Page 1

Installation Instructions for:

Grade A and B Central Station Burglary, Grade A Proprietary Burglary,

Grade A Local Burglary, Grade A Police Station Connected Burglary,

Central Station Fire, Household Fire, Household Burglary, and

Combination Household Fire & Burglary Systems

(P/N: AVR PLUS)

P/N 09820450

Revision A

See the Advantage plus Service Manual (P/N 09820460) for operational theory and service procedures.

See the SONICS Database Management Manual (P/N 09820426) for options programming procedures.

___________________________________________________________

Copyright © 1997 by Advantor Corporation. All rights reserved.

No part of this document may be reproduced or distributed in any form or by any means, or stored

in a database or retrieval system, without the prior written permission of Advantor Corporation.

GLOSSARY OF ADVANTAG

Access Module - Access Modules are Base Module add-on units that

provide facility access control. Each Access Module controls up to

four facility doors, provides ten general purpose alarm loops and six

auxiliary outputs. The Advantage plus Base Module can interface and

control up to seven Access Modules.

Advantor Audio Sensor - An audio sensing device capable of

receiving audio and reporting sounds to an audio detection circuit for

audio detection alarm monitoring. The AudioSensor also supplies the

central station operator with verification audio to help identify the

cause of an alarm loop violation.

Advantor Glass Break - The Advantor Glass Break is a versatile,

dual-function, audio verification sensor and glass break detector. It

contains an adjustable glass breakage detector and verification audio

capability in a single unit.

Audio Detection - Audio detection describes the proven method of

using AudioSensors in combination with SmartAudio Modules for

volumetric detection of intrusions. An unrecognized sound triggers an

AUDIO Activation and alerts the central monitoring central station.

Audio Verification - Audio verification is live audio sent to the

central monitoring station console when a violation occurs. The

monitoring operator uses this audio to assist in identifying the cause

of an alarm loop violation.

Base Module - The primary control unit for Advantage plus systems.

The Base Module directs and controls all other optional modules and

devices and provides communication with the SONICS central

monitoring console.

The Base Module provides sixteen programmable alarm loops, up to

eight separate zones, a Wiegand card reader input, and four balanced

audio inputs for verification audio. The Base Module’s RS-485

communication port can interface and control the following:

• any combination of 16 LCD plus and LED plus keypads

• eight alarm loop Expansion Modules

• any combination of up to eight SmartAudio Modules or

ListenIn Modules

• one Wireless Module*

• seven Access Modules

*NOTE: This module has not been investigated and installation is

not permitted in UL Listed systems.

E plus

TERMS

Expansion Module - The Expansion Module is a Base Module addon unit that provides the system with an additional sixteen supervised,

programmable alarm loops and four additional auxiliary outputs. The

Advantage plus Base Module can interface and control up to eight

Expansion Modules.

LCD plus Keypad - The LCD plus keypad is a fifteen button wall-

mounted keypad in its own enclosure. The keypad contains a four

line, twenty character per line Liquid Crystal Display (LCD) that

displays the Advantage plus' status in plain English.

ListenIn Module- The ListenIn is an optional unit that when added

to the Advantage plus Base Module gives the system the ability to

support sixteen additional audio verification sensors (AudioSensors or

GlassBreaks). The Advantage plus Base Module can interface and

control any combination of up to eight ListenIn Modules and/or

SmartAudio Modules.

SmartAudio Module - An optional add-on module that gives the

Advantage plus system audio detection capability. The SmartAudio

Module supplies eight audio detection circuits and connections for up

to sixteen audio sensors (Advantor Audio Sensors). The Advantage

plus Base Module can interface and control any combination of up to

eight SmartAudio Modules and/or ListenIn Modules.

TelPlus - The TelPlus is an optional add-on unit that, when added to

the Advantage plus Base Module, provides a second telephone line

interface with the SONICS central station monitoring console.

You can configure the TelPlus for either a second dial telephone

interface,

Base Module’s telephone interface for a backup dial communication.

NOTE: You can configure the Base Module’s telephone line

Wireless Module - An optional add-on module that interfaces the

Base Module with up to 63 spread spectrum (long range) wireless

transmitters with individual detector identification. The Base Module

can control one Wireless Module.

NOTE: This module has not been investigated and installation is

or as the primary dedicated telephone line and use the

connection for either dial line or dedicated line connection (but not both). Only use the TelPlus to provide a

second telephone line interface.

not permitted in UL Listed systems.

Downloaded from - http://www.guardianalarms.net

1

Page 2

Zone - An area of the facility that contains alarm loops that arm and

disarm as a group with associated auxiliary outputs and audio

verification or audio detection AudioSensors.

SCOPE

These instructions provide the information and references needed to

install, set up, and option UL Listed Advantage plus systems

using the UL Listed Base Module as the system control unit. The

“Advantage plus Service Manual” (P/N 09820460) covers system

maintenance and service.

Each of the listed add on devices and modules can be located up to

2,000* feet from the Base Module giving the Advantage plus the

following maximums:

• 214 alarm loops split into eight separate zones

• any combination of up to 128 audio detection/audio verification audio sensors

• access control of up to 28 separate doors

• up to 82 programmable auxiliary outputs

*NOTE: At least one LCD plus or LCD plus keypad must be

powered directly from the Base Module.

THE ADVANTAG

The Advantage plus system has following UL Listings and

agency approvals:

• FCC Part 15, Class B

• UL 294, “Access Control System Units”

• UL 365, “Police Station Connected Burglary Alarm Units and

Systems”

• UL 609, “Local Burglar Alarm Systems and Units”

• UL 864, “Control Units for Fire Protective Signaling Service”

• UL 985, “Household Fire Warning System Units”

• UL 1023, “Household Burglar-Alarm Systems”

• UL 1076, “Proprietary Burglar Alarm Units and Systems”

• UL 1610, “Central Station Burglar Alarm Units”

• CSFM (California State Fire Marshal)

The Advantage plus Base Module is the primary control unit for

Advantage plus systems. The Base Module directs and controls

all other optional modules and devices and provides communication with the SONICS central station monitoring console.

The Base Module, without any optional add-on modules, has the

following features and capabilities:

• sixteen programmable alarm loops

• up to eight separate zones

• four auxiliary outputs

• four audio inputs for verification audio

• dedicated or dial telephone line operation

• one Wiegand card reader input

• an RS-485 communication port

The Base Module’s RS-485 communication port can interface and

control the following optional add-on modules and devices to expand

the system’s features and capabilities:

• any combination of 16 LCD plus and LED plus keypads

• eight alarm loop Expansion Modules

• a combined total of eight SmartAudio Modules and/or

ListenIn audio verification modules

• seven Access Modules

NOTE: See the following documents for Advantage plus

optional module installation instructions:

• Access Module Installation, P/N 09820451

• Smart Audio Module Installation, P/N 09820452

• Expansion Module Installation, P/N 09820453

• TelPlus Module Installation, P/N 09820454

• Wireless Module Installation, P/N 09820456

• ListenIn Module Installation, P/N 09820455

• Cellular Module Installation, P/N 09820457

• APS12V1A-S Power Supply, P/N 09820458

• LED plus Keypad Installation, P/N 09830030

• LCD plus Keypad Installation, P/N 09830046

• Fire Control Panel Interface Installation, P/N 09820459

E plus

UL SYSTEMS

ADVANTAG

E plus

PROPRIETARY AND

CENTRAL STATION BURGLARY SYSTEMS

The major differences between the Advantage plus UL Propri-

etary Burglary systems and standard Advantage plus installations are:

• Must be installed per UL 681, “Installation and Classification of

Mercantile and Bank Burglar Alarm Systems” and UL 611,

“Central Station Burglar Alarm Systems.”

• Requires the UL Listed chassis and the tamper switch assembly, available from Advantor.

• UL Certificated Burglary Systems may use only LCD or LCD

plus keypads as the system Arming/Disarming device.

• Proprietary burglar alarm systems provide Grade AA alarm

loops.

• UL Burglary Systems require a minimum of 4 hours of standby

(battery) power.

OPTIONS SELECTION AND PROGRAMMING

NOTE: See the “SONICS Database Management Manual”

The alarm monitoring console displays different screens for each

Advantage plus series. For example, selecting the Panel Type

and UL Fire automatically locks in many UL required options and

limits other option selections in specific fields.

Advantage

The following lists the required central station fire options.

Equipment Options

• Select “ADV” panel type and “plus” for the series

• Select “LCD Keypad.”

• Select “TelPlus.”

• An annunciator (if used) must be supervised. (See the Household

File loop and auxiliary output options.)

Phone Options

• Program the Wait for Dial Tone option for 7 seconds or less.

• Option the Central Station Response Time (CSR) option for 45

seconds or less.

• Program the Enable Line Monitor 2 for Yes.

Loop Options

• To meet the UL requirement that fire alarms have the highest

priority, Fire-related Alarm Codes should be the following:

- FIRE ALARM - FIRE LOOP #

• All UL Fire-related loops restricted to 24-Hour security.

• All UL Fire-related loops restricted to Send Restoral Code.

• All UL Fire-related loops default to Alarm on Short.

• All UL Fire-related loops restricted to Send Trouble When Armed.

• All UL Fire-related loops restricted to Drop Line alarm reporting.

• All UL Fire-related loops restricted to Fire Loop.

(P/N 09840015) for complete option descriptions.

plus

Central Station Fire Options

2

Page 3

Advantage

plus

Grade A Proprietary & Grade A

Central Station (Multiplex) Burglary Options

The following lists the required proprietary burglary options:

Equipment Options

• Select “ADV” panel type and “plus” for the series

• Select "LCD Keypad".

Phone Options

• (Proprietary only). Select the ERAD mode for the telephone line.

Loop Options

• Program all UL Burglary alarm circuits for Alarm on Open and

Alarm on Short.

NOTE: UL requires that an alarm be generated if the initiating

Miscellaneous Options

• If a bell is present, program the Bell Ring Length option for a

Advantage

loop is opened or shorted when the system is armed.

minimum of 15 minutes.

plus

Grade A Police Station Connected,

Grade B Local, and

Grade B Central Station (DAC) Burglary Options

The following lists the required options for a police station connected

burglary system:

Equipment Options

• Select “ADV” panel type and “plus” for the series

• Select “"LCD Keypad".

Phone Options

• Program the Wait for Dial Tone option for 7 seconds or less.

