Page 1

For review by:

Issue No. Date

Description of Revision Rev. Date Prepared: A. Piccioli

1.3 12/04/07

5 2706/07

Approved:

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 1 of 70

Page 2

NOTES:

This apparatus and its documentation must be thoroughly reviewed, to

become familiar with safety instructions before starting operating

procedures.

To assure a correct and safe utilisation, the user of this apparatus shall

observe all information and warnings contained herein.

The Apparatus must be connected to an electrical system that complies

with current national standards.

The information contained herein is subjected to change without

advance notice.

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including

interference that may cause undesired operation.

Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the

equipment.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 2 of 70

Page 3

TABLE OF WRITTEN CONTENTS

1. SECURITY INSTRUCTIONS AND CONSIDERATIONS.............................. 1-5

2. ABBREVIATIONS ................................................................................... 2-5

3. GENERAL INFORMATION ...................................................................... 3-6

3.1. OPERATING PRINCIPLE OF THE LNX SYSTEM 3-6

STANDARD, FAST and APB Mode .......................................................................... 3-7

TRACK Mode ........................................................................................................... 3-8

ECM Mode ............................................................................................................... 3-9

BEEPER FAST Mode ............................................................................................. 3-10

3.2. E

4. TECHNICAL DESCRIPTION OF THE DEVICES..................................... 4-13

XAMPLES OF APPLICATIONS OF THE LNX SYSTEM 3-11

4.1. I

LLUMINATOR UKOPLX2101FHU 4-13

Mechanical Characteristics ................................................................................... 4-13

Mechanical Characteristics ................................................................................... 4-14

Wiring for UKOPLX2101FHU ................................................................................ 4-14

POSITION OF LABEL................................................................................................... 4-14

4.2. TAG DUALFREQUENCY UKOPLX1004STU & UKOPLX1004QDU 4-15

Mechanical Characteristics ................................................................................... 4-15

Wiring for UKOPLX1004STU or UKOPLX1004QDU............................................... 4-16

POSITION OF LABEL................................................................................................... 4-16

4.3. UKOPLX2002 RADIO RECEIVER 4-17

Mechanical Characteristics ................................................................................... 4-17

Wiring for UKOPLX2002........................................................................................ 4-17

POSITION OF LABEL................................................................................................... 4-18

5. INSTALLATION .................................................................................... 5-19

5.1. I

5.2. P

NTRODUCTION 5-19

Illuminator UKOPLX2101FHU............................................................................... 5-19

Receiver UKOPLX2002.......................................................................................... 5-19

Transponder UKOPLX1004STU or UKOPLX1004QDU.......................................... 5-19

RECAUTIONS 5-20

Initial Inspection.................................................................................................... 5-20

Packing and Unpacking ........................................................................................ 5-20

Preparation for Use ............................................................................................... 5-20

Caution.................................................................................................................. 5-20

Connection to Power Supply Mains....................................................................... 5-21

5.3. TECHNICAL CHARACTERISTICS OF THE MATERIALS EMPLOYED 5-21

Power supply cord................................................................................................. 5-21

Data cables ........................................................................................................... 5-21

Auxiliary cables .................................................................................................... 5-22

Environmental conditions...................................................................................... 5-22

Cleaning the instrument........................................................................................ 5-22

Caution.................................................................................................................. 5-22

5.4. N

Installation ............................................................................................................ 5-22

Equipment required for installation....................................................................... 5-22

Notes on installation ............................................................................................. 5-23

OTES ON INSTALLATION 5-22

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 3 of 70

Page 4

Caution.................................................................................................................. 5-23

5.5. INSTALLATION OF THE APPARATUS 5-24

5.6. STARTING THE APPARATUSES 5-27

5.7. CONFIGURATION OF ILLUMINATOR UKOPLX2101FHU 5-28

5.8. CONFIGURATION OF TRASPONDER UKOPLX1004STU / UKOPLX1004QDU 540

5.9. CONFIGURATION OF RECEIVER UKOPLX2002 5-44

Supplementary power supply ............................................................................... 5-44

External interface.................................................................................................. 5-45

Operating mode..................................................................................................... 5-48

Startup .................................................................................................................. 5-48

LEDs...................................................................................................................... 5-48

Button functions .................................................................................................... 5-48

STAND ALONE MODE ........................................................................................... 5-49

ASCII Stand Alone data format............................................................................. 5-49

Programming ......................................................................................................... 5-51

NETWORKING ....................................................................................................... 5-54

Binary communication protocol ............................................................................. 5-54

6. ELECTRICAL AND MECHANICAL SPECIFICATIONS............................. 6-64

6.1. ACTIVATOR UKOPLX2101FHU 6-64

Mechanical characteristics.................................................................................... 6-64

External interface.................................................................................................. 6-64

Electrical characteristics ....................................................................................... 6-64

Environmental specifications ................................................................................ 6-64

Radio unit specifications ....................................................................................... 6-64

Antenna specifications: AME ANT 2.44................................................................. 6-65

6.2. TRASPONDER UKOPLX1004STU & UKOPLX1004QDU 6-66

Mechanical characteristics.................................................................................... 6-66

UKOPLX1004STU.................................................................................................. 6-66

UKOPLX1004QDU................................................................................................. 6-66

Electrical characteristics ....................................................................................... 6-66

Environmental specifications ................................................................................ 6-66

Radio Frequency Specifications ............................................................................ 6-67

433 MHz. transmitter............................................................................................ 6-67

2.45 GHz receiver.................................................................................................. 6-67

6.3. R

Mechanical characteristics.................................................................................... 6-68

Electrical characteristics ....................................................................................... 6-68

Specific external interfaces ................................................................................... 6-68

Radio Frequency Specifications ............................................................................ 6-68

Environmental specifications ................................................................................ 6-68

ECEIVER UKOPLX2002 6-68

7. LAN PLX2002 CONFIGURATION (OPTIONAL FUNCTION) ..................... 7-69

8. STARTING THE APPARATUS................................................................ 8-69

9. TEST ................................................................................................... 9-69

10. PRECAUTIONS .................................................................................. 10-69

11. MAINTENANCE.................................................................................. 11-70

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 4 of 70

Page 5

1. SECURITY INSTRUCTIONS AND CONSIDERATIONS

This apparatus complies with the safety requirements set out by current standards. To

assure a proper and safe use of this apparatus, it is necessary thoroughly to understand

and carefully to observe the following instructions, before starting operating procedures.

If the unit is to be connected to other apparatuses or accessories, before

powering each unit ensure that there is continuity in the ground connection

between them.

For units connected permanently without protection fuses, automatic breaking

circuits or similar solutions, mains voltage must be supplied through fuses or

protections connected to the units themselves.

Every interruption or loosening of the protective conductor, inside or outside the

unit or in a connection to other units, will cause a potential electric shock hazard

which could result in personal injuries.

The protective conductor must not be interrupted intentionally.

To prevent electric shocks, do not remove protections or lids from the unit; to

service the apparatus, contact a qualified service centre.

To assure continuous protection against the risk of fire, replace the fuses on the

power supply mains only with fuses of the same type and size.

Comply with safety standards and rules, and also with the additional accident

prevention instructions specified herein.

2. ABBREVIATIONS

RFID Radio Frequency Identification

PLX1004STU Similar to UKOPLX1004STU, Identifying code for the rectangular TAG

PLX1004QDU Similar to UKOPLX1004QDU, Identifying code for the square TAG

PLX2002

PLX2101FHU Similar to UKOPLX2101FHU, Identifying code for the ILLUMINATOR

IT System IT apparatus dedicated to managing the data acquired by the system

Activtor Similar to UKOPLX2101FHU

Illuminator Similar to UKOPLX2101FHU

Receiver Similar to UKOPLX2002

ILL Similar to UKOPLX2101FHU

RIC Similar to UKOPLX2002

TAG Similar to UKOPLX1004STU or UKOPLX1004QDU

User Manual Updated as of

Similar to UKOPLX2002, Identifying code for the RECEIVER

27 giu. 07 – Rel.1.3.5 Page 5 of 70

Page 6

3. GENERAL INFORMATION

3.1. Operating Principle of the LNX System

The system proposed herein is based on the extensive use of LNX technology

apparatuses. Therefore, it is essential to provide a short note describing the specific

characteristics and potential of this technology.

The LNX system is based on the operating principle of

Radio Frequency Identification (RFID) systems with

ACTIVE transponder.

An active transponder is a self-powered electronic

device with the ability to receive data through a

transmission at 2.45GHz, process them, and make the

results available through a transmission at 433MHz.

The system as a whole is thus formed by three

elements:

• The ILLUMINATOR, tasked with generating the transmission at 2.45GHz and

produce a coverage area.

• The ACTIVE TRANSPONDER, which will be designated with the acronym TAG

(whose operation we have already described)

• The RECEIVER, tasked with receiving the data transmitted by the TAG and

transferring them in turn to the IT system above it.

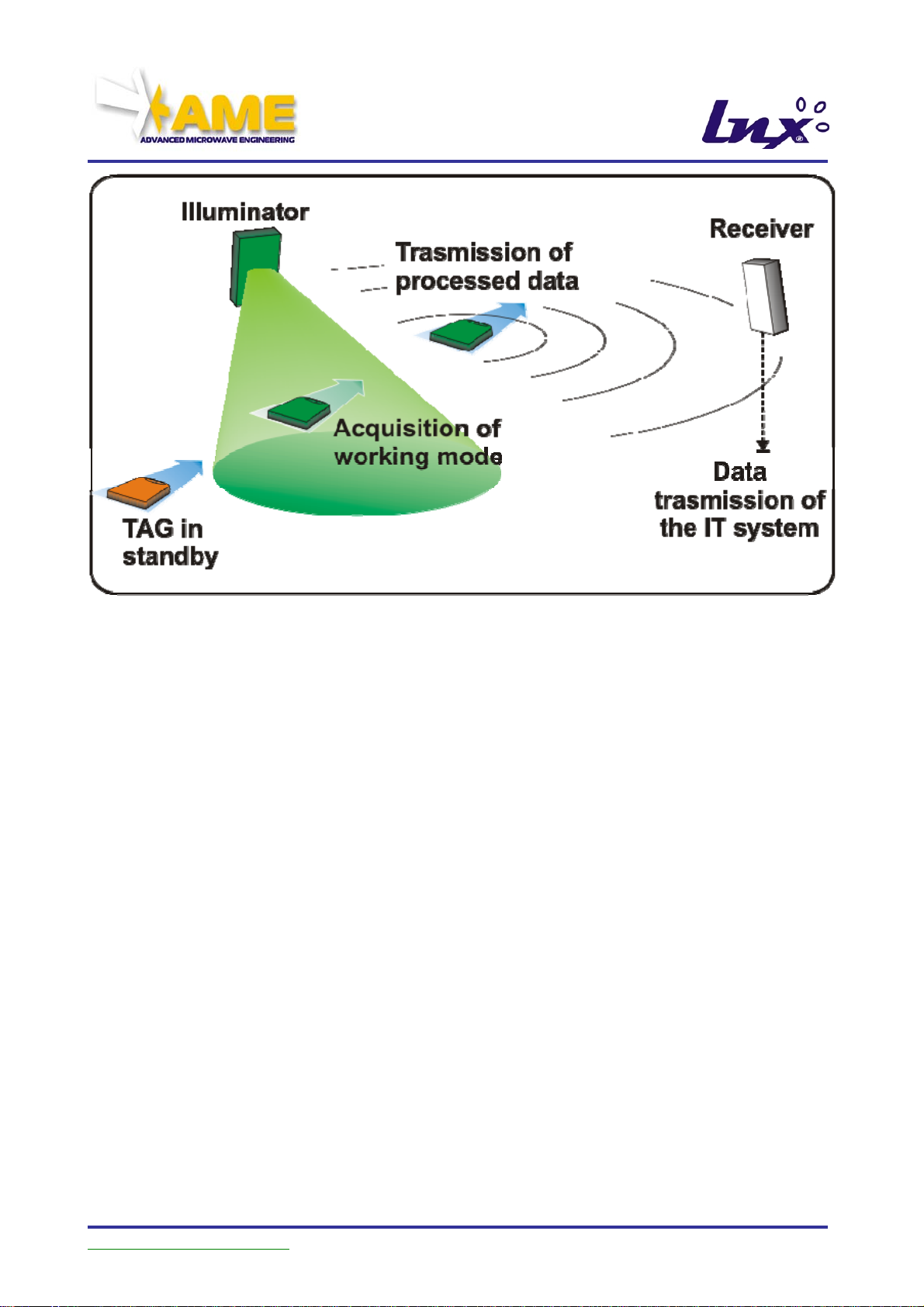

The operating principle is extremely simple: the transponder lies in a stand-by state until it

is “illuminated” by the microwave source which “awakens” it.

