Page 1

PCI-1718 Series

12-bit Multifunction Cards with

Universal PCI Bus

User Manual

Page 2

Copyright

The documentation and the software included with this product are copyrighted 2005 by Advantech Co., Ltd. All rights are reserved. Advantech

Co., Ltd. reserves the right to make improvements in the products

described in this manual at any time without notice. No part of this manual may be reproduced, copied, translated or transmitted in any form or

by any means without the prior written permission of Advantech Co., Ltd.

Information provided in this manual is intended to be accurate and reliable. However, Advantech Co., Ltd. assumes no responsibility for its use,

nor for any infringements of the rights of third parties, which may result

from its use.

Acknowledgements

Intel and Pentium are trademarks of Intel Corporation.

Microsoft Windows and MS-DOS are registered trademarks of

Microsoft Corp.

All other product names or trademarks are properties of their respective

owners.

This Manual Covers the Following Models

• PCI-1718HDU

• PCI-1718HGU

Part No. 2003171800 1st Edition

Printed in Taiwan March 2005

PCI-1718 Series User Manual ii

Page 3

Product Warranty (2 years)

Advantech warrants to you, the original purchaser, that each of its products will be free from defects in materials and workmanship for two years

from the date of purchase.

This warranty does not apply to any products which have been repaired or

altered by persons other than repair personnel authorized by Advantech,

or which have been subject to misuse, abuse, accident or improper installation. Advantech assumes no liability under the terms of this warranty as

a consequence of such events.

Because of Advantech’s high quality-control standards and rigorous testing, most of our customers never need to use our repair service. If an

Advantech product is defective, it will be repaired or replaced at no

charge during the warranty period. For out-of-warranty repairs, you will

be billed according to the cost of replacement materials, service time and

freight. Please consult your dealer for more details.

If you think you have a defective product, follow these steps:

1. Collect all the information about the problem encountered. (For

example, CPU speed, Advantech products used, other hardware

and software used, etc.) Note anything abnormal and list any

onscreen messages you get when the problem occurs.

2. Call your dealer and describe the problem. Please have your manual, product, and any helpful information readily available.

3. If your product is diagnosed as defective, obtain an RMA (return

merchandize authorization) number from your dealer. This allows

us to process your return more quickly.

4. Carefully pack the defective product, a fully-completed Repair and

Replacement Order Card and a photocopy proof of purchase date

(such as your sales receipt) in a shippable container. A product

returned without proof of the purchase date is not eligible for warranty service.

5. Write the RMA number visibly on the outside of the package and

ship it prepaid to your dealer.

iii

Page 4

CE

This product has passed the CE test for environmental specifications

when shielded cables are used for external wiring. We recommend the use

of shielded cables. This kind of cable is available from Advantech. Please

contact your local supplier for ordering information.

Technical Support and Assistance

Step 1. Visit the Advantech web site at www.advantech.com/support

where you can find the latest information about the product.

Step 2. Contact your distributor, sales representative, or Advantech's cus-

tomer service center for technical support if you need additional

assistance. Please have the following information ready before

you call:

- Product name and serial number

- Description of your peripheral attachments

- Description of your software (operating system, version, application software, etc.)

- A complete description of the problem

- The exact wording of any error messages

Packing List

Before setting up the system, check that the items listed below are

included and in good condition. If any item does not accord with the

table, please contact your dealer immediately.

• PCI-1718HDU/HGU DA&C card

• PCI-1718HDU/HGU User Manual

• Companion CD-ROM with DLL drivers

Safety Precaution - Static Electricity

Follow these simple precautions to protect yourself from harm and the

products from damage.

1. To avoid electrical shock, always disconnect the power from your

PC chassis before you work on it. Don't touch any components on

the CPU card or other cards while the PC is on.

2. Disconnect power before making any configuration changes. The

sudden rush of power as you connect a jumper or install a card may

damage sensitive electronic components.

PCI-1718 Series User Manual iv

Page 5

Contents

Chapter 1 Introduction ..................................................... 2

1.1 Features ............................................................................. 3

1.2 Applications ..................................................................... 4

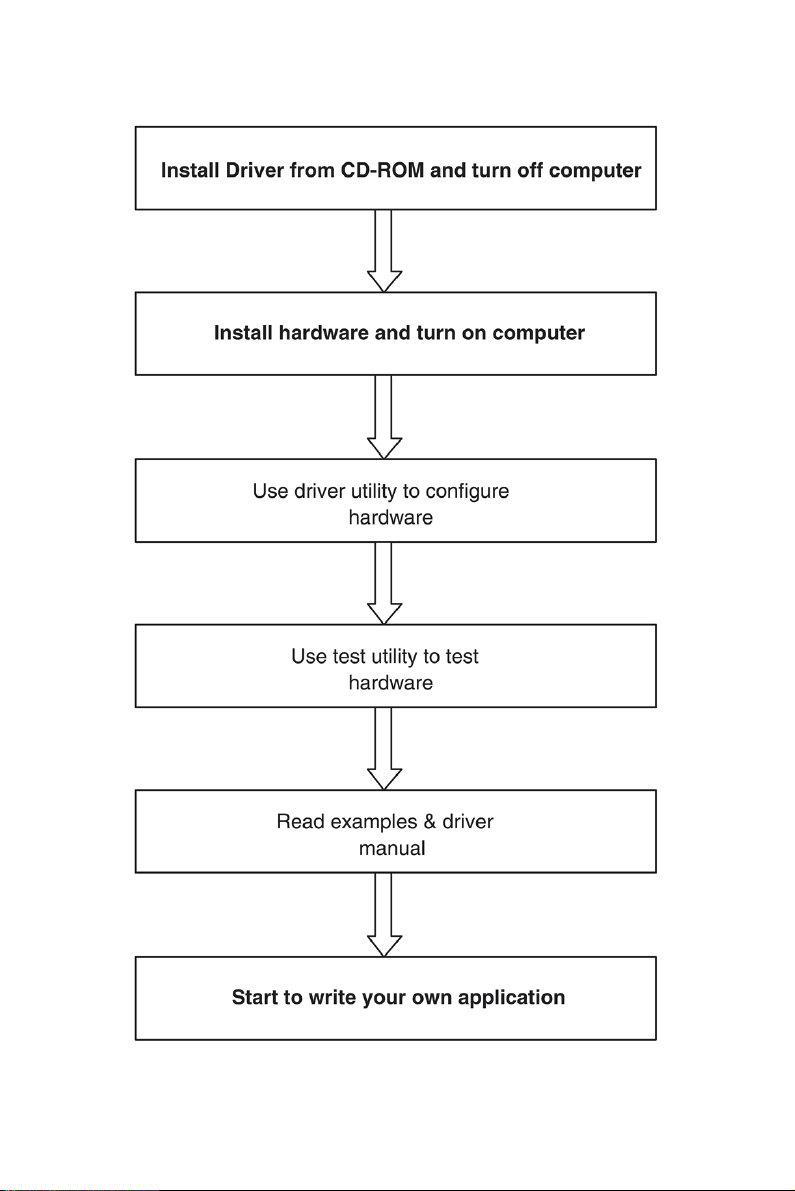

1.3 Installation Guide ............................................................. 5

1.4 Software Overview ........................................................... 7

1.5 Device Driver Programming Roadmap ............................ 8

1.6 Accessories...................................................................... 10

Chapter 2 Installation ..................................................... 12

2.1 Unpacking ....................................................................... 12

2.2 Driver Installation ........................................................... 13

2.3 Hardware Installation ...................................................... 15

2.4 Device Setup & Configuration ....................................... 16

Chapter 3 Signal Connections ........................................ 20

3.1 Overview ......................................................................... 20

3.2 Switch and Jumper Settings ........................................... 20

3.3 Signal Connections.......................................................... 28

Figure 1.1:Installation Flow Chart ................................. 6

Figure 2.1:Setup Screen of Automation Software ....... 14

Figure 2.2:Different Options for Driver Setup ............ 14

Figure 2.3:The Device Manager Dialog Box ............... 16

Figure 2.4:The Device Setting Dialog Box ................. 17

Figure 2.5:Device Name Appearing on the List of Devic-

es Box .............................................................. 17

Figure 2.6:The Test Utility Dialog Box ....................... 18

Figure 3.1:Card Conn., Jumper & Switch Locations ... 20

3.2.1 Setting the BoardID Switch (SW1) ............................. 21

Table 3.1:Board ID Setting (SW1) .............................. 21

3.2.2 Channel Configuration, S/E or DIFF (SW2) ............... 22

Table 3.2:Summary of Switch SW2 Settings .............. 22

3.2.3 D/A Reference Voltage, int./ext. (JP11) ...................... 22

Table 3.3:Summary of Jumper JP11 Settings .............. 22

3.2.4 Internal Voltage Reference, -10 V or -5 V (JP10) ....... 23

Table 3.4:Summary of Jumper JP10 Settings .............. 23

3.2.5 Timer Clock Selection (JP8) ........................................ 24

Table 3.5:Summary of Jumper JP8 Settings ................ 24

3.2.6 Ext. trigger and Counter Gate 0 Control (JP5) ............ 25

Table 3.6:Summary of Jumper Settings ....................... 25

3.2.7 Digital Output, 20-pin or 37-pin Connector (JP1) ....... 25

Table 3.7:Summary of Jumper Settings ....................... 26

3.2.8 Setting the Time to Reset Digital Outputs ................... 27

Table 3.8:JP21 Jumper Settings ................................... 27

Figure 3.2:I/O Connector Pin Assignments for the PCI-

1718 Series ....................................................... 28

3.3.1 I/O Connector Signal Description ................................ 29

v

Page 6

Table 3.9:I/O Connector Signal Descriptions .............. 29

3.3.2 Analog Input Connections ........................................... 30

Figure 3.3:Analog Output Connections ....................... 33

3.3.3 Digital Signal Connections .......................................... 34

3.4 Field Wiring Considerations .......................................... 35

Chapter 4 Programming Guide ..................................... 38

4.1 Overview ......................................................................... 38

4.2 Programming with the Driver ......................................... 38

4.3 Register Programming..................................................... 38

4.3.1 Software Trigger and Polling ....................................... 39

4.3.2 Pacer Trigger Mode with Interrupt .............................. 41

4.3.3 Pacer Trigger Mode with Interrupt and FIFO .............. 45

4.4 Programming with LabVIEW and ActiveDAQ .............. 49

Appendix A Specifications ................................................. 52

A.1 Analog Input.................................................................... 52

A.2 Analog Output ................................................................. 53

A.3 Digital Input .................................................................... 53

A.4 Digital Output.................................................................. 54

A.5 Counter/Timer ................................................................. 54

A.6 General ............................................................................ 55

Appendix B Block Diagrams ............................................. 58

Appendix C Register Structure & Format ....................... 60

C.1 Overview ......................................................................... 60

C.2 I/O Port Address Map .................................................... 60

C.3 A/D Data and Channels — BASE+00H~01H ................ 64

C.4 Software A/D Trigger — BASE+00H ............................ 64

C.5 A/D Range Control — BASE+01H ............................... 65

C.6 MUX Scan Channel Control — BASE+02H.................. 67

C.7 MUX Scan Channel Status — BASE+02H .................... 68

C.8 Digital I/O Registers - BASE + 03/0BH ......................... 68

C.9 D/A Output — BASE+04/05H ....................................... 69

C.10 FIFO Interrupt Control — BASE+06H........................... 70

C.11 Clear Interrupt Request — BASE+08H .......................... 71

C.12 A/D Status — BASE+08H .............................................. 71

Table C.1:PCI-1718HDU/HGU Reg. Format (Part 1) 61

Table C.2:PCI-1718HDU/HGU Reg. Format (Part 2) 62

Table C.3:PCI-1718HDU/HGU Reg. Format (Part 3) 63

Table C.4:Register for A/D Data and Channels .......... 64

Table C.5:Register for Software A/D Trigger ............. 64

Table C.6:Register for A/D Range Control ................. 65

Table C.7:Register for MUX Scan Channel Control ... 67

Table C.8:Register for MUX Scan Channel Status ..... 68

Table C.9:Register for Digital Output ......................... 68

Table C.10:Register for Digital Output ...................... 69

Table C.11:Register for D/A Output ........................... 69

Table C.12:Register for FIFO Interrupt Control .......... 70

Table C.13:Register for Clear Interrupt Request ......... 71

Table C.14:Register for A/D Status ............................. 71

PCI-1718 Series User Manual vi

Page 7

C.13 A/D Control — BASE+09H ........................................... 73

C.14 Timer/Counter Enable — BASE+0AH ........................... 74

Table C.15:Register for A/D Control ......................... 73

C.15 Programmable Timer/Counter — BASE+0C~0FH ........ 74

Table C.16:Register for Timer/Counter Enable ........... 74

C.16 Clear FIFO Interrupt Request — BASE+14H ................ 75

C.17 A/D Data and Channel from FIFO - BASE + 17/18H .... 75

Table C.17:Register for Clear FIFO Interrupt Request 75

Table C.18:Register for A/D Data and Channel from

FIFO ................................................................. 75

C.18 FIFO Status — BASE+19H ............................................ 76

C.19 FIFO Clear — BASE+19H ............................................. 76

Table C.19:Register for FIFO Status ........................... 76

C.20 Register Programming Flow Chart ................................. 77

Table C.20:Register for FIFO Clear ............................ 76

C.20.1 Software Trigger Mode with Polling ........................... 77

C.20.2 Pacer Trigger Mode with Interrupt .............................. 78

C.20.3 Pacer Trigger Mode with Interrupt [FIFO Used] ......... 79

Appendix D Calibration ..................................................... 82

D.1 VR Assignment .............................................................. 83

D.2 A/D Calibration ............................................................... 84

D.3 D/A Calibration ............................................................... 85

Figure D.1:PCI-1718 VR Assignment ......................... 83

vii

Page 8

PCI-1718 Series User Manual viii

Page 9

2

1

CHAPTER

Introduction

This chapter introduces the PCI-1718

cards and their typical applications.

