INSTALLATION

INSTRUCTIONS

Table Of Contents

SEP Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CSA Requirements in USA . . . . . . . . . . . . . . . . . . . . . . . . 4

CSA Requirements in Canada . . . . . . . . . . . . . . . . . . . . . 4

Additional Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unit Heater Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Combustion and Ventilation Air . . . . . . . . . . . . . . . . . . 5

Rotation of Combustion Air Inducer . . . . . . . . . . . . . . . . . 5

Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Typical SEP Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . 11

Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Leak Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SEP

100,000 to 400,000 Btuh Series

UNIT HEATERS

IM-SEP-0652453-07

November 2011

Supersedes 65245306

Unit Start−Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

To Turn Off Gas to Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Heating Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . 14

Ignition Control LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

High Altitude Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Gas Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Gas Pressure Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Limit Control Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Louver Vane Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Combustion Air Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . 16

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Start−Up and Performance Checklist . . . . . . . . . . . . . . . . . . . . 17

Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

RETAIN THESE INSTRUCTIONS

Failure to follow safety warnings

exactly could result in serious injury,

death, or property damage.

Be sure to read and understand the

installation, operation and service instructions in this manual.

Improper installation, adjustment, alteration, service or maintenance can cause

serious injury, death or property damage.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of this or any other appliance.

Installation and service must be per-formed

by a qualified installer, service agency or

the gas supplier.