Only then does it “activate”, interpret the signal transmitted by the illuminator, perform the

necessary operations and transmit its code and the results obtained on the RF channel to

the receiver located within the coverage range.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 6 of 70

Page 7

Moreover, since the active transponder of the LNX system is an apparatus with on-board

frequency generation and it is provided with battery as well as a chip and a transmitter, the

TAG can become a transmission device irrespective of whether it is located in the

activation area.

This allows the firmware loaded in the TAG’s memory to perform numerous processes and

to transmit the result at any time and for an infinite number of times.

This intrinsic characteristic of the LNX system enables to use the same products (receiver,

illuminator, TAG) in various applications, even very different ones.

The following is the description of the work modes currently implemented on the LNX

system.

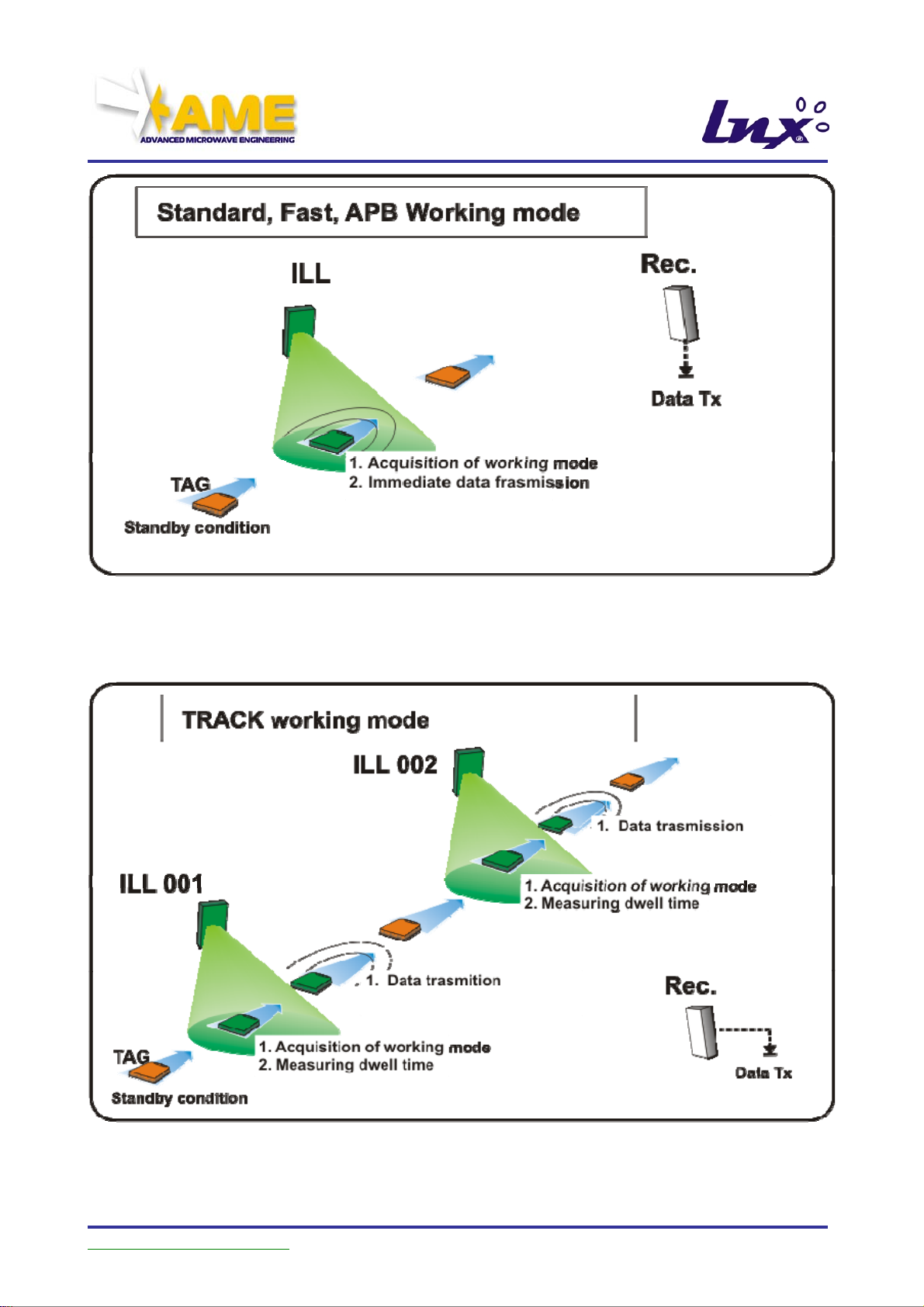

STANDARD, FAST and APB Mode

In this mode, the TAG activates its transmission when it is illuminated by an illuminator.

A similar operation to standard mode also occurs with the FAST and APB modes

(described below); for now, suffice it to know that they are differentiated by the

transmission and waiting times.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 7 of 70

Page 8

TRACK Mode

Operating mode that enables to track a TAG’s path through an area where multiple

illuminators are positioned.

From the data transmitted by the TAG it is possible to know by which illuminators the TAG

was successively illuminated and how long it remained within their operating range.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 8 of 70

Page 9

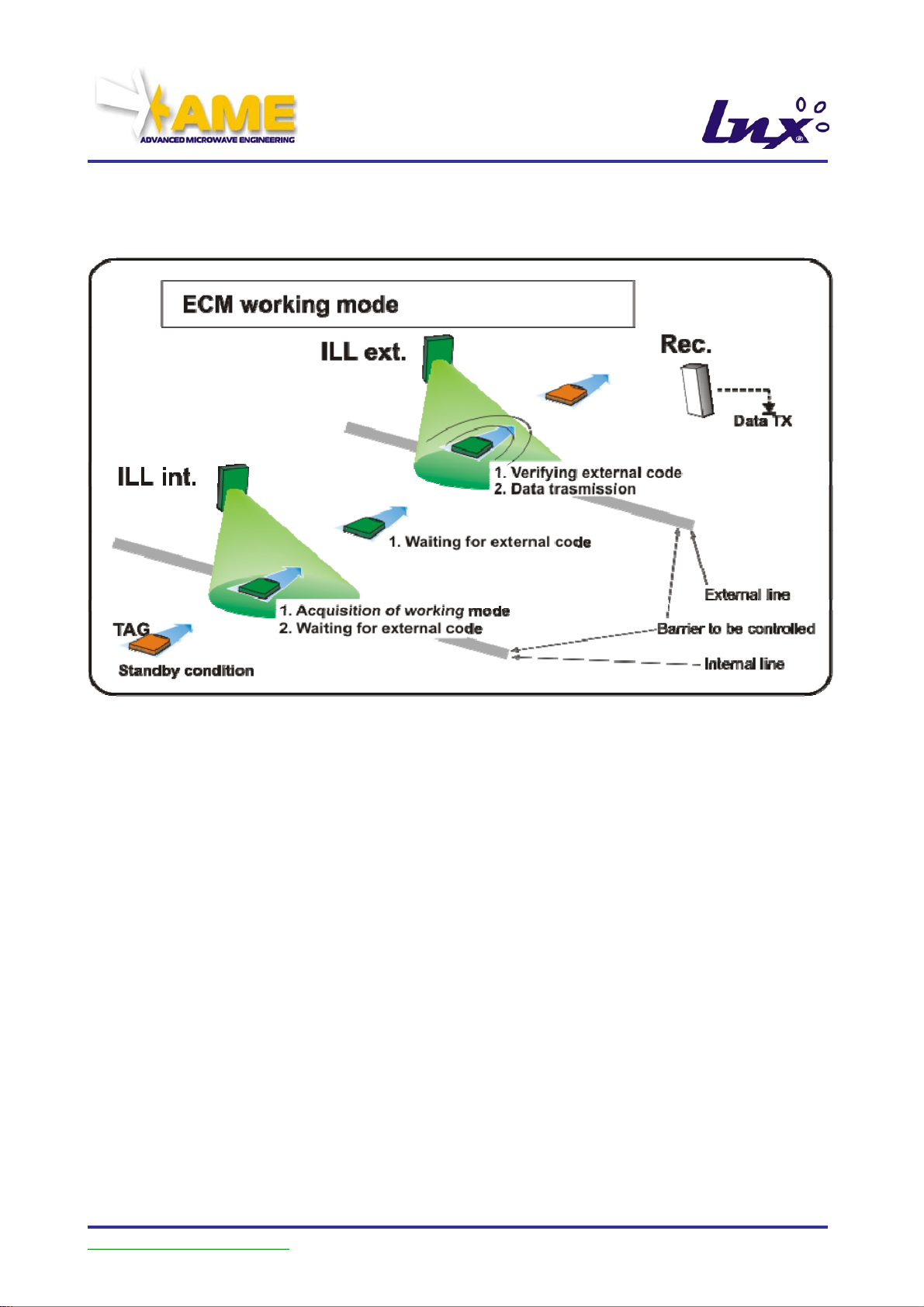

ECM Mode

Operating mode that enables to a TAG’s passage through a barrier, while also keeping

track of the direction of travel.

If the barrier is wide, the system provides for the illuminators to be so configured as to

enable the creation of barriers of up to 15m, with performance optimisation.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 9 of 70

Page 10

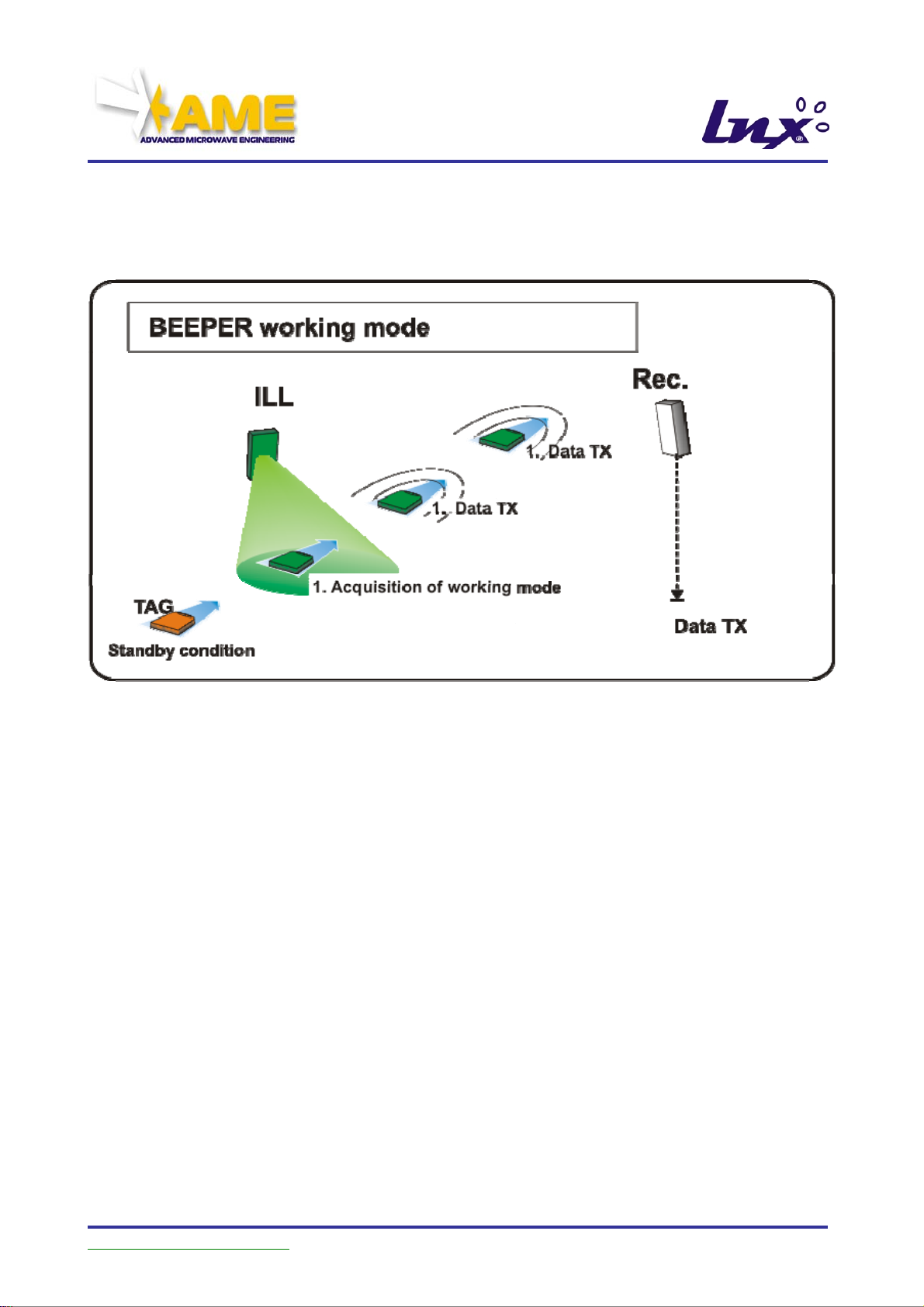

BEEPER FAST Mode

This mode enables to excite the TAG and to set it to a condition of repetitive transmission

of the same message for a defined time, even after it leaves the activation area.

