Page 1

APOLLO SERIES GX-A | GF-A

Precision Balances

Taking Weighing Precision and Protection to New Heights

Page 2

DISCOVER PRECISION

Advanced Technologies Providing Innovative Solutions

Smart SHS Technology

A&D’s Smart-Super Hybrid Sensor (SHS) technology is the foundation

of the innovative solutions found in the Apollo Series. The Smart sensor

improvements stem from better design, construction, and materials,

resulting in better performance and turbo stabilization times of 1 second.

This increases productivity for all weighing work-flows in both labs and

production environments. Smart-SHS also gives higher maintainability with

a reduced number of parts while still offering maintenance accessibility,

unlike other Mono-type systems which only increase cost of ownership.

A&D’s easy eccentricity adjustment and hybrid design are two prime

examples of this high maintainability. We execute for the highest

performance, and keep our customer’s bottom-line in mind.

Remarkable cost and time savings

at the touch of a button.

Innovative

Technology

Smart

Reasoning

Beneficial

Outcomes

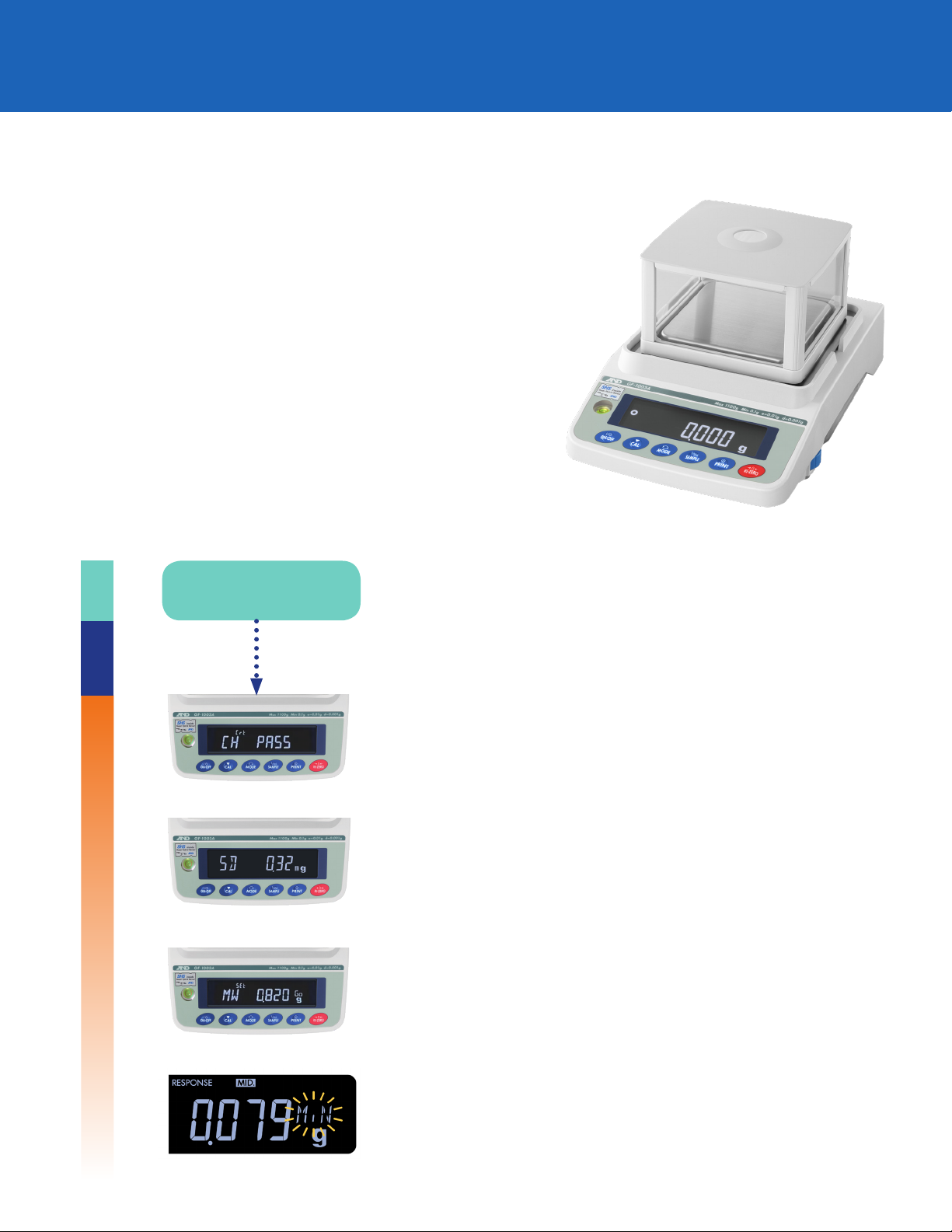

ECL

Auto Precision

Assessment

Dia-Check

Standard deviation

QuickMin-S

Electronically Controlled Load (ECL) Innovation

The operator simply holds the mode key to first perform a self diagnostic check and

