Page 1

LCD

plus

Keypad Installation Instructions

(P/N: LCD PLUS AVR or LCD PLUS GEN)

P/N 09830030

Rev. C

See the Advantage 3000 Series Systems Installation and Service Manual or the

Advantage plus Service Manual for panel theory and service procedures.

See the SONICS Database Management Manual or the Advantage

Copyright © 1996-97 by Advantor Corporation. All rights reserved.

No part of this document may be reproduced or distributed in any form or by any means, or stored

in a database or retrieval system, without the prior written permission of Advantor Corporation.

for options programming procedures.

®

Advantage

is a trademark of Advantor Corporation

®

Access for Windows User’s Guide

GENERAL

The LCD plus keypad shown in Figure 1 is a 15 button wallmounted keypad in its own enclosure. The keypad contains a four

line, 20 character per line Liquid Crystal Display (LCD) that

displays the system's status in plain English.

Figure 1. LCD plus Keypad

LCD plus keypad arming features include Automatic, Secure

(employee verification), and Automatic No-dial arming/disarming.

The keypad also provides the following user initiated functions:

• Emergency Duress (ambush) alarming

• Intermediate arming with OCCUPIED DELAY or OCCUPIED INSTANT alarm reporting

• Chime Mode

• User assistance request

• Cancel alarm generation

• Auxiliary output control

• On-site test procedure.

The following control panels support LCD plus keypads:

• Advantage plus • ADV 3250

• ADV 3450 • AAM4+

• ADV 3650 • AAM4-C+

• ADV 3475 • AAM4-A

• ADV 3350+ • AAM4C-A

The LCD plus keypad communicates with control panels over the

RS-485 communications bus, much like Advantage Access

Modules.

Jumpers inside each LCD plus keypad assign it with a unique keypad

bus address. (Note that LCD plus keypads can share the same

address with an Advantage Access Module).

NOTE: LCD plus KEYPADS INSTALLED IN UL BUR-

LCD

See the SONICS Database Management Manual or the Advantage

Access for Windows User’s Guide for LCD plus keypad options

programming.

GLARY AND FIRE SYSTEMS SHALL BE LOCATED WITHIN 20 FEET OF THE ALARM ENCLOSURE AND ALL KEYPAD WIRING SHALL BE

ENCLOSED IN CONDUIT.

USING THE ADAPTER PLATE (P/N 09004301)

MOUNT THE LCD plus KEYPAD ON A

STANDARD ELECTRICAL UTILITY BOX TO

ALLOW CONDUIT CONNECTION AT THE

KEYPAD.

plus

KEYPAD OPTIONS

®

®

ADVANTOR CORPORATION HARDWARE LIMITED WARRANTY STATEMENT

Advantor Corporation warrants each new product of its manufacture, to be free from defects in material and workmanship.

It will repair or replace defective parts for a period of 24 months from the date of manufacture, providing the equipment has not been subjected to

abnormal conditions such as misuse, abuse, misapplication, alteration, lightning damage or damage by an Act of God. This excludes packing,

handling and shipping charges from the Customer. The limited warranty is restricted to the original purchaser.

ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING MERCHANTABILITY, THE FITNESS OF

EQUIPMENT FOR A PARTICULAR PURPOSE OR WITH RESPECT TO CLAIMS OF ANY THIRD PARTY BY THE

WAY OF INFRINGEMENT OR THE LIKE, ARE EXCLUDED.

1

Downloaded from - http://www.guardianalarms.net

Page 2

Wiring

Access

Vertical junction box mounting with adapter plate.

Horizontal junction

box mounting holes.

Standard wall

mounting holes.

Table 1. LCD plus Keypad Specifications

ALARMS:

Emergency Duress

Cancel/Disregard

Call Central

SUPERVISION:

Communication loss annunciated

at keypad after 1 minute.

INTERCONNECTION:

Four wires, 300 feet maximum

5Ω maximum line resistance.

OPERATING ENVIRONMENT:

32° F to 122° F / 0° C to 50° C

NOTE 1: This restriction is due to power loss through cabling. With a

remote power supply the RS-485 link can extend up to 2,000

feet.

NOTE 2: 25mA for keypad, plus 20mA for backlighting at the 20%

default.

