http://www.BDTIC.com/AMS

Advanced AMS1501

Monolithic 1.5A LOW DROPOUT VOLTAGE REGULATORS

Systems

RoHS compliant

FEATURES APPLICATIONS

• Adjustable or Fixed Output • High Current Regulators

1.5V, 2.5V, 2.85V, 3.0V, 3.3V, 3.5V and 5.0V

• Output Current of 1.5A • Adjustable Power Supply

• Low Dropout, 500mV at 1.5A Output Current • Notebook/Personal Computer Supplies

• Fast Transient Response

• Remote Sense

GENERAL DESCRIPTION

The AMS1501 series of adjustable and fixed low dropout voltage regulators are designed to provide 1.5A output current to

power the new generation of microprocessors. The dropout voltage of the device is 100mV at light loads and rising to 500mV

at maximum output current. A second low current input voltage 1V or greater then the output voltage is required to achieve

this dropout. The AMS1501 can also be used as a single supply device.

New features have been added to the AMS1501: a remote Sense pin is brought out virtually eliminating output voltage

variations due to load changes. The typical load regulation, measured at the Sense pin, for a load current step of 100mA to

1.5A is less than 1mV.

The AMS1501 series has fast transient response. The Adjust pin is brought out on fixed devices. To further improve the

transient response the addition of a small capacitor on the Adjust pin is recommended.

The AMS1501 series are ideal for generating power supplies of 2V to 3V where both 5V and 3.3V supplies are available.

The AMS1501 devices are offered in in 5 lead TO-220, 5L TO-263 (plastic DD) and 5L TO-252 (DPAK) packages.

