Page 1

GXA-03 RS-232C Isolated Interface

GXA-04 Comparator output

GXA-06 Analog voltage output

1WMPD4003498

Page 2

© 2017 A&D Company, Limited. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, or translated

into any language in any form by any means without the written permission of A&D

Company, Limited.

The contents of this manual and the specifications of the instrument covered by this

manual are subject to change for improvement without any notice and obligation on

the part of the manufacturer.

Page 3

Contents

1. Introduction...................................................................................................................................2

2. Features ....................................................................................................................................... 2

3. Packing List..................................................................................................................................3

4. Installing the Option ..................................................................................................................... 3

5. Function Table of Balance........................................................................................................... 4

5.1. Operation Keys and Display of Function Table................................................................... 4

5.2. Items List of the Function Table ........................................................................................... 5

6. GXA-03 Isolated RS-232C interface.......................................................................................... 8

6.1. Specifications of Serial Interface..........................................................................................8

7. GXA-04 Comparator Output.......................................................................................................9

7.1. Specifications of Comparator Output................................................................................... 9

7.2. Using the Comparator Output............................................................................................10

7.3. Comparison Method Selection

7.4. Setting Threshold Values ................................................................................................... 12

7.5. Setting Center Value and Tolerance Range......................................................................13

8. GXA-06 Analog Voltage Output................................................................................................15

8.1. Specifications of Analog Voltage Output............................................................................15

8.2. Function Table of Analog Voltage Output..........................................................................16

8.3. Voltage Output Selection....................................................................................................18

8.4. Voltage Output Fine Adjustment ........................................................................................ 18

8.5. Fixed Voltage Output ........................................................................................................19

(Tolerance Range and Center Value or Threshold Values)

.............. 11

Page 4

1. Introduction

This manual describes options for the GX-A series and GF-A series and how to get the most

out of them in terms of performance. Read this manual thoroughly before using the options

and keep it at hand for future reference.

2. Features

The following options can be used for the GX-A series and GF-A series.

GXA-03 Isolated RS-232C interface

GXA-04 Comparator output (with buzzer) / External contact input x 2

GXA-06 Analog voltage output

GXA-03: Isolated RS-232C interface

Commands from the PLC or other devices installed in the factory environment can be used to

make the following operations : output measurement data from the balance, input parameters

into the balance, control the balance, reference parameters of the balance, etc.

The RS-232C is equipped with a data format to manage the balance in accordance with GLP.

( Refer to the instruction manual of the balance. )

GXA-04: Comparator output / External contact input

The GXA-04 can compare the weighing value and preset threshold values and can output

the result to the contact output.

The GXA-04 is equipped with six contact outputs: "HH", "HI", "OK", "LO", "LL" of the

comparison output and "READY" output to indicate the status of the balance.

3-stage comparison or 5-stage comparison can be selected.

The GXA-04 can sound a buzzer according to the comparison result.

The GXA-04 is equipped with external control input terminals that can make the RE-ZERO

and PRINT key operations. An optional foot switch (AX-SW137-PRINT,

AX-SW137-RE-ZERO ) can be used.

GXA-06: Analog voltage output

The GXA-06 can output analog voltage in the following modes :

"mode where the specified digits of the weighing value are converted to voltage" and

"mode where weighing value is converted to voltage in range between gross zero or net zero

and full scale".

The voltage output range can be selected using the "0V /0.2V " switch on the panel.

It can be selected "0 to 1V" range and "0.2V to 1V" range. The factory setting is "0 to 1V" range.

