AEB QSB, QSC, QSL9, QSM11, QSX15 Diagram

...

Application

Engineering

Bulletin

Subject This AEB is for the following applications:

Installation Recommendations

Automotive Industrial Power Generation

Date April 2001 (Rev Dec 2001) Page 1 of 38 AEB Number 15.44

Engine Models included: QSB,QSC,QSL9,QSM11,QSX15,QSK19,QST30,QSK45,QSK60

Fuel Systems included:

Changes in blue

Introduction

The Quantum Installation Recommendations Technical Package was written to assist OEMs in integrating

Quantum engines into their equipment. This technical package includes the wiring diagram, pinouts, and other

pertinent information needed to install a Quantum engine

Refer to the following other Industrial AEB’s:

AEB 15.40 – Electronic Features

AEB 15.42 – OEM Components and Interfaces

AEB 15.43 – Datalinks and Diagnostics

Authors: Scott Decker, Michael L. Hill, Brian Landes, Jeffrey Martin, Stewart Sullivan, Tiffany Walker

AEB15.44

Page 2 of 38

Table of Contents

Introduction ......................................................................................................................................... 1

Table of Contents................................................................................................................................. 2

Section I – Grid Heaters .................................................................................................................... 3-4

Section II – Power and Ground Requirements..................................................................................4-5

System Grounding Requirements ..................................................................................................... 4

High-Current Accessory Grounds ......................................................................................................4

Cylinder Block as Ground................................................................................................................. 4

Starter Ground .................................................................................................................................4

Frame Returns .................................................................................................................................4

Switches and Sensor Grounding Requirements................................................................................. 5

Solenoid Grounding Requirements.................................................................................................... 5

Section III – Keyswitch Requirements.................................................................................................. 6

Keyswitch Connection Requirements................................................................................................ 6

Sourcing.......................................................................................................................................... 6

Fusing............................................................................................................................................. 6

Inductive Load Sharing ..................................................................................................................... 6

Fault Lamp/Keyswitch Wiring Configuration....................................................................................... 6

Optional 2-Lamp Strategy Wiring...................................................................................................... 6

Section IV – Welding Requirements..................................................................................................... 7

Section V – OEM Harness and Harness Routing ............................................................................... 7-8

Wire Section ....................................................................................................................................7

Contacts and Connectors ................................................................................................................. 7

Protective Covering ..........................................................................................................................8

Harness Routing and Support........................................................................................................... 8

Section VI – Datalink Requirements for QSM11 and QSX15 .................................................................9

Section VII – Wiring Diagrams/Pin Mapping ................................................................................. 10-18

QSK45/60 Cense Wiring Diagram...................................................................................................10

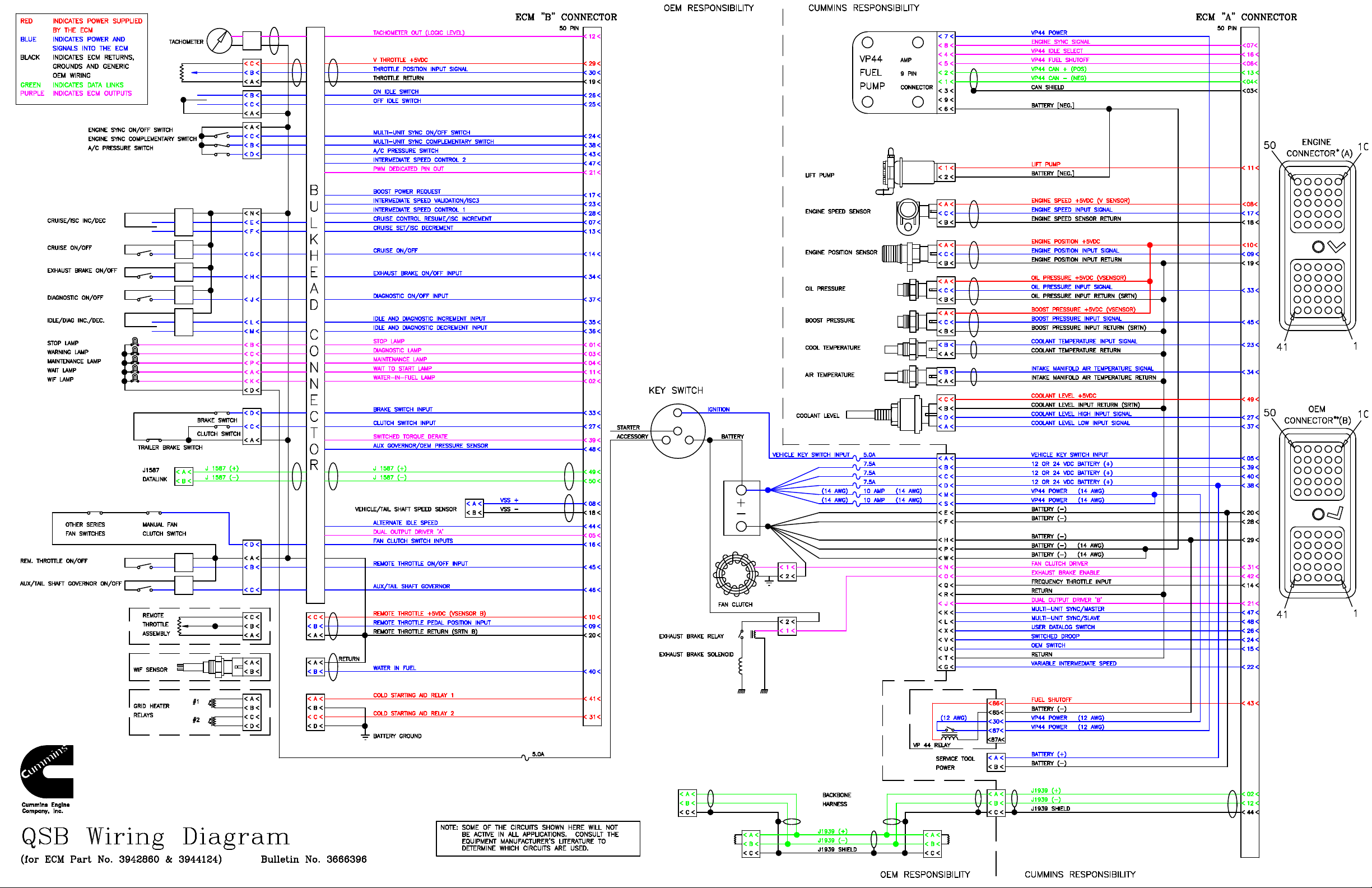

QSB Wiring Diagram ......................................................................................................................12

