SG-UUH-04

February 2018

Specification Guide

FSA, FOA, SEP & HED Series

Unit Heaters and Duct Furnaces

Product improvement is a continuous process at Advanced Distributor Products. Therefore, product specifications are subject to change without notice

and without obligation on our part. Please contact your ADP representative or distributor to verify details.

© by Advanced Distributor Products. All rights reserved.

2175 West Park Place Blvd., Stone Mountain, GA 30087

www.adpnow.com

PRODUCT NOMENCLATURE

FOA / FSA Nomenclature

FOA N - 75

Series

FSA = Low profile unit heat

FOA = Separated combustion unit heaters

Gas

N = Natural gas

P = Propane

SEP / HED Nomenclature

Series

SEP = Unit heaters

HED = Duct furnaces

FSA:

30, 45, 60, 75

FOA:

45, 100, 125, 150, 250, 300

Note: All heaters are 115V / 1ph / 60 Hz

SEP - 100 A - N

Gas

N = Natural gas

P = Propane (SEP only)

Nominal Gas Heat Input

SEP:

100, 115, 145, 175, 200, 230, 250, 300, 345, 400

HED:

75, 100, 125, 150, 200, 250, 300

Heat Exchanger

A = Aluminized steel

S = Stainless steel

Note: All heaters are 115V / 1ph / 60 Hz

2

PRODUCT FEATURES

Efficiency

ADP gas-fired unit heaters and duct furnaces deliver

between 80% and 82% thermal efficiency. This excellent

efficiency sets a new standard when using gas-fired unit

heaters and duct furnaces.

Reliability

ADP heater designs have proven superior for over a

decade and during hundreds of thousands of hours in the

toughest winter climates of North America and under

extreme conditions in laboratory life cycle testing. ADP unit

heaters and duct furnaces have been designed to provide a

long, trouble free service life.

Quality

Every heater undergoes continuous quality checks at all

stages of manufacturing. After assembly, each heater is

test fired and functionally tested to provide final assurance

that it is performing in accordance with ADP’s rigorous

quality standards.

Approvals

All ADP heaters are built in the USA in an ISO 9001:2008

facility. The rating plate of each heater carries the mark

signifying that the heater is design certified by CSA. In

addition, the heater series is listed by the California Energy

Commission (CEC).

Warranty

ADP unit heaters feature a standard 2-year limited

warranty. For FOA, FSA, and SEP Series, the warranty

provides extended coverage on aluminized heat

exchangers for 10 years. For SEP Series, the warranty

provides extended coverage on stainless steel heat

exchangers for 15 years.

Power Exhaust

All heaters have a sealed flue collector and a power

exhaust system which enable conventional vertical venting

or horizontal venting. Power exhaust, when used with

horizontal venting, lowers operating cost because it

reduces stack losses. It also allows the option of not

penetrating the roof, or multiple floors. The versatile power

exhaust (on some models) reduces installation cost further

by allowing the exhaust to be directed upward, left or right,

just by rotating the exhaust assembly.

In Shot Burners

These lightweight aluminized steel burners are

maintenance-free and never require adjustment. The

burner venturi mixes air and gas in the correct proportion

for efficient combustion. The entire burner assembly is

removable as one piece for ease of service.

Tubular Heat Exchangers

Constructed of aluminized steel for superior resistance to

corrosion and oxidation; for additional protection, some

models have an optional stainless steel heat exchanger.

The curving design provides for complete exposure of the

heating surface to the supply air stream. Rounded surfaces

minimize air resistance and permit air to surround all heat

transfer surfaces for excellent heat transfer. Tubular

design means lighter weight and significantly longer service

life due to lower thermal-induced stresses. .

Direct Spark Ignition

In combination with the 24-volt main gas valve with 100%

shutoff for safety, the direct spark ignition control provides

positive, reliable and safe main burner ignition. This

eliminates the need for a pilot light, improving system

efficiency and reliability. A separate flame sensor provides

proof of main burner ignition. If loss of main burner flame

should occur, the control will reinitiate ignition three times

before locking out, thus reducing nuisance service calls.

The unit will reinitiate ignition after the one hour lockout.

The prepurge operation safety removes all gas and flue

products from the system prior to ignition.

