Page 1

ADV ANCE ADAPTERS INC. P/N 713096

P.O. Box 247, 4320 Aerotech Center Way

Paso Robles, CA 93447 PAGE 1 OF 4

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev . Date: 09-17-12

CHEVY 4.3L V-6 ENGINE

TJ WRANGLER MOTOR MOUNTS

KIT CONSISTS OF:

No. Qty Part No. Description

1. 2 713092A BOLT SLEEVE

2. 4 713092B MOTOR MOUNT BUSHING

3. 1 713092C MOTOR MOUNT FRAME FIXTURE

4. 1 713092L MOTOR/TJ FRAME MOUNT (Driver’s)

5. 2 713092M ENGINE MOUNT (Right & Left)

6. 1 713092R MOTOR/TJ FRAME MOUNT (Passenger)

7. 4 713092S SPACERS FOR TJ MOUNTS (both left and right)

8. 8 720038 10MM LOCK W ASHER

9. 8 720044 10MM-1.5 x 20MM(plate mounting)

10. 2 723704 3/8” LOCKWASHER (pillow block)

11. 2 723721 3/8”-16 x 1” H.H.C.S. (pillow block)

12. 2 723735 3/8” FLAT WASHER (pillow block)

13. 6 723718 3/8”-16 x 1” F .H.C.S.

14. 4 725003 1/2” FLAT WASHERS

15. 2 725005 1/2”-13 NYLON LOCK NUT

16. 2 725027 1/2”-13 x 5” H.H.C.S.

17. 1 713096L MOTOR MOUNT PLA TE (left)

18. 1 713096R MOTOR MOUNT PLATE (right)

