Page 1

ADV ANCE ADAPTERS INC.

Fixed Yoke kit (S.Y.E. Kit)

Instruction Sheet

P/N: 50-7905 & 50-7906

KIT CONSISTS OF:

No. Qty Part No. Description

1. 1 51-7906 TAILHOUSING, DIECAST

2. 1 52-7905 SHAFT, MAIN OUTPUT

3. 1 300474 SEAL WASHER, REAR YOKE

4 1 300475 YOKE, C.V. REAR

5. 1 300476 NUT, REAR YOKE

6. 1 300480 SEAL WASHER, FRONT YOKE

7. 1 300625 RING GEAR, SPEED-O

8. 2 300627 SNAP RING, SPEED-O RING GEAR

9. 1 716075 PLUG FOR TAILHOUSING

10. 1 716076 SEAL WASHER FOR PLUG

11. 1 716318 BEARING, 207 OPEN BALL (No Snap Ring)

12. 1 716464 SNAP RING, 207 BEARING

13. 1 716465 RETAINER RING, MODE

14. 1 716751 SEAL, TAILHOUSING

P/N: 50-7906B

KIT CONSISTS OF:

No. Qty Part No. Description

1. 1 51-7906 TAILHOUSING, DIECAST

2. 1 52-7905 SHAFT, MAIN OUTPUT

3. 1 300474 SEAL WASHER, REAR YOKE

4 1 300475 YOKE, C.V. REAR

5. 1 300476 NUT, REAR YOKE

6. 1 300480 SEAL WASHER, FRONT YOKE

7. 1 300625 RING GEAR, SPEED-O

8. 2 300627 SNAP RING, SPEED-O RING GEAR

9. 1 716075 PLUG FOR TAILHOUSING

10. 1 716076 SEAL WASHER FOR PLUG

11. 1 716318 BEARING, 207 OPEN BALL (No Snap Ring)

12. 1 716464 SNAP RING, 207 BEARING

13. 1 716465 RETAINER RING, MODE

14. 1 716751 SEAL, TAILHOUSING

15. 1 113 BOX

Page 2

ADV ANCE ADAPTERS INC. P/N: 50-7905, 50-7906 & 50-7906B

P.O. Box 247, 4320 Aerotech Center Way New Item: (12/98)

Paso Robles, CA 93447 PAGE 2 OF 12

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 07-31-07

NP231 SHORT SHAFT "FIXED YOKE" KIT

INSTALLATION PROCEDURES:

Every effort has been made to make sure your kit fits and works right the first time. However, if you happen to

experience a problem with your kit, please contact us by our toll free

technical assistance line at (800)350-2223, Monday through Friday

8:00 a.m. to 4:00 p.m. PST.

The installation of this kit requires you to nearly disassemble

the entire transfer case. If your transfer case is in need

of a rebuild, now is the perfect time to do it. To install this

kit, it is easier to remove your transfer case and set it on

end upon a workbench, but it is not necessary.

Here are a couple of points to keep in mind that will make the

installation much easier if you've never disassembled a New

Process transfer case:

1. Keep all bolts, nuts, washers, etc. separated into groups as you remove

them. Make sure you keep them in a labeled container that indicates what part of the transfer case they came from.

2. Keep all small parts in separate containers and label as to location and origin.

3. Make sure you have plenty of time and a clean, spacious area to perform the installation.

THINGS TO CONSIDER BEFORE YOU BEGIN:

1. This kit is shipped with a rear 1310 series C.V. type yoke. You will need a C.V. equipped driveshaft. We do also

offer other yoke options. P/N 300369 is a 1330CV yoke that uses the same seal as the 1310CV yoke provided

in this kit. P/N 716295 - 1310 non CV yoke, P/N 300472 - 1350 non CV yoke, P/N 300473 - 1410 non CV yoke,

P/N 300470 - 1300 series flange yoke, and P/N 300471 - 1410 non CV flange yoke. These yokes can also be used

on our fixed yoke kit as long as the tailhousing seal is changed. The seal required is our P/N 716755 or a CR seal

P/N 21061.