FOR FUTURE REFERENCE

WARNING

FIRE OR EXPLOSION HAZARD.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

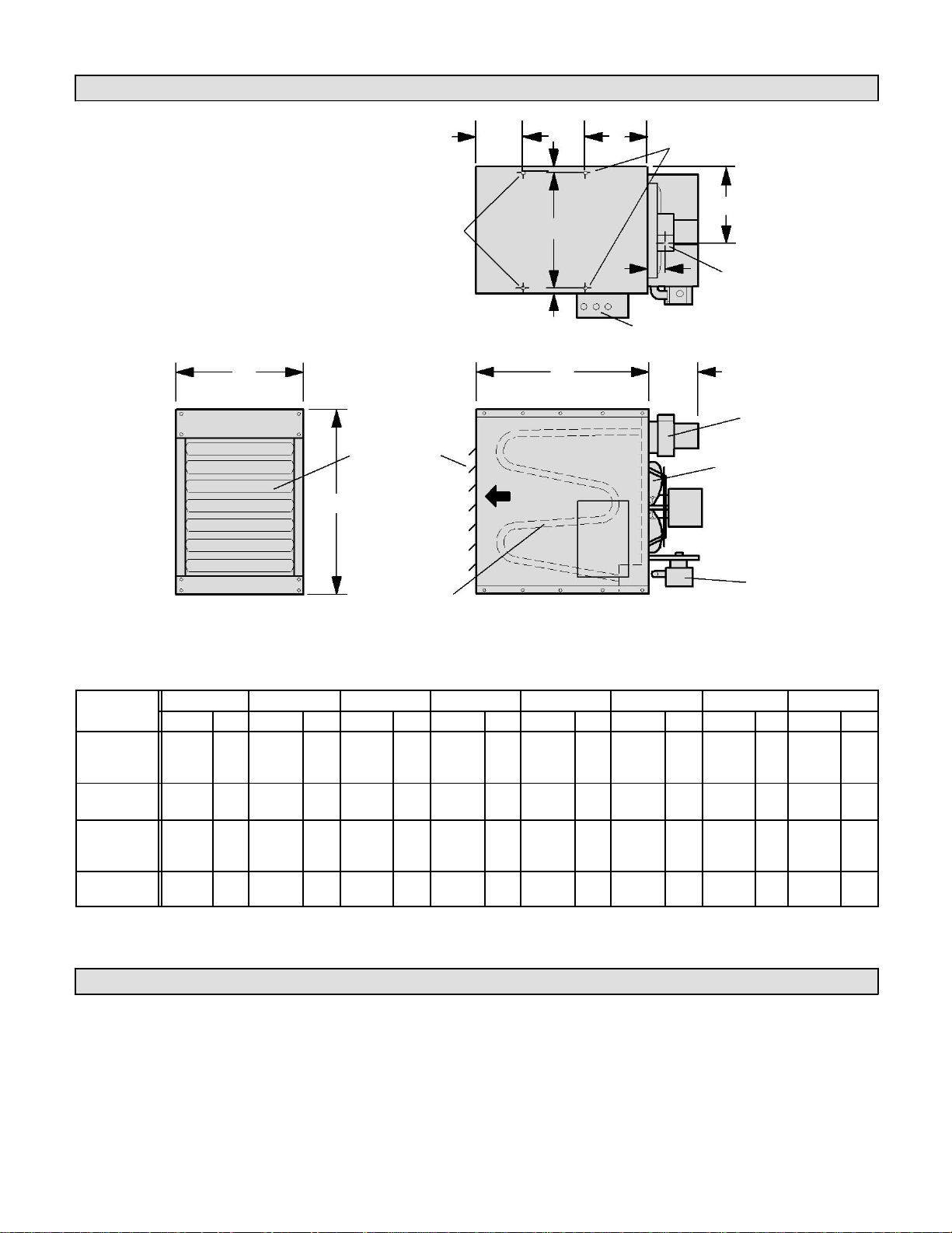

SEP Unit Dimensions

*7-5/8

1/2

D

(194)

FOR UNIT SUSPENSION

Additional

mounting nuts

F

furnished on

E

SEP−250,

SEP−300,

SEP−345 and

G

SEP−400 models

FLUE

only.

OUTLET

(13)

ELECTRICAL INLETS

TOP VIEW

A

H

INDUCER

LOUVERS

DIRECT

AIR

DRIVE FAN

FLOW

GAS

HEAT

VALVE

EXCHANGER

A B C D E F G H

Unit

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

SEP-100

SEP-115

31-5/16

795

32-3/16

817

20-3/16

512

11-1/2

292

19-1/16

484

11-3/4

298

3-1/4

83

7-7/8

200

SEP−145

SEP−175

31-5/16

795

32-3/16

817

23-1/8

588

11-1/2

292

22-1/16

560

8−1/2

216

3-1/4

83

8−11/16

220

SEP−200

SEP-230*

SEP−250*

31-5/16

795

32-3/16

817

41-1/8

1045 3-11/16

97

40

1016

17-3/4

451

3-1/2

89

8-11/16

220 SEP−300*

31-5/16

795

32-3/16

817

41-1/8

1045 3-11/16

97

40

1016

17-1/2

445

3-1/2

89

9-13/16

248

SEP−400*

2

NOTE – SEP models 100, 115, 145, 175 and 200

have a single fan. SEP models 230, 250, 300, 345

and 400 have two fans.

NOTE – Two mounting nuts are furnished on

SEP models 100, 115, 145, 175 and 2 00. F our

mounting nuts ar e f urnished on SEP models

230, 250, 300, 345 and 400 models.

SEP−230,

(13)

1/2

3/8" x 16 MOUNTING NUTS

C

COMBUSTION AIR

ADJUSTABLE

B

END VIEW

SIDE VIEW

SEP-345*

*Unit contains dual fans.

Shipping

The heater is completely assembled and is shipped with installation and operating instructions, warranty certificate

and flue transition. Check the unit for shipping damage. The receiving party should contact the last carrier

immediately if any shipping damage is found.