Cabinet

Constructed heavy gauge painted steel, each cabinet has a

two-point suspension system for easy installation (larger

and two-fan models have four-point suspensions).

Generous use of inside cabinet insulation keeps the outer

surface temperature low. The wiring junction box is

conveniently located on the side of the cabinet (SEP &

HED only) for easy access and adequate protection.

3

FSA SERIES

Low Profile Unit Heaters

Product Features

Residential – low profile units.

Great for garages & shops.

Sidewall venting eliminates roof penetrations.

Wiring junction box is located inside of unit.

1” clearance from ceiling for easy installation.

Heating capacities from 30,000 – 75,000 BTUH.

Up to 81% thermal efficiency.

Self-diagnostic board with LED display improves troubleshooting.

Power exhaust system allows horizontal venting to 25 ft.

Tubular heat exchangers made of aluminized steel.

Aluminized steel in shot burners provide efficient trouble free operation.

Direct drive propeller fans are dynamically balanced for quiet and smooth operation.

Technical Data

Gas Heating

Performance

Connections

Fan Data

Physical Data

Model FSA* -30

Heating Capacity Input (BTUH) 30,000 40,000 60,000 75,000

Heating Output (BTUH) 24,300 32,500 48,000 60,000

Steady State Efficiency 81.0% 81.0% 80.0% 80.0%

Temp Rise (deg F) 42 45 55 60

Flue Size Round (in) 3

Gas Piping Size (in, NPT) 1/2 1/2 1/2 1/2

Num of Fans 1 1 1 1

Diameter (in) 10 10 14 14

Num of Blades 4 4 3 3

Motor Output (hp) 1/20 1/20 1/10 1/10

Motor Full Load Amps 1.7 1.7 4.1 4.1

Motor RPMs 1650 1650 1050 1050

Air Volume (CFM) 535 750 830 950

Overall Dimensions H x W x D (in) 12 x 25 x 24 12 x 25 x 24 17 x 25 x 25 17 x 25 x 25

Ship Weight (lbs) 45 50 87 91

[1]

FSA* -45

[2]

[1]

[2]

3

FSA* -60 FSA* -75

[3]

4

[3]

4

* N = Natural gas; P = LP gas

[1] Sold in pallet quantities of four(4) per model. No mix or match of models.

[2] 2-1/8 x 3 in. (54 x 76 mm) diameter adaptor is furnished with unit for flue connection.

[3] 2 x 4 in. (51 x 102 mm) diameter adaptor is furnished with unit for flue connection.

Note: All models have aluminized steel heat exchanger; all models are 115 V, 60 Hz, 1 phase.

4

FSA SERIES

Dimensions

12−1/2

(318)

6−1/2

(165)

2−3/4

(70)

EXCHANGER

AIR

FLOW

HEAT

HANGING

BRACKETS (2)

12−1/2

(318)

6−1/2

(165)

2−3/4

(70)

MOUNTING SLOTS (Typical)

5/16 x 3 Inches (8 x 76 mm)

1

(25)

1/2

(13)

NOTE: Unit may be rotated 180° top for bottom to

change gas, electrical and flue positions. Hanging

18−1/2

(470)

NOTE − Unit may be rotated 180 top for bottom

brackets may be installed on either top or bottom

of unit.

Model

1

(25)

Low Profile Unit Heaters

to change gas, electrical and flue positions.

Hanging brackets may be installed on

either top or bottom of unit.

A B C

Size

30

45

60

75

in. mm in. mm in. mm

12 305 5-1/2 140 4-1/4 108

17 432 6-1/2 165 6-3/4 171

DIRECT

DRIVE FAN

TOP VIEW

25

(635)

C

FLUE

OUTLET

BACK VIEW

ELECTRICAL

INLETS

6

(152)

1

(25)

A

GAS INLET

B

SERVICE

ACCESS

PAN EL

HANGING

BRACKETS (2)

SIDE VIEW

18−1/2

(470)

AIR

FLOW

ADJUSTABLE

LOUVERS

5

FOA SERIES

Separated Combustion Unit Heaters

Product Features

Perfect for light commercial and greenhouse applications.

Introduces clean combustible outside air when required.

Wiring junction box is located outside of unit.

Ideal for hard-to-heat applications where excessive dust, dirt,

humidity, or negative pressure is a concern.

