The PQI-DA Power Quality Interface & Disturbance Recorder can be connected to

the E-LAN just like all other REGSys devices. A PC is used for the parameterisation

and the management of the synchronisation as well as to display the measurement

data of the networked devices. It is connected to one or more PQI-DAs using

the COM interface. REG-L commands are used for communication and both the

WinPQ and the ParaPQ programs can be utilised.

The data management of the system encompasses both the internal and external

management of the measurement and parameterisation data (within the device

and using a PC respectively). The user can only access the settings, statuses

and measurement data of the devices by using a PC (serial interface) since the

PQI-DAs do not contain an operator interface.

However, the units do not require any external computer to carry out the measurements.

Each PQI-DA can record measurement data for a certain amount of time, after

which the information must be transferred to a PC (database) as offline data.

A selection of online data can also be transferred to the PC, either continuously

or all at once. The selection is not affected by the configuration of the recording of

the measurement data. Both online and offline data can be displayed, but in order

to use the device memory and transfer capacity efficiently, the user must specify

which of the measurement quantities should be permanently displayed.

5.6.1 Parameterising the Device

The PQI-DA offers a wide range of measurement possibilities, and not all measurement quantities are required all the time.

However, the parameterisation principle is the same for all of them.

The following parameterisation steps are required:

5.6.1.1 Transformer configuration

The PQI-DA offers complete freedom with regard to configuring the transformer.

Voltage transformers and current transformers can be parameterised independently of each other, ensuring that (almost) every type of measuring circuit can

be achieved using PQI-DAs.

5.6.1.2 Measurement range

PQI-DAs are particularly suited for use in medium and high voltage networks.

However, their use in low voltage networks (230 V → custom value) is also possible without restrictions.

PQI-DA Operating Manual

34

Page 35

a-eberle

PQI-DA

5.6.1.3 Network frequency

The acceptable frequency range for fundamental current and voltage oscillations

is 45...65Hz.

The WinPQ software can be used to configure the triggering options of an event

or fault record for the individual measurement quantities.

5.6.1.4 System time

The system time can be entered into the PQI-DA or controlled by a radio time

signal (real time clock), e.g. in Great Britain, the MSF signal.

A “time drift” of up to 12 minutes per year may occur if a radio clock synchronisation system is not used.

5.6.1.5 Definition of measurement channels for interval data and

event-triggered measurement data

Specific measurement quantities that are appropriate to the type of task being

carried out can be selected and assigned to a measurement channel. Over 3,000

measurement quantities are available.

5.6.1.6 Configuration of the recording of the measurement data

The available memory can be divided according to the type of task being carried

out. If records or events are of particular interest, a significant part of the memory

can be used for these items.

5.7 Hardware-orientated device versions

The flexibility of the system, i.e. precisely matching specific requirements, can

also be achieved using the hardware characteristics of the input and output configuration.

Table 1 shows the different possibilities.

Measurement inputs

Feature

C00 4 voltage inputs (100 V / 230 V)

C10 2 x 4 voltage inputs (100 V / 230 V) for double busbar system

C20 to C31 4 voltage inputs (100 V / 230 V),

Table 1

PQI-DA Operating Manual

4 current inputs (1 A / 5 A)

35

Page 36

PQI-DA

Results according to EN50160

BB1

4 x U

COM1

T1

4 freely programmable limit

value outputs plus status

4 freely programmable

binary inputs (measurement

start, stop etc.)

PQI-DA

BB1

3 x I4 x U

COM1

T1

Results according to EN50160

4 freely programmable limit

value outputs plus status

4 freely programmable

binary inputs (measurement

start, stop etc.)

PQI-DA

4 x U

4 x U

BB2

COM1

T1

BB1

T2

Results according to EN50160

4 freely programmable limit

value outputs plus status

4 freely programmable

binary inputs (measurement

start, stop etc.)

PQI-DA

4 x U

4 x U

BB1

COM1

T1

Results according to EN50160

4 freely programmable limit

value outputs plus status

4 freely programmable

binary inputs (measurement

start, stop etc.)

