Page 1

ADVANCE ADAPTERS INC. P/N: Orion

P.O. Box 247, 4320 Aerotech Center Way New Item: (06/04)

Paso Robles, CA 93447 PAGE 1 OF 15

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev . Date: 04-19-05

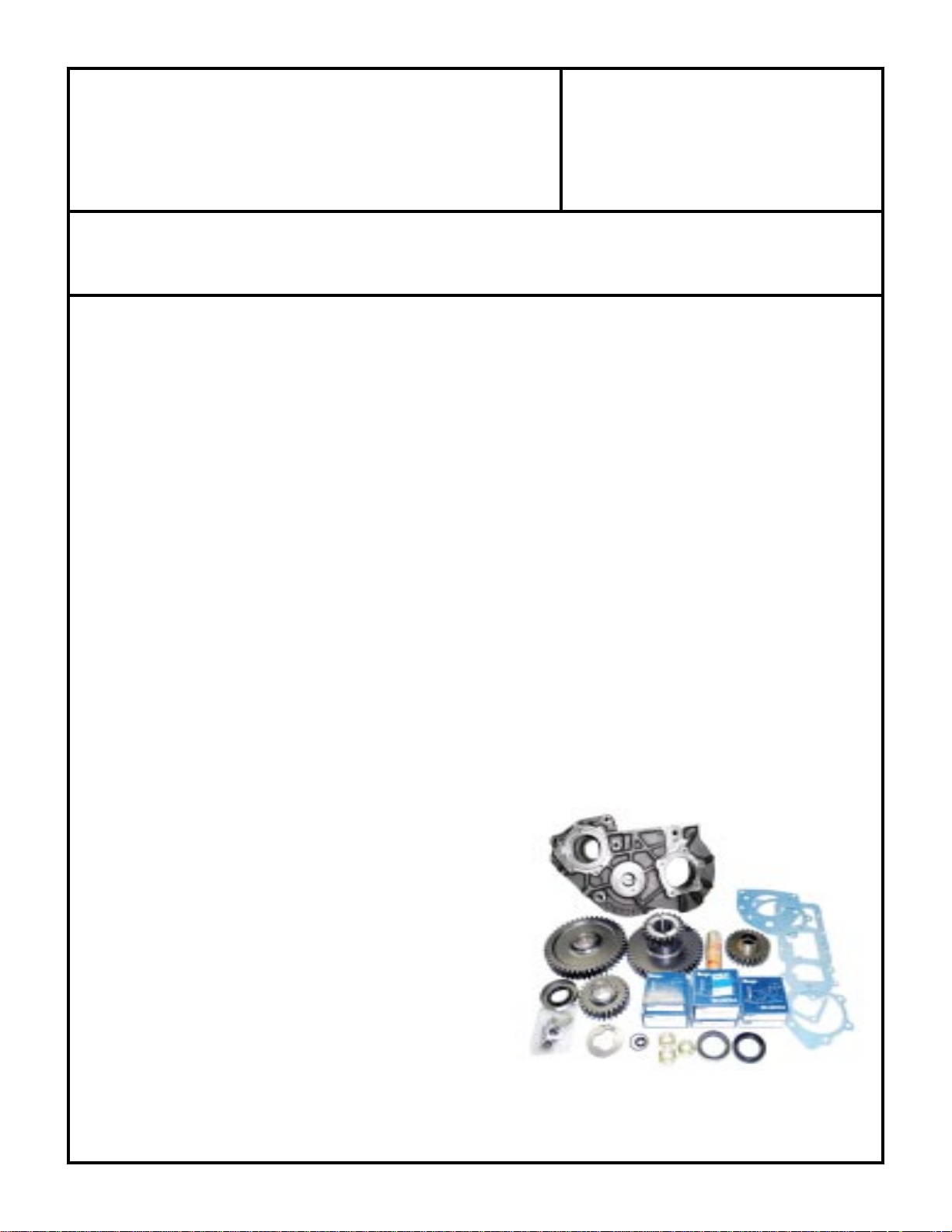

ORION TRANSFER CASE

Assembly & Disassembly

The Orion was created to replace stock transfer cases built between the years of 1963 and July of 1980. This case

replacement is the same external width, eliminating driveline modifications; however, the drain plug may be

approximately .500" lower than a stock case. The supplied 4:1 gear set replaces the existing gear set except for the

P.T.O. gear or P.T.O. spacer sleeve. It is required that you reuse your stock fasteners, front and rear housings,

retainers, shafts, clutch sleeves, and cover plates from your original transfer case. You are supplied a full rebuild kit

to replace all bearings, bearing cups, O-rings, seals, and gaskets. Shims for the rear output shaft retainer are also

supplied to set the bearing pre-load. Do not discard shims, washers, sleeves, and spacers from yokes and

shafts. Throughout the disassembly section, reference will be made to items that may be discarded. Attached you

will find 3 different illustrations referring to each component by our common terms.

site address to an interactive identification page @ www.advanceadapters.com/orion.html providing

actual photos of each component included in your Orion kit. In addition, this site address will include the

colored version of this instruction sheet.