proceed to ECL where internally a repeatability test is performed without use of an

external weight. This critically checks the stability of analog-to-digital conversion

before applying a controlled load inside the balance (between 0.3% to 3% of the

weighing capacity). It does this by altering the equilibrium state of the weigh sensor

and takes 10 repeated measurements. The entire process takes only 1.5 minutes

versus traditional repeatability procedures which can take up to 10 minutes,

ultimately giving greater convenience and time savings to customers.

The ECL technology provides valuable information which Auto Precision

Assessment (APA) smartly processes into meaningful, beneficial outcomes

such as Dia-Check, Standard Deviation, Quick Min-S, and Min-S-Alert.

Dia-Check quickly gives users peace of mind to proceed with daily weighing

routines, providing a critical pass or fail indication. A powerful, dynamic tool to

diagnose, and verify balance performance.

ECL steps it up a notch by producing the most valuable information, the

Standard Deviation (SD), allowing users to quickly assess the balance

performance under any given environment. This is helpful to include in daily

SOP checks.

SD also can determine the minimum sample weight with a feature called

QuickMin-S. QuickMin-S helps to overcome challenges with handling small weights,

accessibility to in-line systems, and in tough environmental conditions

Min-S Alert blinks

ECL goes one step further allowing users to set the minimum sample weight limit and

provides a real time alert with Min-S-Alert. Users always feel secure knowing they

are in compliance of USP 41 and does not limit how often a minimum sample weight

can be determined. This gives more flexibility to follow recommendations of USP

1251. What is so remarkable is this can be performed at the touch of a button, within

minutes, in challenging conditions, without the need of an external calibration weight.