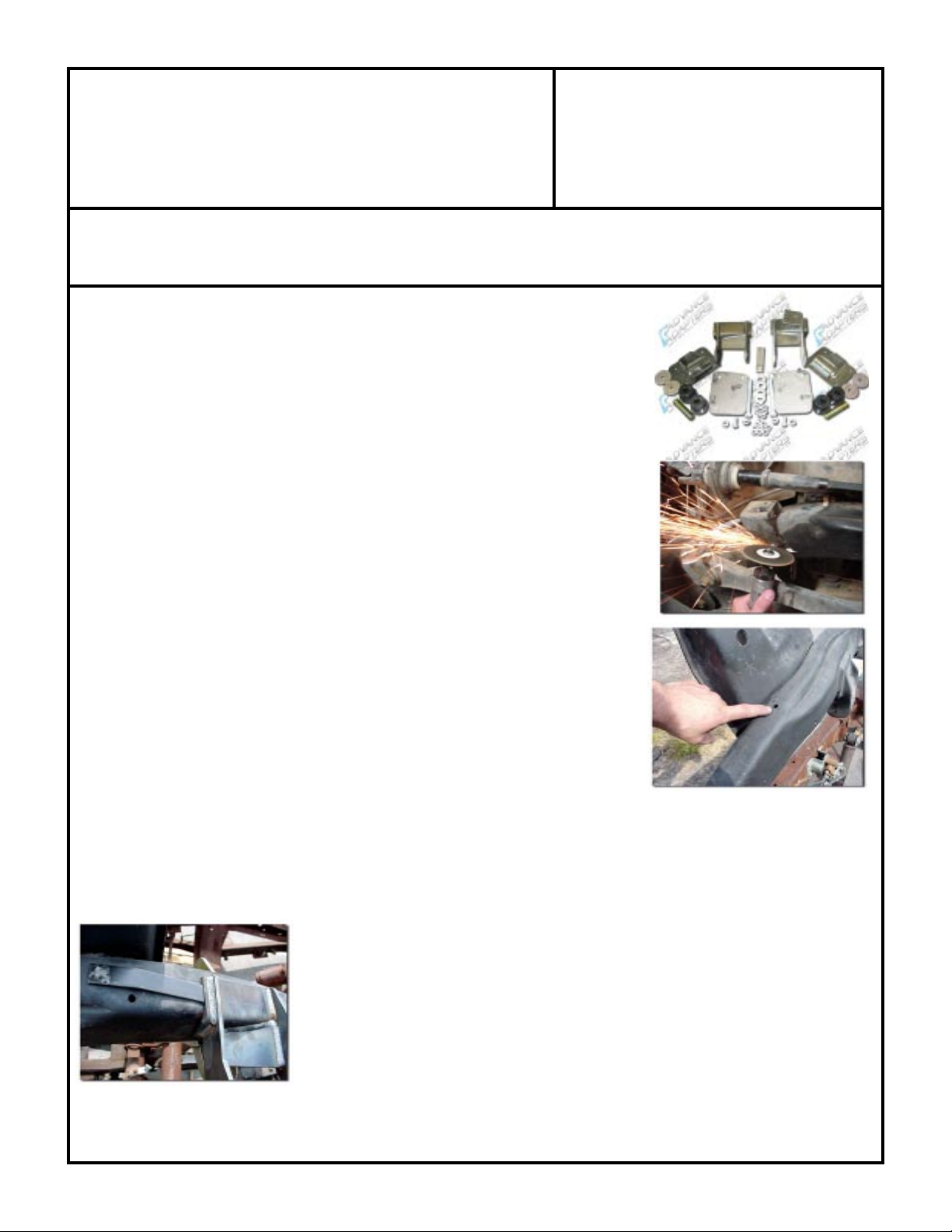

INSTALLATION INSTRUCTIONS: We recommend that your Jeep TJ have

1” of body lift before starting. The front suspension may need to be adjusted to

allow for the additional engine weight.

a 1997-2006 4 cylinder steering bracket, Part# 52058855AB. If your replacing a 6

cylinder, you will need this Jeep part number or our 713093P.

This motor mount is designed to work with

New Mount Installation:

Refer to the owner’s manual for the stock engine removal. Once the stock engine is removed, cut the original motor

mounts from the frame. Also remove the steering pillow block bracket and discard. Clean all remnants of weld so that the

frame is smooth. Make sure that the frame surface for the mounts is bare metal so that there are no contaminants in the

weld area. The TJ frame has a small hole on both sides that originally held the brake lines. By removing the brake line

mounting bracket you expose the hole that is used for our fixture bracket. Take the fixture bracket and lay it on the frame

using the 1/4” bolt as a dowel. Lay the new motor mount frame bracket over the frame and slide it towards the front until

it hits the fixture. Clamp or tack weld the mount to the frame. Do not weld the fixture

bracket to the frame. It is only used to locate the new motor mount. Repeat the

clamping and/or welding procedure for the other side. When both sides are in a fixed

position, use a tape measure and check from the center of the passenger side hole to the

center of the driver’s slot. You should come close to 19.5”. It is also a good idea to

check to see if both of the new frame mounts are located the same distance back on the

frame. Next, verify that the steering pillow block fits to our mount, (6 cylinder Jeeps

must purchase the 4 cylinder pillow block listed above) without any interference. When

the mounts have been correctly positioned, weld them in place and paint.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 2