2. Medium strength threadlocker is recommended on all threaded fasteners.

3. A sealant such as RTV, (like the OEM sealant) is needed and is available from your local Jeep/Dodge dealer.

P/N 82300234.

4. The shift rail on the New Process transfer case may require shortening. Please refer to Page 9 of these instructions

to verify. If your transfer case requires this modification, then it can be done as described on Page 9 or the rail

can be removed from the case and modified while the case is disassembled. If the rail is going to be removed

and modified, please take note to how this mechanism is installed into the case assembly.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 3

ADV ANCE ADAPTERS INC. P/N: 50-7905, 50-7906 & 50-7906B

P.O. Box 247, 4320 Aerotech Center Way New Item: (12/98)

Paso Robles, CA 93447 PAGE 3 OF 12

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 07-31-07

NP231 SHORT SHAFT "FIXED YOKE" KIT

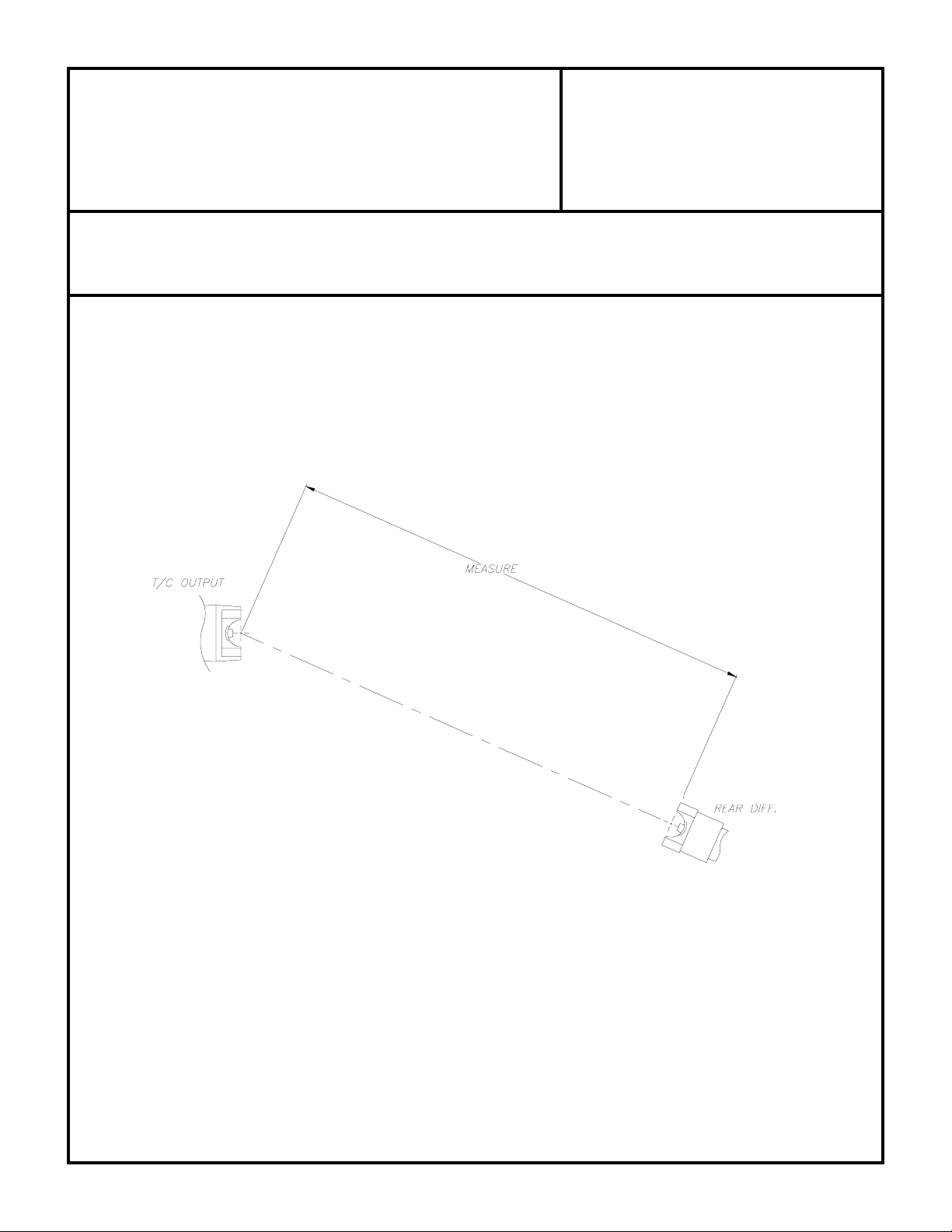

DRIVE SHAFT MODIFICATION:

This job should be performed by a local driveline repair shop capable of balancing the finished assembly. (Use a C.V.

joint & long slip spline style shaft assembly.)

With the vehicle finished and on the ground, measure a straight line between the transfer case output yoke and the rear

pinion yoke center mating flanges. (Fig. A)

(Fig. A)

For proper C.V. type drive shaft operation, the rear differential should be pointed at the transfer case output yoke under

normal driving load.

If install is performed on jack stands, make sure you have supported the vehicle well!

Place the transfer case range selector in the 4L position.

Remove front & rear drive shafts and begin at the disassembly procedures. (Step 1, Fig. 1)

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 4

ADV ANCE ADAPTERS INC. P/N: 50-7905, 50-7906 & 50-7906B

P.O. Box 247, 4320 Aerotech Center Way New Item: (12/98)