Observing the configuration tables provided in the remainder of this manual, it will be

readily apparent that for this particular configuration, 32 versions are available, plus 22 of

the BEEPER FAST mode.

The difference between the BEEPER FAST mode is that with the former the TAG changes

working mode only at the end of its transmission cycle, or upon receiving the code 999I or

999E code by an illuminator. With the BEEPER FAST mode, instead, the TAG changes its

operating mode every time it is activated by an illuminator with different work settings.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 10 of 70

Page 11

3.2. Examples of Applications of the LNX System

There are many applications of the LNX system in the various work modes described

above.

STANDARD Mode: example of

application for the management of

vehicle accesses.

The TAG is positioned on the vehicle,

the illuminator and the receiver are

positioned near the motorised barrier.

When the illuminator activates the

TAG, the latter transmits its code to

the receiver. The receiver processes

the data, verifies the TAG’s

authorizations and proceeds to open

the barrier.

FAST Mode: allows to use the system

described above to monitor travel times

between an illuminator and the next

one. In this mode, therefore, the system

functions as a time-measuring system.

TRACK Mode: enables to monitor the

movements of “labeled” objects or to

verify at any time their stage of

production.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 11 of 70

Page 12

LNX is able to cover any activation radius of the transponder, up to about 12 meters; in

turn, the transponder is able to communicate efficiently up to about 60 meters in a free

area.

The LNX technology allows to produce even highly complex systems at low costs, allowing

to automate both industrial and private facilities.

Today, the LNX system is the most modern, effective and economical solution of handsfree short-range automatic identification and data exchange indoors and outdoors (Italian

patent FI2000A000221 of November 6, 2000, and European Patent (pending) no.

EP1209615)

• ability to modulate activation ranges (up to 12 m)

• large code communication coverage areas (up to 60 m)

• multi-receiver operation

• very low consumption for long transponder operating times

• precise spatial definition of the activation area

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 12 of 70

Page 13

A

A

A

4. TECHNICAL DESCRIPTION OF THE DEVICES

The following is the description of the components of the LNX system:

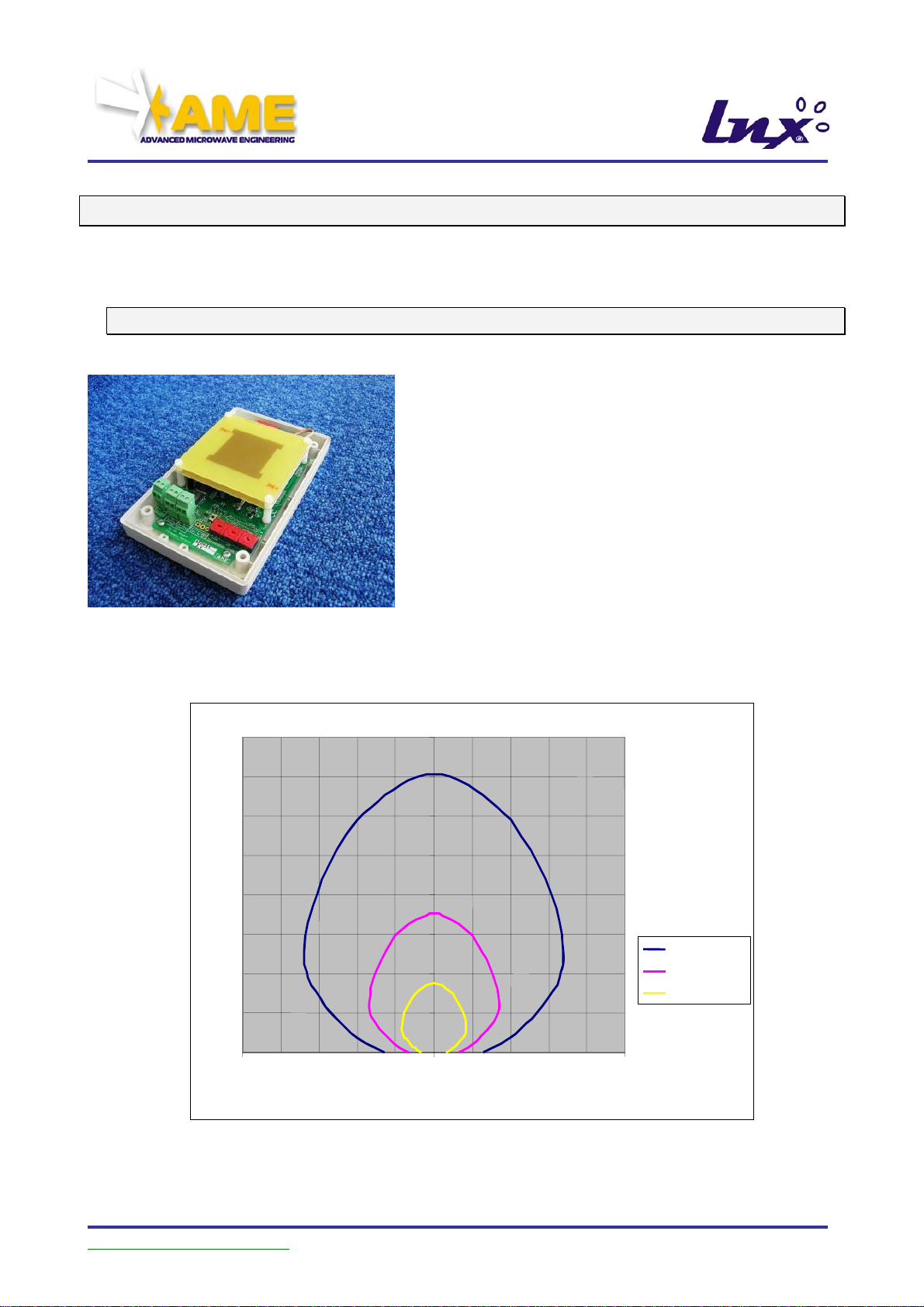

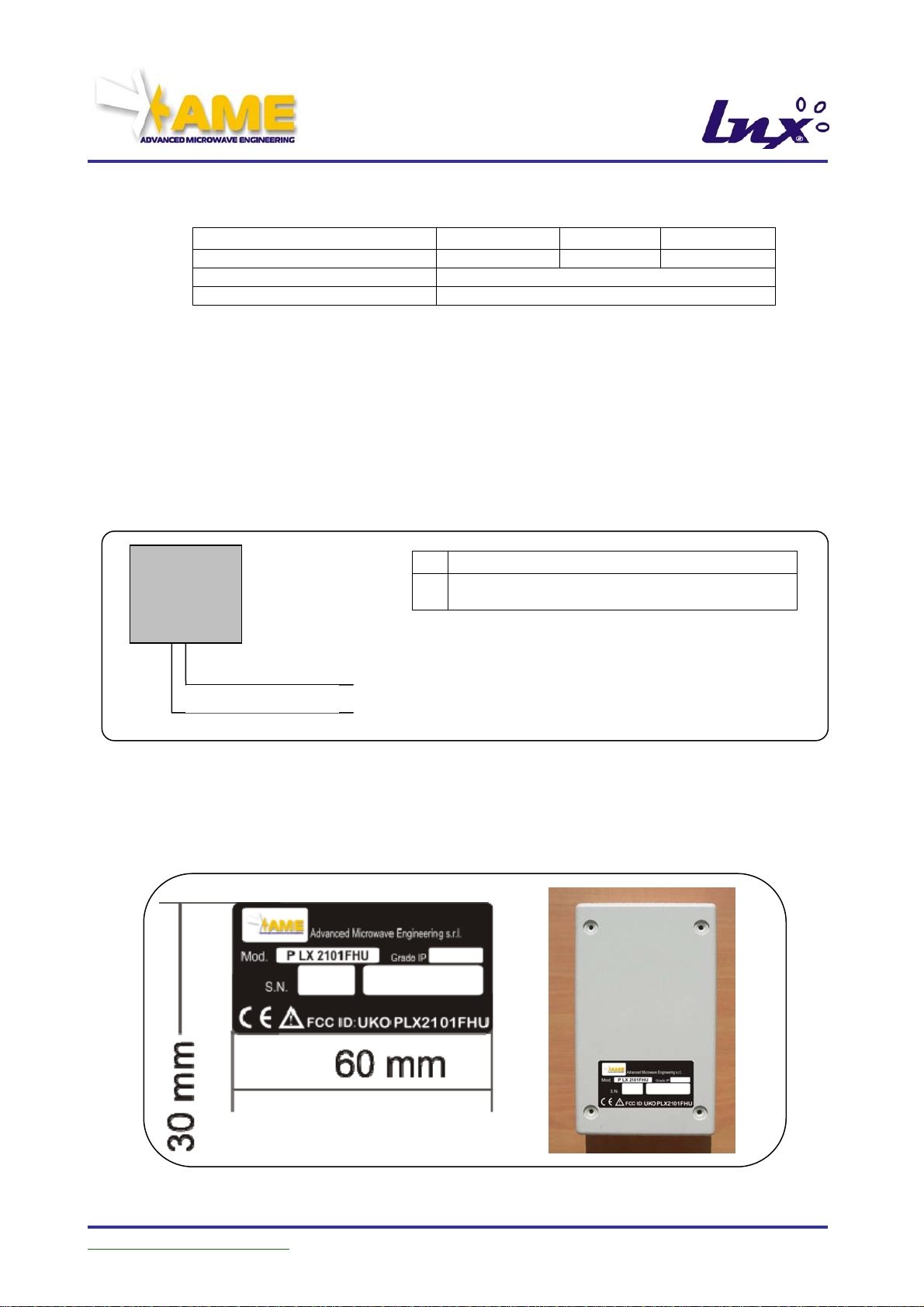

4.1. Illuminator UKOPLX2101FHU

CODED ILLUMINATOR LX2101 generates an

encoded signal at 2.45GHz to activate the LX1004

Dual Frequency Tag.

The device needs only the 12/24V direct (Vdc) or

alternating (Vac) power supply; once it is powered, it

will start continuously transmitting its own code.

In compliance with the ETSI EN 300-440 standard,

it transmits with power levels below +20 dBm (100

mW), which cannot be incremented.

The influence lobe with circular conical shape

which emits microwaves has an overall opening of

about 90° - 100°, within which are activate the

LX1004 transponders.