Heating capacities from 40,000 – 300,000 BTUH.

Up to 82% thermal efficiency.

Compact cabinet design on 40,000 – 75,000 BTUH models.

Hinged door allows easy access to components.

Sidewall venting eliminates roof penetrations.

Self-diagnostic board with LED display improves troubleshooting efficiency and accuracy.

Tubular heat exchangers made of aluminized steel.

Power exhaust system allows horizontal venting to 25 ft.

Direct drive propeller fans are dynamically balanced for quiet and smooth operation.

Technical Data

Gas Heating

Performance

Connections

Fan Data

Physical Data

[2]

Thermal Efficiency -- Natural Gas 81% 82% 81% 80% 81% 80%

Thermal Efficiency -- LPG / Propane 81% 81% 81% 81% 82% 81%

39-5/8

[1]

FOA* -250

39 x 36-1/2 x

Model FOA* -45 FOA* -100 FOA* -125 FOA* -150

Heating Capacity Input (BTUH) 40,000 100,000 125,000 150,000 240,000 300,000

Output Natural Gas (BTUH) 32,400 81,000 101,500 120,000 194,400 240,000

Output LPG / Propane (BTUH) 32,400 82,700 101,500 121,500 196,800 243,000

Temp Rise (deg F) 45 31 39 38 35 43

Flue Size Round (in) 3 5 5 5 5 6

Combustion Air Size Round (in) 3 4 4 4 4 4

Gas Piping Size

(in, NPT)

Number of Fans 1 1 1 1 2 2

Diameter (in) 10 16 16 18 16 16

Number of Blades 5 4 4 4 4 4

Motor Output (hp) 1/20 1/8 1/8 1/8 1/8 1/8

Motor Full Load Amps 1.7 2.7 2.7 2.7 2.7 2.7

Motor RPMs 1650 1075 1075 1075 1075 1075

Air Vol. (CFM) 750 2435 2435 2955 5215 5215

Overall Dimensions

H x W x D (in)

Ship Weight (lbs) 84 188 204 261 307 323

1/2 1/2 1/2 1/2 3/4 3/4

12 x 26 x 24

21 x 36-1/2 x

39-5/8

21 x 36-1/2 x

39-5/8

27 x 36-1/2 x

39-5/8

[1]

FOA* -300

39 x 36-1/2 x

39-5/8

[1]

* N = Natural gas; P = LP gas

[1] Models not approved for residential applications.

[2] Fan motor type: SP for models 45; PSC for models 100, 125, 150, 250, 300.

Note: All models are 115 V, 60 Hz, 1 phase.

6

FOA SERIES

Dimensions (45 model)

BRACKETS (2)

HANGING

18-1/2

(470)

SERVICE

ACCESS

DOOR

MOUNTING SLOTS (Typical)

5/16 x 3 Inches (8 x 76 mm)

5-1/2 (140)

GAS

INLET

FLUE

OUTLET

5-1/4 (133)

045 MODEL

7-1/4

(184)

3-1/4

(83)

5-3/4

(146)

Separated Combustion Unit Heaters

13 (330)

HANGING

BRACKETS

(2)

4-1/4 (108)

TOP VIEW

26

(660)

(330)

AIR

FLOW

HEAT

EXCHANGER

13

7

(178)

(76)

3

1/2

(13)

1

(25)

18-1/2

(470)

1

(25)

1

(25)

12

(305)

ADJUSTABLE

BURNER VIEWING PORT

LOUVERS

SIDE VIEW

Dimensions (100—300 models)

Model

Size

100

125

150

250

300

A B

in. mm in. mm

21 533 8-1/2 216

27 686 8-5/8 219

39 991 22-1/2 572

32−3/8

(822)

THUMB

SCREW

SERVICE

ACCESS

DOOR

THUMB

SCREW

1-3/4

(44)

ELECTRICAL

BOX

100 / 125 / 150 / 250 / 300 MODELS

THREADED STUDS

32−3/8

(822)

7−1/4 (184)

7−3/8

(187)

B

ELECTRIC

BOX

COMBUSTION AIR

INLET

BACK VIEW

24−7/16

AIR FLOW

EXCHANGER

TOP VIEW

36−1/2

(927)

FLUE

OUTLET

(621)

HEAT

DIRECT

DRIVE FAN

1

DIRECT

DRIVE FAN

5−1/2

(140)

21−5/16

(541)

1/2

(13)

A

ADJUSTABLE

LOUVERS

BURNER VIEWING

PORT

SIDE VIEW

7 (178)

GAS INLET

7

7−3/4

(197)

COMBUSTION AIR INLET

BACK VIEW

1

FOA250 and FOA300 models have two fans.