Paso Robles, CA 93447 PAGE 4 OF 12

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 07-31-07

NP231 SHORT SHAFT "FIXED YOKE" KIT

DISASSEMBLY

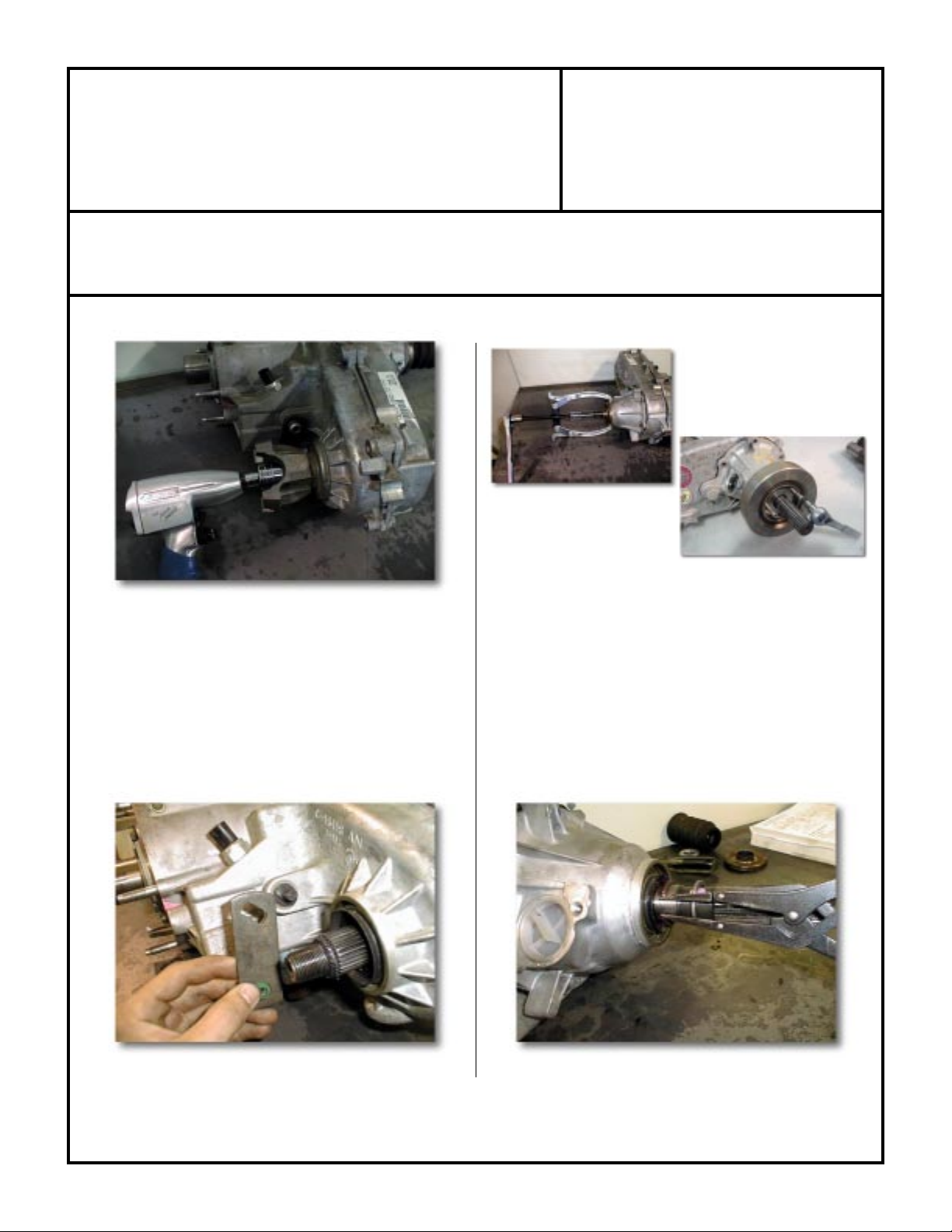

(Fig. 1) Yoke Nut Removal

(1) Remove Speed-o-drive.

(2) Remove front yoke nut.

(a) Move range lever to 4L position.

(b) Remove front yoke nut with 1-1/8" socket using an impact

wrench. (Fig. 1)

(3) Remove yoke.

(Discard seal washer).

(4) Remove selector lever. (Fig. 2)

Note: If difficult, use a puller.

(Fig. 3) Slinger Removed / Harmonic Dampener

(5) Remove the output shaft boot. Spread band clamps with a Awl.

Slide boot off.

(6) Remove slinger (this one is tough)! Good thing you won't need

this later. (Fig. 3)

(6a) On newer transfer cases, Jeep used a harmonic dampener. The

dampener has 3 tapped metric holes (6mm-1.00). By installing

bolts into these holes, they will go through the dampener and

press against the stock tailhousing, pressing the harmonic

dampener off the output shaft.

(7) Remove stop spacer & snap ring. (Fig. 4)

(Fig. 2) Range Selector Removal

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

(Fig. 4) Stop Spacer & Snap Ring Removal

Page 5