A representation of the antenna radiation lobe at 2.45GHz is provided below

16

14

12

10

m

8

6

4

2

0

-10 0 10

m

Linx

Illuminator

Coverage

AME ANT 2. 4 4

tt (dB)= 0

tt (dB)= 6

tt (dB)= 12

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 13 of 70

Page 14

[1]

pply

Mechanical Characteristics

Parameter

External dimensions (L x H x P)

Colour

Degree of protection

158 mm 95 mm 45 mm

Ivory RAL 9002

IP56

Wiring for UKOPLX2101FHU

The wiring provides the following connections:

• Power Supply [1]: (12/24V ac, dc) with maximum utilisation power 20W

• RS422 [2]: connection on serial line RS422, to be activated to

communicate with other illuminators installed and generate a

synchronism in the transmission.

Illuminator

LX 2101

Power su

[2] Line RS422

Figure 1: LNX Illuminator Wiring

OSITION OF LABEL

P

Power supply PCV, 2 wires x 0.75mm

1

Line RS422 suitable cable for

2

RS422 line

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 14 of 70

Page 15

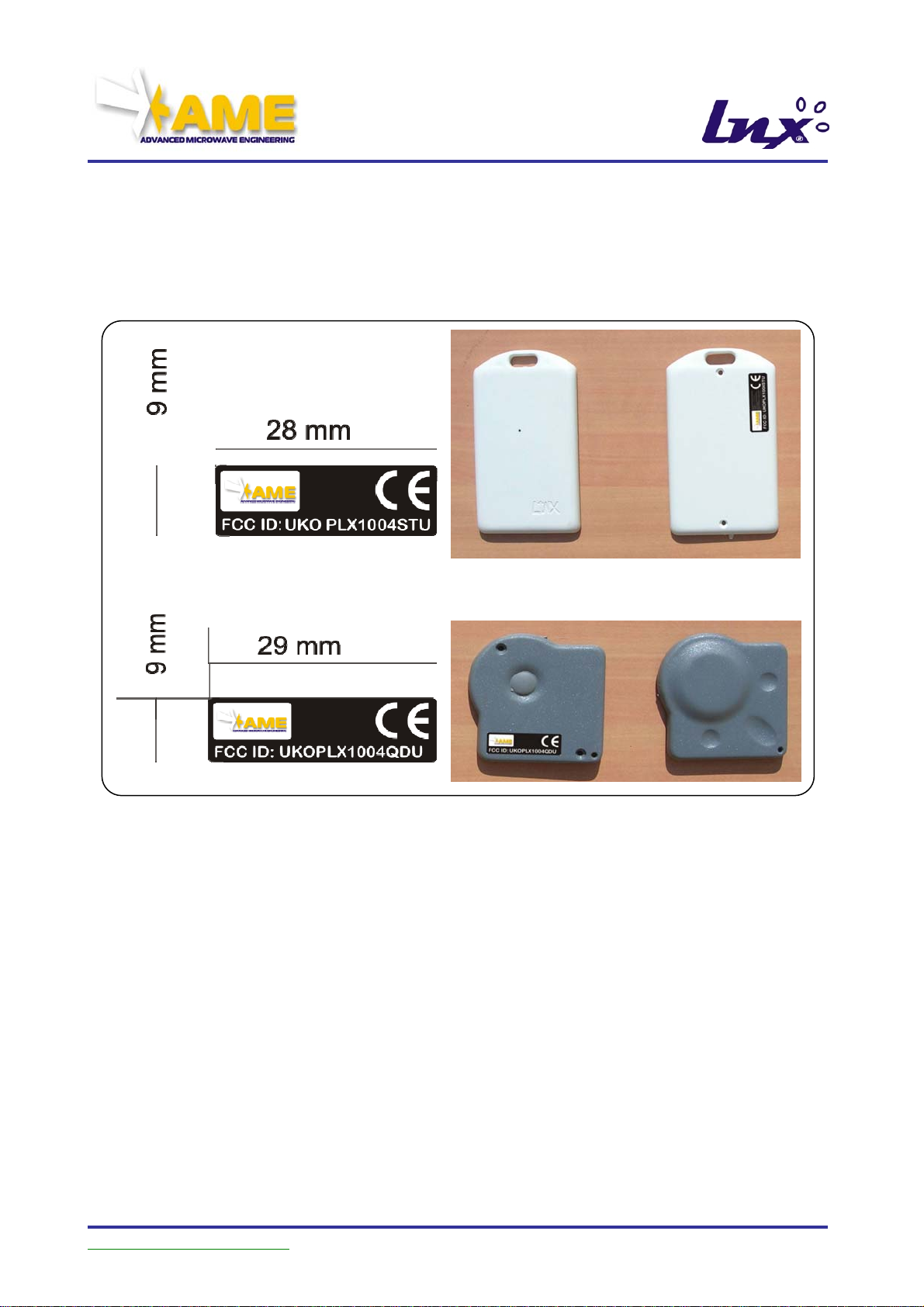

4.2. TAG DualFrequency UKOPLX1004STU & UKOPLX1004QDU

Normally off, it activates in the area of influence of the

PLX2101FHU illuminator. In reply, it transmits its own code

preceded by the code of the illuminator in whose area the

TAG was activated, at a reply frequency of 433MHz.

Equipped with replaceable lithium battery, it has an

endurance of over 100,000 transmissions.

The activation range at 2.45 GHz under the PLX2101FHU

illuminator is about 12 meters in free area; the transmission

at 433 MHz to the receiver PLX2002, compliant with ETSI

EN 300-220, can vary between 40 meters and 60 meters in

free area.

Mechanical Characteristics

Parameter

External dimensions UKOPLX1004STU (L x H x P)

External dimensions UKOPLX1004QDU (L x H x P)

Colour

95 mm 56 mm 9 mm

52 mm 52 mm 9 mm

White

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 15 of 70

Page 16

Wiring for UKOPLX1004STU or UKOPLX1004QDU

The system is self-powered and requires no wiring.

POSITION OF LABEL

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 16 of 70

Page 17

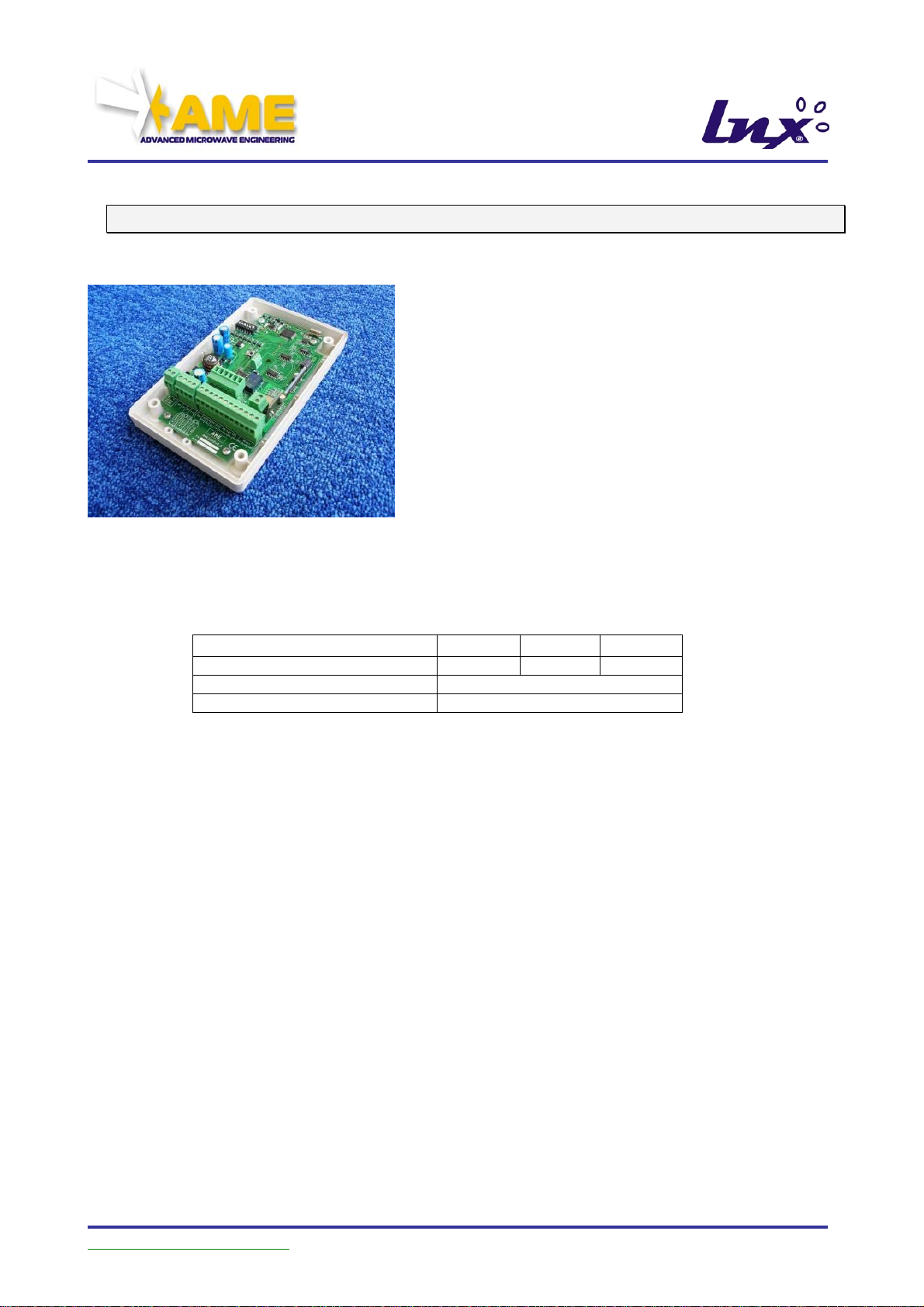

4.3. UKOPLX2002 Radio Receiver

Radio Receiver (433 MHz) for Dual Frequency TAG

The device, powered with direct (Vdc) or alternating

(Vac) 12/24 V voltage, interfaces to the external

devices through its communications interfaces,

which are a relay and the standard serial

communication channels (RS232, RS422 ethernet,

wiegand, magstripe). In compliance with ETSI EN

300-220, in this configuration the reception range of

the PLX1004STU or PLX1004QDU TAGs can vary

between 40 and 60 meters in free area.

The receiver provides for filtering the data receive

according to the code of the PLX2101FHU illuminator that activated the transponder.

Mechanical Characteristics

Parameter

External dimensions (L x H x P)