We have also provided a web

Although this instruction sheet will initiate the steps to install the Orion, it is advised that you obtain a shop or repair

manual that covers your specific application.

Tools required:

Safety Glasses

Metric drive sockets

Metric wrenches

#10 hex bit

Foot Pound Torque Wrench (Torque Range of 10-125 ft./lbs.)

Drift Punch for both Hi and Low Shift Rail and 4 speed stake nut

Dead Blow Hammer

Pliers

Press (hand press)

Universal Puller for stock 3 and 4 speed transmissions

Flat Head Screw Driver

"A” kits (Bolt pack #400222) will also require:

5/8” socket

1-1/4” socket

3/8” hex bit

Note: When using the Orion transfer case

with a Marlin Toy Box, the Orion requires

modifications to the top of the case for the

Toy Box shifter rail. A special machined

case can be ordered from us with this

modification,

P/N O20001.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components

will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we strongly

recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter components. We

recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment. These manuals are normally

available at automotive dealerships and parts stores.

Page 2

ADVANCE ADAPTERS INC. P/N: Orion

P.O. Box 247, 4320 Aerotech Center Way New Item: (06/04)

Paso Robles, CA 93447 PAGE 2 OF 15

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev . Date: 04-19-07

ORION TRANSFER CASE

POINTS OF CONCERN (PLEASE READ)

The success of an Orion Transfer case installation is dependant on the condition of the necessary components that are

to be reused from your stock case. Some of the most critical components that require your attention to detail are as

follows:

G26- HI/LOW CLUTCH SLEEVE - Inspect for excessive or worn splines. The splines should not be tapered throughout

the sleeve width. You will notice the “V” looking tapers or “boat tails” only at the last .070” to the contact sides

of the sleeve towards each gear. If you need a new sleeve, purchase Toyota Part # 36235-60010

S2- LOCK PLATE ASSEMBLY - This lock plate needs to be inspected to insure the proper fit into the notch of the

Hi/Low shift fork shaft. The machined recessed area provided in the case of Orion will establish the location of this plate.

Do not attempt to shim the location of the plate; this will only change the location of the clutch sleeve rendering neutral

to be out of position. Measure the thickness of the lock plate. A stock lock plate should measure on average .123”. If

you need to purchase a new lock plate, use Toyota # 36726-60010. These may be subject to low availability from a dealer.

S5 & S6- SHIFT FORK LOCK BALL AND COMPRESSION SPRING - We have provided a new ball, spring, and

brass set screw to be used for your installation. The ball provided measures 10mm and will tighten up the tolerance in

the shift fork bore. We have also provided a new spring which has a greater holding capacity than an older worn out

spring. The new brass set screw will take the guess work out of setting the tension on the spring and ball inside the new

shift fork. The brass set screw should be installed with a bit of Loctite to retain it, and the hex should be seated completely

to the shift fork. P/N O60050 - 10mm Ball, P/N O60051 - Shift Fork Spring, P/N O60052 - Set Screw

New Shift Rail P/N O60040 & O-RINGS O60041.

G22 & G29- THRUST WASHERS - The thrust washers are an important and critical area when installing the Orion

gears on your Toyota shaft. The first step is to inspect the transfer case output shaft for excessive wear and to make

sure the gears fits the shaft. If your shaft is worn excessively, the gear will be a loose fit or will be able to wobble. If

this is the case with your shaft, replace it. We do offer replacement shafts.

If the shaft is in good shape, then proceed. The end play of the gear on the shaft must be set. The new Orion gears

are the same width as a stock gear set. On the early Orions the stock thrust washers were retained and the end play

on the gears is what the stock unit had. Unfortunately, in some applications the end play ended up to be close to .030".

The factory could have been off or if at some time the output shaft was changed, it could have had

different than stock measurements. The shaft and gears should be set at .008"-.012" of end play.

We now include two new thrust washers to help set up the transfer case with the correct end play.