ADV ANCE ADAPTERS INC. P/N: 50-7905, 50-7906 & 50-7906B

P.O. Box 247, 4320 Aerotech Center Way New Item: (12/98)

Paso Robles, CA 93447 PAGE 5 OF 12

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 07-31-07

NP231 SHORT SHAFT "FIXED YOKE" KIT

(Fig. 5) Rear Seal Removal

(8) Remove rear seal. Collapse with punch if needed. (Fig. 5)

(Fig. 6) Rear O.D. Snap Ring Removal

(9) Remove rear bearing retaining rings. (Fig. 6) & (Fig. 7)

(Fig. 7) Rear I.D. Snap Ring Removal

(Fig. 8) Rear Tailhousing Removal

(10) Remove tailhousing bolts with 10mm socket & remove

tailhousing. (Fig. 8)

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 6

ADV ANCE ADAPTERS INC. P/N: 50-7905, 50-7906 & 50-7906B

P.O. Box 247, 4320 Aerotech Center Way New Item: (12/98)

Paso Robles, CA 93447 PAGE 6 OF 12

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 07-31-07

NP231 SHORT SHAFT "FIXED YOKE" KIT

(Fig. 11) Front Drive Chain & Shaft Removal

(Fig. 9) Rear Case Half Removal

(11) Remove the rear case bolts. A 10mm 12 pt. socket is needed

for the spline head bolt and a 15mm socket for the remaining

bolts. NOTE: The two black oxide finished bolts are located at

the case dowel positions and require a washer under them.