Colour

Degree of protection

158 mm 95 mm 45 mm

Ivory RAL 9002

IP56

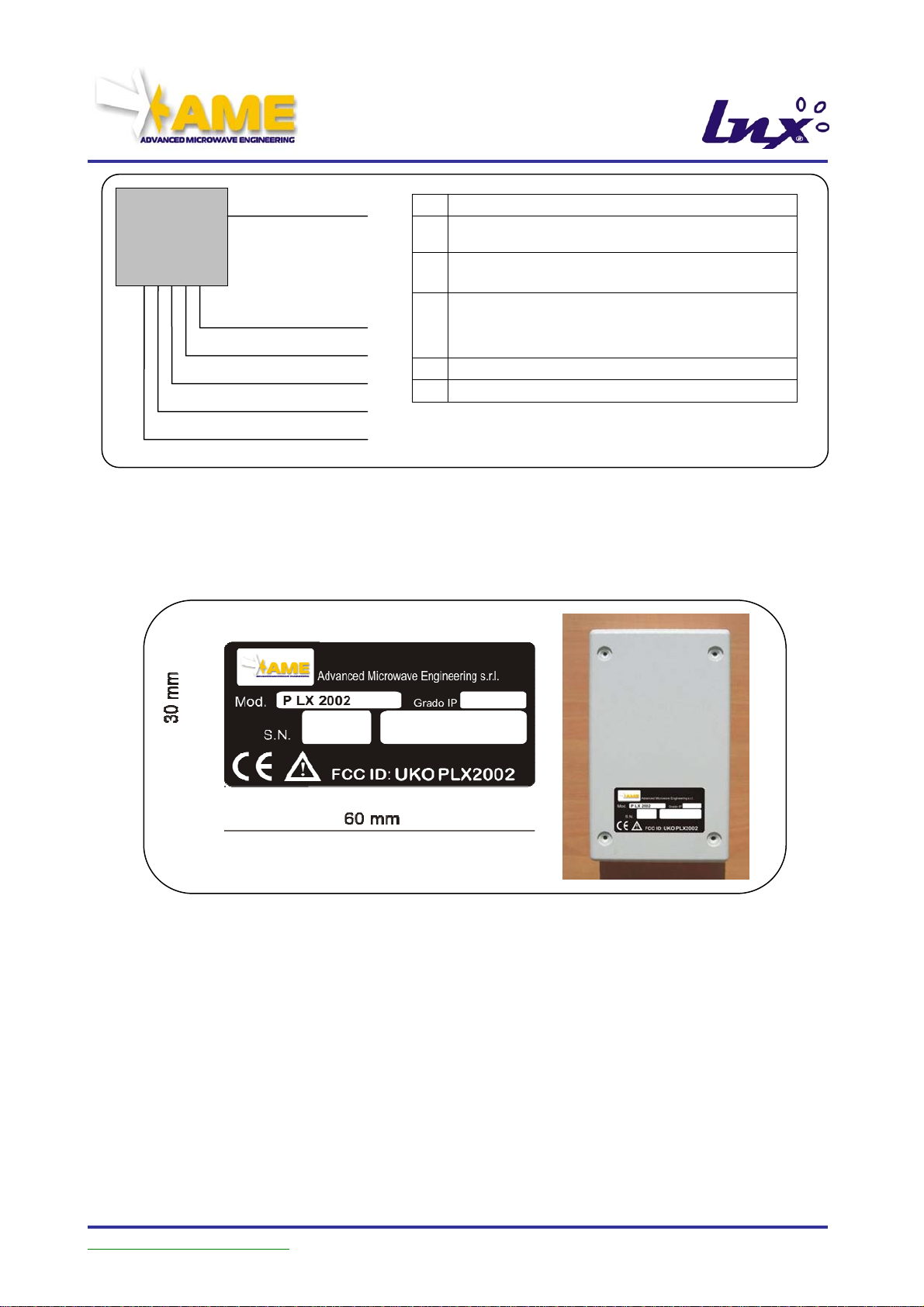

Wiring for UKOPLX2002

The wiring provides the following connections:

• Power Supply [1]: (12/24V ac, dc) with maximum utilisation power 20W

• RS232 [2]: connection on serial line RS232, always active

• RS422 [3]: connection on serial line RS422, to be activated

• Magstripe [4]: Magstripe ISO 7811 TRACK 2 connection (standard used by

access control peripherals), to be activated

• Wiegand [5]: Wiegand connection, 37BIT protocol (standard used by access

control peripherals), to be activated

• TCP/IP [6]: connection to the LAN (NEEDS ADDITIONAL ELECTRONICS;

the relevant documentation is not included in the present

manual), to be activated

• Service [7]: Relay output, to be activated.

• Tag Present [8]: signals the reception of data from a TAG

• Aux Pwr Sup [9]: (5V dc stabilised) auxiliary power supply line

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 17 of 70

Page 18

PLX2002

Receiver

[3] or [4] or [5] or [6] Data Line

[8] Tag present Line

[9] AUX Pwr Supply

Figure 2: LNX Receiver Wiring

[7] Serv.

[1] Pwr Sup.

[2] RS232 Line

POSITION OF LABEL

Power supply PCV, 2 wires x 0.75mm

1

Auxiliary power supply

9

PCV, 2 wires x 0.75mm

RS232 Line suitable cable for

2

RS232 line

3

Data Cat. 5 UTP 8 wires

..

6

Tag present Line PCV, 2 wires x 0.50mm

7

Relay Line PCV, 2 wires x 0.50mm

5

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 18 of 70

Page 19

5. INSTALLATION

5.1. Introduction

Certain specific functional characteristics are required for the identification system:

Illuminator UKOPLX2101FHU

9 It should be installed according to the following procedures:

o position it above the centre of the lane to be illuminated, not exceeding 4

metres; otherwise, it may be positioned laterally as shown in the following

figure. In this second case, it should be positioned at a height of 2.20

metres to 3.00 metres, orienting it towards the area to be covered by the

activation lobe; for the installation, the dedicated bracket can be purchased

and used.

o it must be positioned in such a way that there are no obstacles of any kind

between the device and the area to be covered by the activation lobe.

o the devices that will be used will transmit their identifying code which will be

received by the transponder; the code will be set during the installation

phase using the selectors present on the device.

Note any body (in particular, metal surfaces such as walls, nets, etc.) which

comes into the area of influence of the device can interact with the

electromagnetic fields produced by the illuminator, generating reflection and

attenuation phenomena that can alter the radiation lobe even to a considerable

extent.

Receiver UKOPLX2002

9 It should be installed near the barrier. The recommendations to observe are:

o The device (or alternatively the external antenna) must be positioned in an

open environment, in the absence of metal surfaces or reinforced concrete

structures, to facilitate the reception of the data sent by the transponders;

o no transmitter devices with the same working frequencies as the LNX

system may be present in the vicinity of the receiving antenna.

o As an alternative to the antenna integrated internally to the device, an

external antenna, not supplied, at 433 MHz – 50 provided with 50

coaxial cable, maximum length 8 metres can be used.

Transponder UKOPLX1004STU or UKOPLX1004QDU

9 it can be installed inside transportation means, or worn by people. Inside

transportation means, to obtain the best performance, we recommend to:

o position the TAG at the centre of the windshield using the adhesive Velcro,

in such a way as to make it removable;

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 19 of 70

Page 20

o position it on the upper part of the windshield in automobiles and in the

lower part of the windshield for lorries;

o not position it behind shield glasses; if the vehicle is fitted with them, the

TAG shall be positioned in the areas of the glass not provided with

shielding.

Note: the activation range at 2.45 GHz under the Illuminator is about 12

meters in free area; positioning the transponder behind the glass of the

vehicle, this range is reduced differently according to the type of glass.

When instead it is worn by people, the following measures shall be observed:

o it has to be “worn” in plain view, preferably with a string around the neck or

with a badge holder band secured to the clothes;

o IT MUST NOT be carried in suitcases, bags, clothes pockets;

o IT MUST NOT be placed in contact with other bodies, metallic or

otherwise (coins, cell phones, object cases, glass cases, etc…)

5.2. Precautions

Initial Inspection

Packing and

Unpacking

Preparation for Use

To avoid electric shock hazards, do not turn the instrument on

if it shows signs of damage in any of its parts.

Check the instruments’ shipping package for damages. If it is

damaged, retain it until the condition of each individual

accessory has been thoroughly checked and the instruments

have been checked both mechanically and electrically. Check

that the checklist matches the supplied material, including the

Documentation. Notify the shipping personnel and Our

Servicing Department of any damages.

Verify that the power supply system is compliant with current

safety standards.

Caution

User Manual Updated as of

Before connecting the apparatus to the power supply mains,

ensure that the voltage is within 30V

ac

.

Before connecting the apparatus to the user’s line, ensure

that the current that flows through the line in short circuit

condition is less than 1°.

27 giu. 07 – Rel.1.3.5 Page 20 of 70

Page 21

Connection to Power

Supply Mains

The two apparatuses have an identical power supply system.

Each apparatus operates with direct or alternating voltage

with a value ranging from a minimum of 12V and a maximum

of 24V.

WARNING

The LNX (SELV) power supply system must

assure adequate separation from the power

supply mains (230 / 110 Vac). On the low voltage

line to each individual apparatus must be

installed a protecting fuse, rated at 600mA for

the power supply, be it at 12V or 24V.

5.3. Technical Characteristics of the Materials Employed

Power supply cord

Data cables

From the electrical switchboard indicated above starts the

electrical power supply cord (recommended model shown in

Figure 2 and in Figure 1) for the two apparatuses.

For the receiver, 4 communication protocols are provided

RS232 (Figure 2: LNX Receiver Wiring [2])

RS422 (Figure 2: LNX Receiver Wiring [3])

Magstripe (Figure 2: LNX Receiver Wiring [4])

Wiegand (Figure 2: LNX Receiver Wiring [5])

TCP/IP (Figure 2: LNX Receiver Wiring [6])

Based on the implementation requirements Figure 2, the

characteristics of the respective cables are indicated.

For the illuminator, the RS422 is provided for connection

with one or more illuminators.

The interconnection allows to synchronise the transmission of

the various apparatuses.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 21 of 70

Page 22

Auxiliary cables

Environmental

conditions

Cleaning the

instrument

Two auxiliary outputs are provided on the receiver:

Relay (Figure 2: LNX Receiver Wiring [7])

Tag Present (Figure 2: LNX Receiver Wiring [8])

Both lines are activated in the presence of a TAG, but as the

section dedicated to the programming of the Receiver clearly

specifies, they have independent settings.

The type of signal they generate is very important; the Relay

output manages a power signal, while the TAG present

output manages a digital signal.

These apparatuses are specified to operate within the

following limits:

MAX Temperature: 60°C

Humidity: MAX 95% non condensing

Installation: the apparatus is immune to indirect water

splashes

These apparatuses must be stored in a clean, dry

environment. Storage and transports are specified with the

following environmental limits: temperature, humidity,

elevation.

Use a clean, non abrasive, soft and dry cloth.

Caution

5.4. Notes on Installation

Installation

Equipment required

for installation

To clean the apparatuses, do not use any solvent, dilutant,

turpentine, acid, acetone or similar materials, to avoid

damaging the outer case.

To install the LNX apparatuses, carefully follow the

instructions contained in the following paragraphs.

Medium sized Phillips head screwdriver

Small screwdriver (for watch makers)

Electrician’s scissors

Wire stripper

Drill

Tester

Conical tip, min ø 25 mm

All materials useful for fastening the apparatuses to a wall

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 22 of 70

Page 23

Notes on installation

Caution

Depending on the degree of protection to be reached, a

different type of installation is required.

IP55: Using a ducting system made up of corrugated tube

(recommended model GEWISS DX 30 320) and nut union

fitting (recommended models GEWISS DX 54 420 with DX 54

520) it is possible to achieve the IP55 Degree of Protection,

i.e. rain-proofing.

A similar level of protection is obtained using the sealed cable

duct (recommended model GEWISS GW 52 042), provided

that only one cable passes inside the duct.

A fundamental condition to achieve and maintain the degree

of protection selected for the installation is that every time the

lid is removed, it is repositioned correctly with the gasket in

the proper position and free of damages or twists which could

cause water infiltrations.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 23 of 70

Page 24

5.5. Installation of the Apparatus

The procedure to follow to install the two apparatuses of the system is identical and it

comprises 7 steps:

a) Preparation of the electrical system

b) Drilling holes in the boxes

c) Fastening the boxes or the joint (if provided)

d) Laying the power supply cords

e) Laying the data cables

f) Housing the apparatuses

g) Initialising the system

h) Tests and checks

Preparation of the

electrical system

Usually, the power supply system comprises a

magnetothermic breaker, 500 mA fuse with FAST action and

SELV 200V/24V mains transformer, all within an electrical

switchboard that may be dedicated or incorporated in a

general one.

Drilling holes in the boxes

The recommended mounting methods have already been

described; for the illuminator apparatus, often connected only

to the power supply, cable duct mounting is recommended

(see Figure 4: mounting with cable duct).

For the receiver apparatus, connected to multiple wires,

wiring with corrugated hose and junction is recommended

(see Figure 3: mounting with corrugated hose).

The dimensions of the junction and of the cable duct depent

on mounting requirements.

If mounting is completed correctly, this type of wiring

guarantees the degree IP55

Figure 3: mounting with corrugated hose Figure 4: mounting with cable duct

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 24 of 70

Page 25

Fastening the boxes

Laying the power supply

cords

The apparatus can be fastened directly to the wall with

adhesives, or through four tabs (not supplied) for fastening in

the way that best suits the support structure (e.g.: Fischerr for

wall, self-threading screws for metals, suitable screws for

wood, etc.)

A joint (not supplied) can be used, allowing to orient the

apparatus after mounting (Figure 5: fastening articulated

joint).

Figure 5: fastening articulated joint

Connect the power supply cord from the electrical

switchboard to the apparatuses. Let 15 cm of cord project

outside the box and connect the 2-pole female terminal,

included in the supply.