Sections include:

• Features

• Applications

• Installation Guide

• Software Overview

• Device Driver Programming Roadmap

• Accessories

Page 10

Chapter 1 Introduction

Thank you for buying the Advantech PCI-1718HDU/HGU. PCI1718HDU/HGU is a PCI-Bus multifunction card for IBM PC/XT/AT or

compatible computers. It offers the five most desired measurement and

control functions:

• 12-bit A/D conversion

• D/A conversion

• Digital input

• Digital output

• Timer/counter.

A programmable-gain instrument amplifier lets you acquire different

input signals without external signal conditioning. An onboard 1 K word

FIFO buffer provides high-speed data transfer and predictable performance under Windows. Automatic channel scanning circuitry and

onboard SRAM let you perform multiple-channel A/D conversion with

DMA and individual gains for each channel.

PCI-1718HDU/HGU is compatible* with its ISA-Bus predecessor, the

PCL-818HD/HG. This puts rich software support and a wide variety of

external signal conditioning boards at your disposal.

The following sections of this chapter will provide further information

about features of the multifunction cards, a Quick Start for installation,

together with some brief information on software and accessories for the

PCI-1718 cards.

Note*

PCI-1718 Series User Manual 2

1. PCI-1718HDU/HGU is register-level- programming compatible with PCL-818HD/HG

2. Due to the difference between ISA and PCI

architecture, we use “interrupt + FIFO” to emulate the DMA function. But it makes no difference to your programming and applications.

Page 11

1.1 Features

• Register level programming compatible with PCL-818HD/HG

• 16 single-ended or 8 differential A/D inputs, switch selectable

• 12-bit A/D converter, up to 100 kHz sampling rate

• Programmable gain for each input channel

• Automatic Channel/Gain Scanning

• On-board 1 K word FIFO buffer with software selectable interrupt

• Software selectable Bipolar/Unipolar analog input ranges

• 16 digital inputs and 16 digital outputs, TTL/DTL compatible

• One 12-bit analog output channel

• Data transfers by program control and interrupt handler routine

• Universal PCI-Bus (Support 3.3V or 5V PCI-Bus signal)

• BoardID switch

PCI-1718HDU/HGU offers the following main features:

PCI-Bus Plug & Play

The PCI-1718 cards use a PCI controller to interface the card to the PCI

bus. The controller fully implements the PCI bus specification Rev 2.2.

All configurations related to the bus, such as base address and interrupt

assignment, are automatically controlled by software. No jumper or

switch is required for user configuration.

Automatic Channel/Gain Scanning

PCI-1718HDU/HGU features an automatic channel/gain scanning circuit.

This circuit, instead of your software, controls multiplexer switching during sampling. On-board SRAM stores different gain values for each channel. This combination lets user perform multi-channel high-speed

sampling (up to 100 kHz) for each channel.

3 Chapter 1

Page 12

Onboard FIFO

There are 1 K samples FIFO for A/D (AI) on PCI-1718HDU/HGU. This

is an important feature for faster data transfer and more predictable performance under Windows system.

Onboard Programmable Timer/Counter

PCI-1718HDU/HGU provides a programmable timer counter for generating pacer trigger for the A/D conversion. The timer/counter chip is

82C54, which includes three 16-bit counters of 10 MHz clock. One

counter is used as an event counter for counting events coming from the

input channel. The other two are cascaded together to make a 32-bit timer

for pacer trigger time base.

BoardID Switch

PCI-1718HDU/HGU has a built-in DIP switch that helps define each

card’s ID when multiple PCI-1718HDU/HGU cards have been installed

on the same PC chassis. The BoardID setting function is very useful when

building a system with multiple PCI-1718 cards. With the correct BoardID settings, you can easily identify and access each card during hardware configuration and software programming.

Note: For detailed specifications of the PCI-

1718HDU/HGU, please refer to Appendix A.

1.2 Applications

• Transducer and sensor measurements

• Waveform acquisition and analysis

• Process control and monitoring

• Vibration and transient analysis

PCI-1718 Series User Manual 4

Page 13

1.3 Installation Guide

Before you install your PCI-1718HDU/HGU card, please make sure you

have the following necessary components:

• PCI-1718HDU/HGU DA&C card

• PCI-1718HDU/HGU User Manual

• Driver software Advantech DLL drivers (included in the companion

CD-ROM)

• Personal computer or workstation with a PCI-bus slot (running Windows 98/2000/XP)

• PCL-10120 or PCL-10137 Wiring cable (optional)

• ADAM-3920/3937, PCLD-7216/780/782/782B/785/785B/786/788/

789D/880/885/8115 Wiring board (optional)

Some other optional components are also available for enhanced operation:

• ActiveDAQ, ADAQView, LabView or other third-party software packages

After you get the necessary components and maybe some of the accessories for enhanced operation of your multifunction card, you can then

begin the installation procedure. Figure 1.1 on the next page provides a

concise flow chart to give users a broad picture of the software and hardware installation procedures:

5 Chapter 1

Page 14

Figure 1.1: Installation Flow Chart

PCI-1718 Series User Manual 6

Page 15

1.4 Software Overview

Advantech offers a rich set of DLL drivers, third-party driver support and

application software to help fully exploit the functions of your PCI1718HDU/HGU card:

• Device Drivers (on the companion CD-ROM)

• LabVIEW driver

• Advantech ActiveDAQ

• Advantech ADAQView

Programming choices for DA&C cards

You may use Advantech application software such as Advantech Device

Drivers. On the other hand, advanced users can use register-level programming, although this is not recommended due to its laborious and

time-consuming nature.

Device Drivers

Advantech Device Driver software is included on the companion CDROM at no extra charge. It also comes with all Advantech DA&C cards.

Advantech’s Device Drivers features a complete I/O function library to

help boost your application performance. Advantech Device Drivers for

Windows 98/2000/XP works seamlessly with development tools such as

Visual C++, Visual Basic, Borland C++ Builder and Borland Delphi.

Register-level Programming

Register-level programming is available for experienced programmers

who find it necessary to write code directly at the level of the device register. Since register-level programming requires much effort and time, we

recommend that you use the Advantech Device Drivers instead. However, if register-level programming is indispensable, you should refer to

the relevant information in Appendix C, Register Structure and Format,

or to the example codes included on the companion CD-ROM.

7 Chapter 1

Page 16

1.5 Device Driver Programming Roadmap

This section will provide you a roadmap to demonstrate how to build an

application from scratch using Advantech Device Drivers with your

favorite development tools such as Visual C++, Visual Basic, Delphi and

C++ Builder. The step-by-step instructions on how to build your own

applications using each development tool will be given in the Device

Drivers Manual. Moreover, a rich set of example source code is also

given for your reference.

Programming Tools

Programmers can develop application programs with their favorite development tools:

• Visual C++

• Visual Basic

• Delphi

• C++ Builder

For instructions on how to begin programming works in each development tool, Advantech offers a Tut orial Chapter in the Device Drivers

Manual for your reference. Please refer to the corresponding sections in

this chapter on the Device Drivers Manual to begin your programming

efforts. You can also look at the example source code provided for each

programming tool, since they can get you very well oriented.

The Device Drivers Manual can be found on the companion CD-ROM.

Alternatively, if you have already installed the Device Drivers on your

system, The Device Drivers Manual can be readily accessed through the

Start button:

Start\Advantech Automation\Device Manager\Device Driver's Manual

The example source code could be found under the corresponding installation folder such as the default installation path:

Program Files\Advantech\ADSAP\Examples

For information about using other function groups or other development

tools, please refer to the Creating Windows 98/2000/XP Application with

Device Drivers chapter and the Function Overview chapter on the Device

Drivers Manual.

PCI-1718 Series User Manual 8

Page 17

Programming with Device Drivers Function Library

Advantech Device Drivers offer a rich function library that can be utilized in various application programs. This function library consists of

numerous APIs that support many development tools, such as Visual

C++, Visual Basic, Delphi and C++ Builder.

According to their specific functions or services, APIs can be categorized

into several function groups:

• Analog Output Function Group

• Digital Input/Output Function Group

• Counter Function Group

• Port Function Group (direct I/O)

• Event Function Group

For the usage and parameters of each function, please refer to the Func-

tion Overview chapter in the Device Drivers Manual.

Troubleshooting Device Drivers Error

Driver functions will return a status code when they are called to perform

a certain task for the application. When a function returns a code that is

not zero, it means the function has failed to perform its designated function. To troubleshoot the Device Drivers error, you can pass the error

code to DRV_GetErrorMessage function to return the error message.

Alternatively, you can refer to the Device Drivers Error Codes Appendix

in the Device Drivers Manual for a detailed listing of Error Codes, Error

IDs and Error Messages.

9 Chapter 1

Page 18

1.6 Accessories

Advantech offers a complete set of accessory products to support the

PCI-1718HDU/HGU card. These accessories include:

Wiring Cables

PCL-10120

The PCL-10120 cable is a 20-pin flat cable for PCI-1718HDU/HGU

cards.

PCL-10137

The PCL-10137 shielded cable is specially designed for PCI-1718HDU/

HGU cards to provide high resistance to noise. To achieve a better signal

quality, the signal wires are twisted in such a way as to form a “twistedpair cable”, reducing cross-talk and noise from other signal sources. Furthermore, its analog and digital lines are separately sheathed and shielded

to neutralize EMI/EMC problems.

Wiring Boards

• ADAM-3920 20-pin wiring terminal for DIN-rail mounting

• ADAM-3937 37-pin D-type wiring terminal for DIN-rail mounting

• PCLD-7216 16-channel SSR I/O module carrier board

• PCLD-780 Universal screw-terminal board

• PCLD-782 16-channel opto-isolated D/I board

• PCLD-782B 24-channel opto-isolated D/I board

• PCLD-785 16-channel relay output board

• PCLD-785B 24-channel relay output board

• PCLD-786 8-channel SSR I/O module carrier board

• PCLD-788 16-channel relay multiplexer board

• PCLD-789D Amplifier and multiplexer board

• PCLD-880 Universal screw-terminal board

• PCLD-885 16-channel power relay output board

• PCLD-8115 Industrial wiring terminal with CJC circuit

PCI-1718 Series User Manual 10

Page 19

2

2

CHAPTER

Installation

This chapter provides a packaged item

checklist, proper instructions for

unpacking and step-by-step procedures

for both driver and card installation..

Sections include:

• Unpacking

• Driver Installation

• Hardware Installation

• Device Setup & Configuration

Page 20

Chapter 2 Installation

2.1 Unpacking

After receiving your PCI-1718HDU/HGU package, please inspect its

contents first. The package should contain the following items:

• PCI-1718HDU or PCI-1718HGU card

• Companion CD-ROM (Device Drivers included)

• User Manual

The PCI-1718 cards harbor certain electronic components vulnerable to

electrostatic discharge (ESD). ESD can easily damage the integrated circuits and certain components if preventive measures are ignored.

Before removing the card from the antistatic plastic bag, you should take

the following precautions to ward off possible ESD damage:

• Touch the metal part of your computer chassis with your hand to discharge the static electricity accumulated on your body. Alternatively,

one can also use a grounding strap.

• Touch the anti-static bag to a metal part of your computer chassis

before opening the bag.

• Take hold of the card only by the metal bracket when removing it out of

the bag.

After taking out the card, you should first:

• Inspect the card for any possible signs of external damage (loose or

damaged components, etc.). If the card is visibly damaged, please

notify our service department or our local sales representative immediately. Do not install a damaged card into your system.

Also, pay extra caution to the following aspects during installation:

• Avoid physical contact with materials that could hold static electricity

such as plastic, vinyl and Styrofoam.

• Whenever you handle the card, grasp it only by its edges. DO NOT

TOUCH the exposed metal pins of the connector or the electronic components.

PCI-1718 Series User Manual 12

Page 21

.

Note: Keep the anti-static bag for future use. You

might need the original bag to store the card if

you have to remove the card from a PC or transport it elsewhere.

2.2 Driver Installation

We recommend you install the driver before you install the PCI1718HDU/HGU card into your system, since this will guarantee a smooth

installation process.

The Advantech Device Drivers Setup program for the PCI-1718HDU/

HGU card is included in the companion CD-ROM that is shipped with

your DA&C card package. Please follow the steps below to install the

driver software:

1. Insert the companion CD-ROM into your CD-ROM drive.

2. The Setup program will be launched automatically if you have the

autoplay function enabled on your system. When the Setup Program is launched, you will see the following Setup Screen.

Note: If the autoplay function is not enabled on

your computer, use Windows Explorer or

Windows Run command to execute

SETUP.EXE on the companion CD-ROM.

