Advanced Power Technology APT ARF1502 Datasheet

DGSS

RF POWER MOSFET

DSS

ARF1500

BeO 135-05

GSS

SS

ARF1502

D

G

S

N - CHANNEL ENHANCEMENT MODE 65V 1500W 40MHz

The ARF1500 is an RF power transistor designed for class C/E operation in very high power scientific, commercial,

medical and industrial RF power generator and amplifier applications up to 40 MHz.

Specified 65 Volt, 27.12 MHz Characteristics:

Output Power = 900 Watts.

Gain = 17dB (Class C)

Efficiency > 75%

MAXIMUM RATINGS All Ratings: TC = 25°C unless otherwise specified.

High Performance Power RF Package.

Very High Breakdown for Improved Ruggedness.

Low Thermal Resistance.

Nitride Passivated Die for Improved Reliability.

Symbol

V

DSS

V

DGO

I

V

P

TJ,T

T

Parameter

Drain-Source Voltage

Drain-Gate Voltage

Continuous Drain Current @ T

D

Gate-Source Voltage

GS

Total Device Dissipation @ T

D

Operating and Storage Junction Temperature Range

STG

Lead Temperature: 0.063" from Case for 10 Sec.

L

= 25°C

C

= 25°C

C

STATIC ELECTRICAL CHARACTERISTICS

Symbol

BV

DSS

V

(ON)

DS

I

DSS

I

GSS

g

fs

V

isolation

V

(TH)

GS

Characteristic / Test Conditions

Drain-Source Breakdown Voltage (V

On State Drain Voltage

Zero Gate Voltage Drain Current (V

Zero Gate Voltage Drain Current (V

Gate-Source Leakage Current (VGS = ±30V, V

Forward Transconductance (V

RMS Voltage

Gate Threshold Voltage (VDS = VGS, ID = 50mA)

ADVANCED

1

(I

= 35A, VGS = 10V)

(ON)

D

DS

DS

INFORMATION

= 25V, ID = 35A)

DS

(60Hz Sinewave from terminals to mounting surface for 1 minute)

= 0V, ID = 250 µA)

GS

= V

, VGS = 0V)

DSS

= 0.8 V

, VGS = 0V, TC = 125°C)

DSS

= 0V)

DS

ARF 1500

UNIT

200

200

Volts

70

±30

1500

Amps

Volts

Watts

-55 to 200

300

MIN TYP MAX

°C

UNIT

200

4.0

Volts

100

1000

±400

811

2500

µA

nA

mhos

Volts

35

Volts

THERMAL CHARACTERISTICS

Symbol

R

R

USA: 405 S.W. Columbia Street Bend, Oregon 97702 -1035 Phone: (541) 382-8028 FAX: (541) 388-0364

EUROPE: Chemin de Magret F-33700 Merignac - France Phone: (33) 5 57 92 15 15 FAX: (33) 5 56 47 97 61

Characteristic (per package unless otherwise noted)

Junction to Case

θJC

Case to Sink

θCS

CAUTION: These Devices are Sensitive to Electrostatic Discharge. Proper Handling Procedures Should Be Followed.

(Use High Efficiency Thermal Joint Compound and Planar Heat Sink Surface.)

APT Website - http://www.advancedpower.com

MIN TYP MAX

0.09

0.12

UNIT

°C/W

050-5600 Rev - 7-01

DYNAMIC CHARACTERISTICS

ARF1502

Symbol

C

iss

C

oss

C

rss

t

d(on)

t

r

t

d(off)

t

f

Characteristic

Input Capacitance

Output Capacitance

Reverse Transfer Capacitance

Turn-on Delay Time

Rise Time

Turn-off Delay Time

Fall Time

Test Conditions

V

= 0V

GS

VDS = 50 V

f = 1 MHz

VGS = 15 V

VDD = 0.5 V

ID = I

D[Cont.]

R

= 1.6 Ω

G

@ 25°C

DSS

FUNCTIONAL CHARACTERISTICS

Symbol

G

η

ψ

1

Pulse Test: Pulse width < 380 µS, Duty Cycle < 2%.

APT Reserves the right to change, without notice, the specifications and information contained herein.