Illuminator Power Supply

Supply power to the device by means of the J1 screw

connector positioned on the left side; it is possible to supply

both direct voltage Vdc and alternating voltage Vac with

voltage value 12V or 24V. It is not important to match terminal

polarity.

The red LED indicates the correct operation of the device.

Receiver Power Supply

Supply power to the device by means of the J1 screw

connector positioned on the left side; it is possible to supply

both direct voltage Vdc and alternating voltage Vac with

voltage value 12/24V. It is not important to match terminal

polarity.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 25 of 70

Page 26

Laying the data cables

Laying the auxiliary cables

Housing the apparatuses

Receiver Auxiliary Power Supply

Pin 2 of the connector J6 (+5V Vdc) can be used to power the

device by means of stabilised direct voltage at 5 V.

Vmax = 5 V continuous stabilised

NOTE: Make absolutely sure that pin 3 of the

connector J6 (GND) is used as reference.

NOTE: the input line is NOT protected; use a

stabilised reference voltage.

NOTE: DO NOT simultaneously power the board

using the supplementary input at 5 Vdc and the

standard power supply of the connector J1

Check voltage levels with a TESTER.

Based on the type of connection selected for the receiver (see

paragraph “

Wiring for UKOPLX2002”) connect the data cable to a PC if

RS232, or to the network access point if LAN or RS422.

For easier maintenance, each individual wire should be

labelled.

Verify the Intranet connection through the LAN data cable.

WARNING: DO NOT CONNECT THE APPARATUS TO THE

LAN NOW

Laying the auxiliary cables.

RELAY: Let 10 cm of cord project outside the box and

connect the 12-pole female terminal, included in the supply;

based on the position, operation will be as follows.

11 – 12 : NORMALLY OPEN operation

10 – 11 : NORMALLY CLOSED operation

Opening and delay times can be set via software

Verify the connection short-circuiting, or opening the line and

checking whether the expected operation is performed.

TAG PRESENT: Let 10 cm of cord project outside the box

and connect the terminals, one to pin 3 of the 12-pole female

terminal and one to pin 3 of the 4-pole connector, included in

the supply

House the apparatuses, securing them with the supplied

screws as shown in Figure 6: receiver apparatus and Figure

7: illuminator apparatus

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 26 of 70

Page 27

Figure 6: receiver apparatus Figure 7: illuminator apparatus

Closing the lids

Position the o-ring inside the groove,

position the gaskets to the screws,

fasten the lid with the screws.

5.6. Starting the apparatuses

Start

To set up the LNX apparatuses, carefully follow the

instructions contained in the following paragraphs.

Equipment required for

starting

PC with DRS232 port, or USB (use a commercial USBRS232 converter)

Serial cable

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 27 of 70

Page 28

5.7. Configuration of illuminator UKOPLX2101FHU

This device is an activator for 2.45 GHz transponders active in the LINX system, which not

only generates a carrier at the preset frequency but transmits data according to the

parameters set.

The device also generates synchronization commands for other PLX2101FHU devices set

as slaves, so as to form a network providing more specific radio coverage.

J1 RC1 RC2 RC3

J11 J12 J13

connector

Power supply

Hook the device up to the power supply using the special threaded connector J1 placed on

its left side; it can be powered with 12/24 V voltage, both DC and AC. The polarity of the

electric terminals is not relevant.

The red led indicates correct operation of the device

External interface

The device has an external RS422 interface (

not terminated with a 120 Ω resistor) used for

both programming its own identification code as an external unit, and for

transmitting/receiving synchronization commands to/from other PLX2101FHU connected

to the network.

On connector J11, pins 1 and 2 (Tx+, Tx-) are lines “Tx+” and “Tx-“ of the RS422 serial

interface (RS485 full duplex); on connector J11, pins 1 and 2 (Rx+, Rx-) are lines “Rx+”,

“Rx-“ of the RS422 serial interface (RS485 full duplex).

NOTE: The use of connectors J10 and J13 is reserved for factory testing

procedures, and we recommend that NO external electric signal be interfaced.

NOTE: for network connections, refer to the paragraph on “Operating Modes”.

Operating modes

3 different operating modes are possible:

1. Standalone master (SA master)

2. Piconet master (PN master)

3. Slave

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 28 of 70

Page 29

The device is unequivocally identified by the 3-byte factory code (F.C.).

These 3 different modes permit 3 different installation configurations:

host SA master SA master SA master

Up to 32 readers can be networked, all managed by the host using

addressable protocol. Each device can be programmed

independently.

host PN master

Slave

Slave

The host can manage a single piconet made up of 1 Master pn and

up to 31 Slaves. The settings transmitted to the Master are

automatically extended to the connected slaves.

piconet

PN master

Slave

Slave

The piconet is stand alone and NOT connected to a host. The settings

made to the master are automatically extended to the connected

slaves.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 29 of 70

Page 30

p

Set the operating mode with the SW1 dipswitch at the top of the board.

SEL1 SEL2

1 2 3 4 5 6

SW1 di

switch details

Selector Position 0 (down) Position 1 (up)

1 Slave Master

2 External Internal

3 Line 1 (tx in antiphase with master) Line 0 (tx in phase with master)

4 Duty cycle transmission Continuous transmission

5 SW parameters HW parameters

6 PN master SA master

To make the settings effective the device must be reset.

Selector 1: by pushing up the switch, the device is set as Master (ON); when turned on, it

sends its identification code over the RS422 interface, and after a few seconds the

synchronization commands of any other LX2101 devices connected in slave mode.

In this configuration, switches 2 and 3 become irrelevant. By pushing down the

switch (OFF), the device is set as Slave and transmits only when it receives the

synchronized command sent over the RS422 interface by a reader set as Master. In

this configuration, switches 2 and 3 become operative.

Selector 2: if pushed up (ON), the device transmits the identification code with the suffix “I”

(Internal); if pushed down (OFF) the device transmits the identification code with the

suffix “E” (External).

NOTE: if the device is set as Slave, the device transmits the identification code of

the Master unit which manages the RS422 network .

Selector 3: active only if the device is set as Slave; if pushed up (ON), the device transmits

in phase (simultaneously) with the Master unit which manages the RS422 network;

if pushed down (OFF) it transmits in antiphase (alternating) with the Master unit.

Selector 4: active only if the device is set as Master; if pushed up (ON), it allows

continuous transmission of data; otherwise, if pushed down (OFF) it allows

discontinuous transmission (one code in each factory set time interval) of the

identification code.

NOTE: if continuous transmission of the code is activated (ON), the Master

device NO LONGER manages the synchronization of any other devices connected

as slaves through the RS422 interface.

Selector 5: active only if the device is set as Master; if pushed up (ON), the device

transmits the parameters set by the RC1, RC2, RC3, Sel1 and Sel2 selectors;

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 30 of 70

Page 31

otherwise, if pushed down (OFF) the device transmits via radio channel the

parameters set by the commands on the serial RS422 interface (See “Binary

communication protocol”)

Selector 6: active only if the device is set as Master; if pushed up (ON), the device does

not manage any slave devices connected to it, and moreover, responds only to the

binary protocol commands on the RS422 interface addressed to it; if pushed down

(OFF), the Master device manages the connected piconet and transmits operating

parameters to its Slave devices.

NOTE: all changes to settings become operative after the device is reset (see "button

functions" below)

Button functions

When pushed down, the SW2 button has different functions according to how it is pressed:

• Pressed for under 3 seconds: resets the receiver, as if it were turned off and back on

• Pressed for over 3 seconds: the device transmits its own diagnostics data via radio to

the transponder.

LEDs

LED1 (D10): always lighted, it indicates correct power supply to the board

LED2 (D11): when flashing, indicates transmission at microwaves (phase

Master/Slave line 0)

LED3 (D7): ): when flashing, indicates transmission at microwaves of the slave line1

(antiphase Master)

LED4 (D8): lighted when carrier frequency is locked

LED5 (D9): when flashing, indicates the transmission/receive on RS422 channel

User Manual Updated as of

SEL1

SEL2

1 2 3 4 5 6

External Led

Led 1

Led 2

Microwave Section

Led 3

Led 4

Led 5

Detail of LED

27 giu. 07 – Rel.1.3.5 Page 31 of 70

Page 32

Led Function

1 Power-On

2 Master/Slave0 Tx

3* Slave1 Tx

4 Lock Frequency

5 RS422 Tx/Rx

External Master Tx

LED’s Table

* Active only in “Master” configuration.

Reader Code

The RC1, RC2, RC3 rotary codes on the bottom right allow the serial number (S.N.) of the

device to be set.

This code is transmitted only if selector 5 on the SW1 dipswitch is pushed up (ON).

1. RC1 (x100): sets the hundreds in the code to be transmitted

2. RC2 (x10): sets the tens in the code to be transmitted

3. RC3 (x1): sets the units in the code to be transmitted

NOTE: To make the settings operative, press the reset button.

Product Code

The SEL1 and SEL2 rotary codes on the top left allow one to set the product code to be

transmitted to the transponder.

This code is transmitted only if selector 5 on the SW1 dipswitch is pushed up (ON).

1. SEL1 (x10): sets the tens in the code to be transmitted

2. SEL2 (x1): sets the units in the code to be transmitted

For more details on the operating modes, refer to the documentation on the CAP

“5.8 Configuration of trasponder UKOPLX1004STU / UKOPLX1004QDU”.

NOTE: To make the settings operative, press the reset button.

Binary communication protocol

The device can be completely controlled and parameterized through the RS422 serial

interface, and all packets are addressed using the factory code (F.C.)

Communication is made through a predefined data format, as follows:

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 32 of 70

Page 33

2 byte header

55h 55h

variable payload

1 byte check sum

In the entire packet the order of the bytes within the words is LSB-MSB.

The check sum (CS) is calculated as module 2 (XOR) of the PAYLOAD.

Payload

The length of the payload is variable and depends on the command it refers to.

COMMAND PARAMETERS

1 N

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 33 of 70

Page 34

The command set is:

Code (decimal) Description Parameters Parameter

length (bytes)

1 Set S.N. F.C. + S.N. 3+2=5

2 Get S.N. F.C. 3

3 Not implemented - -

4 Get duty cycle F.C. 3

5 Not implemented - -

6 Not implemented - -

7 Not implemented - -

8 Not implemented - -

9 Set product code F.C.+product code 3+1=4

10 Get product code F.C. 3

11 Get dipswitch

settings

12 Microwave power on F.C. 3

Commands from host to device

Commands from

Commands from

* the power transmission is NOT implemented, therefore this data does not have validity

13 Microwave power off F.C. 3

14 Get microwave

supply status

15 Ack F.C. 3

16 Nack F.C.+error code 3+1=4

17 TX S.N. F.C.+S.N. 3+2=5

18 TX duty cycle F.C.+d.c. 3+2=5

19 TX power F.C +power. 3+1=4 4 bit lsb

20 TX frequency F.C.+frequency 3+1=4 4 bit lsb

21 TX product code F.C.+product code 3+1=4

device to host

22 TX dipswitch settings F.C.+settings 3+1=4

23 TX microwave

supply status

24 Initialization S.N.+product

25 TX Slave 0 no. of packets to

26 TX Slave 1 no. of packets to

device to device

F.C. 3

F.C. 3

F.C.+status 3+1=4

2+1+1=4 Power = 4

code+power/frequency

1

transmit

1

transmit

Note

bit msb

Frequency

= 4 bit lsb

NOTE: F.C. = individual device factory code

S.N. = Serial Number which the device transmits for its identification

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 34 of 70

Page 35

CMD 01

Allows one to set the Serial Number (S.N.) to be transmitted via radio:

S.N.

2

in which

• S.N.: number between 0 and 999, including the Internal or External suffix.

bit 11 Meaning

0 S.N. INTERNAL

1 S.N. EXTERNAL

CMD 02

Requests the serial number currently set. The device may respond by transmitting the S.N.