• Option the Central Station Response Time (CSR) for 45 seconds

or less.

Keypad Options

• Option the Entry Delay Time for 60 seconds or

• Option the Exit Delay Time for 60 seconds or

Loop Options

• Program all UL Burglary alarm circuits for both Alarm on Open

and Alarm on Short.

Line Down Options

• All UL-related loops restricted to YES Send Restoral Code for

Line Down.

Miscellaneous Options

• Program the AC Power Down option as

NOTE: In UL Listed systems, the Base Module sends the AC

• Program the Bell Ring Length option for 15 minutes or

ADVANTAG

An efficient sequence for a typical installation is as follows:

1. Complete the “Advantage plus UL Standby Battery Chart”

2. Check the option sheet and enter the selected options into the

3. Enter database information (and employee numbers if a Secure

alarm six hours after AC power loss. In non-UL systems,

the Base Module sends the AC alarm one minute after

losing AC power.

The LCD plus keypad immediately indicates the “AC

OFF” condition on all systems

The Advantage plus Base Module must be connected to a

compatible Listed sounding device suitable for the application, rated for at least 85 dB operating over the voltage range

of 9.6 to 13 VDC.

E plus

computer.

arming system).

SEQUENCE OF INSTALLATION

less.

less.

YES.

longer.

4. Mount the cabinet, install any optional modules and the RJ31X

jack. Ensure correct RJ31X wiring. Existing RJ31X jacks are

often wired incorrectly.

All UL systems must use the fused RJ31X jack(s) included in

the ULB or ULF Installation Kit.

5. Connect the phone line(s) and perform the “Base Module PreInstallation Test”.

6. Complete the field wiring (AudioSensors, GlassBreaks, smoke

detectors, door switches, LCD keypads, etc.).

7. Download options from the programming computer into the

Advantage plus Base Module and all optional add-on

modules.

8. Adjust and calibrate (if applicable) system audio.

9. Test the system to ensure communications and proper

options.

AC POWER BUDGET

The Base Module’s AC power supply can continuously supply a total

of 1.9 Amps (thermally limited) at 12 VDC. By installing a battery,

the Base Module can supply up to 1.9 Amps of device current and

1.5 Amps of annunciation current for short periods of time.

The Base Module’s annunciator and auxiliary outputs are individually

protected by Positive Temperature Coefficient resistors (PTCs).

However, since UL requires internally fusing the AC power transformer, shorting an output with no battery present often blows the

transformer fuse before the PTC can react.

* The current drawn by the Base Module’s Audible/Visual

annunciators

Amps).

* The Normal Standby or Alarm currents (excluding annuncia-

tors)

cannot exceed the PTC limited 1,900mA (1.9 Amps).

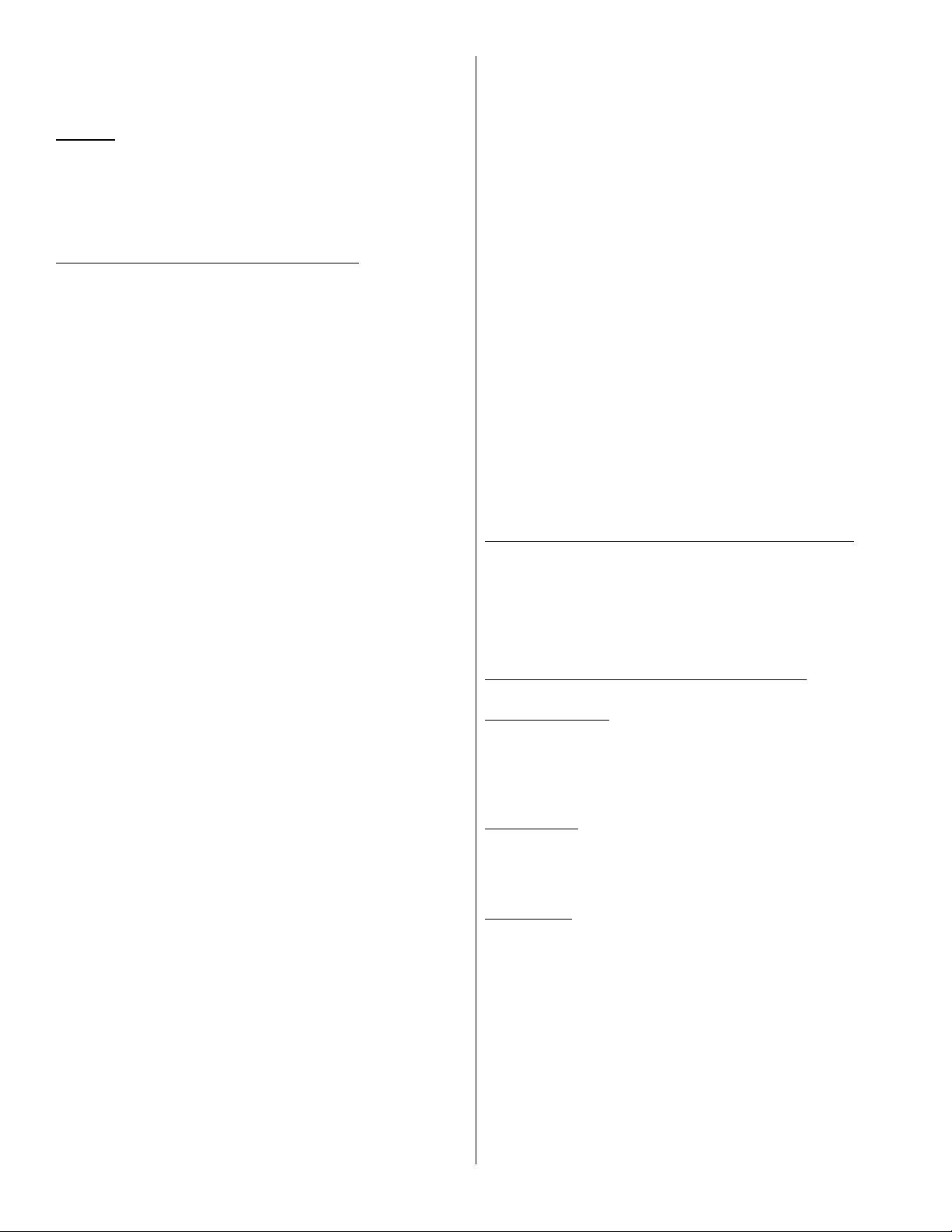

The UL Standby Battery Chart in the following section can also be

used to calculate the AC operation power budget. Adding an

additional 400 mA for charging dead batteries is recommended.

cannot exceed the PTC limited 1,500mA (1.5

CALCULATING BATTERY STANDBY

In UL installations, the Normal Standby Current is limited by backup

capacity of the installed battery(s) rather than the available AC power.

To ensure the required backup power, you must always use this

lower current value in certificated UL installations. Table 1 shows

estimates of the maximum Normal Standby current available from

one or two 7AH batteries for UL requirements for 4 or 24 hour

battery operation

Table 1. Battery versus Standby Current

pukcaByrettaBderiuqeRyrettaBenOseirettaBowT

setuniM51+sruoH4A2.1A9.1

setuniM5+sruoH42A2.0A4.0

Before installation, compute the required standby current for all

accessories powered by the Base Module. The following factors

limit the equipment and devices powered by the Base Module:

• The current drawn by the equipment and devices powered from

the Base Module

• The UL requirement for at least 4 hours plus 15 minutes of

alarm battery life for UL Central Station Burglary, Proprietary

Burglary, Household Burglary, and Household Fire.

• The UL requirement for at least 24 hours (plus 5 minutes of

alarm) battery life for UL Central Station Fire.

3

Page 4

Knowing this, the following rule applies for battery operation:

• The Base Module’s maximum Normal Standby current

cannot exceed the battery(s) Ampere-Hour (AH)

capacity divided by the number of hours of required

battery operation.

Example: two 7 AH batteries installed in a system

requiring 24 hours of backup operation.

7 x 2 = 14 AH

14 AH ÷ 24 Hours required backup = 0.58 Amp

Normal Standby current cannot exceed 0.58 Amps

To properly calculate the Advantage plus system’s battery

capacity you

current required by the system. Calculate a system’s AmpereHour requirements using the following factors:

• the total system standby current load

• hours of required standby operation (24 hours for UL

Central Station Fire, 4 hours for other UL configurations)

• the required duration of alarm signaling (normally 4

minutes for fire, 15 minutes for central station burglary).

NOTE: Consult the Authority Having Jurisdiction (AHJ)

MUST evaluate the Normal Standby and Alarm

before installing any Fire system. Local and/or

state fire ordinances could impose limitations on

the maximum number of smoke detectors

installed in one system.