QSC Wiring Diagram......................................................................................................................14

QSM11 Wiring Diagr am..................................................................................................................16

QSX15 Wiring Diagram..................................................................................................................18

QSK19/45/60 Wiring Diagram .........................................................................................................20

QST30 Wiring Diagram ..................................................................................................................22

QSB Pin Mapping ..........................................................................................................................24

QSC/QSL9 Pin Mapping............................................................................................................ 25-26

QSM11/QSX15 Pin Mapping..................................................................................................... 26-28

QSK19 Pin Mapping.................................................................................................................. 29-30

QST30 Pin Mapping .................................................................................................................. 30-31

Section VIII – Pinout Specifications.............................................................................................. 32-43

5V Sensor Voltage Source Pinout Specifications ..............................................................................32

5V Switched Pullup Input Pinout Specifications................................................................................33

10V Switched Pullup Input Pinout Specifications..............................................................................34

ECM Supply and Return Pinout Specifications.................................................................................35

Ratiometric Analog Input Pinout Specifications ................................................................................36

Resistive Analog Input Pinout Specifications ....................................................................................37

Switched Pulldown Input Pinout Specifications .................................................................................38

Switched Sink Driver Output Pinout Specifications ...........................................................................39

Switched Source Driver Output Pinout Specifications .......................................................................40

Tachometer Source Driver Output Pinout Specifi cations...................................................................41

Variable Reluctance Input Pinout Specifications (Differential Input)...................................................42

Variable Reluctance Input Pinout Specifications (Single-Ended Input)...............................................43

AEB15.44

Page 3 of 38

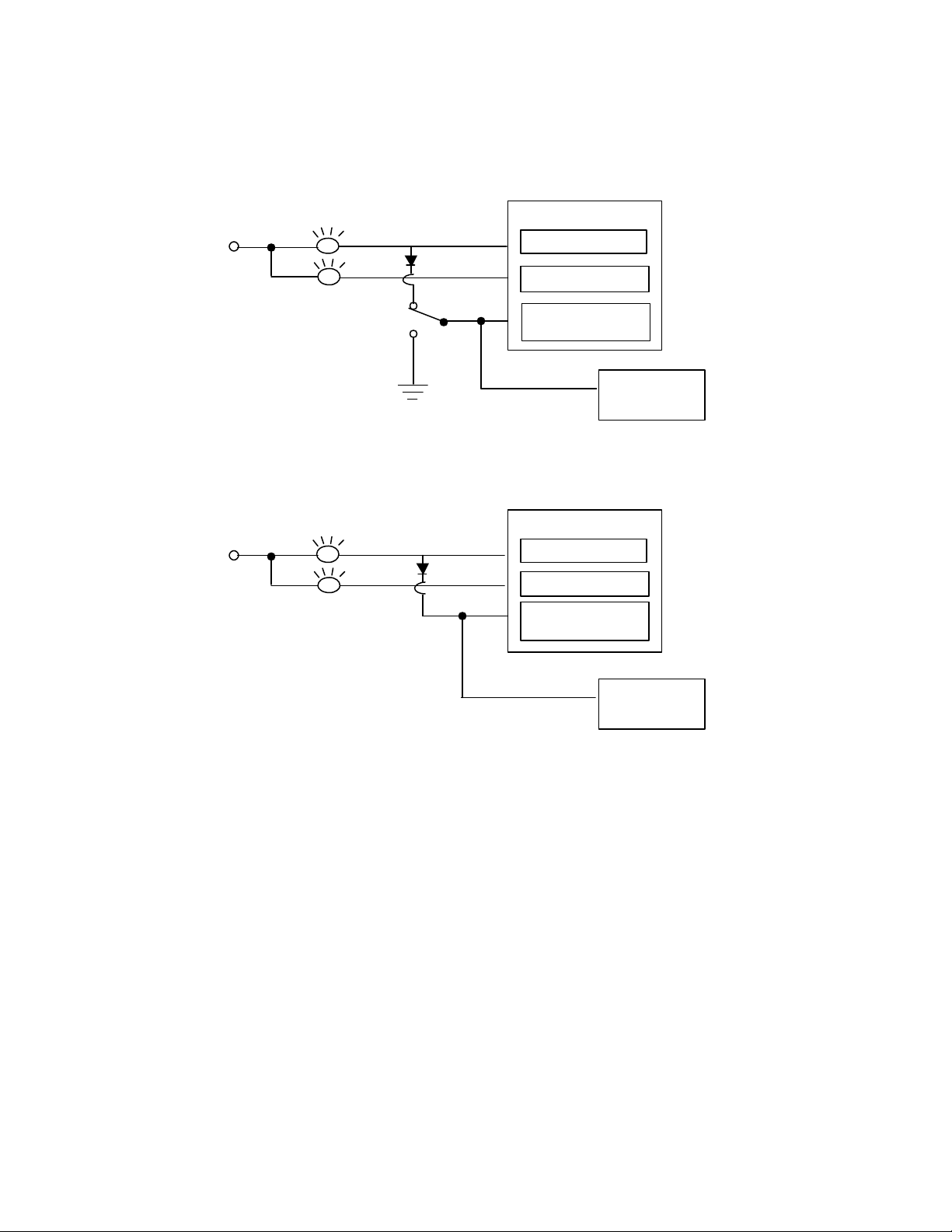

Section I - Grid Heaters

QSB, QSC, QSL9

The intake air heater system is used to aid in starting during cold temperatures and to reduce white smoke after

such a start. The system consists of two heater elements that are controlled by the ECM via two high current

relays. Grid heaters are required for QSB/C/L9 engines.