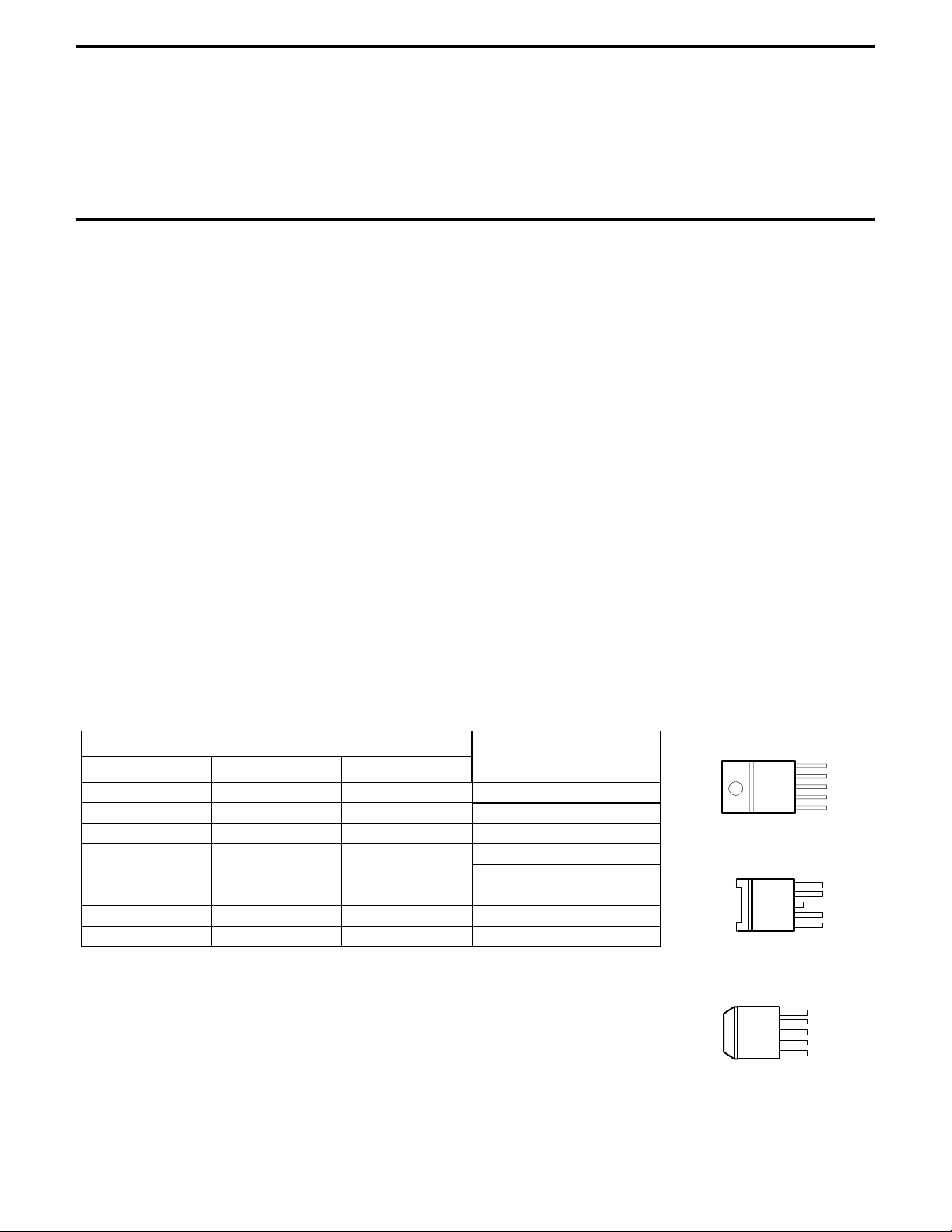

ORDERING INFORMATION: PIN CONNECTIONS

5 LEAD TO-263 5 LEAD TO-220 5 LEAD TO-252

AMS1501CM AMS1501CT AMS1501CD

AMS1501CM-1.5 AMS1501CT-1.5 AMS1501CD-1.5

AMS1501CM-2.5 AMS1501CT-2.5 AMS1501CD-2.5

AMS1501CM-2.85 AMS1501CT-2.85 AMS1501CD-2.85

AMS1501CM-3.0 AMS1501CT-3.0 AMS1501CD-3.0

AMS1501CM-3.3 AMS1501CT-3.3 AMS1501CD-3.3

AMS1501CM-3.5 AMS1501CT-3.5 AMS1501CD-3.5

AMS1501CM-5.0 AMS1501CT-5.0 AMS1501CD-5.0

PACKAGE TYPE OPERATING JUNCTION

• Post Regulators for Switching Supplies

5 LEAD TO-220

TEMPERATURE RANGE

0 to 125° C

0 to 125° C

0 to 125° C

0 to 125° C

0 to 125° C

FRONT VIEW

5 LEAD TO-252

0 to 125° C

0 to 125° C

0 to 125° C

FRONT VIEW

5 LEAD TO-263

5

4

3

2

1

FRONT VIEW

5

4

3

2

1

5

4

3

2

1

V

POWER

V

CONTROL

OUTPUT

ADJUST/GND

SENSE

Vpower

Vcontrol

OUTPUT

ADJUST/GND

SENSE

Vpower

Vcontrol

OUTPUT

ADJUST/GND

SENSE

Advanced Monolithic Systems, Inc.

http://www.BDTIC.com/AMS

AMS1501

ABSOLUTE MAXIMUM RATINGS (Note 1)

V

Input Voltage 7V Thermal Resistance

POWER

V

CONTROL

Input Voltage 13V TO-220 package

Operating Junction Temperature TO-252 package

Control Section

Power Transistor

Storage temperature

Soldering information

Lead Temperature (25 sec)

0°C to 125°C

0°C to 150°C

- 65°C to +150°C

265°C

TO-263 package

*Minimum pad size is 0.038in

** With package soldering to 0.5in2 copper area over backside

ground plane or internal power plane ϕ

>40°C/W depending on mounting technique.