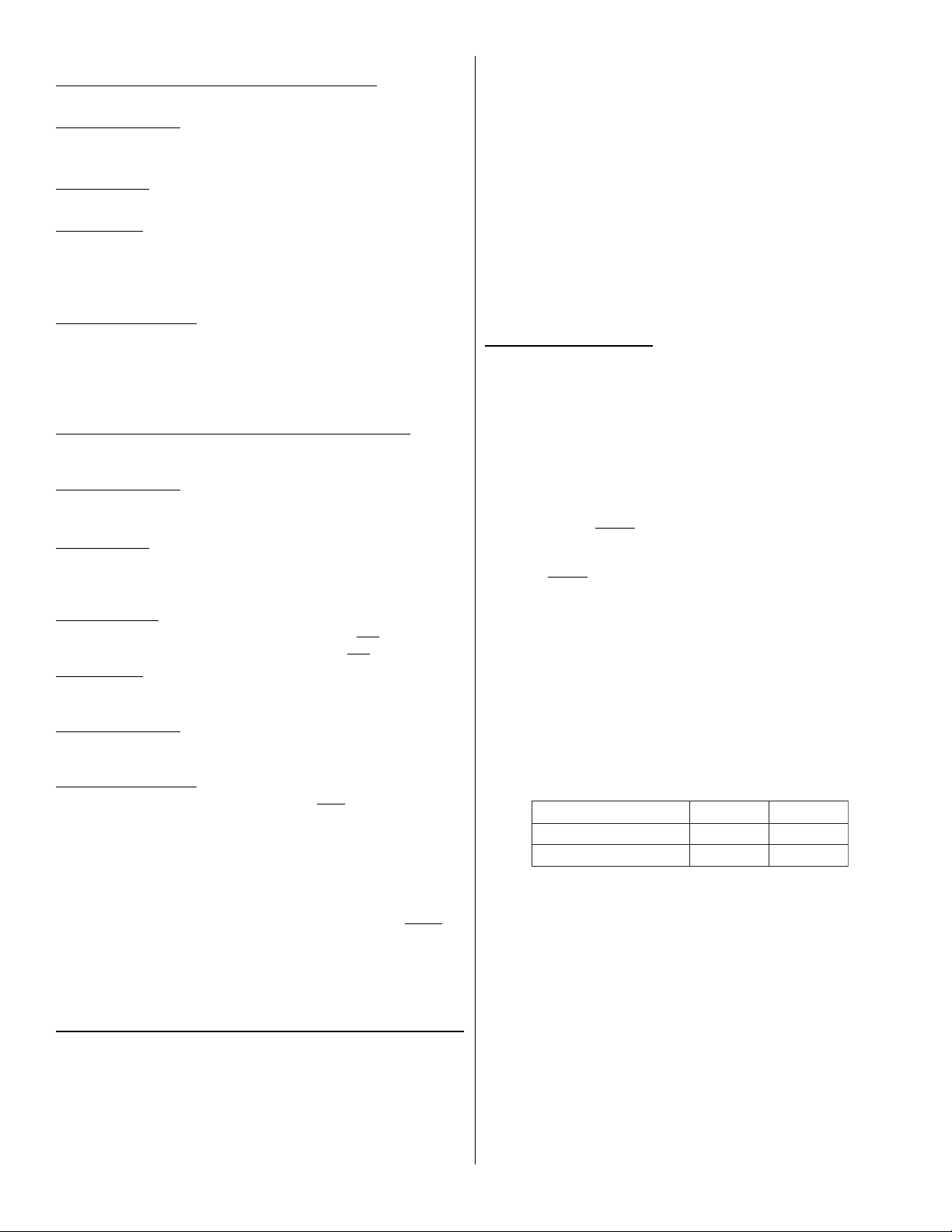

CABINET AND MODULE INSTALLATION

DO NOT INSTALL ADVANTAGE plus IN

LOCATIONS WHERE TEMPERATURES DROP

BELOW 0°F OR RISE ABOVE 122°F.

Mount the enclosure next to a standard 120VAC power

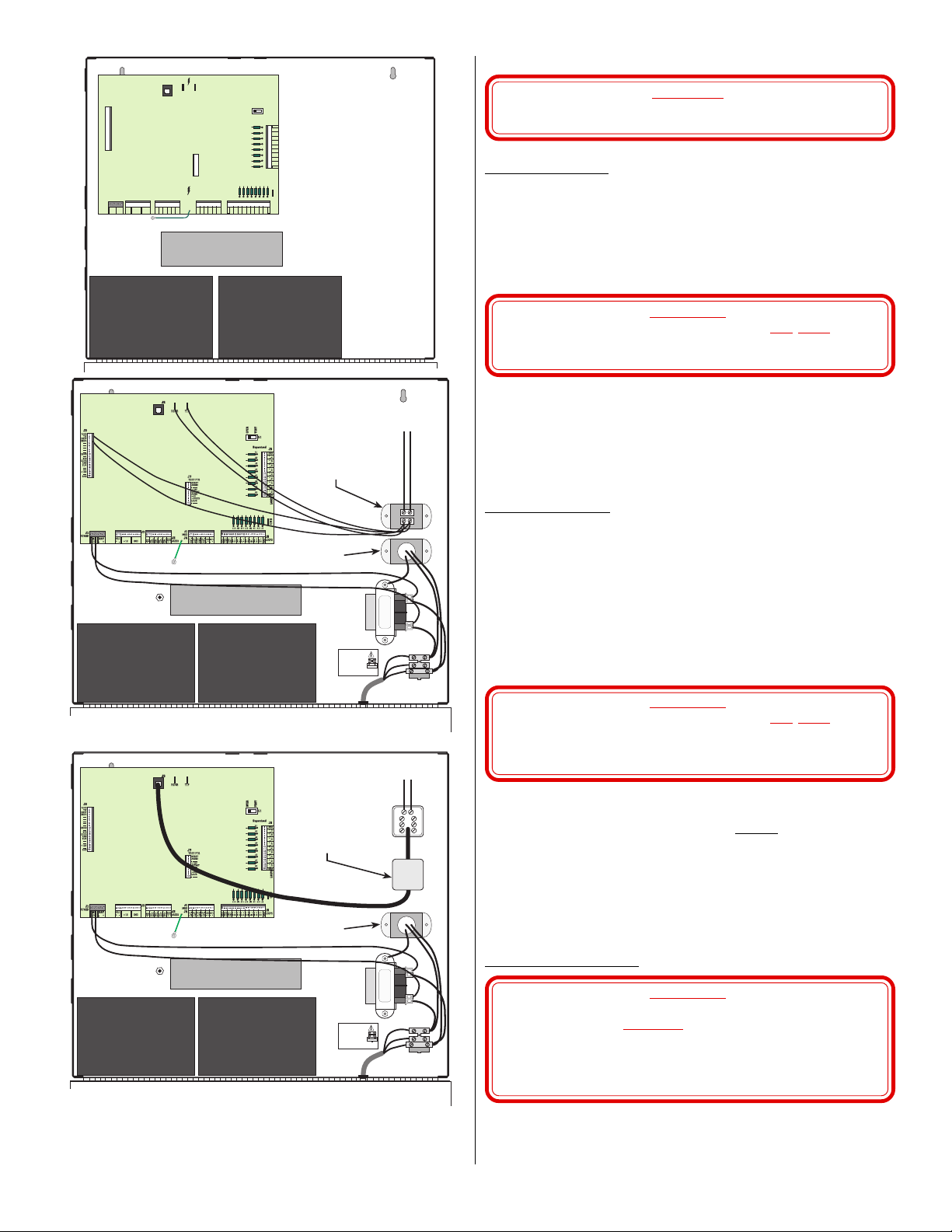

source to simplify AC wiring. See Figure 3 and do the

following:

1. Install the six Base Module standoffs by pressing them in

from the back of the cabinet. Also install the standoffs for

any optional modules.

2. Using the cabinet as a guide, mark the top two mounting

hole locations on the mounting surface.

3. Mount the top screws and place the cabinet keyholes on

the screws. Tighten the top screws and secure the cabinet

with the bottom screws.

4. Mount the Base Module on the standoffs installed in step

#1.

5. Mount any additional modules inside the cabinet on the

pop-in standoffs installed in step #1.

CAUTION!

ybdnatS

tnerruC

emaNyrosseccAytQ

latoT

.Am).aE(

mralA

ybdnatS

tnerruC

tnerruC

latoT

mralA

.Am).aE(

tnerruC

eludoMesaB 1051051002002

sulp

DCL

dapyeK52521

DELsulpdapyeK5259-52

eludoMoiduAtramS002002

eludoMnoisnapxE031031

eludoMsulPleT054

eludoMnInetsiL0303

eludoMsseleriW )1etoNees( 051051

rosneSoiduAegatnavdA55

kaerBssalGegatnavdA2162

redaeRdraCelbitapmoCdnageiW

XX0-78303detsiLgnireenignErosneS

XX0-51813detsiLgnireenignErosneS

XX1-51813detsiLgnireenignErosneS

XX1-08813detsiLgnireenignErosneS

X-30513detsiLgnireenignErosneS

4#hguorht1#stuptuOyrailixuA

W4-002SD

W4-DH002SD

)

esaB

W4BM

AW4BM

)yaleRxuA/w

EW4BM

SW4BM

)rednuoSBd58/w

002LOE

)esaBW4-002BM/w002SD(

W4-002BM/wDH002SD(

)daeHeriW-4052SD/wesaB(

esaB/wdaeHeriW-4052SD(

esaB/wdaeHeriW-4052SD(

)noisivrepuSrewoPdnayaleRxuA/w

esaB/wdaeHeriW-4052SD(

)eludoMeniLfodnE(

80.052

80.052

80.084

80.065

80.008

80.036

0303

SLATOT)1(

srotaicnunnAlausiVdnaelbiduA

)2(

SLATOT)3(

.smetsys

tnerruCmralAmretgnolro,tnerruCybdnatSlatoT,rebmunsihT)1( TONNACehtdeecxe

.)1elbaTees(sruohpukcabforebmun

.)spmA5.1(Am005,1otdetimilsitnerruclleBeludoMesaBehT)2(

tnerruClleBdnatnerruCmralAlatoTdenibmoceht,rebmunsihT)3( TONNACdeecxe

.remrofsnart

Figure 2. Advantage plus UL Standby Battery Chart

detacifitreCLUnidesuebtonyamdna,detsiLLUTONsieludoMsseleriWehT:1ETON

emarfnepoehtgnisufiAm006,1ro,remrofsnartdetnuom-gulpehtgnisufiAm009,1

4

Page 5

Base Module

AC AND EARTH GROUND WIRING

CAUTION!

DO NOT CONNECT BASE MODULE JACK J1 UNTIL

ALL TRANSFORMER WIRING IS COMPLETE.

Earth

GND

BatteryBattery

Dedicated

Phone Line

Optional Ditek Data

Loop Protector

(P/N 08061698)

DITEK

DANGER

Fuse

DITEK

WHT

GRN

BLK

Strain Relief

To Dial

Telephone Line

Ditek 120 VAC Surge

Protector (P/N 08061699)

BatteryBattery

115 VAC via either power cord (included)

or from direct supply (enclosed in conduit).

AC Power Wiring

(using plug-mounted transformer)

Run an 18AWG (or larger) 2-conductor cable out the hole in the

cabinet bottom to the plug-mount transformer (or the transformer

enclosure).

The Base Module J1 screw terminal block pins 1 and 2 (labeled AC

16.5V) provides the connections for the 16.5VAC, 50 VA input from

the plug-mount transformer. Connect the power wires into the J1-1

and 2 terminals (polarity is not important).

WARNING!

UNLESS OTHERWISE INSTRUCTED,

DO NOT PLUG

THE TRANSFORMER INTO THE AC OUTLET UNTIL

ALL WIRING IS COMPLETE.

Connect the wires to the transformer terminals.

When ready to plug the transformer into the AC outlet, remove the

outlet cover plate screw and place it through the transformer case tab.

Plug the transformer into the bottom outlet, insert the screw through

the transformer and cover plate, then tighten. This secures the

transformer, preventing accidental disconnection.