2

Page 5

y

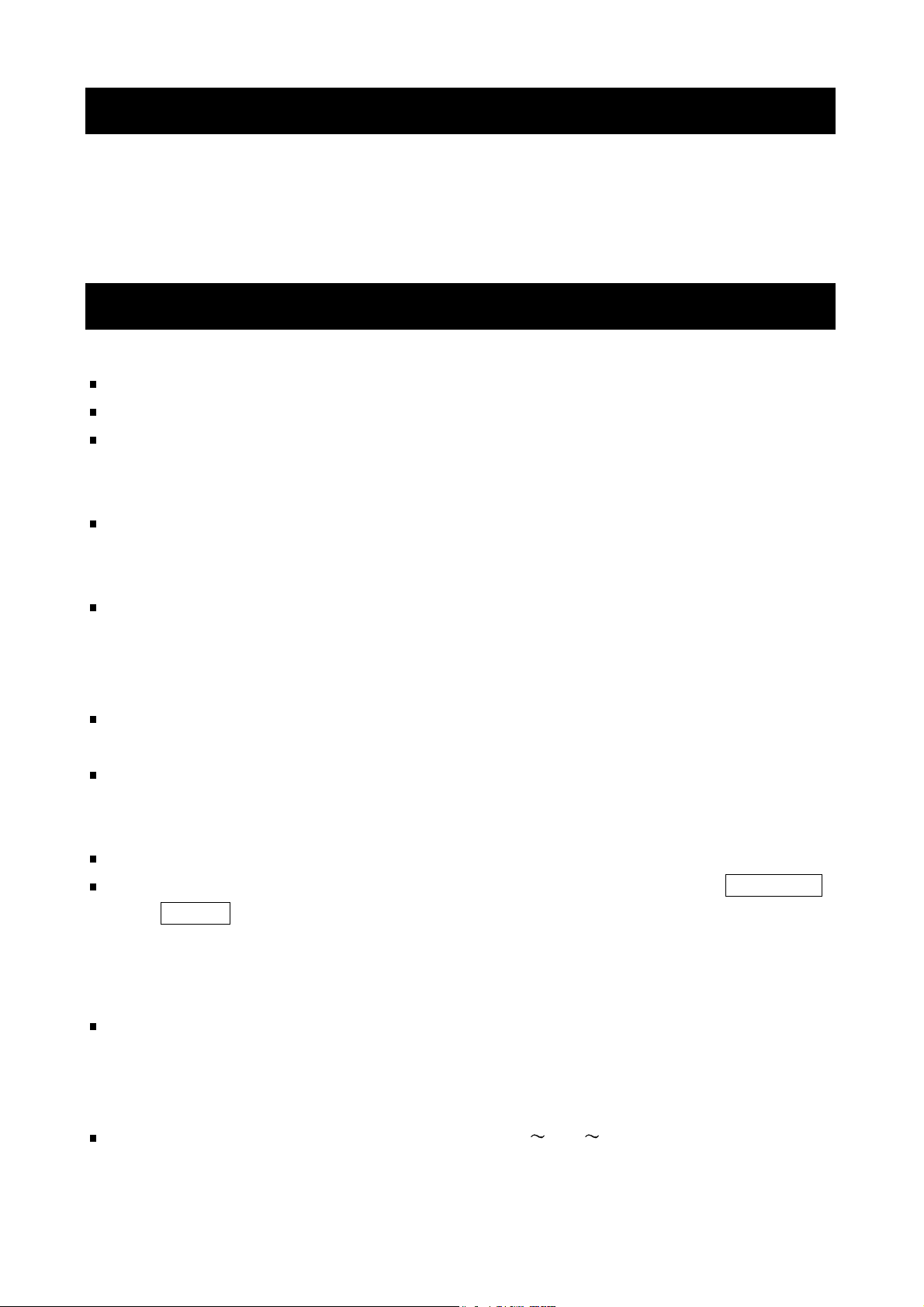

3. Packing List

GXA-03

GXA-04

GXA-06

...............

...............

...............

This manual 1

Mini DIN connector ( 8 pin, plug ) 1

Cable with connector ( AX-KO5692 ) 1

This manual 1

Screwdriver for adjustment 1

Mini DIN connector ( 4 pin, plug ) 1

Cable with connector ( AX-KO5692 ) 1

This manual 1

4. Installing the Option

Caution

Installing the option board to the balance

Step1

Step2

Disconnect the AC adaptor before installing the option to the balance.

Remove the two screws from the panel.

Pull gently the cable and option board

from the balance.

Peel off the connector that is affixed

to the panel with double-sided tape

and insert it into the socket of the

option board.

Option panel: Confirm

the layout of terminal,

etc. on the option.

Socket : Confirm the position

of the socket on the option.

Panel

Screws

Connector

Step3

Attach the option board to the balance.

Secure with the two screws removed in step 1.

Assembling the mini-DIN connector

You can use the GXA-04 ( AX-K0592 ) and GXA-06 ( AX-K0593 )

of the option cable assembled with the mini-DIN connector.

Step 1

Pass the cable through the rubber sleeve.

Step 2

Solder wires and terminal.

Step 3

Cover the terminal with the top

metal case and bottom metal case.

Step 4

Fasten wires with the top metal case.

Step 5

Insert the assembled parts into the

rubber sleeve.