Optional Accessories

SEP−100 to SEP−230

Gas Part No. − Stainless Steel

SEP−100S

SEP−115S

SEP−145S

SEP−175S

SEP−200S

Heating

Performance

Part No. − Aluminized Steel

SEP−100A

SEP−115A

SEP−145A

SEP−175A

SEP−200A

Hanging Bracket

100001381

X X X X X

Kit

High Altitude

Pressure Switch

176722600

X 1

X 1

X 1

X 2

− − −

Kit

165296401

X

LPG/Propane Kit

165295202

X X X

165295205

X

165295203

SEP−230 to SEP−400

Gas Part No. − Stainless Steel

SEP−230S

SEP−250S

SEP−300S

SEP−345S

SEP−400S

Heating

Performance

Part No. − Aluminized Steel

SEP−230A

SEP−250A

SEP−300A

SEP−345A

SEP−400A

Optional Accessories − Must Be Ordered Extra

Hanging Bracket

100001381

X X X X X

Kit

165296403

X

X

LPG/Propane Kit

165295203

X

X

165295206

X

3

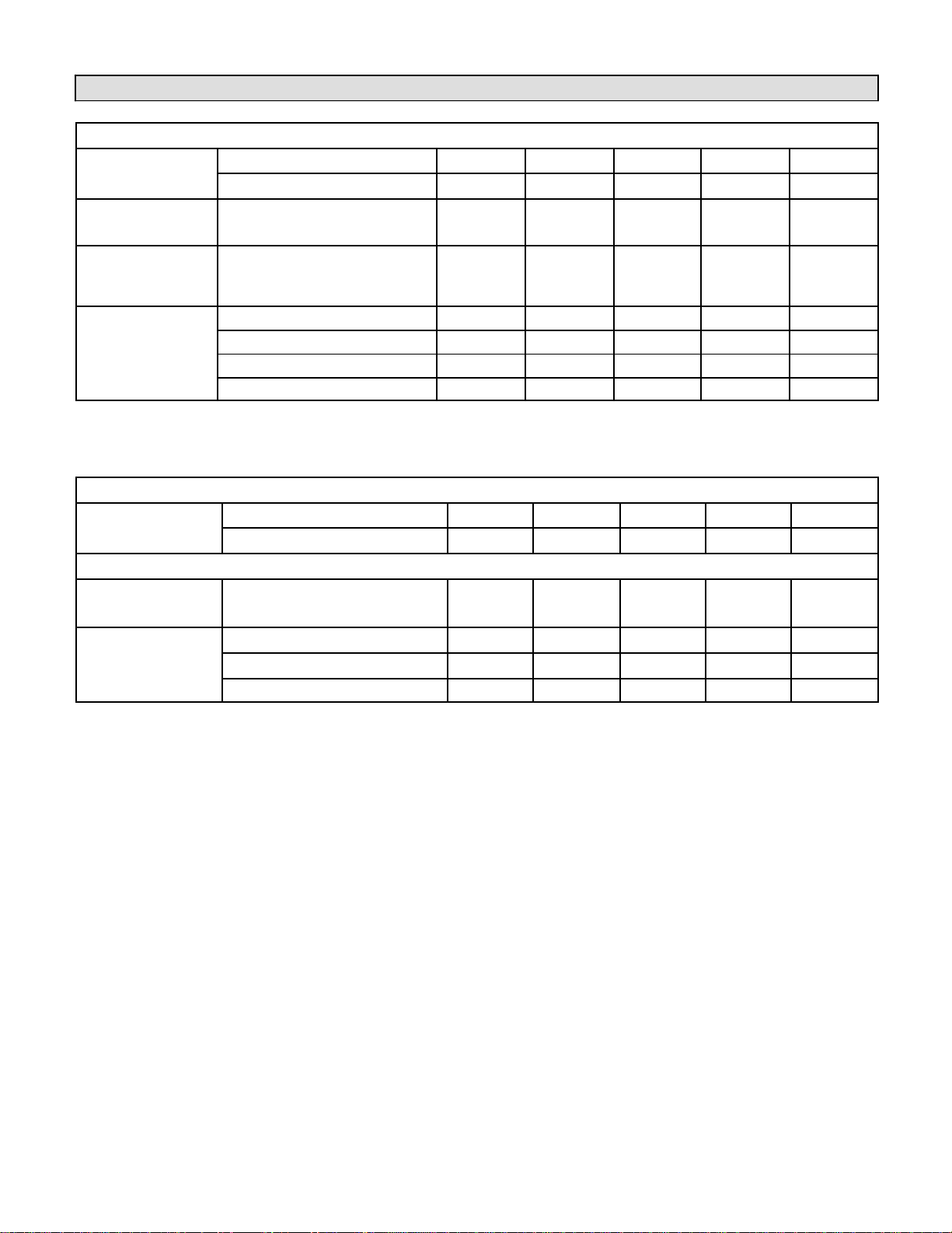

TABLE 1

1

SEP−100 through −145 require replacement combustion air inducer pressure switch at altitudes over 5500 feet above sea level.

2

SEP−175 requires replacement combustion air inducer pressure switch at altitudes over 2500 feet above sea level.

TABLE 2

Top

Sides

Bottom

Rear

Flue

in

mm

in

mm

in

mm

in

mm

in

mm

0 18

Combustible materials that are affected by

units can approach 200°F.

4

CSA Requirements in USA

Installation of gas unit heaters must conform with local

building codes or, in the absence of local codes, with the

current edition of ANSI−Z223.1, National Fuel Gas Code.

Installation in aircraft hangers must be in accordance with

the current edition of ANSI/NFPA No. 409, Standard for

Aircraft Hangers.

Installation in parking structures must be in accordance

with the current edition of ANSI/NFPA No. 88A,

Standard for Parking Structures.

Installation in repair garages must be in accordance

with the current edition of ANSI/NFPA No. 88B,

Standard for Repair Garages.