(12) Start to remove the rear case from the front case by inserting

pry bars at the cast-in locations ONLY! (Fig. 9)

(a) Pry apart evenly to break the sealer bead along the case

mating surfaces.

(13) (Fig. 10)

back of the case until the back half of the case has been taken

off far enough to disengage the pump drive splines on the stock

output shaft. At that time, you can either slide the pump up on

the housing and remove the pump pickup tube or just remove the

pump and pickup tube complete with the rear case half.

(a) Inspect the pickup tube "o-ring" in the pump and replace if

(b) Remove, clean and inspect the inner case for wear.

The oil pump pickup tube is not accessible from the

needed. The same goes for the front shaft seal in the pump.

Do NOT disassemble the pump; it is not a serviceable item.

(14) Front output shaft removal:

(a) Pull the front output shaft out of the front bearing. (Fig. 11)

(b) Slide drive chain off the rear output shaft and remove both

shaft and chain for cleaning & inspection.

(15) Rear output shaft removal:

(a) Grasp the main shaft and remove the shaft, drive sprocket

and mode hub assembly.

(Fig. 12) Front Drive Chain & Shaft Removal

(16) Output shaft disassembly:

(a) Remove the mode hub retaining ring with heavy duty snap

ring pliers. (Fig. 12)

(b) Slide remaining components, mode hub & drive sprocket off

shaft.

(17) This is as far into the case you need to go unless you find foreign

(Fig. 10) Oil Pump Removal

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

material inside usually caused by a worn or stretched drive

chain. You will need to be the judge.

Page 7

ADV ANCE ADAPTERS INC. P/N: 50-7905, 50-7906 & 50-7906B

P.O. Box 247, 4320 Aerotech Center Way New Item: (12/98)