2

ϕ

can vary from 20°C/W to

JA

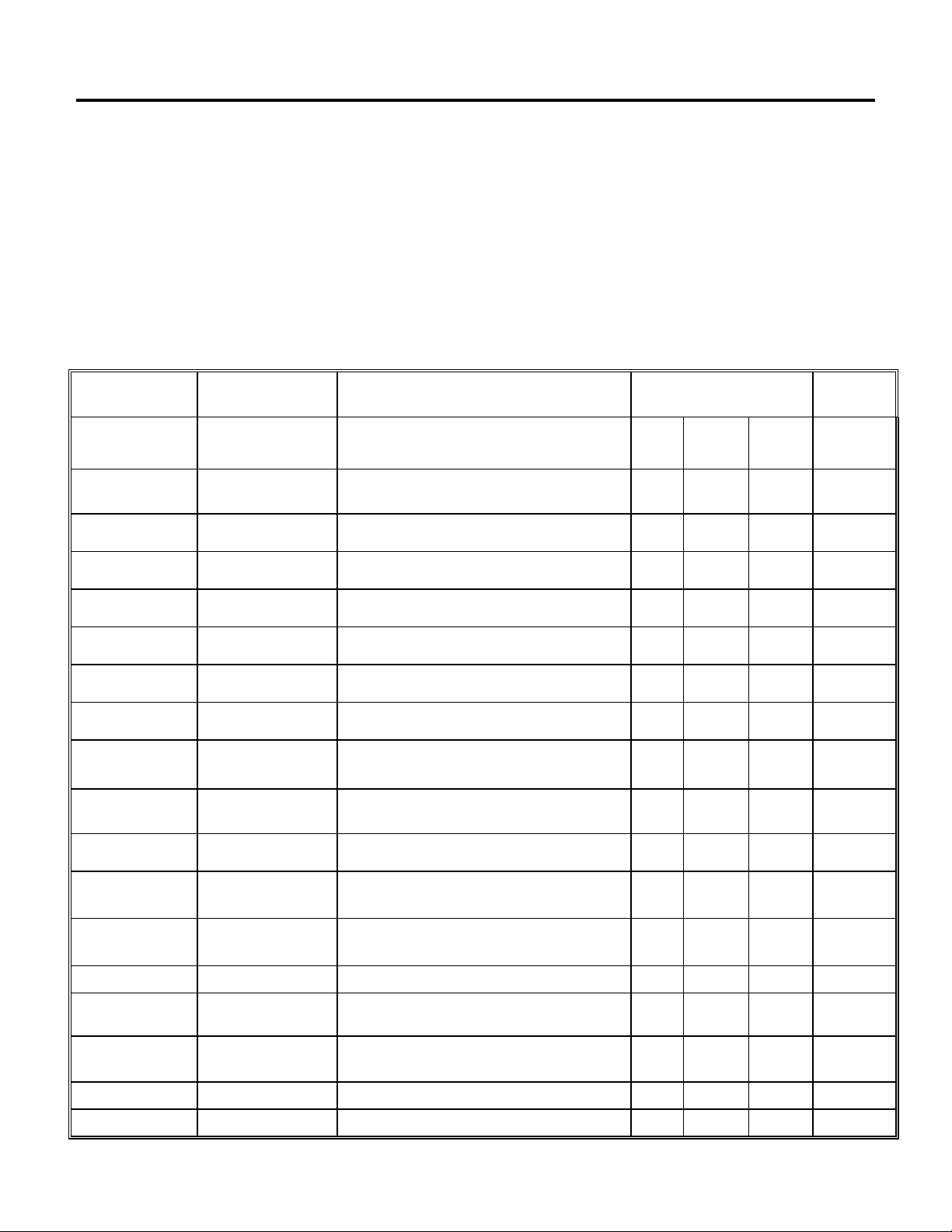

ELECTRICAL CHARACTERISTICS

Electrical Characteristics at I

= 0 mA, and TJ = +25°C unless otherwise specified.

LOAD

= 50°C/W

ϕ

JA

= 92°C/W*

ϕ

JA

= 30°C/W**

JA

Parameter

Device Conditions Min Typ Max Units

Reference Voltage AMS1501 V

Output Voltage

AMS1501-1.5 V

AMS1501-2.5 V

AMS1501-2.85 V

AMS1501-3.0 V

AMS1501-3.3 V

AMS1501-3.5 V

AMS1501-5.0 V

Line Regulation AMS1501/-1.5/-2.5/

-2.85/ -3.0/-3.3/-3.5/-5.0

Load Regulation

Minimum Load

AMS1501/-1.5/-2.5/

-2.85/-3.0/-3.3/-3.5/-5.0

AMS1501 V

= 2.75V, V

CONTROL

= 2.7V to 12V, V

V

CONTROL

I

= 10mA to 1.5A

LOAD

= 4V, V

CONTROL

= 3V, V

V

CONTROL

= 5V, V

CONTROL

= 4V, V

V

CONTROL

= 5.35V, V

CONTROL

V

= 4.4V, V

CONTROL

= 5.5V, V

CONTROL

= 4.5V, V

V

CONTROL

= 5.8V, V

CONTROL

= 4.8V, V

V

CONTROL

= 6V, V

CONTROL

= 5V, V

V

CONTROL

= 7.5V, V

CONTROL

= 6.5V, V

V

CONTROL

I

= 10 mA , 1.5V≤ (V

LOAD

0.8V≤ (V

V

I

POWER

= V

CONTROL

= 10mA to 1.5A

LOAD

= 5V, V

CONTROL

POWER

POWER

POWER

POWER

POWER

POWER

- V

+ 2.5V, V

OUT

POWER

POWER

POWER

POWER

POWER

POWER

POWER

POWER

POWER

POWER

) ≤ 5.5V

OUT

=2V, I

POWER

=2.V, I

=2.3V, I

=3.3V, I

=3.3V, I

=3.35V, I

=3.7V, I

=3.5V, I

=3.8V, I

=3.8V, I

=4.1V, I

=4V, I

LOAD

=4.3V, I

=5.5V, I

=5.8V, I

CONTROL

POWER

=3.3V, V

= 10mA

LOAD

=3.3V to 5.5V,

= 0mA

LOAD

= 0mA to 1.5A

LOAD

= 0mA

LOAD

= 0mA to 1.5A

LOAD

= 0mA

LOAD

= 0mA to 1.5A

LOAD

= 0mA

LOAD

= 0mA to 1.5A

LOAD

= 0mA

LOAD

= 0mA to 1.5A

LOAD

= 0mA

= 0mA to 1.5A

LOAD

= 0mA

LOAD

= 0mA to 1.5A

LOAD

- V

) ≤ 12V

OUT

=V

+ 0.8V,

OUT

= 0V (Note 3)

ADJ

1.243

1.237

1.491

1.485

2.485

2.475

2.821

2.833

2.982

2.970

3.280

3.235

3.479

3.430

4.930

4.950

Current

Control Pin Current

(Note 4)

Ground Pin Current

(Note 4)

