http://www.BDTIC.com/AMS

Advanced AMS2907

Monolithic 500mA LOW DROPOUT VOLTAGE REGULATOR

Systems

RoHS compliant

FEATURES APPLICATIONS

•••• Three Terminal Adjustable or Fixed Voltages* •••• High Efficiency Linear Regulators

1.5V, 1.8V, 2.5V, 2.85V, 3.3V and 5.0V

• Output Current of 500mA •••• 5V to 3.3V Linear Regulator

•

•

•

•••• Operates Down to 1V Dropout •••• Battery Chargers

•••• Line Regulation: 0.2% Max. •••• Sound Cards

•••• Load Regulation: 0.4% Max. •••• Power Management for Notebook

•••• TO-252, SOT-223 and SOT-89 packages •••• Battery Powered Instrumentation

GENERAL DESCRIPTION

The AMS2907 series of adjustable and fixed voltage regulators are designed to provide 500mA output current and to operate

own to 1V input-to-output differential. The dropout voltage of the device is guaranteed maximum 1.3V at maximum output

d

current, decreasing at lower load currents.

On-chip trimming adjusts the reference voltage to 1%. Current limit is also trimmed, minimizing the stress under overload

conditions on both the regulator and power source circuitry.

The AMS2907 devices are pin compatible with other three-terminal regulators and are offered in the low profile surface mount

TO-252(DPAK), SOT-223 and SOT-89 packages.