Note: The installer is responsible for procuring and mounting the grid heater power relays in a location

free of road splash and also for routing battery connections through the relay contacts to the (2) grid

heaters which are shipped with the engines. The intake air heater relays must not be mounted on engine.

Since power routed to the grid heaters is through one wire then the gauge of the wire should be 2 AWG minimally

since each of the grid heating elements require 105 amps during the heating cycle. The gauge of the wire from

the grid heater, relays to the grid heater elements, also need to be 6 AWG minimally to carry the required current.

Fuses or fusible links set to 125 amps are advocated for the grid heating elements. The 24 V DC heater-relay is

connected to the OEM interface connector. The ECM can source up to 3 amps to turn this relay on. The switch

contact of this relay must carry the current from battery (+) to the grid heating elements. Only one relay is

required to drive both grid heaters on 24 V DC systems since the grid heaters are wired in series.

QSM11, QSX15

The intake air heater system is used to aid in starting during cold temperatures and to reduce white smoke after

such a start. The system consists of one heater elements that are controlled by the ECM via one high current

relay.

Note: The installer is responsible for procuring and mounting the grid heater power relays in an

acceptable location in respect to vibration and environmental influences such as road splash. The intake

air heater relays must not be mounted on engine.

The gauge of the wire from the grid heater, relays to the grid heater elements, also need to be sized for the

heater's current requirement. Typically, a 6 AWG minimally to carry the required current. Fuses or fusible links

set to 125 amps are advocated for the grid heating elements. The 24 V DC heater-relay is connected to the OEM

interface connector. The ECM can source up to 3 amps to turn this relay on. The switch contact of this relay

must carry the current from battery (+) to the grid heating elements. Only one relay is required to drive both grid

heaters on 24 V DC systems since the grid heaters are wired in series.

The QSM11 grid heater requires that the installer provide the ground wire or strap. This ground wire should be

routed directly to the starter ground connection or the battery ground. It is not acceptable to ground the grid

heater to the engine block or cylinder head.

The QSX15 grid heater is grounded directly to the engine's ground lug. The QSX15 grounding wire is supplied

with the engine.

QST 30

The intake air heater system is used to aid in starting during cold temperatures, while helping to reduce white

smoke. The system consists of twelve heater elements that are controlled by a primary and secondary ECM via

two high current relays. The ECM can source up to 3 amps.

Note: The installer is responsible for routing battery (+) connections to the contacts of the grid heater

relays, which are shipped with each engine.

Each grid heater element is rated for 86A@12V. As a result, each bank of grid heater elements will draw 258

amps in an ideal 24-volt system and have a total current draw of 512 amps for both banks. Therefore, the

AEB15.44

Alternator

Cylinder

Block

Starter

Battery

(+)

ECM

(+)

(+)

OOOO(+)

O

.

.

Optional

Cylinder Block or

2 AWG Flat Braided

Battery

Disconnect

Page 4 of 38

equipment manufacturer must be sure to size the supply wire appropriately to support the grid heater current draw

requirements. A minimum #000 gauge cable routed to each bank is recommended.