Adjust Pin Current AMS1501 V

Current Limit

Ripple Rejection AMS1501/-1.5/-2.5/

AMS1501/-1.5/-2.5/

-2.85/-3.0/-3.3/-3.5/-5.0

AMS1501-1.5/-2.5/

-2.85/-3.0/-3.3/-3.5/-5.0

AMS1501/-1.5/-2.5/

-2.85/-3.0/-3.3/-3.5/-5.0

-2.85/-3.0/-3.3/-3.5/-5.0

V

= V

CONTROL

I

= 10mA to 1.5A

LOAD

V

= V

CONTROL

I

= 10mA to 1.5A

LOAD

= 2.75V, V

CONTROL

(VIN - V

OUT

V

= V

CONTROL

I

= 1A

LOAD

OUT

OUT

) = 5V

POWER

+ 2.5V, V

+ 2.5V, V

POWER

= V

OUT

=V

POWER

=V

POWER

= 2.05V, I

+ 2.5V, V

+ 0.8V,

OUT

+ 0.8V,

OUT

= 10mA

LOAD

= 1V

RIPPLE

P-P

1.5 2.0 2.8

60 80 dB

Thermal Regulation AMS1501 TA = 25°C, 30ms pulse 0.002 0.020 %W

1.250

1.250

1.500

1.500

2.500

2.500

2.850

2.850

3.000

3.000

3.300

3.300

3.500

3.500

5.000

5.000

1 3

1

1.258

1.263

1.509

1.515

2.515

2.525

2.879

2.867

3.018

3.030

3.320

3.333

3.521

3.535

5.030

5.050

5

5 10

10 16

6 10

50 120

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

mV

mV

mA

mA

mA

µA

A

Thermal Resistance T Package: Control Circuitry/ Power Transistor 0.65/2.70 °C/W

Advanced Monolithic Systems, Inc.

Junction-to-Case M & D Package: Control Circuitry/ Power Transistor 0.65/2.70 °C/W