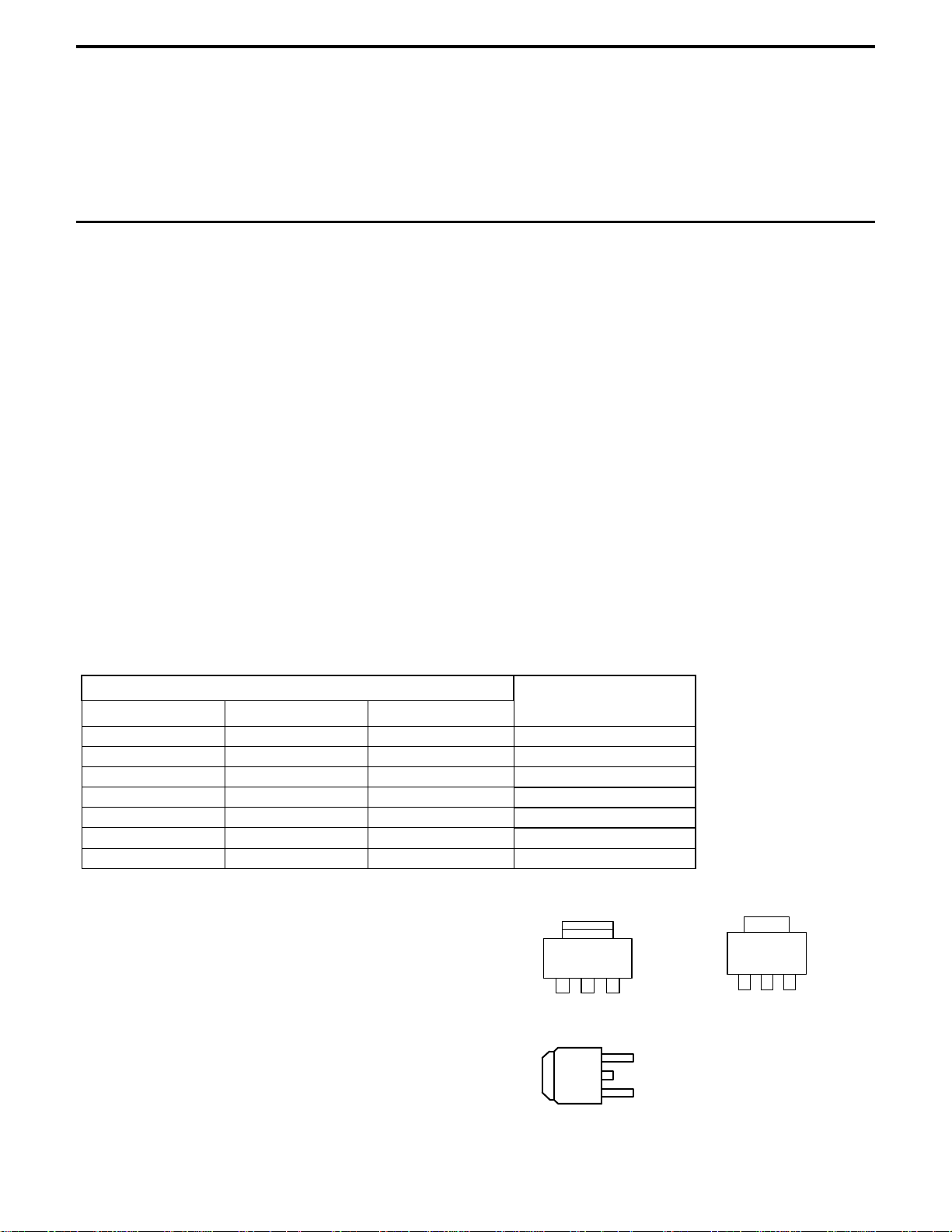

ORDERING INFORMATION:

SOT-89 TO-252 SOT-223

PACKAGE TYPE O

AMS2907CL AMS2907CD AMS2907

AMS2907CL-1.5 AMS2907CD-1.5 AMS2907-1.5

AMS2907CL-1.8 AMS2907CD-1.8 AMS2907-1.8

AMS2907CL-2.5 AMS2907CD-2.5 AMS2907-2.5

AMS2907CL-2.85 AMS2907CD-2.85 AMS2907-2.85

AMS2907CL-3.3 AMS2907CD-3.3 AMS2907-3.3

AMS2907CL-5.0 AMS2907CD-5.0 AMS2907-5.0

*For additional available fixed voltages contact factory.

PIN CONNECTIONS

FIXED VERSION

1- Ground

2- VIN

V

OUT

3-

ADJUSTABLE VERSION

1- Adjust

2- VIN

3- V

OUT

•••• Post Regulators for Switching Supplies

PERATING JUNCTION

TEMPERATURE RANGE

-40 to 125° C

-40 to 125° C

-40 to 125° C

-40 to 125° C

-40 to 125° C

-40 to 125° C

-40 to 125° C

SOT-223 Top View

1

2

3

TO-252 Front View

3

2

1

SOT-89 Top View

321

updated April 24, 2009

http://www.BDTIC.com/AMS

AMS2907

ABSOLUTE MAXIMUM RATINGS (Note 1)

Power Dissipation Internally limited

OPERATING CONDITIONS (Note 1)

Maximum Input Voltage 15V Input Voltage Range 2.6V to 12V

Thermal Resistance Junction Temperature

SOT-89 package

TO-252 package

SOT-223 package

Storage temperature

ϕ JA= 110°C/W

ϕ JA= 80°C/W

ϕ JA= 90°C/W*

65°C to +150°C

-

Control Section -40ºC to 125 ºC

Power Transistor -40ºC to 150 ºC

Lead Temperature (Sold. 25 sec) 265 ºC

* With package soldering to copper area over backside ground

plane or internal power plane ϕ

46°C/W to >90°C/W depending on mounting technique and the

size of the copper area.