ENCLOSURE:

4.0" H x 7.275" W x 0.88" D

POWER (from control panel):

9-15VDC

45mA Standby current

25-125mA Alarm current

(programmable)

ARM/DISARM:

1

.

Secure

Automatic

Automatic No-Dial

Single Key Arming

2

CABLING CONSIDERATIONS

The maximum cable run for each LCD plus keypad is 300 feet from

the control panel.

Advantor recommends that you use 22AWG

twisted pair, shielded cable. When running LCD plus keypad cables:

1. DO NOT run cables parallel to AC wiring, unless the AC is in

metallic conduit.

2. Avoid mounting the keypad next to a light switch or electrical

outlet.

3. Keep wires away from fluorescent light fixtures. Fluorescent

lights produce a high level of electrical noise.

4. Keep cables away from high current devices (i.e., motors,

welders, etc.) which might induce spikes into the wires.

REMOVING THE BACK PLATE

The LCD plus keypad has four snaps around the edge of the enclosure. To open the keypad, insert a small screwdriver into one of the

slots and gently turn the screwdriver until the enclosure snap opens.

Move to the next slot and repeat this procedure until the enclosure

opens. Usually only two adjacent snaps need to be opened to remove

the cover.

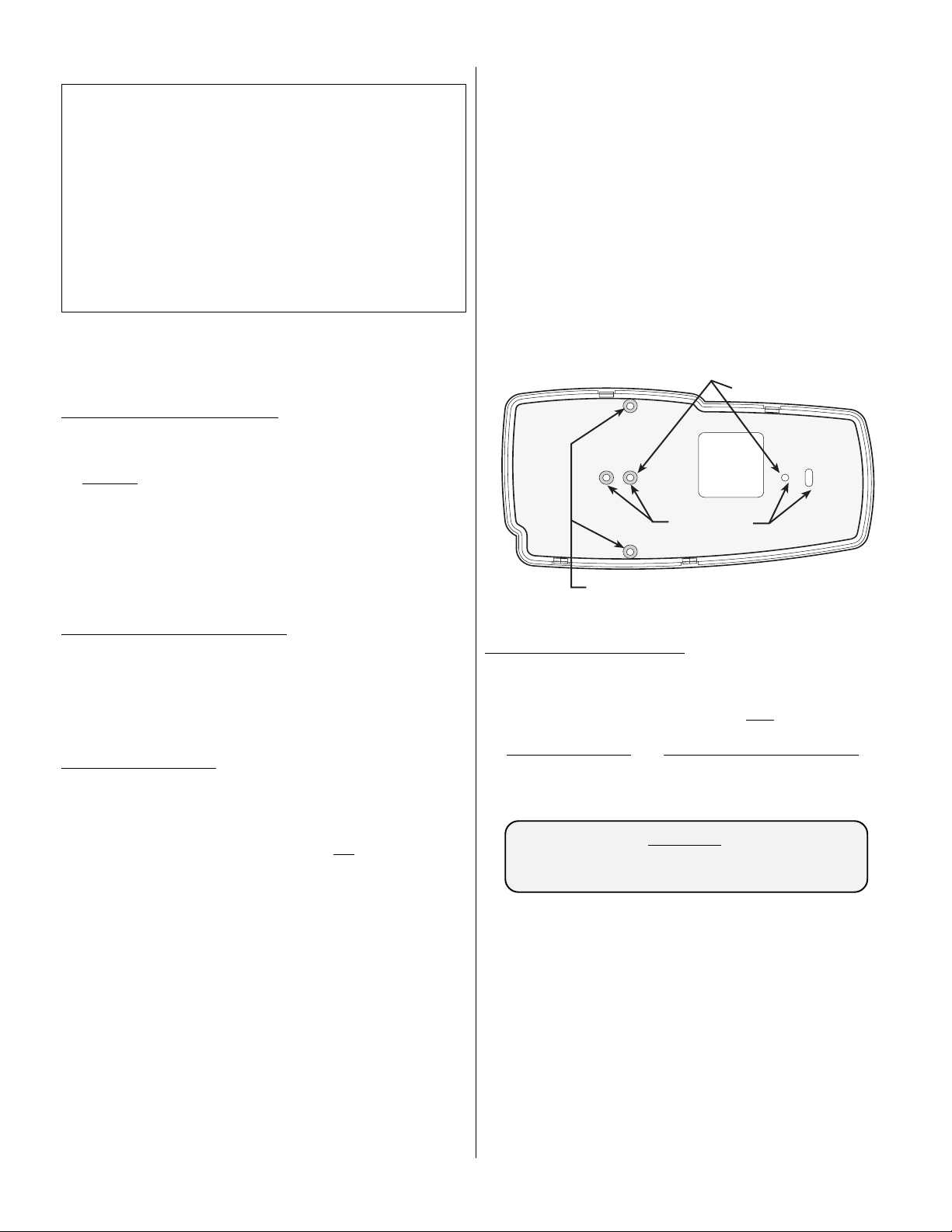

KEYPAD MOUNTING

WALL MOUNTING

The LCD plus keypad backplate has several mounting hole locations

(see Figure 2). For wall mounting use two of the middle mounting

holes.

Hold the back plate against the wall and mark

holes. Using a level draw a horizontal line through the marked hole.

Place the backplate against the wall again and line up the mounting

holes with the level line and mark the second hole location.

Since the LCD plus keypad does not have a straight edge, using a

level to mark mounting hole locations ensures level keypad mounting.

one of the mounting

JUNCTION BOX MOUNTING

Depending on the orientation of the junction box, the LCD plus has

two sets of mounting holes that can be used for junction box

ing.

You can mount the LCD plus directly to a double or triple gang

mount-

outlet box, however, be aware that the backplate may not completely

cover the box.

To completely cover the junction box use the LCD plus adapter plate

(P/N 09004301).

NOTE: The adapter plate can only be used on a horizontally

mounted junction box. Junction boxes are normally

