Page 1

ADV ANCE ADAPTERS INC. P/N 713098

P.O. Box 247, 4320 Aerotech Center Way

Paso Robles, CA 93447 PAGE 1 OF 3

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev . Date: 11-12-10

HEMI V8

TJ WRANGLER MOTOR MOUNTS

KIT CONSISTS OF:

No. Qty Part No. Description

1. 2 713092A BOLT SLEEVE

2. 4 713092B MOTOR MOUNT BUSHING

3. 1 713092C MOTOR MOUNT FRAME FIXTURE

4. 1 713092L MOTOR/TJ FRAME MOUNT (Driver’s)

5. 1 713092R MOTOR/TJ FRAME MOUNT (Passenger)

6. 4 713092S SPACERS FOR TJ MOUNTS

7. 1 713098L ENGINE MOUNT (DRIVERS 7” BLOCK MOUNT)

8. 1 713098R ENGINE MOUNT (PASS.)

9. 7 720073 10mm - 1.5 x 25mm H.H.C.S.

10. 8 720038 10mm LOCK WASHER

11. 1 720011 10mm X 1.50 NUT

12. 1 720071 10mm - 1.5 x 35mm STUD

13. 4 725003 1/2” FLAT WASHERS

14. 2 725005 1/2”-13 NYLON LOCK NUT

15. 2 725027 1/2”-13 x 5” H.H.C.S.

Hemi TJ Swap Information:

The Dodge truck engine is the most preferred engine with the 545RFE automatic transmission. If a non 4WD

transmission is obtained, the tailhousing can be changed without disassembling the transmission. Jeep TJ’ s from 1997

to 2000 will not be able to use the stock instrument cluster. The Jeep instrument cluster from 2001-2006 4 & 6 cylinder

engines works fine with the Hemi engines.

Hemi Requirements and Recommendations:

The Jeep TJ must have at least 1” of body lift before starting and we recommend a 3” or greater suspension lift

with adjustable bump stops. This motor mount is designed to work with a 1997-2006 4 cylinder steering bracket, Part#

52058855AB. If your replacing a 6 cylinder, you will need this Jeep part number.

Note: The 10MM stud is used for upper rear block mount on the passengers side of the block.

Optional items:

P/N 716601 Hemi exhaust manifolds

P/N 716688-AA Hemi engine with automatic transmission

P/N 716688-AB Hemi engine with manual transmission

P/N 716607 A/C lines kit

P/N 716609 Gas Pedal bracket

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 2

ADV ANCE ADAPTERS INC. P/N 713098

P.O. Box 247, 4320 Aerotech Center Way

Paso Robles, CA 93447 PAGE 2 OF 3

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev . Date: 06-22-09

HEMI V8

TJ WRANGLER MOTOR MOUNTS

INST ALLA TION INSTRUCTIONS:

The Jeep TJ should have at least 1” of body lift before starting. The front suspension will need to be adjusted to allow for

the additional engine weight.

New Mount Installation:

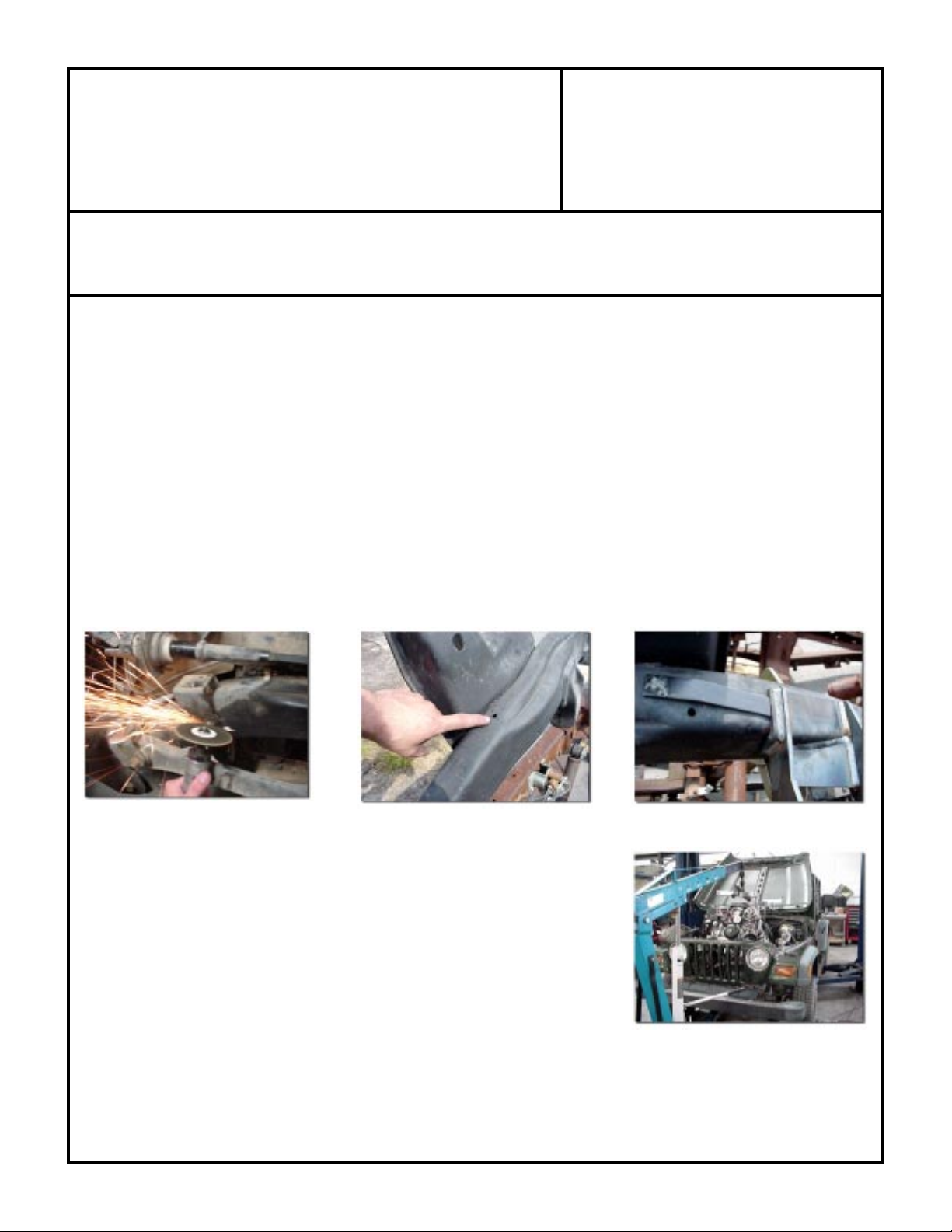

Refer to the owner’s manual for the stock engine removal. Once the stock engine is removed, cut the original motor

mounts from the frame. Also remove the steering pillow block bracket and discard. Clean all remnants of weld so that the

frame is smooth. Make sure that the frame surface for the mounts is bare metal so that there are no contaminants in the

weld area. The TJ frame has a small hole on both sides that originally held the brake lines. By removing the brake line

mounting bracket you expose the hole that is used for our fixture bracket. Take the fixture bracket and lay it on the frame

using the 1/4” bolt as a dowel. Lay the new motor mount frame bracket over the frame and slide it towards the front until

it hits the fixture. Clamp or tack weld the mount to the frame. Do not weld the fixture bracket to the frame. It is only

used to locate the new motor mount. Repeat the clamping and/or welding procedure for the other side. When both sides

are in a fixed position, use a tape measure and check from the center of the passenger side hole to the center of the

driver’s slot. You should come close to 19.5”. It is also a good idea to check to see if both of the new frame mounts are

located the same distance back on the frame. Next, verify that the steering pillow block fits to our mount without any

interference. When the mounts have been correctly positioned, weld them in place and paint.

Engine Installation:

* For ease of installation, leave the engine motor mount brackets off until the engine is in place.

* A trial run is highly recommended.

* The engine and transmission should be bolted together for an easier installation.

Using an approved engine hoist, lower the engine into the compartment. Pay attention to the exhaust manifolds and the radiator (removing the radiator is a good idea).

Using the supplied hardware, attach the engine mounts to the block. Take the four

large 1/4” spacers (2 per side) and trial fit them to get a comfortable front-to-rear

engine placement. These mounts have up to 1/2” movement front-to-rear to account for any differences in frame locations and to “fine tune” engine placement.

Use the 1/2” bolts and nylon nuts to secure the engine to the frame. Bolt the steering pillow block assembly to the mount.

Take a quick look around the engine and steering to make sure there are no clearance issues. You should have just enough

room to fit your hand between the engine and firewall/frame.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 3

ADV ANCE ADAPTERS INC. P/N 713098

P.O. Box 247, 4320 Aerotech Center Way

Paso Robles, CA 93447 PAGE 3 OF 3

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev . Date: 06-22-09

HEMI V8

TJ WRANGLER MOTOR MOUNTS

Power S teering:

The Jeep and the HEMI blocks should have matching fittings. In most cases, the stock Dodge pressure line can be

rerouted to work on the Jeep box. The low pressure return line could be any approved oil hose since it sees only minimal

line pressure. The low pressure hose should always be secured with hose clamps. Make sure the hoses have clearance

in the routing to avoid rubbing on anything. Fill the pump reservoir with fluid and replace the cap when all connections

are secure.

Exhaust:

The stock manifolds from a Grand Cherokee are required for the Hemi to fit in the Jeep TJ’s, we carry these manifolds

under part number 716601.

Wire Harness:

Hotwire (Squire Inc.) is who we recommend on the harness for the Jeeps. You would need to send your Hemi harness

along with the stock Jeep harness. They build a new harness from these two systems. The PCM should be a 05/06 truck

unit which they can re-flash. If you don’t have the correct PCM they can provide a new one.

Radiator:

W e of fer a new aluminum radiator for the Hemi conversions, P/N 716688-AA for auto transmissions and P/N 716688-AB

for manual transmissions. The electric puller fan works great on these radiators, or you can use a mechanically-driven

fan from a 4.7 Durango.

Fuel System:

The stock tank from 2005 & 2006 can be retained without any modifications. Jeeps 1997 to 2004 will require a late model

fuel tank or you can use an upgraded fuel tank from GEN-Right. This is a 19 gallon tank that fits the TJ without any

modifications, P/N GST-2002-2. You will also need a few additional Chrysler part numbers: Fuel pump 05161335AB,

o-ring 55366298AA, and locking ring 55366299AA. These item are available from Advance Adapters.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Loading...

Loading...