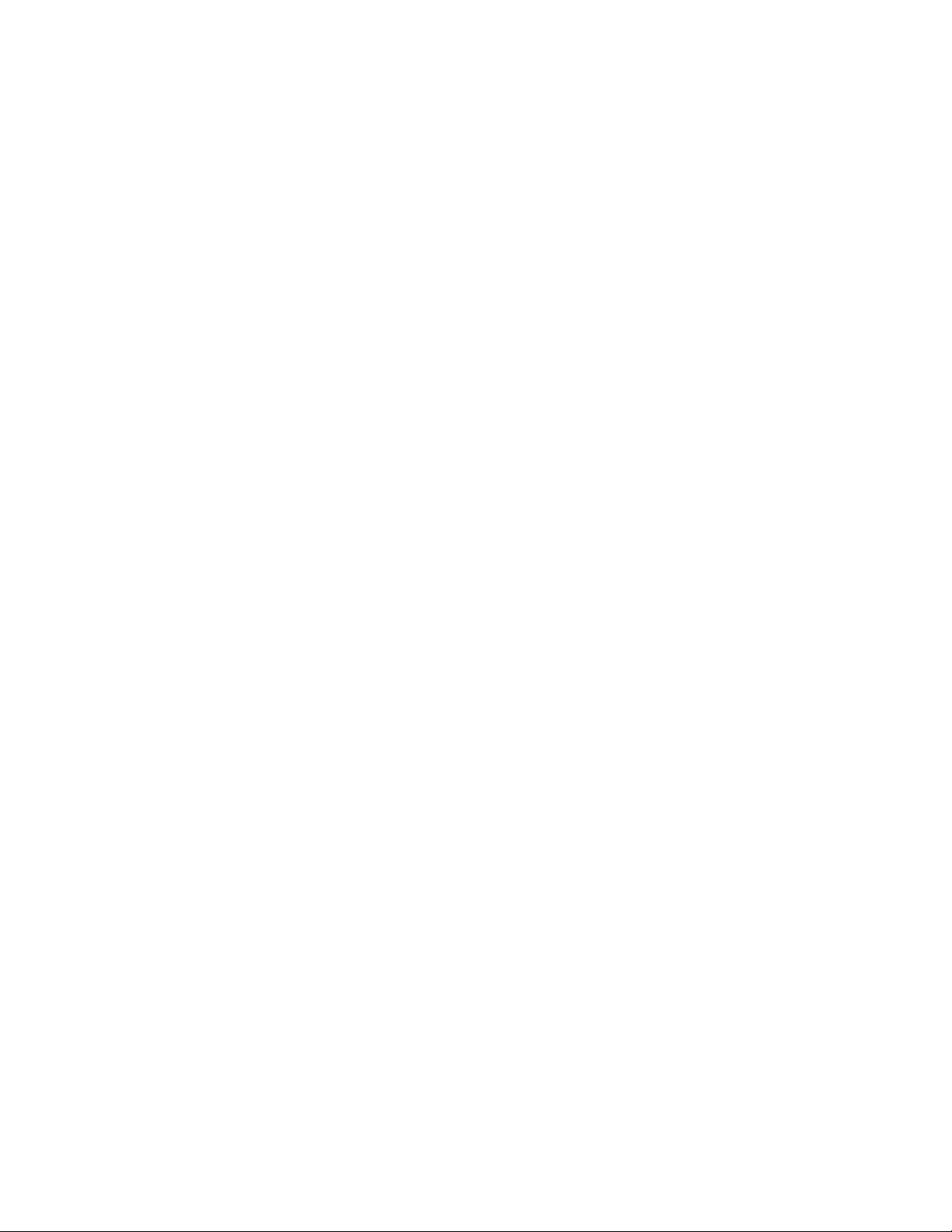

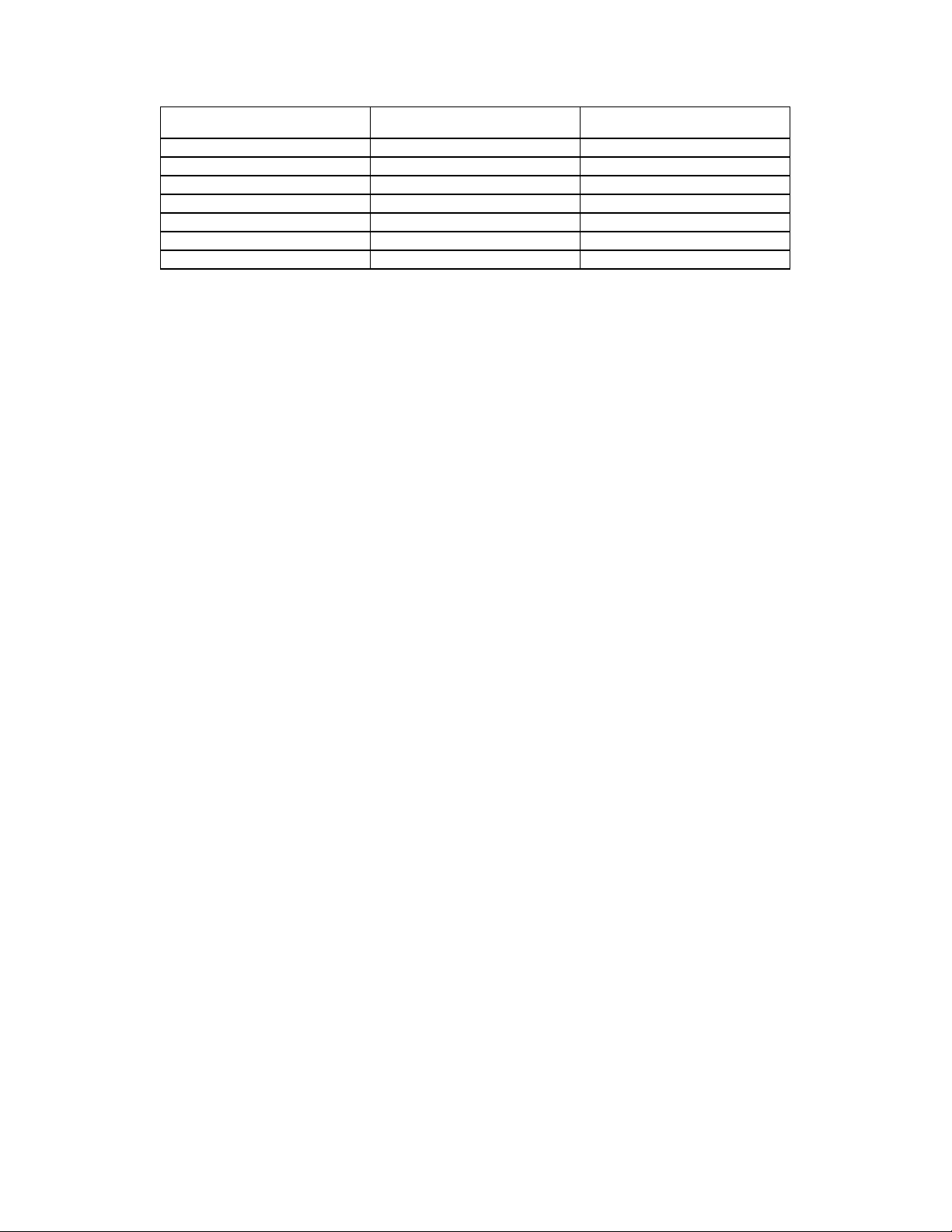

Engine Family Voltage Heater Current ECM Relay Source

QSB/QSC/QSL9 12 210 3 Amps

QSB/QSC/QSL9 24 105 3 Amps

QSM11 24 90 2 Amps

QSX15 24 105 2 Amps

QST30 24 258 amps/bank

512 amps total

3 Amps

Section II - Power and Ground Requirements

Power and Ground

System Grounding Requirements - Ground loops and electrical noise is a source of numerous problems with

today's electronic engines. For example, a high current device such as an alternator can inject electromagnetic

interference (EMI) through the cylinder block back through the ECM, which is case-grounded to the block to shunt

radio frequency noise. Other examples are relays that switch at high speeds introducing high frequency noise

into the cylinder block, which can introduce noise into the ECM. To minimize these problems, follow the practices

described in interface specification IS-1377-9807 and the following paragraphs. Refer to the Power Connection

Layout figure below.

.O.

(-)OO

Starter Negative

Power Connection Layout

High-Current Accessory Grounds - Alternators and other engine accessories greater than 10 amps should be

grounded to the starter negative terminal (always follow starter manufacturer's recommendations) rather than to

the cylinder block. This minimizes the electrical noise and ground loops present in the overall system. Optional

locations are to the battery negative terminal or a central location on the cylinder block. If the alternator is

grounded to a central location on the cylinder block, e.g. ground stud or ground boss, it must be attached to the

same location as the starter or battery negative.