These thrust washer are stepped. One side has a recess of .015" - .017" and the other side of the

washer has a .008" - .010" recess. So by using one side or the other of the washer or using your

stock washers, you should be able to get close to the required tolerance. P/N O60080 (2 required)

If you should have any further questions please call us @ 1-800-350-2223.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 3

ADV ANCE ADAPTERS INC. P/N: Orion

P.O. Box 247, 4320 Aerotech Center Way New Item: (06/04)

Paso Robles, CA 93447 PAGE 3 OF 15

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev . Date: 04-18-05

ORION TRANSFER CASE

Assembly & Disassembly

Orion Instructions:

The following instructions cover the disassembly of your stock transfer case along with the assembly of the Orion

transfer case. Listed throughout these instructions, we refer to various item numbers. These item numbers represent

components on one of the three schematics shown at the end of these instructions. The item numbers listed represent

the following: "C" is the case schematic, "G" is the gear schematic, and "S" is the shifter schematic. These drawings

also have an index page that corresponds the common terminology of these components.

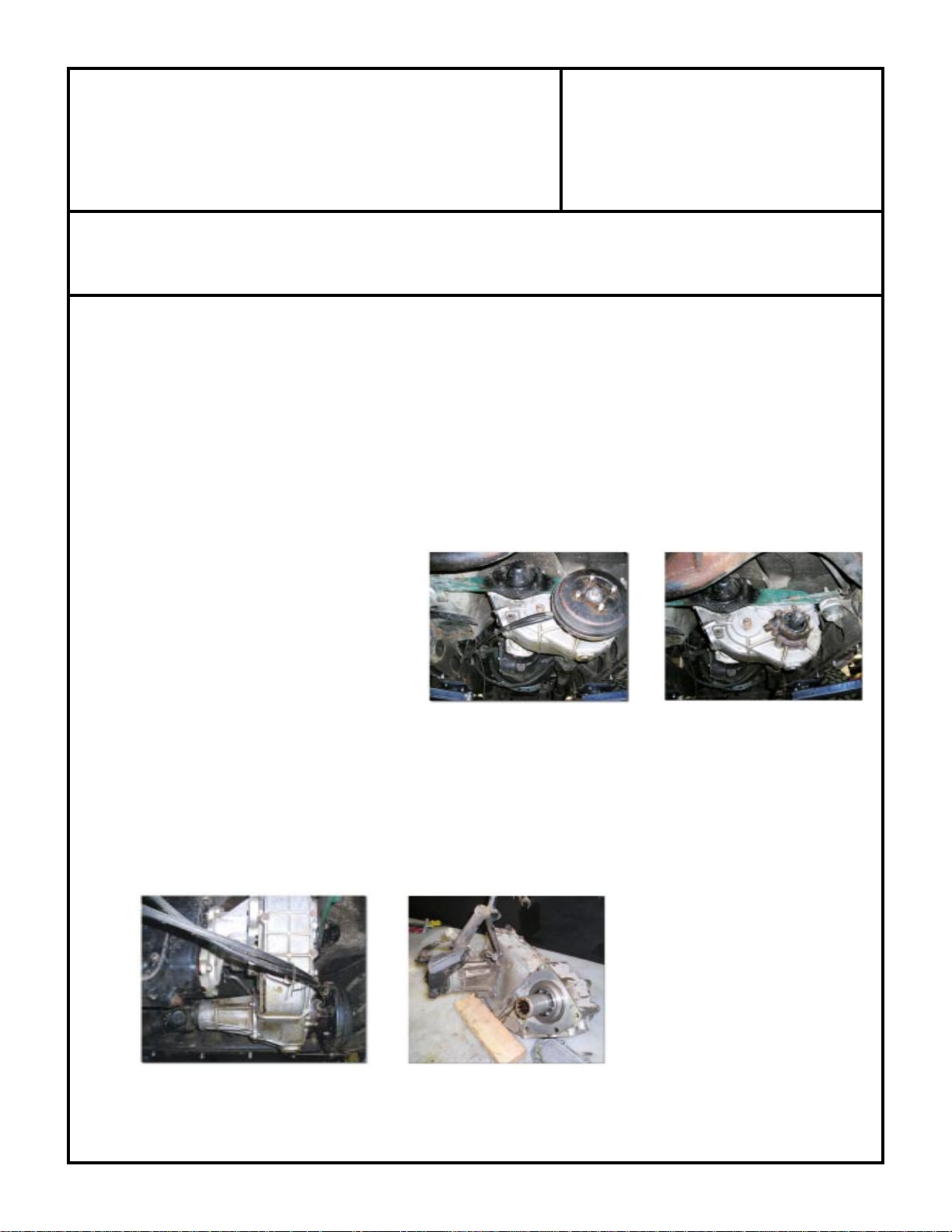

Drain gear lubricants from transmission and transfer case.