AC Power Wiring

(using open frame transformer)

The open frame transformer comes pre-installed inside the chassis

with a fuse block and a DITEK 120 VAC surge protector.

AC power coming inside the chassis connects at the fuse block as

shown in Figure 3. You can bring AC power to the fuse block via

either the AC power cord (included), or wire it directly from a 120

VAC power line.

The Base Module J1 screw terminal block pins 1 and 2 (labeled AC

16.5V) provides the connections for the 16.0VAC, 43 VA input from

the open frame transformer. Connect the power wires from the

transformer to the J1-1 and 2 terminals (polarity is not important).

WARNING!

UNLESS OTHERWISE INSTRUCTED,

DO NOT PLUG

THE TRANSFORMER CORD INTO THE AC OUTLET

OR TURN THE CIRCUIT BREAKER “ON” UNTIL

ALL WIRING IS COMPLETE.

Optional Ditek

Data Protector

(P/N 08060085)

Ditek 120 VAC Surge

Protector (P/N 08061699)

Earth

GND

DANGER

BatteryBattery

115 VAC via either power cord (included)

or from direct supply (enclosed in conduit).

Fuse

Strain Relief

Figure 3. Advantage plus Enclosure Layout

DITEK

3

2

1

WHT

GRN

BLK

5

4

6

7

8

SYSTEM GROUNDING

NOTE: All Advantage plus modules isolate earth ground

from signal ground. This is done to meet UL

requirements, and also allows all the interconnect

modules to share the same signal ground when there

may be a large difference in potential between earth

grounds. Earth ground must remain isolated from

signal ground.

Earth Ground Wiring

WARNING!

IF USING THE 115 VAC, 43 VA OPEN FRAME

TRANSFORMER

EARTH GROUND TO THE CHASSIS EARTH GROUND

STUD. THE ELECTRICAL GROUND AT THE OPEN

FRAME TRANSFORMER ACTS AS THE EARTH

NOTE: Always install AC and Earth Ground wiring per Article

250 of the National Electrical Code.

5

DO NOT CONNECT AN EXTERNAL

GROUND IN THIS CHASSIS.

Page 6

Connect one end of a heavy gauge wire (12 gauge solid recommended) to a known good earth ground. Keep the distance from the

earth ground as short as possible, with no sharp bends.

Strip the other end of the earth ground wire and crimp it into the lug

supplied in the installation kit. Secure the lug, along with the Base

Module Earth Ground lead to the chassis stud located on the left side

of the chassis. Tighten the screw, ensuring all wires make good

connection.

NOTE: Also connect the Earth Ground leads of all other

optional modules installed inside the chassis to the

chassis earth ground stud.

The earth ground provides the modules protection against static

electrical shocks and high power surges. It also provides a convenient earth ground connection for lightning protection.

Bonding Signal Grounds

The signal ground of all interconnected modules must always be

bonded together. Bonding the signal grounds of interconnected

modules greatly reduces communication problems and lightning

damage.

The bonding conductor should follow the data bus (RS-485)

wherever it goes. You can accomplish this using a spare wire inside

an interconnecting cable, the cable’s drain wire, or a shield of the

individually twisted pair, individually shielded RS-485 data cable.

Convenient Base Module signal ground connections can be found at

on J5 pins 1, 19 and 20 labeled “GND” (this is

NOT Earth Ground).

If using a cable’s foil shield for bonding, terminate the shield to a

short length of uninsulated 22 AWG wire before punching down to

an unused GND pin.

NOTE: See each module’s installation instructions for the

appropriate bonding connections.

BASE MODULE PRE-INSTALLATION TEST

WHEN PLUGGING IN THE TRANSFORMER, A SHORT

ON A BASE MODULE 12 VOLT LINE CAN BLOW THE

TRANSFORMER. ALWAYS USE BATTERY POWER

TO PERFORM THE PRE-INSTALLATION TEST.

If the Base Module cannot pass this test, replace it and test the new

unit. Do this test with no telephone or field wiring connections and

only battery power applied.

1. Set the LCD plus keypad’s internal jumper to address #1.

2. Connect the LCD plus keypad ground and power to Base Module

J2 pins 1 and 6 respectively.

3. Connect the LCD keypad DATA+ and DATA- to Base Module

J4 pins 1 and 2 respectively.

4. Place the Base Module TEST/OPER switch (S1) in the TEST

position.

5. Power the panel up by carefully plugging the battery leads to the

backup battery(s). The Black lead connects to the negative

terminals of the 12VDC batteries. Connect the Red lead to the

positive battery terminals.

6. If within 5 seconds a “SETUP MODE” message appears on the

LCD display, the Base Module is probably operational.

7. Power the panel down by carefully unplugging the battery leads

from the backup battery(s).

ADVANTAG

E plus

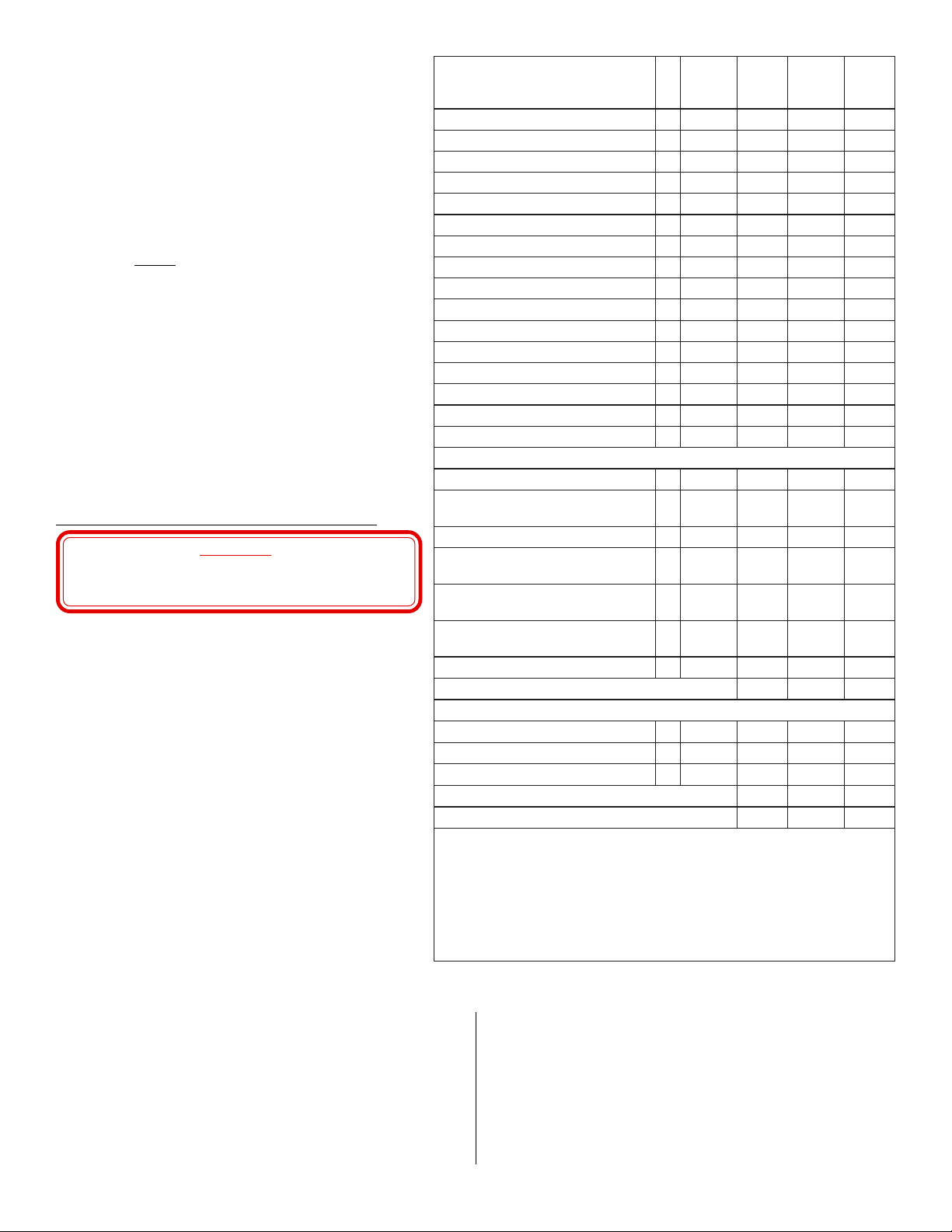

Throughout these procedures refer to the Installation Diagram shown

in Figure 7.

NOTE: Before installing a UL Certified Fire System read and

understand the requirements in chapter two (residential)

or chapter three (commercial) of NFPA 72, “National

Fire Alarm Code.”

CAUTION!

WIRING

BATTERY WIRING

To supply the minimum required backup power in case of AC power

loss, install the 12VDC, 7AH, sealed lead acid battery(s) inside the

enclosure. For UL Fire installations, use the fused battery leads and

the second 7 AH battery from the ULF Install Kit.

Connect the Black lead to J1 pin 3 (labeled BAT-) and the Red lead

to J1 pin 4 (labeled BAT+) . Connect the Black lead to the negative

terminal of the 12VDC battery(s) and connect the Red lead to the

positive battery(s) terminal.

Observe polarity when making the battery connections. Connecting

the leads backward can overheat the power supply.

WARNING!

UNLESS OTHERWISE INSTRUCTED,

DO NOT

CONNECT THE BATTERY(S) UNTIL ALL

WIRING IS COMPLETE.

BASE MODULE J2 WIRING

“GND” and “+12V” and (J2 Pins 1-4 and 6-9)

Base Module J2 pins 1 through 4 (labeled GND) and J2 pins 6

through 9 (labeled +12V) serve as un-switched +12VDC auxiliary

power connections for optional devices.

These current limited outputs can supply up to 1,600mA of current

for optional devices.

NOTE: UL requires that at least one LCD plus keypad be

powered directly from the Base Module. This LCD

plus keypad can display module down status if modules

lose power.

Bell (J2 Pins 11 and 12)

Base Module J2 pins 11 and 12 (labeled BELL- and + respectively) are the connections for bells, horns or combination horn/

strobes operating on 12 VDC up to 1,500 mA (1.5 Amps). Select the

bell or DC option if a siren has a built-in driver.

Observe polarity when connecting wires.