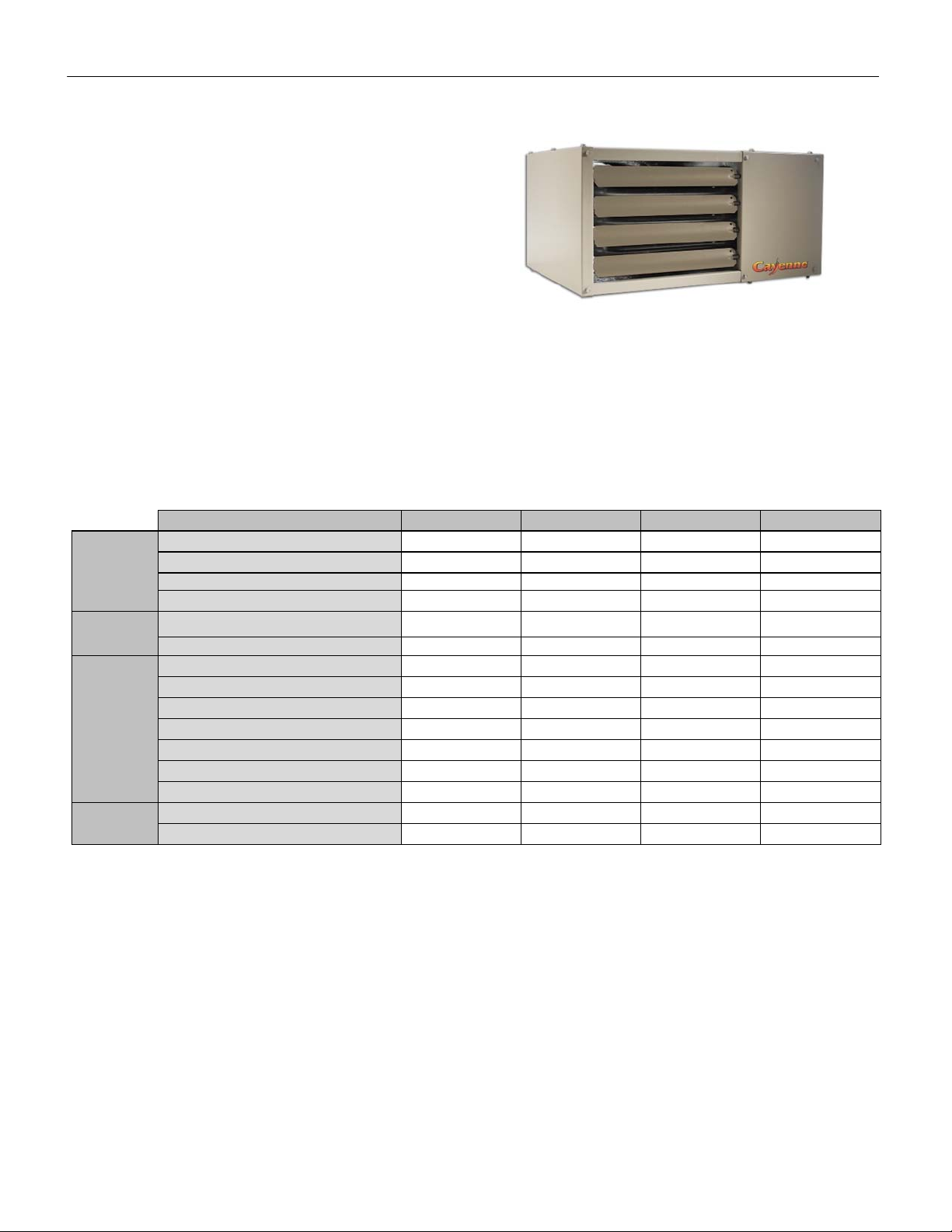

SEP SERIES

Commercial Unit Heaters

Product Features

Heating capacities from 100,000 – 400,000 BTUH.