Page 3

APOLLO SERIES

Factory Tough–Laboratory Precise

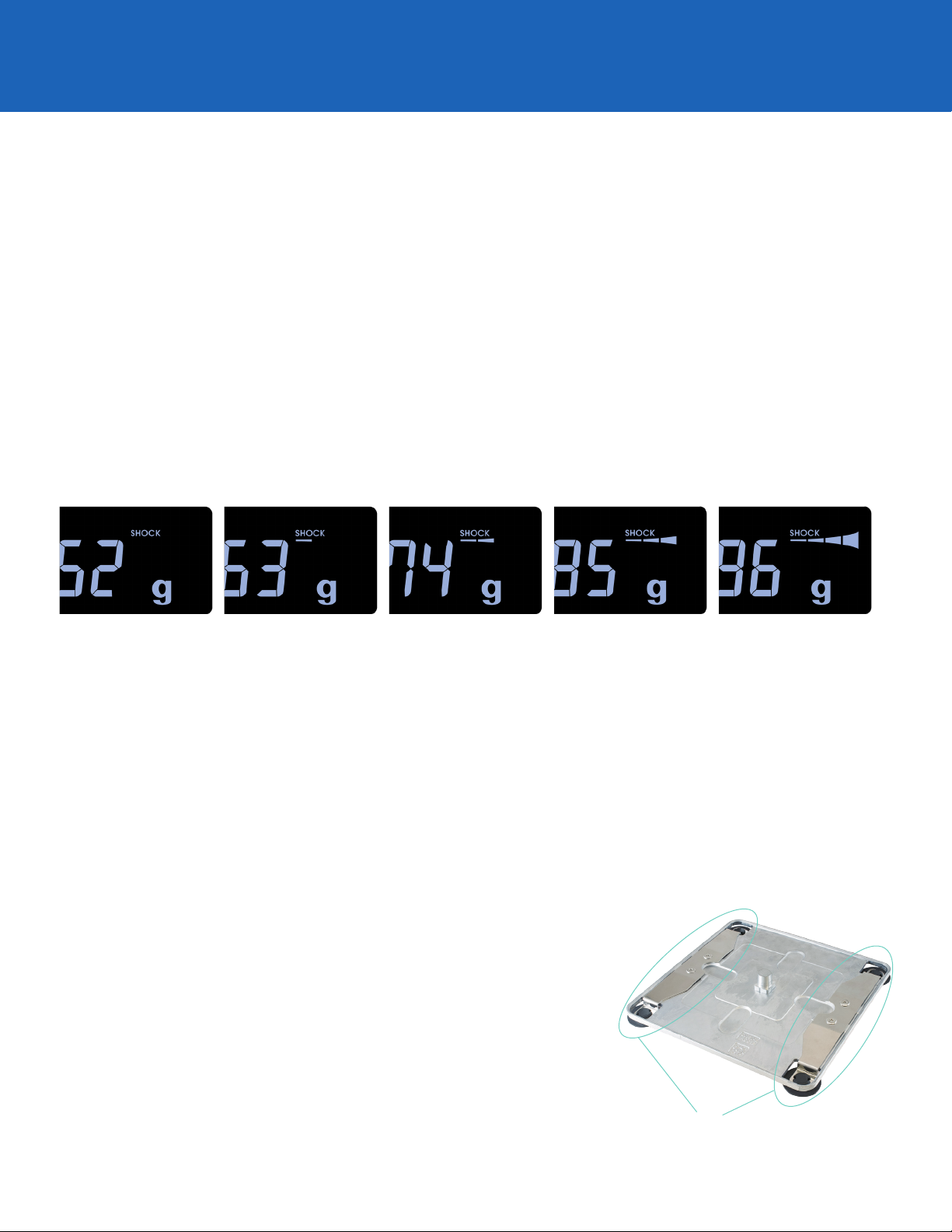

Impact Shock Detection (ISD) Innovation

Often balances can be damaged or errors can occur due to sharp impacts

from automated machine loading or operators dropping material onto

the pan. The Apollo series educates, prevents and documents such

scenarios. ISD visually indicates the magnitudes of impact shocks that

a weigh sensor receives at four different levels. It audibly beeps once at

Level 3 and twice at Level 4 delivered through the feature of Impact-Alert.

This patented technology provides real-time feedback mechanisms

that prevent the sensor from being damaged and can ultimately train

and influence operator behaviors. ISD smartly strives for operators

to have better weighing techniques, while also helping to program

or modify loading in-line automated processes. Impact-Alert ensures

the investment of the balance is protected, helps to extend the life of

balance, reduce repair and replacement cost and ensure productivity can

be maintained by reducing downtime.

Real-time feedback

prevents the

sensor from being

damaged.

No Impact Shock Level 1 Level 2 Level 3 Level 4

ISD takes protection one step higher with Shock-log that documents the

date, time, and shock level. This enables managers and quality officers to

pinpoint the exact moment a critical shock occurred to quickly assess and

fix critical failure to get operations back online.

Shock-log

pinpoints the exact moment a critical shock

occurred to quickly assess and fix critical failure to get

operations back online

Overload Protection

The weight sensor is well protected against vertical and transverse static

overloading. It won’t break due to malfunction of the weighing system’s

actuator and the resulting excess “E” load. Additionally there are two leaf

springs that support the weighing pan of the Apollo series also mitigate

impact shocks significantly. A&D once again takes protection to heart

ensuring the Apollo series is the same A&D strong, A&D tough you’ve

come to know in labs and factories alike.

Leaf Springs

Page 4

DISCOVER PRECISION

Keeping Your Devices in Sync for

Better Accuracy & Precision

Flow Rate Display (FRD) Innovation

Many operators use a stopwatch or PC to determine a flow rate. FRD helps to streamline

and improve both by offering a synced solution that improves accuracy and precision in

filling or dosing applications. For example, the internal clocks of external devices are never

in complete sync with precision balances. Therefore there is a time-clock disparity that is

most noticeable when measuring and recording flow rates of pumps, feeders and other

devices at short intervals*1. Therefore command speed and refresh rate will cause the PC to

intermittently produce irregular values or spikes even if the actual flow rate is constant.

The Apollo series through an FR-Cal function calculates, displays, & outputs (WinCT-FRD)

the mass flow rate, or the volume flow rate by entering the density of the material. Up to

10 densities can be saved to the device. Both the display refresh rate and interval (set

between 1 second and 1 hour) are regulated by the same internal clock of the balance,

making measurements free from the irregularity that rise from time clock disparity problem.