Remove the parking brake drum retaining nut.

On 1963 to 1973 10-spline T/C, or as we'll term 3 Speeds - Reference item #’s C9, C10, C11. Retain item C9

On 1974 to 1980 16-spline T/C, or as we'll term 4 Speeds - Reference item #’s C6, C7, C8. Retain items C6, C7

This should be done while still in the vehicle after

the front and rear drive shafts are removed. You

will be able to slide the brake drum off and then the

brake plate assembly. This will keep you from

having to remove the brake cable from the brake

plate. Once this is achieved, simply unscrew the

speedometer cable from the speedometer shaft

sleeve.

Stock Transmissions:

We strongly recommend that stock 3 and 4 speed transmission combinations be removed completely from the vehicle.

In order to remove the transfer case from your transmission, please refer to a manual that covers your application.

Advance Adapters (spud shaft style) transfer case adapter systems:

If you are removing a transfer case from a transmission that is using our conversion adapter, it is possible to only remove

the transfer case. It will be up to your own discretion to unbolt either the adapter housing from the transmission or the

transfer case from the adapter housing. In either instance, our conversion adapters require the transfer case to slide

rearwards only a few inches to disengage the transmission output shaft from our adapter spud shaft.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 4

ADVANCE ADAPTERS INC. P/N: Orion

PAGE 4 OF 15

Page Rev . Date: 04-18-05

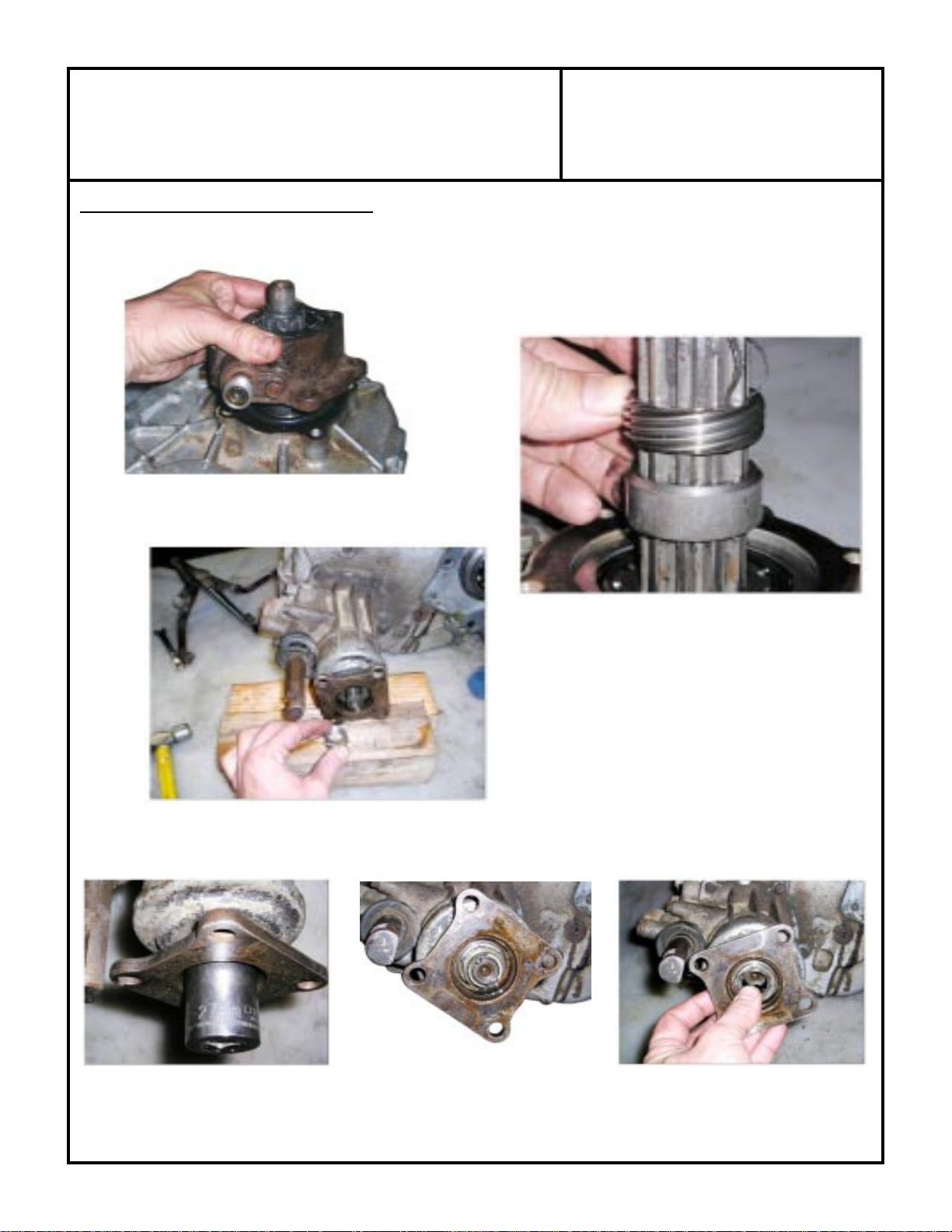

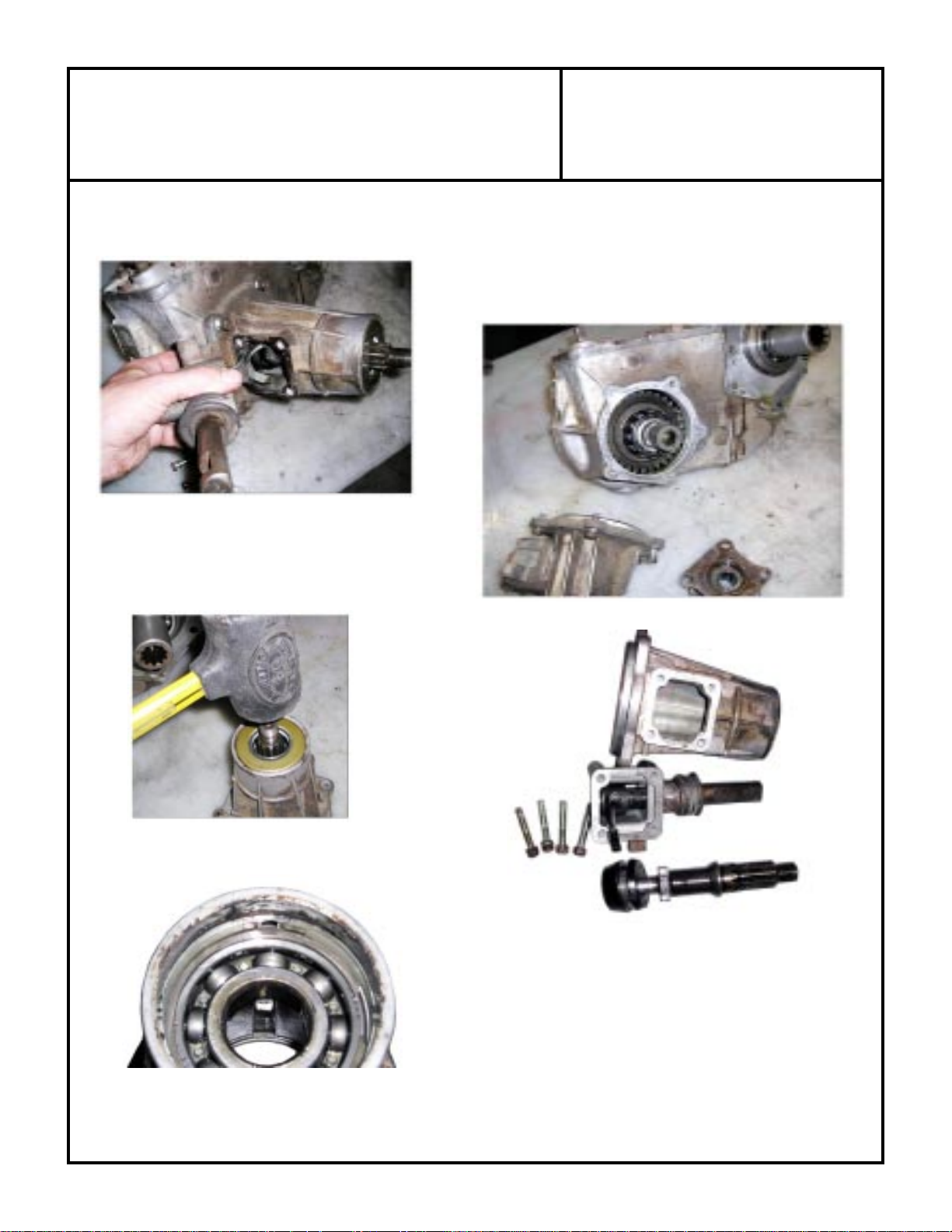

Disassembly of Transfer Case:

Remove and retain output shaft rear bearing retainer C4.

You do not have to remove the speedometer assembly.

Remove and retain the speedometer drive gear and

spacer from the output shaft, Item #’s G32 & G33.

Remove and retain the front transfer

yoke. A wood block during removal

may help keep the flange of the yoke

from spinning.