13 Chapter 2

Page 22

Figure 2.1: Setup Screen of Advantech Automation Software

3. Select the Device Drivers option.

4. Select the specific device then just follow the installation instruc-

tions step by step to complete your device driver installation and

setup.

Figure 2.2: Different Options for Driver Setup

For further information on driver-related issues, an online version of the

Device Drivers Manual is available by accessing the following path:

Start/Advantech Automation/Device Manager/Device Driver’s Manual

PCI-1718 Series User Manual 14

Page 23

2.3 Hardware Installation

Note: Make sure you have installed the

driver before you install the card

(please refer to chapter 2.2 Driver

Installation)

After the Device Drivers installation is completed you can install the PCI1718HDU/HGU card into any PCI slot on your computer. However, it is

suggested that you refer to the computer’s user manual or related documentation if you have any doubts. Please follow the steps below to install

the card onto your system.

1. Turn off your computer and unplug the power cord and cables.

TURN OFF your computer before installing or removing any components on the computer.

2. Remove the cover of your computer.

3. Remove the slot cover on the back panel of your computer.

4. Touch the metal part on the surface of your computer to neutralize

the static electricity that might be on your body.

5. Insert the PCI-1718HDU/HGU card into a PCI slot. Hold the card

only by its edges and carefully align it with the slot. Insert the card

firmly into place. Use of excessive force must be avoided; otherwise, the card might be damaged.

6. Fasten the bracket of the PCI card on the back panel rail of the

computer with screws.

7. Connect appropriate accessories (37-pin cable, wiring terminals,

etc. if necessary) to the PCI card.

8. Replace the cover of your computer chassis. Re-connect the cables

you removed in step 2.

9. Plug in the power cord and turn on the computer.

After your card is properly installed on your system, you can now configure your device using the Advantech Device Manager Program that has

itself already been installed on your system during driver setup. A complete device installation procedure should include device setup, configu-

ration and testing. The following sections will guide you through the

Setup, Configuration and Testing of your device.

15 Chapter 2

Page 24

2.4 Device Setup & Configuration

The Advantech Device Manager program is a utility that allows you to set

up, configure and test your device, and later stores your settings on the

system registry. These settings will be used when you call the APIs of

Advantech Device Drivers.

Setting Up the Device

1. To install the I/O device for your card, you must first run the

Device Installation program (by accessing Start/Advantech Automation/Device Manager/Advantech Device Manager ).

2. You can then view the device(s) already installed on your system

(if any) on the Installed Devices list box. Since you have not

installed any device yet, you might see a blank list such as the one

below (Fig. 2-3).

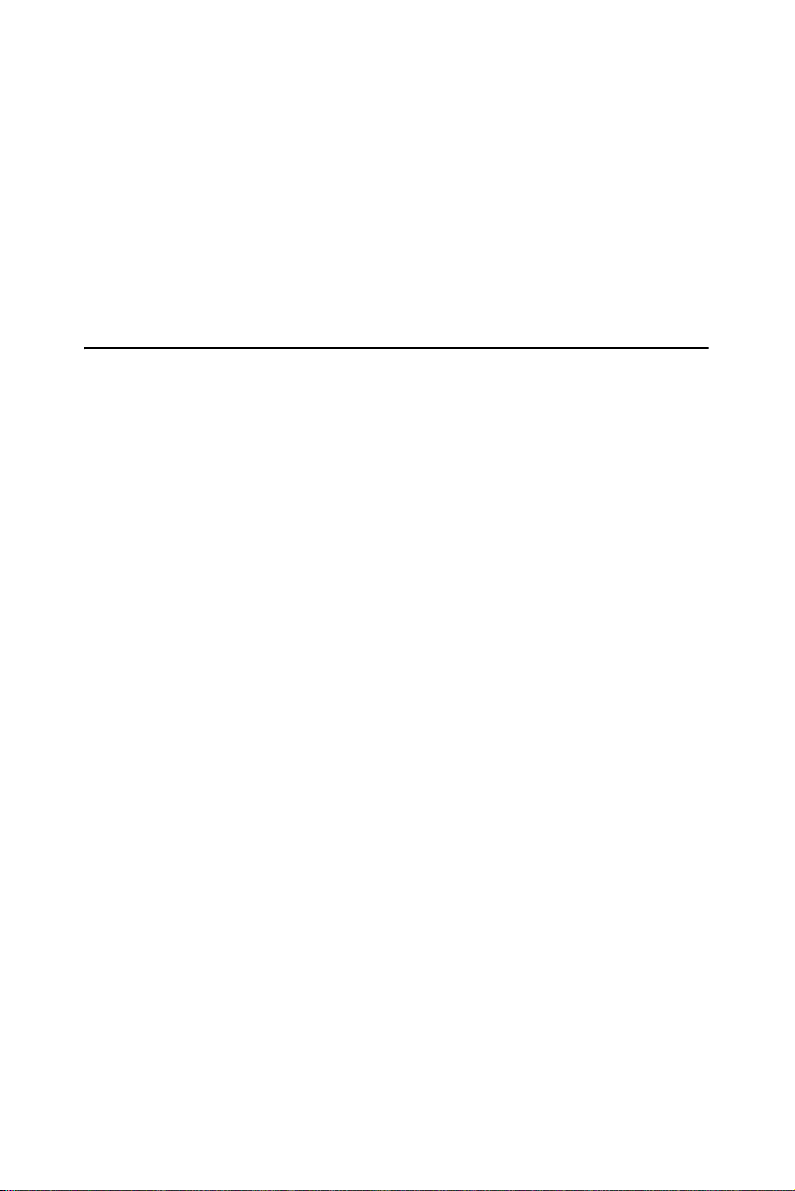

Figure 2.3: The Device Manager Dialog Box

3. Scroll down the List of Devices box to find the device that you wish

to install, then click the Add… button. You will see a Device Set-

ting dialog box such as the one in Fig. 2-4.

PCI-1718 Series User Manual 16

Page 25

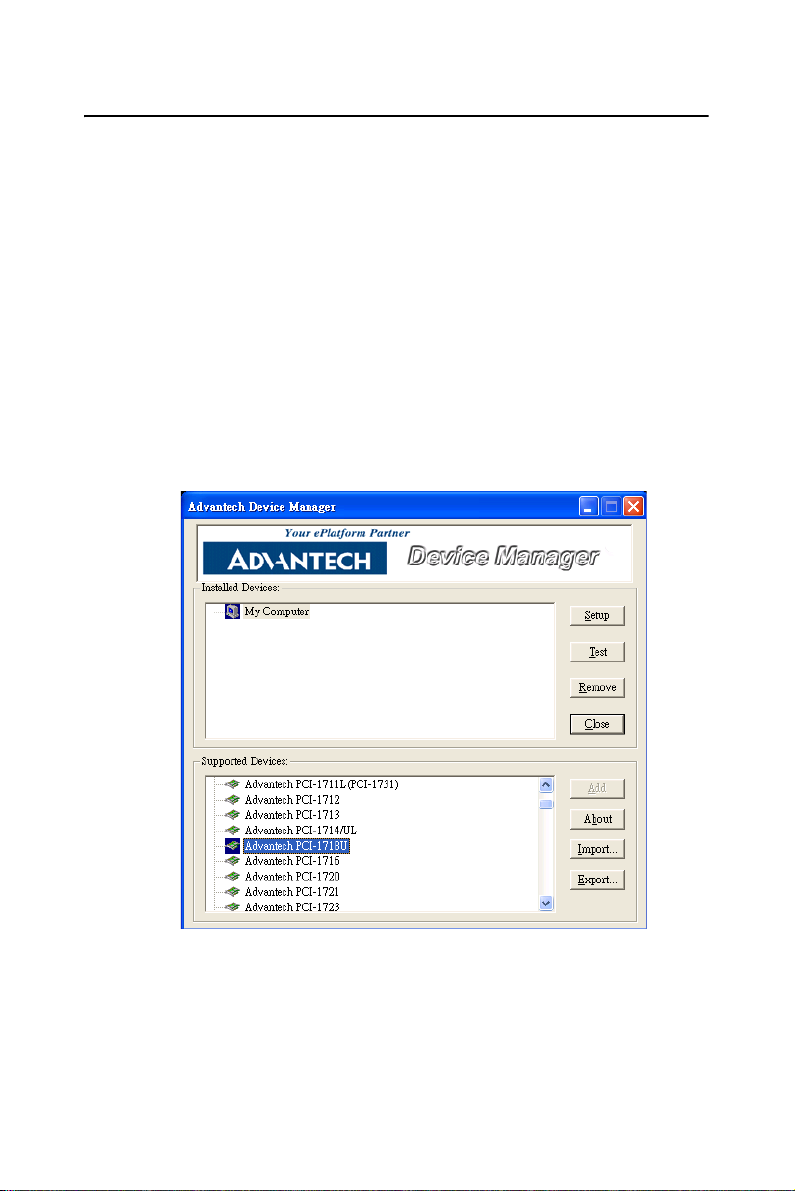

Configuring the Device

4. On the Device Setting dialog box (Fig. 2-4), you can configure the

A/D channels configuration either as 8 Differential or 16 Single-

ended, and specify the D/A voltage reference either as External or

Internal.

Figure 2.4: The Device Setting Dialog Box

5. After you have finished configuring the device, click OK and the

device name will appear in the Installed Devices box as seen below:

Figure 2.5: Device Name Appearing on the List of Devices Box

17 Chapter 2

Page 26

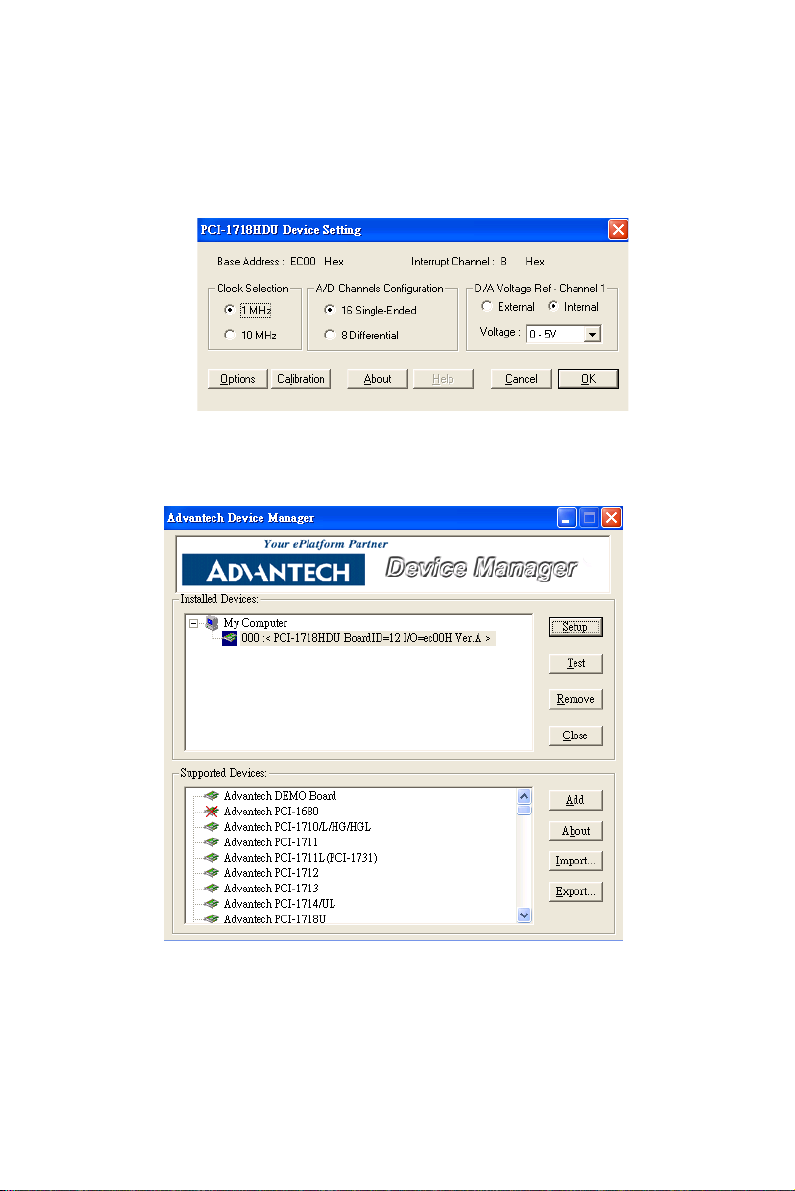

After your card is properly installed and configured, you can click the

Tes t… button to test your hardware by using the testing utility supplied.

Figure 2.6: The Test Utility Dialog Box

For more detailed information, please refer to Chapter 2 of the Device

Drivers Manual.

You can also find rich examples on the CD-ROM to speed up your programming.

PCI-1718 Series User Manual 18

Page 27

2

3

CHAPTER

Signal Connections

This chapter provides useful information about how to connect input and

output signals to the PCI-1718 cards

via the I/O connector..

Sections include:

• Overview

• Switch and Jumper Settings

• Signal Connections

• Field Wiring Considerations

Page 28

Chapter 3 Signal Connections

3.1 Overview

Maintaining signal connections is one of the most important factors in

ensuring that your application system is sending and receiving data correctly. A good signal connection can avoid unnecessary and costly damage to your PC and other hardware devices. This chapter provides useful

information about how to connect input and output signals to the PCI1718 cards via the I/O connector.