Authorities having jurisdiction should be consulted

before installation. Air for combustion and ventilation

must conform to the methods outlined in the current

edition of ANSI Z223.1, Section 5.3, Air for Combustion

and Ventilation, or applicable provisions of local

building codes.

The National Fuel Gas Code (ANSI-Z223.1) is

available from:

These units are CSA international design−certified. These

unit heaters are certified for clearances to combustible

material as listed in table 1 and on unit rating plate.

Accessibility and service clearances must be observed

in addition to fire protection clearances.

All electrical wiring and grounding for unit must be in

accordance with the regulations of the current edition of

ANSI/NFPA No. 70, National Electric Code.

The National Electric Code is available from:

American National Standard Institute Inc.

11 West 42nd Street

New York, NY 10036

National Fire Protection Association

1 Batterymarch Park

PO Box 9101

Quincy, MA 02269−9101

CSA Requirements in Canada

These instructions are intended only as a general guide

and do not supersede local codes in any way.

Authorities having jurisdiction should be consulted

before installation. The installation must conform with

local building codes or, in the absence of local codes,

with the current edition of CSA-B149 installation

compliance codes. All electrical wiring and grounding

for the unit must also comply with the current edition of

CSA C22.1, Canadian Electrical Code.

These unit heaters are CSA-certified for clearances to

combustible material listed on the rating plate and table

3. Adequate clearance must be provided around the

appliance and around air openings into the combustion

chamber. Provision must be made for service

accessibility.

NOTE: Fire protect ion clearances may be exceeded to

provide additional space for service and accessibility.

UNIT CLEARANCES TO COMBUSTIBLE MATERIALS

6 152 6 152 0

TABLE 3

457 6 152

GARAGE / WAREHOUSE INSTALLATIONS

1 − In a storage area, clearance from the heater to

combustible materials must be such that the

combustible material must not attain a

temperature above 160°F (71°C) during

continuous operation of the unit.

WARNING

exposure to temperatures less than 160°F

(plastics, plastic wrap, styrofoam, cardboard,

etc.) must be stored well away from this

heater. Discharge air temperatures for these

2 − Maintain an 8−foot (2.5 m) minimum clearance

from the floor to the bottom of the heater. Refer to

the current edition of CSA-B149 installation

compliance codes.

1 − In an area where aircraft are housed or serviced, a

10−foot (3 m) minimum clearance from the highest

surface of the aircraft to bottom of the heater must

be maintained.

2 − In other areas, an 8-foot (2.5m) minimum

clearance from the floor to bottom of heater must

be maintained.

3 − Heaters should be located so that they are

protected from damage from aircraft or other

appliances needed for servicing of aircraft. Refer

to requirements of the enforcing authorities.

In a confined area, the heater must be installed in

accordance with the current edition of CSA-B149

installation compliance codes. Be sure to check with

local codes and ordinances for additional requirements.

AIRCRAFT HANGER

Model Number

Feet (Meters)

SEP−100 and SEP−115

16 (4.9)

SEP−145, SEP−175, and

20 (6.1)

SEP−200

SEP−230, SEP−250,

SEP−300, SEP−345 and

30 (9.1)

SEP−400

Improper installation, adjustment, alteration, ser-

agency or the gas supplier.

As with any mechanical equipment, personal

equipment.

Do not use the gas manifold pipe to lift unit. Any

misaligned.

Insufficient combustion air can cause headaches,

nausea, dizziness, asphyxiation or death.

5

Additional Requirements

The Commonwealth of Massachusetts stipulates the

following additional requirements:

1 − Gas furnaces shall be installed by a licensed

plumber or gas fitter only.

2 − The gas cock must be T handle" type.

Unit Heater Installation

WARNING

vice or maintenance can cause property damage,

personal injury or loss of life. Installation and

service must be performed by a licensed

professional installer (or equivalent), service

CAUTION

injury can result from contact with sharp sheet

metal edges. Be careful when you handle this

The appliance shall not be installed downstream from

evaporator coils or cooling units.

Install the unit in the desired location as governed by

clearances, vent connection, air direction, gas supply,

electrical supply and service accessibility.

On SEP models 100, 115, 145, 175, and 200, mounting

nuts are furnished at the balance point (two positions

only). On SEP models 230, 250, 300, 345 and 400,

mounting nuts are furnished at each corner of the unit.

Mounting nuts will accommodate 3/8" x 16 threaded rods.

1 − Cut threaded rods to desired length and slide a

3/8" nut onto the rod.