3

Top metal case

Terminal

Part to secure wires

Cable

Rubber sleeve

Fasten wires tightl

Solder wires and terminal

Bottom metal case

Page 6

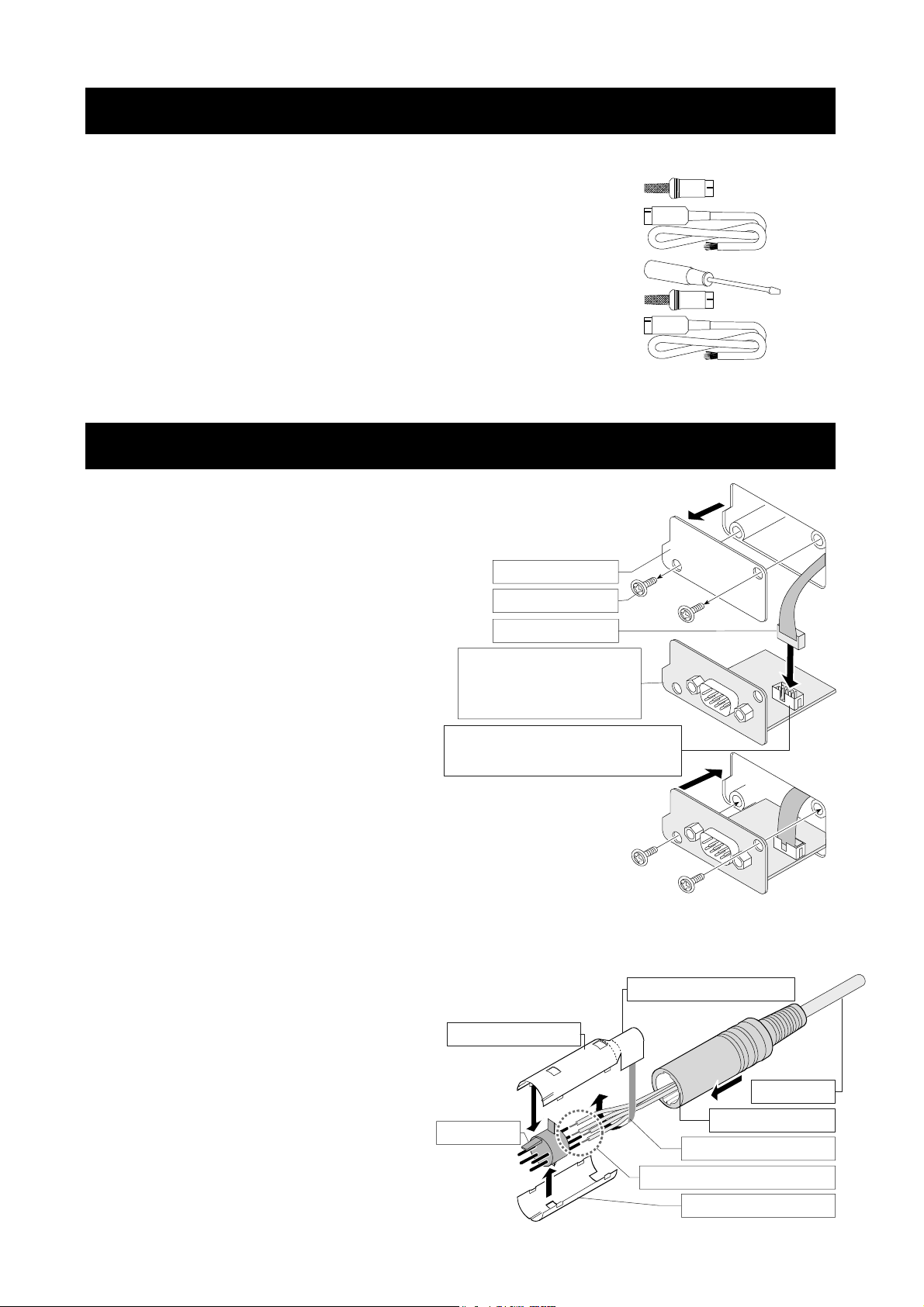

5. Function Table of Balance

The function table stores parameters that specify how to operate the balance, and it is used to

mointor or update those parameters. These parameters are stored in memory even if the AC

adaptor is removed and are retained until overwritten. Balance operations are specified by

this table when using the GXA-03, GXA-04 and GXA-06. The table menu consists of two

layers as shown in the diagram below. The first layer is the “Class” and the second layer is the

“Item”. Each item stores a "parameter". The last displayed parameter is in effect. After the

PRINT key is pressed, these updated parameters are applied to operations of the balance.

Example of settings and menu structure

Example : Set to "

Start from weighing mode

Caution

The balance may not function properly, depending on the settings and the operating

environment. Be sure to set parameters correctly.

Press and hold

Press several times

Class

Finish to weighing mode

Center value using sample weight input

Press several times

Press several times

Item

Input method

" of "

Input method

Parameter

Center value using numerical input

Parameter

Center value using sample weight

Press Press

" in "

Comparator

".

5.1. Operation Keys and Display of Function Table

The 〇 indicates that the parameter displayed is in effect.

Enters the function table when pressed and held in the weighing mode.

Selects the class or item in the function table.

Changes the parameter.

Moves to an item in the class when a class is displayed.

Stores the new parameter and displays the next class when an item is displayed.

Cancels new parameter and displays the next class when an item is displayed.

Exits the function table and returns to the weighing mode when a class is displayed.