Cylinder Block as Ground - The cylinder block represents a very large capacitance to system ground, which

makes it a highly effective RF shunt. Therefore, many devices, including the engine ECM, prefer to shunt RF

noise to the cylinder block. However, if the block contains current-induced voltage noise, it can become a point of

noise entry for devices using it as a RF shunt. It is acceptable to use the cylinder block as a return for devices

that are powered continuously. For devices that carry high currents (engine accessories greater than 10 amps) or

that switch on and off rapidly, the return should route to starter or battery negative.

(-)

(-)

(-)

O

AEB15.44

Page 5 of 38

Starter Ground - Ground the starter negative with a 2 AWG wire or larger to the cylinder block to help shunt RD

noise. A flat, braided wire is more effective than a round, stranded cable. An insulated welding cable is also

acceptable. Since the braided wire is not insulated, the welding cable is acceptable and typically has a longer

service life. This low impedance ground path design should take into account long-term degradation.

Frame Returns - Cab and chassis components should have common ground points to reduce ground loops.

Frame ground returns are often a source of problems and should be avoided. The frame ground alternative adds

more resistance to a return circuit.

Minimum wire size – The preferred method of connecting the ECM power supply to the batteries is by

maintaining the required number of stranded 18 AWG wires over the entire length of the connection (see each

engine family wiring diagram). When splices occur, a minimum of four stranded 10 AWG or larger wires must be

used between the splices and the battery, two for (+) and two for (-). Circuit resistance must not exceed 40

milliohms, but 10 milliohms is desirable. This circuit resistance limit includes the OEM-supplied circuit protection

system and any switches or interconnects.

Switches and Sensors Grounding Requirements

All switches and sensors that are wired directly to the ECM must be referenced to an ECM switch return. These

components use inputs that are susceptible to noise and voltage offsets that can be introduced through the return

path. Follow these guidelines when designing the machine wiring.

Inductive Load Sharing - When used as a switch return, an ECM switch return must never be used to return

unsuppressed inductive loads. Relay coils on the same circuit should be avoided. However, if a relay is used, it

should contain a suppression diode. This will isolate noise from the return, which can impair the reliability of a

switch or sensor input.

Sensor Dedication - When used as a return for certain analog sensors (i.e. pressure, temperature, or APS), an

ECM switch return should be dedicated solely to that sensor. Radiometric and resistive ECM inputs are very

sensitive, even a small change in voltage drop will affect the detected parameter.

Isolation - An ECM switch return must be kept isolated from machine chassis ground. This will prevent

undesirable ground loops.

Sourcing - An ECM switch return should not be used to return any voltage that has not been sourced from the

ECM. This will prevent overloading of the ECM supply returns.

Star Ground - For switch panels that contain critical switches such as the MUS on/off switch, it is good practice to

establish a "star" ground fed by dual redundant ECM switch returns. A proper star ground will have a separate

return to each switch. When designed in this manner, a single-point open-circuit return fault will result in the loss

of no more than one switch.

Solenoid Grounding Requirements

Solenoids and relay coils that are wired directly to the ECM may be referenced either to a good chassis ground or

to an ECM solenoid return. The ECM solenoid return is a convenience and is not a requirement. If an ECM

solenoid return is used, follow these guidelines when designing the machine wiring.

Inductive Load Sharing - When used as a solenoid return, an ECM solenoid return must not be used as a return

for critical components such as switches or sensors. Guidelines for these components are more extensive as

detailed in the previous paragraphs.

Isolation - An ECM solenoid return must be kept isolated from machine chassis ground. This will prevent

undesirable ground loops.

Sourcing - An ECM switch return should not be used to return any voltage that has not been sourced from the

ECM. This will prevent overloading of the ECM supply returns.

AEB15.44

Page 6 of 38

Section III - Keyswitch Requirement

Keyswitch Connection Requirements

Proper connections of the keyswitch to the ECM are critical for proper operation of the engine. The keyswitch

signal must be continuously present in order for the engine to operate. A loss of this signal, even a momentary

loss, can cause undesirable ECM resets, which can stall the engine and cause fault codes. Follow the installation

guidelines in interface specification IS-1377-9807 and the following paragraphs.

Sourcing - The keyswitch must be connected directly to the ECM. There must be no switches or relay contacts

between the keyswitch and the pinouts at ECM connector. Any engine shutdown systems designed to interrupt

key switch power must have a Cummins application review completed and approved for that system.

Fusing - The keyswitch signal must be fused so that an electrical short due to some other component does not

affect voltage at the ECM keyswitch input.

Inductive Load Sharing - The keyswitch signal must not share its circuit with unsuppressed inductive loads.

Relay coils on the same circuit should be avoided. However, if a relay is used, it should contain a suppression

diode. This will isolate noise, which can impair the reliability of the keyswitch input.