2 − Slide a flat washer onto the threaded rod AFTER

the nut (7/16" inside diameter X 1" outside

diameter X 1/16" thick washer).

3 − Screw the rods (two or four) into the mounting

nuts on the unit.

4 − Tighten nuts to secure unit to rods.

IMPORTANT

excessive upward or downward force on the

manifold pipe and bracket assembly can cause

the ignition burner and igniter to become

MAXIMUM MOUNTING HEIGHTS

TABLE 4

Combustion and Ventilation Air

Adequate facilities for supplying air for combustion and

ventilation must be provided in accordance with the

current edition of ANSI Z223.1, section 5.3, and

CSA−B149 installation compliance codes, or applicable

provisions of local building codes.

All gas−fired appliances require air to be used for the

combustion process. In many buildings today, there is a

negative indoor air pressure caused by exhaust fans, etc.

If sufficient quantities of combustion air are not

available, the heater or another appliance will operate

in an inefficient manner, resulting in incomplete

combustion which can result in the production of

excessive carbon monoxide.

CAUTION

If indoor air is to be used for combustion, it must be free

of the following substances or the life of the heat

exchanger will be adversely affected: chlorine, carbon

tetrachloride, cleaning solvent, halogen refrigerants,

acids, cements and glues, printing inks, fluorides, paint

removers, varnishes, or any other corrosives.

Rotation of Combustion Air Inducer

(SEP−100, −115 and −145 Only)

The combustion air inducer on SEP models −100, −115

and −145 may be rotated 90° either to the left or right of

the original vertical position in order to better suit the

application.

NOTE − It is not permissible to rotate the combustion

air inducer on SEP models −175, −200, −230, −250,

−300, −345 and −400.

Rotate the combustion air inducer assembly as follows:

1 − Remove the heater from the carton. Decide the best

unit heater orientation. The vent can be installed in

one of three discharge positions: up, left, or right.

2 − If the inducer is to be rotated, follow the

6

instructions in this section; otherwise, refer to

instructions under Venting" section.