Paso Robles, CA 93447 PAGE 7 OF 12

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 07-31-07

NP231 SHORT SHAFT "FIXED YOKE" KIT

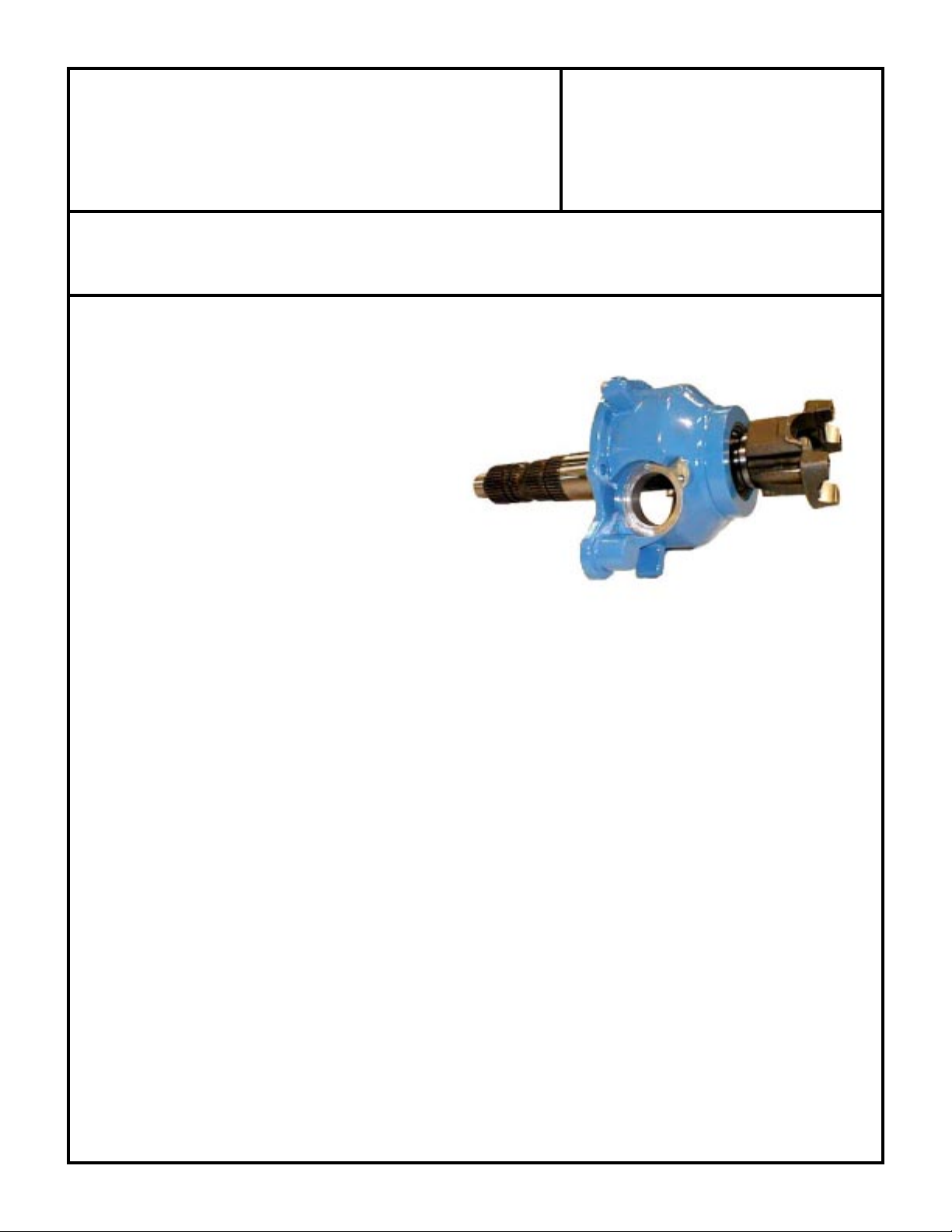

New Process 231 transfer cases have used two types or styles of output shafts. The current style New Process output

shaft started to be used in 1997 and is still being used. This newer style shaft eliminated the caged needle bearings in the

drive sprocket.

We have designed our Heavy Duty fixed yoke output shaft kit with the most current design shaft found in the New Process

231 transfer case. Our shaft looks like the shaft below left - listed as "TJ" style. Jeeps having the earlier style output

shaft, listed as "YJ" style, can use this kit by simply removing the caged needle bearing from the stock drive sprocket.

TJ style shaft q

Current NP231 shaft design

and our kit design. No needle

bearings required.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

p YJ style shaft

Early style NP231 shaft design.

The caged needle bearing from the

drive sprocket must be removed for

proper installation on our output

shaft.

Page 8

ADV ANCE ADAPTERS INC. P/N: 50-7905, 50-7906 & 50-7906B

P.O. Box 247, 4320 Aerotech Center Way New Item: (12/98)

Paso Robles, CA 93447 PAGE 8 OF 12

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 07-31-07

NP231 SHORT SHAFT "FIXED YOKE" KIT

New Shaft

ASSEMBLY CONSIDERATIONS

(Fig. 1A) Drive Sprocket Needle Bearings

(1) These bearings must be removed. Once the bearings are

removed, clean the inside of the drive gear to make sure it is free

of any type of debris.

On 1997 and newer transfer cases, the drive sprocket

does not use caged needle bearings. If you have this

newer style, then continue on to Fig. 3A (2).

(Fig. 2A) Pull the Needle Bearings Out

(Fig. 3A) New Main Output Shaft Assembly

(2) Main shaft assembly:

(a) Clean all components.

(b) Prelube all components with a quality assembly lubricant.

(Fig. 3A)

(c) Slide drive sprocket into position.

(d) Slide mode hub into position.

(e) Install the retaining ring into position after the mode hub.

(Fig. 4A)

(Fig. 4A) (Large) Retaining Ring Installation

CONTINUE TO PAGE 9

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 9

ADV ANCE ADAPTERS INC. P/N: 50-7905, 50-7906 & 50-7906B

P.O. Box 247, 4320 Aerotech Center Way New Item: (12/98)

Paso Robles, CA 93447 PAGE 9 OF 12

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 07-31-07

NP231 SHORT SHAFT "FIXED YOKE" KIT

(Fig. 5A) New Main Output Shaft Assembly

(3) Output shaft and drive chain assembly:

(a) Lubricate chain & shaft with ATF.