can vary from

JA

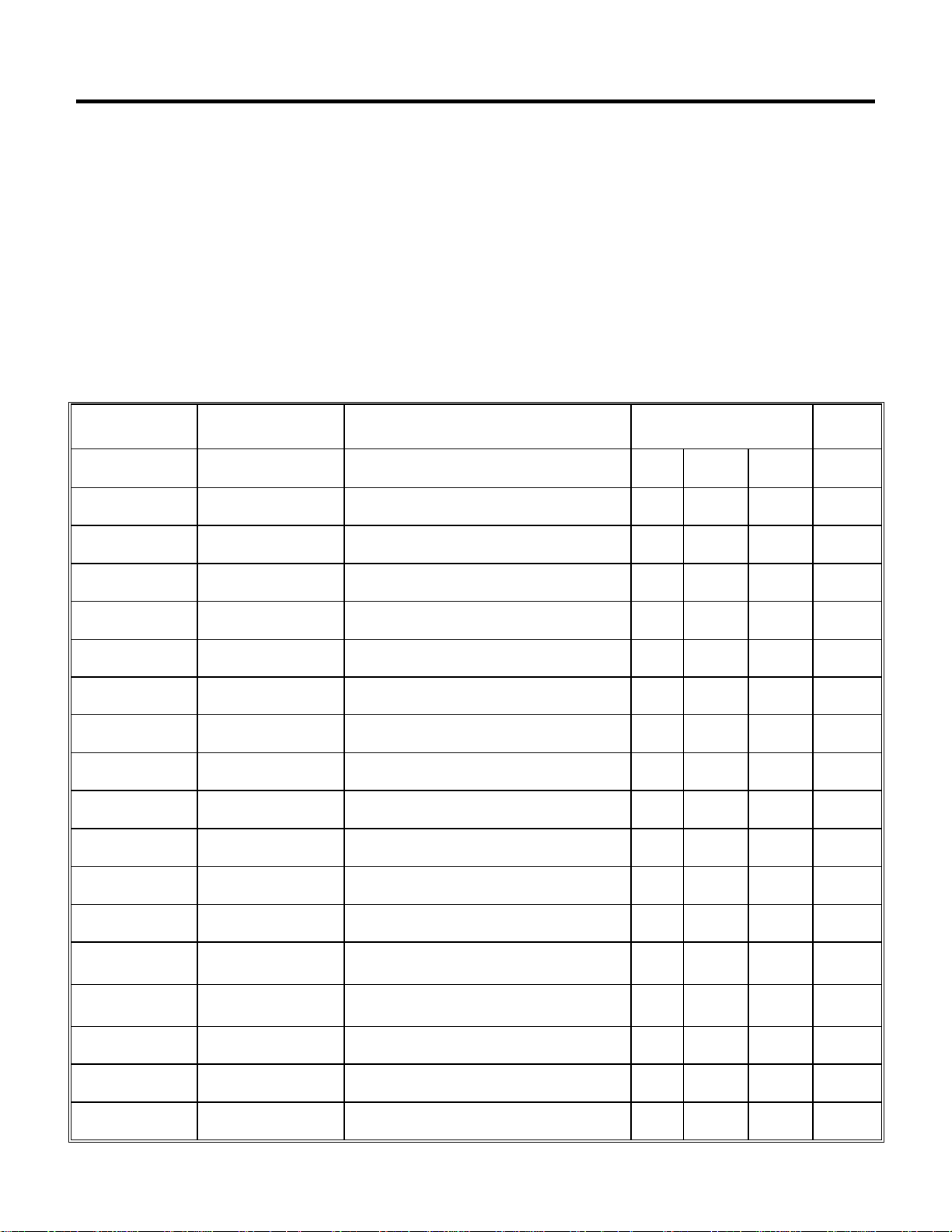

ELECTRICAL CHARACTERISTICS

Electrical Characteristics at I

= 0 mA, and TJ = +25°C unless otherwise specified.

OUT

Parameter

Device Conditions Min Typ Max Units

Reference Voltage

(Note 2)

Output Voltage

(Note 2)

Line Regulation AMS2907

AMS2907-1.5

AMS2907-1.8

AMS2907-2.5

AMS2907-2.85

AMS2907-3.3

AMS2907-5.0

Load Regulation

(Notes 2, 3)