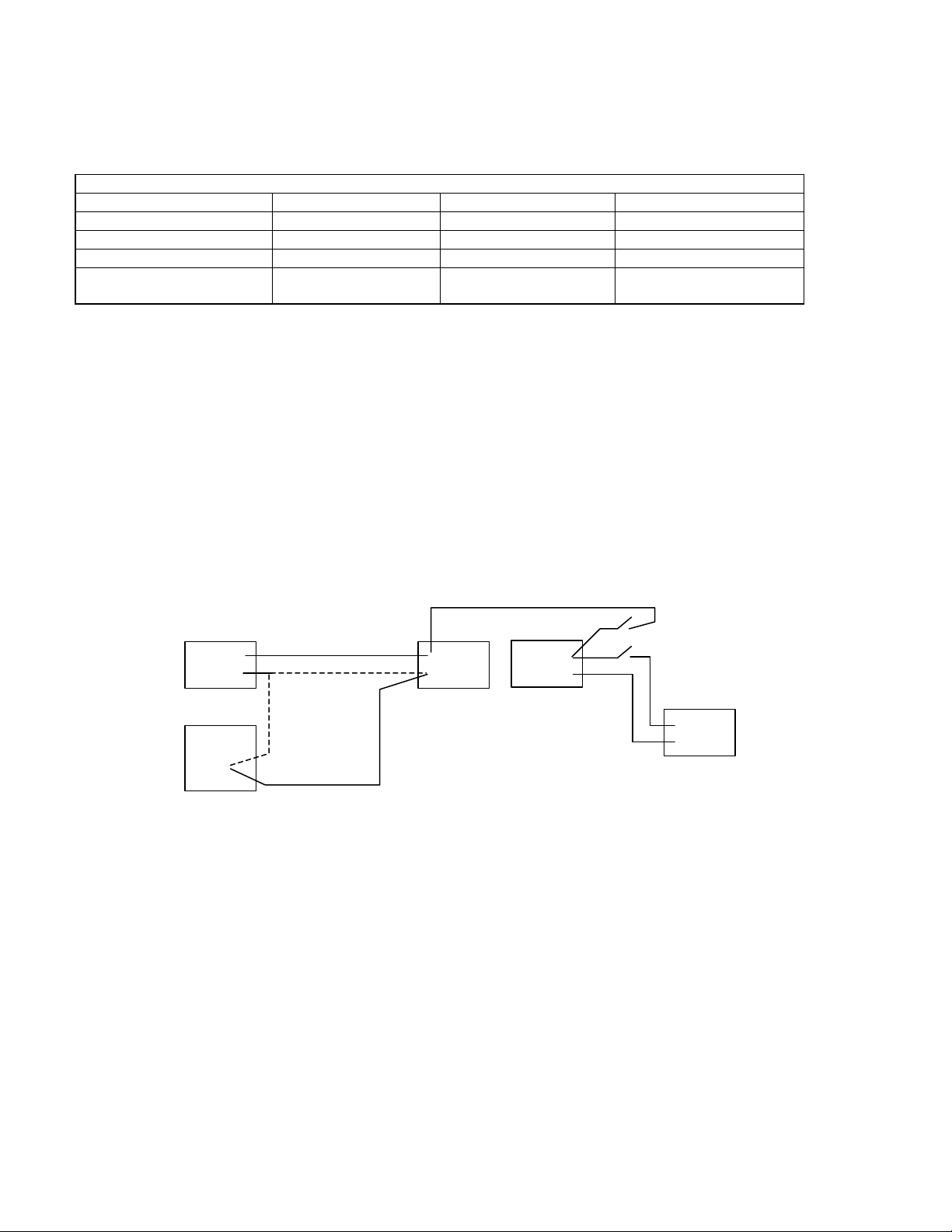

Lamp/Keyswitch Wiring Configuration

Fault

AEB15.44

DIAGNOSTIC

ENGINE PROTECTION

TO VEHICLE

(WHEN USED

)

STOP LAMP DRIVE

ENGINE PROTECTION

KEYSWITCH

(WHEN USED

)

Page 7 of 38

Optional - 2 Lamp Strategy - QSK19/45/60 - The Optional 2-lamp strategy will eliminate the Engine Protection

(white) Lamp. Therefore, the operator will only have a warning (yellow) and stop (red) lamp on the dashboard. All

of the faults that were mapped to the Engine protection lamp will become annunciated through the stop (red)

lamp. This change will only affect the wiring of the fault lamps and not the software or calibration. See wiring

below.

ENGINE ECU

KEYSWITCH

POWER

STOP LAMP DRIVE

WARNING LAMP DRIVE

POWER

SWITCH

LAMP DRIVE

2-Lamp Strategy with Cense

CENSE ECU

WARNING LAMP DRIVE

LAMP DRIVE

2-Lamp Strategy without Cense

PROPEL CIRCUIT

TO VEHICLE

PROPEL CIRCUIT

AEB15.44

Page 8 of 38

Section IV - Welding Requirements

Welding

Welding on the engine or engine mounted components is not recommended. Cummins recommends

disconnecting all OEM connectors. Attach the welder ground cable no more than two feet from the part being

welded. Never connect the ground cable of the welder to the ECM.

Section V - OEM Harness and Harness Routing

Wire Selection

Wire selection is critical for proper operation of the engine. Follow these guidelines when designing the OEM

wiring harness.

Wire Size - The size requirement for the harness wiring is 18 AWG stranded wire, covered with GXL or TXL

insulation for all underhood wiring. Diameter range including insulation is 0.040-0.095 inches. This wire size and

insulation type is the only one tested and approved by Cummins with the Deutsch 50-pin connector.

Twisted Pairs - There are three sets of twisted-pair wires. The wires are twisted at a rate of one twist per inch

and are used with the Shaft Speed sensor, the tachometer and the J1587 datalink.

Twisted Triplets - There are three sets of twisted-triplet wires. The wires are twisted at the rate of one twist per

inch and are used with the base throttle, remote throttle, and variable throttle option of the Intermediate Speed

Control (ISC) feature.

Datalinks - A separate cable must be used on the J1939 datalink. Refer to SAE J1939/11 and J1939/13 for

detailed specifications on the datalink wire requirements. Refer to AEB 15.43 Datalink and Diagnostics.

Contacts and Connectors

The connection points of the OEM wiring harness must be adequately protected from vibration and moisture

intrusion. The design practices and manufacturing methods for typical 12- and 24- volt systems are not adequate

when the subsystem operates with low signal level electronics on some circuits. Follow the guidelines in the

following paragraphs.

Datalinks - The quantum electronic subsystem requires gold plating for the OEM connector terminals and any

J1939 and J1708 datalink connections.

Switches - The Quantum subsystem recommends that all switch contacts (except keyswitch) be gold flashed to

ensure reliable switching at low voltages and currents. Ring terminals may be either solder dipped or tin plated.

Follow the guidelines in interface specification IS-1377-9802.

Connectors - Chassis-mounted connectors should be environmentally sealed and, at a minimum, be tin-plated or

nickel-plated. A lubricant should be applied to connector terminal surfaces as an added safeguard for use with

tin-plated or nickel-plated contacts to reduce the risk of fretting corrosion. In the cab area, tin plating should be on

wire-to-wire and wire-to-switch interconnections. This is a minimum requirement.