4

Page 7

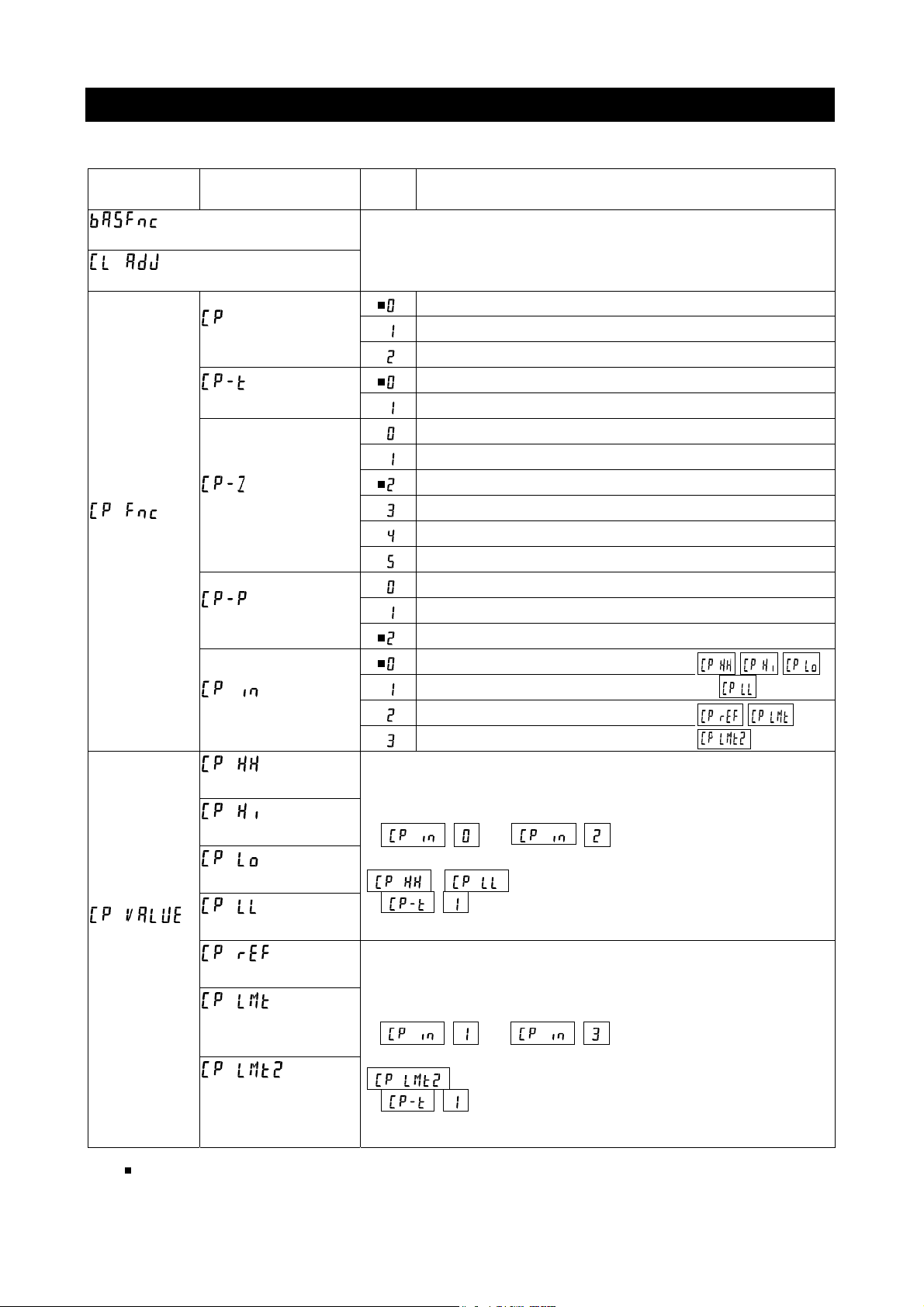

5.2. Items List of the Function Table

Note Functions available differ by model of the balance.

Class Item

Environment, display

Clock adjustment

Comparator

Comparator

threshold

value

Comparator mode

Comparison method

Near zero

Polarity

Input method

Second upper limit

Upper limit

Lower limit

Second lower limit

Center value

Tolerance range

from center value

Second tolerance

range from center

value

Param

eter

( Refer to the instruction manual of main unit )

No comparison (Comparator is not used)

Comparison when stable value or overloaded

Comparison always

3-stage comparison HI, OK, LO

5-stage comparison HH, HI, OK, LO, LL

Comparison including near zero

Comparison excluding ±5 digits (counts) from zero

Comparison excluding ±10 digits (counts) from zero

Comparison excluding ±20 digits (counts) from zero

Comparison excluding ±50 digits (counts) from zero

Comparison excluding ±100 digits (counts) from zero

Comparison of positive values only

Comparison of negative values only

Comparison of both polarities

Threshold value using numerical input

Threshold value using sample weight

Center value using numerical input

Center value using sample weight

Refer to explanation of "7. GXA-04 Comparator output".

Input number when numerical input

(

( ) is selected.

Refer to explanation of "7. GXA-04 Comparator output".

Input sample weight when sample weight input

(

( ) is selected.

or ) is selected.

,

or

is displayed when 5-stage comparison

are displayed when 5-stage comparison

Description

, ,

and are used

) is selected.

, and

are used

indicates factory settings. Digit is the unit of minimum division (minimum weighing value).