AMS2907-1.5

AMS2907-1.8

AMS2907-2.5

AMS2907 I

AMS2907-1.5

AMS2907-1.8

AMS2907-2.5

AMS2907-2.85

AMS2907-3.3

AMS2907-5.0

AMS2907

= 10 mA

OUT

10mA ≤ I

0 ≤ I

0 ≤ I

0 ≤ I

0 ≤ I

0 ≤ I

0 ≤ I

I

LOAD

3.0V≤ VIN ≤ 12V

3.0V≤ VIN ≤ 12V

4.0V≤ VIN ≤ 12V

4.35V≤ VIN ≤ 12V

4.75V≤ VIN ≤ 12V

6.5V≤ VIN ≤ 12V

(VIN - V

VIN = 5V, 0 ≤ I

VIN = 5V, 0 ≤ I

VIN = 5V, 0 ≤ I

≤ 500mA, 1.5V≤ (VIN - V

OUT

≤ 500mA , 4.35V≤ VIN ≤ 12V

OUT

≤ 500mA , 4.35V≤ VIN ≤ 12V

OUT

≤ 500mA , 4.35V≤ VIN ≤ 12V

OUT

≤ 500mA , 4.35V≤ VIN ≤ 12V

OUT

≤ 500mA , 4.75V ≤ VIN ≤ 12V

OUT

≤ 500mA , 6.5V ≤ VIN ≤ 12V

OUT

= 10 mA , 1.5V≤ (VIN - V

) =3V, 10mA ≤ I

OUT

≤ 500mA

OUT

≤ 500mA

OUT

≤ 500mA

OUT

OUT

≤ 500mA

OUT

OUT

) ≤ 12V

) ≤ 12V

updated April 24, 2009

1.238

1.225

1.485

1.476

1.782

1.772

2.475

2.460

2.82

2.79

3.267

3.235

4.950

4.900

0.015

0.3

0.3

0.3

0.3

0.5

0.5

3

3

3

1.250

1.250

1.500

1.500

1.800

1.800

2.500

2.500

2.850

2.850

3.300

3.300

5.000

5.000

0.035

0.6

0.6

0.6

0.6

1.0

1.0

0.1

0.2

6

6

6

1.262

1.270

1.515

1.524

1.818

1.828

2.525

2.560

2.88

2.91

3.333

3.365

5.050

5.100

0.2

0.2

5

6

5

6

6

6

6

6

10

10

10

10

0.3

0.4

10

20

11

20

12

20

V

V

V

V

V

V

V

V

V

V

V

V

V

V

%

%

mV

mV

mV

mV

mV

mV

mV

mV

mV

mV

mV

mV

%

%

mV

mV

mV

mV

mV

mV

http://www.BDTIC.com/AMS

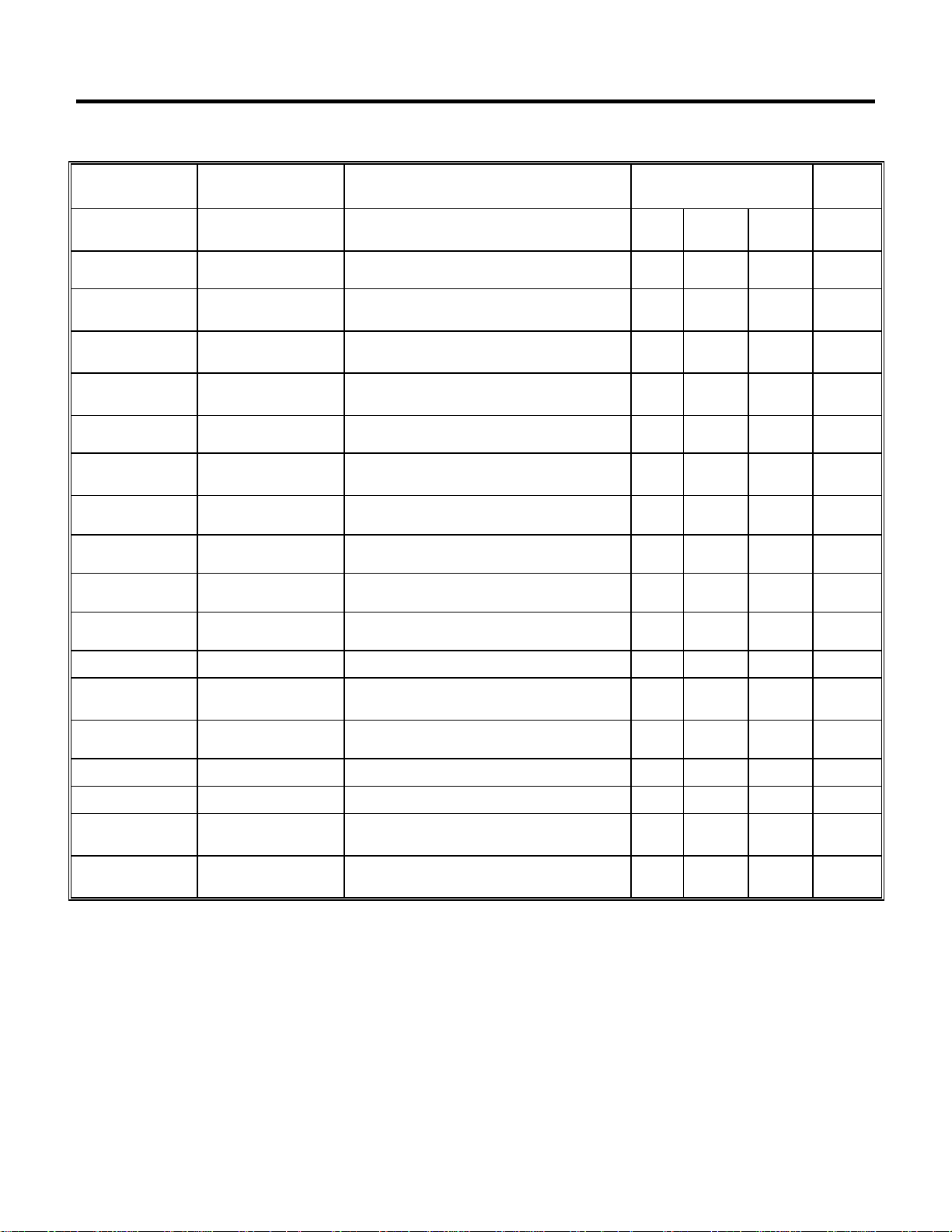

ELECTRICAL CHARACTERISTICS

Electrical Characteristics at I

= 0 mA, and TJ = +25°C unless otherwise specified.

OUT

AMS2907

Parameter

Device Conditions Min Typ Max Units