ADV ANCE ADAPTERS INC. P/N 713096

P.O. Box 247, 4320 Aerotech Center Way

Paso Robles, CA 93447 PAGE 2 OF 4

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev . Date: 03-17-04

CHEVY 4.3L V-6 ENGINE

TJ WRANGLER MOTOR MOUNTS

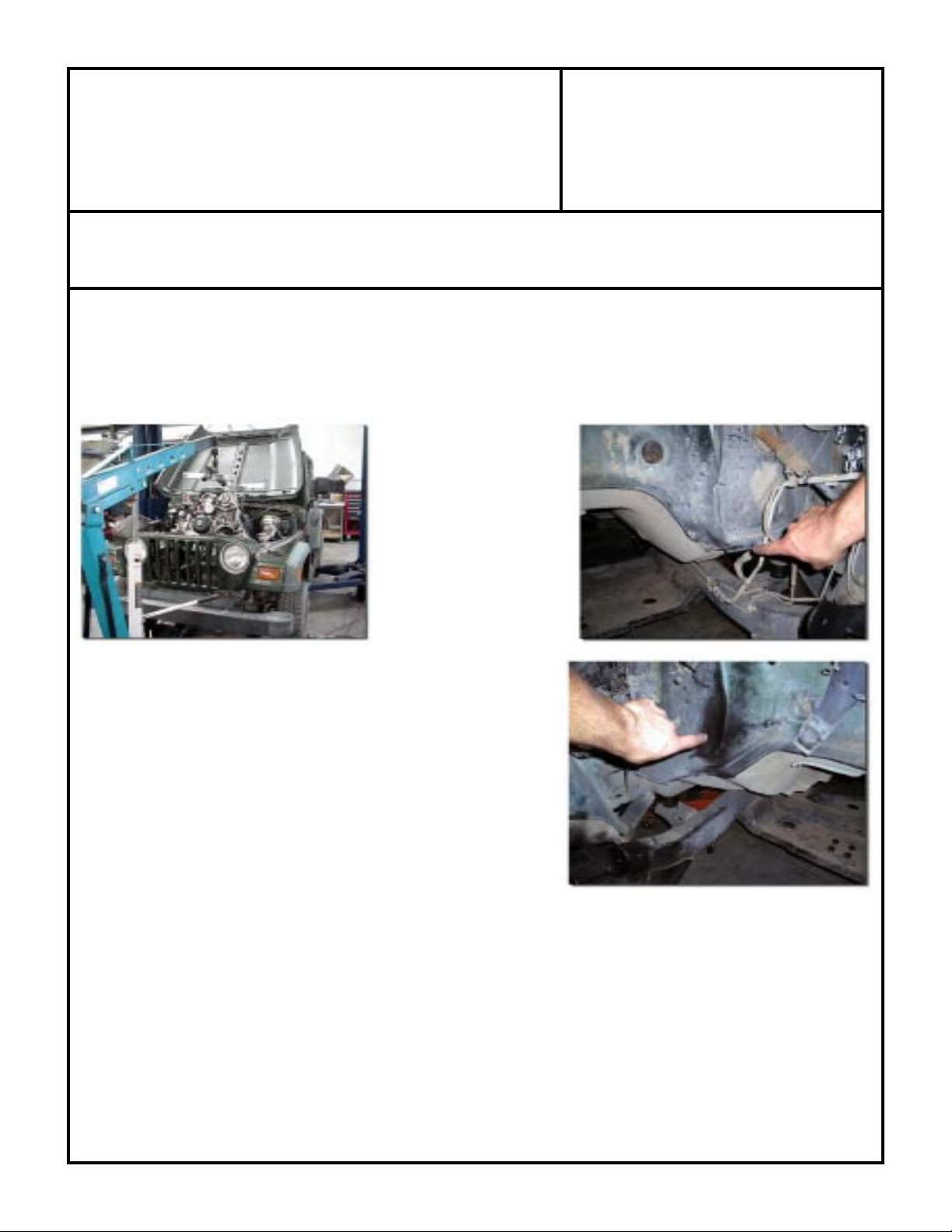

Engine Installation:

* For ease of installation, leave the engine motor mount brackets off until the engine is in place.

* The new 4.3L engine is slightly different that the original one. Firewall modifications may be necessary.

* A trial run is highly recommended.

* The engine and transmission should be bolted together for an easier installation.

Using an approved engine

hoist, lower the engine into

the compartment. Pay attention to the exhaust manifolds

and the radiator (removing

the radiator is a good idea).

The engine may not slide fully

into the compartment due to

firewall interferences (check

the clearance on both the

driver’s and passenger side

around the engine heads

and above both of the exhaust manifolds/headers). Mark these spots

with a pen, remove engine, and clearance the firewall accordingly. Lower

the engine back in and check the clearance. Using the supplied hardware, attach the engine plates to the block. When secured, guide the

upper mount portions through the frame brackets and bolt them into

place. Take the four large 1/4” spacers (2 per side) and trial fit them to

get a comfortable front-to-rear engine placement. These mounts have

up to 1/2” movement front-to-rear to account for any differences in

frame locations and to “fine tune” engine placement. Use the 1/2” bolts

and nylon nuts to secure the engine to the frame. Bolt the steering pillow

block assembly to the mount. Take a quick look around the engine and

steering to make sure there are no clearance issues. You should have just

enough room to fit your hand between the engine and firewall/frame.

Gauge Wiring:

The Chevy V-6 and the Jeep systems do not “speak the same language”. In our installations, we retained the stock Jeep

computer as well as installed the new 4.3L computer. We retained the stock Jeep sending units and attached them to the

GM block (oil pressure, temperature, and fuel level). All of them work fine except the tachometer. An aftermarket

tachometer would be the easiest option at this point, or a “black box” to modify the signal. Since you are using the stock

sending units, the Jeep computer thinks that the original engine is still sending information. The Jeep service manual

identifies the color coded wires in the harness; we retained the ones for the gauges and the other leads that are not used

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 3

ADV ANCE ADAPTERS INC. P/N 713096

P.O. Box 247, 4320 Aerotech Center Way

Paso Robles, CA 93447 PAGE 3 OF 4

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev . Date: 03-17-04

CHEVY 4.3L V-6 ENGINE

TJ WRANGLER MOTOR MOUNTS

from the stock Jeep harness were clipped. Before clipping wires, you should double check with the service manual and

determine what is “not needed”. (Remember: It is easier to cut wires later than to solder them back together). It is

possible to run the Chevy “check engine” light if you wire it behind the dash and replace the stock Jeep light. Removing

the dash and instrument bezel will give you easy access to the check engine light.