3.2 Switch and Jumper Settings

PCI-1718 cards have two function switches and five jumper settings.

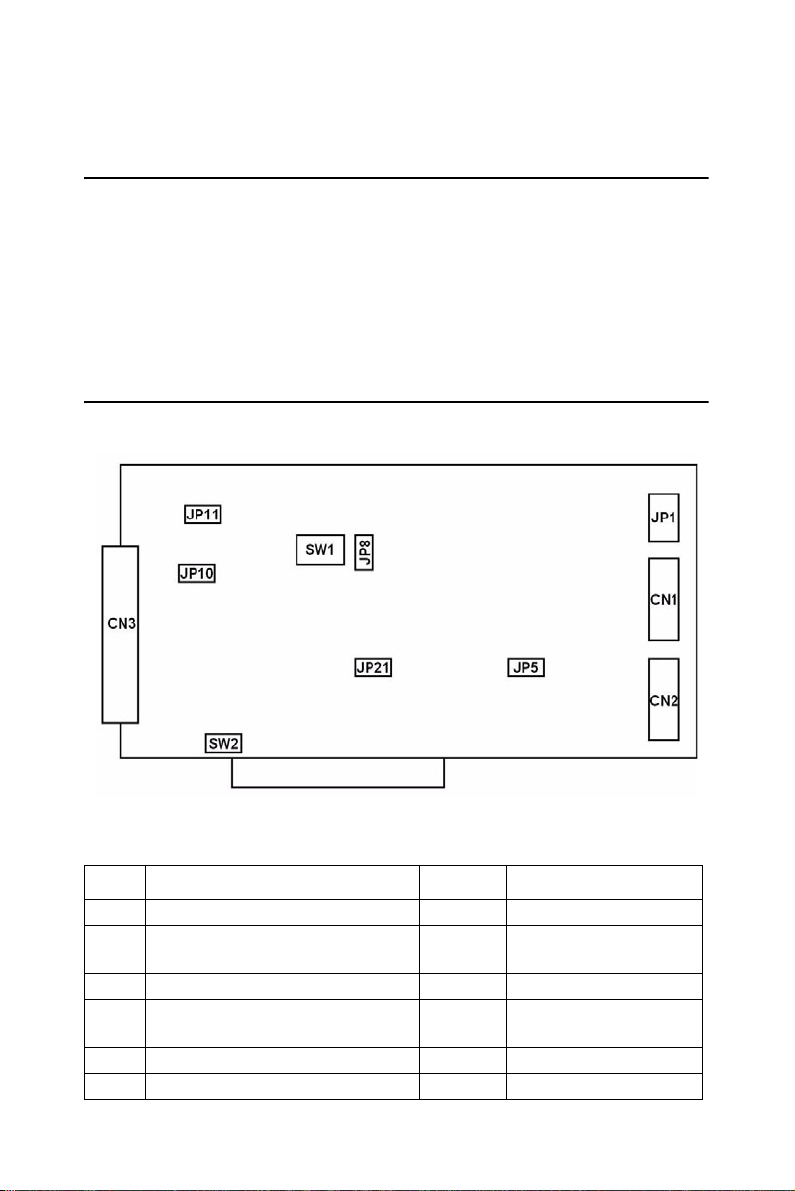

Figure 3.1: Card Connector, Jumper and Switch Locations

JP Description SW/CN Description

JP1 Digital Output Connector Setting SW1 BoardID Setting

JP5 Trigger Source & Gate Control

Setting

JP8 Timer Clock Setting CN1 IDE 20-pin Header 1

JP10 Internal Reference Voltage Set-

ting

Jp11 D/A Reference Voltage Setting CN3 DB-37 Pin Connector

JP21 Reset Protection Setting

PCI-1718 Series User Manual 20

SW2 S.E/Diff Connection

Setting

CN2 IDE 20-pin Header 2

Page 29

3.2.1 Setting the BoardID Switch (SW1)

BoardID settings are used to set a board’s unique identifier when multiple

identical cards are installed in the same system.

PCI-1718 cards have a built-in DIP switch (SW1), which is used to define

each card’s unique identifier. You can determine the unique identifier in

the register as shown in Table 3.1. If there are multiple identical cards in

the same chassis, the BoardID switch helps differentiate the boards by

identifying each card’s device number with the switch setting. The BoardID switch’s unique identifier has been set to 0 at the factory.

If you need to adjust it to other numbers, set SW1 by referring to DIP

switch settings below.

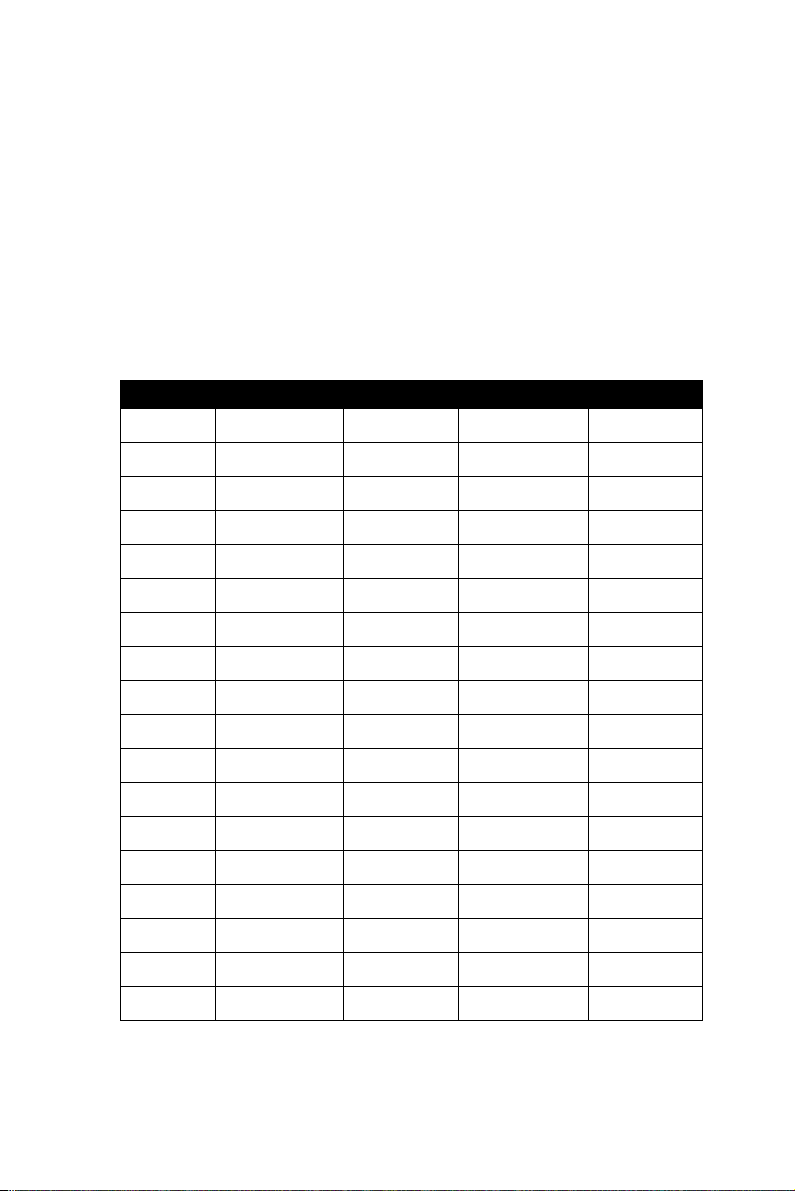

Table 3.1: Board ID Setting (SW1)

SW1 3 2 1 0

BoardID ID3 ID2 ID1 ID0

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

ON ON ON ON

ON ON ON OFF

ON ON OFF ON

ON ON OFF OFF

ON OFF ON ON

ON OFF ON OFF

ON OFF OFF ON

ON OFF OFF OFF

OFF ON ON ON

OFF ON ON OFF

OFF ON OFF ON

OFF ON OFF OFF

OFF OFF ON ON

OFF OFF ON OFF

OFF OFF OFF ON

OFF OFF OFF OFF

Default Setting is 0

21 Chapter 3

Page 30

3.2.2 Channel Configuration, S/E or DIFF (SW2)

The PCI-1718 cards offer 16 single-ended or eight differential analog

input channels. Slide switch SW2 changes the channels between singleended or differential input. Slide the switch to the left-hand position,

marked DIFF, for eight differential inputs (the default) or to the righthand position, marked S/E, for 16 single-ended inputs.

Table 3.2: Summary of Switch SW2 Settings

Switch Function description

SW2 Differential (default)

Single-ended

3.2.3 D/A Reference Voltage, int./ext. (JP11)

Jumper JP11 selects reference voltage source for PCI-1718 cards’ D/A

converters. You can use the cards’ internal reference, or supply an external reference.

Table 3.3: Summary of Jumper JP11 Settings

Jumper Function description

JP11 External

Internal (default)

When you set JP11 to INT, the D/A converter takes its reference voltage

input from the card's onboard reference. Jumper JP10 selects either -5 V

or -10 V onboard reference voltage. With JP11 set to INT the D/A channel has an output range of 0 to +5 V or 0 to +10 V, respectively.

PCI-1718 Series User Manual 22

Page 31

When you set JP11 to EXT, the D/A converter takes its reference voltage

input from pin 31 of connector CN3. You can apply any voltage between

-10 V and +10 V to this pin to function as the external reference. The reference input can be either DC or AC (<100 kHz).

When you use an external reference with voltage V

the D/A channel to output from 0 V to -V

, you can also use the D/A

ref

you can program

ref

converter as a programmable attenuator. The attenuation factor between

reference input and analog output is:

Attenuation factor = G / 4095

G is a value you write to the D/A registers between 0 and 4095. For

example, if you set G to 2048, then the attenuation factor is 0.5. A sine

wave of 10 V amplitude applied to the reference input will generate a sine

wave of 5 V amplitude on the analog output.

3.2.4 Internal Voltage Reference, -10 V or -5 V (JP10)

If you use an internal reference voltage (set with JP11), the PCI-1718

cards provide a choice between -5 V or -10 V DC internal reference voltage sources.

Table 3.4: Summary of Jumper JP10 Settings

Jumper Function description

JP10 5 V (default)

10 V

Table 3-1: Summary of jumper JP10 settings

23 Chapter 3

Page 32

3.2.5 Timer Clock Selection (JP8)

PCI-1718’s JP8 controls the input clock frequency for the 8254 programmable clock/timer. You have two choices: 10 or 1 MHz. This lets you

generate pacer output frequencies from 2.5 MHz to 0.00023 Hz (71 minutes/pulse).

The following equation gives the pacer rate:

Pacer rate = Fclk / (Divl * Div2)

Fclk is 1 MHz or 10 MHz, as set by jumper JP8. Div 1 and Div2 are the

dividers set in counter 1 and counter 2 in the 8254.

Table 3.5: Summary of Jumper JP8 Settings

Jumper Function description

JP8 1 MHz (default)

PCI-1718 Series User Manual 24

10 MHz

Page 33

3.2.6 Ext. trigger and Counter Gate 0 Control (JP5)

JP5 has two jumpers. The upper jumper selects the card's A/D trigger

source when you use external triggering. The lower jumper selects the

gate control for counter 0 of the card's 8254 timer/counter.

Table 3.6: Summary of Jumper Settings

Jumper Function description

JP5

(Upper)

JP5

(Lower)

G0 (default)

DI2

Ext. (default)

DI0

3.2.7 Digital Output, 20-pin or 37-pin Connector (JP1)

The PCI-1718 cards’ JP1 switch digital output channels 0 to 3 between

the card's 20-pin connector and 37-pin connector. If you set the jumpers

to the left (D) side, the digital output signals will come out on connector

CN1 (20-pin). If you set the jumpers to the right (S) side, the output signals will come out on connector CN3 (37-pin).

These four digital output signals select the analog input channel when

you use a multiplexer/amplifier daughter board. Daughter boards with a

DB-37 connector, such as the PCLD-789D, read the digital output signals

from the DB-37 connector (CN3). With other daughter boards you will

need to connect an external 20-pin flat cable from CN1 to the daughter

board.

25 Chapter 3

Page 34

Table 3.7: Summary of Jumper Settings

Jumper Function Description

JP1 (first) S0

D0 (default)

S1

JP1 (second)

D1 (default)

S2

JP1 (third)

JP1

(fourth)

PCI-1718 Series User Manual 26

D2 (default)

S3

D3 (default)

Page 35

3.2.8 Setting the Time to Reset Digital Outputs

Some users will want the capability of clearing each digital output when

the system (or PC) issues a reset signal on the PCI bus. Other users will

want to clear their signal outputs only as part of system power-on.

PCI-1718 cards satisfy both these needs with jumper JP21. Depending on

the application, this capability may allow digital outputs to be “OFF”

without requiring a complete shutdown of processes controlled by the

card.

Complete loss of power to the chip clears the chip memory. Thus, no matter how JP21 is set, if the power to the PCI-1718 card is disconnected, the

digital output channel’s initial power-on state will be “OFF”.

Table 3.8: JP21 Jumper Settings

Jumper Function description

JP21 Keep last status after hot reset.