Time disparity of two different internal clocks

Now what is smart about FRD technology is that we can use a comparator function of

FR-Compare to provide a feedback mechanism to the user if the flow rate is going too

fast or too slow or indicate if flow rate is kept within the designated limits.

Lastly, if the worst happened with a power outage during the “loss-in-weight”

measurement, the tare value is stored in our non-volatile memory. The remaining amount

in the container can be displayed again and the application can continue through our FR-

Secure.*2 This avoids loss of sensitive materials and lost time.

Flow rate measurement using FRD as opposed to the conventional method

*1 Flow rate is determined from the weight variation that occurs during a given interval.

*2 When function is activated, the power-on/rezero/tare is toggled off.

Page 5

APOLLO SERIES

Protecting and Adhering to Good Data Management,

Documentation and Compliance Practices

Quick Min-S

From the standard deviation obtained using ECL described

earlier, the Apollo series also calculates and indicates the

minimum weight at the installation location*3 in accordance

with the United States Pharmacopeia (USP) standard.

Min-S Alert

To ensure that the measured sample quantity meets the

minimum weight requirement, the Apollo series can display

an alert until the sample quantity reaches the value entered

as the minimum weight.

Password-Protect

Use of the balance can be password-protected

for authorized individuals (up to 11 including one

administrator)—the administrator can perform all

operations including calibration while other users can make

measurements only. Moreover, upon receiving a command

to disable its keys, the balance becomes operable only by

sending commands from an external device such as a PC.

GLP/GMP/GCP/ISO Compliant Output

For documentation requirements, the Apollo series can

output its manufacturer, model, serial number, ID number,

date + time, space for signature for calibration report,

calibration test report, and title & end blocks for a series of

weighing results.

Universal Flexi Coms (UFC)

UFC lets you edit serial data output/printout format.

With this function, label printing is also made possible

by connecting the balance to a commercially-available

printer*4, and enabling the arbitrary character strings output.

Statistical Calculation Function (SCF)

The Apollo series can display and output statistical

calculation data including number of data, sum, maximum,

minimum, range (maximum-minimum), average, standard

deviation, and coefficient of variation to facilitate the

analysis of measurements.

Automatic Self-Calibration (ASC)

The GX-A can be set to calibrate itself automatically

using its internal weight either (1) in response to

change in ambient temperature (approx. 10 °C) to

prevent error due to sensitivity drift, (2) at a set interval

time, or (3) at predetermined (up to three) times of the

day. Internal calibration can also be performed any time

with one key press.

*3 The effects of the ambient environmental conditions on repeatability is taken into account, unlike the values shown in catalogs as “ideal” or “typical”.

*4 Printers can be programmed to print from string sent via RS232C. Cross cables may be required based on the external device.

Gross/Net/Tare Output

On receiving a command or with key operation, the

Apollo series outputs the gross, net, and tare values to an

external device such as a printer, PC or PLC.

Page 6

DISCOVER PRECISION

Advanced and Practical Features

RS-232C and USB Interfaces Standard

For the USB interface, you can toggle between the

Quick USB mode (plug-and-play with weighing data

output to a PC only) and the Virtual COM mode (for

bi-directional communication) with internal settings.

A USB cable is provided as standard.

Bright Bubble

Large, easy-to-see spirit level

with LED Illumination

The illumination blinks for 5 seconds after the

display is turned on to indicate that the balance

level needs to be checked.

Security Slot

An off-the-shelf (such as

Kensington) anti-theft lock can

be used to prevent the balance

from being lost.

Stainless

Steel Pan &

Dustplate

Easy to clean

Large Reverse

Backlit LCD

Display

The contrast of black

and white provides

excellent visibility

even in poorly-lit

areas and also

prevents eye fatigue.

Easy 6 key

controls

Easy unit

toggle

One-touch Cal Easy resolution

toggle

Die cast

Aluminum

Housing

Top & Bottom

to increases

stabilization.

FlyThumbwheel

Anti-slip Feet

The leveling feet can be

adjusted up or down smoothly

using large thumbwheels.

Page 7

APOLLO SERIES

Options

GXA-03

GXA-04

GXA-06

GXA-09

GXA-10

GXA-12

GXA-13

GXA-17

GXA-23-PRINT

GXA-23-REZERO

GXA-23-PLUG

GXA-24

GXA-25

GXA-26

FXi-08

2nd RS-232C interface

Comparator relay output/buzzer/external key input interface

Enables signaling check weighing results (5 steps) by buzzer and/or external comparator

(traffic) lights. It also has two jacks for separately-sold foot switches.