mounted in the horizontal position. This adapter plate is a

spacer that goes between the junction box and the LCD

plus backplate.

To install the adapter plate line up the mounting holes of the adapter

plate with the LCD plus backplate. Insert two screws through the

backplate and the adapter plate and attach it to the junction box.

Attach the LCD plus keypad to the backplate after completing all

wiring and checks.

Figure 2. LCD plus Keypad Backplate Mounting Holes

LCD

plus

KEYPAD WIRING

Remove the LCD plus keypad Panduit connector and connect the

cable wires into the connector. To ensure proper connections, each

connection is silkscreened on the keypad circuit board.

The keypad connections at the control panel

must match the

connections at the LCD plus keypad. For example:

LCD plus KEYPAD CONTROL PANEL/MODULE

GND 24-Hour GND Source

DATA- DAT-, DATA- or DATALINE -

DATA+ DAT+, DATA+ or DATALINE +

+12V 24-Hour +12VDC Source

WARNING!

REVERSING THE +12V AND GND WIRES WILL

DAMAGE THE KEYPAD. CHECK POLARITY

BEFORE APPLYING POWER.

Table 2 lists compatible control panel and module connections

where you can find the required +12VDC keypad power and ground.

NOTE: Subtract each LCD plus keypad’s 45mA Normal Standby

and 25 to 125mA Alarm current from the control panel’s

backup battery loading chart.

2

Page 3

Table 2. Keypad Power Connections

eludoMrolenaPlortnoCniP-kcaJlebaLgnitaRtnerruC

eludoMesaB9,8,7,6-2J21+1etoNAm006,1

eludoMnoisnapxE

7,5,3,1-1J21+

4,3,2,1-3J21+

2etoN

eludoMnInetsiL21,11-1J21+2etoN

2-6J/5J/4J/3JV21+

6-2JV21+

Am054

4-2J21+2etoN

71-9J/8J/7J/6JDER

41,31-5JV21+

11,01,9,8-7JV+

6,1-4JDER

Am054

Am054

eludoMsseleriW

+C-4MAA/+4MAA

+1PC

)A-4MAA(eludoMsseccA

)detsiLLUtoN(

5-7J*+LEBAm059

6-1J+1XA

+2PC

Am0078-3J1DER

21-3J2DER

2-1JV21+

4-PC

9,5-3JDER

71-4J+1XUA

Am007

91-4J+2XUA

tnerrucgniwardeunitnoctiucriclleB+1PCehtmorfderewopsdapyeK*

)94301890N/P("snoitcurtsnInoitallatsnIsulpegatnavdA"ehttlusnoC:1ETON

.noitacilpparuoyroftnerrucelbaliavamumixamehtrof

.)S-A1V21SPAroeludoMesaB(ecruosrewopnotnadnepeD:2ETON

LCD

.nwodflestisrewop+1PCehtretfa

plus

KEYPAD FAST/SLOW JUMPER

Each LCD plus keypad is shipped from the factory ready for

installation in fast RS-485 applications (Fast/Slow jumper in place).