When removing the yoke on 3 speed cases, retain washer C25; and

on 4 speed cases, retain both washer and shim C21 and C22.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 5

ADVANCE ADAPTERS INC. P/N: Orion

PAGE 5 OF 15

Page Rev . Date: 04-18-05

Remove and retain the front driveshaft shift assembly from your transfer case:

Vacuum- Diaphragm cylinder and transfer front drive fork

Mechanical- Transfer front drive shift shaft guide assembly (pictured)

Remove and retain the transfer extension housing with

its internal parts, Items C28, G16, G17, G18, G20.

With a dead blow hammer, drive out

the front output shaft G18.

Remove and retain snap ring G16

from extension housing C28. Press

out ball bearing G17 and discard.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 6

ADVANCE ADAPTERS INC. P/N: Orion

PAGE 6 OF 15

Page Rev . Date: 12-29-05

Remove and retain case cover C13.

Remove the cotter pin, screw plug, compression spring, and shift fork lock ball from the

HI and LOW shift fork, Items S5, S6, S7, S8. Invert the case, if need be, to have the spring

and ball fall out. These parts will not be reused since a new shift assembly has been

provided.

Remove and retain the HI and LOW shift fork shaft lock plate and bolt S2.

Using a drift punch, lightly drive out the HI and LOW shift fork shaft S1

towards the rear of the transfer case.

Remove and discard the HI and LOW shift fork S4 and shift rail S1.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 7

ADVANCE ADAPTERS INC. P/N: Orion

PAGE 7 OF 15

Page Rev . Date: 04-18-05

Remove and retain the transfer case output shaft G25. This may be

accomplished by wedging the low speed output gear, G28, with a suitable

tool against the case to keep it from moving forward. Using a dead blow

hammer, lightly tap the shaft from the rear to drive it forward. This shaft

will come out the front of the case with the tapered roller bearing G21,

thrust washer G22, high speed gear G24, and the HI and LOW clutch

sleeve G26. You must retain the HI and LOW clutch sleeve G26, and

thrust washer G22. The tapered roller bearing may be discarded.

Remove and retain the transfer case idler gear shaft

lock plate and bolt G15 only. The idler gear shaft, idler

gear, and case may be discarded.

Remove remaining seals, bearings, roller bearing cups,

and gears from the original components to be assembled

onto Orion. Clean all components thoroughly.

Remaining in the case will be the low speed

output gear, G28, thrust washer G29, and

tapered roller bearing G30. You need only to

retain thrust washer G29. The low speed

gear and roller bearing may be discarded.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 8

ADVANCE ADAPTERS INC. P/N: Orion

PAGE 8 OF 15

Page Rev . Date: 04-18-05

Assembly:

With the rebuild kit provided, install the new seals, bearings, and roller bearing cups.

Press seal C18 into the Orion. Press seal C5 into the output shaft rear bearing retainer C4. Press ball bearing G17

into extension housing C28 and retain it with the original snap ring G16. Press seal C26 into extension housing.

Press tapered roller bearing cups G21 and

G30 into the Orion case and extension

housing C28. Note: G21 and G30 may be

installed after the output shaft assembly, HI

and LOW clutch sleeve, and low speed gear

are installed into the case.

Install the bearing spacer G10 between

needle bearings G9 into the new idler

gear G11. Add assembly lube.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Now, place the idler gear in position

in the case.

Place idler gear thrust washers G8

into position. Be sure to align the

locating tabs on the thrust washers

to the channels located on the inner

walls of the case.

Page 9

ADVANCE ADAPTERS INC. P/N: Orion

PAGE 9 OF 15

Page Rev . Date: 12-29-05

With idler gear and thrust washers in position, apply assembly lube to idler gear shaft G13.

Locate the groove cut into the idler shaft for the lock plate. Lightly lubricate and install the O-ring on this end

only. Install the opposite end of the idler shaft , into the rear side of the transfer case. Using a dead blow hammer,

lightly drive the shaft into the idler gear from the rear of the case. We advise that extreme care should be taken

during this installation to prevent any risk of damage to the O-rings. We have included two additional O-rings

in the event that damage should occur. Drive the shaft beyond flush so that the idler gear shaft protrudes just far enough

to expose the O-ring groove on the front of the transfer case. Lightly lubricate and install the O-ring on the idler shaft

on the front side of the case. Lightly drive the shaft rearwards to its final position and install the lock plate and bolt G15.

Caution:

cause the O-ring to bulge into this oil grove. When tapping the idler shaft back into its final position it would then cut the Oring causing the Orion to leak.