Load Regulation

(Notes 2, 3)

AMS2907-5.0

Dropout Voltage

(V

- V

OUT

)

IN

Current Limit

Minimum Load

Current

Quiescent Current AMS2907-1.5/-1.8/-2.5/-

Ripple Rejection AMS2907

AMS2907-3.3

AMS2907-5.0

Thermal Regulation AMS2907 TA = 25°C, 30ms pulse 0.008 0.04 %W

AMS2907-2.85

AMS2907-3.3

VIN = 5V, 0 ≤ I

VIN = 5V, 0 ≤ I

VIN = 8V, 0 ≤ I

AMS2907-1.5/-1.8/-2.5/-

2.85/-3.3/-5.0

AMS2907-1.5/-1.8/-2.5/-

2.85/-3.3/-5.0

∆V

OUT

(VIN - V

AMS2907 (VIN - V

VIN ≤ 12V

2.85/-3.3/-5.0

f =120Hz , C

(VIN-V

AMS2907-1.5/ -1.8/ -2.5

/-2.85

f =120Hz , C

VIN = 6V

f =120Hz , C

VIN = 6.3V

f =120Hz , C

VIN = 8V

≤ 500mA

OUT

≤ 500mA

OUT

≤ 500mA

OUT

, ∆V

= 1%, I

REF

) = 5V

OUT

) = 12V (Note 5)

OUT

= 25µF Tantalum, I

OUT

) = 3V, C

OUT

= 25µF Tantalum, I

OUT

= 25µF Tantalum, I

OUT

= 25µF Tantalum, I

OUT

= 500mA (Note 4)

OUT

=25µF

ADJ

= 500mA,

OUT

= 500mA,

OUT

= 500mA

OUT

= 500mA

OUT

3

6

3

7

5

10

1.1 1.3

1,000

5 10

5

60 75

60

72

60 72

60 68

12

20

15

25

20

35

10

dB

mV

mV

mV

mV

mV

mV

V

mA

mA

mA

dB

dB

dB

Adjust Pin Current AMS2907

Adjust Pin Current

AMS2907

Change

Temperature Stability

10mA ≤ I

10mA ≤ I

≤ 500mA , 1.5V≤ (VIN - V

OUT

≤ 500mA , 1.5V≤ (VIN - V

OUT

OUT

OUT

) ≤ 12V

) ≤ 12V

55

0.2

0.5

120

5

µA

µA

µA

%

Long Term Stability TA =125°C, 1000Hrs 0.3 1 %

RMS Output Noise

(% of V

OUT

)

Thermal Resistance

Junction-to-Case

TA = 25°C , 10Hz ≤ f ≤ 10kHz

0.003

15 °C/W

%

Parameters identified with boldface type apply over the full operating temperature range.