PS

Characteristic

Common Source Amplifier Power Gain

Drain Efficiency

Electrical Ruggedness VSWR 10:1

Test Conditions

f = 27.12 MHz

= 0V VDD = 65V

V

GS

= 900W

P

out

MIN TYP MAX

UNIT

4820 6000

800 1100

pF

210 290

510

3.0 7

ns

15 25

37

MIN TYP MAX

15 17

70 75

UNIT

dB

%

No Degradation in Output Power

G

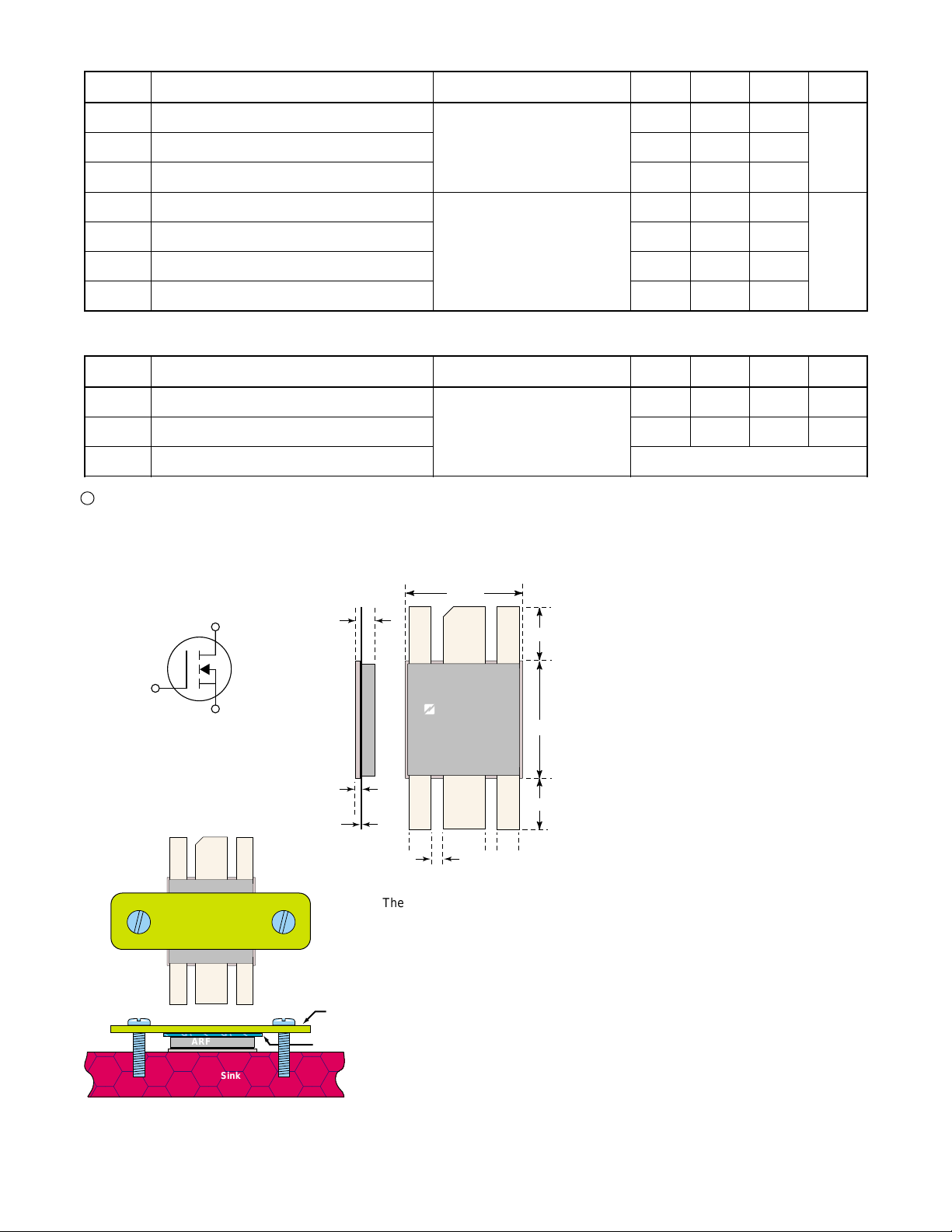

dims: inches

ARF 1500

Heat Sink

1.065

D

S

.160

ADVANCED

.045

.005

INFORMATION

Clamp

Compliant

layer

.207 .207.375

Thermal Considerations and Package Mounting:

The rated 1500W power dissipation is only available when the package mounting

surface is at 25˚C and the junction temperature is 200˚C. The thermal resistance

between junctions and case mounting surface is 0.12 ˚C/W. When installed, an additional thermal impedance of 0.09 ˚C/W between the package base and the mounting

surface is typical. Insure that the mounting surface is smooth and flat. Thermal joint

compound must be used to reduce the effects of small surface irregularities. The heatsink should incorporate a copper heat spreader to obtain best results.

The package is designed to be clamped to a heatsink. A clamped joint maintains the

required mounting pressure while allowing for thermal expansion of both the device

and the heat sink. A simple clamp, a compliant layer of plastic or rubber, and two 6-32

(M3.5) screws can provide the minimum 85 lb required mounting force. T = 6 in-lb.

D

D SS

ARF1500

BeO 135-05

G

G

.105 typ.

SS

.500

1.065

SS

SS

.500

HAZARDOUS MATERIAL

WARNING

The ceramic portion of the

device between leads and

mounting surface is beryllium

oxide. Beryllium oxide dust is

highly toxic when inhaled. Care

must be taken during handling

and mounting to avoid damage

to this area. These devices

must never be thrown away with

general industrial or domestic

waste.

050-5600 Rev - 7-01

Loading...

Loading...