Page 1

ATI-MFFII Revision 2 Effective Date: 8/5/12

MirroFlex™ Structures

Fabrication and Installation Instructions

MirroFlex™ Structures are decorated thermoplastic sheets with high impact resistance and are

available in a wide variety of patterns and colors. They can be used as a value-added product in areas

that vertical grade High Pressure Laminates (HPL) are typically used.

General

Sizes - 4’ x 8’ x .032” (1220 x 2440 x .8 mm). MirroFlex Structures are also available as 2’ x 2’ and

2’ x 4’ Lay-in (grid) ceilings tiles; 2’ x 2’ and 2’ x 4’ Glue-up tiles; 18” x 24” Backsplash tiles; and 30”32” x 48” Wainscot tiles.

Most product ships with clear protective film or with TuffCote™.

Slight imperfections and color variations from sheet to sheet are possible and considered normal.

Please inspect each sheet carefully before fabrication to insure it meets your needs.

Storing

Store flat and acclimatize in the same environment for at least 24 hours before fabrication.

Cutting/Fabricating

MirroFlex™ Structures can easily be cut to size with razor knife and scissors or with routers, saw

blades, and drilling tools for thermoplastics. When fabricating MirroFlex always cut from the

decorated side.

Lamination

Like HPL, Structures sheets can be bonded with contact cement, but you must use a product

compatible with PVC.

Cleaning and Care

Clean only with warm soapy water. Never use abrasive cleaners.