(b) Insert main shaft assembly into the housed planetary

assembly.

(c) Install the drive chain onto the front output shaft.

(d) Insert them into the bearing. Lift upward and tilt the shaft

toward the main shaft to work the chain into position.

(Fig. 5A)

(4) Make sure the mode spring is in place, seen in the middle.

(Fig. 5A)

(Fig. 7A) Thin film RTV Applied Prior to Mating

Case Halves.

(Fig. 6A) Case Half Pre-assembly

(5) Rear case assembly:

(a) With all components clean, install oil pump.

(b) Seat the pickup tube into the pump "o-ring". (Fig. 6A)

(c) Prelube the front output shaft bearing located in the rear

case.

(6) Apply a thin film of sealant to the front case. Use a good RTV,

like the OEM sealant, available from your local Jeep dealer.

(Fig. 7A) P/N = 82300234.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

(7) Assembly of case halves: (Fig. 8A)

(Fig. 8A) Case Halves Assembled

(a) Slide the pump & case into position.

(b) If you have difficulty, check for possible problems. DO NOT

FORCE! Mode fork rail extends through rear case!

(c) Install all fasteners in their original positions. (Black bolts

at dowel locations!)

(d) Torque evenly to 27-34 N.m (20-25 ft./lbs.)

Page 10

ADV ANCE ADAPTERS INC. P/N: 50-7905, 50-7906 & 50-7906B

P.O. Box 247, 4320 Aerotech Center Way New Item: (12/98)

Paso Robles, CA 93447 PAGE 10 OF 12

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 07-31-07

NP231 SHORT SHAFT "FIXED YOKE" KIT

(Fig. 9A) Speed-o- Ring Gear Install

(8) Assemble speed-o-drive

(a) Install retaining ring, located just behind the pump.

(b) Slide ring gear into position.

(c) Install retaining ring behind ring gear. (Fig. 9A)

NOTE: On some NP231 transfer cases, the shift rail must be shortened.

This shift rail protrudes out of the transfer case and goes into the

tailhousing. The new tailhousing has a pocket depth of 1.125".

Shift your transfer case into 4WD so the shift rod is protruding the

furthest out of the transfer case. If this shifter rod protrudes more than

1" out of the back side of the transfer case, then the shift rail must be

shortened. Ideally the shift rod should protrude exactly 1".

Transfer cases that will normally require this rail to be shortened

measure 1.5" (photo above left).

Using a hack saw or cutoff wheel (and safety glasses), trim the shift

rail shaft so that it protrudes only 1" (photo above right).

This kit is designed for both the Cherokees and Wranglers. The

Cherokees use a vacuum actuator on the New Process tailhousing; our

casting has this provision. On Wranglers, this threaded hole must be

plugged. We have provided a plug and washer for this purpose. We

also recommend that you use a bit of silicone to properly seal the plug.

(Fig. 10A) Bearing Installed

and Retained with the 716464

Snap Ring

(10) Short Tailhousing Installation:

(a) Prelube bearing & seal in new short tailhousing assembly.

(Fig. 11A)

(b) Apply sealant to tailhousing, mating surface of rear case.

(thin film)

(c) While supporting main shaft, slide new tail assembly into

position.

(d) Use care when indexing pump outer tabs and aligning tail

assembly for installation. (Fig. 12A) NOTE: Pull back on

the output shaft to seat it against the rear bearing.

(e) Install the (5) 10mm bolts that retain the tailhousing and

torque evenly to 20-27 N.m (15-20 ft./lbs.)

(Fig. 12A) Tailhousing Installation

(Fig. 11A) Seal

Installed

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 11

ADV ANCE ADAPTERS INC. P/N: 50-7905, 50-7906 & 50-7906B

P.O. Box 247, 4320 Aerotech Center Way New Item: (12/98)

Paso Robles, CA 93447 PAGE 11 OF 12

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 07-31-07

NP231 SHORT SHAFT "FIXED YOKE" KIT

(Figures 13A) Final Installation

(11) Yoke & Seal Washer installation: (This will apply to both Front & Rear yoke assembly)

(a) Slide the yoke seal into position on the shaft thread.