Refer to Figure 3 and locate the jumper at the bottom left of the LCD

plus keypad’s circuit board.

LEAVE THIS JUMPER IN PLACE when using the LCD plus

keypad with AAM4-A & AAM4C-A access systems

CUT THIS JUMPER when using the LCD plus keypad with the

following:

• ADV 3450* • ADV 3250*

• ADV 3650* • AAM4+

• ADV 3475* • AAM4-C+

• ADV 3350+*

*NOTE: These systems require version 6.0 (or higher)

firmware.

SETTING LCD

plus

KEYPAD ADDRESSES

Assign LCD plus keypad addresses in consecutive order, starting

with Address #1 and

not skipping any addresses:

Alarm Panel Zone A Keypads (0-3)

Alarm Panel Zone B Keypads (0-3)

AAM Module #1 Door #1

AAM Module #1 Door #2

•

•

•

AAM Module #7 Door #4

Table 3 will assist you in setting LCD PLUS keypad addresses.

Table 3. LCD plus Keypad Address Jumpering

Keypa

Addre

Keypad Jumper

#

1 2 4 8 1 2 4 8

Keypa

Addre

Keypad

Jumper#

1 X 9 X X

2 X 10 X X

3 X X 11 X X X

4 X 12 X X

5 X X 13 X X X

6 X X 14 X X X

7 X X X 15 X X X X

NOTE: X = jumper in place.

REV

S/N

90242

CUT

FOR SLOW

JPR

J1

1

1

2

3

2

4

8

GND

4

5

6

7

8

9

10

11

12

13

ADDRESS

JUMPERS

BEEPOUT

+12V IN

-DATA

+DATA

LCD

PLUS

Figure 3. LCD plus Keypad Circuit Board

3

J2

KP2

1

Page 4

For example, a system has two LCD plus keypads in Zone A and

three LCD plus keypads in Zone B. The system also has two LCD

plus keypads on AAM Module #3, Door #2, and one additional

keypad on AAM Module #7, Door #4.

The following shows the LCD plus keypad address scheme in this

sample integrated system:

Address Location

1 Zone A Keypad #1

2 Zone A Keypad #2

3 Zone B Keypad #1

4 Zone B Keypad #2

5 Zone B Keypad #3

6 AAM #3, Door #2

7 AAM #3, Door #2

8 AAM #7, Door #4

External Beeper Output

NOTE: UL requires that there be NO CONNECTION to this

output, which goes low while the keypad is beeping.

Pressing the Status button displays the system status. Displayed

status messages may include:

Pressing the Quit button returns you to the initial Setup Mode

screen (Figure 4).

Pressing the Loops button

displays the status of

system alarm loops (open,

shorted, normal). The

word “tested” appears in

the display if the loop was

tested during a Walk Test

(see Figure 7 for an

example).

While viewing the Loop Status screen pressing Prior displays the

previous alarm, pressing Next displays the next alarm.

Pressing Quit returns you to the Setup Mode screen (Figure 4).

• low battery • RPU down

• memory error • options error

• preamp down • cut telephone line

LOOP STATUS

Loop # 16 shorted

tested

Prior Quit

Figure 7. Loop Status Screen

LCD

plus

KEYPAD SETUP MODE

NOTE: Only LCD plus keypad #1 operates while the system is in

Place a system with no options into the Test Mode by powering it up

with the TEST/OPER switch (S1) in the TEST position.

NOTE: 3350+ and 3250 systems enter Test Mode by powering up

The keypad displays a

“Waiting for Master

Controller” message.

After approximately 15

seconds the LCD plus

keypad displays the Setup

Mode screen shown in

Figure 4, indicating the

system is in the Test Mode.