Molding

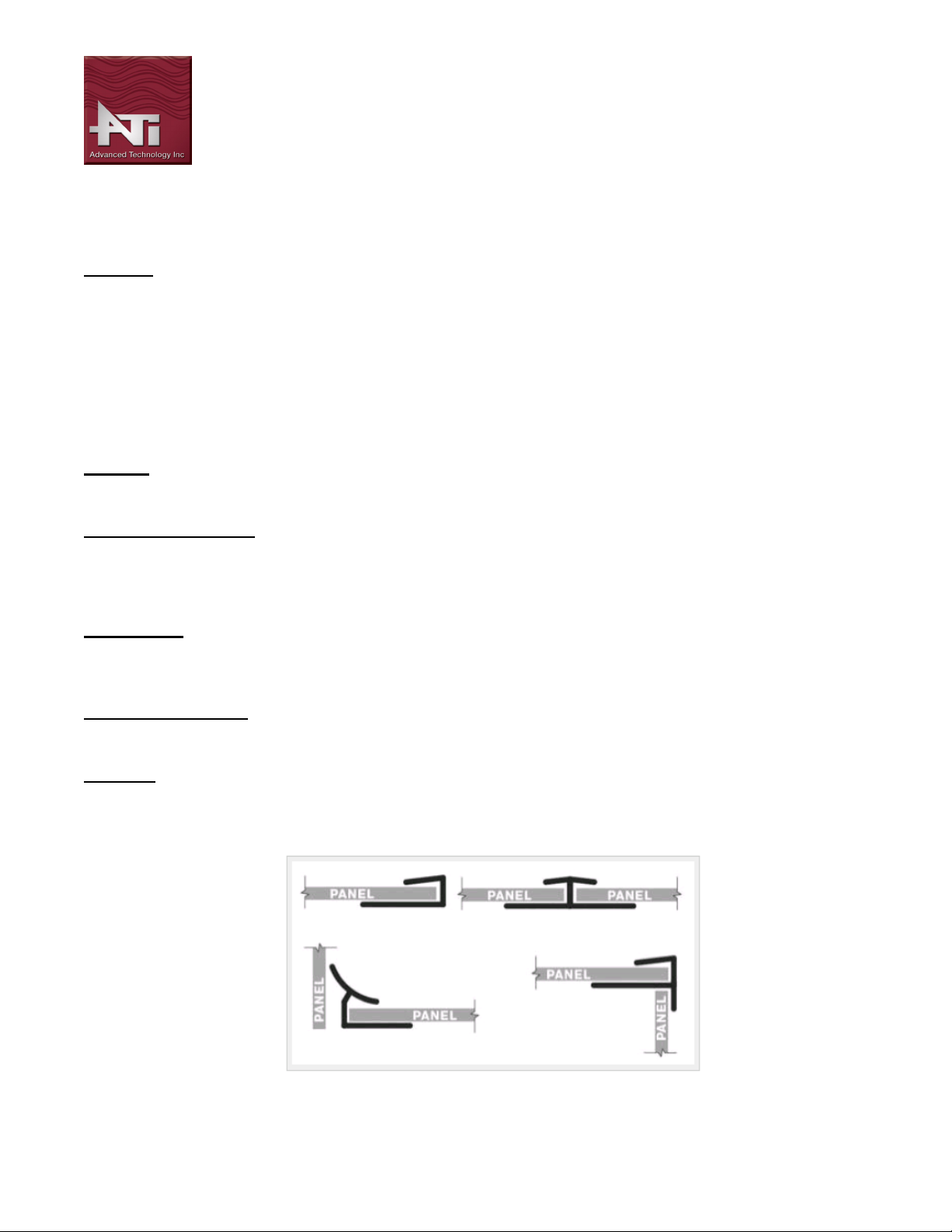

Molding is available to join and finish Structures sheets. Inside corners, outside corners, edge trim

and universal trim strips are shown below.

Trims available in 4’ or 8’ lengths.

Advanced Technology, Inc (800) 849-1320 www.advtechnology.com

Page 1 of 6

Page 2

ATI-MFFII Revision 2 Effective Date: 8/5/12

GridMax™

GridMax is a patented ceiling grid cover system that fits all 15/16 suspension grid systems.

GridMax 4ft Mains, 2&4ft Tees and4ft Wall Covers are available in most MirroFlex Structures

finishes.

BOXES containing enough GridMax cover to do 100 sq. ft. ceilings are available in most Structures

finishes and this is the preferred method of our inventory.

Painting Guide

If a custom color is desired, choose our standard MirroFlex Paintable (white) or EccoFlex Paintable

(beige) finish. Use recommended paints in accordance with manufacturer’s recommendations. Due to

the high chemical resistance of it, only certain paints adhere well. It is very important to use

recommended paints to paint MirroFlex Structures Paintable and EccoFlex Paintable sheets.

The following paints have been tested and are recommended:

MirroFlex Paintable Painting Guide

Vendor Product Prep 1 Prep 2

Sherwin

Williams Acrolon 218HS SSPC-SP1Solvent Cleaner DTM Bonding Primer

Signature Interior

or

Lowes

Benjamin Moore

Pratt & Lambert

American Tradition

Exterior Duramax

Paints

Benjamin Moore

Latex or Oil Paint

Pratt&Lambert

Latex

Paint

EccoFlex Paintable Painting Guide

TSP Cleaner Plastic Primer Spray

TSP Cleaner Fresh Start Primer

Supreme Interior /

Scuff Sanding/TSP Cleaner

Exterior Multi Purpose

Primer

Vendor Product Prep 1 Type

Sherwin

Williams

Sherwin

Williams

Cardinal

* For external applications using Sherwin-Williams Polane Series, use exterior catalyst V66V27. The ratio is 6 parts

paint, one part catalyst.

SuperPaint® or

Duration™ or

similar

Polane™ Series*

or Similar

Polyurethane 6400

Series

Paints Not Recommended: The following types of paints have provided poor adhesion in laboratory

testing. Advanced Technology does not recommend the use of the following paint types for MirroFlex

Paintable or for EccoFlex Paintable: Epoxy Paints, Water-Based Latex Paints, and Oil-Based Enamels.

Even though Advanced Technology has experienced difficulties with the paints listed above, customers

may experience success with these paint types in the field.

Advanced Technology, Inc (800) 849-1320 www.advtechnology.com

Wiping the sheet with

Isopropyl Alcohol (IPA) will

help promote paint

adhesion. To prepare the

surface: EccoFlex sheet

surface can be wiped using

IPA or rubbing alcohol prior

to painting. This method of

treatment helps paint attack

the surface and create a

strong bond to the EccoFlex

sheet.

Brush application

Spray application

Spray application

Page 2 of 6

Page 3

ATI-MFFII Revision 2 Effective Date: 8/5/12

CAUTION: All MirroFlex sheets being applied to surfaces with any recommended adhesive systems

must be acclimatized.

A. All components to be joined must be acclimatized for 24 hours prior to installation.

B. Installation between 65° F and 80° F and humidity of 80% or less is necessary.

C. For every 4-foot wide sheet an expansion space of 1/32” (8-foot sheet = 1/16”) is necessary.

Failure to comply with the above in addition to adhesive manufacturers’ installation instructions may

result in significant installation problems.