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. For guaranteed specifications and test conditions, see the

Electrical Characteristics. The guaranteed specifications apply only for the test conditions listed.

Note 2: Line and Load regulation are guaranteed up to the maximum power dissipation of 1.2W for SOT-223 package and 0.9W for SOT-89 package. Power

dissipation is determined by the input/output differential and the output current. Guaranteed maximum power dissipation will not be available over the full

input/output range.

Note 3: See thermal regulation specifications for changes in output voltage due to heating effects. Line and load regulation are measured at a constant

junction temperature by low duty cycle pulse testing. Load regulation is measured at the output lead ~1/8” from the package.

Note 4: Dropout voltage is specified over the full output current range of the device.

Note 5: Minimum load current is defined as the minimum output current required to

guaranteed to regulate if the output current is greater than 10mA.

maintain regulation. When 1.5V ≤ (VIN - V

) ≤ 12V the device is

OUT

updated April 24, 2009

http://www.BDTIC.com/AMS

APPLICATION HINTS

The AMS2907 series of adjustable and fixed regulators are easy to

use and are protected against short circuit and thermal overloads.

Thermal protection circuitry will shut-down the regulator should

the junction temperature exceed 165°C at the sense point.

Pin compatible with older three terminal adjustable regulators,

these devices offer the advantage of a lower dropout voltage, more

precise reference tolerance and improved reference stability with

temperature.

Stability

The circuit design used in the AMS2907 series requires the use of

an output capacitor as part of the device frequency compensation.

The addition of 150µF aluminum electrolytic or a 22µF

tantalum on the output will ensure stability for all operating

conditions.

When the adjustment terminal is bypassed with a capacitor to

improve the ripple rejection, the requirement for an output

capacitor increases. The value of 22µF tantalum or 150µF

aluminum covers all cases of bypassing the adjustment terminal.

Without bypassing the adjustment terminal smaller capacitors can

be used with equally good results.

To further improve stability and transient response of these

devices larger values of output capacitor can be used.

Protection Diodes

Unlike older regulators, the AMS2907 family does not need any

protection diodes between the adjustment pin and the output and

from the output to the input to prevent over-stressing the die.

Internal resistors are limiting the internal current paths on the

AMS2907 adjustment pin, therefore even with capacitors on the

adjustment pin no protection diode is needed to ensure device

safety under short-circuit conditions.

Diodes between the input and output are not usually needed.

Microsecond surge currents of 50A to 100A can be handled by the

internal diode between the input and output pins of the device. In

normal operations it is difficult to get those values of surge

currents even with the use of large output capacitances. If high

value output capacitors are used, such as 1000µF to 5000µF and

the input pin is instantaneously shorted to ground, damage can

occur. A diode from output to input is recommended, when a

crowbar circuit at the input of the AMS2907 is used (Figure 1).

solid

AMS2907

D1

V

IN

Output Voltage

The AMS2907 series develops a 1.25V reference voltage between

the output and the adjust terminal. Placing a resistor between these

two terminals causes a constant current to flow through R1 and

down through R2 to set the overall output voltage. This current is

normally the specified minimum load current of 10mA. Because

I

is very small and constant it represents a small error and it can

ADJ

usually be ignored.

V

IN

Figure 2. Basic Adjustable Regulator

Load Regulation

True remote load sensing it is not possible to provide, because the

AMS2907 is a three terminal device. The resistance of the wire

connecting the regulator to the load will limit the load regulation.

The data sheet specification for load regulation is measured at the

bottom of the package. Negative side sensing is a true Kelvin

connection, with the bottom of the output divider returned to the

negative side of the load.

The best load regulation is obtained when the top of the resistor

divider R1 is connected directly to the case not to the load. If R1

were connected to the load, the effective resistance between the

regulator and the load would be:

R

R1

x ( R2+R1

P

AMS2907

IN OUT

ADJ

C

ADJ

10µF

R

R

Figure 1.