http://www.BDTIC.com/AMS

AMS1501

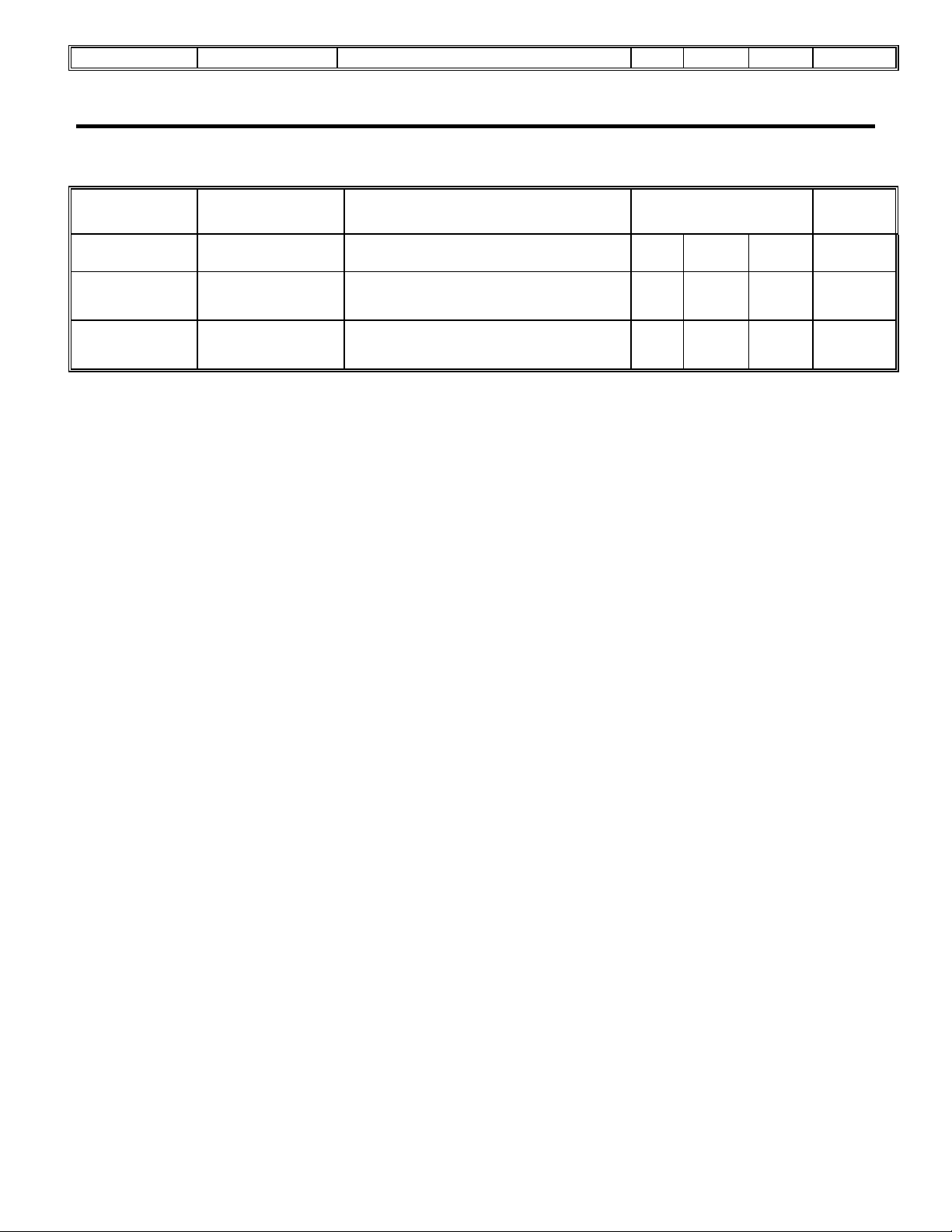

ELECTRICAL CHARACTERISTICS

Electrical Characteristics at I

= 0 mA, and TJ = +25°C unless otherwise specified.

OUT

Parameter

Device Conditions Min Typ Max Units

Dropout Voltage

Control Dropout

(V

Power Dropout

(V

CONTROL

POWER

- V

- V

OUT

OUT

)

AMS1501/-1.5/-2.5/

)

-2.85/-3.0/-3.3/-3.5/-5.0

AMS1501/-1.5/-2.5/

-2.85/-3.0/-3.3/-3.5/-5.0

Note 2

V

POWER

V

POWER

V

CONTROL

V

CONTROL

=V

=V

=V

=V

OUT

OUT

OUT

OUT

+ 0.8V, I

+ 0.8V, I

+ 2.5V, I

+ 2.5V, I

LOAD

LOAD

LOAD

LOAD

= 10mA

= 1.5A

= 10mA

= 1.5A

1.00

1.15

.10

.45

1.15

1.30

0.17

.50

V

V

V

V

Parameters identified with boldface type apply over the full operating temperature range.

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. For guaranteed specifications and test conditions, see the

Electrical Characteristics

Note 2: Unless otherwise specified V

. The guaranteed specifications apply only for the test conditions listed.

= V

OUT

. For the adjustable device V

SENSE

ADJ

= 0V.

Note 3: The dropout voltage for the AMS1501 is caused by either minimum control voltage or minimum power voltage. The specifications represent the

minimum input/output voltage required to maintain 1% regulation.

Note 4: For the adjustable device the minimum load current is the minimum current required to maintain regulation. Normally the current in the resistor

divider used to set the output voltage is selected to meet the minimum load current requirement.

Note 5: The control pin current is the drive current required for the output transistor. This current will track output current with a ratio of about 1:100. The

minimum value is equal to the quiescent current of the device.

PIN FUNCTIONS

Sense (Pin 1): This pin is the positive side of the reference

voltage for the device. With this pin it is possible to Kelvin

sense the output voltage at the load.

Adjust (Pin 2/5): This pin is the negative side of the

reference voltage for the device. Adding a small bypass

capacitor from the Adjust pin to ground improves the

transient response. For fixed voltage devices the Adjust

pin is also brought out to allow the user to add a bypass

capacitor.

GND (Pin 2/5): For fixed voltage devices this is the

bottom of the resistor divider that sets the output voltage.

V

POWER

device of the AMS1501. The output load current is

supplied through this pin. The voltage at this pin must

be between 0.1V and 0.8V greater than the output

voltage for the device to regulate.

V

CONTROL

control circuitry of the device. The current flow into

this pin will be about 1% of the output current. The

voltage at this pin must be 1.3V or greater than the

output voltage for the device to regulate.

Output (Pin 3/4): This is the power output of the

device.

(Pin 5/6): This pin is the collector to the power

(Pin 4/3): This pin is the supply pin for the

Advanced Monolithic Systems, Inc.

http://www.BDTIC.com/AMS

APPLICATION HINTS

The AMS1501 is designed to make use of multiple power

supplies, existing in most systems, to reduce the dropout voltage.

One of the advantages of the two supply approach is maximizing

the efficiency.

The second supply is at least 1V greater than output voltage and is

providing the power for the control circuitry and supplies the drive

current to the NPN output transistor. This allows the NPN to be

driven into saturation; thereby reducing the dropout voltage by a

VBE compared to conventional designs. For the control voltage

the current requirement is small equal to about 1% of the output

current or approximately 15mA for a 1.5A load. Most of this

current is drive current for the NPN output transistor. This drive

current becomes part of the output current. The maximum voltage

on the Control pin is 13V. The maximum voltage at the Power pin

is 7V. Ground pin current for fixed voltage devices is typical 6mA

and is constant as a function of load. Adjust pin current for

adjustable devices is 60µA at 25°C and varies proportional to

absolute temperature.

The improved frequency compensation of AMS1501 permits the

use of capacitors with very low ESR. This is critical in addressing

the needs of modern, low voltage high sped microprocessors.

Output voltage tolerances are tighter and include transient

response as part of the specification. Designed to meet the fast

current load step requirements, the AMS1501 also saves total cost

by needing less output capacitance to maintain regulation.