Up to 80.5% thermal efficiency.

Stainless steel heat exchanger is available for longer product life.

Heat exchangers are laboratory life-cycle tested.

Tubular heat exchangers made of aluminized steel or stainless steel.

Aluminized steel in shot burners provide efficient trouble free operation.

Sidewall venting eliminates roof penetrations.

Wiring junction box is located outside of unit.

Safe direct spark ignition. No standing pilot light.

Self-diagnostic board with LED display improves troubleshooting efficiency and accuracy.

3/8 x 16 rivet nuts are located on the top of cabinet for suspending unit using threaded rod.

Power exhaust system with a sealed flue collector allows conventional vertical or horizontal venting to 35 ft

(depends on unit size).

Direct drive propeller fans are dynamically balanced for quiet, smooth operation.

Technical Data

Gas

Heating

Performance

Connec-

tions

Fan

Data

Physical

Data

Model

Heating Capacity Input

(BTUH)

Output Natural Gas

(BTUH)

Output LPG/Propane

(BTUH)

Steady State Efficiency

-- Natural Gas

Steady State Efficiency

-- LPG / Propane

Flue Size Round (in) 4

Gas Piping Size

(in, NPT)

Number of Fans 1 1 1 1 1 2 2 2 2 2

Diameter (in) 16 16 16 16 16 16 16 16 16 16

Number of Blades 4 4 4 4 4 4 4 4 4 5

Motor Output (hp) 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

Motor Full Load Amps 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1

Motor RPMs 1075 1075 1075 1075 1075 1075 1075 1075 1075 1075

Air Volume (CFM) 1900 1900 1900 2200 2200 4400 4400 4400 4400 4400

Overall Dimensions

H x W x D (in)

Ship Weight (lbs) 150 150 165 185 185 275 275 280 310 315

SEP

-100#-&

100,000 115,000 145,000 172,500 195,000 230,000 250,000 300,000 345,000 390,000

80,500 92,000 116,000 138,000 156,000 184,000 201,250 241,500 276,000 312,000

82,000 92,000 115,000 138,000 156,000 184,000 205,000 246,000 281,200 312,000

80.5% 80.0% 80.0% 80.0% 80.0% 80.0% 80.5% 80.5% 80.0% 80.0%

82.0% 80.0% 80.0% 80.0% 80.0% 80.0% 82.0% 82.0% 81.5% 80.0%

[1]

1/2 1/2 1/2 1/2 1/2 3/4 3/4 3/4 3/4 3/4

32-3/16 x

20-3/16 x

39-3/16

SEP

-115#-&

[1]

4

32-3/16 x

20-3/16 x

39-3/16

SEP

-145#-&

[1]

4

32-3/16 x

20-3/16 x

39-3/16

SEP

-175#-&

[2]

5

32-3/16 x

23-1/8 x

39-3/16

SEP

-200#-&

[2]

5

32-3/16 x

23-1/8 x

40

SEP

-230#-&

[2]

5

32-3/16 x

41-1/8 x

40

SEP

-250#-&

[2]

5

32-3/16 x

41-1/8 x

40

SEP

-300#-&

[2]

5

32-3/16 x

41-1/8 x

40

SEP

-345#-&

[3]

6

32-3/16 x

41-1/8 x

41-1/8

SEP

-400#-&

[3]

6

32-3/16 x

41-1/8 x

41-1/8

[1] 2-1/8 x 4 in. (54 x 102 mm) diameter adaptor is furnished with unit for flue connection.

[2] 2-1/4 x 2-3/4 in. (57 x 70 mm) rectangular to 5 in. (127 mm) round adaptor is furnished with unit for flue connection.

[3] 2-1/4 x 2-3/4 in. (57 x 70 mm) rectangular to 6 in. (152 mm) round adaptor is furnished with unit for flue connection.

# A = Aluminized steel heat exchanger; S = Stainless steel heat exchanger; All models are 115 volts, 60 Hz, 1 phase.

& N = Natural Gas; P = LP Gas

Note: SEP unit heaters are not approved for residential applications.

8

SEP SERIES

Dimensions

NOTE: Single fan model shown.