Reset status after hot reset

(default)

27 Chapter 3

Page 36

3.3 Signal Connections

Pin Assignment

Figure 3-2 shows the pin assignments for the 37-pin I/O connector on the

PCI-1718HDU/HGU.

CN1 CN2

D/O 0 1 2 D/O 1 D/I 0 1 2 D/I 1

D/O 2 3 4 D/O 3 D/I 2 3 4 D/I 3

D/O 4 5 6 D/O 5 D/I 4 5 6 D/I 5

D/O 6 7 8 D/O 7 D/I 6 7 8 D/I 7

D/O 8 9 10 D/O 9 D/I 8 9 10 D/I 9

D/O 10 11 12 D/O 11 D/I 10 11 12 D/I 11

D/O 12 13 14 D/O 13 D/I 12 13 14 D/I 13

D/O 14 15 16 D/O 15 D/I 14 15 16 D/I 15

D.GND 17 18 D.GND D.GND 17 18 D.GND

+5 V 19 20 +12 V +5 V 19 20 +12 V

CN3 (Single ended) CN3 (Differential)

A/D S0 1 20 A/D S8 A/D H0 1 20 A/D L0

A/D S1 2 21 A/D S9 A/D H1 2 21 A/D L1

A/D S2 3 22 A/D S10 A/D H2 3 22 A/D L2

A/D S3 4 23 A/D S11 A/D H3 4 23 A/D L3

A/D S4 5 24 A/D S12 A/D H4 5 24 A/D L4

A/D S5 6 25 A/D S13 A/D H5 6 25 A/D L5

A/D S6 7 26 A/D S14 A/D H6 7 26 A/D L6

A/D S7 8 27 A/D S15 A/D H7 8 27 A/D L7

A.GND 9 28 A.GND A.GND 9 28 A.GND

A.GND 10 29 A.GND A.GND 10 29 A.GND

VREF 11 30 DA0.OUT VREF 11 30 DA0.OUT

S0* 12 31 DA0.VREF S0* 12 31 DA0.VREF

+12 V 13 32 S1* +12 V 13 32 S1*

S2* 14 33 S3* S2* 14 33 S3*

D.GND 15 34 D.GND D.GND 15 34 D.GND

NC 16 35 EXT.TRIG NC 16 35 EXT.TRIG

Counter 17 36 Counter 0 Counter 0 17 36 Counter 0

Counter 18 37 PACER Counter 0 18 37 PAC ER

+5 V 19 +5 V 19

..

Figure 3.2: I/O Connector Pin Assignments for the PCI-1718 Series

Note: S0/S1 is NC, and S2/S3 is AGND for PCI-1718HGU

PCI-1718 Series User Manual 28

Page 37

3.3.1 I/O Connector Signal Description

Table 3.9: I/O Connector Signal Descriptions

Signal

Name

A/D S

<0..15>

A/D H

<0..7>

A/D L

<0..7>

D/A A.GND Output Analog output

AGND - -

D/O D.GND Output Digital output, channels 0 through 15.

D/I D.GND Input Digital input, channels 0 through 15.

CLK D.GND Input Clock input for the 8254.

GATE D.GND Input Gate input for the 8254.

OUT D.GND Output Signal output for the 8254.

VREF D.GND Output Voltage reference.

REFIN D.GND Input External voltage reference input.

S1-S4 D.GND Output Daughterboard channel select.

DGND - -

+12V D.GND Output

+5V D.GND Output

NC - - No connection.

Refere

nce

A.GND Input

A.GND Input

A.GND Input

Direct

ion

Description

Analog input (single-ended), channels 0

through 15.

Analog input high (differential), channels 0

through 7.

Analog input low (differential), channels 0

through 7.

Analog Ground. The two ground references

(A.GND and D.GND) are connected together

on the PCI-1718HDU/HGU card.

Digital Ground. The two ground references

(A.GND and D.GND) are connected together

on the PCI-1718HDU/HGU card.

+12 VDC Source (from ISA bus directly with

FUSE protection).

+5 VDC Source (from ISA bus directly with

FUSE protection).

29 Chapter 3

Page 38

3.3.2 Analog Input Connections

PCI-1718HDU/HGU supports either 16 single-ended or 8 differential

analog inputs. Switch SW2 selects the input channel configuration.

Single-ended Channel Connections

Single-ended connections use only one signal wire per channel. The voltage on the line references to the common ground on the card. A signal

source without a local ground is called a "floating" source. It is fairly simple to connect a single ended channel to a floating signal source. A standard wiring diagram looks like this:

Signal Input

+

Vs

-

A.GNDA.GND

Differential Channel Connections

Differential input connections use two signal wires per channel. The card

measures only the voltage difference between these two wires, the HI

wire and the LOW wire. If the signal source has no connection to ground,

it is called a "floating" source. A connection must exist between LOW

and ground to define a common reference point for floating signal

sources. To measure a floating sources connect the input channels as

shown below:

To A/D

A.GND

HIGH

+

Vs

-

PCI-1718 Series User Manual 30

LOW

A.GND

+

+

Vin

-

-

Page 39

If the signal source has one side connected to a local ground, the signal

source ground and the PCI-1718HDU/HGU ground will not be at exactly

the same voltage, as they are connected through the ground return of the

equipment and building wiring. The difference between the ground voltages forms a common-mode voltage.

To avoid the ground loop noise effect caused by common-mode voltages,

connect the signal ground to the LOW input. Do not connect the LOW

input to the PCI-1718HDU/HGU ground directly. In some cases you may

also need a wire connection between the PCI-1718HDU/HGU ground

and the signal source ground for better grounding. The following two diagrams show correct and incorrect connections for a differential input with

local ground:

Correct Connection

HIGH

+

+

Vs

-

+-

Vcm GND

Incorrect Connection

+

Vs

-

Vcm

LOW

+-

+

Vin

-

Vin=Vs

-

HIGH

+

+

Vin

-Vin=Vs+Vcm

LOW

GND

31 Chapter 3

-

Page 40

Expanding Analog Inputs

You can expand any or all of the PCI-1718HDU/HGU's A/D input channels using multiplexing daughterboards. Daughterboards without D-type

connectors require the PCLD-774 Analog Expansion Board.

The PCLD-789(D) Amplifier and Multiplexer multiplexes 16 differential

inputs to one A/D input channel. You can cascade up to eight PCLD789(D)s to the PCI-1718HDU/HGU for a total of 128 channels. See the

PCLD-789(D) user's manual for complete operating instructions.

The PCLD-774 Analog Expansion Board accommodates multiple external signal-conditioning daughter boards, such as PCLD-779 and PCLD789(D). It features five sets of on-board 20-pin header connectors. A special star-type architecture lets you cascade multiple signal-conditioning

boards without the signal-attenuation and current-loading problems of

normal cascading.

The PCLD-8115 Screw Terminal Board makes wiring connections easy.

It provides 20-pin flat cable and DB-37 cable connectors. It also includes

CJC (Cold Junction Compensation) circuits.

Special circuit pads on the PCLD-8115 accommodate passive signal conditioning components. You can easily implement a low-pass filter, attenuator or current shunt by adding resistors and capacitors.

PCI-1718 Series User Manual 32

Page 41

Analog Output Connection

The PCI-1718HDU/HGU provides one D/A output channel. You can use

the internal precision -5 V or -10 V reference to generate 0 to +5 V or 0 to

+10 V D/A output. Use an external reference for other D/A output ranges.

The maximum reference input voltage is ±10 V and maximum output

scaling is ±10 V. Loading current for D/A outputs should not exceed 5

mA.

Connector CN3 provides D/A signals. Important D/A signal connections

such as input reference, D/A outputs and analog ground appear below:

CN3-31 D/A REF IN

ON-Board

REF

D/A

JP11

-5V

-10V

JP10

Figure 3.3: Analog Output Connections

CN3-30 D/A OUT

CN3-9,10,28,29 A.GND

CN3-11 VREF

33 Chapter 3

Page 42

3.3.3 Digital Signal Connections

The PCI-1718HDU/HGU has 16 digital input and 16 digital output channels. The digital I/O levels are TTL compatible. The following figure

shows connections to exchange digital signals with other TTL devices:

DO

DI

D.GND

D.GND

TTL Devices

To receive an OPEN/SHORT signal from a switch or relay, add a pull-up

resistor to ensure that the input is held at a high level when the contacts

are open. See the figure below:

+5V

4.7K

D.GND

PCI-1718 Series User Manual 34

Page 43

3.4 Field Wiring Considerations

When you use PCI-1718 cards to acquire data from outside, noises in the

environment might significantly affect the accuracy of your measurements if due cautions are not taken. The following measures will be helpful to reduce possible interference running signal wires between signal

sources and the PCI-1718 card.

• The signal cables must be kept away from strong electromagnetic

sources such as power lines, large electric motors, circuit breakers or

welding machines, since they may cause strong electromagnetic interference. Keep the analog signal cables away from any video monitor,

since it can significantly affect a data acquisition system.

• If the cable travels through an area with significant electromagnetic

interference, you should adopt individually shielded, twisted-pair wires

as the analog input cable. This type of cable has its signal wires twisted

together and shielded with a metal mesh. The metal mesh should only

be connected to one point at the signal source ground.

• Avoid running the signal cables through any conduit that might have

power lines in it.

• If you have to place your signal cable parallel to a power line that has a

high voltage or high current running through it, try to keep a safe distance between them. Alternatively, you can place the signal cable at a

right angle to the power line to minimize the undesirable effect.

• The signals transmitted on the cable will be directly affected by the

quality of the cable. In order to ensure better signal quality, we recommend that you use the PCL-10137 shielded cable.

35 Chapter 3

Page 44

PCI-1718 Series User Manual 36

Page 45

2

4

CHAPTER

Programming Guide

This chapter provides useful information about how to do register level programming for PCI-1718 cards.

Sections include:

• Overview

• Programming with the Driver

• Register Programming

• Programming with LabVIEW and

ActiveDAQ

Page 46

Chapter 4 Programming Guide

4.1 Overview

The PCI-1718 cards are delivered with an easy-to-use 32-bit Device

Driver for user programming under the Windows 98/2000/XP operating

systems.

At the Windows driver level, PCI-1718 cards are fully compatible with

the PCL-818 series so you can easily use older applications of the PCL818 series with PCI-1718 cards.We also advise users to program the PCI1718 cards using the 32-bit Device Drivers provided by Advantech to

avoid the complexity of low- level registry programming.

4.2 Programming with the Driver

Your program can perform A/D by writing all the I/O port instructions

directly, or you can take advantage of the PCI-1718 driver. We suggest

that you make use of the driver functions in your program. This will make

you programming job easier and improve your program’s performance.

See the Software Driver User’s Manual for more information.

Start/Advantech Automation/Device Manager/Device Driver’s Manual

4.3 Register Programming.

The most important consideration in programming the PCI-1718 cards at

register level is to understand the function of the card's registers and the

process of programming. The information in the following sections is

provided only for users who would like to do their own low- level programming.

Without the driver you would do the following: perform software trigger,

pacer trigger with interrupt, pacer trigger with interrupt and FIFO, and

program a controlled data transfer.