(CMD 17) or a NACK (CMD 16)

CMD 03

NOT IMPLEMENTED

CMD 04

Requests the transmission duty cycle currently set. The device may respond by sending

the duty cycle (CMD 18) or a NACK (CMD 16)

CMD 05

NOT IMPLEMENTED

CMD 06

NOT IMPLEMENTED

CMD 07

NOT IMPLEMENTED

CMD 08

NOT IMPLEMENTED

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 35 of 70

Page 36

CMD 09

Allows one to set the product code to be transmitted via radio:

Product Code

1

in which

• Product Code: number between 0 and 99.

CMD 10

Requests the product code currently set. The device may respond by transmitting the

product code (CMD 21) or with a NACK (CMD 16)

CMD 11

Requests the settings of the SW1 dipswitch. The device may respond by transmitting the

settings (CMD 22) or with a NACK (CMD 16)

CMD 12

Requests activation of radio communication, activating communication with the Lx1004

transponder. The device may respond with an acknowledge (CMD 15) or with a NACK

(CMD 16). If the radio section is power off, the device reset itself.

CMD 13

Requests that radio communication be turned off, disactivating communication with the

Lx1004 transponder. The device may respond with an acknowledge (CMD 15) or with a

NACK (CMD 16)

CMD 14

Requests the status (on or off) of radio transmission. The device may respond by

transmitting the status (CMD 23) or with a NACK (CMD 16)

CMD 15

The device sends an ACK each time a command is correctly carried out

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 36 of 70

Page 37

CMD 16

The device sends a NACK each time a command is NOT correctly carried out,

continuation from the code error.

Command Error Error Code

ALL Checksum 1

1÷14 Command for Master 2

1 S. N. out of range 3

1,9 Setting Hardware Code 4

3 Not Possible set Duty-Cicle 5

7,8 Not Possible set Frequency 7

9 Cod.Prod. out of Range 8

CMD 17

The device transmits its own Serial Number (S.N.):

S.N.

2

in which

• S.N. number between 0 and 999, including the Internal or External suffix.

bit 11 Meaning

0 S.N. INTERNAL

1 S.N. EXTERNAL

CMD 18

The device sends the current duty cycle for frame transmission.

No. of frames to transmit Latency

1 1

in which

• No. of frames to transmit: number of frames that must be sent in each transmission

• Latency: time interval between transmissions (as a multiple of 200mseconds)

CMD 19

NOT IMPLEMENTED

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 37 of 70

Page 38

CMD 20

The device sends the frequency of the radio transmitter; the operating frequency can be

selected out of 16 possible options:

Frequency

1

The lowest 4 bits indicate the operating frequency set.

CMD 21

The device sends the product code transmitted via radio:

Product Code

1

in which

• Product Code: number between 0 and 99.

CMD 22

The device sends the current dipswitch settings:

Dipswitch settings

1

in which

• SETTING bit definition:

BIT0 - Selector 1: 0 (down) OFF; 1 (up) ON

BIT1 - Selector 2: 0 (down) OFF; 1 (up) ON

BIT2 - Selector 3: 0 (down) OFF; 1 (up) ON

BIT3 - Selector 4: 0 (down) OFF; 1 (up) ON

BIT4 - Selector 5: 0 (down) OFF; 1 (up) ON

BIT5 - Selector 6: 0 (down) OFF; 1 (up) ON

BIT6 - N.U.

BIT7 - N.U.

CMD 23

The device transmits the current status of power supply to the radio unit:

Power supply status

1

in which

• Power supply status: 0 (down) OFF; 1 (up) ON.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 38 of 70

Page 39

TEMPORAL DIAGRAM FOR CONFIGURATIONS NET

a) Standalone master

Tx Latency Tx

b) Piconet Master & Slave

Tx

Latency Wait

Tx Line1

Master

Wait

Tx Line0

Latency

Tx

Slave Line1

Tx

Latency Latency

Wait

Tx Line1

Slave Line0

Time Latency is 200msec.

Time Tx is 500msec

Latency

Latency

Latency

Tx

Wait

Tx Line0

Tx

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 39 of 70

Page 40

5.8. Configuration of trasponder UKOPLX1004STU / UKOPLX1004QDU

Introduction

PLX1004STU and PLX1004QDU are an active dual-layer transponder, which upon

activation by a 2.45 GHz carrier can receive data from a reader (uplink) and transmit its

own 32-bit ID code, followed by other data (downlink).

Compatible with the readers in the AME product line and with the PLX2002 receiver.

Versions available

PLX1004STU and PLX1004QDU have the same electrical, radio and operational

properties but different package and mechanical characteristics.

Operating mode

The operating mode is dictated by the product code transmitted by the PLX2101FHU

activator.

During normal operation, the transponder memorizes two pieces of data:

1. number of transmissions made

2. number of resets carried out

and then it transmits this information as follows:

1. every 1000 transmissions

2. when requested by the specific reader which transmits the product code of the tag

diagnostics.

After receiving the data transmitted by the reader, the device sets the correct operational

parameters and configures itself according to the selected mode .

The various operating modes are listed below:

Code

(decimal)

1 STANDARD (3 tx+psr

2 FAST (3 tx + psr 45 msec÷450 msec) (see note 1)

3 APB (3 tx + psr 2 sec+2 tx + apb

4 APB (3 tx + psr 2 sec+2 tx + apb 2 sec)

5 APB (3 tx + psr 2 sec+2 tx + apb 3 sec)

6 APB (3 tx + psr 2 sec+2 tx + apb 5 sec)

7 APB (3 tx + psr 2 sec+2 tx + apb 10 sec)

8 TRACK

9 ECM

10

…

58

59

60

61

62

63

Not allowed

…

Not allowed

BEEPER FAST (Δt=15’ ; TOperation=1h) (see note 1)

BEEPER FAST (Δt=15’ ; TOperation=3h) (see note 1)

BEEPER FAST (Δt=15’ ; TOperation=10h) (see note 1)

BEEPER FAST (Δt=15’ ; TOperation= non stop) (see note 1)

BEEPER FAST (Δt=30’ ; TOperation=3h) (see note 1)

Operation mode description

200 msec÷2 sec+2 tx+pausa 2 sec) (see note 1)

(1)

1 sec)

(2)

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 40 of 70

Page 41

64

65

66

67

68

69

70

71

72

73

74

75

99 TAG Diagnostic

BEEPER FAST (Δt=30’ ; TOperation=5h) (see note 1)

BEEPER FAST (Δt=30’ ; TOperation=10h) (see note 1)

BEEPER FAST (Δt=30’ ; TOperation= non stop) (see note 1)

BEEPER FAST (Δt=60’ ; TOperation=5h) (see note 1)

BEEPER FAST (Δt=60’ ; TOperation=10h) (see note 1)

BEEPER FAST (Δt=60’ ; TOperation=15h) (see note 1)

BEEPER FAST (Δt=60’ ; TOperation= non stop) (see note 1)

BEEPER FAST (Δt=90’ ; TOperation=5h) (see note 1)

BEEPER FAST (Δt=90’ ; TOperation=10h) (see note 1)

BEEPER FAST (Δt=90’ ; TOperation=15h) (see note 1)

BEEPER FAST (Δt=90’ ; TOperation= non stop) (see note 1)

BEEPER FAST (Δt=60 s; TOperation=non stop) (see note 1)

NOTE 1 : IMPORTANT

“Standard”,” Fast” and “beeper fast” operation (code1,2 and 59

to95) of AME UKOPLX1004STU and UKOPLX1004QDU are allowed

ONLY in applications involving fire, security or safety of life

(please refer 15.231 (a) (4)).

(1) Psr=pseudorandom

(2) apb=anti passback

Description of various operating phases (symbols)

• Tx: radio transmission at 433 MHz.

• Psr: variable time interval calculated in pseudorandom mode, during which the device

is inactive

• Pause: fixed time intervalduring which the device is inactive

• apb: time interval during which the device remains inactive if it continues to receive the

same information

STANDARD mode.

IMPORTANT:

“standard mode” is allowed only in fire, security or safety of life

applications. For example applications where the PLX2101FHU

activator is near a dangerous zone for safety of life.

Upon receiving a code from the activator PLX2101FHU, TAG transmit data to PLX2002

receiver. Transmission cycle is compsed by 3 tx+psr (200 msec÷2 sec) +2 tx + 2 sec

pause). After each transmission cicle, TAG wait for 2 seconds before a new receiving is

allowed .

FAST mode

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 41 of 70

Page 42

IMPORTANT:

“fast mode” is allowed only in fire, security or safety of life applications.

For example applications where the PLX2101FHU activator is near a

dangerous zone for safety of life.

Upon receiving a code from the activator PLX2101FHU, TAG transmit data to PLX2002

receiver. Transmission cycle is compsed by 3 tx + psr (45 msec÷450 msec) for a

maximum transmission time of 600msec:

Mode Total transmission

time max (ms)

Standard

Fast

APB

Track

ECM

Beeper

3Tx (150ms) + PSR (max 2s) + 2Tx(100ms) 2250

3Tx (150ms) + PSR (max 450ms) 150

3Tx (150ms) + PSR (max 2s) + 2Tx(100ms) 2250

3Tx (150ms) 150

3Tx (150ms) + PSR (max 2s) + 2Tx(100ms) 2250

3Tx (150ms) 150

NOTE: Tx: packet transmission time (50 ms)

After each transmission cycle, TAG wait for variable time (45ms-450ms) before a new

receiving is allowed .

APB mode

Upon receiving a code from the activator PLX2101FHU, TAG transmit data to PLX2002

receiver. Transmission cycle is composed by 3 tx+ psr (200 msec÷2 sec) +2 tx) for a total

maximum transmission time of about 2,5sec . A new receiving and a following

transmission cycle will be allowed only if the TAG will not be in the activation field of the

same PLX2101FHU for a defined APB time.

TRACK mode

Upon receiving a code from the reader, the counter is activated and increments each

second; when the device ceases to receive this code for more than 3 seconds, or when it

receives a different code, it transmits its own f.c. and the counter total

NOTE: in this modality, for a greater optimization of the consumptions, the

device is placed in reception every second, therefore for facilitate the reception is

advised to use illuminators PLX2101FHU in modality of continuous transmission

ECM mode

When the first activation code is memorized, the device transmits when it receives an

activation signal with the same code, but with a different suffix (Internal /External), or when

it does not receive anything for 3 seconds. During this time, if it mainly continues to pick up

the same activation code (Internal or External), the count is continuously updated. If after

receiving the first code it picks up a different one, it transmits a probable relay signal,

memorizes the code received, and starts the cycle over from the beginning

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 42 of 70

Page 43

The coding is:

CODING VALUE

00 Input

01 Output

02 Prob. Input

03 Prob. Output

BEEPER FAST mode

IMPORTANT:

:”beeper fast” is allowed only in fire, security or safety of life

applications, for determine integrity of transmitters

When the product code has been sensed, the device transmits at regular intervals (Δt) until

the end of the time period (TOperation), or until it locates a reader with a product code of

the same series and with the code 999I or 999E

If it locates a reader with a product code of the same series, it modifies the settings of the

beeper mode; if it locates a reader with a product code different from the last code

received, it immediately changes its operating parameters.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 43 of 70

Page 44

5.9. Configuration of receiver UKOPLX2002

The PLX2002 reception unit (also referred to as receiver or BOA RF) is a control centre

whose operating modes can be programmed and parametrized.

The receiver is in permanent reception of data transmitted by the transponders via radio,

and on receiving valid data transmits them to external units over the communication

interfaces set up.

J4

J3

J5 J6 J1

1 2 1 4 1 -- 12

SW2 Dipswitch details

LED3 BUTTON

1 2 3 4 5 6

LED2 LED1

Selet. 1 Selet. 2 Selet. 3 Selet. 4 Selet. 5 Selet. 6

ETHERNET MAGSTRIPE2/ WIEGAND2 WIEGAND1 MAGSTRIPE1 RS-485 RELAY

It is equipped with a programmable internal clock so that the date and the hour of

reception are recorded for each transponder code (when selected).

Supplementary power supply

Pin 2 of connector J6 (+5 V DC) can be used to power the device with continuous

stabilised 5 V current.

Vmax = 5 V continuous stabilized current

NOTE: Be very careful to use pin 3 of connector J6 (GND) as a reference

NOTE: the supply line is NOT protected; use a stabilised voltage reference

NOTE: do NOT power the board using the alternate 5 DC input line and the

standard connector J1 power supply network at the same time

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 44 of 70

Page 45

External interface

The device has multiple electric communications interfaces for external peripherals.