AMS2907

IN OUT

ADJ

I

ADJ

50µA

V

= V

OUT

(1+ R2/R1)+I

REF

V

REF

ADJ

) , RP = Parasitic Line Resistance

+

1

2

R1

R2

R2

C

OUT

150µF

V

OUT

V

OUT

updated April 24, 2009

http://www.BDTIC.com/AMS

APPLICATION HINTS

Connected as shown , R

V

IN

IN OUT

*CONNECT R1 TO CASE

ONNECT R2 TO LOAD

C

Figure 3. Connections for Best Load Regulation

In the case of fixed voltage devices the top of R1 is connected

Kelvin internally, and the ground pin can be used for negative side

sensing.

is not multiplied by the divider ratio

P

R

P

PARASITIC

LINE

AMS2907

ADJ

RESISTANCE

R1*

R2*

R

L

AMS2907

The

total thermal resistance from junction to ambient can be as

low as 45°C/W. This requires a reasonable sized PC board with at

least on layer of copper to spread the heat across the board and

couple it into the surrounding air.

Experiments have shown that the heat spreading copper layer does

not need to be electrically connected to the tab of the device. The

PC material can be very effective at transmitting heat between the

pad area, attached to the pad of the device, and a ground plane

layer either inside or on the opposite side of the board. Although

the actual thermal resistance of the PC material is high, the

Length/Area ratio of the thermal resistance between layers is

small. The data in Table 1, was taken using 1/16” FR-4 board with

1 oz. copper foil, and it can be used as a rough guideline for

estimating thermal resistance.

For each application the thermal resistance will be affected by

thermal interactions with other components on the board. To

determine the actual value some experimentation will be

necessary.

The power dissipation of the AMS2907 is equal to:

PD = ( VIN - V

imum junction temperature will be equal to:

Max

TJ = T

A(MAX)

)( I

OUT

)

OUT

+ PD(Thermal Resistance (junction-to-ambient))

Maximum junction temperature must not exceed 125°C.

Ripple Rejection

Thermal Considerations

AMS2907 series have internal power and thermal limiting

The

circuitry designed to protect the device under overload conditions.

However maximum junction temperature ratings of 125°C should

not be exceeded under continuous normal load conditions.

Careful consideration must be given to all sources of thermal

resistance from junction to ambient. For the surface mount

package SOT-223 additional heat sources mounted near the device

must be considered. The heat dissipation capability of the PC

board and its copper traces is used as a heat sink for the device.

The thermal resistance from the junction to the tab for the

AMS2907 is 15°C/W. Thermal resistance from tab to ambient can

The ripple rejection values are measured with the adjustment pin

assed. The impedance of the adjust pin capacitor at the ripple

byp

frequency should be less than the value of R1 (normally 100Ω to

200Ω) for a proper bypassing and ripple rejection approaching the

values shown. The size of the required adjust pin capacitor is a

function of the input ripple frequency. If R1=100Ω at 120Hz the

adjust pin capacitor should be >13µF. At 10kHz only 0.16µF is

needed.

The ripple rejection will be a function of output voltage, in circuits

without an adjust pin bypass capacitor. The output ripple will

increase directly as a ratio of the output voltage to the reference

voltage (V

OUT

/ V

REF

be as low as 30°C/W.

Table 1.

COPPER AREA

TOP SIDE* BACK SIDE BOARD AREA (JUNCTION-TO-AMBIENT)

2500 Sq. mm 2500 Sq. mm 2500 Sq. mm

1000 Sq. mm 2500 Sq. mm 2500 Sq. mm

225 Sq. mm 2500 Sq. mm 2500 Sq. mm

100 Sq. mm 2500 Sq. mm 2500 Sq. mm

1000 Sq. mm 1000 Sq. mm 1000 Sq. mm

1000 Sq. mm 0 1000 Sq. mm

* Tab of device attached to topside copper.