MV

HV

PQI-DA

4 x U

4 x U

LV

COM1

T1

MV

Results according to EN50160

4 freely programmable limit

value outputs plus status

4 freely programmable

binary inputs (measurement

start, stop etc.)

a-eberle

PQI-DA

5.8 Application Examples (a selection)

There are 5 typical applications using feature “C”

PQI-DA Operating Manual

36

Page 37

RS232

COM 1

D-sub plug connector

front side

6

1 2 3 4 5

7 8 9

GND

RI

DTR

CTS

TXD

RTS

RXD

DSR

DCD

µP

LED

CLOCK

RAM/ROM

Display

DSP

E-LAN

R

E-LAN

L

414042

39 433844374536

E-

GND

E+

EA+

EA-

EA-

EA+

E+

GND

E-

x9

(optional)

COM 2

RS232

63

62616059

TxD

RxD

GND

RTS

CTS

x8

230 V binary inputs

+-+ + +

- - -

E1 E2 E3 E4

30 31 32 33 34 35

prog.

prog.

prog.

prog.

x7

Trigger

GPS

IRIG-A

IRIG-B

585756

55

54

53

52515049484746

GND

TermTxB

TxB

TxA

TermTxA

RxB

Term RxA

RxA

GND

Term B

B

A

TermA

x6

Strip no.

Terminal no.

prog.

prog.

prog.

prog.

R5

230 V binary outputs

Status

R2

R3

R4

16 19

22

17

20

23

2625 28

18

21 24 27 29

x5

R1

4

6

1

3

7

9

10

12

I

3k

I

2k

I

1k

I

3l

I

2l

I

1l

I

4k

I

4l

x3

2

5

8

11

13

GND

U

1

U

2

U

3

x2

U

4

Auxilliary voltag

AC or DC

U L(+)

H

U L(-)

H

14 15

x1

Strip no.

Terminal no.

RS232

COM 1

6

1 2 3 4 5

7 8 9

GND

RI

DTR

CTS

TXD

RTS

RXD

DSR

DCD

µP

LED

RAM/ROM

DSP

E-LAN

R

E-LAN

L

414042

39 433844374536

E-

GND

E+

EA+

EA-

EA-

EA+

E+

GND

E-

x9

(optional)

COM 2

RS232

63

62616059

TxD

RxD

GND

RTS

CTS

x8

+-+ + +

- - -

E1 E2 E3 E4

30 31 32 33 34 35

prog.

prog.

prog.

prog.

x7

Trigger

GPS

IRIG-A

IRIG-B

585756

55

54

53

52515049484746

GND

TermTxB

TxB

TxA

TermTxA

RxB

Term RxA

RxA

GND

Term B

B

A

TermA

x6

prog.

prog.

prog.

prog.

R5

Status

R2

R3

R4

16 19

22

17

20

23

2625 28

18

21 24 27 29

x5

R1

2.2

5.2

8.2

11.2

GND

2.1

5.1

8.1

11.1

13

U

1

U

2

U

3

x2

U

1

U

2

U

3

U

4

U

4

U L(+)

H

U L(-)

H

14 15

x1

D-sub plug connector

front side

Strip no.

Terminal no.

CLOCK

Display

230 V binary inputs

Strip no.

Terminal no.

230 V binary outputs

Auxilliary voltag

AC or DC

a-eberle

PQI-DA

5.9 Block diagram PQI-DA 4 U/4 I

FeaturesC20,C21,C30,C31

5.10 Block diagram PQI-DA 8xU

Features C10

PQI-DA Operating Manual

37

Page 38

a-eberle

PQI-DA

6. Characteristics of the Voltage Supply

The trend to permanently monitor the quality of the network is constantly increasing.

This is, on the one hand, due to the original specification of the task – the desire

to have fixed monitoring – and, on the other, due to the standards and regulations

that have arisen as a result of this desire.

Previously, a transportable device was installed in the system after a fault occurred.

The time t0 was deduced from the measurement between t1 and t2. If no fault

was detected between t1 and t2, one concluded that a fault also did not occur

between time t0 and t1.

This argument is both false and unscientific.

Due to this, EN 50160 defined a sequence of measurement intervals, which require

continuous measurement.

EN 50160 specifies average values that span 10 minutes, days, weeks and up to

a year. Measurements that last months or years can obviously only be achieved

using permanently installed devices.

The range of values and evaluation parameters for low voltage and medium voltage

networks are listed in the following tables.