NOTE: Cal displays on only 3350+, 3450 and 3475 systems. The

the Test Mode.

with the Tamper loop violated. After power up press

“9+8+7+6+ENTER” on the keypad to stay in Test Mode.

SETUP MODE

HHMM ENTER sets time

select function

Test Cal Download

Figure 4. LCD Setup Mode Screen

3250 system and access modules have no audio detection

capabilities.

SETTING SYSTEM TIME

Any time the LCD plus keypad displays the “HHMM ENTER sets

time” prompt you may set or change the system clock. Using

military time format (i.e., HH=Hours, MM=Minutes, 4 pm = 16:00

hours), enter the current time then press ENTER. The keypad triple

beeps showing the system has accepted the change.

LCD

plus

KEYPAD TEST MODE

From the Setup Mode

s

creen, pressing the Test

button displays the Test

Mode screen shown in

Figure 5. The Test Mode

screen offers the following

system tests:

• Walk Test

• Auxiliary Output Test

• Audio Test

Walk Outputs Audio

Figure 5. System Test Screen

TEST MODE

press * for status

select function

System Status (*)

From the System Test

screen you can check the

system status at any time by

pressing the keypad “*”

key. Pressing “*” displays

the STATUS screen in

Figure 6.

select display

Status Quit Loops

Figure 6. Status Screen

Walk Test

From the Test Mode

screen, pressing the Walk

button places the system in

the Walk Test Mode and

displays the WALK TEST

screen shown in Figure 8.

Using Walk Test you can perform a functional system test by

entering Walk Test then walking around the facility violating alarm

loops. Each loop violation and restoral sounds the local bell for 1

second.

After violating the loops return to the keypad and press ENTER to

exit the Walk Test. The System Test screen in Figure 5 reappears.

You can press the keypad “*” key (system status) to see the Walk

Test results. Pressing “*” displays the TEST RESULT screen shown

in Figure 7.

Outputs Test

From the Test Mode

screen (Figure 5), pressing

the Outputs button

displays the OUTPUTS

TEST screen shown in

Figure 9.

Pressing the associated keypad key toggle the outputs on and off.

Press the number key to turn each output on, and press it a second

time to return the output to its original state.

• “1” for Aux Output #1 • “4” for Aux Output #4

• “2” for Aux Output #2 • “5” for the local bell

• “3” for Aux Output #3

OUTPUTS ON: 1 2 3 4 BELL

toggle by entering

aux # or 5 for Bell

Figure 9. Outputs Test Screen

Audio Test

From the Test Mode screen

(Figure 5), pressing the

Audio button displays the

AUDIO TEST screen shown

in Figure 10.

In addition to displaying

the Audio Test screen, pressing the Audio button automatically

sends a test tone to all audio sensors.

NOTE: Stored audio is not available on 3250 and access systems.

Ring Audio Done

WALK TEST

in progress

push ENTER when done

Figure 8. Walk Test Screen

push ENTER when done

AUDIO TEST

select function

Tip Stored

Figure 10. Audio Test Screen

4

Page 5

Tip Ring Audio TestTip Ring Audio Test

Tip Ring Audio Test

Tip Ring Audio TestTip Ring Audio Test

From the Audio Test

screen, pressing the Tip

Ring button displays the

TIP/RING AUDIO TEST

screen shown in Figure 11.

Using the Tip/Ring Audio

Test you can route audio to the TIP and RING test points on the

panel. Connecting a handset to these test points allows you to check

the quality of the audio that will be sent to the central station.

With the phone line disconnected, pressing the On button routes

audio from all system audio sensors to the TIP and RING test points

on the panel.

Pressing the Off button removes the audio from the TIP and RING

test points.

Pressing the Done button returns you to the initial Setup Mode

screen (Figure 4).

Stored Audio TestStored Audio Test

Stored Audio Test

Stored Audio TestStored Audio Test

From the Audio Test

screen, pressing the

Stored Audio button

displays the STORED

AUDIO TEST screen

shown in Figure 12.

NOTE: Stored audio is not available on 3250 or access systems.

With the phone line disconnected, pressing the Store button forces

the panel to store the next 5 seconds of audio.