Recommended Plating - A detailed review of the termination and connector uses is to be conducted with the

connector supplier. A sample of typical connector supplier recommendations for plating subsystems used in low

current signal applications is shown in the Recommended Plating Systems table.

AEB15.44

Page 9 of 38

Recommended Plating Systems Table

Surface Plating Underplating Terminal material

Gold, cobalt hardened Nickel, matte Brass

120-200 Knoop 180-300 Knoop

50-80 micro-inches 80-110 micro-inches

Tin, Matte Nickel, matte Brass

30-120 micro-inches 50-120 micro-inches

<250 micro-inches/pair

Plating Systems Not Recommended - The following plating systems are not recommended: Tin with >250

micro-inches per terminal pair (male + female interface), gold with no underplating barrier, brass, silver, and

copper.

Dissimilar Metals - The use of dissimilar metals for any terminal pair (male + female interface) is not

recommended. Use of dissimilar metals will cause galvanic corrosion, resulting in terminal pitting and premature

circuit failure.

Throttle Circuit - It is recommended that the connector terminal between the base throttle pedal and ECM be

gold plated. This recommendation also applies to the remote throttle circuit and the variable ISC throttle circuit.

OEM Sensor Circuit - It is recommended that the connector terminals between the OEM temperature sensor and

the ECM and between the OEM pressure sensor and the ECM, be gold plated.

Protective Covering

The protective covering for the OEM wiring harness should have high abrasion and cut resistance, continuous

temperature capability to 125o C (257o F) and intermittent temperature capability to 150o C (302o F). The material

should also have high chemical resistance to fuel, engine oil and engine coolant. The harness covering should

not strain the wire or the wire seal at the connector and typically should be terminated approximately 1/2 inch from

the connector shell. Convoluted tubing, woven braid, or overfoamed is recommended as protective covering.

Convoluted Tubing - If convoluted conduit is selected, nylon material should be specified. The material should

be slit lengthwise and have drainage provisions for fluids. Conduit ends should be secure to prevent unraveling.

Woven Braid - If woven braid is selected, the material should consist of a nylon core with a vinyl covering. The

covering should be a minimum of 12 picks per inch and a tight, non-slip covering over the cables should be

provided. The braid tail should be secured to prevent unraveling.

Harness Routing and Support

The physical routing and support of the OEM wiring harness should minimize strain in the wire seals and of all

connectors and should protect the harness from damage due to abrasion, heat and sharp objects. The harness

should be clamped at any location on the engine/machine where support is required to protect the harness from

strain damage. Wherever possible, wires associated with the OEM harness should be routed physically close to

metals connected to battery (-) (e.g. frame rails, engine block) to minimize electromagnetic interference with other

electronic subsystems in the vehicle. All wiring should be kept free from sharp bends around components that

can cause nicks, cuts or other damage. The harness should be routed away from sharp objects, exhaust system

components and other high temperature components.