SEP models 100, 115, 145, 175 and 200 have a single fan.

SEP models 230, 250, 300, 345 and 400 have two fans.

* NOTE: Two mounting nuts are furnished on

SEP models 100, 115, 145, 175 and 200.

Four mounting nuts are furnished on

SEP models 230, 250, 300, 345 and 400 models.

A

ADJUSTABLE

LOUVERS

32-3/16

(817)

Furnished on

SEP−230,

250, 300,

345 and 400

models only.

*7-5/8

(194)

AIR

FLOW

1/2

(13)

C

1/2

(13)

TOP VIEW

31-5/16

(795)

Commercial Unit Heaters

B

E

ELECTRICAL INLETS

3/8-16 RIVETNUTS

FOR UNIT SUSPENSION

D

FLUE

OUTLET

F

COMBUSTION AIR

INDUCER

DIRECT

DRIVE FAN

Model

Size

100

115

145

175

200

230

250

300

345

400

GAS

HEAT

FRONT VIEW

A B

in. mm in. mm in. mm in. mm in. mm in. mm

20-3/16 512 11-1/2 292 19-1/16 484 11-3/4 298 3-1/4 83 7-7/8 200

23-1/8 588 11-1/2 292 22-1/16 560 8-1/2 337 3-1/4 83 8-11/16 220

41-1/8 1045 3-11/16 97 40 1016 17-3/4 451 3-1/2 89 8-11/16 220

41-1/8 1045 3-11/16 97 40 1016 17-1/2 445 3-1/2 89 9-13/16 248

EXCHANGER

SIDE VIEW

C D E

VALV E

F

9

HED SERIES

Product Features

Specially designed for applications requiring duct systems.

Heating capacities from 75,000 – 300,000 BTUH.

80% thermal efficiency.

Stainless steel heat exchanger is available for longer product life.

Sidewall venting eliminates roof penetrations.

Wiring junction box is located outside of unit.

Self-diagnostic board with LED display improves troubleshooting efficiency and accuracy.

3/8 x 16 rivet nuts are located on the top of cabinet for suspending unit using threaded rod.

Heat exchangers are laboratory life-cycle tested.

Aluminized steel in shot burners provide efficient trouble free operation.

Power exhaust system with a sealed flue collector allows conventional vertical or horizontal

venting to 35 ft. (depending on unit size).

Safe direct spark ignition. No standing pilot light.

Tubular heat exchangers made of aluminized steel or stainless steel.

Factory installed condensate drain allows for use downstream of cooling systems.

Duct Furnaces

Technical Data

Heating Capacity Input (BTUH) 75,000 100,000 125,000 150,000 200,000 250,000 300,000

Heating Output (BTUH) 60,000 80,000 100,000 120,000 160,000 200,000 240,000

Gas Heating

Performance

Connections

Physical Data

# A = Aluminized steel heat exchanger; S = Stainless steel heat exchanger; all models are 115 volts, 60 Hz, 1 phase.

[1] 2-1/4 x 4 in. (57 x 102 mm) round flue adaptor is furnished with unit for flue connection.

[2] 2-1/4 x 2-3/4 in. (57 x 70 mm) rectangular to 5 in. (127 mm) round adaptor is furnished with unit for flue connection.

Note: HED duct furnaces are not approved for residential applications.

Steady State Efficiency 80.0% 80.0% 80.0% 80.0% 80.0% 80.0% 80.0%

Air Volume Throughput (CFM) 780- 2700 870 - 3700 1020 - 4700 1320 - 5600 1480 - 4230 1850 - 5290 2220 - 6200

Model HED-75# HED-100# HED-125# HED-150# HED-200# HED-250# HED-300#

Temp Rise (deg F) 21 - 71 20 - 85 20 - 91 20 - 84 35 - 100 35 - 100 36 - 100

Flue Size Round (in) 4

Gas Piping Size

(in, NPT)

Cond. Drain Size (in) 1/4 1/4 1/4 1/4 1/4 1/4 1/4

Overall Dimensions

H x W x D (in)

Ship Weight (lbs) 115 140 150 165 270 285 305

[1]

1/2 1/2 1/2 1/2 3/4 3/4 3/4

28-5/16 x

19-1/2 x

34-11/16

[1]