Adhesives

Trowel on latex adhesives can be used for adhering MirroFlex sheets to a wall. The following is

meant as a guideline for adhesives:

1. MirroFlex Pressure Sensitive Adhesive Backing - can be supplied to most products. Usually

requires the wall or ceiling to be treated with a contact adhesive to insure proper bond. Some

Tin type (Our Old World Collection) “glue-up” designs work well with this type and are ideally

suited to backsplash applications.

2. MirroFlex Pressure Sensitive Adhesive Rolls (double sided) - bonds

MirroFlex sheets to most surfaces. Each roll contains 40 linear feet x 1½” wide (12.15 meters x

38mm).

3. Contact Adhesives – Brush or roller-on types, non-flammable, and water based contact

adhesives, suitable for PVC, work well. Follow the manufacturer’s instructions carefully before

installation. Spray-on aerosol types like 3M 77 works well.

4. Other Adhesives –

Adhesive Item Raw MDF

Unpainted

Sheetrock

Painted

Sheetrock

Lowes #100575 Poly Premium Poor Acceptable Acceptable

Lowes #164280 PL Latex FRP Good Good Good

Liquid Nails LN 950 Good Very Good Excellent

Liquid Nails FRP-300 Excellent Excellent Excellent

Franklin Woodise Powergrab Good Acceptable Acceptable

Durabond D-745 (Class A Fire Rated)

Very Good Very Good Very Good

DAP Weldwood FRP Very Good Very Good Very Good

Locktite PL Premium (Henkel

Brand) Very Good Very Good Very Good

Locktite PL Premium Advance

(Henkel Brand) Excellent Excellent Excellent

5. Cold Press Adhesives – MirroFlex Structure sheets may be laminated in a cold press using

Wilson Art adhesive 3301 and Wilson Art adhesive3310. Pressure must be adjusted to the

lowest amount that will produce an acceptable bond so that formed pattern will not be

damaged. Pressure needed will vary with each structure pattern.

Advanced Technology, Inc (800) 849-1320 www.advtechnology.com

Page 3 of 6

Page 4

ATI-MFFII Revision 2 Effective Date: 8/5/12

Installations

Glue-Up Ceiling Tiles

1. Before starting the installation, surface must be dry, smooth and free from dust, grease, wax,

and other particles*.

2. Measure the area to be covered to determine how many tiles you will need. Draw a plan to

visualize how the edges and corners will work. When drawing your plan, it is best to center

MirroFlex panels on the ceiling leaving equal margins on opposite sides of the room.

3. Now transfer the plan to the ceiling snapping chalk lines to help you keep the tiles aligned.

4. MirroFlex ceiling tiles should be installed from left to right, starting at the farthest point away

from the room entrance. When overlapping 4 MirroFlex panels, it is necessary to cut a ½” notch

in panel numbers 2 and 3 to avoid an overlap buildup that causes a “bump” (see sketch 2).

Sketch 2

5. Carefully apply the adhesive to the ceiling (or wall for 2’ x 2’ wall applications) and lay up your

first tile applying pressure as you hold it. (If installing a tile with protective masking, you can

remove it at this step of the installation. Make sure the tile is straight before you continue with

the next one.

6. Repeat this process, working left to right (and removing the protective masking after installing

each panel, if applicable). When finished, use a paint roller on an extension pole to apply

additional pressure to the ceiling. Filler strips can be installed around the perimeter of the room

if desired.

* The method you choose for cleaning prior to application must be compatible with the surface you are cleaning

(e.g. denatured alcohol, degreaser, soap & water, TSP, Greased Lightning, etc.). Check the manufacturer’s label

directions for instructions on using the product.

Advanced Technology, Inc (800) 849-1320 www.advtechnology.com

Page 4 of 6

Page 5

ATI-MFFII Revision 2 Effective Date: 8/5/12

Lay-In Ceiling Tiles

1. Count how many tiles you will need for the installation. For panels that need to be trimmed, use

the mineral tile as a template and using your marker and utility knife (razor, scissors, etc.) score

the MirroFlex tile to size and then snap the pieces apart.

2. Install the Grid Max covers to the t-bar suspension grid to allow for a seamless look on your

ceiling. Be sure to install all the 4 foot Main covers first and then install the 2 foot or 4 foot Tee

covers. The Main covers already come with sections notched out where the Tee grid crosses

under it.