Careful design of the AMS1501 has eliminated any supply

sequencing issues associated with a dual supply system. The

output voltage will not turn on until both supplies are operating. If

the control voltage comes up first, the output current will be

limited to a few milliamperes until the power input voltage comes

up. If power input comes up first the output will not turn on at all

until the control voltage comes up. The output can never come up

unregulated. By tying the control and power inputs together the

AMS1501 can also be operated as a single supply device. In single

supply operation the dropout will be determined by the minimum

control voltage.

The new features of the AMS1501 require additional pins over the

traditional 3-terminal regulator. Both the fixed and adjustable

versions have remote sense pins, permitting very accurate

regulation of output voltage at the load, rather than at the

regulator. As a result, over an output current range of 100mA to

1.5A with a 2.5V output, the typical load regulation is less than

1mV. For the fixed voltages the adjust pin is brought out allowing

the user to improve transient response by bypassing the internal

resistor divider. Optimum transient response is provided using a

capacitor in the range of 0.1µF to 1µF for bypassing the Adjust

pin. The value chosen will depend on the amount of output

capacitance in the system.

In addition to the enhancements mentioned, the reference accuracy

has been improved by a factor of two with a guaranteed initial

tolerance of ±0.6% at 25°C. This device can hold 1% accuracy

over the full temperature range and load current range,

AMS1501

guaranteed, when combined with ratiometrically accurate internal

divider resistors and operating with an input/output differential of

well under 1V.

Typical applications for the AMS1501 include 3.3V to 2.5V

conversion with a 5V control supply, 5V to 4.2V conversion with

a 12V control supply or 5V to3.6V conversion with a 12V control

supply. Capable of 1.5A of output current with a maximum

dropout of 0.8V the AMS1501 also has a fast transient response

that allows it to handle large current changes. The device is fully

protected against overcurrent and overtemperature conditions.

Grounding and Output Sensing

The AMS1501 allows true Kelvin sensing for both the high and

low side of the load. As a result the voltage regulation at he load

can be easily optimized. Voltage drops due to parasitic resistances

between the regulator and the load can be placed inside the

regulation loop of the AMS1501. The advantages of remote

sensing are illustrated in figures 1 through 3.

Figure 1 shows the device connected as a conventional 3 terminal

regulator with the Sense lead connected directly to the output of

the device. R

between the device and the load. Typically R

PC traces and /or connector resistances (in the case of a modular

regulator) between the regulator and the load. Trace A of figure 3

illustrates the effect of RP. Very small resistances cause

significant load regulation steps.

Figure 2 shows the device connected to take advantage of the

remote sense feature. The Sense pin and the top of the resistor

divider are connected to the top of the load; the bottom of the

resistor divider is connected to the bottom of the load. R

connected inside the regulation loop of the AMS1501 and for

reasonable values of R

negligible. The effect on output regulation can be seen in trace B

of figure 3.

3.3V

is the parasitic resistance of the connections

P

the load regulation at the load will be

P

is made up of the

P

5V

CONTROL

POWER SENSE

AMS1501

ADJ

OUTPUT

R1

R2

R

P

LOAD

R

P

Figure 1. Conventional Load Sensing

is now

P

+

V

OUT

-

Advanced Monolithic Systems, Inc.

APPLICATION HINTS

http://www.BDTIC.com/AMS

5V

CONTROL

3.3V

POWER SENSE

AMS1501

OUTPUT

ADJ

R1

R2

Figure 2. Remote Load Sensing

V

OUT

FIGURE 1

V

OUT

FIGURE 2

(∆I

AMS1501

to allow this capability. To ensure good transient response with

heavy load current changes capacitor values on the order of 100µF

are used in the output of many regulators. To further improve

stability and transient response of these devices larger values of

output capacitor can be used.

The modern systems generate large high frequency current

transients. The load current step contains higher order frequency

R

P

LOAD

R

P

+

V

OUT

-

)(RP)

OUT

components than the output coupling network must handle until

the regulator throttles to the load current level. Because they

contain parasitic resistance and inductance, capacitors are not

ideal elements. These parasitic elements dominate the change in

output voltage at the beginning of a transient load step change.

The ESR of the output capacitors produces an instantaneous step

in output voltage (∆V=∆I)(ESR). The ESL of the output

capacitors produces a droop proportional to the rate of change of

the output current (V= L)(∆I/∆t). The output capacitance produces

a change in output voltage proportional to the time until the

regulator can respond (∆V=∆t) (∆I/C). Figure 4 illustrates these

transient effects.

ESR

EFFECTS

ESL

EFFECTS

CAPACITANCE

EFFECTS

I

OUT

TIME

Figure 3. Remote Sensing Improves Load Regulation

Voltage drops due to R

are not eliminated; they will add to the

P

dropout voltage of the regulator regardless of whether they are

inside or outside the regulation loop. The AMS1501 can control

the voltage at the load as long as the input-output voltage is

greater than the total of the dropout voltage of the device plus the

voltage drop across R

.