4

32-3/16 x

20-1/8 x

40

[1]

4

32-3/16 x

20-1/8 x

40

[1]

4

32-3/16 x

23-1/8 x

40

[2]

5

32-3/16 x

41-1/8 x

40

[2]

5

32-3/16 x

41-1/8 x

40

[2]

5

32-3/16 x

41-1/8 x

40

10

HED SERIES

Performance Ratings

Air

Unit Size

75

100

125

150

Volume

(CFM)

780 0.01 71

1000 0.02 56

1300 0.05 43

1600 0.07 35

1900 0.10 29

2200 0.12 25

2500 0.17 22

2700 0.20 21

870 0.02 85

900 0.02 82

1300 0.03 57

1700 0.06 44

2100 0.09 35

2500 0.12 30

2900 0.15 26

3300 0.18 22

3700 0.23 20

1020 0.03 91

1100 0.03 84

1600 0.06 58

2100 0.11 44

2600 0.16 36

3100 0.21 30

3600 0.26 26

4100 0.31 23

4600 0.36 20

4700 0.37 20

1320 0.02 84

1400 0.03 79

2000 0.07 56

2600 0.12 43

3200 0.20 35

3800 0.28 29

4400 0.37 25

5000 0.45 22

5600 0.55 20

Total

Resistance

(inches W.C)

Temp

Rise

(deg F)

Unit Size

200

250

300

Duct Furnaces

Air

Volume

(CFM)

1480 0.03 100

1500 0.03 99

2000 0.04 74

2500 0.07 59

3000 0.09 49

3500 0.13 42

4000 0.15 37

4230 0.16 35

1850 0.04 100

2000 0.05 93

2500 0.08 74

3000 0.11 62

3500 0.13 53

4000 0.17 46

4500 0.19 41

5000 0.23 37

5290 0.25 35

2220 0.07 100

2800 0.11 79

3400 0.14 65

4000 0.18 56

4600 0.23 48

5200 0.26 43

5800 0.31 38

6190 0.33 36

6200 0.33 36

Total

Resistance

(inches W.C)

Temp

Rise

(deg F)

11

HED SERIES

Dimensions

* NOTE: Two rivet nuts are furnished

on HED models 75, 100, 125 and 150.

Four rivet nuts are furnished on HED

models 200, 250 and 300

C

4−3/16

(106)

Additional

3/8-16 rivet nuts for

unit suspension

(furnished on HED

models 200, 250

and 300.

1

(25)

*7-5/8

(194)

1/2

(13)

E

1/2

(13)

TOP VIEW

A

D

G

ELECTRICAL INLETS

7-11/16

(195)

Duct Furnaces

3/8-16 SPOTNUTS

FOR UNIT SUSPENSION

2−1/4 (57)

F

L

OPENING

FLUE

OUTLET

COMBUSTION AIR

INDUCER

M

J

SUPPLY

AIR

OPENING

END VIEW

1

(25)

H

3 (76)

B

HEAT

EXCHANGER

CONDENSATE DRAIN

LOCATION

(On Burner Box)

AIR

FLOW

SIDE VIEW

OPENING

K

3/4

(19)

GAS

VALVE

Model Size A B C D E F G H J K L M

in.

26 28-5/16 19-1/2 8-1/2 18-1/2 11-3/4 2-1/2 21-1/8 17-1/2 13-3/8 15 7-5/16

75

660 719 495 216 469 298 64 537 445 340 381 186

31-5/16 32-3/16 20-1/8 10-1/2 19-1/16 11-3/4 3-1/4 25 18-1/8 15-3/8 15-5/8 9-5/16

795 818 511 267 484 298 83 635 460 391 397 237

31-5/16 32-3/16 23-1/8 11-3/8 23-1/16 8-1/2 3-1/4 25 21-1/8 15-3/8 17-1/8 8-15/16

100

125

mm

in.

mm

in.

150

795 818 587 289 586 216 83 635 537 391 435 227

31-5/16 32-3/16 41-1/8 3-11/16 40 17-1/2 3-1/4 25 39-1/8 15-3/8 35-1/16 9

795 818 1045 97 1016 445 83 635 994 391 891 229

200

250

300

mm

in.

mm

Loading...

Loading...