3. After all the covers are in place, begin to install all the panels into the suspension grid.

4. If making room for a ceiling lamp, be sure to cut out an opening on the tile where the lamp will

be attached.

Backsplashes

1. Before starting the installation, surface must be dry, smooth and free from dust, grease, wax,

and other particles*.

1. Measure the area to be covered horizontally to determine how many tiles and how many

adhesive rolls you will need across (if using adhesive strips) and then measure the height of

your backsplash to determine if any trimming is necessary.

2. Apply desired method of adhesive, according to manufacturer’s instructions.

3. Starting at the left side of your backsplash, place tiles with some pressure to ensure a strong

hold. (Be sure to remove protective masking if your tiles came with one). As you work from left

to right you want to make sure that the flat edge is always on the right.

4. Make sure to apply a bit of your selected adhesive over the flat edge and the wall between tiles

for extra hold.

5. Carefully apply your second tile making sure to line them up correctly and apply pressure to the

tile for a strong bond.

6. Continue this process until you reach the last tile. Depending on the size of your backsplash,

you may need to cut the last tile to fit. If so, measure the area and the tile and then use your

straight edge and marker to mark the cut line. Using your scissors or utility knife, cut firmly on

the decorative side of the tile and snap the pieces apart—note: if your tiles came with protective

masking you must cut from the backside.

* The method you choose for cleaning prior to application must be compatible with the surface you are cleaning

(e.g. denatured alcohol, degreaser, soap & water, TSP, Greased Lightning, etc.). Check the manufacturer’s label

directions for instructions on using the product.

Advanced Technology, Inc (800) 849-1320 www.advtechnology.com

Page 5 of 6

Page 6

ATI-MFFII Revision 2 Effective Date: 8/5/12

4’ x 8’ Wall Panels

1. Before starting the installation, surface must be dry, smooth and free from dust, grease, wax,

and other particles*.

1. Measure the area to be covered to determine how many panels you will need.

2. MirroFlex wall panels should be installed from left to right, making sure the small flats of the

panel are to the top and right (if your panel has Built-in-Overlap or BIO). After applying your

selected adhesive to the wall, according to manufacturer’s instructions, lay up your first tile

applying pressure as you hold it (if your panel came with protective masking, gently remove it

now). Make sure the panel is straight before you continue with the next one.

3. Repeat this process, working left to right (removing the protective masking after installing each

panel, if your tile came with masking). When finished, use the paint roller on an extension pole

to apply additional pressure to the wall.

* The method you choose for cleaning prior to application must be compatible with the surface you are cleaning

(e.g. denatured alcohol, degreaser, soap & water, TSP, Greased Lightning, etc.). Check the manufacturer’s label

directions for instructions on using the product.

Outlet Covers

1. Some outlet covers (simple, inexpensive) can be covered with matching covers. To do this, peel

the backing off of the outlet cover piece and lay flat, placing the sticky side up. Place the outlet

cover centered and face down on the adhesive sheet. Using a utility knife, cut a square away

from each corner. Fold the edge of the adhesive sheet over the outlet cover to create a

seamless finish. Turn the cover over, and use a utility knife to carefully cut away the outlet

openings.

Installation Videos

MirroFlex Structures Installation Videos can be found on our website at

www.advtechnology.com/how-to-install

Conditions & Warranty

Advanced Technology, Inc. believes all information contained herein to be correct. It is the

responsibility of the fabricator/customer to completely test the adhesives and methods of fabrication to

ensure that the results are satisfactory. ATI is not responsible for any fabrication or ancillary costs

involved with using MirroFlex products.

All shipments are to be inspected within 10 working days after delivery. We are to be informed in writing

of any potential adjustment necessary. The seller’s only obligation will be to replace defective sheets on

a one to one basis. Neither the manufacturer nor the seller shall be liable for any additional damage or

loss, directly or indirectly, arising as a result of using MirroFlex products.

Slight imperfections and color variations from sheet to sheet are possible and considered normal.

Please inspect each sheet carefully before fabrication to ensure it meets your needs.

Visit us online at advtechnology.com for the latest patterns and finishes.

Advanced Technology, Inc (800) 849-1320 www.advtechnology.com

Page 6 of 6

Loading...

Loading...