5

Page 8

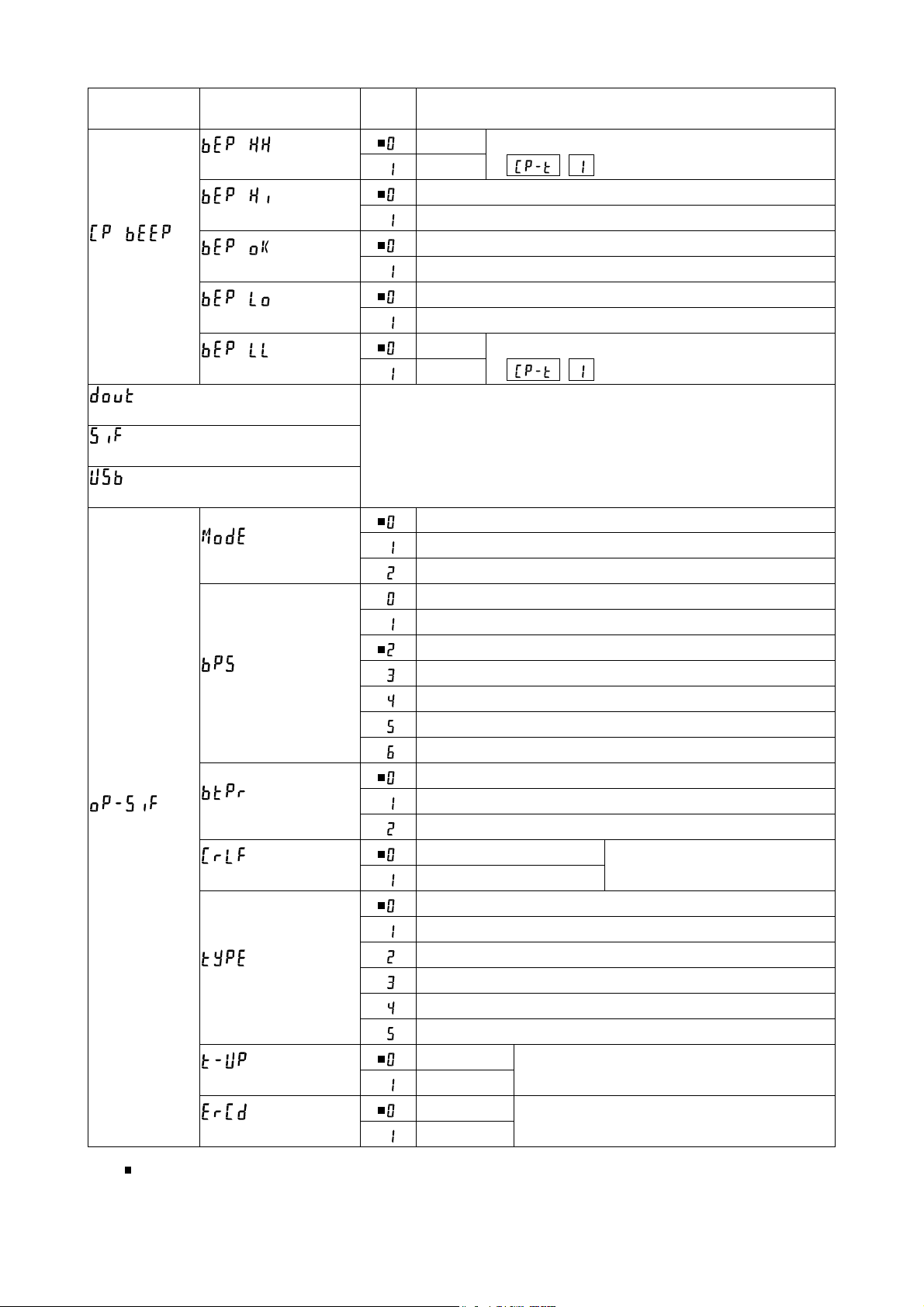

Class Item

HH buzzer

Hi buzzer

Comparator

buzzer

Data output

Serial interface

USB interface

Option serial

interface

OK buzzer

Lo buzzer

LL buzzer

Connection

Baud rate

Data bit, parity bit

Te r m in a t or

Data format

Timeout

AK, Error code

Param

eter

Off

On

Off

On

Off

On

Off

On

Off

On

( Refer to instruction manual of main unit )

Computer

Printer

External display

600 bps

1200 bps

2400 bps

4800 bps

9600 bps

19200 bps

38400 bps

7 bits, Even

7 bits, Odd

8 bits, None

CR LF CR: ASCII code 0Dh

Do not use LF: ASCII code 0Ah

A&D standard format

DP format

KF format

MT format

NU format

CSV format

No limit

1 second

No output

Output

Displayed only when 5-stage comparison

( ) is selected.

Displayed only when 5-stage comparison

( ) is selected.

Select wait time to receive a command

AK: ASCII code 06h

Description

indicates factory settings.

6

Page 9

Class Item

Analog output mode

Analog output

Output digit

selection

Application

Alarm function for minimum

weighing value

Unit

Density function

ID number

Password lock

Automatic calibration

Internal mass value correction

#

#

Param

eter

2-digit output mode

3-digit output mode

Net full scale output mode

Gross full scale output mode

First digit

Second digit

Third digit

4th digit

5th digit

6th digit

7th digit

( Refer to instruction manual of main unit )

( Refer to instruction manual of main unit )

Description

Displayed only when

the GXA-06 is

connected.

Displayed only when

the GXA-06 is

connected.

indicates factory settings.

7

# : Settings for GX-A ser ies.

Page 10

6. GXA-03 Isolated RS-232C interface

This isolated RS-232C interface is used to communicate with peripherals.

Connect the AC adaptor to this option (GXA-03) when AD-8529R-W or AD-8529PC-W is used.

Refer to the instruction manual of main unit concerning function of RS-232C

6.1. Specifications of Serial Interface

This interface is DCE. Use straight cable to connect to a computer ( DTE ).

Transmission system EIA RS-232C

Transmission Asynchronous, bi-directional, half-duplex

Data format Baud rate: 600, 1200, 2400, 4800, 9600, 19200, 38400 bps

Data bits: 7 bits or 8 bits

Parity bit: Even, Odd (Data length 7 bits)

None (Data length 8 bits)

Stop bit: 1 bit

Code: ASCII

Connector D-Sub9 pin [male]

RS-232C

-5 V to -15 V

+5 V to +15 V

Data bits Stop bit

Start bit Parity bit

Pin assignments

Pin No. Signal Direction Description

1 - N.C. No connection

2 RXD Output Transmit data

3 TXD Input Receive data

4 - N.C. No connection

5 SG Signal ground

6 DSR Output Data set ready

7 RTS Input Request to send

8 CTS Output Clear to send

9 - N.C. No connection

Signal names are those of the DTE side.

Balance (DCE) Computer (DTE)

Inside balance Terminal example

Straight cable

Inch screw

#4-40UNC

Approx. 5 V

8

Page 11

7. GXA-04 Comparator Output

The comparator output (GXA-04) has the function to compare between the weighing value

and preset second upper limit, upper limit, lower limit or second lower limit. The result of

comparison can be output to the contact. When the contact is shorted, this option can select

whether or not to sound the buzzer.

Optional foot switch ( AX-SW137-PRINT, AX-SW137-RE-ZERO ) or other external switches

can be used.

7.1. Specifications of Comparator Output

Maximum contact voltage: 50 V DC

Maximum contact current: 100 mA DC

Maximum contact resistance: 20 Ω

Output connector Compatible plug : 8 pin mini DIN connector [Female](Accessory)

E8-200J-100 or equivalent

External contact input connector Compatible plug : φ3.5 mm 3 pole mini stereo jack

MP-013LC or equivalent parts

Panel External View

8 7 6 3 Comparator output connector

4 External contact input x2

5 2 3 1

2

1 Example of contact input terminal

Comparator output circuit Pin assignments and wire colors of

accessory cable

External contact input circuit

Pin No. Description Wire color

1 READY Output Red

2 LL Output White

3 LO Output Black

4 N.C. No connection Yellow

5 OK Output Blue

6 HI Output Green

7 HH Output Brown

8 COM Gray

Housing Case Shield

Pin No. Description

1 GND

2 RE-ZERO External contact input

3 PRINT External contact input

Optional foot switch can connect to either input.

9

Page 12

Using External Contact Input

When 1 pin and 3 pin or 1 pin and 2 pin of lead wire of optional foot switch

( AX-SW137-PRINT, AX-SW137-RE-ZERO ) is shorted 100 ms or longer, it can be

operated the same as the PRINT key and RE-ZERO key on the panel.