*5

*5

Analog output interface*5 0-1 V, or 0.2-1 V for conversion to 4-20 mA.

Built-in rechargeable battery (factory-installed/dealer option)

10 hours of charging for 14 hours of operation (the remaining battery level will be

indicated on the display). The balance can be used while recharging the battery.

*5

Large glass breeze break

Animal weighing pan (for models of 320 g capacity or higher)

Use together with the animal weighing (average & hold) mode.

Density determination kit (for the 1 mg models only)

Makes weighing the sample in air and in water quicker, easier and more precise. The

GX-A/GF-A series can then perform a density calculation automatically.

Large glass breeze break with built-in fanless ionizer

(static eliminator) The fanless ionizer can neutralize even extremely fine powders

without disturbance.

External key input interface with the AX-SW137-PRINT foot switch

*5

External key input interface with the AX-SW137-REZERO foot switch

External key input interface with the AX-T-314A-S plug

USB host interface (factory-installed/dealer option)

Accepts an off-the-shelf USB flash drive to save weighing results in CSV format.

External fanless ionizer (static eliminator)

Power is supplied from the balance. Activated for a set duration with an IR sensor.

*5

*5

*5

External IR switch*5

For touchless operation of print or re-zero (tare).

Ethernet interface

*5

GXA-10 Large Glass

Breeze Break

*5

AX-SW137-PRINT

Accessories

AD-1641

AD-1682

AD-1683

AD-1684A

AD-1687

AD-1688

AD-1689

AD-1691

AD-8127

AD-8526

AD-8920A

AD-8922A

AX-GXA-31

AX-USB-9P

AD-8529PC-W

AD-8529PR-W

*5 Only one of GXA-03, GXA-04, GXA-06, FXi-08, GXA-09, GXA-23-PRINT/REZERO/PLUG,GXA-24, GXA-25 or GXA-26 can be installed.

*6 9V Power needs to be supplied from an AC adapter.

Air flow logger

Rechargeable battery unit

Static eliminator

*6

Electrostatic field meter

Weighing environment logger

Weighing data logger

Tweezers for calibration weight

Weighing environment analyzer

Compact printer

Serial/Ethernet converter

Remote display

Remote controller

Main unit cover (5 pcs)

USB to Serial converter w/9pin to 9pin cable

Bluetooth Converter for PC

Bluetooth Converter for Printer

AD-8127 with AD-8529PR-W

Page 8

Specifications

GF-123A

GF-203A GF-303A GF-403A GF-603A GF-1003A GF-1603A

Capacity 122 g 220 g 320 g 420 g 620 g 1100 g 1620 g

Readability 0.001 g

GX-203A GX-303A GX-403A GX-603A GX-1003A GX-1603A

Repeatability (std. deviation) 0.001 g

0.002 g (for 1600 g)

0.001 g (for 1000 g)

Linearity ±0.002 g ±0.003 g

Accuracy immediately after internal

calibration (for the GX-A series)

i

± 0.010 g

Stabilization Time Approx. 1 sec (approx 0.8 sec for 5 g)

± 0.010 g (for

1000 g)

Approx 1.5 sec

(approx 0.8 sec for 5 g)

Sensitivity drift ±2 ppm / ˚C (10 ˚C to 30 ˚C / 50 ˚F to 86 ˚F, when automatic self-calibration is OFF)

Type External GX Internal / GF External

Calibration

Wt. g.

50 g

100 g

50 g

100 g

200g

50 g

100 g

200 g

300 g

50 g

100 g

(100 g interval)

400 g

50 g

100 g

(100 g interval)

600 g

50 g

100 g

(100 g interval)

1000 g

50 g

100 g

(100 g interval)

1600 g

Display Reverse Backlit LCD (Character height: 17.8 mm)

Display Refresh Rate 5 times / second, 10 times / second or 20 times / second

Units of Measure

Counting

mode

Percent

mode

Min unit mass 0.001 g

Number of samples 5, 10, 25, 50 or 100 pieces

Min 100% ref mass 0.100 g

Min 100% display 0.01%, 0.1% or 1% (depends on the reference mass stored)

ii

g (gram), oz (ounces), lb (pound), lb-oz (pound-ounce), ozt (troy ounce), ct (metric carat), mom (momme), dwt (pennyweight), gr (grain),

pcs (counting mode), % (percent mode), SG (specific gravity), and a user-programmable unit.