Table 2 lists audible and visual devices that are compatible with

Advantage plus.

Table 2. Compatible Audible/Visual Devices

kcoleehW

)s(ledoM

2FD-HC,2FC-HC,FB-HCV6.51-0.01Am02--semihC

RFH-21-PSL,RFV21-M1SLV5.61-5.01--Am551ebortS

RFV-21-MPSL,RFV-21-M1SLV5.61-5.01--Am012ebortS

R-21-6G-BMV4.41-6.9Am08--lleB

R-FH-W-21-01G-BMV4.41-6.9Am08Am05ebortS/lleB

RFH-21-PSM,RFV-21-1SMV6.51-5.01--Am722ebortS

R-42/21-4TM,R42/21TMV6.51-5.01Am001--nroH

RFV-SL-4TM,RFV-SL-21-TMV6.51-5.01Am001Am551ebortS/nroH

RFV-MSL-4TM,RFV-MSL-21-TMV6.51-5.01Am001Am012ebortS/nroH

RFV-SM-21-4TM,RFV-SM-21-TMV6.51-5.01Am001Am722ebortS/nroH

W-21-ZIM,R-21-ZIM5.01V6.51-Am8nroHiniM

RFV-SL-21-ZIM5.01V6.51-Am861ebortS/nroH

RFV-MSL-21-ZIM5.01V6.51-Am822ebortS/nroH

RFV-SM-21-ZIM5.01V6.51-Am342ebortS/nroH

RFV-5121-SAV6.51-5.01Am562ebortS/nroH

RFV-575121-SAV6.51-5.01Am953ebortS/nroH

RFV-0321-SAV6.51-5.01Am353ebortS/nroH

R-21-HA6.51-0.9Am49nroH

R-42/21-MS

R-42/21-MSD

gnitarepO

egatloV

5.01

6.51-

5.01

6.51-

rednuoS

ebortS

tnerruC

tnerruCstnemmoC

Am52eludoMcnyS

Am83eludoMcnyS

6

Page 7

BASE MODULE J3 WIRING

AX2

9

s

All Base Module audio inputs are balanced and there are two ways to

use them:

• audio verification sensor inputs

• audio from optional SmartAudio or ListenIn Modules

NOTE: When installing SmartAudio or ListenIn Modules in the

Advantage plus system we strongly recommend that you

not connect AudioSensors to the Base Module audio

inputs.

Audio from SmartAudio and ListenIn Modules is a balanced signal,

requiring

two wires for each audio input and output. If you install

either of the modules you must connect the Base Module AU+ and

AU- inputs to the corresponding outputs from the modules.

Audio Input Wiring

YOU MUST USE SEPARATE TWISTED PAIR,

INDIVIDUALLY SHIELDED CABLES FOR THE

AUDIO AND RS-485 DATA BUSSES. RUNNING DATA

AND AUDIO IN THE SAME CABLE CAN RESULT IN

SERIOUS DATA NOISE IN THE AUDIO SIGNAL.

If not installing SmartAudio Modules or ListenIn modules, you can

connect up to four verification AudioSensors to Base Module jack J3.

Audio verification devices should only be Advantage AudioSensors.

NOTE: Advantage plus is NOT compatible with the older

Advantor PA-15 and GBD-III audio sensors.

General Advantage AudioSensor placement rules are:

1. Mount AudioSensors on solid,

2. The AudioSensor should always face toward the protected area

and away from ambient noise sources.

3. Mount the AudioSensor as close as possible to the area being

protected.

4. Mount AudioSensors high enough to avoid blockage, damage

and tampering, but give more thought to sound factors. The ideal

mounting height is 8 to 10 feet from the floor. Never exceed 13

feet unless special circumstances require such height.

5. Mount AudioSensors at least one foot away from corners.

Power, ground, and audio wiring is identical for all system audio

sensors. We recommend using an audio color code of Black

(ground), Green (audio), and Red (+12VDC). Figure 4 and the

installation diagram shows examples of proper wiring using the

standard (BLK, GRN, RED) color code.

NOTE: For best audio quality, the +AS and -AS terminals on

Base Module jack J3 should be the

AudioSensor power and ground.

101112

BAT

V

- +

BELL

+ -

IMPORTANT!

+12 GND

non-vibrating surfaces.

J2

101112

123456789

-AS

-AS

AU-

AU+

AU-

AU+

AU-

AU+

AU-

only source for

AX

MOD

J4

AU+

123456789

+AS

J3

AUDIO

+AS

+12

AX1-

101112

+12

To save wire you may parallel power (Red) and ground (Black) to

several audio sensors.

Always home run and connect each audio

(Green) wire to the Base Module audio sensor input number designated on the Option Summary Sheet. For best audio quality, install

one AudioSensor at each audio input.

Do not connect a ground wire to a +AS terminal, which is +12VDC.

DAT1 & DAT2 (J4 Pins 1 through 4)

Base Module J4 pins 1 through 4 are the RS-485 communication port

connections. The RS-485 communications port gives Advantage

plus its flexibility and expandability.

The Base Module’s RS-485 communication port can interface and

control the following optional modules and devices:

• any combination of up to 16 LCD plus and LED plus

keypads

• eight alarm loop Expansion Modules

• any combination of up to eight SmartAudio Modules and

ListenIn Modules

• seven Access Modules

Use the following guidelines when running cables for an RS-485

communication link:

• Never exceed 2,000 feet from the Base Module

• Always use 22 AWG, individually twisted pair, individually

shielded cable. (See Note below)

• Always observe the proper polarity when making connections

(e.g., DAT+ to DAT+ and DAT- to DAT-).

• Always verify the proper RS-485 address jumper settings on

each module or device.

• Always use the cable’s drain wire, one of the cable’s spare

wires, or a shield to bond the signal grounds (

grounds) of the interfacing modules.

NOTE: RS-485 cable runs of less than 30 feet should not require

twisted pair, individually shielded cable.

Although RS-485 uses a two-wire differential communication, it is

imperative that the signal grounds of the interfacing modules be

bonded together. This common signal ground provides an overall

reference level, eliminating most RS-485 communications problems.

When running RS-485 cables to several modules or devices you can

use both daisy chain and star configurations (see Figure 5).

UL WARNING:

LCD/LCD plus KEYPADS WITH A BLINKING YELLOW

LED, A BLINKING CURSOR AND BEEPING EVERY 10

SECONDS, INDICATE AN RS-485 COMMUNICATIONS

PROBLEM. THE SYSTEM MAY BE INCAPABLE OF

REPORTING FIRE OR BURGLARY ALARMS.

UL requires that at least one LCD/LCD plus keypad be powered

directly from the Base Module to permit display if other modules lose

power.

NOT earth

+

(Supv.)

ealed

years.

ensor Power Rating:

0 Ohms maximum Line

istance

Module and/or ListenIn Module audio outputs

+

Composite audio from optional SmartAudio

J2

TMP

TMP

TEST

GND

+12V

AUD

J1

AudioSensor

SENS

BLK

BLK

GRN

GRN

RED

RED

Ground

6

5

4

3

2

1

J1

SENS

Earth

TMP

TMP

TEST

GND

+12V

AUD

AudioSensor

Figure 4. Advantage plus Jack J3 Wiring

7

Page 8

1 2 3

ux l ary Output Power

4 5 6

7 8 9

0 #

LCD plus

Keypad

Keypad

LCD

Expansion

ListenIn

Module

* Not UL Listed

Module

Access

Module

LCD plus

Keypad

Access

Module

1 2 3

4 5 6

7 8 9

0 #

ListenIn

Module

Base

Module

SmartAudio

Module

SmartAudio

Module

SmartAudio

Module

Expansion

Module

Access

Module

Figure 5. RS-485 Cable Configurations

Auxiliary Outputs (J4 Pins 5 Through 12)

Base Module J4 pins 16 through 19 (labeled AX1- through AX4and their respective +12 outputs) are the Base Module’s four

Auxiliary Outputs. Each output consists of a +12 volt line and a

switched ground.

The “+12” lines supply the power for external devices. You may

daisy-chain external device power from one “+12” line, but home run

the “AX1-” through “AX4-” lines from the Base Module.

NOTE: If optioned for Enable Line Monitor 2, the AX4 output

is automatically dedicated to the line monitor feature.

The current drawn by existing devices (i.e., sensors and keypads)

determines the current available for auxiliary devices. If the current is

available, each auxiliary output can control up to 100mA.

BASE MODULE J5 WIRING

Alarm Loop Wiring

Base Module jacks J5 and J6 contain the inputs for the Base

Module’s 16 alarm loops (labeled A1 through A16). Each loop

location is labeled on the board to assist in installation.

NOTE: Certificated UL systems use the 1KEOL assembly from

their respective UL Installation Kit.

Fire Alarm Loop Wiring

Table 3 lists smoke detectors and other devices compatible with

Advantage plus Fire systems. When installing 4-wire smoke

detectors you must also install Power Supervision Unit(s). Recommended is the DSI EOL 200 (12VDC), or another UL Listed device

of equivalent ratings.

Install the power supervisory unit at the sensor farthest from the Base

Module on each alarm circuit.

Table 3. Compatible Smoke Detectors and Devices

ledoM/rerutcafunaM

)Am(tnerruC

W4-002SD,smetsySnoitceteD80.052CDV72-01

DH002SD,smetsySnoitceteD80.052CDV72-01

W4BM,smetsySnoitceteD80.084CDV03-01

AW4BM,smetsySnoitceteD80.065CDV03-01

EW4BM,smetsySnoitceteD80.008CDV03-01

SW4BM,smetsySnoitceteD80.036CDV03-01

002LOE,smetsySnoitceteD0303CDV03-01

ybdnatS

mralA

If installing 4-wire smoke detectors, wire the detectors as shown in

Figure 6, wiring detector power to an auxiliary output optioned for

Base

Module

1 2 3

4 5 6

7 8 9

0 #

Wireless

Module*

LCD plus

Keypad

LCD

Keypad

1 2 3

4 5 6

7 8 9

LCD plus

Keypad

“DS or PU Resets Smokes.” This configuration allows a system user

to reset the smoke detectors from a keypad.

9.7-12VDC, 100mA each

X

D

Option the Auxiliary Output for "DS

0 #

or PU Resets Smokes" to allow

detector reset from a keypad.