7.2. Using the Comparator Output

This option can output results of the 3-stage comparison or 5-stage comparison that is

specified at "Comparison method (

Comparison results are displayed using HI , OK , LO and are output using contacts of

I/O terminals. Comparison tolerance ranges are the following 3 types and they can be

specified at "Comparator mode (

"No comparison", "Comparison when stable value or overloaded", or "Comparison always"

The range of near zero can is specified at "Near zero (

There are two types of comparison method. One is the method using second upper limit,

upper limit, lower limit and second lower limit. Another is the method using center value and

tolerance range. There two types of input methods for second upper limit, upper limit, lower

limit and second lower limit. One is the numerical input. Another is the input using sample

weight. Balance can sound a buzzer according to the comparison result. That can be

specified at "Comparator buzzer (

When weighing value is not displayed in performing RE-ZERO, etc., READY contact

becomes "open". When weighing value is displayed, READY contact becomes "short".

)" in the function table of the balance.

)" in the function table.

)" in the function table.

)" in the function table.

3-stage comparison result 3-stage comparison - display, contact output

Weighing value Contact output

Threshold value Formula

UL < WV HI

UL

LL ≦ WV ≦ UL OK

LL

WV < LL LO

Weighing value: WV, Upper limit: UL, Lower limit: LL

Result Display

HI illuminated

OK illuminated

LO illuminated

HI OK LO

Buzzer

Short Open

Short

Open Short

5-stage comparison result 5-stage comparison - display, contact output

Weighing value Contact output

Threshold value Formula

SUL

SLL

10

SUL < WV HH

UL < WV ≦ SUL HI

UL

LL ≦ WV ≦ UL OK

LL

SLL ≦ WV < LL LO

WV < SLL LL

Weighing value: WV, Second upper limit: SUL, Upper limit: UL, Lower limit: LL, Second lower limit: SLL

Result Display

HI blinking

HI illuminated

OK illuminated

LO illuminated

LO blinking

HH HI OK LO LL

Buzzer

Short

Short Open

Short

Open Short

Short

Page 13

7.3. Comparison Method Selection

(Tolerance Range and Center Value or Threshold Values)

Setting Example

Comparison always ......................................................................

5-stage comparison

Comparison excluding ±5 digits (counts) from zero ...................

Comparison of both polarities ......................................................

Center value using numerical input

Center value using sample weight

......................................................................

...................................................

....................................................

Procedure

Step

1 Press and hold the SAMPLE key to enter the function table.

Step

2 Press the SAMPLE key to display

Step

3 Press the PRINT key to enter

Step

4 Press the RE-ZERO key several times to display

(Comparison always).

is displayed.

(Comparator).

(Comparator).

Factory setting

or

Step

5 Press the SAMPLE key to display

method).

Step

6 Press the RE-ZERO key to display

comparison).

Step

7 Press the SAMPLE key to display

Step

8 Press the RE-ZERO key several times to display

(Comparison excluding ±5 digits (counts) from zero).

Step

9 Press the SAMPLE key several times to display

(Input method).

Step

10 Press the RE-ZERO key several times to select input method.

Step

11 Press the PRINT key to store new settings and use them.

(

Center value using numerical input

(

Center value using sample weight

(Comparison

(5-stage

(Near zero).

) or,

)

or

11

Page 14

7.4. Setting Threshold Values

This explanation uses (5-stage comparison) and specifies

(Threshold value using numerical input) or

weight) to

(input method) in the function table and inputs the threshold value.

(Threshold value using sample

Selecting a input method (If or )

Step

1 Press and hold the SAMPLE key to enter the function table.

Step

2 Press the SAMPLE key several times to display

Step

3 Press the PRINT key to enter

Step

4 Press the SAMPLE key several times to input threshold value. Refer to the following

"Threshold value using numerical input" or "Threshold value using sample weight".

Step

5 If the PRINT key is pressed when threshold value is displayed, the current parameters

are displayed ( all digits blinks ).

(Comparator threshold value).

(Comparator threshold value).

Numerical input of threshold values (If

Step

6 If changing the parameters, press the RE-ZERO key to store the following keys.

is displayed.

)

SAMPLE key Moves blinking digit.

RE-ZERO key Changes value of blinking digit.

MODE key Changes polarity.

PRINT key Stores and proceeds to step 7.

CAL key Cancels and proceeds to step 7.

If the current parameters will be maintained, press the PRINT or CAL key to

proceed to step 7.

Step

7 Repeat step 4, 5 and 6 for other threshold values.

Storing threshold values using sample weight (If

Step

8 Press the RE-ZERO key to display 0.00 g .

Put the sample on the weighing pan and press the PRINT key to store weighing value

as the threshold value.

RE-ZERO key Resets display of the balance to zero .

)

PRINT key Stores weighing value and proceeds to step 9.

Step

9 Repeat step 4, 5 and 6 for other threshold values.

12

Page 15

Storing threshold values using RS-232C commands from peripherals

The second upper limit, upper limit, lower limit and second lower limit can be specified using

#

RS-232C commands from peripherals.

Example command HH: +1000.000 g second upper limit

HI: +0800.000 g upper limit

LO: +0600.000 g lower limit

LL: +0400.000 g second lower limit

: space of ASCII code 20 h

7.5. Setting Center Value and Tolerance Range

This explanation uses (5-stage comparison), specifies

(Center value using numerical input) or

weight input) to

center value and numerical input of tolerance range.

(input method) in the function table, and compares using the

(Center value using sample

Selecting a input method (If or )

Step

1 Press and hold the SAMPLE key to enter the function table.

Step

2 Press the SAMPLE key several times to display

value).

Step

3 Press the PRINT key to display

Step

4 Press the SAMPLE key several times to display "

"

Center value using sample weight

tolerance range.

is displayed.

(comparator threshold

(comparator threshold value).