Operating environment 5 ˚C to 40 ˚C / 41 ˚F to 104 ˚F, 85% R.H. or less (no condensation)

Power supply / consumption AC adapter / approx. 30 VA

Communication Interface RS-232C and USB

Weighing pan size 128 mm × 128 mm / 5 × 5 in

Dimensions (W × D × H) 212 (W) × 317 (D) × 93 (H) mm / 8.3 (W) × 12.5 (D) × 3.7 (H) in

Net weight Approx. 5 kg / 11 lb

Specifications

GF-1202A

GX-2002A GX-3002A GX-4002A GX-6002A GX-10002A GX-6001A GX-10001A

GF-2002A GF-3002A GF-4002A GF-6002A GF-10002A GF-6001A GF-10001A

Capacity 1220 g 2200 g 3200 g 4200 g 6200 g 10200 g 6200 g 10200 g

Readability 0.01 g 0.1 g

Repeatability (std. deviation) 0.01 g

0.02 g (for 10000 g)

0.01 g (for 5000 g)

0.1 g

Linearity ±0.02 g ±0.03 g ±0.1 g

Accuracy immediately after internal

calibration (for the GX-A series)

i

Stabilization Time Approx. 1 sec (approx 0.8 sec for 50 g)

± 0.10 g ± 0.15 g ± 0.15 g (for 5000 g) ± 0.5 g (for 5000 g)

Approx 1.5 sec

(approx 0.8 sec for 50 g)

Approx 1 sec

(approx 0.8 sec for 500 g)

Sensitivity drift ±2 ppm / ˚C (10 ˚C to 30 ˚C / 50 ˚F to 86 ˚F, when automatic self-calibration is OFF)

GX Internal / GF External

500 g

1000 g

(1000 g interval)

4000 g

500 g

1000 g

(1000 g interval)

6000 g

500 g

1000 g

(1000 g interval)

10000 g

500 g

1000 g

(1000 g interval)

6000 g

500 g

1000 g

(1000 g interval)

10000 g

Calibration

Display

Type External

Wt. g.

500 g

1000 g

500 g

1000 g

2000g

500 g

1000 g

2000 g

3000 g

Reverse Backlit LCD (Character height: 17.8 mm)

Display Refresh Rate 5 times / second, 10 times / second or 20 times / second

Units of Measure

Counting

mode

Percent

mode

Min unit mass 0.01 g 0.1 g

Number of samples 5, 10, 25, 50 or 100 pieces

Min 100% ref mass 1.00 g 10.0 g

Min 100% display 0.01%, 0.1% or 1% (depends on the reference mass stored)

ii

g (gram), oz (ounces), lb (pound), lb-oz (pound-ounce), ozt (troy ounce), ct (metric carat), mom (momme), dwt (pennyweight), gr (grain),

pcs (counting mode), % (percent mode), SG (specific gravity), and a user-programmable unit.

Operating environment 5 ˚C to 40 ˚C / 41 ˚F to 104 ˚F, 85% R.H. or less (no condensation)

Power supply / consumption AC adapter / approx. 30 VA

Communication Interface RS-232C and USB

Weighing pan size 165 mm × 165 mm / 6.5 × 6.5 in

Dimensions (W × D × H) 212 (W) × 317 (D) × 93 (H) mm / 8.3 (W) × 12.5 (D) × 3.7 (H) in

Net weight Approx. 5 kg / 11 lb

i Under stable environment (no rapid temperature/humidity change, vibration, draft, magnetism, static, etc). The mass of the internal weight may vary with age.

ii One additional unit from tael (Singapore/HK jewelry/Taiwan/China), tola or Newton can be added upon request.

SMART

Super

Hybrid

Sensor

GX-A

Internal

Calibration

GF-A

External

Calibration

ISD

FRD

Impact

Shock

Detection

Flow Rate

Display

ECL

Electronically

Controlled

Load

1756 Automation Parkway

San Jose, CA 95131

(800) 726-3364 or

(408) 263-5333

www.andweighing.com

Reverse

Black Lit

LCD

USB

Bidirectional

RS-232C Clock

Calendar

Counting

Percentage

Function

Function

Compliance Universal

Animal

Weighing

Flexi Coms

Statistical

Calculation

Data Memory Auto

Comparator

Function

Power

Underhook LAN-Ethernet

WinCT

Software

Password

Protect

Interface

Optional

Rechargable

USB Host

Battery

©2018 A&D Weighing

Loading...

Loading...