You must also install

(P/N 1KEOL from the ULF Installation Kit) on each Base Module

alarm loop to provide fire loop supervision. Install the 1KEOL

resistors at the farthest point from the Base Module in each active

alarm loop, in parallel with an alarm-on-short sensor.

INACTIVE alarm loops do not require jumpers. See the Options

Sheet for more information.

To meet UL requirements for annunciation supervision, unique

fire sound, and power limit, the annunciators must be wired as

shown on sheet 2 of Figure 7. The Wheelock MT annunciators

must be set for “Code 3” pattern, or the Wheelock AS or AH

sounders used with Wheelock DSM synchronizers.

NOTE: You must use separate burglary annunciators (if

The relay connects between Bell (+) and the Base Module auxiliary

output optioned with the Independent Zone Bell option.

The Tamper alarm loop supervises the annunciator output, sending a

Tamper alarm if the annunciator circuit is cut or shorted. The Tamper

alarm is ignored if it is received with a FIRE alarm.

Intrusion Alarm Loop Wiring

Power and ground to alarm sensors, detectors or devices requiring

auxiliary power must be run on separate wires from the alarm loop.

Obtain 24-hour power from Base Module board J2 pins labeled

“+12” and “GND” respectively.

To provide the required alarm circuit supervision, you must install

one of the supplied 1KEOL end-of-line resistors in series with alarmon-open contacts (such as door switches), or in parallel with alarmon-closure contacts. Install the 1KEOL resistors at the

initiating device from the Base Module on each of the circuits.

NOTE: The Tamper alarm loop does not require a 1KEOL

)Am(tnerruCegatloV

OPTIONAL CARD READER WIRING

The Base Module can support one access controlled door, but be

aware that the access events cannot be uploaded for report generation. Authorized users can view the last 100 events at an LCD plus

keypad. The Base Module maximum number of card holders is also

restricted to 99 (employees 01-99).

NOTE: The card reader is always assigned to Zone A.

The application uses a Base Module auxiliary output for the door lock

interface, and the Base Module’s existing card reader interface.

+12

101112

AX1-

Rating:

maximum

+12

AX2-

+12

AX3-

+12

DAT2

AX4-

- +

DAT1

- +

123456789

TMP

A15 A14 A13 A12 A11 A10 A9

- +

- +

A15

A16

GND

+5V

CR0

CR1

- +

A14

1011121314151617181920

- +

- +

- +

- +

A13

A12

A11

A10

Figure 6. Wiring 4-Wire Smoke Detectors

one 1K Ohm End-of-Line assembly

present).

resistor if the loop does not extend outside the Base

Module chassis.

123456789

J5

LOOPS

GND

BLK

RED

BLU

BLU

1KEOL

farthest

EOL-200

DS

8

Page 9

Dial Telephone Line

Connection

To House

Telephone

678

5

4

321

To Dial

Telco Line

Dedicated Line

Figure 7. Advantage plus Installation Diagram (Sheet 1 of 2)

Connection

To

Dedicated

Line

678

5

4

321

To Base

Module J8

RJ Jack

9

18AWG, 2-Conductor Cable

(15 feet maximum)

Transformer:

Input-120VAC, .31A

Output-16.5 VAC, 50VA

(Supervised)

WARNING!

DO NOT connect the

transformer to a

receptacle controlled by

a switch!

Battery Charging :

400mA max., 10mA min., 12V, 7AH

Sealed Lead-Acid Batteries,

estimated life 3 years.

NOTE: All UL Fire and Burglary installations

must use the fused RJ31X jack included

in the ULB and ULF Installation Kits.

WARNING!

Detection Systems, DS200-4W (Smoke Detector)

Detection Systems, DS200HD-4W (Smoke Detector)

Detection Systems, MB4W (Smoke Detector)

Detection Systems, MB4WA (Smoke Detector)

Detection Systems, MB4WE (Smoke Detector)

Detection Systems, MB4WS (Smoke Detector)

Detection Systems, EOL200 (End of Line Module)

Wheelock CH-BF, CH-CF2, CH-DF2

Wheelock LS1M-12VFR, LSP-12-HFR

Wheelock LS1M-12-VFR, LSPM-12-VFR

Wheelock MB-G6-12-R

Wheelock MMB-G10-12-W-HFR-R

Wheelock MS1-12-VFR, MSP-12-HFR

Wheelock MT12/24R, MT4-12/24-R

Wheelock MT-12-LS-VFR, MT4-LS-VFR

Wheelock MT-12-LSM-VFR, MT4-LSM-VFR

Wheelock MT-12-MS-VFR, MT4-12-MS-VFR

Wheelock MIZ-12-R, MIZ-12-W

Wheelock MIZ-12-LS-VFR

Wheelock MIZ-12-LSM-VFR

Wheelock MIZ-12-MS-VFR

Wheelock AS-1215-VFR

Wheelock AS-121575-VFR

Wheelock AS-1230-VFR

Wheelock AH-12-R

Wheelock SM-12/24-R and DSM-12/24-R

J9

RING

TIP

DEDT

DEDR

----

----

----

----

----

EGND

----

XF2

DUPO

ANS

TLM

----

----

+12V

----

GND

Electrical shock hazard present

during telephone line servicing.

UL LISTED POWER LIMITED CIRCUITS:

1. J2-11,12 Local Bell

2. A1 through A16 Alarm Loops

3. AX1- through AX4- Auxiliary Outputs

4. J3-1 & 2 and 11 & 12 Audio Sensor connections

5. J1-1 through 4 and J1-6 through 9 Voltage Out

1

COMPATIBLE UL LISTED SENSORS & DEVICES:

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Bell Power Rating :

9.2-12VDC, 1.5 A maximum

+

BELL

+ -

101112

+12 GND

J1

POWER

(Supv.)

AC

BAT

16.5V

- +

+

(Supv.)

See Sheet 2 for

Supervised Fire

Annunciator Wiring

+

Advantage GlassBreak (GBD-S) Power Rating:

+12VDC, 26mA, 100 Ohms max. Line Resistance

Composite audio from optional SmartAudio

Module and/or ListenIn Module audio outputs

COM

GND

+12V

AUD

NO

NC

SENS

GBD-S

Advantage plus Installation Diagram

11/10/97

Recommended Fire Initiating

TELEPHONE LINE:

J8

RING TIP

NOTE:

UL Certificated Fire systems shall be installed

in accordance with Chapter 2 of the National

Fire Alarm Code, ANSI/NFPA 72-1993.

J7

TEST PTS

1

2

3

4

5

6

7

8

9

10

Voice Grade - 300-3300HZ, 16dB loss (typical)

TERMINATIONS:

Use Panduit tool number MCT-100F for all Panduit

connections.

Use UL Recognized limited energy copper cables for all

terminations.

CAUTION!

Incorrect wiring may result

in damage to the unit!

RESET

AUDIO

------+12V

GSTART

AGND

+5V

+5VSTB

LAUD

-------

Alarm Loop Power Rating :

5V, 5mA, 470 Ohms maximum

line resistance

OPER

Supervised

A1

A2

A3

A4

A5

A6

A7

A8

TEST

S1

J6

GND

1

2

A1

- +

3

4

A2

- +

5

6

A3

- +

7

8

A4

- +

9

10

A5

- +

11

12

A6

- +

13

14

A7

- +

15

16

A8

- +

17

18

A9

- +

19

20

GND

Enclosure

LOOPS

Tamper

Auxiliary Output Power Rating :

123456789

J5

LOOPS

GND

1K

Ohm

N/O Loop

No Connection

GND

9.7-12VDC, 100mA each

maximum

J3

AUDIO

RED

AX

MOD

J4

Earth

Ground

+12

AX1-

101112

+12

AX2-

+12

AX3-

+12

DAT2

AX4-

123456789

DAT1

- +

- +

Reader

LED

J2

101112

123456789

-AS

-AS

AU-

AU+

AU-

J1

BLK

BLK

GRN

AU+

AU-

AU+

AU-

AU+

GRN

123456789

+AS

+AS

RED

Card Reader

TMP

6

AudioSensor

TMP

5

4

J2

TEST

3

GND

2

+12V

1

AUD

J1

SENS

RS-485 data to optional Expansion Modules,

SmartAudio Modules, ListenIn Modules,

Access Modules, Wireless Module* and LCD

plus keypads. (* not UL Listed)

GND

GND

+5V

(optional)

A16

A15 A14 A13 A12 A11 A10 A9

1011121314151617181920

- +

- +

- +

- +

A16

CR0

CR1

A15

A14

A13

N/C Loop

1K

Ohm

- +

A12

- +

A11

- +

A10

Advantage AudioSensor Power Rating:

+12VDC, 5mA, 100 Ohms max. Line Resistance

Loop Connection

(Style B)

DS

EOL-200

RED

BLK

BRN

BRN

1KEOL

Listed

4-Wire Smoke

Detectors

Ground and Power from

Base Module J4 pins 11

and 12 respectively.

Switch

1KEOL

Automatic, Manual,

Sprinkler Supervisory or

Waterflow Devices.

LCD/LCD plus Keypad Power Rating:

9-15VDC, 45mA, 5 Ohms maximum

Line Resistance

(Keypad Must Be Supervised)

1

1248

2

3

4

5

6

ADDRESS

JUMPERS

7

8

9

BEEPOUT

10

GND

11

DATA-

12

DATA+

13

+12VIN

Page 10

BELL

+ -

+12 GND

-AS

-AS

AU-

AU+

AU-

AU+

AU-

AU+

AU-

AU+

+AS

+AS

+12

AX1-

+12

AX2-

+12

AX3-

+12

AX4-

DAT2

- +

DAT1

- +

J2

J3

AUDIO

AX

MOD

J4

- +

A10

GND

GND

+5V

CR0

CR1

- +

A11

- +

A12

- +

A13

- +

A14

- +

A15

- +

A16

A16

J5

LOOPS

A15 A14 A13 A12 A11 A10 A9

123456789

1011121314151617181920

123456789

101112

123456789

101112

123456789

101112

GND

-

Burg

Sounder

(Optional)

+

1 4 7 13

NC N0

NC N0

3 6 9 14

NC N0

2 5 8

- Strobe +

COM

COM

COM

Fire

(Optional)

Figure 7. Advantage plus Installation Diagram (Sheet 2 of 2)

AUX 1 (-)

(Fire Bell)

BELL

SUPERVISION

RELAY

Loop 16 (+)

(Tamper)

-

-

MT

HORN

+

-

MT

HORN

+

AUD

+

AUD

OUT

OUT

-

STROBE

+

STROBE

-

+

-

AS

HORN

+

-

AS

HORN

+

SM

CODE 3 FIRE SOUNDERS

NOTE:

UL Certificated Fire systems shall be installed

in accordance with Chapter 2 of the National

Fire Alarm Code, ANSI/NFPA 72-1993.