Take care when soldering and striping wires. It is always best to unplug the battery and also disconnect the plugs from

both the Jeep and GM computers. It only takes a minimal amount of voltage on the wrong circuit to damage these

computers. Likewise, only approved test probes should be used. Please read and understand all the warnings printed in

both owners manuals. Make sure to secure the GM computer in a place that will be free from dirt, water, and physical

damage. Also place all relays and fuse block out of harms way (inside the tub is best).

Power S teering:

The Jeep and the GM blocks should have matching fittings. In most cases, the stock GM truck pressure line can be

rerouted to work on the Jeep box. The low pressure return line could be any approved oil hose since it sees only minimal

line pressure. The low pressure hose should always be secured with hose clamps. Make sure the hoses have clearance

in the routing to avoid rubbing on anything. Fill the pump reservoir with fluid and replace the cap when all connections

are secure.

Radiator:

We used our custom Rad-a-Kool radiator for this conversion to make sure cooling would not be an issue. The radiator

fit into the stock location on the Jeep TJ. Please pay attention to the type of engine coolant recommended for your

particular engine; it may vary from what was in the Jeep.

Throttle Linkage:

The throttle cable in the TJ is different than the on used on GM blocks. It may be

necessary to either modify the GM cable to fit or to get an aftermarket cable assembly

(Lokar throttle cables are offered through Advance Adapters).

Fans:

Either a stock clutch fan or an electric fan will work with these motor mounts. W ith our aluminum radiator, there should

be ample room to run a clutch fan or a short profile flex fan. A custom shroud will have to be fabricated if you use a

mechanical fan.

By far, new conversions are most popular with an electric fan. There is ample clearance in the engine compartment which

allows for good air circulation. We offer a Spal fan and mounting brackets to fit our radiator under Part No. 716670.

This fan is rated at 2360 CFM. Not all fans are created equal, so make sure that your electric fan has enough CFM for

your setup. Also keep in mind that a “puller” fan will draw in more air and cools better than a “pusher” fan.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 4

ADV ANCE ADAPTERS INC. P/N 713096

P.O. Box 247, 4320 Aerotech Center Way

Paso Robles, CA 93447 PAGE 4 OF 4

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev . Date: 03-17-04

CHEVY 4.3L V-6 ENGINE

TJ WRANGLER MOTOR MOUNTS

Exhaust:

All of the stock exhaust system must be removed for the V-6 conversion. New pipe

should be run from the manifolds all the way out. Routing the exhaust around the

frame should not be a problem. If you are doing an E.F.I. smog legal conversion, you

may need to find a stock GM vehicle to measure the location of where the oxygen

sensors and cats are located on the stock pipes. Also make sure proper heat shielding

is used between exhaust components and the floorboard. Use the stock “donor” vehicles’ exhaust size as a start for your new system. For pollution controlled vehicles,

please refer to the owner’s manual for the stock exhaust configuration.

Headers are also a good choice for this conversion. They fit very well with these mounts and add to the performance

look of your TJ. Recommended headers are AA Part No. 717056 and are NOT for pollution controlled vehicles.

Fuel System:

Refer to the fuel section of your Jeep owner’s manual before servicing or taking apart any piece of the fuel system.

Special fittings, pressurized line, and certain procedures must be taken into consideration before work can be done on the

fuel system. Do not take short cuts on fuel systems. The new GM fuel systems run mainly high pressure out of the

pumps. Only approved high pr essure hose and fittings should be used. Take care when routing fuel lines, and make sure

all fittings are secure. The newer engines require around 3/8” line on the pressure side, and around 5/16” on the return

(3/8” is O.K. for the return line). The stock Jeep fuel pump comes close to feeding the new block, but could fall short.

The stock Jeep fuel pump is internally regulated in the fuel tank at 46 psi. Check the fuel pressure needed to run the new

V-6 block (both P.S.I. and G.P.M.). Keep in mind that since the Jeep regulated the pressure at the tank, it did not run a

return fuel line.

We opted to run two new 3/8” lines, one pressure and one return. The pressure line needs to be installed by drilling and

installing a bulkhead-type “AN” fitting alongside the stock Jeep pump assembly . A fuel tank pick up must also be installed.

Make sure the new pick up line draws from the bottom of the tank and has no restrictions. The old Jeep “pressure” line

out of the tank can be used as a return line connection from the 4.3. To use this connection you must take all the “guts”

out of the stock internal regulator. The photos on this page show the modifications we did.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Loading...

Loading...