P

Stability

The circuit design used in the AMS1501 series requires the use of

an output capacitor as part of the device frequency compensation.

The addition of

150µF aluminum electrolytic or a 22µF solid

tantalum on the output will ensure stability for all operating

conditions. For best frequency response use capacitors with an

ESR of less than 1Ω.

In order to meet the transient requirements of the load larger value

capacitors are needed. Tight voltage tolerances are required in the

power supply. To limit the high frequency noise generated by the

load high quality bypass capacitors must be used. In order to limit

parasitic inductance (ESL) and resistance (ESR) in the capacitors

to acceptable limits, multiple small ceramic capacitors in addition

to high quality solid tantalum capacitors are required.

When the adjustment terminal is bypassed to improve the ripple

rejection, the requirement for an output capacitor increases. The

Adjust pin is brought out on the fixed voltage device specifically

SLOPE, V/t = ∆I/C

POINT AT WHICH REGULATOR

TAKES CONTROL

Figure 4.

Output Voltage

The AMS1501 series develops a 1.25V reference voltage between

the Sense pin and the Adjust pin (Figure5). Placing a resistor

between these two terminals causes a constant current to flow

through R1 and down through R2 to set the overall output voltage.

In general R1 is chosen so that this current is the specified

minimum load current of 10mA.The current out of the Adjust pin

is small, typically 50µA and it adds to the current from R1.

Because I

very precise output voltage setting is required. For best regulation

the top of the resistor divider should be connected directly to the

Sense pin.

V

POWER

V

OUT

is very small it needs to be considered only when

ADJ

V

CONTROL

CONTROL

POWER OUTPUT

AMS1501

SENSE

ADJ

I

ADJ

µ

A

50

R2

ADJ

V

REF

R1

R2

= V

+

+

1+ R2/R1)+I

(

REF

Figure 5. Setting Output Voltage

V

+

OUT

Advanced Monolithic Systems, Inc. www.advanced-monolithic.com Phone (925) 443-0722 Fax (925) 443-0723

APPLICATION HINTS

http://www.BDTIC.com/AMS

Protection Diodes

Unlike older regulators, the AMS1501 family does not need any

protection diodes between the adjustment pin and the output and

from the output to the input to prevent die over-stress. Internal

resistors are limiting the internal current paths on the AMS1501

adjustment pin, therefore even with bypass capacitors on the

adjust pin no protection diode is needed to ensure device safety

under short-circuit conditions. The Adjust pin can be driven on a

transient basis ±7V with respect to the output without any device

degradation.

Diodes between the Output pin and V

needed. Microsecond surge currents of 25A to 50A can be handled

by the internal diode between the Output pin and V

the device. In normal operations it is difficult to get those values

of surge currents even with the use of large output capacitances. If

high value output capacitors are used, such as 1000µF to 5000µF

and the V

can occur. A diode from output to input is recommended, when a

crowbar circuit at the input of the AMS1501 is used (Figure 6).

Normal power supply cycling or even plugging and unplugging in

the system will not generate current large enough to do any

damage.

V

Input Crowbar Circuits

If the AMS1501 is connected as a single supply device with the

control and power input pins shorted together the internal diode

between the output and the power input pin will protect the control

input pin. As with any IC regulator, none the protection circuitry

will be functional and the internal transistors will break down if

the maximum input to output voltage differential is exceeded.

Thermal Considerations

The AMS1501 series have internal power and thermal limiting

circuitry designed to protect the device under overload conditions.

However maximum junction temperature ratings should not be

exceeded under continuous normal load conditions. Careful

consideration must be given to all sources of thermal resistance

from junction to ambient, including junction-to-case, case-to-heat

sink interface and heat sink resistance itself.

pin are not usually

POWER

pin is instantaneously shorted to ground, damage

POWER

V

CONTROL

POWER

+

CONTROL

POWER OUTPUT

+

AMS1501

ADJ

SENSE

D2*D1*

+

R1

R2

Figure 6. Optional Clamp Diodes Protect Against

POWER

pin of

V

OUT

AMS1501

Thermal resistance specification for both the Control Section and

the Power Transistor are given in the electrical characteristics.

The thermal resistance of the Control section is given as

0.65°C/W and junction temperature of the Control section can run

up to 125°C. The thermal resistance of the Power section is given

as 2.7°C/W and junction temperature of the Power section can run

up to 150°C. Due to the thermal gradients between the power

transistor and the control circuitry there is a significant difference

in thermal resistance between the Control and Power sections.

Virtually all the power dissipated by the device is dissipated in the

power transistor. The temperature rise in the power transistor will

be greater than the temperature rise in the Control section making

the thermal resistance lower in the Control section. At power

levels below 12W the temperature gradient will be less than 25°C

and the maximum ambient temperature will be determined by the

junction temperature of the Control section. This is due to the

lower maximum junction temperature in the Control section. At

power levels above 12W the temperature gradient will be greater

than 25°C and the maximum ambient temperature will be

determined by the Power section. In both cases the junction

temperature is determined by the total power dissipated in the

device. For most low dropout applications the power dissipation

will be less than 12W.