Supervised Code 3 Fire Annunciator

1KEOL

Connect the card reader to Base Module J5 pins 16 through 19 using

a 22AWG cable and following the color code shown in the Installation Diagram. Connect the card reader’s LED lead to an available

auxiliary output on J4.

NOTE: See the card reader manufacturer’s installation instruc-

tions for reader connections to the card reader cable.

For optimum performance and reliability, the card reader cable run

should be less than 300 feet from the Base Module.

Option the Base Module for the following:

Required Options:

NOTE: All of the following options are for Module 0 (Base

Module).

Modify-Module-Operation

- Enter a name for the door.

Modify-Module-Door-Equipment

- Enter YES for “Door is Active.”

Modify-Module-Door-Codes

- Enter NO for “Toggle security with Card Read.”

Modify-Module-Door-Lock

- Enter door unlocks for XX seconds. (Traditionally 5 - 10

seconds)

NOTE: You may also have door unlocked during shift or fire and

locked when zone is armed as required.

Examples:

A. Customer requests a storage area door be unlocked from 8 - 5,

with a card swipe required for after hour entry. Use door

“Unlocked during shift” assign a period from 08:00 - 17:00 to

a shift and assign this shift as “Storage room door.”

B. Customer requests the door be unlocked during the day, but

automatically lock at System arming. “Option Door Locks

when armed Y.”

C. A combination of A and B works nicely. Door Unlocked from

8 to 5, however if customer leaves early or arrives late door

remains locked until the zone disarms.

Modify-Opn/Close-Levels

- Assign a valid shift to door #1. Enter the desired Arm/

Disarm Level.

Modify-Module-Door-Alarms

- Enter door is allowed open for XX seconds (traditionally 30

- 120 seconds).

Modify-ASOP-Outputs

- Select “Door Lock Control” for one of the auxiliary outputs.

Select “Card reader LED” for one of the auxiliary outputs.

Modify-ASOP-Loop-Options

- Designate an alarm loop as a special input Free Exit (Loop 2

- 16, #1 is used for door contact).

FIELD DOWNLOADING PROCEDURES

Complete the following steps before downloading options:

1. Load the selected account options from the Account Options

Summary Sheet into the options programmer. (See the “SONICS

Database Management Manual,” P/N 09820426).

2. Ensure all account and employee information is in the SONICS

monitoring console database.

3. If the system contains

to Base Module J8.

NOTE: It is crucial that ALL system (Base Module as well as all

optional modules) options be downloaded

attempting system calibrations or tests.

10

no options, connect the dial telephone line

before

Page 11

NEW ACCOUNT DOWNLOADING

Use one the two following procedure for new equipment (no

previous options) or equipment with failed options:

Base Module Calls Monitoring Station Method

1. Inform the operator you are ready to download and give the

account number.

2. Connect the telephone line and place the Base Module TEST/

OPER switch (S1) in the TEST position.

3. Power the panel up by carefully plugging the transformer into the

AC outlet. The LCD plus keypad displays SETUP MODE.

4. Press the “Download” key.

5. Press the “Call” key.

6. Press the “Enter Options” key.

7. Press the “Enter Phone #” key.

8. If the Base Module uses a dial line, enter the monitoring central

station telephone number and press the “Done” key.

If the Base Module uses a dedicated line, simply press the “Done”

key.

9. Press the “Enter Acct #” key.

10.Enter the appropriate 4-digit account number, then press “ENTER.”

NOTE: If the Base Module communicates over a dedicated line

this 4-digit number is determined by the phone line

connection at the ERAD Speaker Module in the

monitoring central station.

11.Press the “Quit” key.

12.Press the “Dial” key.

13.Place the OPER/TEST switch (S1) in the OPER position.

14.The LCD plus keypad displays a “calling for download”

message while the Base Module connects with the Speaker

Module.

15.The SONICS operator selects “Account-Panel-Program ASOP.”

The programming computer transfers account options to the Base

Module. During the download process the LCD plus keypad

displays “DOWNLOADING ACTIVE.”

16.After completing the Base Module options download the

programming computer sends a “MASTER RESET” command.

The Base Module then recontacts SONICS with an “UP Panel”

alarm.

NOTE: An “Error 06” appears in the monitoring console’s

status area if an error occurs during the download

sequence.

17.After receiving the “UP Panel” alarm, the operator must

download all add-on module options using the “Account-Panel-

Download Module,” command and selecting the “All” option.

The LCD plus keypad displays a “DOWNLOADING ACTIVE,

please wait” message during the second options download.

18.After finishing the optional module options download, the

operator must reset the system to complete the download sequence.

Monitoring Station Calls Base Module Method

Use all of the previous steps, except:

5. Press the LCD plus keypad “Answer” key.

Skip steps 6 through 12.

14.LCD plus keypad displays “ready for download.” The Base

Module will answer the telephone line on the first ring.

Proceed with steps 15 through 18.

LCD KEYPAD SETUP AND TEST MODES

NOTE: Only LCD plus keypad #1 operates before the system is

downloaded.

Place an Advantage plus system with no options into the Test Mode

by powering it up with the TEST/OPER switch (S1) in the TEST

position.

The keypad displays a

“Waiting for Master

Controller” message.

After approximately 15

seconds the keypad

displays the Setup Mode

screen shown in Figure 8,

indicating the system is in

the Test Mode.

Test Download

Figure 8. LCD Setup Mode Screen

SETUP MODE

HHMM ENTER sets time

select function

SETTING SYSTEM TIME

Any time the LCD plus keypad displays the “HHMM ENTER sets

time” prompt you may set or change the system clock. Using

military time format (i.e., HH=Hours, MM=Minutes, 4 pm = 16:00

hours), enter the current time then press ENTER. The keypad triple

beeps showing the system has accepted the change.

LCD

plus

KEYPAD TEST MODE

From the Setup Mode

screen, pressing the Test

button displays the Test

Mode screen shown in

Figure 9. The Test Mode

screen offers the following

system tests:

• Walk Test

• Auxiliary Output Test

• Audio Test

Walk Outputs Audio

Figure 9. System Test Screen

TEST MODE

press * for status

select function

Walk Test

NOTE: Walk Test does not operate until the entire Advantage

From the Test Mode

screen, pressing the Walk

button places the system in

the Walk Test Mode and

displays the WALK TEST

screen shown in Figure 10.

Using Walk Test you can

perform a functional system test by entering Walk Test then walking

around the facility violating alarm loops. Each loop violation and

restoral sounds the local bell for 1 second.

After violating the loops return to the keypad and press ENTER to

exit the Walk Test. The System Test screen in Figure 9 reappears.

You can press the keypad “*” key (system status) to see the Walk

Test results. Pressing “*” displays the TEST RESULT screen shown

in Figure 12.

plus system has been downloaded.

WALK TEST

in progress

push ENTER when done

Figure 10. Walk Test Screen

System Status (*)

From the System Test

screen you can check the

system status at any time by

pressing the keypad “*”

key. Pressing “*” displays

the STATUS screen shown

in Figure 11.

Pressing the Status button displays the system status. Displayed

status messages may include:

• low battery • cut telephone line

• RPU down • preamp down

• memory error • options error

select display

Status Call Loops

Figure 11. Status Screen

11

Page 12

Pressing the Loops or Call

buttons displays the status

of system alarm loops

(open, shorted, normal).

The word “tested” appears

in the display if the loop

was tested during a Walk

Test (see Figures 12 and 13

for examples).

While viewing the Loop

Status screen pressing

Prior displays the previous

alarm, pressing Next

displays the next alarm.

tested

Prior Quit

FIRE tested

(loop description text)

Prior Quit

LOOP STATUS

Loop # 16 shorted

Figure 12. Loop Status Screen

Event 01 TUE 17:53

Figure 13. Loop Status Screen

(after Download & Walk Test)

Pressing Quit returns you

to the Setup Mode screen (Figure 8).

Outputs Test

From the Test Mode screen

(Figure 9), pressing the

Outputs button displays

the OUTPUTS TEST

screen shown in Figure 14.

Pressing “0” selects the

Base Module. Pressing

numbers 1 through 8 selects

an attached Expansion

Module (see Figure 15).

After selecting a module,

pressing the associated

keypad key toggle the

outputs on and off. Press the number key to turn each output on, and

press it a second time to return the output to its original state.

• “1” for Aux Output #1 • “4” for Aux Output #4

• “2” for Aux Output #2 • “5” for the local bell

• “3” for Aux Output #3

Pressing ENTER returns you to the Outputs Test screen (Figure 14).

OUTPUT TEST - SELECT

0 = BASE MODULE

1 - 8 = EXPANSION MODULE

EXIT

Figure 14. Outputs Test Screen

OUTPUT TEST MOD #1

toggle by entering

aux output #

push ENTER when done

Figure 15. Outputs Test Screen

Audio Test

From the Test Mode screen

(Figure 9), pressing the

Audio button displays the

AUDIO TEST screen

shown in Figure 16.

NOTE: SAM appears

Tip

Ring SAM Done

Figure 16. Audio Test Screen

on the Audio

Test screen ONLY if the system was downloaded with

SmartAudio Module options.

In addition to displaying the Audio Test screen, pressing the Audio

button automatically sends a test tone to all audio sensors.

Pressing the SAM button

displays the STORED

AUDIO TEST screen

shown in Figure 17.

Pressing the Select button

displays a select SAM to

enable screen that allows

Select Store Done

Figure 17. Stored Audio Test Screen

you to enable any of the

connected SmartAudio Modules for testing. Selecting a SmartAudio

Module (pressing any of keys 1 though 8) redisplays the STORED

AUDIO TEST screen shown in Figure 17.

AUDIO TEST

select function

STORED AUDIO TEST

select function

With the phone line

disconnected, pressing the

Store button forces the

REPLAY SAM AUDIO

TEST

panel to store the next 5

seconds of audio and

displays the REPLAY SAM

AUDIO TEST screen

shown in Figure 18.