Relay: pins 10, 11, and 12 (NCL, COM, NOP) on connector J6 correspond to the "normally

closed”, “common”, and “normally open” outputs of the relay on the side of the

device. This interface can be activated or disactivated by pushing switch 6 of SW2 up

(ON) or down (OFF), as shown on the diagram.

RS232: pins 3, 4, and 5 on connector J6 (GND, Rx, Tx) are, respectively, the "ground",

"Rx", and "Tx" signals of the standard serial interface. This interface is usable only

when the device is operating in Stand Alone mode, whereas in networking mode, the

information is not transmitted. Data are transmitted in ASCII mode (see ASCII data

format).

RS485: pins 6, 7, 8, and 9 (Tx-, Tx+, Rx-, and Rx+) on connector J6 are lines “Tx-”, “Tx+“,

“Rx-” and “Rx+“ of the RS485 serial interface.

If activated through switch 5 on SW2, data are transmitted in the form of an ASCII

string (See ASCII data format).

NOTE: This interface is NOT managed as an addressable multipoint serial

interface, and an anti-clash protocol is NOT provided for access to the data bus. For

the addressable multipoint operating mode, see the paragraph on “RS485

NETWORKING operation”

If the cables are particularly long, it may be necessary to terminate the farthest

receiver with two external 120 Ω resistors to be positioned on the connector between

pins 6 and 7 and between pins 8 and 9.

Ethernet: this interface is an alternative to the RS485 interface.

If activated using switch 1 on SW2, data are transmitted in the form of an ASCII string

(See ASCII data format).

With this interface is enabled also the binary protocol (see binary protocol in

Networking configuration), made exception for the clearing of the memory buffer.

NOTE: if the device is asked to clear all memory buffer through the binary

protocol, it answers with NACK, because the management of the memory is possible

single in the Networking configuration.

NOTE: If activated using switch 1 of SW2, the RS485 interface MUST be

disactivated by pushing down (OFF) switch 5 on SW2 (see Networking configuration)

NOTE: for the configuration of ethernet operating parameters, refer to the

relevant instruction manual.

Tag Present (TP): on connector J5, pin 4 (T.P.) and pin 3 (GND) of connector J6 define

the TTL open collector interface used to indicate reception of a correct transponder

code. The line is activated for a preset time and CANNOT be disactivated.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 45 of 70

Page 46

Wiegand1: on connector J5, pins 1(D0) and 2 (D1), and pin 3 (GND) of connector J6

determine the standard Wiegand HID10302 37-bit interface (first LOW and then

HIGH) in which the first 32 bits are the Tag Code Number

This interface can be activated through switch 3 on SW2.

NOTE: Wiegand1 interface and Magstripe1 interface cannot at the same time

be activated

Wiegand2: on connector J4, pin 2(D4), pin 3 (D5) and pin 4 (GND) determine the standard

Wiegand HID10302 37-bit interface (first LOW and then HIGH) in which the first 32

bits are the Tag Code Number

This interface can be activated through switch 2 on SW2.

NOTE: Wiegand2 interface can be activated only if Wiegand1 interface is

activated .

NOTE: The Wiegand2 port, if activated, transmits only data from transponders

activated by the PLX2101FHUs which are set as external, in which case the

Wiegand 1 port transmits only data from transponders activated by readers set

as Internal (lsb to msb):

Magstripe1: on connector J5, pins 1(D0), 2 (D1), 3 (D2) and pin 3 (GND) of connector J6

are used for data transmission in ISO7811 TRACK 2 format (lsb to msb):

D0 DATA

D1 CLK

D2 STROBE

The data transmitted are divided into two packets totalling 26 bytes.

The 15 bytes of PAN information contain:

PAN 15

Tag F.C. Reader F.C. Product Code

9 3 2 1

NULL

The 11 bytes of ADDITIONAL DATA contain additional information on the receiver:

ADDITIONAL DATA (11)

Receiver S.N. (5 digits)

5 6

NULL

If the PLX2101FHS reader which has activated the transponder is External (“E”),

the data are transmitted in the opposite direction (msb to lsb) as compatible with the

ISO7811 TRACK 2 standard.

This interface can be activated through switch 4 on SW2.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 46 of 70

Page 47

NOTE: the Wiegand1 interface and Magstripe1 CANNOT be simultaneously

activated

Magstripe2: on connector J4, pins 1(D3), 2 (D4), 3 (D5) and pin 4 (GND) are used for the

transmission of data in the ISO7811 TRACK 2 format (lsb to msb):

D3 DATA

D4 CLK

D5 STROBE

the data transmitted are divided into two packets totalling 26 bytes.

The 15 bytes of PAN information contain:

PAN (15)

Tag F.C. Reader F.C. Product Code

9 3 2 1

NULL

The 11 bytes of ADDITIONAL DATA contain additional information on the receiver:

ADDITIONAL DATA (11)

Receiver S.N. (5 digits)

5 6

NULL

This interface can be activated through switch 2 on SW2.

NOTE: Magstripe2 interface can be activated only if Magstripe1 interface is

activated

NOTE: The magstripe 2 port, if activated, trasmits only data from transponders

activated by the LX2101s which are set as external, in which case the magstripe

1 port transmits only data from transponders activated by readers set as Internal

(lsb to msb):

IN1

: on connector J6, pin 1 (IN1) is a 3.3V NON-managed CMOS entrance

NOTE: we recommend that NO external electrical signal be interfaced

IN2: on connector J4, pin 5 (IN2) is a 3.3V NON-managed CMOS input

NOTE: we recommend that NO external electrical signal be interfaced

IN1: on connector J4, pin 6 (IN3) is a 3.3V NON-managed CMOS input

NOTE: we recommend that NO external electrical signal be interfaced

Antenna: on connector J3, connect the hot lead and ground of a 433 MHz antenna to

the ANT and GND terminals

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 47 of 70

Page 48

NOTE: keep the two ground connections for the RF circuit and the power supply

circuit separated.

Operating mode

Set the operating mode with the dipswitch at the top of the board. The positions of the

switches activate or disactivate the corresponding outputs as shown on the diagram.

Pushing the switches up (ON) activates the respective outputs, while pushing them down

(OFF) disactivates the outputs.

To make the settings effective the device must be reset (see button functions).

The data are transmitted in the following order (on the interfaces activated via the

dipswitch)

1. TP - Tag Present (cannot be disactivated)

2. RS232 (cannot be disactivated)

3. RS485 – ethernet

4. Magstripe1

5. Magstripe2

6. Wiegand1

7. Wiegand2

8. Relay

Startup

When it is turned on, the device transmits a verification string with the version of firmware

installed.

LEDs

LED1 (top right): when flashing, indicates reception of a correct piece of data at 433 MHz,

always lighted, it indicates memory buffer full.

LED2 (top right): always lighted, it indicates correct power supply to the board

LED3 (center of card): indicates three different operating states

• one flash per second: correct operation

• two flashes per second: an invalid operating mode set on SW2

• steady: entry into stand-alone programme mode

Button functions

The button has different functions according to how it is pressed:

• Pressed for under 3 seconds: resets the receiver, as if it were turned off and back

on

• Pressed for over 3 seconds: enters standard RS232 data mode at 9600 bps

(9600,n,8,1) and waits for the password to be entered. This state is signalled by the

led first flashing and then remaining steadily lit. One can thus enter programming

mode from RS232 even without knowing the correct port setting. After reset, the

RS232 port reverts to its original setting.

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 48 of 70

Page 49

STAND ALONE MODE

In this mode, communication with the HOST is unidirectional and is always from device to

host.

The programming interface is through a terminal menu in ASCII format, both on the RS232

serial interface and the RS485 serial interface. In the latter case, the RS485 connection, or

alternatively, the ethernet connection, may be selected.

Select. 1 Select. 2 Select. 3 Select. 4 Select. 5 Select. 6 Meaning

ON/OFF - OFF ON OFF OFF ON/OFF - OFF any NOT PERMITTED

ON/OFF - OFF ON ON OFF ON/OFF - OFF any

ON/OFF - OFF ON OFF ON ON/OFF - OFF any

ON/OFF - OFF ON ON ON ON/OFF - OFF any Networking

ON/OFF - OFF OFF OFF OFF ON/OFF - OFF any Ethernet or RS485

ON/OFF - OFF OFF ON OFF ON/OFF - OFF any Wiegand1

ON/OFF - OFF OFF OFF ON ON/OFF - OFF any Magstripe1

ON/OFF - OFF OFF ON ON ON/OFF - OFF any NOT PERMITTED

ON any any any ON any NOT PERMITTED

Wiegand1,

Wiegand2

Magstripe2 ,

Magstripe1

ASCII Stand Alone data format

Data are transmitted in the form of an ASCII string in which the fields, separated by the

character “;” are the following:

tag F.C. (9 digits); receiver S.N. (5 digits); reader S.N. (3 digits); Reader Extension (1

digit, “I” or “E”);Product Code (2 digits); Time Present (1 digits); reader diagnostics (1

digit); tag diagnostics (1 digit)

These fields are always present, and there are optional fields which may be present in

specific circumstances. The string ends with CR(0x0D) + LF(0x0A)

Time Present

Byte value Meaning

0 No information

1 Followed by time information

tag F.C. (9 digits); receiver S.N. (5 digits); reader S.N. (3 digits); Reader Extension (1 digit,

“I” or “E”); Product Code (2 digits); Time Present (1 digits); Time (17 digits); reader

diagnostics (1 digit); tag diagnostics (1 digit)

The time has the following format: DD/MM/YY hh:mm:ss

Reader diagnostics

Byte value Meaning

0 No information

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 49 of 70

Page 50

1 Followed by diagnostics information

tag F.C. (9 digits); receiver S.N. (5 digits); reader S.N. (3 digits); Reader Extension (1 digit,

“I” or “E”);Product Code (2 digits); Time Present (1 digits); reader diagnostics (1 digit);

diagnostics information (5digits); tag diagnostics (1 digit)

The diagnostics information has the following format: frequency (2 digits); power (2 digits)

TAG diagnostics

Byte value Meaning

0 No information

1 Followed by diagnostics information

tag F.C. (9 digits); receiver S.N. (5 digits);reader S.N. (3 digits); Reader Extension (1 digit,

“I” or “E”);Product Code (2 digits); Time Present (1 digits); reader diagnostics (1 digit); tag

diagnostics (1 digit); diagnostics information (7 digits)

The diagnostics information has the following format: transmission cycles (3 digits);

number of resets (3 digits)

ADDITIONAL INFORMATION

Following this there could be additional information, depending on the product code of the

transponder.

TRACK mode

Counter: 5 digits

ECM mode

Direction: 1 digit

The coding is:

CODING VALUE

0 Input

1 Output

2 Prob. Input

3 Prob. Output

Additional data

Are information that can be inserted in particular applications (es. Booster) and for this

reason they do not have one fixed length. They come shown in format ascii like

esadecimali values from the more significant byte (MSB) to the less significant byte (LSB)

User Manual Updated as of

27 giu. 07 – Rel.1.3.5 Page 50 of 70

Page 51

Programming

To access programming mode, send the character “!!”, and the receiver will respond to the

command by requesting a 4-digit password (the default password is “0000”) confirmed by

“SEND”.

Each menu of settings shows the parameter currently set

After entry of the correct password, the receiver transmits the more important informations

and the command menu:

Factory code: 00000001

Serial number: 00001

RS232: 115200,8,N,1

RS485: 115200,8,N,1

Ethernet: 115200,8,N,1

TAG Filters: No

ACT Filters: No

A.P.B.: 00000

A.B.D.: No

Clock: 06/05/05 11:16:01

COMMAND MODE:

(1)-TAG database reading

(2)-TAG database writing

(3)-TAG database adding

(4)-ACT database reading

(5)-ACT database writing

(6)-ACT database adding

(7)-Settings

(8)-Clock reading

(9)-Save and exit

(0)-Exit without saving

Select the desired item by pressing the corresponding number.

TAG database reading