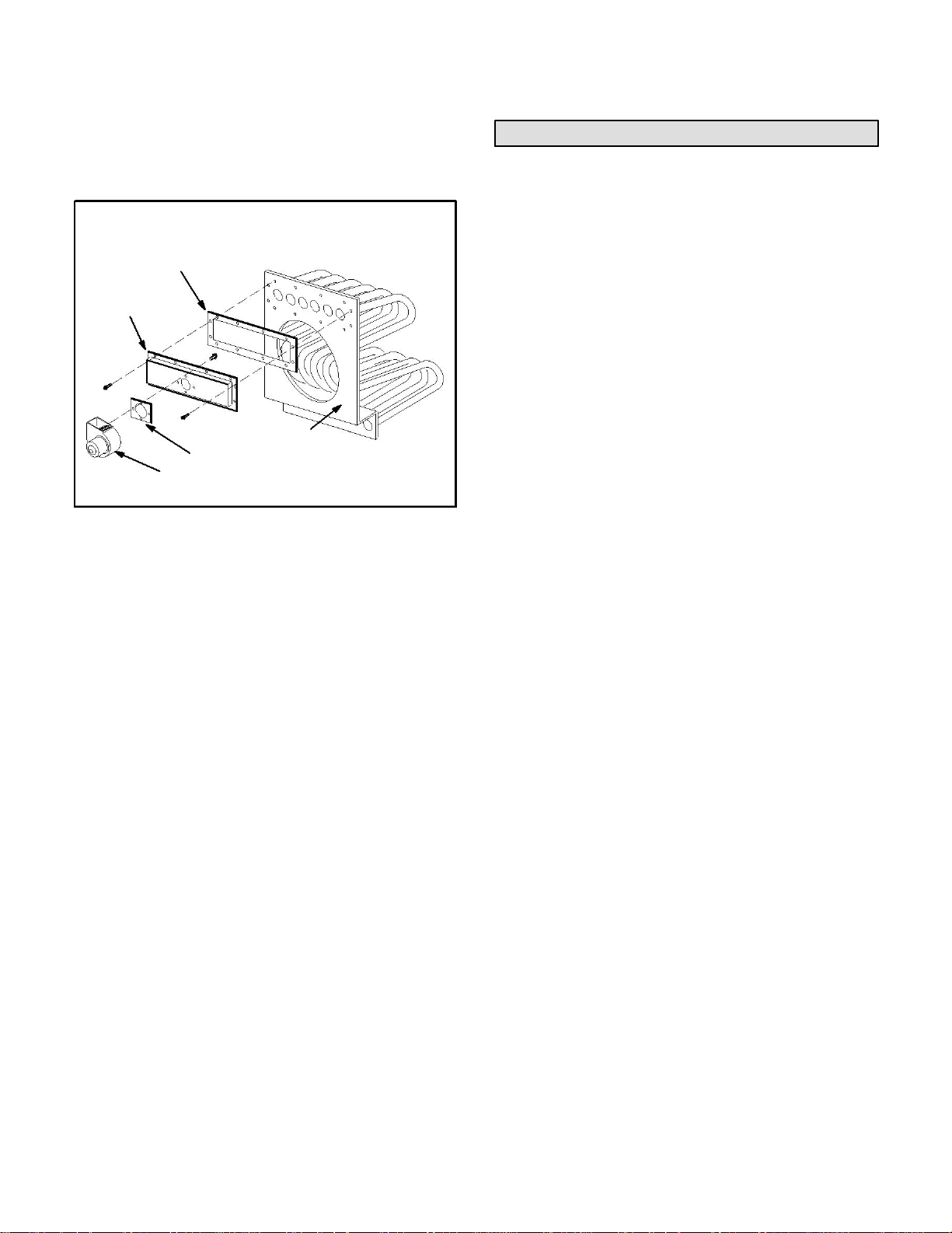

3 − Before making an electrical or gas connections,

remove the securing screws on the flue

box/combustion air inducer. See figure 1.

FLUE BOX AND

COMBUSTION AIR INDUCER ASSEMBLY

FLUE BOX GASKET

FLUE BOX

COMBUSTION AIR INDUCER

VEST PANEL

COMBUSTION AIR INDUCER GASKET

4 − Remove the flue box/combustion air inducer

assembly, ensuring that the gasket is not

damaged. If the gasket is damaged, replace it.

5 − Use a 1/4" socket to remove the three screws

which secure the combustion air inducer to the

flue box.

Remove the inducer and gasket from the flue box

ensuring that the gasket is not damaged. If the

gasket is damaged, replace it.

6 − Use the template provided in the back of this

manual to mark new hole locations. Use a 7/32"

drill bit to drill holes in flue box.

7 − Place the gasket between the combustion air

inducer and the flue box. Rotate both the inducer

and the gasket 90° to the desired position.

Reinsert and tighten the three inducer securing

screws

(#8−16 X 1/2" HWHSMS).

8 − Place the gasket between the flue box and the

vest panel. Position the flue box/combustion air

inducer assembly on the vest panel. Fasten the

flue box to the vest panel using the flue box

securing screws (#10−16 X 5/8" HWHSMS) and a

5/16" driver.

FIGURE 1

9 − The unit heater is now ready for installation as

described in the Venting section.

Venting

NOTE − The vent is a passageway, vertical or nearly

so, used to convey flue ga ses from an applianc e, or its

vent connector, to the outside atmosphere. The vent

connector is the pipe or duct that connects a fuel-gas

burning appliance to a vent or chimney.

NOTE − Local codes may supersede any of these

provisions.

GENERAL RECOMMENDATION AND

REQUIREMENTS

SEP unit heaters must be vented in compliance with

the latest edition of the National Fuel Gas Code (NFPA

54 / ANSI Z223.1) in the USA and with CSA-B149.1

codes in Canada, as well as applicable provisions of

local building codes, and the following instructions.

A sheet metal flue transition is supplied with this

certified unit. It must not be modified or altered and

must be installed on the outlet of the combustion

air inducer assembly prior to the installation of the

vent connector. Failure to comply with this

requirement will void the certification of the unit by

the approval agencies.

A single-wall vent connector may be used in all

applications between the furnace and the vertical vent

pipe.

A single−wall vent pipe used as a vent connector or as

a vertical vent, must have all seams and joints sealed

with pressure-sensitive aluminum tape or silicone

rubber sealant. Aluminum tape must meet the

provisions of SMACNA AFTS−100−73 Standards. The

aluminum tape must have a temperature rating of

400°F (204°C).

Silicone rubber sealant must have a temperature rating

of 482°F (250°C), i.e., Dow Corning RTV−736 or

equivalent.

All joints must be secured with at least two corrosion

resistant screws. All joints must be checked for gas

tightness after installation. Single-wall vent pipe used

as vertical vent must not pass through any attic, interior

wall, concealed space, or floor.

Loading...

Loading...