If this shaft is driven too far forward the rear O-ring will become exposed to an oil grove in the inner case. This would

Apply assembly lube and slide high speed gear G24 onto output shaft G25. Next, slide your stock thrust washer or one

of the new stepped thrust washer provided (G22) onto shaft. (NOTE: Two new thrust washers have been provided.

You will find that each side of the new thrust washers have a recess/step. One side of the washer is .008"-.010" and

the other is .015"-.017". These steps will ride against the shoulder of the shaft and provides a tighter tolerance or end

play on the gear. The ideal end play on the gear to the thrust washer should be .008" to .012". A feeler gage should

be used to obtain the correct end play.) Drive on the front tapered roller bearing G21 using a dead blow hammer and

P/N 400250 tubular bearing tool. Be sure to drive against the inner race only.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 10

ADVANCE ADAPTERS INC. P/N: Orion

PAGE 10 OF 15

Page Rev . Date: 04-18-05

Apply assembly lube and place low speed output gear G28 and HI and LOW clutch sleeve G26 in position within the

case. Install output shaft assembly G25 into the case. Install stock thrust washer G29 and rear tapered roller bearing

G30 onto output shaft G25. Lightly drive rear tapered roller bearing using a dead blow hammer and P/N 400250 tubular

bearing tool (make sure bearing is seated). Again, only drive against the inner race of the bearing.

If you have not done so, install tapered roller bearing cups G21 and G30 into the Orion case, and extension housing C28

in addition to ball bearing G17, snap ring G16, and seal C26.

Lubricate the seal lip and install output front shaft G18 into the extension housing C28. Install front yoke, washer, and

nut, Items C20-C22 or C23-C25. Tighten nut. Torque range will be 101-123 ft./lbs.

Install extension housing assembly C28, gasket C29, and the front drive clutch sleeve G26 onto the case. Gasket C29

must be used. Do not use any other gasket substitute. Be sure to assemble the front drive clutch sleeve with

the tapered side of the sleeve towards the rear of the case. Tighten extension housing bolts to 7-11 ft./lbs. of torque.

Re-assemble transfer front drive shift assembly:

Vacuum- Diaphragm cylinder and transfer front drive fork

Mechanical- Transfer front drive shift shaft guide assembly

Slide spacer G32 and speedometer gear

G33 onto the output shaft.

Included in your Orion kit are 8 adjusting shims in varied thicknesses. Place bearing adjusting shim(s) G31 in position

on the output shaft rear bearing cup G30. Install output shaft rear bearing retainer C4 and gasket C3. Gasket C3

must be used. Do not use any other gasket substitute. Tighten retainer bolts to 7-11 ft./lbs. of torque.

Use nut C10 or C8 and run the nut down tight until it stops on output shaft G25. Do not use the cotter pin or stake

the nut. The HI and LOW clutch sleeve must be in the neutral position and the front drive disengaged. Check the

output shaft bearing pre-load by turning the shaft, if using a torque wrench on nut C10 or C8.

have a resistance of 10-20 in./lbs. of torque. If using a fish or pull scale coupled to a brake drum

bolt a 10 to 13 pound measurement should be obtained. If necessary, adjust the pre-load by selecting a

new shim(s). Improper bearing pre-load setting may cause bearing and/or transfer case failure.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

The output shaft must

Page 11

ADVANCE ADAPTERS INC. P/N: Orion

PAGE 11 OF 15

Page Rev . Date: 03-16-10

Once you have established bearing pre-load, remove and retain nut C10 or C8.

Place the new transfer case HI and LOW shift fork S4 into the transfer case. Align fork with the HI and LOW clutch

sleeve and then drive the new shift fork shaft S1. Just beyond the front side of the fork but before the rail enters the

case, install the o-rings to the front and rear of the shifter rail. Finish installing the shift rail into the case. Install shift

fork shaft lock plate and bolt S2.

Install shift fork lock ball, compression spring, and new brass set

screw Items S5, S6, and S7. The new brass set screw will take the

guess work out of setting the tension on the spring and ball inside the

new shift fork. The brass set screw should be installed with a bit of

Loctite to retain it, and the hex should be seated completely to the shift

fork. Bolt case cover C13 using gasket C12 to the Orion case. Be

sure to properly align the HI and LOW shift lever S9 with the HI and

LOW shift fork S4.

Using gasket C19, install the Orion onto

your transmission or AA adapter housing,

loading items G1 through G7. Be sure to

use supplied mounting bolts for specified locations as outlined on your kit

instruction sheet. Torque the transmis-

sions rear output shaft nut G7 to 101-108 ft./lbs.

(AA nut 75 ft./lbs.).