Replay Done

Figure 18. Replay SAM Audio

Test Screen

Pressing the Replay button routes the stored audio to the TIP and

RING test points on the panel. Connecting a handset to these test

points allows you to check the system’s audio storage circuitry and

the quality of the audio that will be sent to the central station.

Pressing the Done button returns you to the previous screen.

Tip Ring Audio Test

From the Audio Test

screen, pressing the Tip

Ring button displays the

TIP/RING AUDIO TEST

screen shown in Figure 19.

Using the Tip/Ring Audio

Test you can route audio to

the TIP and RING test points on the panel. Connecting a handset to

these test points allows you to check the quality of the audio that will

be sent to the central station.

With the phone line disconnected, pressing the On button routes

audio from all system audio sensors to the TIP and RING test points

on the panel.

Pressing the Off button removes the audio from the TIP and RING

test points.

Pressing the Done button returns you to the initial Audio Test screen

(Figure 16).

LCD

plus

KEYPAD DOWNLOAD MODE

From the Setup Mode

screen, pressing the

Download button displays

the Download Mode screen

shown in Figure 20. The

Download Mode screen

offers Answer, Call and

Quit options.

TIP/RING AUDIO TEST

select function

On Off Done

Figure 19. Tip/Ring Audio Test Screen

DOWNLOAD MODE

select function

Answer Call Quit

Figure 20. Download Mode Screen

Answer Mode

Use the Answer Mode when you contact the central station and

request an options download. While in the Answer Mode the panel

seizes the line and answers the phone (goes off-hook) on the first

ring.

From the Download Mode

screen, pressing the

Answer button places the

system in the Answer

Mode and displays the

screen in Figure 21.

The Exit button gives you

the option of exiting Download Mode and returns you to the initial

Setup Mode screen (Figure 8).

While at the Answer Mode screen, switching the Base Module’s

TEST/OPER switch (S1) back to OPERATE prepares the panel for

options downloading.

The keypad screen clears, then a “Waiting for download” message

appears on the bottom display line until the central station computer

contacts the panel. Once the download begins the keypad display

changes to a “receiving download” message.

Switch to operate

Exit

Figure 21. Answer Mode Screen

12

Page 13

Call Mode

Use the Call Mode to initiate the options download from the LCD

plus keypad connected to

the Base Module.

From the Download Mode

screen, pressing the Call

button places the system in

the Call Mode and displays

the Call Mode screen

shown in Figure 22.

NOTE: The Quit button in all Download screens gives you the

option of exiting and returning to the initial Setup Mode

screen (Figure 8).

From the Download Mode

screen, pressing the Enter

Options button displays the

screen shown in Figure 23.

Pressing the Quit button

returns you to the Call

Mode screen (Figure 22).

Use this screen to enter the

information required to

begin the download. This

includes the central station

telephone number. Pressing

the Enter Phone# button

displays the screen shown

in Figure 24.

Enter the phone number you want the panel to call. Pressing the

Delay button anywhere in the phone number inserts a three second

delay before continuing the dialing sequence. The telephone number

appears on the second line of the display as you enter it.

Press Done after entering the phone number.

Pressing the Enter Acct#

button displays the screen

shown in Figure 25 and

allows you to enter the

optioned account number

(see the options sheet). The

account number appears on

the second line of the

display as you enter it.

Pressing the Quit button returns you to the Call Mode screen (Figure

22).

Figure 23. Download Mode Screen

DOWNLOAD MODE

select function

Enter

Options Dial Quit

Figure 22. Call Mode Screen

DOWNLOAD MODE

select function

Enter Enter

Phone# Acct# Quit

DOWNLOAD MODE

Enter phone# to call

Delay Done

Figure 24. Phone# Screen

DOWNLOAD MODE

Enter panel account#

Push ENTER when done

Figure 25. Account# Screen

COMMUNICATION LOSS

The LCD plus keypad senses a loss of RS-485 communication with

the control panel and annunciates the loss. One minute after communication loss the keypad alerts the user by beeping once each 10

seconds, blinking the yellow LED and blinking the cursor.

The beeping continues until the user presses any key, at which time

the beeping stops and displays a “System Down Call for Service”

message. The message remains until communications restore.

SYSTEM TEST PROCEDURES

Before turning the system over to the customer always perform a

complete functional test to ensure the system is operating properly.

Use the test procedures detailed on the previous pages as a general

reference to test each Advantage plus system’s operation.

AUDIO TEST

Perform an operational audio test by arming the system and creating

alarms that trigger listenback audio. If the system contains SmartAudio Modules, use the Advantor Calibrator set to AUDSEN and

TRIP to trigger audio activations.

Have the operator verify receiving the stored audio (if applicable) and

that the listenback audio is distortion free in all areas. Ensure the

impact sounds are clearly distinguishable and that normal level

speech is intelligible.

RS-485 pickup in audio sounds like clicking. Hearing this clicking

indicates improper data and audio bus wiring between modules.

Dial Mode

Use the Dial Mode to force

the Base Module to dial the

central station. From the

Download Mode screen,

pressing the Dial button

places the system in the

Dial Mode and displays the

Dial Mode screen shown in Figure 26.

While at the Dial Mode screen, switching the panel’s TEST/OPER

switch (S1) back to OPERATE prepares the panel to dial for options

downloading.

The keypad screen clears, then a “Calling for download” message

appears on the bottom keypad display line. Once the download

begins the keypad display changes to a “receiving download”

message.

After completing the download the keypad display automatically

returns to the main screen shown in Figure 8.

Switch to operate

Exit

Figure 26. Dial Mode Screen

13

Page 14

FCC REGULATIONS

This equipment has been tested and found to comply with the limits

set for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interferences in a residential installation.

This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a

particular installation.

If the equipment does cause harmful interference with radio or

television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try and correct the

interference by one or more of the following measures:

• Reorient the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different

from that of the receiver

• Consult the dealer or an experienced radio/TV technician for

help

The user may find the following booklet prepared by the Federal

Communications Commission helpful: “How to Identify and Resolve

Radio-TV Interference Problems.” This booklet is available from the

U.S. Government Printing Office, Washington DC 20402, Stock No.

004000003454.

FCC TELEPHONE REQUIREMENTS

This equipment complies with Part 68 of the FCC Rules. Included

with the system is a label that must be affixed on the lower right

outside of the cabinet. The label contains, among other information,

the equipment’s FCC Registration Number (2J8USA-23510-AL-E)

and the Ringer Equivalence Number (REN, 0.3B). This information

must be provided to the telephone company upon request.

The REN determines the number of devices that can connect to a

telephone line and still have all devices ring when called. In most

areas the sum of the REN’s of all devices on one line should not

exceed five (5.0). To be certain of the number of devices that may be

connected to a line, as determined by the REN, contact the local

telephone company for the maximum REN for the calling area.

If this equipment harms the telephone network, the Telephone

Company may temporarily discontinue service. If possible, they will

notify the customer in advance. When advance notice is not practical,

the customer is notified as soon as possible and informed of his right

to file a complaint with the FCC. The telephone company may ask

that you disconnect the equipment until you correct the problem or

until you are sure that the equipment is not malfunctioning.

The telephone company may make changes in its facilities, equipment, operations, or procedures that could affect the proper functioning of this equipment. If they do, the customer is notified in advance

to provide them the opportunity to maintain uninterrupted telephone

service.

This equipment may not be used on coin service provided by the

telephone company. Connection to party lines is subject to state

tariffs.

When installing the Advantage plus alarm dialing system, call your

local telephone company and give them the following information:

1. The telephone number of the line the Advantage plus alarm

dialing system will be attached.

2. The FCC Registration number of the Advantage plus alarm dialing

system.

3. The Advantage plus alarm dialing system Ringer Equivalence

Number (REN), which is 0.3B.

The Base Module connects to the telephone line via a standard USOC

RJ31X jack (supplied). If this type of jack is not available where

installing the Base Module you will need to order it from the telephone company.

CANADIAN IC EQUIPMENT WARNING

To ensure that certified equipment is attached correctly and only to

the networks of participating carriers, Industry Canada (IC) requires

the following written statement:

NOTICE: The Industry Canada label identifies certificated

“

equipment. This certification means that the equipment meets certain

telecommunications network protective, operational, and safety

requirements. IC does not guarantee the equipment will operate to the

user’s satisfaction.

Before installing this equipment, user’s should ensure that it is

permissible to connect to the facilities of the local telecommunications

company. Users must also install the equipment using an acceptable

method of connection.

In some cases, the company’s inside wiring associated with a single

line individual service may be extended by means of a certified

connector assembly (telephone extension cord). The customer should

be aware that compliance with the above conditions may not prevent

degradation of service in some situations.

Repairs to certified equipment should be made by an authorized

Canadian maintenance facility designated by the supplier. Any repairs

or alterations made by the user to this equipment; or equipment

malfunctions, may give the telecommunications company cause to

request the user to disconnect the equipment.

User’s should ensure for their own protection that the electrical ground

connections of the power utility, telephone lines and internal metallic

water pipe system, if present, are connected together. This precaution

may be particularly important in rural areas.”

USERS SHOULD NOT ATTEMPT TO MAKE SUCH

CONNECTIONS THEMSELVES, BUT SHOULD CONTACT

THE APPROPRIATE ELECTRIC INSPECTION

AUTHORITY, OR ELECTRICIAN, AS APPROPRIATE.

The Load Number (LN) assigned to each terminal device denotes the

percentage of the total load to be connected to a telephone loop which is

used by the device, to prevent overloading. The termination on a loop

may be any combination of devices subject only to the requirement that

the total of the Load Numbers of all the devices does not exceed 100.

The Load Number for this product is 4.

CAUTION!

ADVANTOR CORPORATION HARDWARE LIMITED WARRANTY STATEMENT

Advantor Corporation warrants each new product of its manufacture, to be free from defects in material and workmanship.

It will repair or replace defective parts for a period of 24 months from the date of manufacture, providing the equipment

has not been subjected to abnormal conditions such as misuse, abuse, misapplication, alteration, lightning damage or

damage by an Act of God. This excludes packing, handling and shipping charges from the Customer. The limited warranty

is restricted to the original purchaser.

ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING MERCHANTABILITY, THE

FITNESS OF EQUIPMENT FOR A PARTICULAR PURPOSE OR WITH RESPECT TO CLAIMS OF ANY

THIRD PARTY BY THE WAY OF INFRINGEMENT OR THE LIKE, ARE EXCLUDED.

14

Loading...