Page 1

ADVANCE ADAPTERS INC. P/N: 713094

P.O. Box 247, 4320 Aerotech Center Way New Item: (08/02)

Paso Robles, CA 93447 PAGE 1 OF 2

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 10-10-08

DODGE V8 WELD-IN MOUNTS

1997-06 JEEP TJ

KIT CONSISTS OF:

No. Qty Part No. Description

1. 1 713008-NS RUBBER MOUNTS

2. 1 713094L LEFT MOUNT

3. 2 713094M BLOCK MOUNTS

4. 1 713094R RIGHT MOUNT

5. 4 713094S DRIVER SIDE SPACER FOR 360 ENGINES

6. 8 724301 NYLON LOCK NUT 7/16"-14

7. 16 724302 FLAT WASHER 7/16"

8. 4 724308 H.H.C.S. 7/16"-14 x 1-3/4"

9. 4 724309 H.H.C.S. 7/16"-14 x 2"

INSTALLATION PROCEDURES:

This mount kit is designed as a weld-in application. Cutting, grinding, and welding is required. These mounts can

be used when replacing both a stock 6 cylinder or 4 cylinder engine.

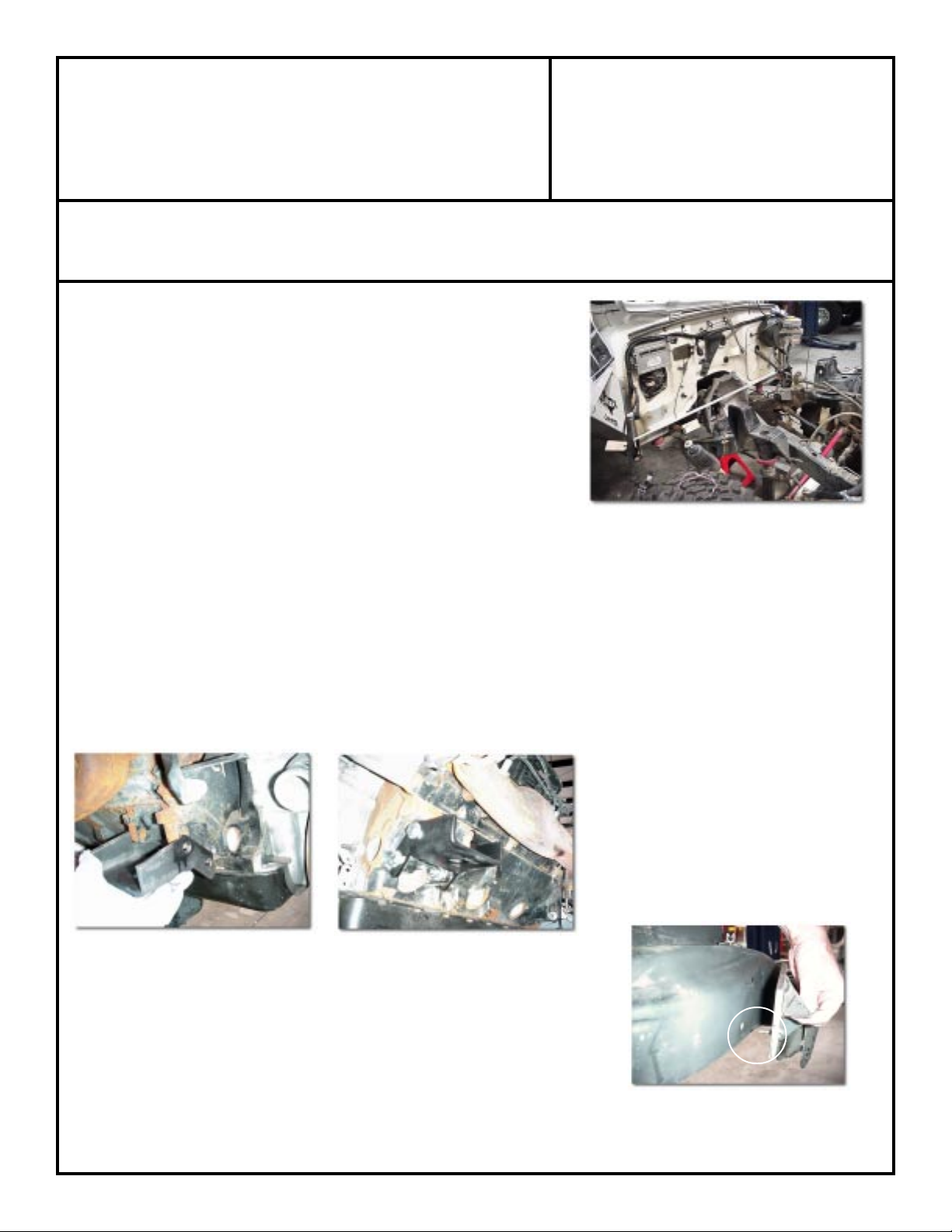

To install a Dodge V8 into a Jeep TJ, we recommend that the entire front clip of the vehicle be removed for ease

of installation. This would also include the hood, grille, both fenders, and miscellaneous components. Some of the

components in the engine compartment may need to be relocated (i.e. smog equipment, battery, radiator, overflow,

etc.). Once the stock engine has been removed, you'll be ready to begin the new engine installation.

Bolt the block mounts to the block using the hardware given. Take note of the thicknesses of each boss and use

the correct length bolt accordingly. Also, one of the bolts may not be used on the block because some Dodge blocks

have only 3 holes on one side.

Grind or torch off the stock frame mounts.

Grind off all the welds, and make the frame

rails smooth. Next, identify the holes on

each side of the frame which you will use

to locate the mounts. They are located on

the inside of the frame, about 23" away

from the front crossmember. Using the

bolt that protrudes from the frame mount

as a alignment pin, C-clamp the mounts to the inside of the frame (the

front-to-back angle of the mounts will be determined later). Place the

engine in the engine compartment and align the holes from the block

mounts to the frame mounts. Rotate the doweled frame mounts so they

hit parallel to the engine mounts. Tighten the C-clamp and/or tack weld

them in place. Remove the engine assembly and full-weld the mounts to

the frame.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components will void

any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we strongly recommend that

you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter components. We recommend that a service

manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment. These manuals are normally available at automotive dealerships

and parts stores.

Page 2

ADVANCE ADAPTERS INC. P/N: 713094

P.O. Box 247, 4320 Aerotech Center Way New Item: (8/02)