PCI-1718 Series User Manual 38

Page 47

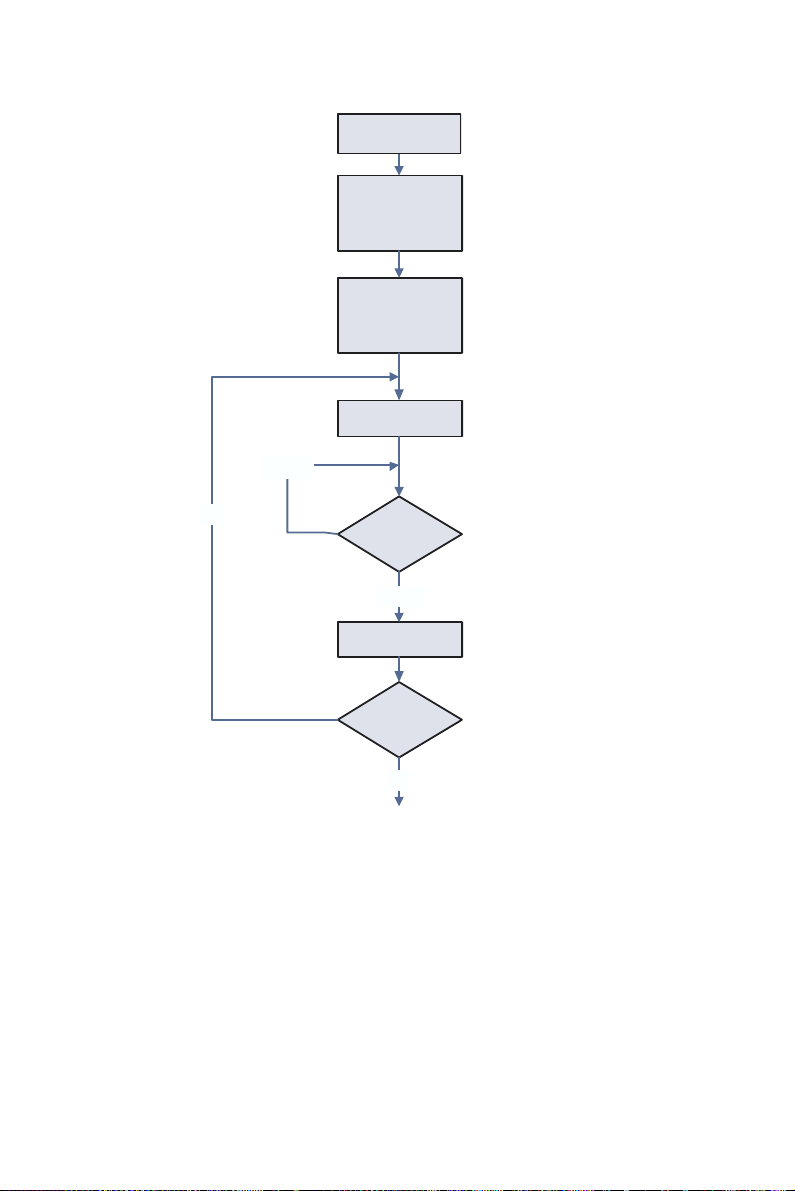

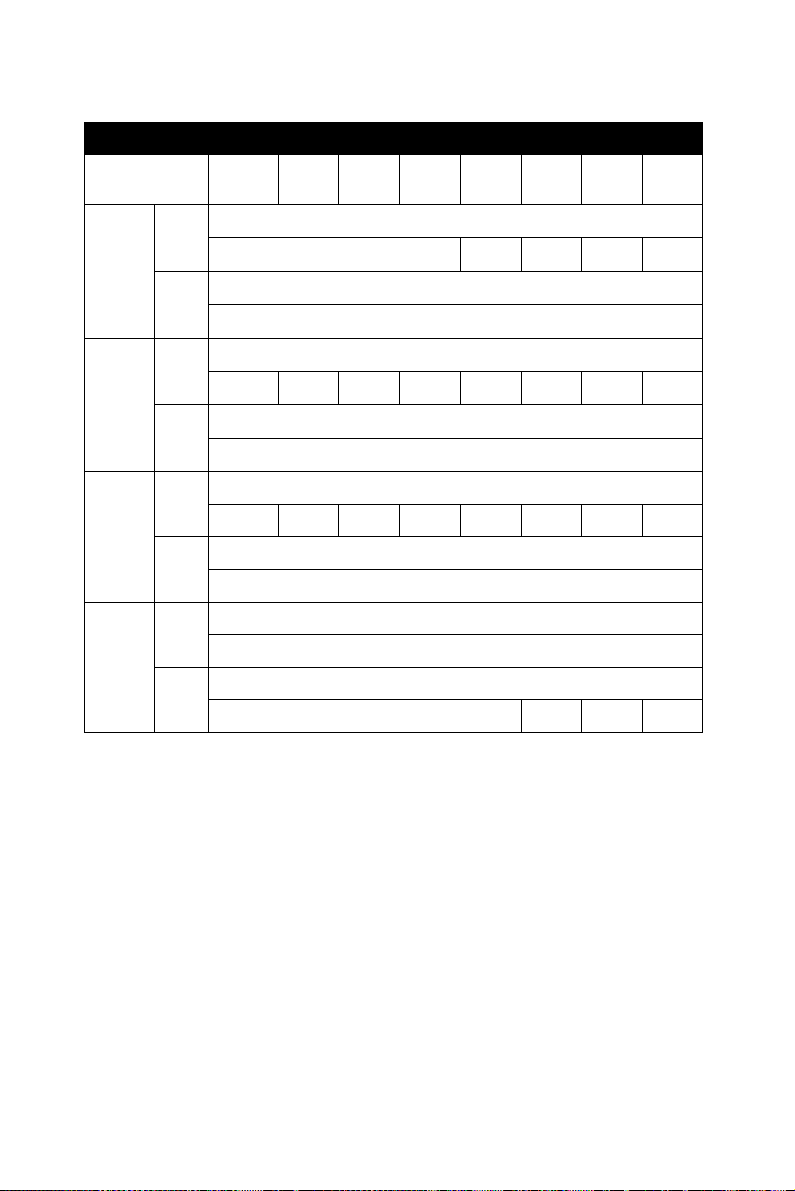

4.3.1 Software Trigger and Polling

Set Scan Channel

w Base+0 2H

Yes

EOC!=0

MUX Scan

Channel Control &

A/D Range

Control

Set Software

Trigger and

Disable Generated

Interrupt

Software A/D

Trigger

Check EOC

EOC=0

Get Data

More Data?

w Base+0 1H

w Base+ 09H

w Base+ 00H

r Base+ 08H

r Base+ 00H

r Base+01H

No

1. Set the input range for each A/D channel

2. Set the input channel by specifying the MUX scan range

3. Trigger the A/D conversion by writing to the A/D low byte register

(BASE+0) with any value.

4. Check for the end of the conversion by reading the A/D status register (BASE+8) EOC bit.

5. Read data from the A/D converter by reading the A/D data register

(BASE+0 and BASE+1)

6. Convert the binary A/D data to an integer.

39 Chapter 4

Page 48

Example Code:

/********This code supports TurboC 3.0 or later versions********/

#include <stdio.h>

#include <DOS.h>

#define AD_NO 4096; // Number of Samples

int base_addr;

void main(void)

{

int ad_lb,ad_hb; //Declaration

int i;

int eoc;

/****** Access your base address ******/

//Add your code here

/*******************************************/

outportb(base_addr+0x02,0x00); //Set Channel 0

outportb(base_addr+0x01,0x00); //Set A/D range

outportb(base_addr+0x02,0x11); //Set Channel 1

outportb(base_addr+0x01,0x01); //Set A/D range

outportb(base_addr+0x02,0x10); //Scan Channel 0-1

outportb(base_addr+0x09,0x00);

while(i<AD_NO){

outportb(base_addr+0x00,0); //Software Trigger

do {eoc=inportb(base_addr+0x08);

eoc=eoc&0x01;//Get EOC}

while(eoc!=0); //Check EOC

ad_lb=inportb(base_addr+0x00);// A/D LowByte

ad_hb=inportb(base_addr+0x01);// A/D HighByte

i++;

}

}

PCI-1718 Series User Manual 40

Page 49

4.3.2 Pacer Trigger Mode with Interrupt

Set to Software

Trigger Mode To

Disable Trigger.

MUX Scan

Channel Control &

A/D Range

Control

Set Scan Channel

Set Pacer Rate

Set ISR

Set To Pacer

Trigger Mode and

Enable Device

Interrupt

Enable System To

Accept Interrupt

w Base+ 09H

w Base+0 2H

w Base+0 1H

w Base+0 2H

Base+0 CH~

Base+0FH

w Base+ 09H

ISR

Get Data

Clear Device

Interrupt Request

Clear System

Device Interrupt

End of ISR

Stop ISR

Set To Software

Trigger Mode To

Disable Trigger

Restore ISR

r Base+ 00H

r Base+01H

w Base+ 08H

w Base+0 9H

Clear Device

Interrupt Request

Clear System

Interrupt Request

Set To Pacer

Trigger Mode To

Enable Trigger

System Ready For

Data Acquisition

w Base+ 08H

w Base+ 09H

Interrupt

Disable Generated

Interrupt

Disable System

To Accept

Interrupt

w Base+0 9H

41 Chapter 4

Page 50

1. Set the input range for each A/D channel

2. Set the input channel by specifying the MUX scan range

3. Set pacer rate and interrupt service routine (ISR)

4. Enable device to generate interrupts and system to accept interrupts

5. Trigger the A/D conversion by writing “1” to the A/D control

register (BASE+9)

6. Interrupts generate by the device when the A/D conversion is

completed.

7. Read data from the A/D converter by reading the A/D data register

(BASE+0 and BASE+1)

8. Convert the binary A/D data to an integer.

Example Code:

/******This code supports TurboC 3.0 or later versions********/

#include <stdio.h>

#include <DOS.h>

void interrupt isr(void);

#define AD_NO 4096; //Number of Samples

int iflag;

int base_addr;

void main(void)

{

int ad_lb,ad_hb; //Declaration

int i=1;

/****** Access your base address ******/

Add you code here

/*******************************************/

outportb(base_addr+9,0x00); //Set Software Trigger and Disable INT.

outportb(base_addr+2,0x00); //Mux Scan Channel Control

outportb(base_addr+1,0x00); //A/D Range Control

PCI-1718 Series User Manual 42

Page 51

/***** Set Pacer *****/

outportb(base_addr+0x0f,0x7E); //Pacer=1M/clk1/clk2

outportb(base_addr+0x0d,0x0A); //clk1

outportb(base_addr+0x0d,0x00); //10=0x0A ; 100=0x64 ;

1000=0x3E8

outportb(base_addr+0x0f,0xBE);

outportb(base_addr+0x0e,0x0A); //clk2

outportb(base_addr+0x0e,0x00);

/***** Pacer=1M/10/10=10k ******/

/***** Set ISR *****/

Add you code here

/********************/

/***** Set Interrupt *****/

Add you code here

/********************/

outportb(base_addr+8,0); //Clear Interrupt

outportb(base_addr+9,0xf3); //Set Pacer Trigger and Enable INT

/***** Ready for Data Acquisition *****/

while(i<AD_NO)

{

while(iflag==0) {;}//Wait for Interrupt

ad_lb=inportb(base_addr+0); //Get A/D LowByte

ad_hb=inprrtb(base_addr+1);//Get A/D HighByte

i++

}

/***** END *****/

}

43 Chapter 4

Page 52

void interrupt isr(void)

{

disable();

/***** Add code on here *****/

iflag = 1; //Interrupt Flag

outportb(base_addr+0x08,0);// Clear Interrupt

/****************************/

outportb(0x20,0x20);

outportb(0xA0,0x20);

enable();

}

PCI-1718 Series User Manual 44

Page 53

4.3.3 Pacer Trigger Mode with Interrupt and FIFO

Set To Software

Trigger Mode To

Disable Trigger

MUX Scan

Channel Control &

A/D Range

Control

Set Scan Channel

Set Pacer Rate

Set ISR

Enable System To

Accept Interrupt

Set Pacer Trigger

and Disable

Generated

Interrupt

Enable FIFO

Interrupt

Clear FIFO

Interrupt Request

Clear System

Interrupt Request

Clear FIFO

w Base+ 09H

w Base+0 2H

w Base+0 1H

w Base+0 2 H

Base+0 CH~

Base+0FH

w Base+0 9H

w Base+0 6H

w Base+ 14H

w Base+ 19H

Start ISR

Get 512

Samples data

(Half-Full of FIFO)

Clear FIFO

Interrupt Request

Clear System

Interrupt request

End of ISR

Stop ISR

Set To Software

Trigger Mode To

Disable Trigger

Restore ISR

Disable Generated

Interrupt

Disable System

To Accept

Interrupt

r Base+ 17H

r Base+18H

w Base+ 14H

w Base+0 9H

w Base+0 9 H

Set To Pacer

Trigger Mode To

Enable Trigger

System Ready For

Data Acquisition

Clear FIFO w Base+ 19H

w Base+ 0AH

Interrupt

45 Chapter 4

Page 54

1. Set the input range for each A/D channel

2. Set the input channel by specifying the MUX scan range

3. Set pacer rate and interrupt service routine (ISR)

4. Enable FIFO to generate interrupts and system to accept interrupts

5. Trigger the A/D conversion by writing “1” to the A/D control

register (BASE+9)

6. Interrupts generate by FIFO when FIFO is half-full.

7. Read data from the A/D converter by reading the FIFO A/D data

register (BASE+17 and BASE+18)

8. Convert the binary A/D data to an integer.

Example Code:

/**********This code supports TurboC 3.0 or later versions********/

#include <stdio.h>

#include <DOS.h>

void interrupt isr(void);

#define AD_NO 4096;

int iflag;

int base_addr;

void main(void)

{

int ad_lb,ad_hb;

int i=1;

int k=0; //FIFO index

/****** Access your base address ******/

Add you code here

/*******************************************/

// Set Software Trigger and Disable Nor INT

outportb(base_addr+0x09,0x00);

PCI-1718 Series User Manual 46

Page 55

outportb(base_addr+0x02,0x00); //MUX Scan Channel Control

outportb(base_addr+0x01,0x03); //Channel 1 Gain Setting

outportb(base_addr+0x02,0x11); // MUX Scan Channel Control

outportb(base_addr+0x01,0x08); // Channel 2 Gain Setting

outportb(base_addr+0x02,0x10); //Scan Channel 0-1

/***** Set Pacer *****/

outportb(base_addr+0x0f,0x7e);

outportb(base_addr+0x0d,10); //Divide By 1

outportb(base_addr+0x0d,0);

outportb(base_addr+0x0f,0xbe);

outportb(base_addr+0x0e,20); //Divide By 2

outportb(base_addr+0x0e,0);

/***** Set ISR *****/

Add your code here

/********************/

/***** Set System Interrupt *****/

Add your code here

/*********************************/

outportb(base_addr+0x09,0x00); // Disable Nor INT and Set Pacer

Trigger

outportb(base_addr+0x06,0x01); // Enable FIFO INT

outportb(base_addr+0x14,0x00); // Clear FIFO Interrupt

/***** Clear System Interrupt*****/

Add you code here

/*********************************/

outportb(base_addr+0x19,0x00); // Clear FIFO

outportb(base_addr+10,0); // Enable Pacer

while(i<=AD_NO)