Center value using numerical input

". Specify the center value, tolerance range and second

" or

Numerical input of center value (If )

Step

5 Press the PRINT key while displaying

digits blinking). If parameter does not need to be changed, press the PRINT key or CAL

key and proceed to step 6. If the parameter is to be changed, press the RE-ZERO key and

change it using the following keys.

SAMPLE key Moves blinking digit.

RE-ZERO key Changes value of blinking digit.

MODE key Changes polarity.

PRINT key Stores and proceeds to step 6.

CAL key Cancels and proceeds to step 6.

Step

6 Proceed to "Storing tolerance range from center value using numerical input".

13

.

The current parameter is displayed (all

Page 16

Storing center value using sample weight (If

Step

7 Press the PRINT key while displaying

(all digits blinks). Press the RE-ZERO key to enter to the sample weight input mode.

Press the RE-ZERO key to display 0.00 g . Put sample of center value on the pan

and press the PRINT key. The current parameter can be confirmed (all digits blinking).

Press the PRINT key to store the center value.

Step

8 Next,

Step

9 Proceed to "Storing tolerance range from center value using numerical input".

is displayed.

.

The current parameter is displayed

Storing tolerance range from center value using numerical input

Step

10 Press the PRINT key while displaying

If the tolerance range is to be changed, change it using the following keys.

Input the tolerance range with center value assumed to be 100 %.

SAMPLE key Moves blinking digit.

RE-ZERO key Changes value of blinking digit.

.

The current parameter is displayed.

)

PRINT key Stores and proceeds to step 11.

CAL key Cancels and proceeds to step 11.

Step

11 Press the PRINT key while displaying

If the second tolerance range is to be changed, change it using the following keys.

Input the second tolerance range with center value assumed to be 100 %.

SAMPLE key Moves blinking digit.

RE-ZERO key Changes value of blinking digit.

PRINT key Stores and proceeds to step 12.

CAL key Cancels and proceeds to step 12.

Step

12 Press the CAL key to return to weighing mode.

.

The current parameter is displayed.

14

Page 17

A

8. GXA-06 Analog Voltage Output

The analog voltage output (GXA-04) can convert the specified weighing value to analog

voltage between 0 and 1 V and output it.

8.1. Specifications of Analog Voltage Output

Analog Voltage Output

Output impedance 100 or less

Linearity ±0.3 % or less

Output connector Compatible plug: 4 pin mini DIN connector [Female](Accessory)

E4-200J-100 or equivalent

Pin connections Output 4 pin

GND 3 pin

Output range 0 V to 1 V With the slide switch set to "0V "

0.2 V to 1 V With the slide switch set to "0.2V "

Input impedance of 10 k or greater

the device connected

Panel External View

Analog output connector 3 Analog GND Slide switch: Output range

4 Analog voltage output Zero volume for fine adjustment

Span volume for fine adjustment

2

1

Pin assignments and

Output circuit wire colors of accessory cable

nalog voltage output

Pin No. Description Wire color

1 N.C. No connection Black

2 N.C. No connection Blue

3 Analog GND (0 V) Red

4 Analog voltage output White

Housing Case Shield

15

Page 18

8.2. Function Table of Analog Voltage Output

of the function table can be selected when this option is connected.

Analog output

Item Parameter Description

2-digit output mode Converts 2 consecutive digits with minimum digit

selected by

3-digit output mode Converts 3 consecutive digits with minimum digit

selected by

Net full scale output mode

Outputs 0.000 V when the net weight is zero.

Outputs 1.000 V when the net weight is full scale.

Output is 0.000 V when zero is set using the RE-ZERO key.

Gross full scale output mode

Outputs 0.000 V when the gross weight is zero.

Outputs 1.000 V when the gross weight is full scale.

Tare operation using the RE-ZERO key will not affect the output.

(Note: If tare is extremely light, tare operation might change the zero

point. Thus affecting the output.)

Analog

output mode

to voltage.

to voltage.

Output digit

selection

indicates factory settings.

Specify minimum digit to be output at

When is set to or , the setting is in effect.

Specify first digit as minimum digits.

Specify second digit as minimum digits.

Specify third digit as minimum digits.

Specify 4th digit as minimum digits.

Specify 5th digit as minimum digits.

Specify 6th digit as minimum digits.

Specify 7th digit as minimum digits.

mode.

Example

If Analog voltage output ( 0 V to 1 V )

0.67 V

0.56 V

0.45 V

0.34 V

0.23 V

0.12 V

0.01 V

.

Caution The hidden high-order digits are regarded as zero.

The hidden least significant digit is regarded as zero (when the least significant digit is

hidden using the SAMPLE key).

16

Page 19

If Analog voltage output ( 0 V to 1 V )

0.567 V

0.456 V

0.345 V

0.234 V

0.123 V

0.012 V

0.001 V

.

If

Model Full scale Model Full scale

GX-203A 220 g GF-203A 220 g

GX-303A 320 g GF-303A 320 g

GX-403A 420 g GF-403A 420 g

GX-603A 620 g GF-603A 620 g

GX-1003A 1100 g GF-1003A 1100 g

GX-1603A 1620 g GF-1603A 1620 g

GX-2002A 2200 g GF-2002A 2200 g

GX-3002A 3200 g GF-3002A 3200 g

GX-4002A 4200 g GF-4002A 4200 g

GX-6002A 6200 g GF-6002A 6200 g

GX-6001A 6200 g GF-6001A 6200 g

GX-10001A 10200 g GF-10001A 10200 g

Example When the GX-2002A displays 200 g, the voltage output of

or

( Using "0V " of the slide switch )

is 0.1 V.

1.000 V × = 0.100 V

Caution "Full scale" of the full scale output mode indicates the full scale values shown in the

tables above. The output voltage may exceed 1.000 V, depending on the weighing value.