(b) Lube the yoke as well as the seal with ATF.

(c) A little trick to keep the spline seal in good shape is to slide the yoke half way on and walk the yoke into position

with the retaining nut. Torque to 140-150 ft./lbs. with 1-1/8" socket.

(d) Install your stock speedometer housing into the new tailhousing. Depending on which speedometer gear (tooth

count) you are using will determine the proper rotation of the speedometer housing. Each housing has 4 possible

rotation options. Identify you speedometer gear tooth count and locate that tooth count on your speedometer

housing. The number range on your housing will need to be lined up with the housing retaining clip (see photo).

A touch of RTV Blue silicon around the "o"-ring will help seal the housing to the tailhousing.

(12) Fill to recommended level with ATF.

(13) Reconnect all exterior items: driveshafts, 4WD switch, speedometer cable, etc.

(14) Happy Trails!

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 12

ADV ANCE ADAPTERS INC. P/N: 50-7905, 50-7906 & 50-7906B

P.O. Box 247, 4320 Aerotech Center Way New Item: (12/98)

Paso Robles, CA 93447 PAGE 12 OF 12

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 07-31-07

If you have not changed your tire size or your axles, your stock speedometer drive gear will remain the same.

However, if a new axle ratio and/or tire size is used, see Fig. A & B. These new speedometer drive gears

can be purchased at your local Jeep dealership.

(Fig. A)

TIRE

DIAMETER

5.38 5.13 4.88 4.56 4.10 3.73 3.55 3.07

44” 32T 31T 29T 27T

42” 34T 32T 30T 28T

40” 35T 34T 32T 30T 27T

39” 36T 34T 33T 31T 28T

38” 37T 35T 34T 31T 28T 26T

37" 38T 36T 35T 32T 29T 26T

36” 39T 37T 36T 33T 30T 27T

35" 40T 38T 37T 34T 31T 28T 27T

33" 41T 39T 36T 33T 30T 28T

32" 40T 37T 34T 31T 29T

31" 41T 39T 35T 32T 30T 26T

30" 40T 36T 33T 31T 27T

29" 41T 37T 34T 32T 28T

28" 38T 35T 33T 29T

AXLE GEAR RATIOS

CHRYSLER SPEEDOMETER DRIVE

PART NUMBERS

When installing a speedometer gear with either 39, 40, 41 or 42 teeth,

the gear and the housing must be installed separately. These are all

large diameter speedometer gears. By first installing the gear into the

tailhousing you will be able to tilt the gear shaft up allowing you to

position the gear past the Atlas output shaft. Once this gear is in place,

the speedometer housing must be aligned with the speedometer

gear shaft and indexed into the tailhousing. When installing the

speedometer housing, lube the o-ring that contacts the Atlas

tailhousing with a bit of Torco oil. This will prevent the o-ring from being

nicked upon installation or rotation, causing this housing to leak.

SPECIAL NOTE: The components packaged in this kit have been assembled and

machined for specific type of conversions. Modifications to any of the components will

void any possible warranty or return privileges. If you do not fully understand modifications

or changes that will be required to complete your conversion, we strongly recommend that

you contact our sales department for more information. This instruction sheet is only

to be used for the assembly of Advance Adapter components. We recommend that a service

manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams

and other related equipment. These manuals are normally available at automotive

dealerships and parts stores.

(Fig. B)

Part Number TEETH COLOR

52067628 28T

52067629 29T

52067630 30T

52067631 31T

52067632 32T BLACK

52067633 33T YELLOW

52067634 34T GREEN

52067635 35T ORANGE

52067636 36T RED

52067637 37T

52067638 38T BLUE

52067639 39T GREEN

52067640 40T ORANGE

52067641 41T RED

52067642 42T WHITE

52067643 43T BLUE

Loading...

Loading...