6.1. Limit Values Specified in EN 50160

DIN EN 50160 “Voltage characteristics of electricity supplied by public distribution

systems”: 2008 generally leaves the precise specification of limits to be jointly

agreed upon by the energy supplier / distributor and the consumer.

This is to be expected, since this area is not uniform throughout Europe.

A feature that is essential for one recipient could have a much lower priority for a

different recipient.

Therefore, it is not only sensible, but also essential, that the voltage quality that

is to be supplied is defined in the negotiations between the energy suppliers and

the consumers.

Table 1 summarises the quality parameters specified in EN 50160 that are most

frequently used.

An example based on the row in Table 1 labelled “Random long interruptions to

the supply (>3 minutes )” (highlighted in grey) shows that the standard is only

applicable via negotiations between the energy supplier and the recipient.

For example, the Standard permits 10 to 50 interruptions of random length to the

voltage supply per year that may each last > 3 minutes.

There are 8760 hours in a year, and if one defines a voltage interruption as 175.2

hours (permissible since 175.2 hours > 3 minutes), it would be possible to not

supply any energy for an entire year and still remain within the framework of EN

50160 (8760 hours = 50 interruptions * 175.2 hours).

PQI-DA Operating Manual

38

Page 39

a-eberle

PQI-DA

This extreme example shows that the regulation only specifies the framework,

within which an individual voltage quality can be defined.

The PQI-DA Power Quality Interface & Disturbance Recorder measures all the

quality parameters and enables the user to define his/her own limit values.

Summary of the important specifications contained in EN 50160

Characteristics of the

supply voltage

Frequency (when connected

to integrated network)

Slow voltage change 230 V

Fast voltage change 5 % 4 % R.m.s. value 10 min 1 day often

Flicker (specification only for

long flicker)

Voltage dips *)

(< 1 min)

Short interruptions to the

supply (< 3 min)

Random long interruptions to

the supply (>3 min)

Intermittent overvoltage at

the network frequency

(extern. conductor - earth)

Transient overvoltage

(extern. conductor - earth) Normally < 6 kV

Voltage asymmetry

(relationship between with

system and contra-system)

Harmonic voltage

(reference Un or Uc)

Inter-harmonic voltage Values not yet available Values not yet available

Signal voltages

(reference value, Un or Uc)

Values / ranges of values Measurement & evaluation params.

Low voltage Medium voltage

49.5 Hz to 50.5 Hz

47 Hz to 52 Hz

Uc

10 %

P = 1

10 to 1000 per year

(under 85 % Uc)

10 to 50 per year R.m.s. value 10 ms 1 year 100 %

10 to 50 per year

(under 1 % U)

Normally < 1.5 kV

Normally 2 %

In special cases up 3 %

Total harmonic distortion

(THD) = 8 %

(MS: 9 to 95 kHz range

not yet available)

±10 %

1.7 to 2.0 Uc

(depending. on

neutral-point

handling)

depending on

isolation

coordination

Basic

quantity

Integration

Interval

Average

value

R.m.s. value 10 s 1 week 95 %

Flicker

algorithm

R.m.s. value 10 ms 1 year 100 %

R.m.s. value 10 ms 1 year 100 %

R.m.s. value 10 ms None 100 %

R.m.s. value None None 100 %

R.m.s. value 10 min 1 week 95 %

R.m.s. value 10 min 1 week 95 %

R.m.s. value 3 s 1 day 99 %

10 s 1 year

2 h 1 week 95 %

Monitoring

period

99.5 %

100 %

Required

percentage

*) IEC 61000-4-30

Table 1

PQI-DA Operating Manual

39

Page 40

a-eberle

PQI-DA

7. Measurement Circuits

Transformer Configuration

In general:

If the neutral earth voltage UNE is not available, terminal “N” must be con-

nected to terminal “E”.

The choice of the type of connection is made via WinPQ.

Voltage transformer configuration and current transformer configuration can

be set independently of each other and therefore they can be adjusted to

any network situation.

Information:

WinPQ offers a button to carry out this procedure as simple as possible.