{

47 Chapter 4

Page 56

while(iflag==0) {;}

/***** FIFO HALF Interrupt and Get Data *****/

for(k=0;k<512;k++)

{

iflag=0;

ad_lb=inportb(base_addr+0x17);

ad_hb=inportb(base_addr+0x18);

/***** Save to Memory *****/

Add your code here

/**************************/

i++;

}

/*******************************************/

}

}

void interrupt isr(void)

{

disable();

iflag = 1;

/***** Add your code here *****/

outportb(base_addr+0x14,0); // Clear FIFO Interrupt

/******************************/

outportb(0x20,0x20);

outportb(0xA0,0x20);

enable();

}

PCI-1718 Series User Manual 48

Page 57

4.4 Programming with LabVIEW and ActiveDAQ

Advantech offers not only a rich set of DLL drivers, but also third-party

driver support and application software to help fully exploit the functions

of your PCI-1718 cards. For more detailed information for these

applications, please refer to:

LabView

Start\Advantech Automation\LabVIEW\LabVIEW Driver's Manual

(To install Labview driver, please access: \CDROM\LabVIEW)

ActiveDAQ

Start\Advantech Automation\ ActiveDAQ \ ActiveDAQ Driver's Manual

(To install ActiveDAQ, please access: \CDROM\ActiveDAQ)

49 Chapter 4

Page 58

PCI-1718 Series User Manual 50

Page 59

2

A

APPENDIX

Specifications

Page 60

Appendix A Specifications

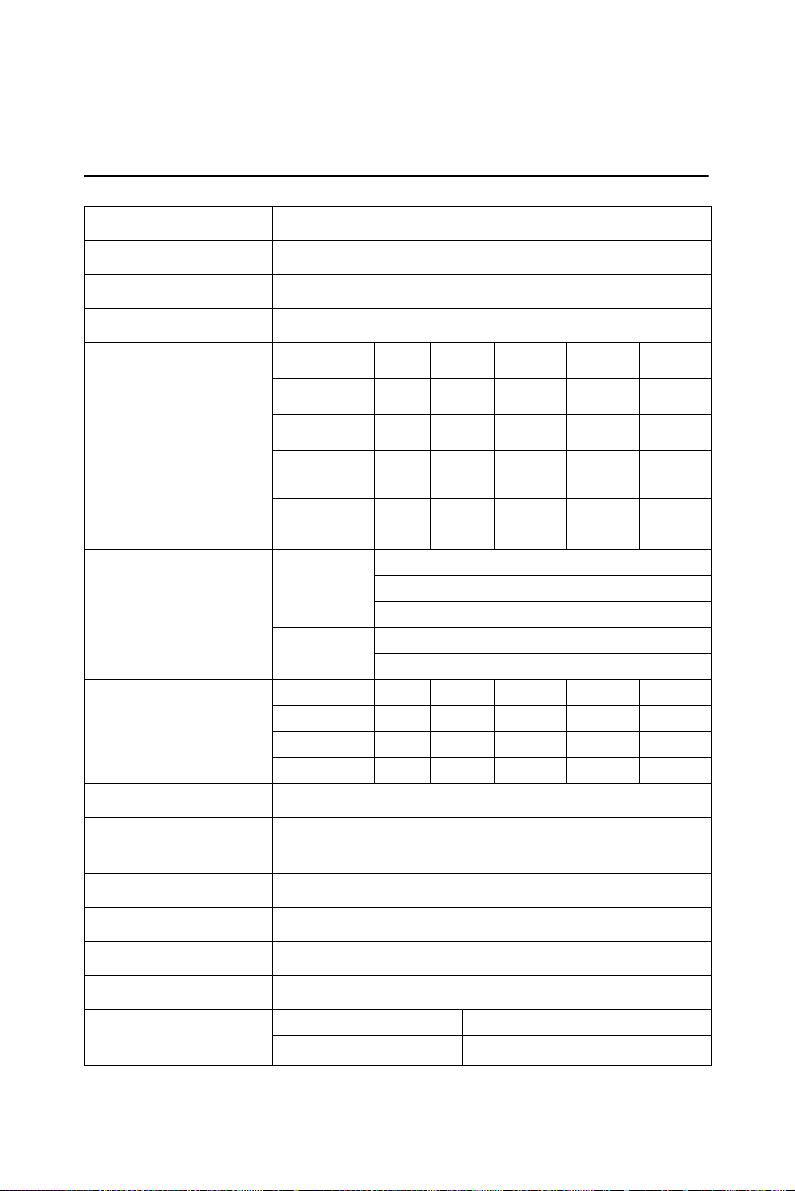

A.1 Analog Input

Channels

Resolution

FIFO Size

Max. Sampling Rate

Input range and

Gain List for PCI1718HDU

PCI-1718HDU

Accuracy

Zero Drift ( µV/°C)

Gain Drift (PPM/°C)

Common Mode

Vol tag e

Max. Input Voltage

Input Protect

Input Impedance

Trigger Mode

External TTL

Trigger Input

16 single-ended or 8 differential or combination

12-bit

1K samples

100 kS/s

Gain 0.5 1 2 4 8

Unipolar N/A 0~10 0~5 0~2.5 0~1.25

Bipolar ±10 ±5 ±2.5 ±1.25 ±0.625

Bandwidth 4

Gain error

(% FSR)

DC DNLE: ±1LSB

AC THD: -80 dB

Range 0~10 0~5 0~2.5 0~1.25

Range ±10 ±5 ±2.5 ±1.25 ±0.625

40

±11 V max. (operational)

±15 V

30 Vp-p

100 MΩ/10pF(Off); 100 MΩ/100pF(On)

Software, on-board Programmable Pacer or External

Low 0.8 V max.

High 2.0 V min.

400

Mhz

kHz

0.01 0.01 0.04

INLE: ±1LSB

Offset error: Adjustable to 0

ENOB: 11 bits

480 240 120 60

160 80 40 20 10

400

kHz

(1LSB)

350

kHz

0.07

(3LSB)

300

kHz

0.1

(4LSB)

PCI-1718 Series User Manual 52

Page 61

A.2 Analog Output

Channels

Resolution

Max. Transfer

Rate

Output Range

(Internal &

External

Reference)

Accuracy

Dynamic

Performance

Driving

Capability

Output

Impedance

1

12-bit

100 kS/s

Using Internal

Reference

Using External

Reference

INLE ±1LSB

DNLE ±1LSB (monotonic)

Offset error Adjustable to ±1 LSB

Gain error Adjustable to ±1 LSB

Slew Rate 10 V / µs

Settling Time 2 µs to 0.01% of FSR

±10mA

0.1 Ω max.

0~+5V,0~+10 V

0 ~ x V @ x V (-10 =< x =< 10)

A.3 Digital Input

Input Channels

Input Voltage

Input Load

16

Low 0.4V max.

High 2.4 V min.

Low 0.4 V max.@ -0.2mA

High 2.7 V min.@20µA

53 Appendix A

Page 62

A.4 Digital Output

Output Channels

Output Voltage

16

Low 0.4 V max.@ +8.0mA (sink)

High 2.4 V min.@ -0.4mA(source)

A.5 Counter/Timer

Counter chip

Channels

Resolution

Compatibility

Base Clock

Max. Input

Frequency

Clock Input

Gate Input

Counter Output

82C54 or equivalent

3 channels, 2 channels are permanently configured as

programmable pacers; 1 channel is free for user application

16-bit

TTL level

Channel 1: 10 MHz

Channel 2: Takes input from output of channel 1

Channel 0: Internal 100 kHz or external clock

(10 MHz max.) selected by software

10 MHz

Low 0.8 V max.

High 2.0 V min.

Low 0.8 V max.

High 2.0 V min.

Low 0.5 V max.@+24 mA

High 2.4 V min.@-15 mA

PCI-1718 Series User Manual 54

Page 63

A.6 General

I/O Connector

Typ e

Dimensions

Power

Consumption

Temperature Operating

Relative Humidity Operating

Certifications

37-pin DSUB female for Analog

One 20-pin Box Header for DI

One 20-pin Box Header for DO

175 x 100 mm (6.9" x 3.9")

Typ ical

Max.

Storage

Storage

CE certified

+5 V @ 850 mA

+5 V @ 1 A

0~60° C (32~158° F)

(refer to IEC 68-2-1,2)

-20~ 70° C (-4~158° F)

5~85%RH non-condensing

(refer to IEC 68-1,-2,-3)

5~95%RH non-condensing

(refer to IEC 68-1,-2,-3)

55 Appendix A

Page 64

PCI-1718 Series User Manual 56

Page 65

2

B

APPENDIX

Block Diagrams

Page 66

Appendix B Block Diagrams

PCI-1718 Series User Manual 58

Page 67

2

C

APPENDIX

Register Structure &

Format

Page 68

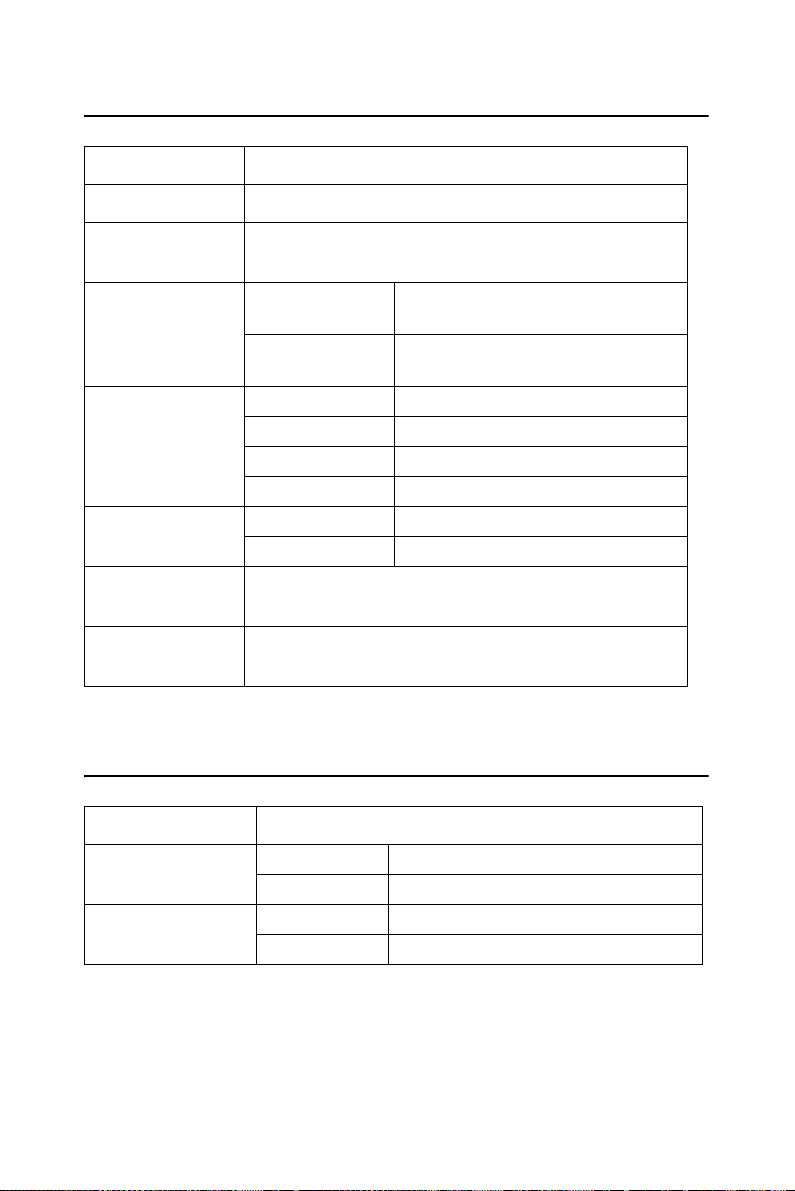

Appendix C Register Structure & Format

C.1 Overview

PCI-1718 cards are delivered with an easy-to-use 32-bit Device Drivers

for user programming under the Windows 98/2000/XP operating systems. We advise users to program the PCI-1718 cards using the 32-bit

Device Drivers provided by Advantech to avoid the complexity of lowlevel registry programming.

The most important consideration in programming the PCI-1718 cards at

the register level is to understand the function of the cards’ registers. The

information in the following sections is provided only for users who

would like to do their own low-level programming.

To get the DOS example programs, please access:

\CDROM\DOS\PCI\1718\

C.2 I/O Port Address Map

PCI-1718 cards require 32 consecutive addresses in the PC's I/O space.

The address of each register is specified as an offset from the card's base

address. For example, BASE+0 is the card's base address and BASE+7 is

the base address plus seven bytes.

Table C.1 shows the function of each register of PCI-1718 or driver, and

its address relative to the card's base address.