The power in the device is made up of two components: the power

in the output transistor and the power in the drive circuit. The

power in the control circuit is negligible.

The power in the drive circuit is equal to:

P

= (V

DRIVE

where I

I

OUT

CONTROL

/58(max).

The power in the output transistor is equal to:

P

= (V

OUTPUT

The total power is equal to:

P

= P

TOTAL

DRIVE

Junction-to-case thermal resistance is specified from the IC

junction to the bottom of the case directly below the die. This is

the lowest resistance path for the heat flow. In order to ensure the

best possible thermal flow from this area of the package to the

heat sink proper mounting is required. Thermal compound at the

case-to-heat sink interface is recommended. A thermally

conductive spacer can be used, if the case of the device must be

electrically isolated, but its added contribution to thermal

resistance has to be considered.

- V

CONTROL

OUT

)(I

CONTROL

is equal to between I

-V

)(I

POWER

+ P

OUT

OUTPUT

)

OUT

)

/100(typ) and

OUT

Advanced Monolithic Systems, Inc.

TYPICAL PERFORMANCE CHARACTERISTICS

http://www.BDTIC.com/AMS

Control Pin Current vs

Output Current Minimum Control Voltage

140

120

2

AMS1501

Dropout Voltage Minimum Power Voltage

1.0

100

80

60

40

20

CONTROL PIN CURRENT (mA)

0

0 0.5 1

TYPICAL

DEVICE

1.5 0

OUTPUT CURRENT (A)

MINMUM CONTROL VOLTAGE

)(V)

OUT

1

- V

CONTROL

(V

0

TJ = 25° CTJ = 125° C

0.5

OUTPUT CURRENT (A)

1 1.5 0 0.5 1 1.5

0.5

MINIMUM POWER VOLTAGE

0

OUTPUT CURRENT (A)

TJ = 125° C

TJ = 25° C

Reference Voltage vs

Temperature

1.258

1.256

1.254

1.252

1.250

1.248

1.246

REFERENCE VOLTAGE (V)

1.244

1.242

-25 0 25 50 75 100 125 150

-50

TEMPERATURE (° C)

V

50µV/DIV

LOAD

400mA

Load Current Step Response

OUT

1.5A

50µ/DIV

Advanced Monolithic Systems, Inc.

PACKAGE DIMENSIONS inches (millimeters) unless otherwise noted.

http://www.BDTIC.com/AMS

5 LEAD TO-220 PLASTIC PACKAGE (T)

0.165-0.180

(4.191-4.572)

(11.684-12.700)

0.980-1.070

(24.892-27.178)

0.460-0.500

0.520-0.570

(13.208-14.478)

0.390-0.415

(9.906-10.541)

0.147-0.155

(3.734-3.937)

0.230-0.270

(5.842-6.858)

0.330-0.370

(8.382-9.398)

DIA

0.570-0.620

(14.478-15.748)

0.045-0.055

(1.143-1.397)

AMS1501

0.090-0.110

(2.286-2.794)

0.028-0.038

(0.711-0.965)

0.013-0.023

(0.330-0.584)

0.095-0.115

(2.413-2.921)

T (TO-220 ) AMS DRW# 042194

5 LEAD TO-263 PLASTIC PACKAGE (M)

0.165-0.180

(4.191-4.572)

(2.74)

0.108

TYP

0.013-0.023

(0.330-0.584)

0.045-0.055

(1.143-1.397)

+0.008

0.004

-0.004

+0.203

(

0.102

-0.102

0.095-0.115

(2.413-2.921)

0.90-0.110

(2.29-2.79)

M (DD5) AMS DRW#042192R1

)

0.057-0.077

(1.447-1.955)

0.390-0.415

(9.906-10.541)

0.060

(1.524)

TYP

0.330-0.370

(8.382-9.398)

0.199-0.218

(5.05-5.54)

0.032

(0.81)

TYP

Advanced Monolithic Systems, Inc.

PACKAGE DIMENSIONS inches (millimeters) unless otherwise noted (Continued).

http://www.BDTIC.com/AMS

5 LEAD TO-252 PLASTIC PACKAGE (D)

0.255-0.265

0.380-0.410

(9.65-10.41)

(6.48-6.73)

0.206-0.214

(5.23-5.44)

0.235-0.245

(5.969-6.223)

0.087-0.094

(2.21-2.39)

7.0°

0.018-0.023

(0.46-0.58)

0.035-0.050

(0.89-1.27)

AMS1501

0.025

(0.635)

TYP

0.045

(1.14)

TYP

0.020

(0.51)

TYP

0.045-0.060

(1.14-1.52)

0.018-0.023

(0.46-0.58)

0.035-0.045

(0.89-1.14)

0.020±0.002

(0.510±0.0508)

D (D5) AMS DRW# 031202

Advanced Monolithic Systems, Inc.

Loading...

Loading...