PQI-DA Operating Manual

40

Page 41

d10

z8

L1

E

d14

z12

L2

E

d18

z16

L3

E

d22

z20

N

E (PE)

d10

z8

L1

d14

z12

L2

d18

z16

L3

d22

z20

E (PE)

d6

z4

PQI-DA simplified connections

Conditions:

- U4 is not required and is therefore short-circuited

- Reference voltage is connected in parallel to L1

- Common zero point

PQI-DA voltage connections

U4

U3

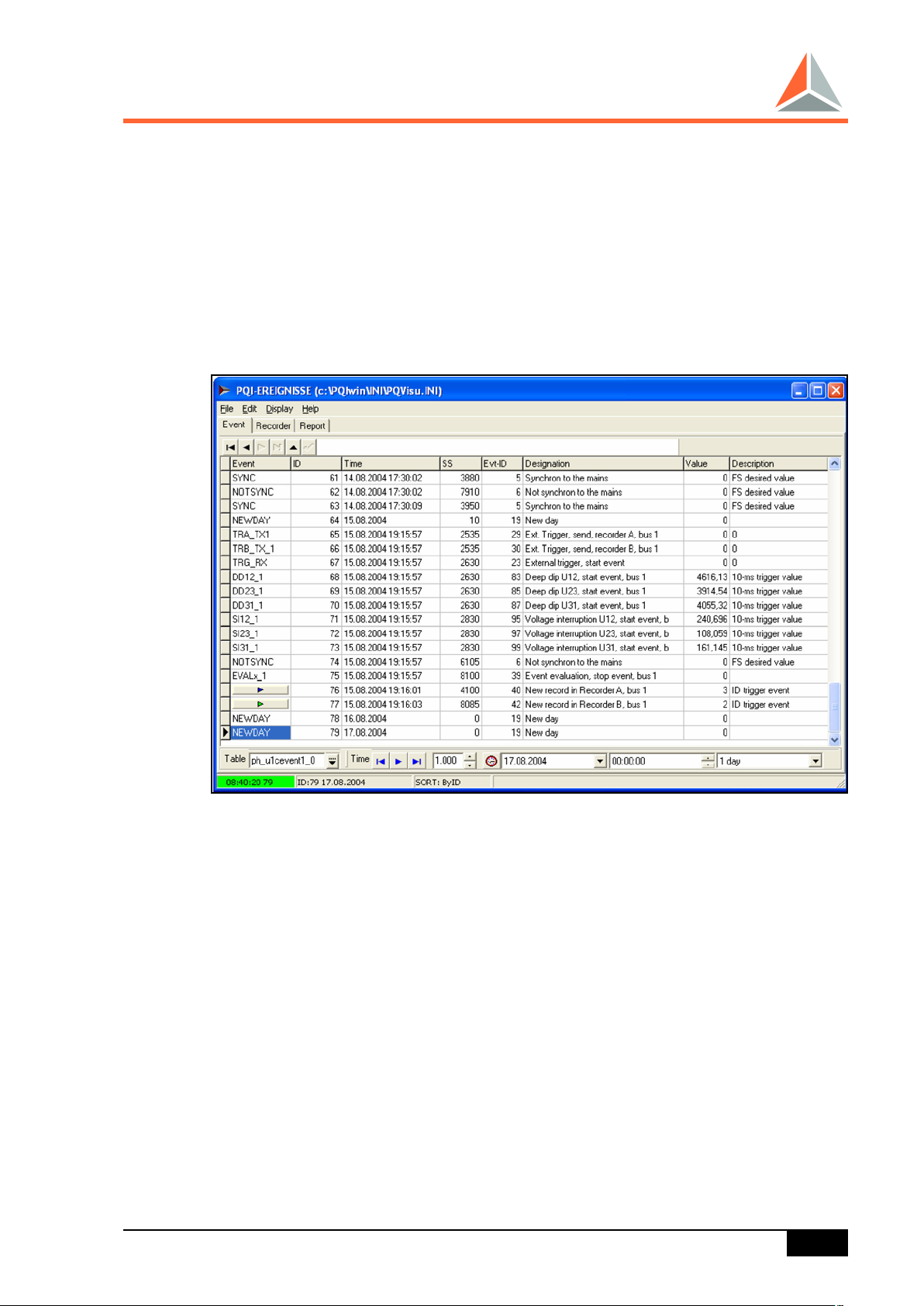

U2