Install the P.T.O. gasket and cover, Items C15 & C16. Install case cover and gasket, Items C1 & C2; OR gasket

C2 and AA rear crossmember mount. Install speedometer cable. Lubricate seal lip of seal C5. Install parking brake

plate assembly and brake drum. Install washer and nut, Items C9-C11, or C6-C8. Torque to 101-123 ft./lbs. and stake

the nut or install the cotter pin. Next, install drain plug C17 and add 2 quarts of (API GL-4 or GL-5 SAE90) for

a 500 mile break in procedure. Install fill plug C17. Lastly, install rear yoke and both driveshafts. Do a visual check

of the installation.

It is recommended that the Orion oil be changed and the magnetic drain plug cleaned after the first 500

miles. The initial break in will produce some metallic debris from the new cast iron case. This debris will

adhere to the drain plug and look like thick grease. After the break in procedure is complete, refill with

the Toyota's specified lubricant (API GL-4 or GL-5 SAE90).

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 12

ADVANCE ADAPTERS INC. P/N: Orion

PAGE 12 OF 15

Page Rev . Date: 04-18-05

Case Schematic Index:

C1 CASE COVER NO.2

C2 GASKET

C3 GASKET

C4 OUTPUT SHAFT REAR BRG. RETAINER

C5 OIL SEAL

C6 SHIM (4 SPEED)

C7 WASHER (4 SPEED)

C8 NUT (4 SPEED)

C9 WASHER (3 SPEED)

C 10 NUT (3 SPEED)

C 11 COTTER PIN (3 SPEED)

C12 GASKET

C1 3 CASE COVER

C14 SEAL

C15 GASKET

C 16 POWER TAKE OFF COVER

C1 7 CASE PLUG

C18 SEAL

C19 GASKET

C 20 NUT (4 SPEED)

C 21 WASHER (4 SPEED)

C 22 SHIM (4 SPEED)

C 23 COTTER PIN (3 SPEED)

C 24 NUT (3 SPEED)

C 25 WASHER (3 SPEED)

C26 SEAL

C27 GASKET

C2 8 EXTENSION HOUSING

C29 GASKET

C3 0 ORION CASE

Gear Schematic Index:

G 1 INPUT GEAR STOPPER (4 SPEED)

G 2 INPUT GEAR

G 3 P.T.O. GEAR / SPACER

G 4 BEARING

G 5 INPUT SHAFT SPACER

G 6 WASHER INPUT

G 7 INPUT SHAFT LOCK NUT

G 8 THRUST WASHER

G 9 NEEDLE ROLLER BEARING - IDLER

G 10 SPACER

G 11 IDLER GEAR

G 1 2 IDLER GEAR SPACER (UP TO APRIL OF 1975)

G 1 3 IDLER SHAFT

G 14 O-RING (2)

G 1 5 LOCK PLATE ASSY. (IDLER)

G 1 6 SNAP RING

G 17 BALL BEARING

G 1 8 FRONT OUTPUT SHAFT

G 19 NEEDLE ROLLER BEARING

G 20 FRONT DRIVE CLUTCH SLEEVE

G 2 1 FRONT TAPERED ROLLER BEARING CUP & CONE

G 2 2 THRUST WASHER

G 2 3 HIGH SPEED GEAR BUSHING (INSTALLED IN GEAR)

G 24 HIGH SPEED GEAR

G 2 5 REAR OUTPUT SHAFT

G 2 6 HI / LOW CLUTCH SLEEVE

G 2 7 LOW SPEED GEAR BUSHING (INSTALLED IN GEAR)

G 28 LOW SPEED GEAR

G 2 9 THRUST WASHER

G 3 0 REAR TAPERED ROLLER BEARING CUP & CONE

G 3 1 ADJUSTING SHIMS

G 32 SPACER (SPEEDOMETER)

G 33 SPEEDOMETER DRIVE GEAR

Shifter Schematic Index:

S1 HI & LOW SHIFT FORK SHAFT

S2 LOCK PLATE ASSEMBLY - HI & LOW SHIFT FORK SHAFT

S3 O-RING

S4 HI & LOW SHIFT FORK

S5 SHIFT FORK LOCK BALL

S6 COMPRESSION SPRING

S7 SCREW PLUG

S8 COTTER PIN

S9 HI & LOW SHIFT LEVER

S1 0 FRONT DRIVE SHIFT SHAFT BOOT

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 13

P/N: Orion

PAGE 13 OF 15

Page 14

P/N: Orion

PAGE 14 OF15

Page 15

P/N: Orion

PAGE 15 OF 15

Loading...

Loading...