Paso Robles, CA 93447 PAGE 2 OF 2

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 11-27-12

DODGE V8 WELD-IN MOUNTS

1997-06 JEEP TJ

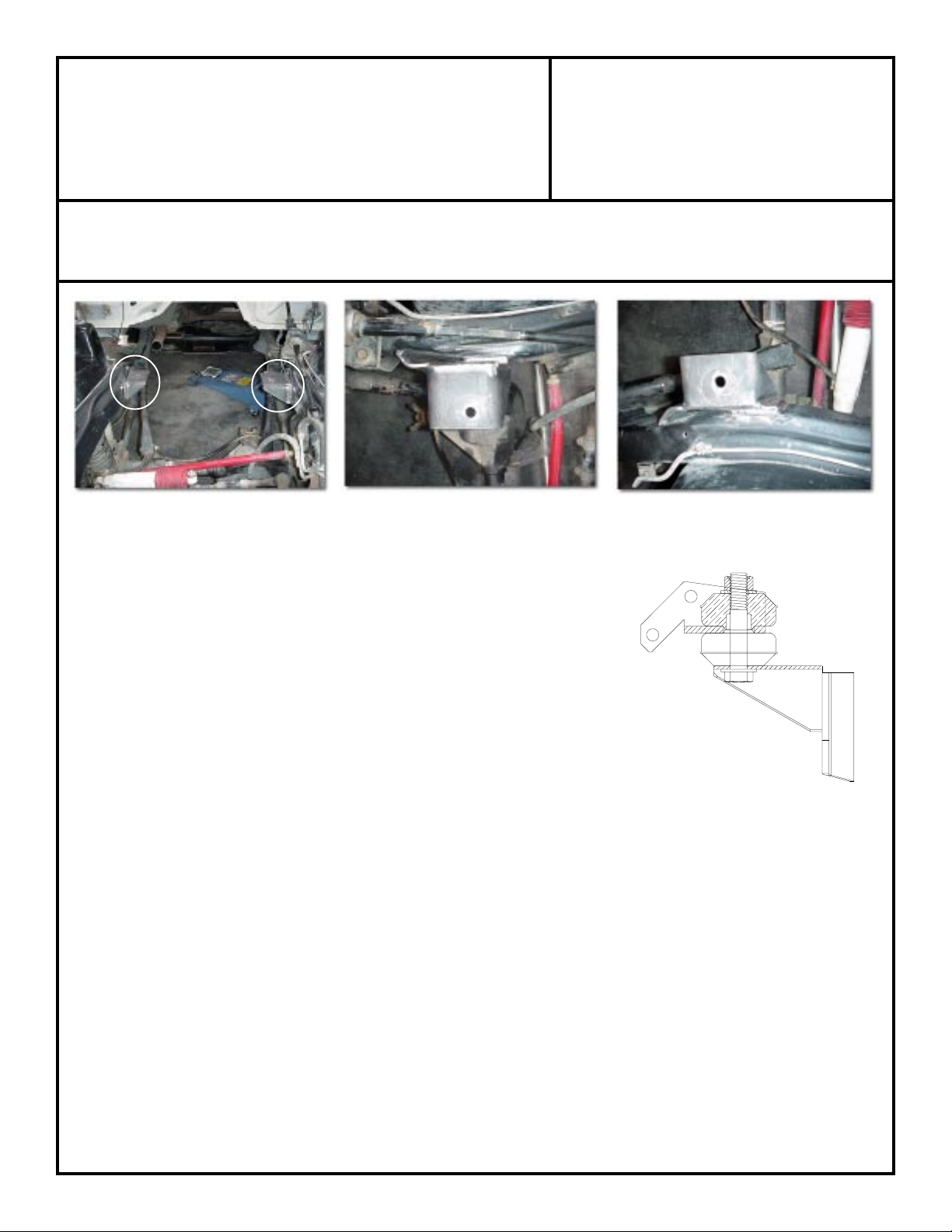

New frame mounts welded into

position

Once the frame mounts are welded into position, the Dodge engine can be

reinstalled. We have provided new rubber indexing donuts for isolating the

engine vibrations from the frame and body. These rubber donuts index on the

top and bottom if the block mount. The large 5/8" bolt is then inserted from the

bottom of the frame mount up through the rubber mounts and the block mount.

The holes on the frame mount are slightly slotted to adjust the block inside the

frame rails. Once the block is in the correct location and the rubber mounts are

installed, tighten the 5/8" locknuts to 25-30 ft./lbs. to secure the engine location.

DODGE 360 INSTALLATION NOTES:

The Dodge 360 driver's side mount is narrower than that of the Dodge 318. When using this mount

on a 360, we have included four 1/4" spacers. These spacers need to be installed between the block

tabs and the block mount. We recommend using two on the front side of the mount and two on the

back side.

INSTALLATION NOTES:

The installation of the Dodge 318 fits well into the Jeep TJs. The application we converted used a stock enginedriven fan, Chrysler P/N 52027888(1998 360 fan). We installed one of our custom radiators (P/N 716687) and used

a 6 cylinder fan shroud, Chrysler P/N5202792S (1998 4.0 TJ shroud). The wire harness off the 1999 Dodge 318

was spliced into the stock TJ wire loom. The service manual for the TJ and the Dodge V8 show the wire schematics

which made this fairly easy.

Driver's side frame mounts welded

into position

Passengers side frame mounts

welded into position

Optional items: 716687 - Brass radiator, 716691-AA - Aluminum radiator with transmission cooler, 716693-AA

Aluminum radiator, 716670 - Electric spal fan kit, 715542 - Jeep TJ transfer case shifter linkage bracket.

On 360/5.9L engine swaps we recommend using the aluminum radiators with the electric fan kits due to the higher

heat produced by the larger engine.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components

will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we strongly

recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter components.

We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment. These manuals

are normally available at automotive dealerships and parts stores.

Loading...

Loading...