Pressing the Replay button routes the stored audio to the TIP and

RING test points on the panel. Connecting a handset to these test

points allows you to check the system’s audio storage circuitry and

the quality of the audio that will be sent to the central station.

Pressing the Done button returns you to the initial Setup Mode

screen (Figure 4).

LCD

plus

KEYPAD CALIBRATION MODE

From the Setup Mode screen, pressing the Cal button displays the

Audio Calibration screen shown in Figure 13. The Audio Calibration Mode screen offers

the following calibration

modes:

• Auto

• Manual

• View

Auto CalibrationAuto Calibration

Auto Calibration

Auto CalibrationAuto Calibration

NOTE: See the Advantage 3000 Series Systems Installation and

From the Calibration

Mode screen, pressing the

Auto button places the

system in the Automatic

Calibration Mode and

displays the Calibration

screen in Figure 14.

From the calibration screen select any audio detectors that you want

to exclude from the calibration. This screen displays the excluded

audio detector number(s) as they are entered on the keypad.

Pressing the Quit button returns you to the Calibration screen

(Figure 13).

Pressing the Start button

displays the Auto Calibra-

tion screen shown in

Figure 15.

Service Manual for detailed Automatic audio calibration

procedures.

TIP/RING AUDIO TEST

select function

On Off Done

Figure 11. Tip/RingAudio Test Screen

STORED AUDIO TEST

select function

Store Replay Done

Figure 12. Stored Audio Test Screen

AUDIO CALIBRATION

select function

Auto Manual View

Figure 13. Calibration Screen

select detector #s

to exclude

excluded:

Start Quit

Figure 14. Calibration Mode Screen

AUTO CALIBRATION

calibrated: 12345678

excluded:

Done

Figure 15. Auto Calibration Screen

The Auto Calibration screen “calibrated” listing shows the audio

detectors that have been calibrated. This listing updates as

detectors are calibrated.

Using the Calibration Mode screen View command, check the

detector(s) sensitivity (see View Calibration).

Pressing Done returns you to the Calibration Mode screen (Figure

13).

View CalibrationView Calibration

View Calibration

View CalibrationView Calibration

From the Calibration

Mode screen, pressing the

View button places the

system in the View Mode

and displays the View

screen in Figure 16.

While viewing the screen pressing Prior displays the previous

audio detector, pressing Next displays the next detector.

Pressing Quit returns you to the Setup Mode screen (Figure 4).

Manual CalibrationManual Calibration

Manual Calibration

Manual CalibrationManual Calibration

NOTE: See the Advantage 3000 Series Systems Installation and

From the Audio Calibration screen, pressing the

Manual button places the

system in the Manual

Calibration and displays

the Manual Calibration

screen shown in Figure 17.

Pressing the Cal button displays the second Manual Calibration

screen shown in Figure 19 and enables all audio detection circuits.

While the keypad displays this screen you can manually adjust the

sensitivity pots on audio sensors without affecting the audio

detector settings.

Entering a valid audio

detector number (or

pressing “0” for all

detectors) displays the

Sensitivity screen shown in

Figure 18.

Pressing the numbers (00-

15) corresponding with the

desired sensitivity and

pressing ENTER displays

the second Manual

Calibration screen shown

in Figure 19.

Using the Audio Calibration screen View command, check the detector(s) sensitivity (see View Calibration).

Pressing ENTER returns you to the Audio Calibration screen

(Figure 13.)

LCD

From the Setup Mode

screen, pressing the

Download button displays

the Download Mode

screen shown in Figure 20.

The Download Mode

screen offers Answer, Call

and Quit options.

Service Manual for detailed Automatic audio calibration

procedures.

plus

KEYPAD DOWNLOAD MODE

Figure 16. Manual Calibration Screen

select detector no.

Figure 17. Manual Calibration Screen

select function

Answer Call Quit

Figure 20. Download Mode Screen

Audio Calibration

Detector number: 1

Sensitivity: 06

Prior Quit Next

MANUAL CALIBRATION

(or “0” for all)

Cal

select sensitivity

from “00 (off) to

“15” (most sensitive)

push ENTER when done

Figure 18. Sensitivity Screen

Audio Calibration

Tripped: 1

Select function

Auto Manual View

Figure 19. Manual Calibration

Screen #2

DOWNLOAD MODE

5

Page 6

Answer ModeAnswer Mode

Answer Mode

Answer ModeAnswer Mode

Use the Answer Mode when you contact the central station and

request an options download. While in the Answer Mode the panel

seizes the line and answers the phone (goes off-hook) on the first

ring.