PCI-1718 Series User Manual 60

Page 69

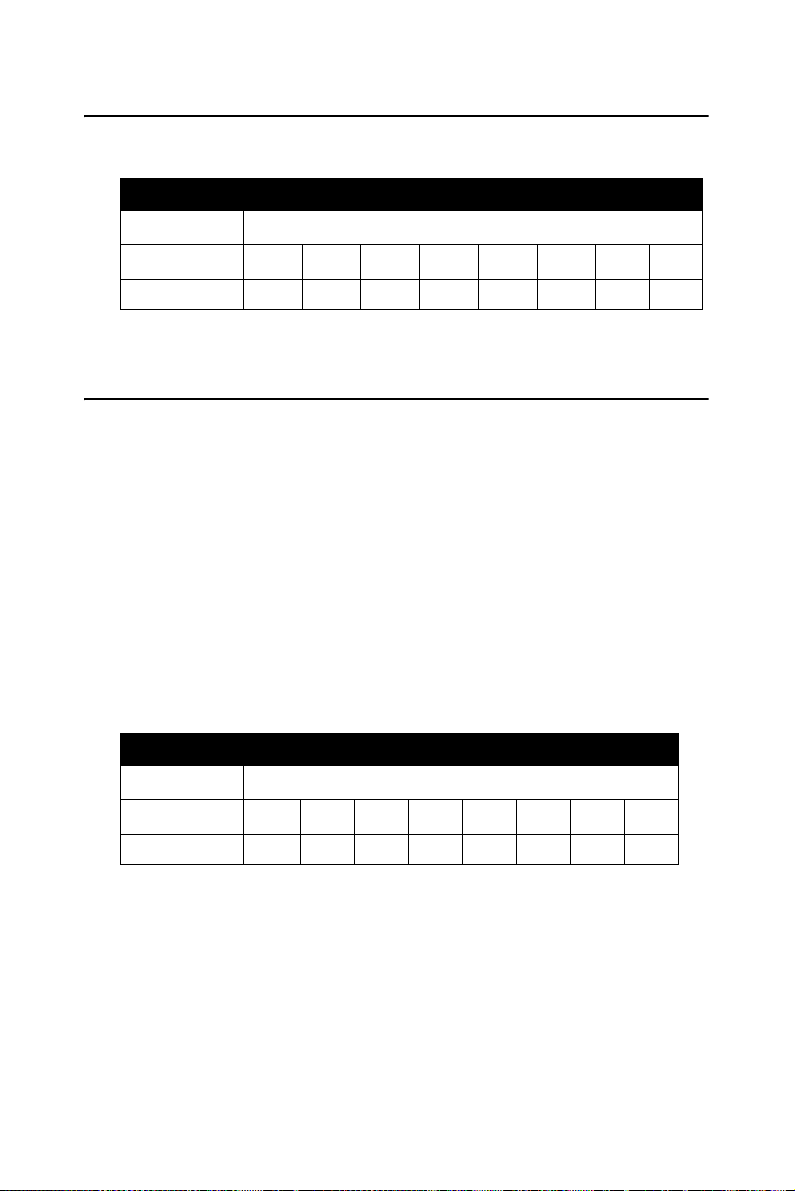

Table C.1: PCI-1718HDU/HGU Register Format (Part 1)

Base Addr.

+HEX

00H

01H

02H

03H

04H

05H

06H

07H

7 6 54 3210

A/D low byte data and channels

R

AD3 AD2 AD1 AD0 C3 C2 C1 C0

Software A/D trigger

W

A/D high byte data and channels

R

AD11 AD10 AD9 AD8 AD7 AD6 AD5 AD4

A/D range control

W

MUX scan channel status

R

MUX scan channel control

W

CH3 CH2 CH1 CH0 CL3 CL2 CL1 CL0

Digital Input (low byte)

R

DI7 DI6 DI5 DI4 DI3 DI2 DI1 DI0

Digital Output (low byte)

W

DO7 DO6 DO5 DO4 DO3 DO2 DO1 DO0

N/A

R

D/A output data

W

DA3 DA2 DA1 DA0

N/A

R

D/A output data

W

DA11 DA10 DA9 DA8 DA7 DA6 DA5 DA4

N/A

R

AD resolution & FIFO interrupt control

W

AD12_16 FINT

N/A

R

N/A

W

G3 G2 G1 G0

CC3 CC2 CC1 CC0

61 Appendix C

Page 70

Table C.2: PCI-1718HDU/HGU Register Format (Part 2)

Base Addr.

+HEX

08H R A/D Status

09H R A/D Control

0AH R N/A

0BH R Digital Input (high byte)

0CH R Counter 0

76 5432 10

EOC U/B MUX INT CN3 CN2 CN1 CN0

W Clear interrupt request

INTE I2 I1 I0 DMAE ST1 ST0

WA/D Control

INTE ST1 ST0

W Timer/Counter Control

DI15 DI14 DI13 DI12 DI11 DI10 DI9 DI8

W Digital Output (high byte)

DO15 DO14 DO13 DO12 DO11 DO10 DO9 DO8

W Counter 0

TC1 TC0

0DH R Counter 1

W Counter 1

Counter 2

R

0EH

0FH

PCI-1718 Series User Manual 62

Counter 2

W

N/A

R

Counter Control

W

Page 71

Table C.3: PCI-1718HDU/HGU Register Format (Part 3)

Base Addr.

+HEX

14H

17H

18H

19H

7 6543210

BoardID

R

ID3ID2ID1ID0

Clear FIFO Interrupt Request

W

A/D data and channels from FIFO

R

AD3 AD2 AD1 AD0 C3 C2 C1 C0

N/A

W

A/D data and channels from FIFO

R

AD11 AD10 AD9 AD8 AD7 AD6 AD5 AD4

N/A

W

FIFO status

R

FIFO clear

W

FF HF EF

63 Appendix C

Page 72

C.3 A/D Data and Channels — BASE+00H~01H

Table C.4: Register for A/D Data and Channels

Read A/D data and channels

Bit # 7 6543210

BASE + 00H AD3 AD2 AD1 AD0 C3 C2 C1 C0

BASE + 01H AD11 AD10 AD9 AD8 AD7 AD6 AD5 AD4

AD11 ~ AD0 Analog to digital data

AD0 The least significant bit (LSB) of the A/D data

AD11 The most significant bit (MSB)

C3 ~ C0 A/D channel number from which the data is derived

C0 The least significant bit (LSB) of the channels

C3 The most significant bit (MSB)

C.4 Software A/D Trigger — BASE+00H

You can trigger an A/D conversion from software, the card's onboard

pacer or an external pulse. If you select software triggering, a write to the

register BASE+00H with any value will trigger an A/D conversion.

Bits 1 and 0 of register BASE+09H select the trigger source. See page 67

for BASE+09H register layout and programming information.

Table C.5: Register for Software A/D Trigger

Write Software A/D trigger

Bit # 7 654321 0

BASE + 00H X X X X X X X X

PCI-1718 Series User Manual 64

Page 73

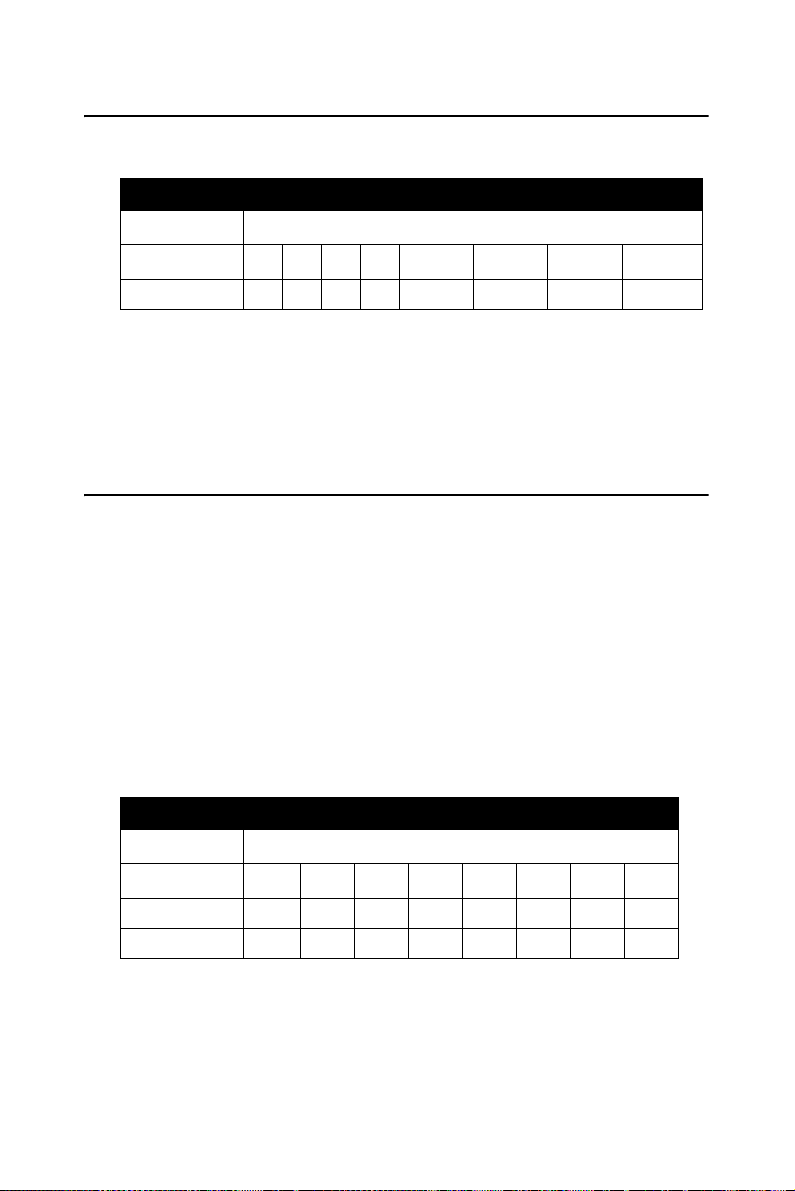

C.5 A/D Range Control — BASE+01H

Each A/D channel has its own individual input range, controlled by a

range code stored in onboard RAM. If you want to change the range code

for a given channel, select the channel as the start channel in register

BASE+02H, MUX scan (described in the next section), then write the

range code to bits 0 to 3 of BASE+01H.

Table C.6: Register for A/D Range Control

Write A/D range control

Bit # 76543210

BASE + 01H XXXXG3*G2*G1G0

G3 ~ G0 A/D range control

G0 The least significant bit (LSB) of the A/D range

G3 The most significant bit (MSB)

Range codes appear below:

PCI-1718HDU

Input Range (V) Unipolar/Bipolar Gain Code

G3 G2 G1 G0

-5 to +5 B 0 0 0 0

-2.5 to +2.5 B 0 0 0 1

-1.25 to +1.25 B 0 0 1 0

-0.625 to +0.625 B 0 0 1 1

0 to 10V U 0 1 0 0

0 to 5V U 0 1 0 1

0 to 2.5V U 0 1 1 0

0 to 1.25V U 0 1 1 1

-10V to +10V B 1 0 0 0

N/A 1 0 0 1

N/A 1 0 1 0

N/A 1 0 1 1

N/A 1 1 0 0

N/A 1 1 0 1

N/A 1 1 1 0

N/A 1 1 1 1

65 Appendix C

Page 74

PCI-1718HGU

Input Range (V) Unipolar/Bipolar

±5V B 0000

±0.5V B 0001

±0.05V B 0 0 1 0

±0.005V B 0011

0 to 10V U 0100

0 to 1V U 0 1 0 1

0 to 0.1V U 0 1 1 0

0 to 0.01V U 0 1 1 1

±10V B 1 0 0 0

±1V B 1001

±0.1V B 1010

±0.01V B 1 0 1 1

N/A 1 1 0 0

N/A 1 1 0 1

N/A 1 1 1 0

N/A 1 1 1 1

Gain Code

G3 G2 G1 G0

Note: G3 and G2 are not used for PCL-818L

PCI-1718 Series User Manual 66

Page 75

C.6 MUX Scan Channel Control — BASE+02H

The write register at BASE+02H controls multiplexer (MUX) scanning.

The high nibble provides the stop scan channel number, and the low nibble provides the start scan channel number. Writing to this register automatically initializes the MUX to the start channel. Each A/D conversion

trigger sets the MUX to the next channel.

With continuous triggering the MUX will scan from the start channel to

the end channel, then repeat. For example, if the start channel is 3 and the

stop channel is 7, then the scan sequence is 3, 4, 5, 6, 7, 3, 4, 5, 6, 7, 3, 4.

Table C.7: Register for MUX Scan Channel Control

Write MUX scan channel control

Bit # 7 6543210

BASE + 02H CH3 CH2 CH1 CH0 CL3 CL2 CL1 CL0

CH3 ~ CH0 Stop scan channel number

CH0 The least significant bit (LSB) of the stop channel

CH3 The most significant bit (MSB)

CL3 ~ CL0 Start scan channel number

CL0 The least significant bit (LSB) of the start channel

CL3 The most significant bit (MSB)

The MUX scan register low nibble, CL3 to CL0, also acts as a pointer

when you program the A/D input range (see previous section). When you

set the MUX start channel to N, the range code written to the register

BASE+01H is for channel N.

Programming example for PCI-1718HDU

This BASIC code fragment sets the range for channel 5 to ±0.625 V:

200 OUT BASE+2, 5 'SET POINTER TO CH.5

210 OUT BASE+1, 3 'RANGE CODE=3 FOR ±0.625 V

Note: The MUX start/stop channel changes each time

you change the input range. Do not forget to reset

the MUX start and stop channels to the correct

values after you finish setting the range.

67 Appendix C

Page 76

C.7 MUX Scan Channel Status — BASE+02H

Read register BASE+02H to get the current multiplexer (MUX) channel.

Table C.8: Register for MUX Scan Channel Status