THERMAL RESISTANCE

45°C/W

45°C/W

53°C/W

59°C/W

52°C/W

55°C/W

updated April 24, 2009

).

http://www.BDTIC.com/AMS

TYPICAL PERFORMANCE CHARACTERISTICS

Minimum Operating Current

(Adjustable Device)

12

AMS2907

Short-Circuit Current

1.25

9

6

3

MINIMUM OPERATING CURRENT (mA)

0

0 5 10 15 20

INPUT/OUTPUT DIFFERENTIAL (V)

TJ = 125°C

TJ = 25°C

Load Regulation

0.10

∆ I

= 500mA

LOAD

0.05

0

-0.05

-0.10

OUTPUT VOLTAGE DEVIATION (%)

-0.15

-0.20

-50 -25 0 25 50 75 100 125

TEMPERATURE (°C)

1.00

0.75

0.50

SHORT CIRCUIT CURRENT (A)

0.25

0

0 5 10 15

INPUT/OUTPUT DIFFERENTIAL

TJ = 125°C

TJ = 25°C

Ripple Rejection vs. Current

100

90

80

70

60

50

40

30

RIPPLE REJECTION (dB)

20

V

10

C

C

0

0 0.15 0.3 0.45 0.6

V

= 5V

OUT

= 25µF

ADJ

= 25µF

OUT

OUTPUT CURRENT (A)

RIPPLE

V

≤

3Vp-p

RIPPLE

≤

0.5Vp-p

f

f

RIPPLE

RIPPLE

= 120Hz

= 20Hz

2.0

1.0

0

-1.0

OUTPUT VOLTAGE CHANGE (%)

-2.0

-50 -25 0 25 50 75 100 125 150

TEMPERATURE (°C)

updated April 24, 2009

Adjust Pin CurrentTemperature Stability

100

90

80

A)

µ

70

60

50

40

30

ADJUST PIN CURRENT (

20

10

0

-50 -25 0 25 50 75 100 125 150

TEMPERATURE (°C)

http://www.BDTIC.com/AMS

PACKAGE DIMENSIONS inches (millimeters) unless otherwise noted.

TO-252 PLASTIC PACKAGE (D)

0.255-0.265

0.380-0.410

(9.65-10.41)

(6.48-6.73)

0.206-0.214

(5.23-5.44)

0.235-0.245

(5.969-6.223)

0.087-0.094

(2.21-2.39)

7.0°

0.018-0.023

(0.46-0.58)

0.035-0.050

(0.89-1.27)

AMS2907

0.025

(0.635)

TYP

0.156-0.204

(3.96-5.18)

0.030

(0.762)

TYP

0.045-0.060

(1.14-1.52)

0.018-0.023

(0.46-0.58)

0.035-0.045

(0.89-1.14)

0.020±0.002

(0.510±0.0508)

D (D3) AMS DRW# 011601

3 LEAD SOT-223 PLASTIC PACKAGE

0.248-0.264

(6.30-6.71)

0.116-0.124

(2.95-3.15)

0.264-0.287

(6.71-7.29)

0.130-0.146

(3.30-3.71)

0.090

(2.29)

NOM

0.033-0.041

(0.84-1.04)

0.071

(1.80)

MAX

updated April 24, 2009

0.025-0.033

(0.64-0.84)

0.181

(4.60)

NOM

0.012

(0.31)

MIN

10°

MAX

10°-16°

0.025-0.033

(0.64-0.84)

0.010-0.014

(0.25-0.36)

10°-16°

(SOT-223 ) AMS DRW# 042292

http://www.BDTIC.com/AMS

PACKAGE DIMENSIONS inches (millimeters) unless otherwise noted (Continued).

SOT-89 PLASTIC PACKAGE (L)

0.173-0.181

0.155-0.167

(3.94-4.25)

0.090-0.102

(2.29-2.60)

(4.40-4.60)

0.064-0.072

(1.62-1.83)

0.035-0.047

(0.89-1.20)

0.055-0.063

(1.40-1.60)

0.084-0.090

(2.13-2.29)

AMS2907

0.014-0.017

(0.35-0.44)

0.059

(1.50)

BSC

0.118

(3.00)

BSC

0.017-0.022

(0.44-0.56)

0.014-0.019

(0.36-0.48)

L (SOT-89 ) AMS DRW# 042392

updated April 24, 2009

Loading...

Loading...