From the Download

Mode screen, pressing the

Answer button places the

system in the Answer

Mode and displays the

screen in Figure 21.

The Exit button gives you

the option of exiting Download Mode and returns you to the initial

Setup Mode screen (Figure 4).

While at the Answer Mode screen, restoring the Tamper loop (3250

and 3350+ systems) or switching the panel’s TEST/OPER switch

(S1) back to OPERATE (3450, 3475 and AAM4-C+) prepares the

panel for options downloading.

The keypad screen clears, then a “Waiting for download” message

appears on the bottom display line until the central station computer

contacts the panel. Once the download begins the keypad display

changes to a “receiving download” message. After completing the

download the keypad displays the main screen shown in Figure 4.

Call ModeCall Mode

Call Mode

Call ModeCall Mode

Use the Call Mode to

initiate the options

download from the LCD

PLUS keypad at the

control panel location.

From the Download Mode

screen, pressing the Call

button places the system in

the Call Mode and displays the Call Mode screen shown in Figure

22.

NOTE: The Quit button in all Download screens gives you the

option of exiting and returning to the initial Setup

Mode screen

(Figure 4).

From the Download Mode

screen, pressing the Enter

Options button displays

the screen shown in Figure

23.

Pressing the Quit button

returns you to the Call

Mode screen (Figure 22).

Use this screen to enter the

information required to

begin the download. This

includes the central station

telephone number.

Pressing the Enter Phone# button displays the screen shown in

Figure 24.

Enter the phone number you want the panel to call. Pressing the

Delay button anywhere in the phone number inserts a three second

select function

Options Dial Quit

select function

Phone# Acct# Quit

Figure 23. Download Mode Screen

Enter phone# to call

Restore Tamper

Switch to operate

Exit

Figure 21. Answer Mode Screen

DOWNLOAD MODE

Enter

Figure 22. Call Mode Screen

DOWNLOAD MODE

Enter Enter

DOWNLOAD MODE

Delay Done

Figure 24. Phone# Screen

delay before continuing the

dialing sequence.

Press Done after entering

the phone number.

Pressing the Enter Acct#

button displays the screen

shown in Figure 25 and

allows you to enter the optioned account number (see the options

sheet).

Pressing the Quit button returns you to the Call Mode screen

(Figure 22).

Dial ModeDial Mode

Dial Mode

Dial ModeDial Mode

Use the Dial Mode to

force the control panel to

dial the central station.

From the Download Mode

screen, pressing the Dial

button places the system

in the Dial Mode and displays the Dial Mode screen shown in Figure

26.

While at the Dial Mode screen, restoring the Tamper loop (3250 and

3350+ systems) or switching the panel’s TEST/OPER switch (S1)

back to OPERATE (3450, 3475 and AAM4-C+) prepares the panel

to dial for options downloading.

The keypad screen clears, then a “Calling for download” message

appears on the bottom keypad display line. Once the download

begins the keypad display changes to a “receiving download”

message.

After completing the download the keypad display automatically

returns to the main screen shown in Figure 4.

DOWNLOAD MODE

Enter panel account#

Push ENTER when done

Figure 25. Account# Screen

Restore Tamper

Switch to operate

Exit

Figure 26. Dial Mode Screen

COMMUNICATION LOSS

The LCD plus keypad senses a loss of communication with the

control panel and annunciates the loss. One minute after communication loss the keypad alerts the user by beeping once each 10

seconds.

The beeping continues until the user presses any key, at which time

the beeping stops and displays a “System Down Call for Service”

message. The message remains until communications restore.

UL WARNING!

LCD plus KEYPADS WITH A BLINKING YELLOW

LED, A BLINKING CURSOR AND BEEPING EVERY 10

SECONDS INDICATES AN RS-485 COMMUNICATIONS

PROBLEM. THE SYSTEM MAY BE INCAPABLE OF

REPORTING FIRE OR BURGLARY ALARMS.

6

Loading...

Loading...