Example When the GX-2002A displays 2200 g, the voltage output is 1.1 V.

( Using "0V " of the slide switch )

1.000 V × = 1.100 V

17

200 g

2000 g

2200 g

2000 g

Page 20

8.3. Voltage Output Selection

The range of output voltage can be change using the slide switch on the panel.

Factory settings is "0V ".

"0V " (0 to 1 V) : Zero 0.000 V, full scale 1.000 V

"0.2V " (0.2 to 1 V) : Zero 0.200 V, full scale 1.000 V

Panel External View

Analog output connector 3 Analog GND Slide switch: Output range

4 Analog voltage output Zero volume for fine adjustment

Span volume for fine adjustment

2

1

8.4. Voltage Output Fine Adjustment

The voltage output has been adjusted at the

factory before shipment.

Using the ZERO volume and SPAN for fine

adjustment and a voltmeter, voltage output can

be finely adjusted.

Procedure

Step

1 Turn off the display using the ON:OFF key.

Voltage output becomes zero point status.

Adjust the ZERO volume so that the voltmeter indicates

0.000 V ( when the slide switch is set to "0V ").

Adjust the ZERO volume so that the voltmeter indicates

0.200 V ( when the slide switch is set to "0.2V ").

Step

2 While pressing and holding the PRINT and

0V~/ 0. 2V~

The display to output 0 V ( 0.2 V).

The display to output 1 V.

ZERO SPAN

SAMPLE keys, press the ON:OFF key to enter

the initializing mode. Then 1 V is output. Adjust the SPAN

volume so that the voltmeter indicates 1.000 V

Step

3 Repeat step 1 and step 2 until the correct voltage output

is obtained.

18

Page 21

8.5. Fixed Voltage Output

The voltage output is fixed under the following conditions:

With the display off, 0 V is output ( or 0.2 V if the slide switch is set to "0.2V ") when not

weighing during calibration, etc..

During the re-zeroing operation in gross full scale output mode (

the previous output value is retained.

During the re-zeroing operation in 2-digit output mode (

0 V is output ( or 0.2 V if the slide switch is set to "0.2V ").

During the re-zeroing operation in 3-digit output mode (

0 V is output ( or 0.2 V if the slide switch is set to "0.2V ").

During the re-zeroing operation in Net full scale output mode (

0 V is output ( or 0.2 V if the slide switch is set to "0.2V ").

When -E (weighing value is negative overload) is displayed,

0 V is output ( or 0.2 V if the slide switch is set to "0.2V ").

When E (weighing value is positive overload) is displayed,

the following voltages are output.

),

),

),

),

Example

GX-203A 1.000 V 1.100 V GF-203A 1.000 V 1.100 V

GX-303A 1.000 V 1.067 V GF-303A 1.000 V 1.067 V

GX-403A 1.000 V 1.050 V GF-403A 1.000 V 1.050 V

GX-603A 1.000 V 1.033 V GF-603A 1.000 V 1.033 V

GX-1003A 1.000 V 1.100 V GF-1003A 1.000 V 1.100 V

GX-1603A 1.000 V 1.013 V GF-1603A 1.000 V 1.013 V

GX-2002A 1.000 V 1.100 V GF-2002A 1.000 V 1.100 V

GX-3002A 1.000 V 1.067 V GF-3002A 1.000 V 1.067 V

GX-4002A 1.000 V 1.050 V GF-4002A 1.000 V 1.050 V

GX-6002A 1.000 V 1.033 V GF-6002A 1.000 V 1.033 V

GX-6001A 1.000 V 1.033 V GF-6001A 1.000 V 1.033 V

GX-10001A 1.000 V 1.020 V GF-10001A 1.000 V 1.020 V

Voltage output when E is displayed if the slide switch is set to "0V ".

Model

.,

.

.,

Model

.

.,

.,

.

.

19

Page 22

MEMO

20

Page 23

Page 24

3-23-14 Higashi-Ikebukuro, Toshima-ku, Tokyo 170-0013, JAPAN

Telephone: [81] (3) 5391-6132 Fax: [81] (3) 5391-6148

A&D ENGINEERING, INC.

1756 Automation Parkway, San Jose, California 95131, U.S.A.

Telephone: [1] (408) 263-5333 Fax: [1] (408)263-0119

A&D INSTRUMENTS LIMITED

Unit 24/26 Blacklands Way, Abingdon Business Park, Abingdon, Oxfordshire OX14 1DY United Kingdom

Telephone: [44] (1235) 550420 Fax: [44] (1235) 550485

A&D AUSTRALASIA PTY LTD

32 Dew Street, Thebarton, South Australia 5031, AUSTRALIA

Telephone: [61] (8) 8301-8100 Fax: [61] (8) 8352-7409

A&D KOREA Limited 한국에이.엔.디(주)

서울특별시 영등포구 국제금융로6길33 (여의도동) 맨하탄빌딩 817 우편 번호 150-749

( 817, Manhattan Bldg., 33. Gukjegeumyung-ro 6-gil, Yeongdeungpo-gu, Seoul, 150-749 Korea )

전화: [82] (2) 780-4101 팩스: [82] (2) 782-4280

OOO A&D RUS OOO "ЭЙ энд ДИ РУС"

121357, Российская Федерация, г.Москва, ул. Верейская, дом 17

( Business-Center "Vereyskaya Plaza-2" 121357, Russian Federation, Moscow, Vereyskaya Street 17 )

тел.: [7] (495) 937-33-44 факс: [7] (495) 937-55-66

A&D INSTRUMENTS INDIA PRIVATE LIMITED

( 509, Udyog Vihar, Phase-

: 91-124-4715555

, Gurgaon - 122 016, Haryana, India )

: 91-124-4715599

Loading...

Loading...