AEB15.44

50 pin

Page 10 of 38

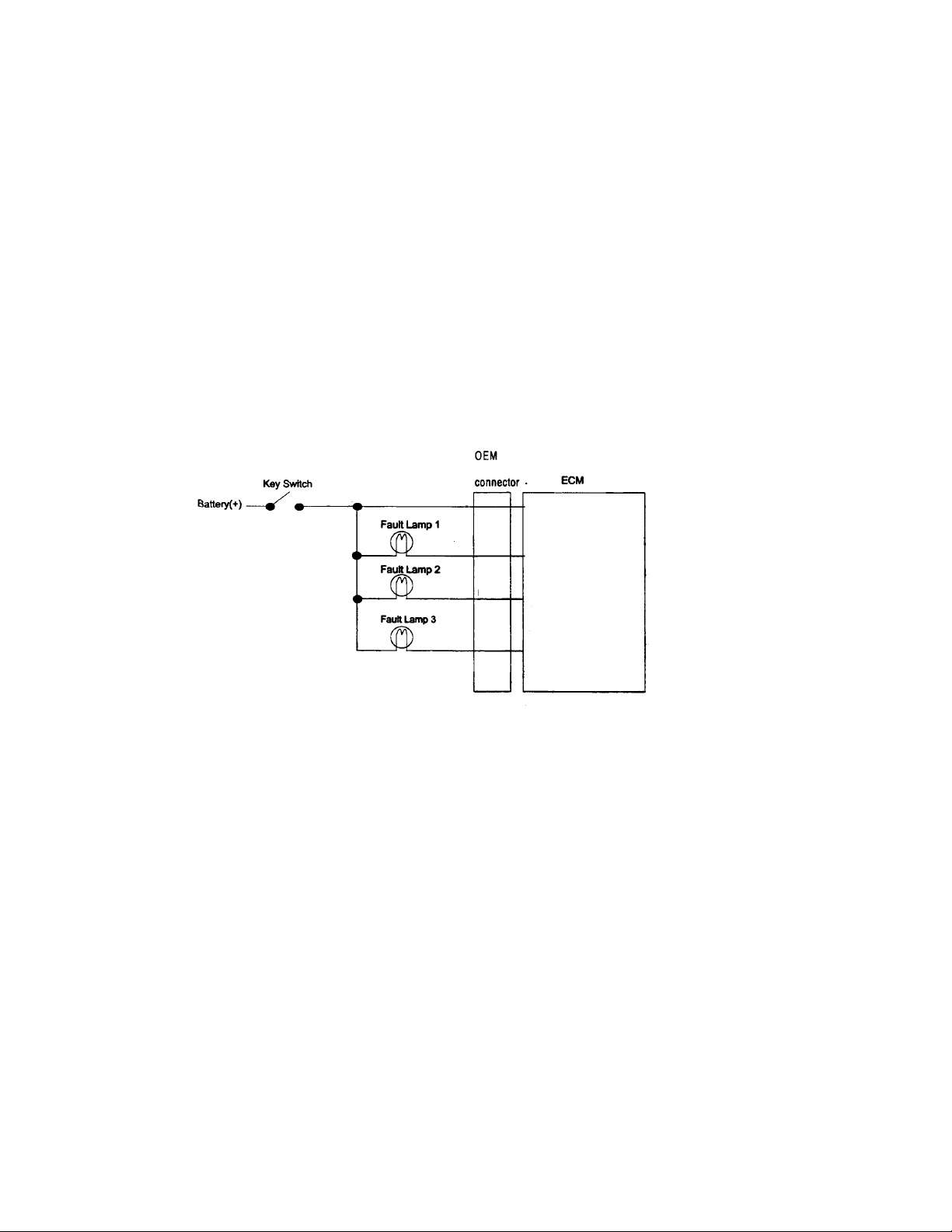

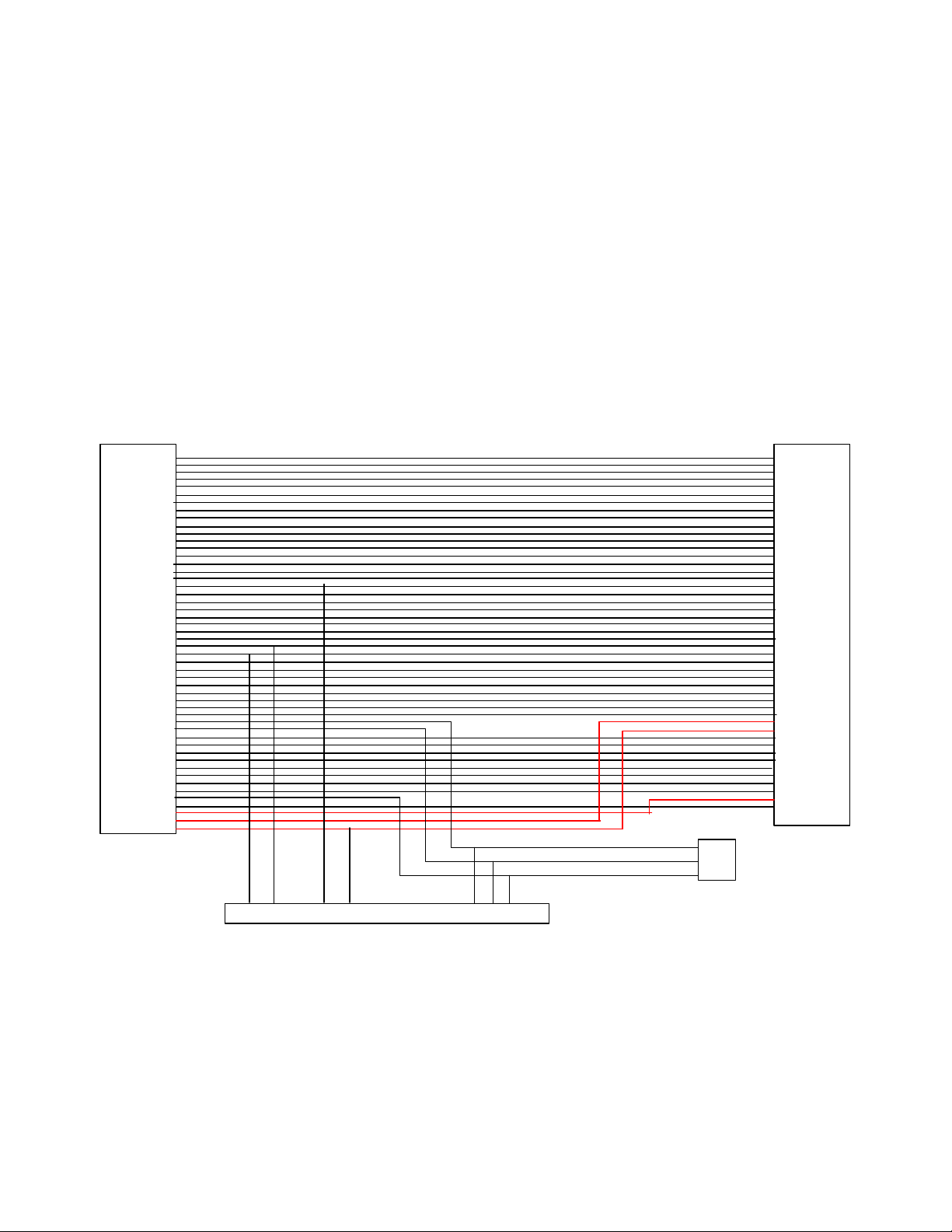

Section VI - Datalink Requirements for QSM11 and QSX15

The 9-pin service datalink does not ship on the QSM11 and QSX15 engine unless you order the designated EA

option. A 47-pin OEM Deutsch connector will also available as the interface instead of connecting directly to the

50-pin OEM connection on the ECM. This option will include a 9-pin connector, 3-pin connector, a 50-pin

connector and a 47- pin round connector. The new 47-pin OEM connector is in a mounting bracket generally

above the ECM. The 9 and 3 pin connectors are in the same location, but are not mounted into the bracket.

They come off the wiring harness extension. See wiring diagram below.

J1939 Backbone - A J1939 backbone is required on every machine that contains a QSM11 or QSX15 engine.

Terminating resistors should be used on the J1939 backbone as specified in AEB 15.43 Datalinks and

Diagnostics technical package. Recommended termination receptacles and stub connectors are defined in the

OEM Components technical package.

Stub Connector - A 3-pin J1939 receptacle stub connector must be inserted between the ECM and the J1939

OEM connector

on ECM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

C

B

A

3 pin

G F B A E D C

9 pin Service Datalink

Connector

connector

for extending

J1939 backbone

47 pin

OEM connector

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

backbone. This is to prevent wiring faults between the ECM and the datalink connector from preventing

communication with the ECM, thus rendering it unserviceable. This stub must be located within 12 inches of the

50-pin OEM connector.

OEM Datalink option wiring diagram

Loading...

Loading...